Patents

Literature

47results about How to "Solve the problem of incineration" patented technology

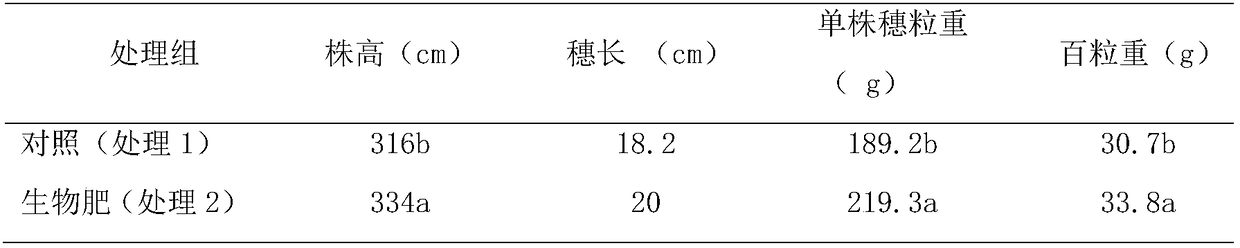

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant plant fiber construction heat-insulation wall material and preparation method thereof

InactiveCN101962272ASolve the problem of incinerationSolve pollutionSolid waste managementFiberFibrillation

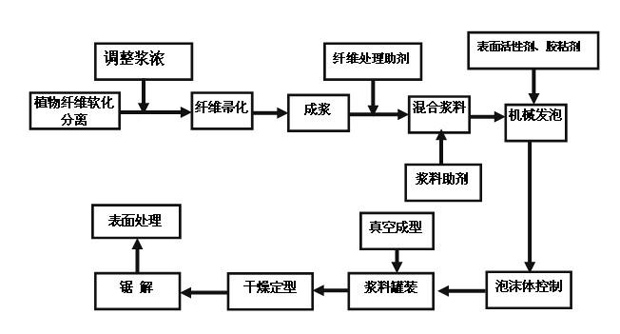

The invention discloses a method for preparing a flame-retardant plant fiber construction heat-insulation wall material. Bamboo, wood and crop straw are taken as raw materials, and the method comprises the following steps of: performing softening treatment, fiber separation, pulp concentration, fiber fibrillation, enhancement treatment, waterproof treatment and flame retardant treatment, injecting a foaming agent and foaming solution through a method for mechanically stirring to introduce air into liquid for foaming; and injecting the foamed solution into a container, dehydrating, drying and setting, sawing into plates, and performing surface coating treatment, drying and other technology so as to prepare the wall material. The method makes branch resources of wood, bosky minor-diameter bamboo, bamboo processing leftover materials and the crop straw become high-additional value high-efficiency construction heat-insulation materials.

Owner:FUJIAN AGRI & FORESTRY UNIV

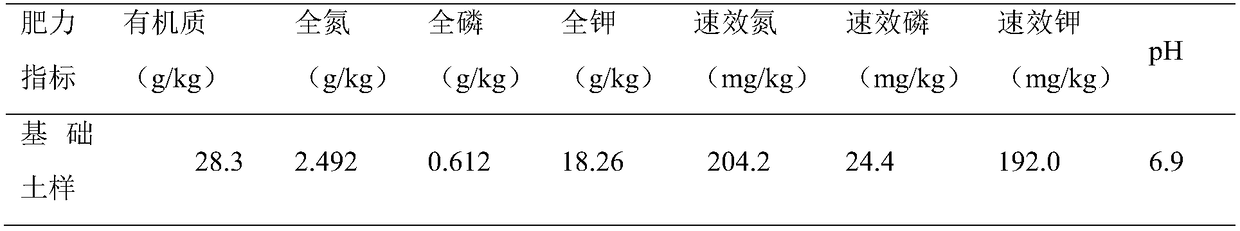

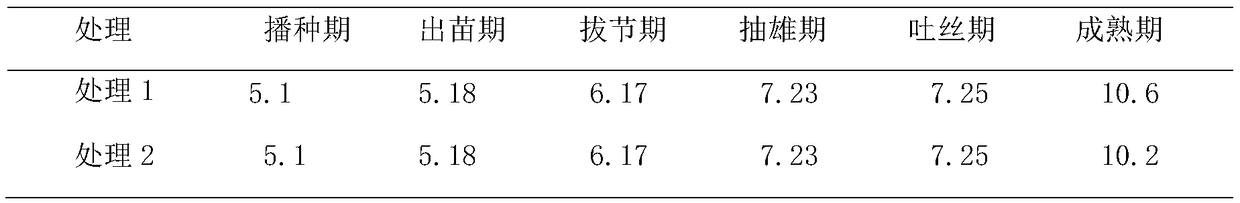

Method for composting and returning crop straws to field

InactiveCN102417377AImprove soil nutrient contentIncrease productionBio-organic fraction processingFertilising methodsEngineeringOrganic matter

The invention provides a method for composting and returning crop straws to a field. The method comprises the following steps: digging a pit in suitable size at a corner of the field; stacking the straws in the pit in a layering way and treading down the straws; spreading a right amount of straw ageing agents and urea in each layer; after finishing stacking the straws, uniformly covering the top of the stack with the soil dug from the pit; after composting for several months, digging out the rotten straws from the pit and returning the straws to the field after harvesting crops in next season; and uniformly spreading the rotten straws in the field and using the rotten straws as base fertilizers, wherein organic matters got after the straws are rotten become clean green fertilizers. Under the condition of using the fertilizers, the hardened land becomes soft and loose, the fertilizer cost of peasants for farming is saved, and the environmental pollution problem caused by burning the straws is relieved.

Owner:FEIDONG AGRI TECH COMPREHENSIVE SERVICE CENT

Method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants

InactiveCN103755400AImprove oxidation activityIncreased redox potentialBio-organic fraction processingFertiliser formsMicroorganismControlled release

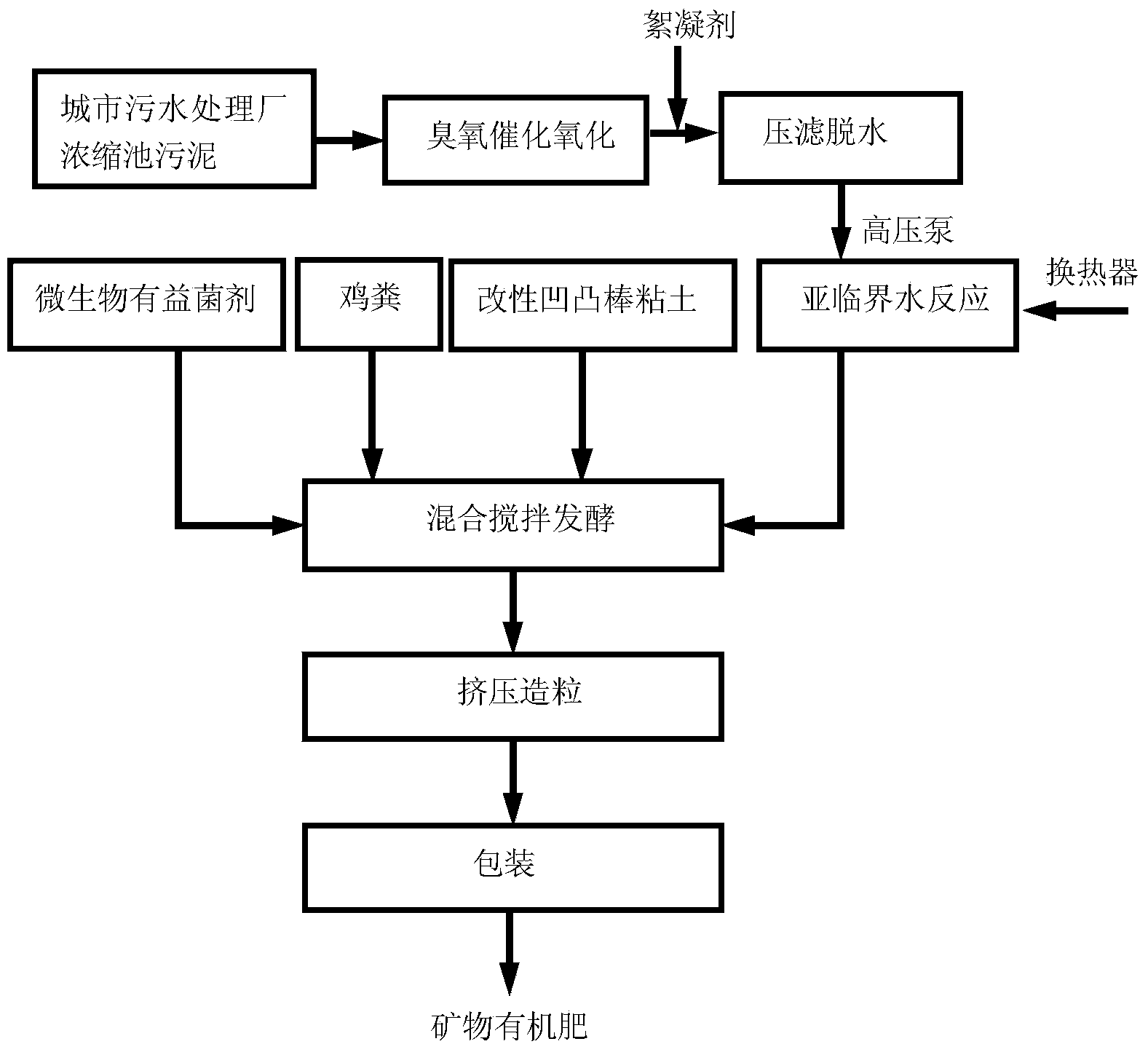

The invention discloses a method for preparing mineral organic fertilizer by using surplus sludge in municipal sewage plants. The method mainly comprises the following three steps: firstly reducing sludge in a sludge thickening tank, dehydrating the reduced sludge by adopting a catalytic ozonation method, carrying out subcritical water reaction on the dehydrated sludge, and discharging solids subjected to harmless treatment; finally mixing modified attapulgite clay with the sludge subjected to harmless treatment, chicken manure and microorganism beneficial microbial agents, and fermenting the mixture to obtain the mineral ecological organic fertilizer. The method is green and environment-friendly and realizes the harmless and resourceful treatment of the sludge; the obtained mineral organic fertilizer is capable of obviously improving the structure of soil, enabling the volume-weight of soil to be reduced, the holes of soil to be increased and the ventilation and water permeability of the soil to become good and adjusting the uniform growth of crops and has a good controlled release effect, thus the quality of the crops is improved.

