Patents

Literature

329 results about "Agriculture crops" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crop, In agriculture, a plant or plant product that can be grown and harvested extensively for profit or subsistence. By use, crops fall into six categories: food crops, for human consumption (e.g., wheat, potatoes); feed crops, for livestock consumption (e.g., oats, alfalfa); fibre crops, for cordage and textiles (e.g., cotton,...

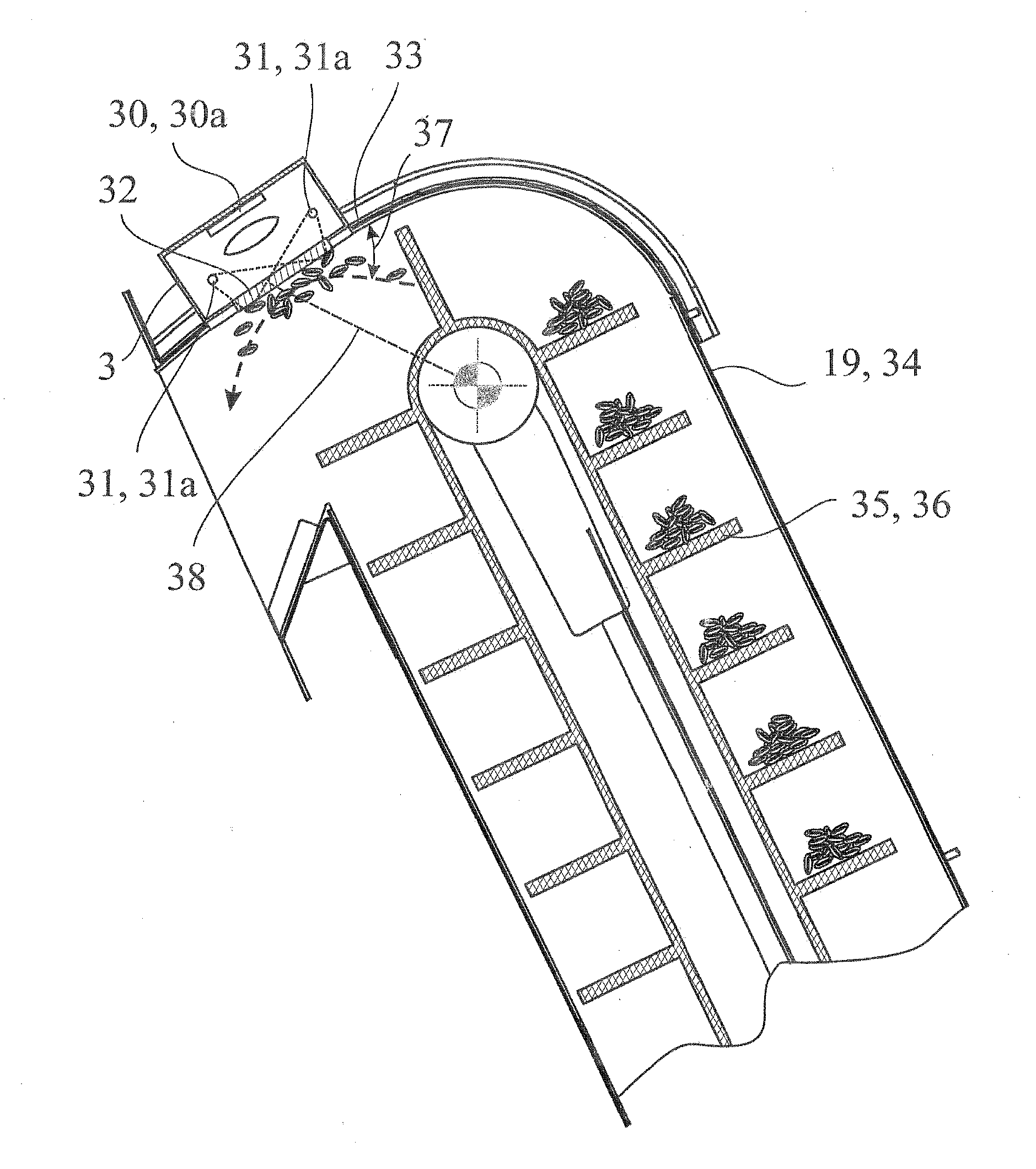

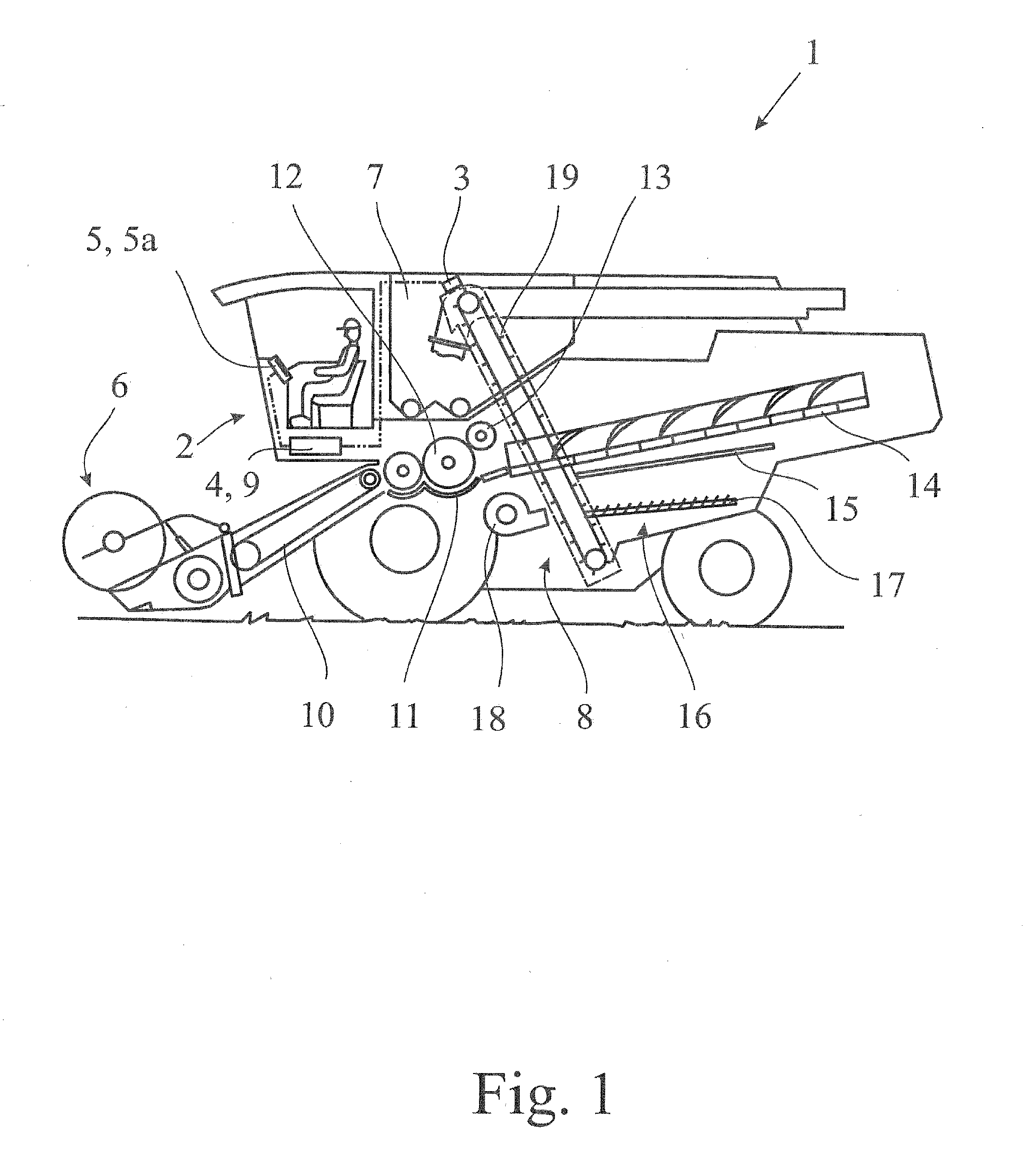

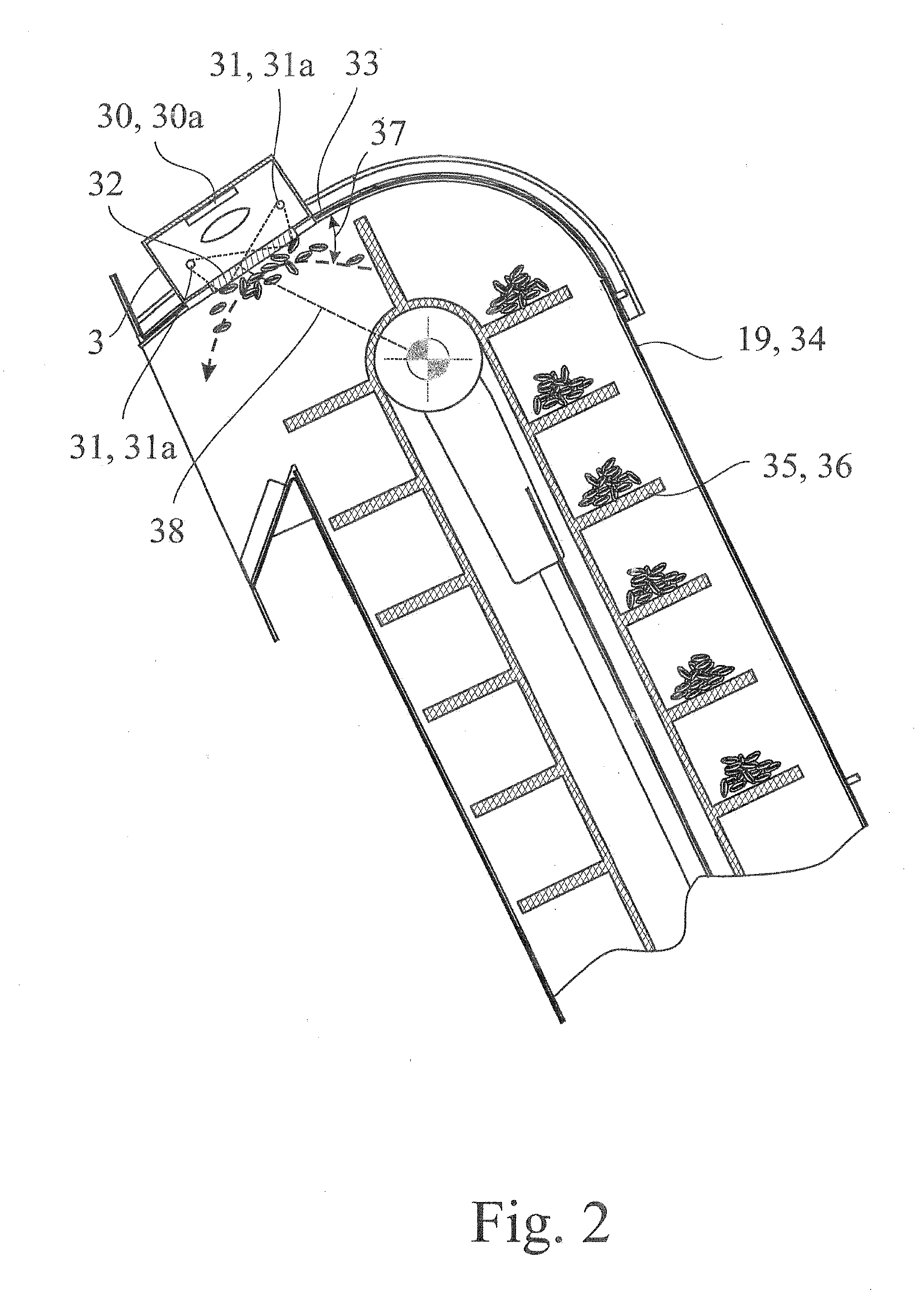

Agricultural harvesting machine

ActiveUS20150009328A1Accurately and rapidly estimatedEasy to identifyMowersColor television detailsAgricultural scienceImaging analysis

An agricultural harvesting machine has a control arrangement including an optical sensor device for recording image series of a continuous main crop stream, an evaluation device for ascertaining a portion of damaged grain, a portion of non-grain in the main crop stream or both, on the basis of an image analysis of the recorded image series and a visualization device for displaying the portion of damaged grain and / or the portion of non-grain. The control arrangement cyclically records image series of the continuous main crop stream and, within a predetermined processing time after an image series has been recorded, displays a current portion of damaged grain, a current portion of non-grain or both, based on the image series.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Method for utilizing waste as soil improvement agent for remediating desertification soil

InactiveCN108353563ASolve pollutionPromote growthOrganic fertilisersSoil conditioning compositionsSludgeDrip irrigation

The invention relates to a method for utilizing waste as a soil improvement agent for remediating desertification soil. The soil improvement agent in the method is prepared by evenly mixing sand grains or sandy soil, grease by-product greasy filth and oil foots, liquor residues, sludge, coal ash and decomposed coal proportionally, then, the soil improvement agent coats the surface of desert or sand, watering or drip irrigation watering is performed, drought-enduring plants or crops are planted on a sandy block to be remediated and can grow well, meanwhile, the soil skin effect can be formed ona desert layer due to coating of the soil improvement agent, and the partial-curing effect is achieved on desert or sand. According to the method, waste is reasonably utilized again, the method conforms to the recycling economic concept, and the problem that environment contamination is caused by waste is solved. The waste obtained after industrial and agricultural production is adopted as raw materials for remediating desert and sand, energy conservation and emission reduction are composited, and the method conforms to the circular economy concept and natural laws.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

