Generation device for generating combustible gas by utilizing biomass fuel efficiently

A biomass fuel and generating device technology, applied in gas dust removal, special form dry distillation, petroleum industry, etc., can solve problems such as poor filtration effect, poor gasification effect, environmental pollution, etc., and achieve high filtration purification rate and structure. Simple, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

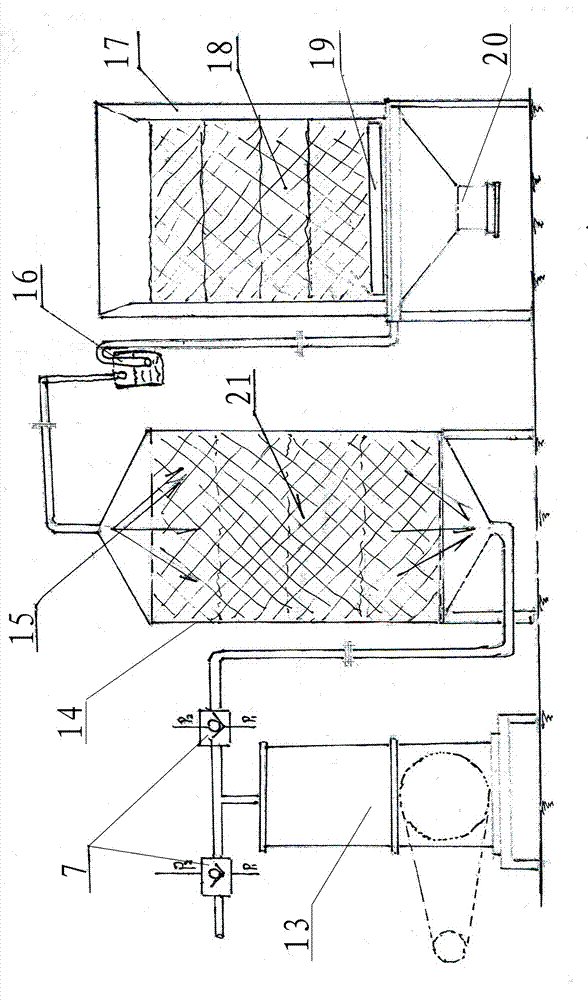

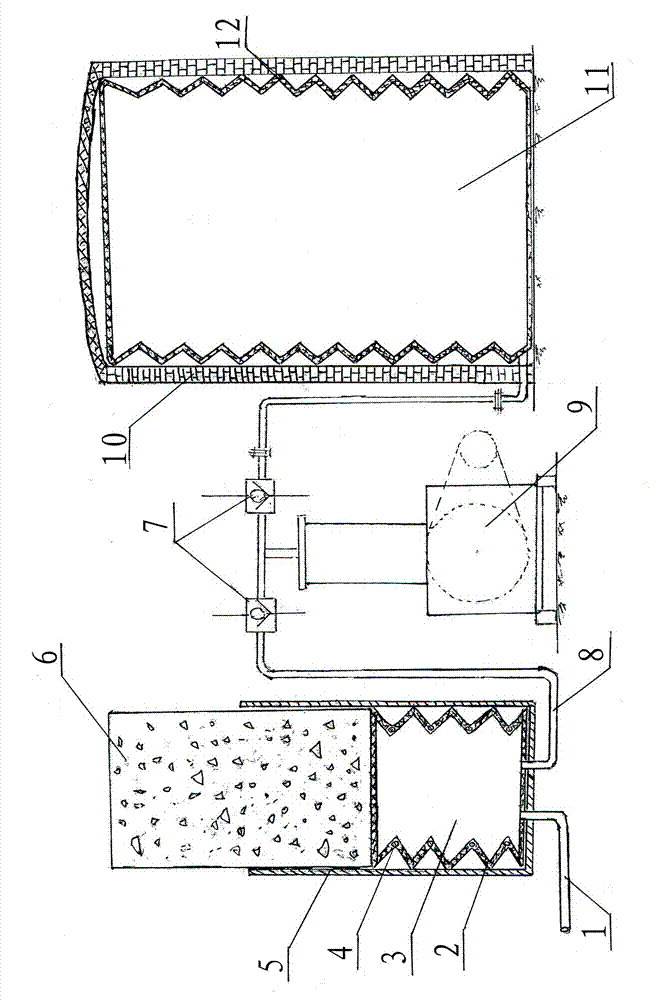

[0015] Embodiment 1, with reference to the accompanying drawings, a generator for efficiently applying biomass fuel to generate combustible gas, including a gasifier 18, a smoke filter tube 15 and an air pump 13, the gasifier 18 includes a furnace drum 17, and the lower end of the furnace drum 17 is connected to There is an ash discharge channel 20, and a furnace bar or a furnace plate 19 with a through hole is provided at the junction of the furnace tube 17 and the ash discharge channel 20, and the ash enters the ash discharge channel 20 from the gap of the furnace bar or the through hole of the furnace plate 19 to be discharged. An air outlet is provided on the furnace wall at the lower part of the furnace tube 17; the smoke filter tube 15 includes a sealed housing 14, and a filter element 21 is arranged inside the sealed housing 14, and the upper part of the sealed housing 14 passes through the air outlet of the pipeline and the gasifier 18 The air outlet pipeline is connect...

Embodiment 2

[0017] Embodiment 2, in the generating device described in embodiment 1, the pipeline between the gasifier 18 and the smoke filter tube 15 is provided with a fire isolation device 16 to prevent sparks in the gasifier 18 from entering into the smoke filter tube 15 and igniting The filter element 21 improves the safety of the equipment.

Embodiment 3

[0018] Embodiment 3, in the generating device described in Embodiment 2, the fire isolation device 16 includes a water tank, and the outlet of the pipeline connected to the air outlet of the gasifier 18 is arranged in the water tank, and the upper part of the water tank passes through the pipeline and the smoke filter tube 15 The upper part of the sealed housing 14 is connected, water is housed in the water tank, and the outlet of the pipeline connected to the air outlet of the gasifier 18 is not in the water, and the gas coming out from the gasifier 18 is filtered through the water in the water tank and then released from the gasification furnace 18. The pipeline on the top of the water tank enters the smoke filter tube 15, which can eliminate naked flames.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com