Owner:安徽乐农环保科技有限公司

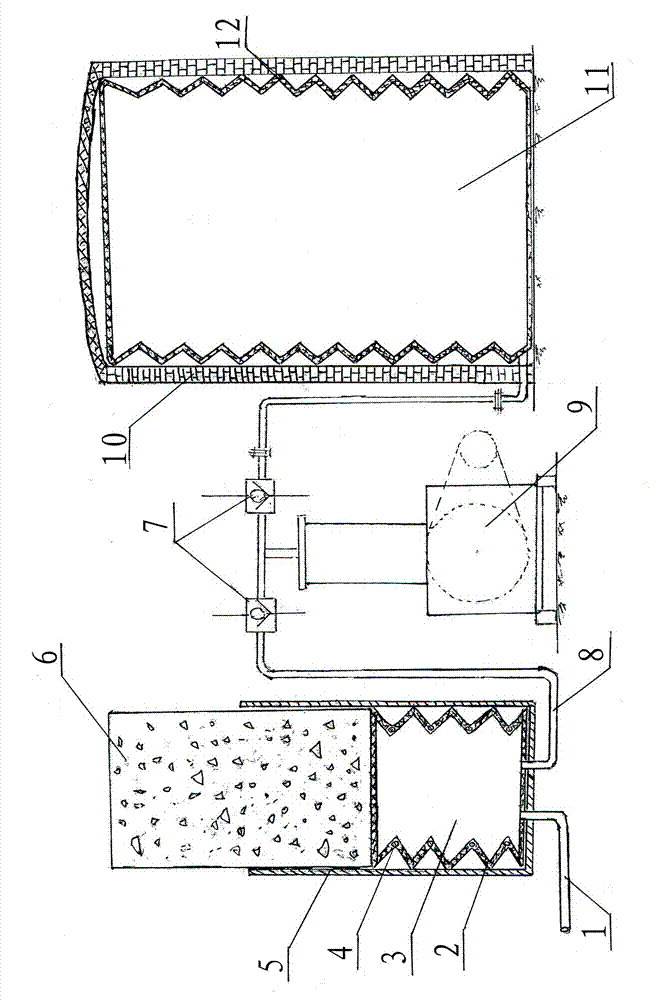

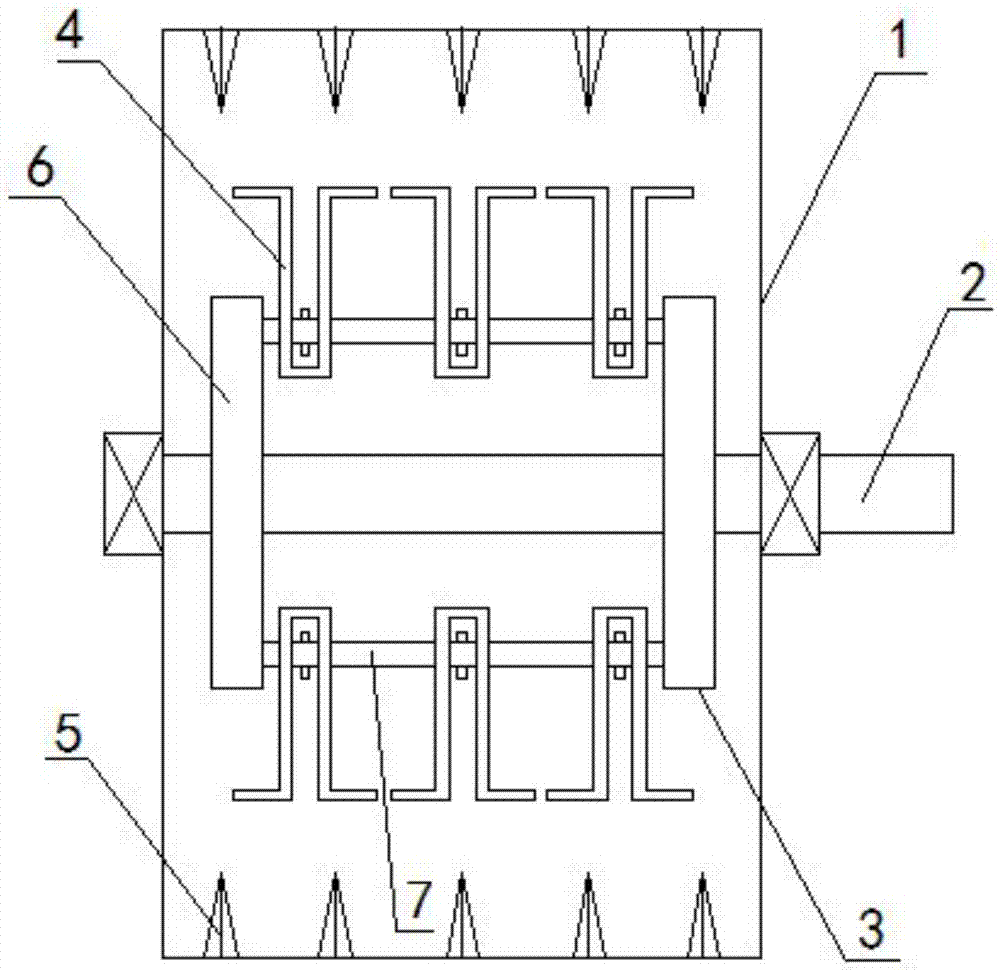

Pig house and method for resource utilization of straw as fermentation bed padding for pigs

InactiveCN104719170AEasy to useSolve the problem of incinerationAnimal housingButt jointResource utilization

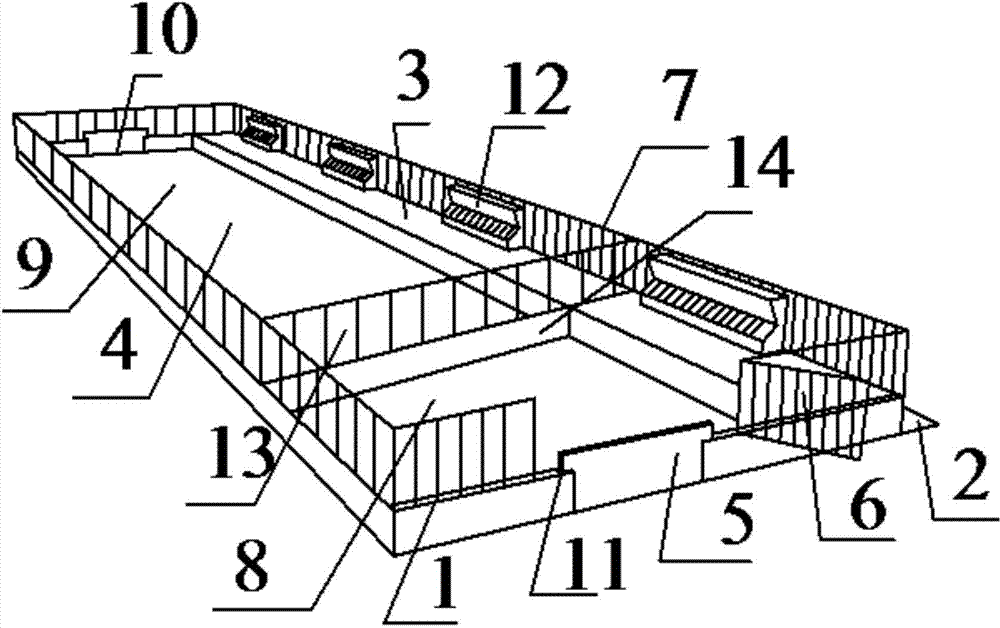

The invention provides a pig house for resource utilization of straw as fermentation bed padding for pigs. The pig house comprises a fermentation bed pigpen, a fence is arranged at the edge of the fermentation bed pigpen, a padding pool is arranged on one side of the fermentation bed pigpen in the long side direction, a sleeping table is arranged on the other side of the fermentation bed pigpen, an automatic feeding trough is formed in the portion, close to the aisle side, of the sleeping table, and an aisle is arranged on the outer side of the fermentation bed pigpen and close to the sleeping table. The invention further provides a method for resource utilization of the straw as the fermentation bed padding for the pigs. The pig house for resource utilization of the straw as the fermentation bed padding for the pigs is adopted. The method specifically includes the steps that the straw is collected, utilized and treated, the padding is raked, accumulated, fermented, transformed to manure and treated after the commercial pigs are delivered out of the pigpen, and seamless butt joint treatment between the fermentation bed colony house use period and the straw centralized generation period is conducted.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Method for producing methane and preparing fertilizer simultaneously

ActiveCN106399385AImprove qualityReduce inhibitionBio-organic fraction processingExcrement fertilisersMixed materialsFermentation

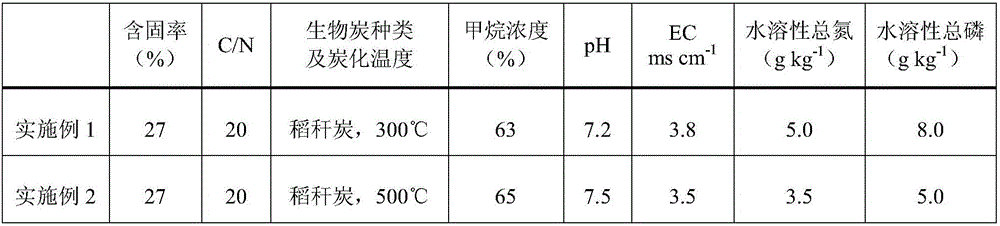

The invention discloses a method for producing methane and preparing a fertilizer simultaneously. The method comprises the following steps: (1) mixing excrement and urine of beasts and birds and crop straw at the weight ratio of (3.5-4.5):1, thus obtaining a mixed material; and (2) mixing rice straw charcoal or rice husk charcoal with the mixed material at the weight ratio of (0.5-2.5):10, placing the obtained mixture in an anaerobic fermentation tank, and carrying out fermentation. With the adoption of the method provided by the invention, the gas dredging and medium delivery generated in a reaction matrix can be effectively improved, the utilization efficiency of microbes for the matrix can be improved, and meanwhile, the high-quality fertilizer is produced.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Organic fertilizer production technology

InactiveCN110204400ASolve the problem of incinerationIncrease temperatureBio-organic fraction processingExcrement fertilisersThermal insulationSoil fertility

The invention discloses organic fertilizer production technology. The organic fertilizer production technology comprises following steps: straw is crushed into pieces with a length lower than 5cm, andis introduced into a straw storage warehouse for further processing; livestock and poultry waste is collected in a storage warehouse for further processing; a fermentation biological bacterium agentis activated for further process; the straw and the livestock and poultry waste are mixed and stirred to be uniform for 2min at a ratio of 1:2, 30kg of the fermentation biological bacterium agent is added for uniform mixing, and water content is adjusted to 45 to 55% so as to obtain a material for fermentation; the material for fermentation is introduced into a fermentation tank, a steam generatoris turned on for heating; thermal insulation treatment is carried out for 180min; a fermentation product is conveyed to a secondary fermentation zone; open air composting natural fermentation is adopted for secondary fermentation for 3 days; after secondary fermentation, an obtained organic fertilizer is introduced into a wet type crushing machine for crushing into powder with a particle size of1mm or lower; drying is carried out until water content is lower than 30% so as to obtain an organic fertilizer. The organic fertilizer production technology is capable of shortening fermentation time, protecting soil, improving soil fertility, and avoiding environment pollution caused by straw burning completely.