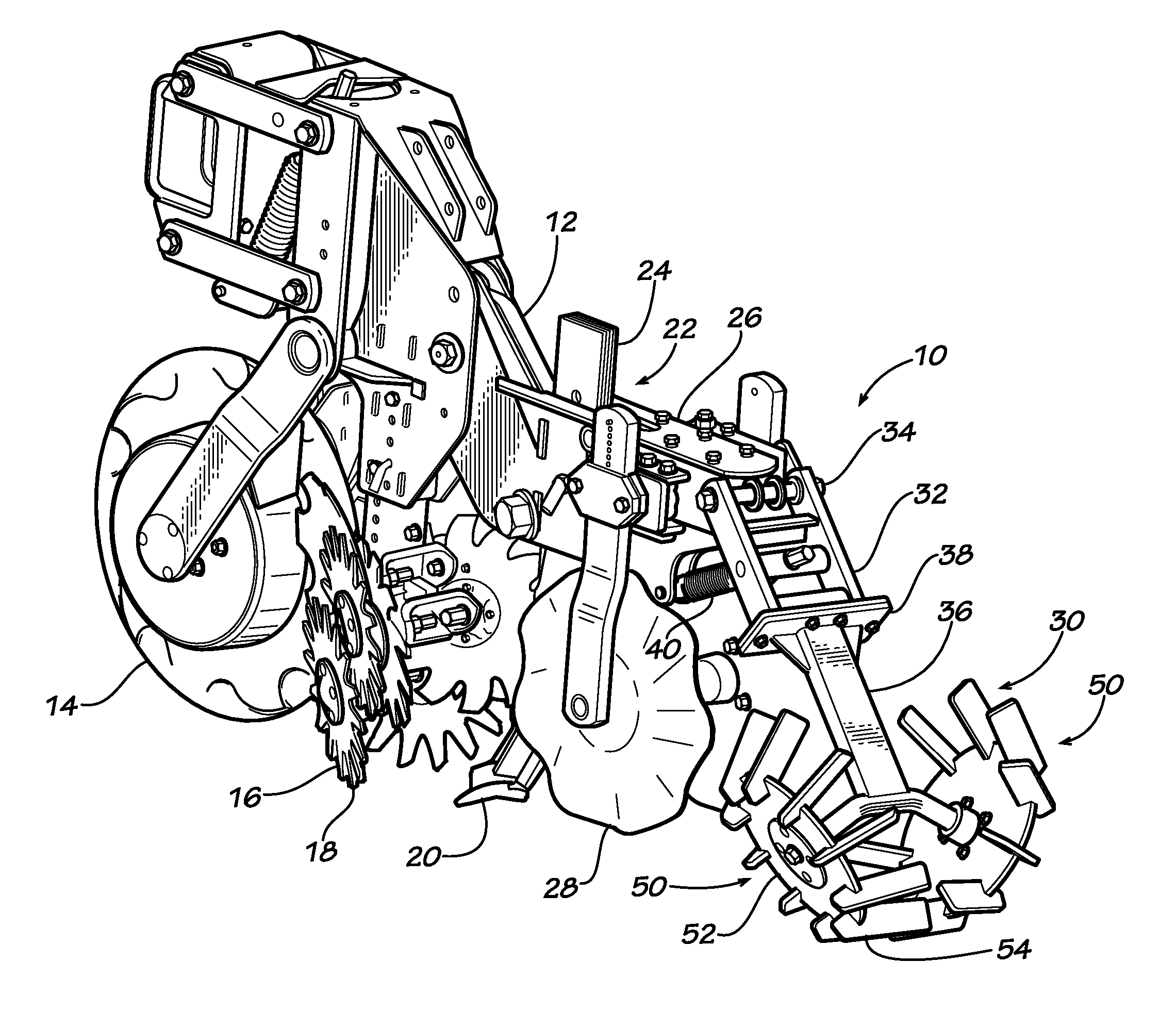

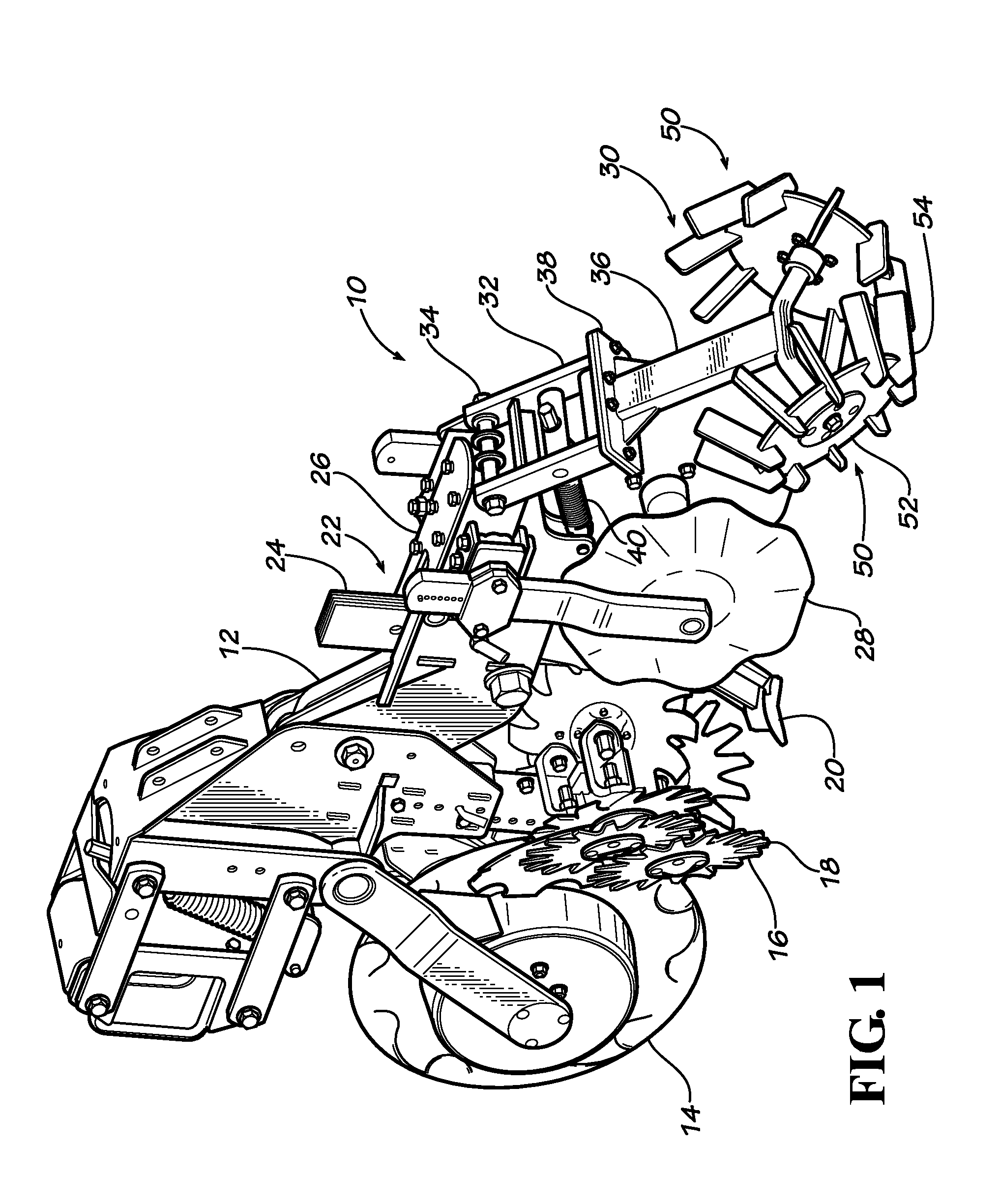

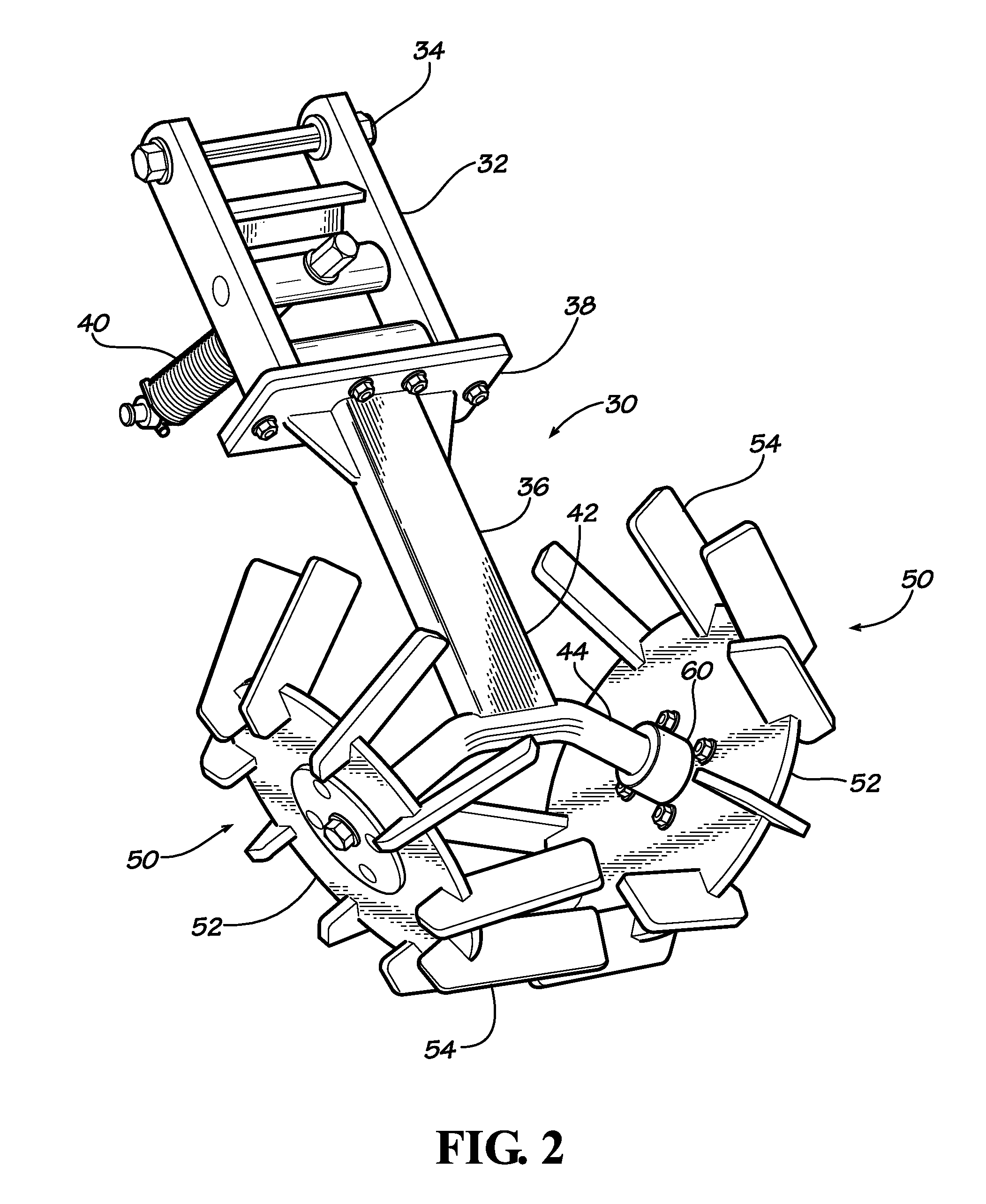

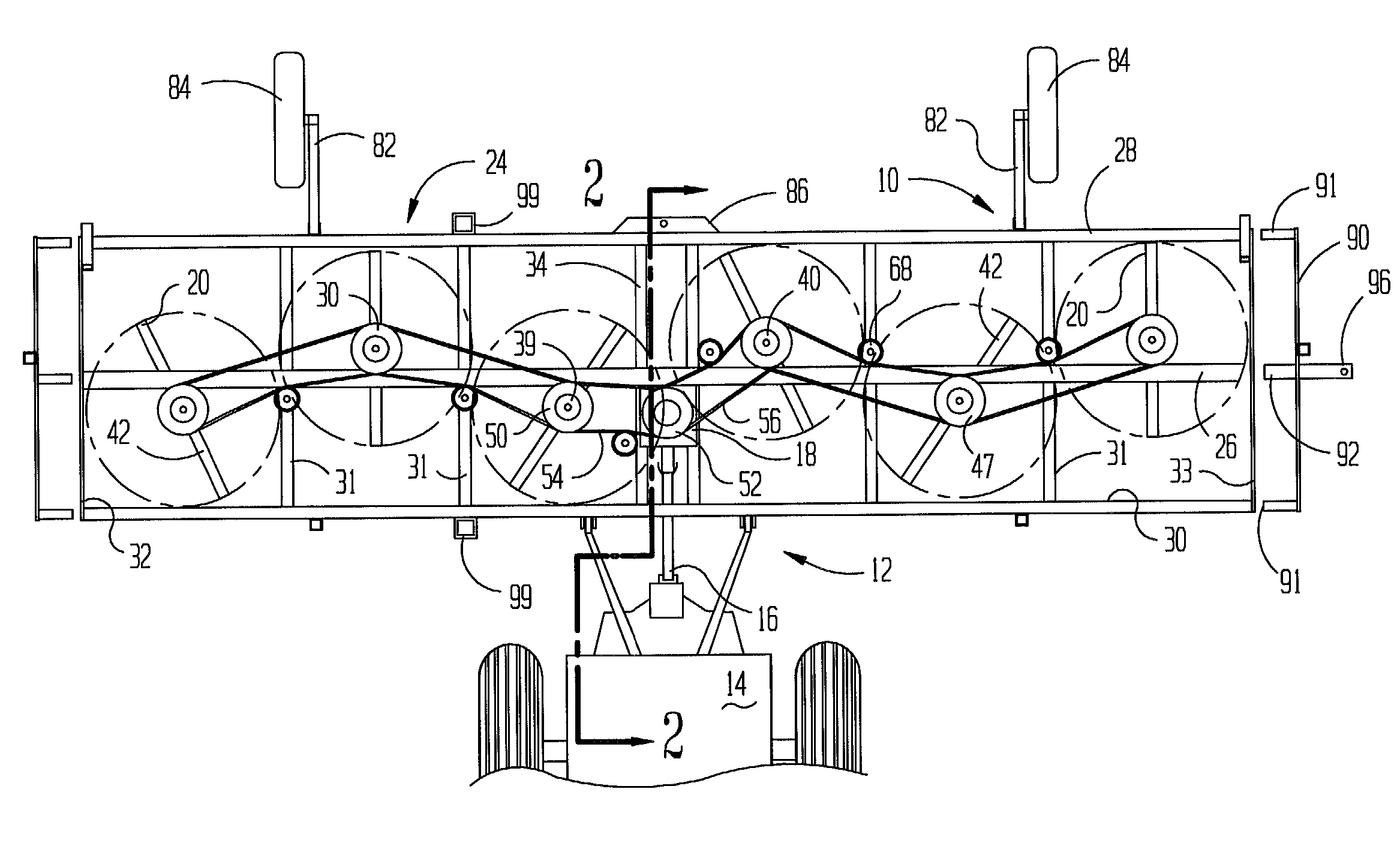

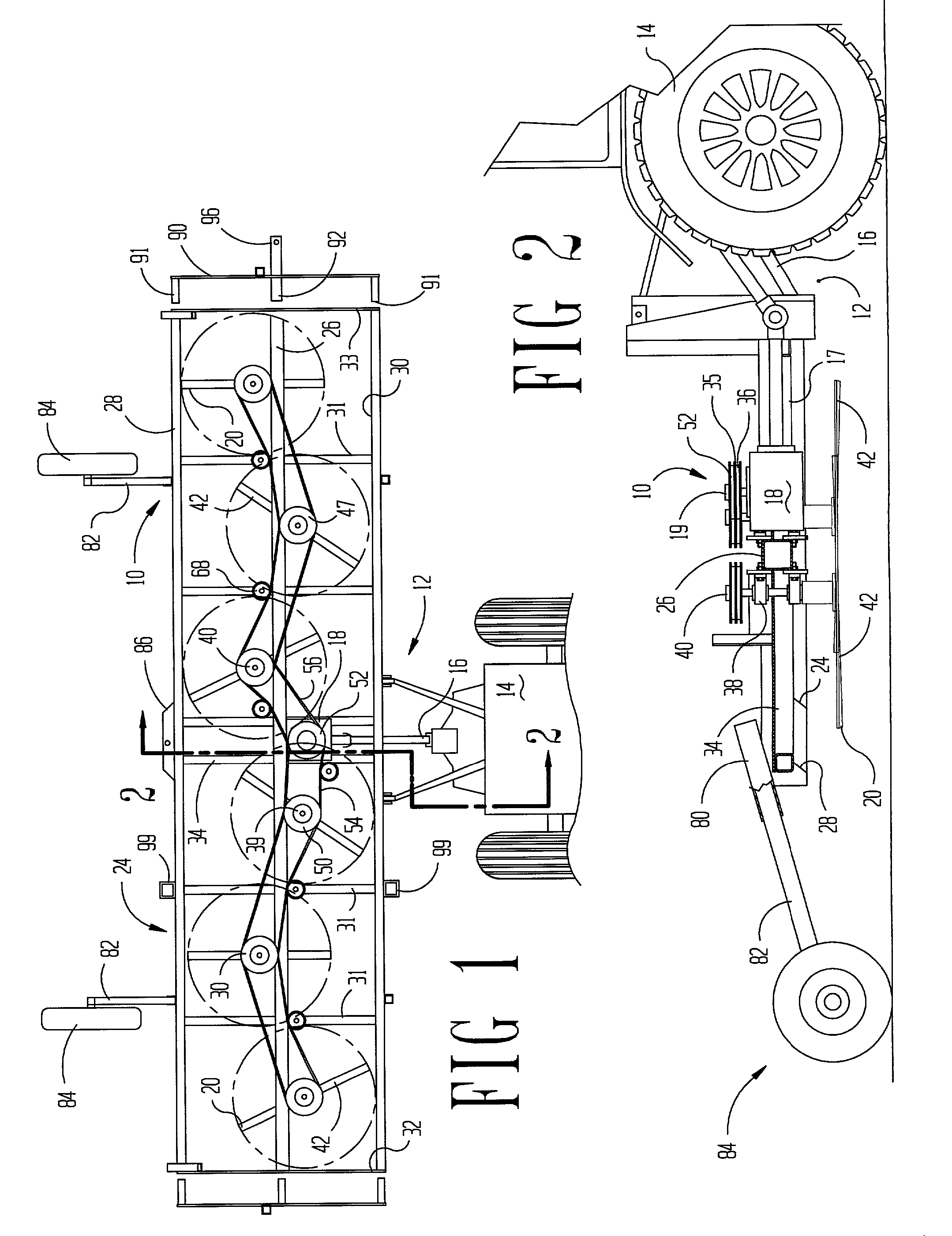

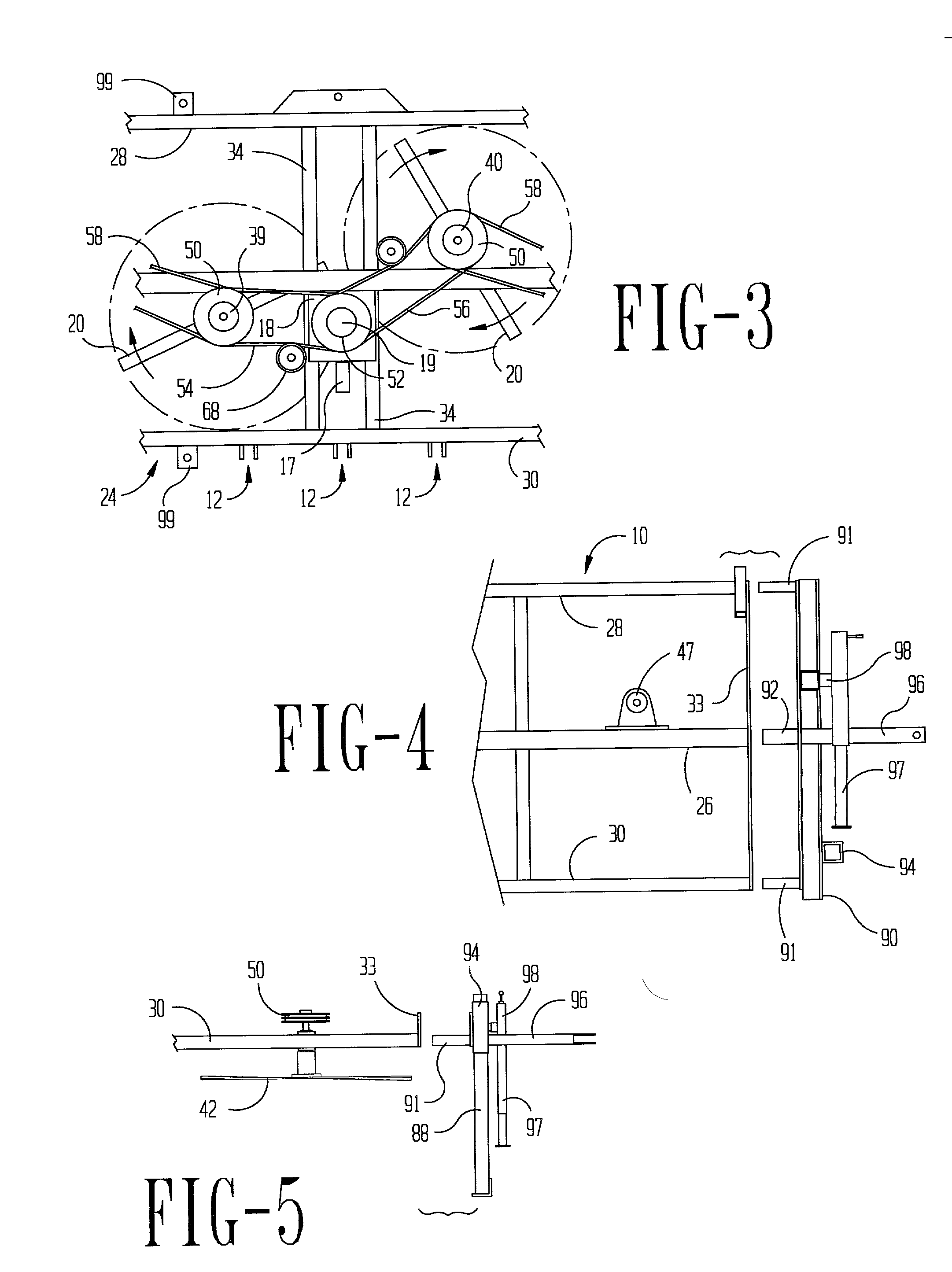

Interlocking Basket for Strip Tillage Machine

A strip tillage implement for movement over a crop berm has a frame configured to carry a coulter, a row cleaner, a shank and closing discs. The implement includes a basket assembly located behind the closing discs having a downwardly and rearwardly