Owner:黑龙江双发环保科技有限公司

Biological composite filler for treating livestock wastewater, preparation method and application of biological composite filler

InactiveCN104261550ASolve the problem of incinerationSolve processing problemsWaste water treatment from animal husbandrySustainable biological treatmentVeterinary DrugsWheat starch

The invention discloses a biological composite filler for treating livestock wastewater, and a preparation method and application of the biological composite filler, and belongs to the field of treatment of livestock breeding wastewater. The preparation method comprises the following steps: (1) washing, air-drying and cutting wheat straws and soybean straws; (2) heating the mixed straws for pyrolysis; (3) preparing an (NH4)2HPO4 solution; (4) feeding the mixed straws into the (NH4)2HPO4 solution; (5) heating willow blocks for pyrolysis; (6) mixing the straws, wheat starch and wheat bran with stirring; (7) impregnating and drying biomass blocks; (8) compressing the biomass blocks into bulks to obtain the biological composite fillers by using a compressor. After the biological composite fillers are fed into the livestock wastewater, macromolecular nutrient elements such as phytate phosphorus, residual veterinary drugs, urea and suspended matters and metallic elements such as copper, iron and zinc in the wastewater can be greatly adsorbed, so that the problem of difficulty in the treatment of the livestock wastewater is effectively solved.

Owner:贵州都匀市黔昌畜牧发展有限责任公司

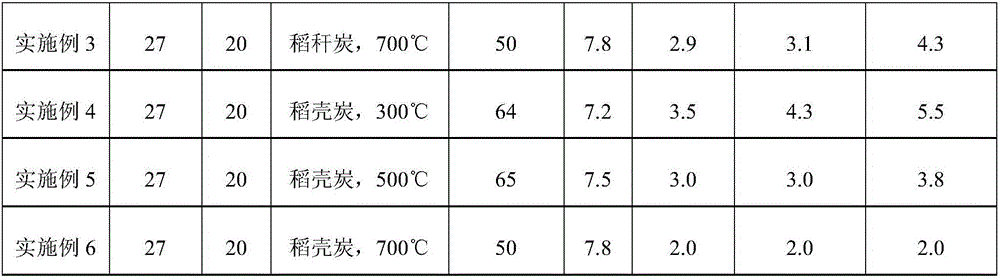

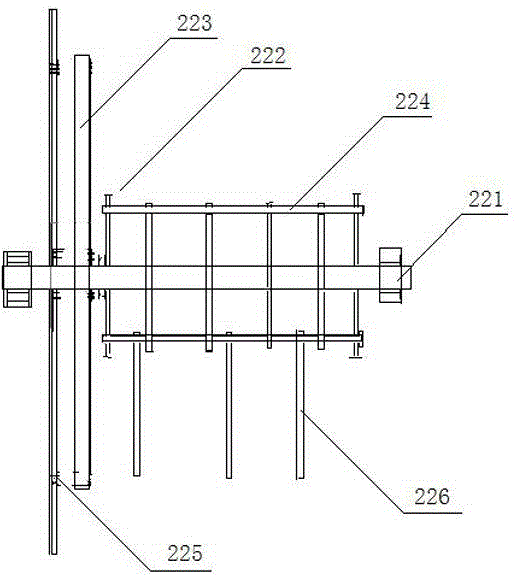

Straw cutting, throwing and returning machine for combined harvester and mounting method of straw cutting, throwing and returning machine

ActiveCN104303718ASolve the problem of incinerationIncrease water permeability and breathabilityCrop conditionersMowersAgricultural engineeringStructural engineering

The invention discloses a straw cutting, throwing and returning machine for a combined harvester. The machine comprises a knife roll assembly and a stationary knife group, wherein the knife roll assembly is connected and fixed with a machine shell through a bearing and a flange, comprises tool magazines and cutting knifes, and is of a cylindrical structure; the cutting knifes are double-face-edge trapezoidal blades; one end of each cutting knife is mounted on the corresponding tool magazine; the tool magazines are welded on the outer wall of the cylindrical knife roll assembly and are arranged in a double-end spiral manner; the knife roll assembly is fixedly welded on a knife shaft; the stationary knife group is arranged at the bottom of the inner wall of a protective shell and is formed by arranging U-shaped stationary knifes; the U-shaped stationary knifes are in positional correspondence to the cutting knifes. The invention further discloses a mounting method of the straw cutting, throwing and returning machine for the combined harvester. The straw cutting, throwing and returning machine for the combined harvester has the advantages that by virtue of the optimized design of a straw cutting and throwing structure, the shape of the machine shell and the structural form of knife rolls, energy consumption can be reduced, the length qualification rate of the cut straws is improved, the throwing uniformity of the straws is improved, and the aims of efficiently returning the straws to the field and protecting the environment are achieved.

Owner:金湖县兴鹏机械制造有限公司

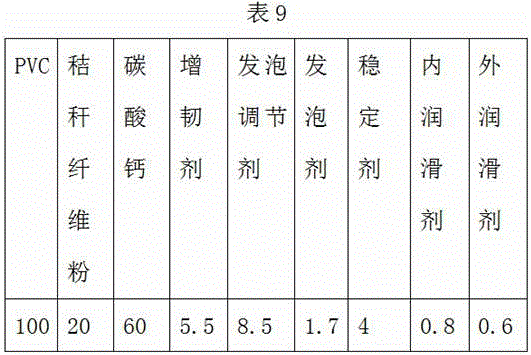

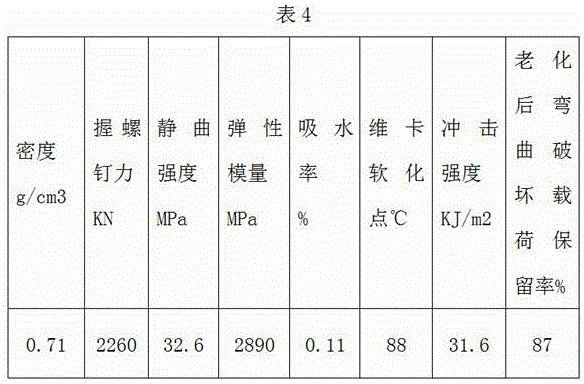

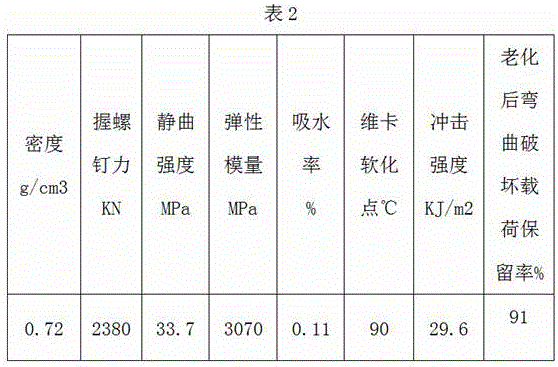

High-strength impact-resistant weather-resistant PVC building board and preparation method thereof

A high-strength impact-resistant weather-resistant PVC building board is made mainly from the following raw materials, by weight part, 100 parts of polyvinyl chloride, 5-80 parts of chlorinated polyvinyl chloride, 5-60 parts of straw fiber powder, 2-15 parts of a toughening agent, 5-100 parts of a functional filling material, 3-6 parts of a stabilizer, 0.2-3.0 parts of a foaming agent, 3-12 parts of a foaming conditioning agent, 0.3-2.0 parts of an inner lubricant and 0.3-2.0 parts of an outer lubricant. Through addition of the functional filling material, the system is stable during PVC foaming, and thermal resistance and aging resistance of the board are obviously improved. The corrosion resistance of the foamed material is obviously improved, so that the application field of the product is widened. The strength and impact resistance of the board is superior to a PVC foamed board in the market at the present. Crop straw powder instead of conventional wood powder is utilized, so that the forest resources are saved and the problem of straw burning is solved.

Owner:新疆嘉锋新型建材开发有限公司

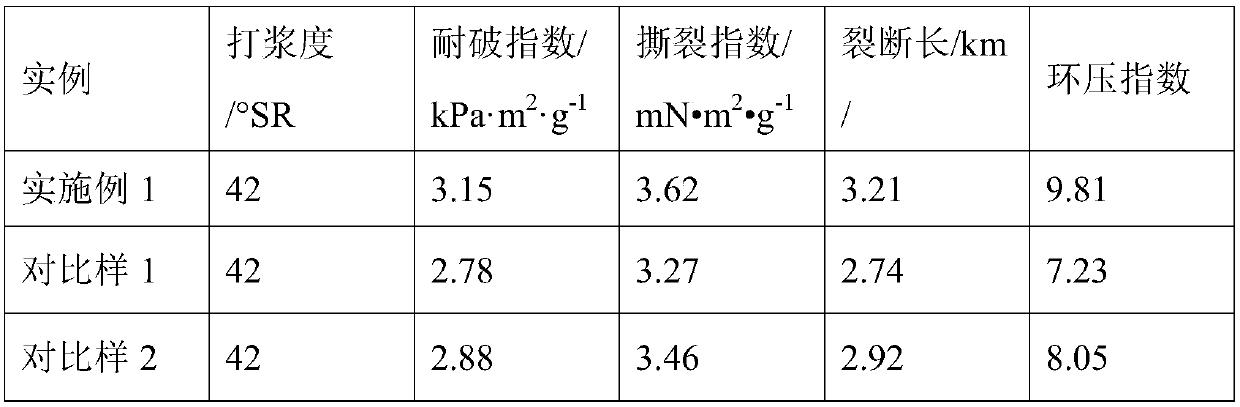

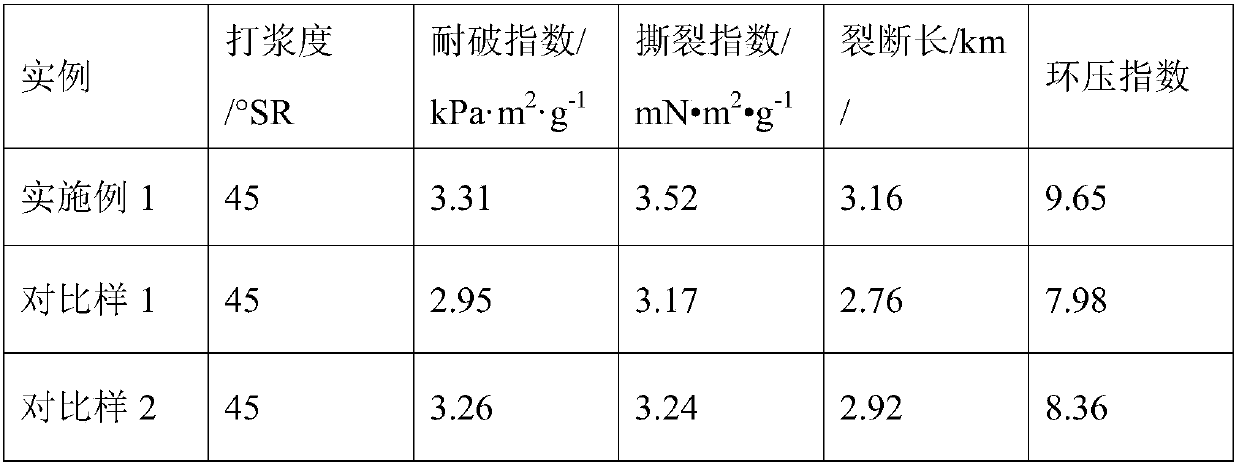

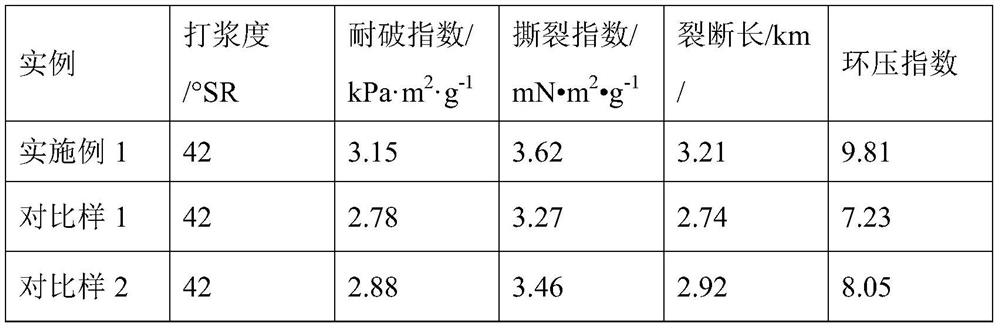

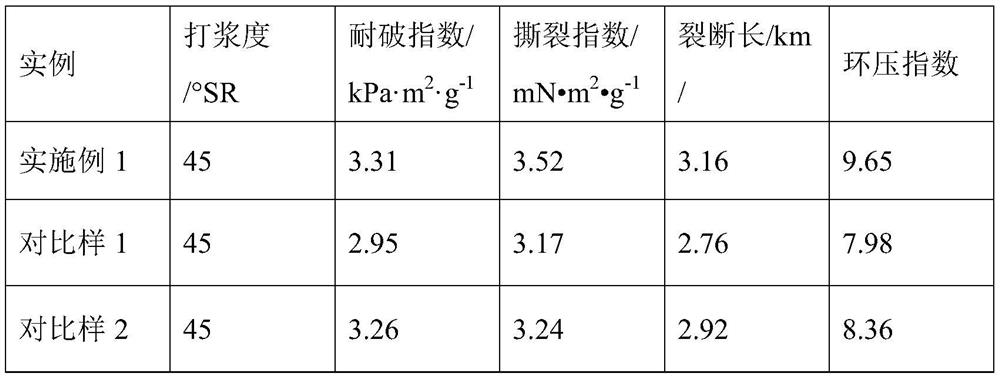

Method for preparing natural biomechanical pulp from wheat straw treated by hot steam combined with biological enzyme

ActiveCN109680530AGuaranteed recyclingEmission reductionCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpFiberWater vapor

The invention relates to a method for preparing natural biomechanical pulp from wheat straw treated by hot steam combined with biological enzyme. The method comprises the following steps: taking wasteof crop wheat as a pulping raw material, treating the wheat straw with the hot steam, further adding a trace amount of alkali to adjust the pH of hot water to be 10 to 14, after dissolving a part ofsubstances of hemicellulose, lignin, pectin and the like in the wheat straw, and after performing hot-saturated softening on the wheat straw by hot water vapor, rolling filaments, physically separating the filaments of the wheat straw, then treating with the biological enzyme, and then further softening fibers, then grinding the wheat straw into pulp to meet the requirements of producing natural packaging paper and paper-based materials.

Owner:QILU UNIV OF TECH +1

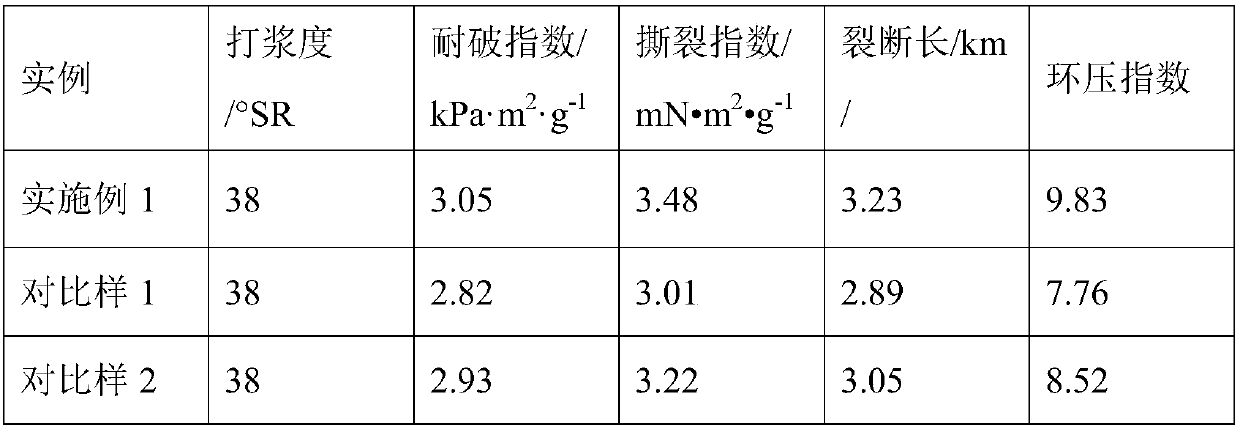

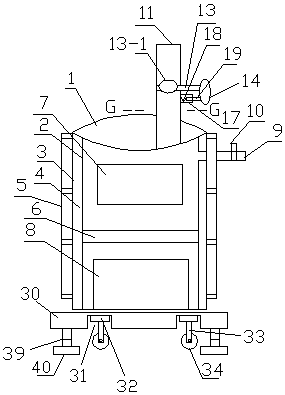

Self-propelled straw treatment machine

InactiveCN104475427AHuge market potentialEasy to handle on siteSolid waste disposalCuttersMarket potentialProcess engineering

The invention discloses a self-propelled straw treatment machine which comprises a body with wheels, a crushing device, a heating and drying device, an extrusion device and a power source, wherein the crushing device, the heating and drying device and the extrusion device are arranged on the body and are sequentially connected with one another, and the power source is arranged on the body, is connected with the previous devices and provides power, a traction machine head is arranged on the body and comprises a driving control room and an engine arranged in the machine head. A fan knife of the crushing device performs high-speed staggered cutting so as to form a wind wheel, the crushed straws are pushed into a bicylindrical inner cavity, the straws are treated by a rolling and cutting knife group until the straws are completely crushed, and the crushed straws are dried and fed into the extrusion device to be extruded into patch fuel or granulated feed by virtue of the heating and drying device. Moreover, due to the traction machine head, the machine can operate in the field, the finished product can be stored in the finished product bin, the field treatment of the straws is conveniently realized, the self-propelled straw treatment machine adapts to the market demands, has great market potential, is used for solving the problem of the existing straw burning, has energy-saving and environment-friendly effect and conforms to the environment development demand.

Owner:李荣刚

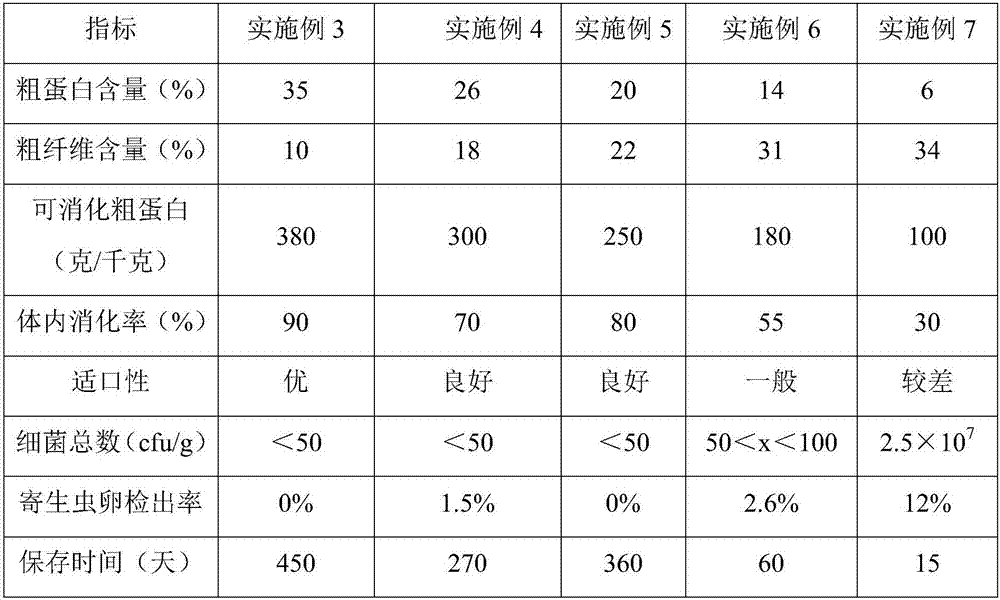

Method for making full-time grains of herbivorous animals with crop straws

InactiveCN107198019ARealize the utilization of feedHigh degree of commercializationFood processingAnimal feeding stuffAnimal scienceHigh energy

The invention discloses a method for making full-time grains of herbivorous animals with crop straws. The method comprises the following steps: taking the crop straws as main raw materials and performing high-temperature and high-pressure gas explosion on the crop straws, so as to obtain a high-energy straw composite feed semi-finished product; adding corns, bean pulp and accessories that are 10-20%, 5-15% and 2-7% of the weight of the crop straws respectively into the semi-finished product, fully and uniformly stirring the mixture and performing extruding granulation or briquetting, so as to obtain a finished product. According to the method, cell walls of the crop straws are destroyed by adopting a high-temperature and high-pressure gas explosion method, so that neutral detergent fibers in the crop straws can be remarkably decreased, and cellulose and hemicellulose rich in the crop straws can be more effectively utilized; compared with the traditional full-time grains of the herbivorous animals, the full-time grains of the herbivorous animals, which are made by the method disclosed by the invention, is low in cost and high in energy efficiency and has a nutrient structure which is more suitable for ruminants such as cattle, sheep and the like, and grains used for fodder can be greatly decreased.