directed basket drawbar that forks into left and right support arms. The basket assembly includes a left basket half section rotatably attached to the left support arm and a right basket half section rotatably attached to the right support arm of the basket drawbar in cantilever fashion. Each of the basket half sections includes a support plate and a plurality of clod-breaking tines spaced about the periphery of the plate. Each plate is substantially perpendicular to the axis of its respective support arms such that the two plates form an upwardly diverging angle with the drawbar acting between the basket half sections to clean residue collected between the half sections.

Owner:AGCO CORP

Spray-filmed composite material for fruit and vegetable or crop bagging, as well as preparation and application thereof

ActiveCN106172400AHas insect and disease resistanceEasy to useBiocideDead animal preservationDiseaseSide effect

The invention discloses a spray-filmed composite material for fruit and vegetable or crop bagging, as well as preparation and application thereof, and belongs to the field of functional composite materials and fruit and vegetable or crop bagging. The material is prepared from the following components in parts by mass: 5-30 parts of a film-forming substance, 58-94 parts of a dispersing agent, 1-10 parts of a pesticide-loading reinforcing material, 0.1-2 parts of an insect-proofing disease-resisting agent and 0-0.1 part of dye. The material has multiple colors and excellent insect-proofing disease-resisting performance, can be adhered to the surface of fruits and vegetables or crops to form a film to achieve the aim of bagging, does not influence growth of the fruits and vegetables or crops, does not have toxic or side effect, and can sustainably release insect-proofing disease-resisting substances. The material is simple in preparation method and low in raw material cost, can be used for replacing pesticide to solve the problem of pesticide residue, can be used for producing green organic foods, has long acting duration for 1-3 months, and can be used for preventing insects and resisting diseases for fruits, vegetables, crops, flowers, woods and the like.