Owner:安徽康桥生物科技有限公司

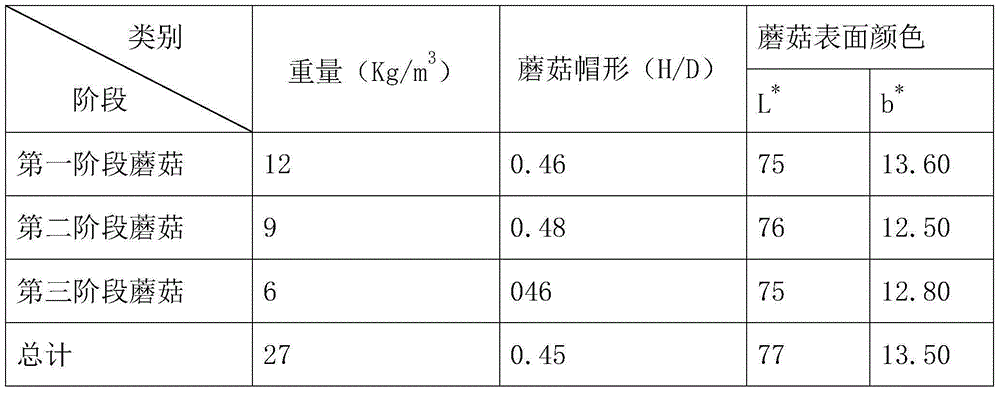

Agaricus bisporus cultivation method

InactiveCN105103963AShorten the fermentation cycleImprove compost qualityCalcareous fertilisersBio-organic fraction processingGypsumAgaricus bisporus

Owner:CHENGDU FU RUI DA BIOTECH

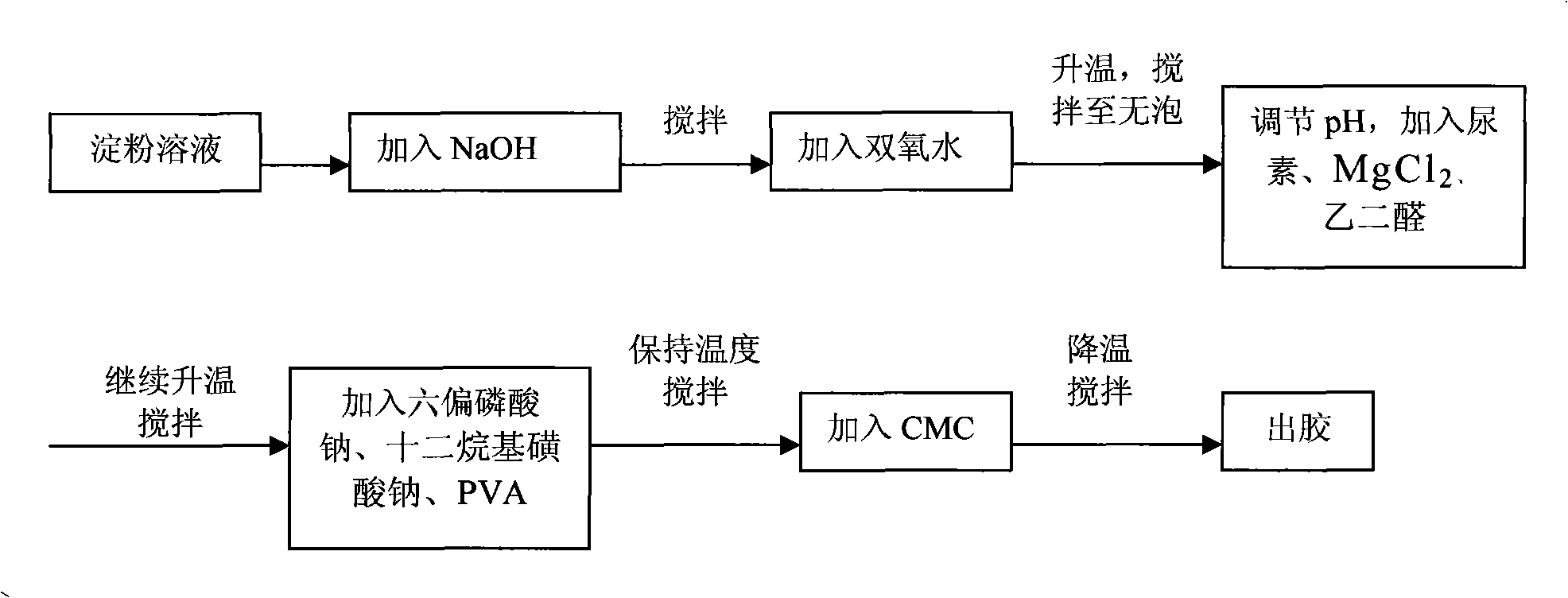

Method for preparing starch gum used for straw fiber products

InactiveCN101514278AImprove water resistanceSolve the problem of incinerationStarch adhesivesWater bathsFiber

The invention relates to a method for preparing starch gum used for straw fiber products, comprising the steps: NaOH is added into starch aqueous solution at the room temperature to be stirred for 15min; then, hydrogen peroxide is added into the mixed solution, and the obtained mixed solution is stirred at 50-70 DEG C in water bath until no bubble is generated; after that, the pH of the mixed solution is adjusted to be 5-6 by using acid liquor, and carbamide, MgCl2, oxalic aldehyde, sodium hexametahposphate, polyvinyl alcohol (PVA), dodecyl sodium sulfate and dissolved carboxymethyl cellulose (CMC) are sequentially added into the mixed solution and stirred for 1h when the temperature is lowered to 60 DEG C, and a right amount of water is added into the mixed solution at the same time, thus the pot is not dried out; finally, dehydration action is carried out until the obtained solution reaches the needed concentration, and temperature reduction as well as gum exudation are carried out. The product obtained by the method provided by the invention has better viscocity and fluidness as well as simple manufacturing technique, is especially suitable for making the straw fiber products; after being solidified, the final straw products have the advantages of low cost, great hardness, degradation property and good water resisting property.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Rice seedling nursing soil, as well as preparation method and application thereof

InactiveCN107500892AReduce usageSimplify nursery proceduresCalcareous fertilisersAlkali orthophosphate fertiliserBacillus licheniformisBacillus thuringiensis

The invention discloses rice seedling nursing soil, as well as a preparation method and application thereof, and relates to the field of rice seedling nursing. The problems of straw combustion and difficulty in soil taking during rice seedling nursing in spring are solved. The rice seedling nursing soil is prepared from the following components in parts by weight: 100 to 200 parts of soil, 80 to 90 parts of straw powder, 10 to 20 parts of a compound microbial agent, 0.1 to 0.15 part of potassium dihydrogen phosphate, 0.1 to 0.4 part of ammonium sulfate and 0.1 to 0.3 part of quicklime, wherein the compound microbial agent is prepared from the following components: pseudomonas syringae, bacillus thuringiensis, bacillus subtilis, bacillus licheniformis, trichoderma and lactobacillus plantarum, and the mass ratio of the pseudomonas syringae, the bacillus thuringiensis, the bacillus subtilis, the bacillus licheniformis, the trichoderma and the lactobacillus plantarum is 1.5:1:1:1:1:1.5. According to the rice seedling nursing soil and the preparation method and application thereof, insect killing, sterilization, pest and disease damage prevention and control and increase of transmission of oxygen in the soil can be simultaneously implemented, growth and reproduction of microorganisms are facilitated, pollution is avoided, and the yield is high.

Owner:吉林省晟华农村电商创业服务有限公司

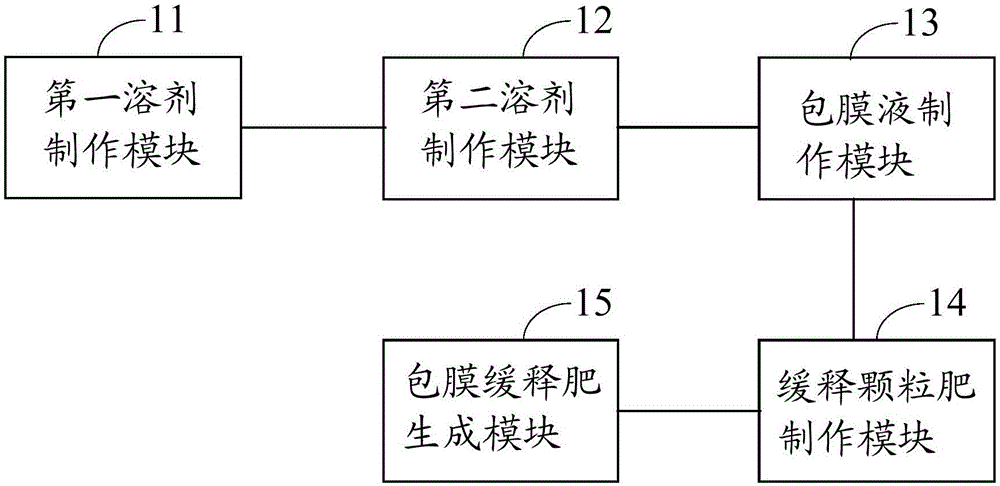

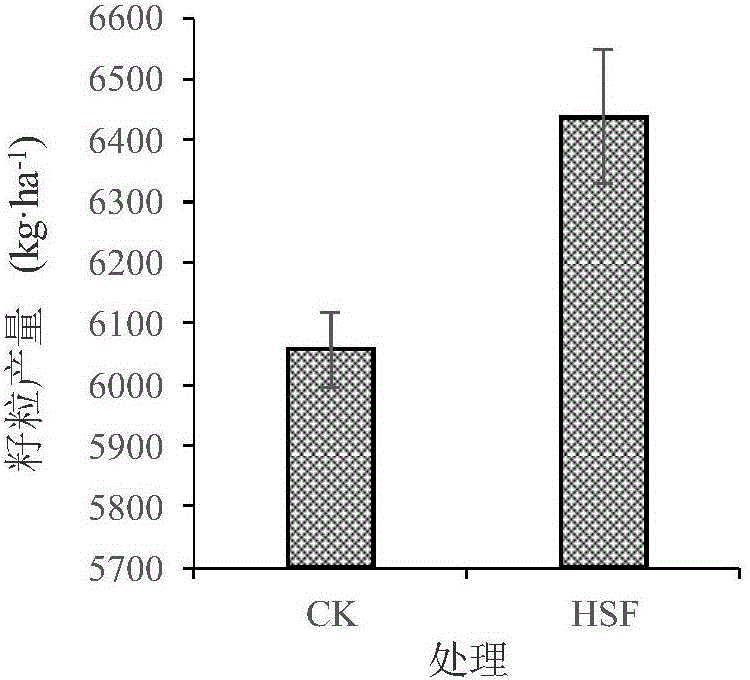

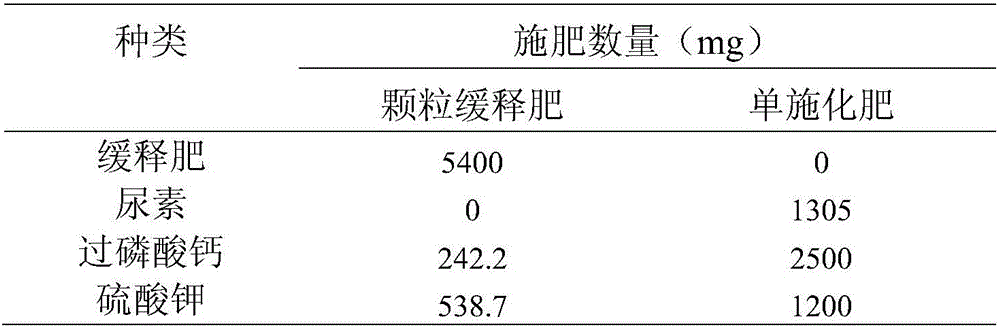

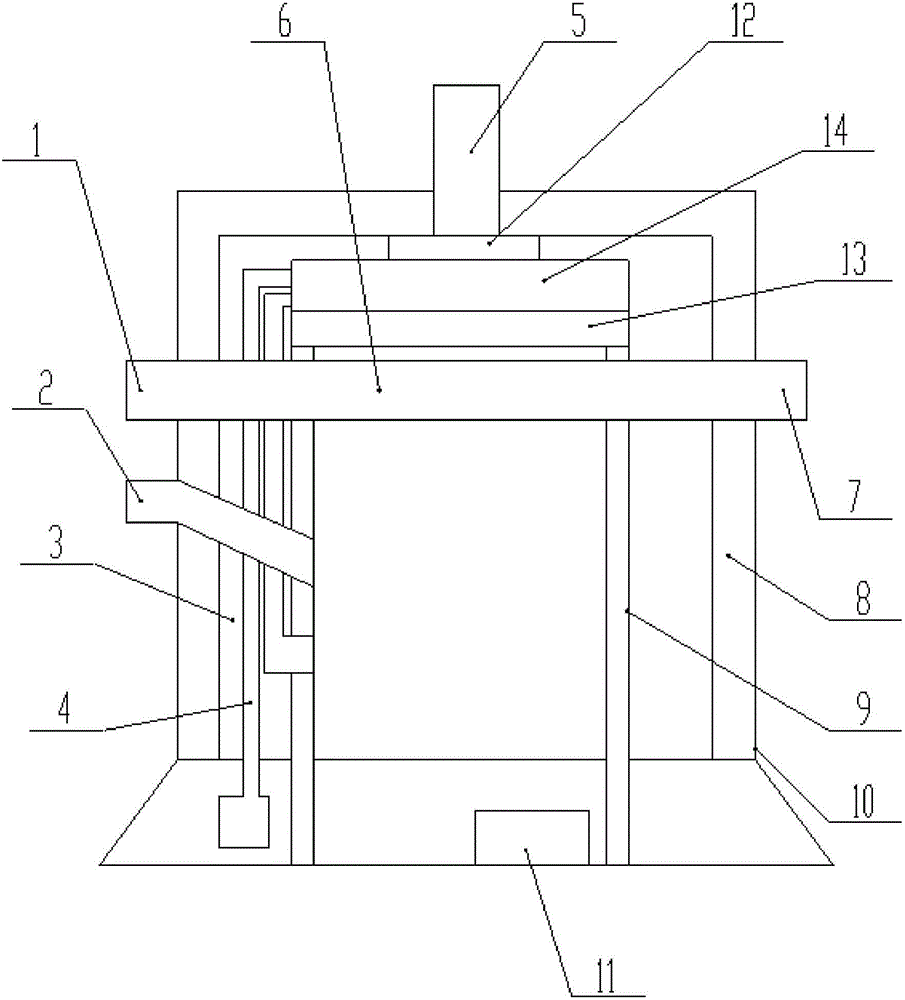

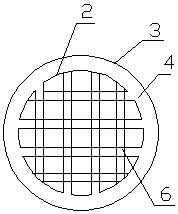

Film-coated slow release fertilizer as well as preparation method and device thereof

InactiveCN106747899ALow costHigh organic contentSuperphosphatesUrea compound fertilisersControl releaseSolvent

The invention discloses film-coated slow release fertilizer as well as a preparation method and device thereof. An outer film coating material for controlled release fertilizer or slow release fertilizer is prepared from crop straw and auxiliaries, wherein the mass percent of the crop straw is 85%-90%. The film-coated slow release fertilizer comprises an outer coating film and inner stuffing coated with the outer coating film, wherein the outer coating film is prepared from the outer film coating material; the inner stuffing is inorganic fertilizer. The device for preparing the film-coated slow release fertilizer comprises a first solvent preparation module, a second solvent preparation module, a film coating liquid preparation module, a slow release granule fertilizer preparation module and a film-coated slow release fertilizer production module which are connected sequentially, wherein the first solvent preparation module comprises a heating unit and a pasting unit which are connected; each of the second solvent preparation module and the film coating liquid preparation module comprises a starrier; the slow release granule fertilizer preparation module comprises a film coating tower; the film-coated slow release production module comprises a blasting device. The cost of the film-coated slow release fertilizer can be reduced, and secondary pollution to the environment can be reduced.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

Straw feed making method

The invention discloses a straw feed making method which includes the following process: straw harvesting, straw rubbing, spraying of additives, compression into blocks, and packaging with bags. The straw feed is high in palatability, the feed intake rate is up to 91% or more, the straw feed overcomes the defects that traditional straw feeds are easy to mildew and rot, and poor in palatability, the rate of finished products and the quality of the straw feed are improved; the straw feed helps effective straw utilization, reduces the environment pollution caused by the straw burning, increases crop added product value, reduces the feeding feed cost, and achieves a win-win situation in the planting and breeding efficiency.

Owner:CHANGSHA CHUANGYUAN ENVIRONMENTAL PROTECTION TECH

Biomass fuel expansion furnace for preparing expanded graphite

The invention relates to a biomass fuel expansion furnace for preparing expanded graphite. The biomass fuel expansion furnace comprises a furnace body, wherein a combustion chamber is formed inside the furnace body; a second air duct is arranged between the combustion chamber and the inner wall of the furnace body; the outer layer of the furnace body is a heat-preservation layer; a graphite flowing expansion pipeline of which one end penetrates through and extends outside the combustion chamber is arranged at the upper part of the furnace body; a biomass fuel feeding hole which is communicated with the combustion chamber is formed in the side wall of the furnace body; a first air duct which is communicated with the combustion chamber and the external environment is arranged inside the furnace body; a slag outlet which is communicated with the combustion chamber is formed in the bottom of the furnace body; an air outlet is formed in the top of the furnace body. The biomass fuel expansion furnace is applicable to biomass fuel to provide a heat source, SO2 discharge can be reduced, the dust standard can be met with low cost, NO<x> generation is also reduced, PM2.5 discharge is reduced, and the idea of low carbon and environment protection can be met; the biomass fuel expansion furnace does not affect the chemical components of expanded graphite worms in a sealed flowing pipeline, and has benefits for later procedures using expanded graphite.

Owner:徐珂

Preparation method of bio-organic fertilizer

InactiveCN111087264ASolve the problem of incinerationSolve pollutionBio-organic fraction processingMicroorganism based treatmentBiotechnologyStraw

The invention discloses a preparation method of a biological organic fertilizer, which comprises the following steps: adding crushed first part straw into a first part container, adding a nitrogen source into the first part straw, adding alkali and water into the first part container to adjust the pH value and water content of the substance in the first part container, stirring the components uniformly, and sterilizing the mixture to obtain a sterilized material; cooling the sterilized material, and mixing the trichoderma liquid culture medium with the sterilized material to obtain an inoculation liquid; culturing the inoculation liquid to obtain trichoderma liquid; spraying an aqueous solution containing a nitrogen source onto the crushed second part of straw to obtain a spraying material, mixing the YM strain with the spraying material to form a stacked material, naturally stacking the stacked material for 1-2 days, and starting to turn over for fermentation to obtain a primary fermentation decomposed material; spraying an aqueous solution containing a nitrogen source to the primary fermentation decomposed material with uniform mixing to obtain a secondary fermentation decomposedmaterial, spraying a trichoderma liquid to the secondary fermentation decomposed material, and composting the material to obtain a finished product. According to the invention, the trichoderma, YM bacteria and straw are combined to generate the bio-organic fertilizer.

Owner:PENYAO ENVIRONMENTAL PROTECTION

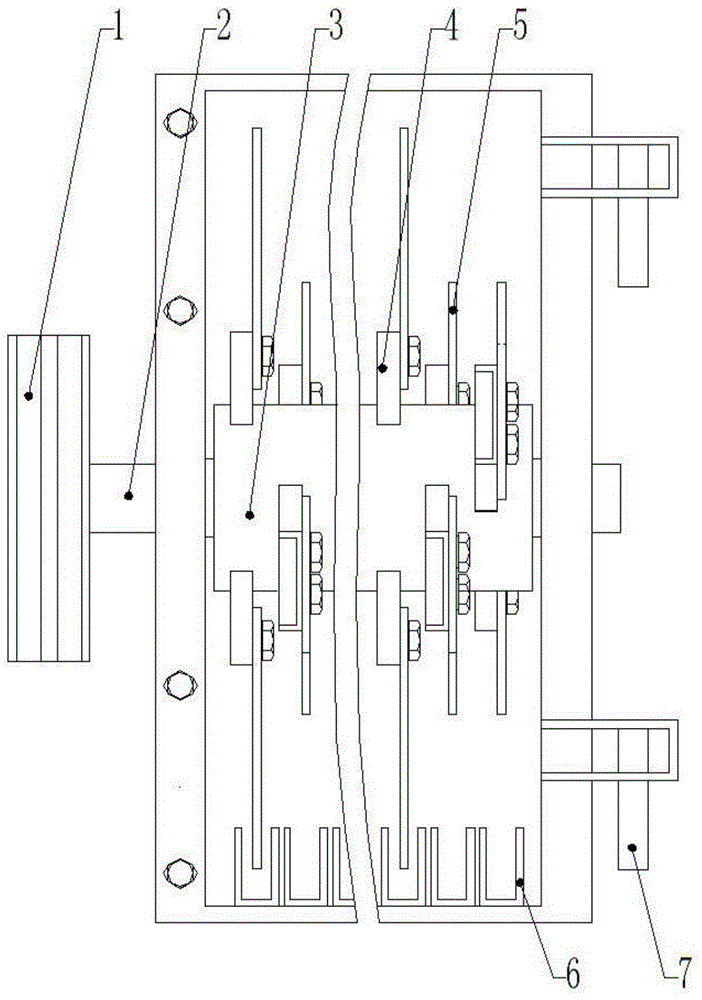

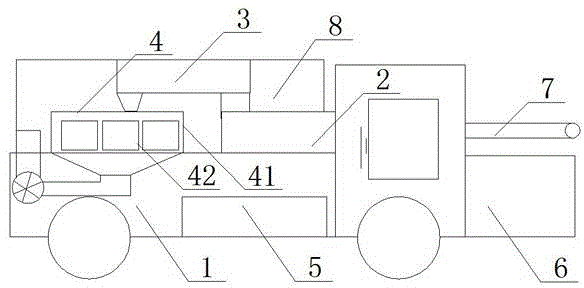

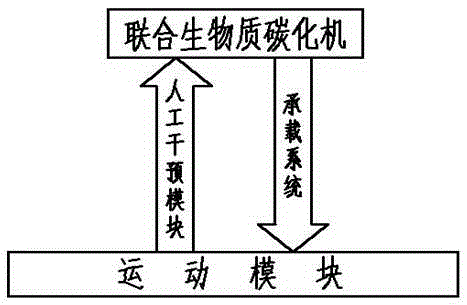

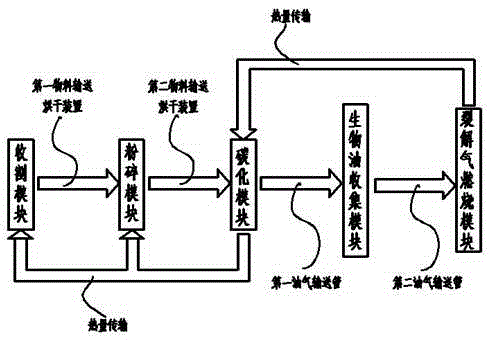

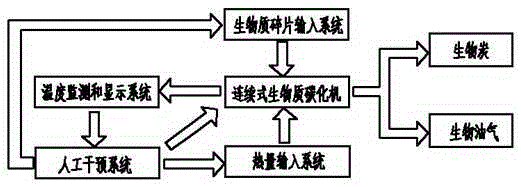

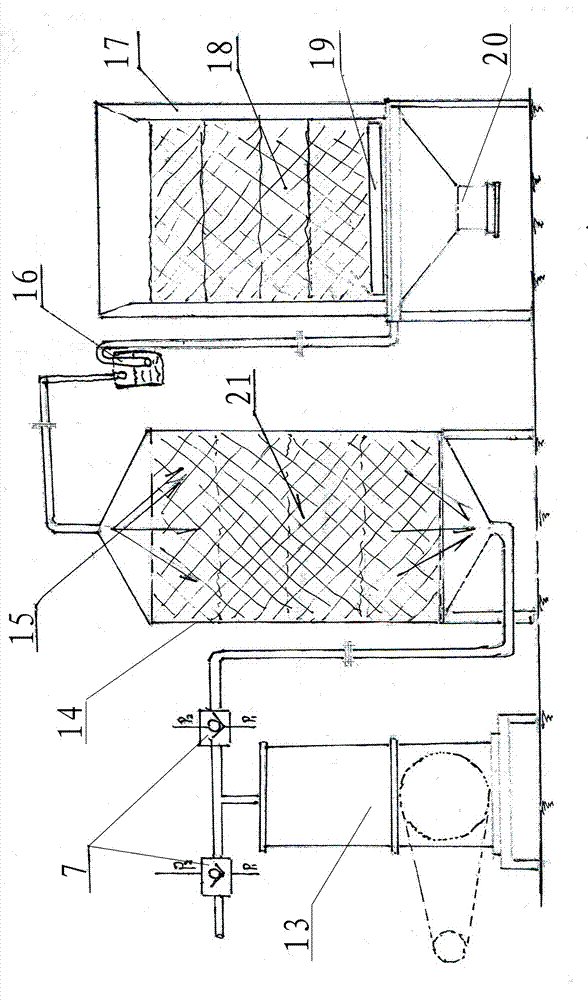

Self-propelled combined biomass carbonization system

ActiveCN105295972ARealize on-site carbonizationSolve the problem of incinerationBiofuelsLiquid hydrocarbon mixture productionCombustionCarbonization

The invention discloses a self-propelled combined biomass carbonization system. A combined biomass carbonization machine is loaded on a motion module. The combined biomass carbonization machine comprises a harvesting module, a crushing module, a carbonization module, a bio-oil collecting module and a cracking gas combustion module. The harvesting module is connected to the crushing module through a first material conveying and drying device. The crushing module is connected to the carbonization module through a second material conveying and drying device. The carbonization module is connected to the bio-oil collecting module through a first oil and gas conveyer pipe. The bio-oil collecting module is connected to the cracking gas combustion module through a second oil and gas conveyer pipe. Heat generated by combustion of the cracking gas combustion module is supplied to the carbonization module. By integrating functions such as movement, biomass harvesting, crushing, carbonization, oil and gas separation and collection and combustion and recycling of cracking gas, etc., on-site carbonization of biomass such as straw and the like can be realized. The invention provides a feasible technical means for large-scale high-value use of biomass wastes such as straw and the like.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

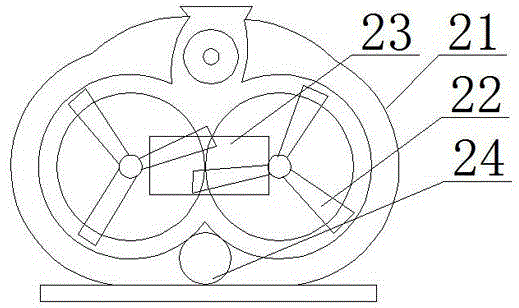

Generation device for generating combustible gas by utilizing biomass fuel efficiently

InactiveCN102786969ASolve the problem of incinerationAvoid blackeningDirect heating destructive distillationSpecial form destructive distillationCombustible gasAir pump

The invention relates to a generation device for generating combustible gas by utilizing a biomass fuel efficiently. The generation device comprises a gasification furnace, a smoke filtering drum and an air pump, wherein the gasification furnace comprises a furnace drum, the lower end of the furnace drum is connected with a dust discharge channel, and a joint of the furnace drum and the dust discharge channel is provided with a fire-grate bar or a furnace plate with a through hole; and the smoke filtering drum comprises a sealing shell, a filter element is arranged in the sealing shell, the upper part of the sealing shell is connected with the gasification furnace through a pipeline, and the lower part of the sealing shell is connected with an air outlet pipeline. According to the gasification furnace and the smoke filtering drum, the biomass fuel generates gas in the gasification furnace, the gas is filtered by the smoke filtering drum, a grass cake can be used as the filter element of the smoke filtering drum to remove the unpleasant smell of tar, smoke dust and the like in the combustible gas, and the grass cake which is used for a long time in the smoke filtering drum can be taken out and used as gasification raw material, and is recycled to save the cost. The generation device for generating the combustible gas by utilizing the biomass fuel efficiently disclosed by the invention has the characteristics of simple structure, high filtering and purifying rate, environmental protection and no pollution.

Owner:宁开敏

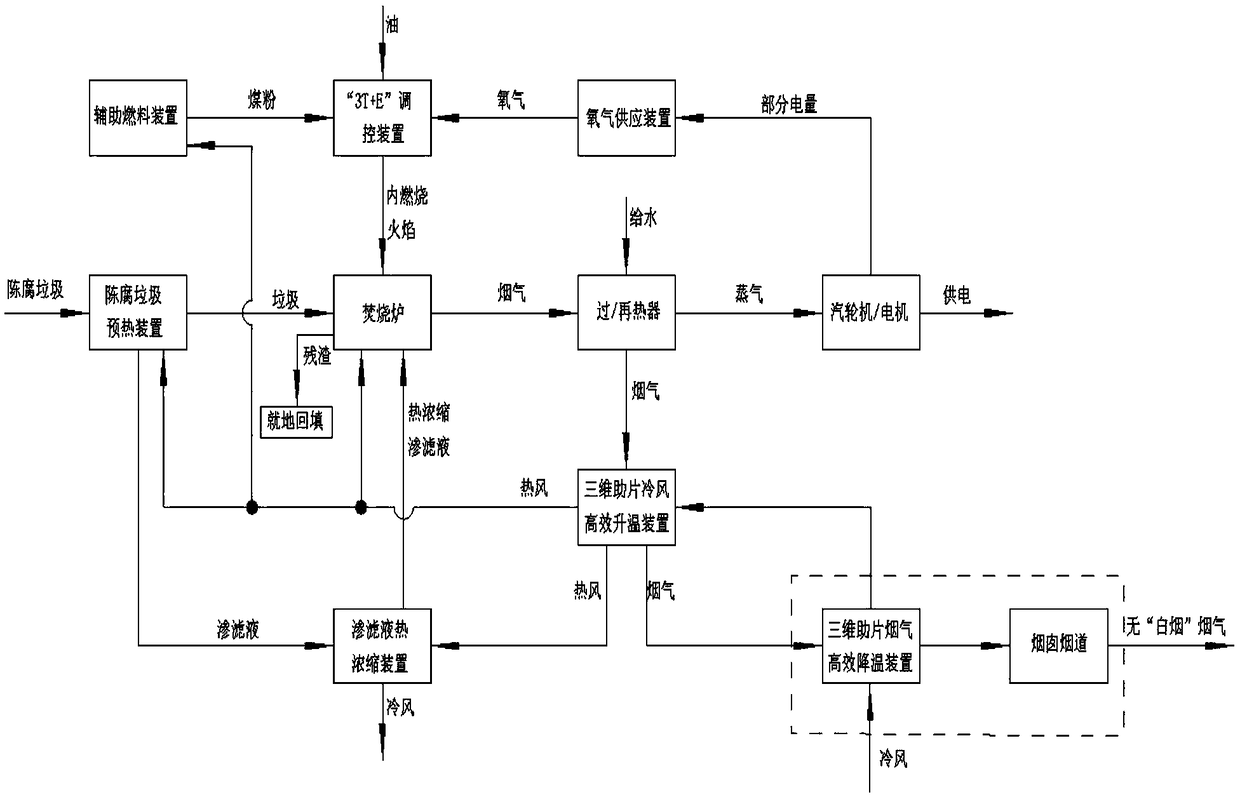

System and method of disposing stale garbage in landfill

PendingCN109185895AEnsure incinerationStable working conditionFuel supply regulationIncinerator apparatusCold airProcess engineering

The invention discloses a system and method of disposing stale garbage in a landfill. The system is characterized by comprising an incinerator, a 3T+E regulation and control device, an oxygen supply device, an auxiliary fuel device, a three-dimensional fin cold air efficient heating device, a three-dimensional fin smoke efficient cooling device, a stale garbage preheating device and a leachate thermal concentration device.

Owner:CHONGQING FURAN TECH

Producing paper pulp by using method of biologic enzymolysis

InactiveCN1563562ASolve the problem of incinerationAvoid pollutionCellulose material pulpingChemical reactionPulp and paper industry

This is a paper pulp productive method to use the biochemical enzymolysis technology. This invention is to use extraordinary power of enzyme and its super efficient of catalysis. The enzyme can increase reaction speed, while cannot appear the remnants, therefore to protect the environment against pollution, and to economize on energy source.

Owner:徐丽敏

Decomposition agent, preparation method thereof and application thereof in returning straw compost to field

InactiveCN109438132AShorten the transportation radiusReduce mechanical costsBio-organic fraction processingExcrement fertilisersChemistryDecomposition

The invention discloses a decomposition agent, a preparation method thereof and application thereof in returning straw compost to a field, and belongs to the technical field of green agricultural production. Aiming to solve the technical problems that an existing composting method is complex and is high in labour cost, the invention provides the decomposition agent which is prepared by mixing a probiotics complex microbial inoculant and organic substance fermentation substrate and then sequentially performing anaerobic fermentation and aerobic fermentation; the probiotics complex microbial inoculant is prepared by EM probiotics fermentation; and the organic substance fermentation substrate consists of soybean meal, rice chaff, wheat bran and corn flour. According to the invention,straw, manure, the prepared decomposition agent and soil are sequentially stacked in sequence from bottom to top, and such stacking is performed for multiple layers according to the stacking sequence of the first layer. The decomposition agent is used for returning straw compost to the field.

Owner:黑龙江雄微生物科技有限公司

Crushing device for wheat straw

InactiveCN106914321ASolve the problem of incinerationImprove crushing effectGrain treatmentsChinese charactersRotary engine

The invention discloses a crushing device for wheat straw. The crushing device comprises a shell, a rotary shaft, fixing discs, rotary knives and cutting knives, wherein the rotary shaft is arranged in the shell through a bearing seat, the fixing discs are fixedly connected to the rotary shaft and are located in the shell, the rotary knives are connected to the fixing disc through pin shafts, the cutting knives are fixedly connected to the upper side and the lower side of the shell, each fixing disc is composed of two rotary discs and a plurality of connecting rods, the two ends of each connecting rod are vertically fixed on the two rotary discs respectively, and the rotary knives are each shaped like a Chinese character shape ''ji''. The crushing device has the advantages of being simple in structure, reasonable in design, high in practicability, easy to popularize and use and the like.

Owner:CHONGQING XIANGGUIYUAN ECOLOGICAL TRAVEL DEV CO LTD

Biomass hot-water boiler

InactiveCN108731258ASolve the problem of incinerationTake advantage ofSolid fuel combustionWater heatersSlagEngineering

The invention relates to a biomass hot-water boiler which comprises a furnace body. A furnace wall of the furnace body is of a dual-layer structure and is divided into an inner furnace wall body and an outer furnace wall body, a furnace body water sleeve is arranged between the inner furnace wall body and the outer furnace wall body, a protecting plate is welded to the outer surface of the outer furnace wall body through a supporting column, a grate is arranged in the furnace body and is formed by welding a plurality of transverse pipes and vertical pipes, ends of the transverse pipes and thevertical pipes are connected with the furnace body water sleeve, the transverse pipes communicate with the vertical pipes, the furnace body is provided with a feeding opening and a discharging opening, and a water outlet pipe is arranged at the upper end of the furnace body and is provided with a flow control valve. By means of the biomass hot-water boiler, the problem about straw burning of a farmer can be solved, meanwhile, resources are sufficiently used, ash slag of burnt straw is very good manure, and multiple purposes are achieved through the boiler.

Owner:ZIBO DINGLI PATENT INFORMATION CONSULTING CO LTD

Preparation method of animal feed added with sorghum straw

InactiveCN109907172AImprove palatabilityOvercoming mildew and rotAnimal feeding stuffWorking-up animal fodderSorghumIntake rate

The invention discloses a preparation method of animal feed added with sorghum straw. The preparation method includes following steps: harvesting the straw, rubbing the straw, spraying an additive, press-baling, bagging and sealing, stacking, and externally packaging. The sorghum straw feed is high in palatability, intake rate can reach higher than 90%, the defect that conventional sorghum straw ensiling technology causes mildewing and rotting and low in palatability is overcome, and yield and quality of the ensiled sorghum straw feed are improved; ecological returning of the sorghum straw tothe field is facilitated, and environment pollution is reduced; product added value of crops is increased, breeding feed cost is lowered, and increase of both planting benefit and breeding benefit isrealized.

Owner:沈爱琴

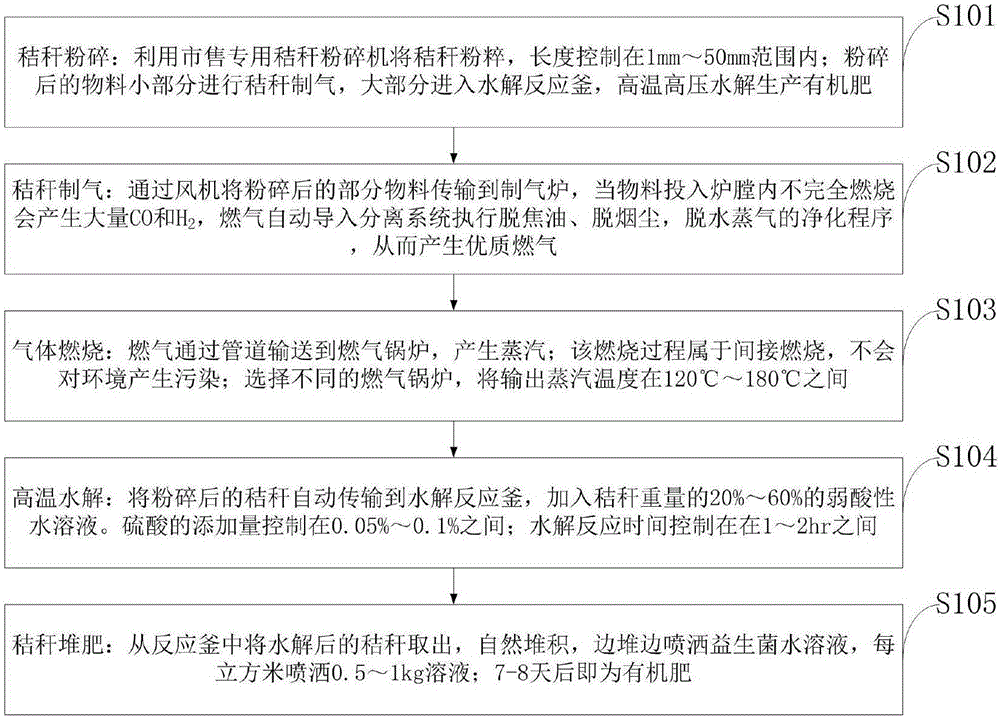

Comprehensive treatment method of straw

InactiveCN106381171AReduce shipping costsImprove economic efficiencyFood processingAnimal feeding stuffChemistryAqueous solution

The invention discloses a comprehensive treatment method of straw. The method comprises the following steps of smashing the straw; preparing gas through the straw; burning the gas; hydrolyzing at high temperature; straw composting; taking the hydrolyzed straw out from a reaction kettle; naturally stacking; spraying a probiotics water solution while stacking; staking for 7 to 8 days to obtain an organic fertilizer. According to the comprehensive treatment method of the straw provided by the invention, a design idea of a movable factory is adopted, and the aim of coming from people, and benefiting the people is achieved, so that the transportation cost of straw raw materials and recycling products is greatly reduced; the straw and the recycling products are fixed, and the factory is moved, so that the economic benefit is improved. The technical principle provided by the invention adopts coming from the straws, and benefiting the straws so as to achieve the aims of energy conservation and cost reduction. According to the comprehensive treatment method of the straw provided by the invention, on the basis of the prior art, various technologies are effectively integrated, so that the cost for a straw recycling process is greatly reduced, the economic benefit is improved, and the problem of straw burning is thoroughly solved.

Owner:吉林市汇禾环境科技有限公司

A method of treating wheat straw with hot steam and biological enzymes to prepare natural color biomechanical pulp

ActiveCN109680530BGuaranteed recyclingEmission reductionCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpFiberAgriculture crops

Owner:QILU UNIV OF TECH +1

Processing method of fully-degradable resin

The invention relates to the technical field of new materials, especially to a processing method of fully-degradable resin. The processing method comprises the following steps: grinding rice straw andrice husk to obtain straw powder, mixing the straw powder with high molecular weight polylactic acid, low molecular weight polylactic acid, a biodegradation additive, reinforced fibers, a silane coupling agent, a heat stabilizer, a plasticizer and a calcium nitrate solution and reacting to obtain a precipitate A; adding a sodium hydroxide solution to obtain a precipitate B; adding dimethyl formamide and maleic anhydride, and mixing to obtain a precipitate C; and mixing the precipitate C with nano-titanium dioxide, a resin material and sodium carboxymethylcellulose to obtain the fully-degradable resin. By using the rice husk and rice straw as the raw materials, the produced resin has strong environmental protection property and is low-cost. The produced fully-degradable resin has high tensile strength; and the postprocessing problem that rice straw needs to be burned or landfilled is solved.

Owner:安庆市泽烨新材料技术推广服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com