Owner:SOUTH CHINA AGRI UNIV

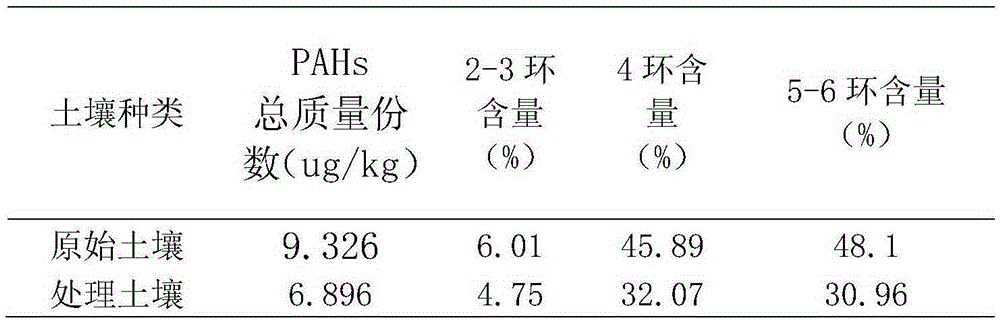

Method for remediating polycyclic aromatic hydrocarbon (PAH) polluted soil through cooperation of alfalfa and complex microbial inoculants

InactiveCN105251763AShorten germination cycleImprove toleranceContaminated soil reclamationSnow moldBiology

The invention discloses a method for remediating polycyclic aromatic hydrocarbon (PAH) polluted soil through cooperation of alfalfa and complex microbial inoculants. Alfalfa seeds are pretreated, and the plant sprouting period is shortened by 2-3 days, so that the tolerance of the plant to soil containing PAHs is enhanced, and the remediating capacity of the plant on the soil is improved. Besides, in an alfalfa-trichoderma-nodule bacterium combined remediating system, the synergistic effect of trichoderma and nodule bacteria is used for promoting degradation of the alfalfa to the PAHs in the polluted soil. Meanwhile, the physiological contour of the microbial population level of alfalfa rhizosphere soil is changed, and the diversity and the stability of the microbial ecological functions of the soil are recovered, so that the growth environment of crops is improved, and the quality and the yield of the crops are improved; the method has wide market application prospects.

Owner:周世永

Topper and shredder

An agricultural implement attached to a farm tractor by a three point hitch is used to cut the top of mature cotton stalks, or shred harvested crops or mow turn rows. Knives are mounted on the bottom of vertical shafts which are rotated by belt driven pulleys. The pulleys are driven from a right angle gear box which is driven from the power take off of the tractor. The knives are staggered along either side of a beam traverse to the direction of travel, so that the knives cannot strike other knives as they mow over-lapping swaths.

Owner:HEARD MARTIN PERRY

Method for producing aldehyde-free soft board made of wheat straw

InactiveCN1861348ASimple processNo environmental pollutionDrying solid materials with heatCane mechanical workingAldehydeEngineering

A soft wheat straw board without aldehyde is prepared through breaking by 10-15 mm, drying, fine breaking by 3-8 mm, sorting, mixing with glue, mechanical spreading, pre-pressing, hot pressing, intermittent pressing, cutting for removing edges, and cooling.

Owner:江苏大盛板业有限公司

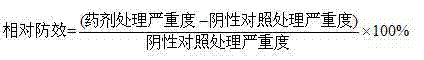

Biocontrol bacterium for controlling plant diseases and preparation method thereof

The invention belongs to the technical field of the biological pesticide and particularly relates to a biocontrol bacterium for controlling plant diseases and a preparation method thereof. The invention has the following main contents: (1) the separation and identification of Bacillussp.CC09 strain; (2) the preparation of Bacillussp.CC09 strain biocontrol microbial inoculum and the applications of the microbial inoculum in the control of plant diseases; and (3) the stability of the Bacillussp.CC09 biocontrol microbial inoculum. The Bacillussp.CC09 biocontrol microbial inoculum is characterized in that the anti-fungal spectrum is wide, the effect is long-lasting, harmful bacteria are difficult to generate drug resistance, the microbial inoculum is safe for human, livestock and crops and is environmentally friendly, etc. The biocontrol bacterium has obvious inhibitory activity for the growth of Fusariumgraminearum, Alternariaalternata, Rhizoctoniasolani and Phytophthoracapsici and especially obvious control effect on wheat powdery mildew and scab.

Owner:NANJING UNIV

Application method of plant straw bioreactor landfill technology

InactiveCN102140040AIncrease productionImprove disease resistanceOrganic fertilisersOrganic farmingBiology

The invention discloses an agricultural practical technology belonging to the field of biology, particularly relates to an application method of a plant straw bioreactor landfill technology. The plant straw bioreactor landfill technology adopts a high-efficiency straw returning mode and can eliminate the pollution of straws on environments and increase the content of organic matters contained in soil; carbon dioxide generated in the biological transformation process can be used for the photosynthesis of crops, and generated heat can effectively increase temperature inside a greenhouse in spring and winter, promote the growth of the crops and enhance the yield and the quality of the crops. The plant straw bioreactor landfill technology can be popularized and used for enabling organic matter fertilizers generated by the straws to meet the requirements for plant growth and vaccines to be beneficial for plants to enhance disease-resistant capacity, realizing that chemical fertilizers and pesticides are not used, removing the residuals of the chemical fertilizers and the pesticides on lands and agricultural products, developing organic agriculture, producing green watermelon, hot pepper, cuke, tomato, and the like and increasing the economic incomes of agriculture, and is an agricultural practical technology which has the advantages of saved investment, quick effect and easy popularization.

Owner:孔赟荣

Method of accelerating decomposition of maize straw retention

ActiveCN104003772APromote decompositionSpeed up the return processOrganic fertilisersDecompositionCellulase

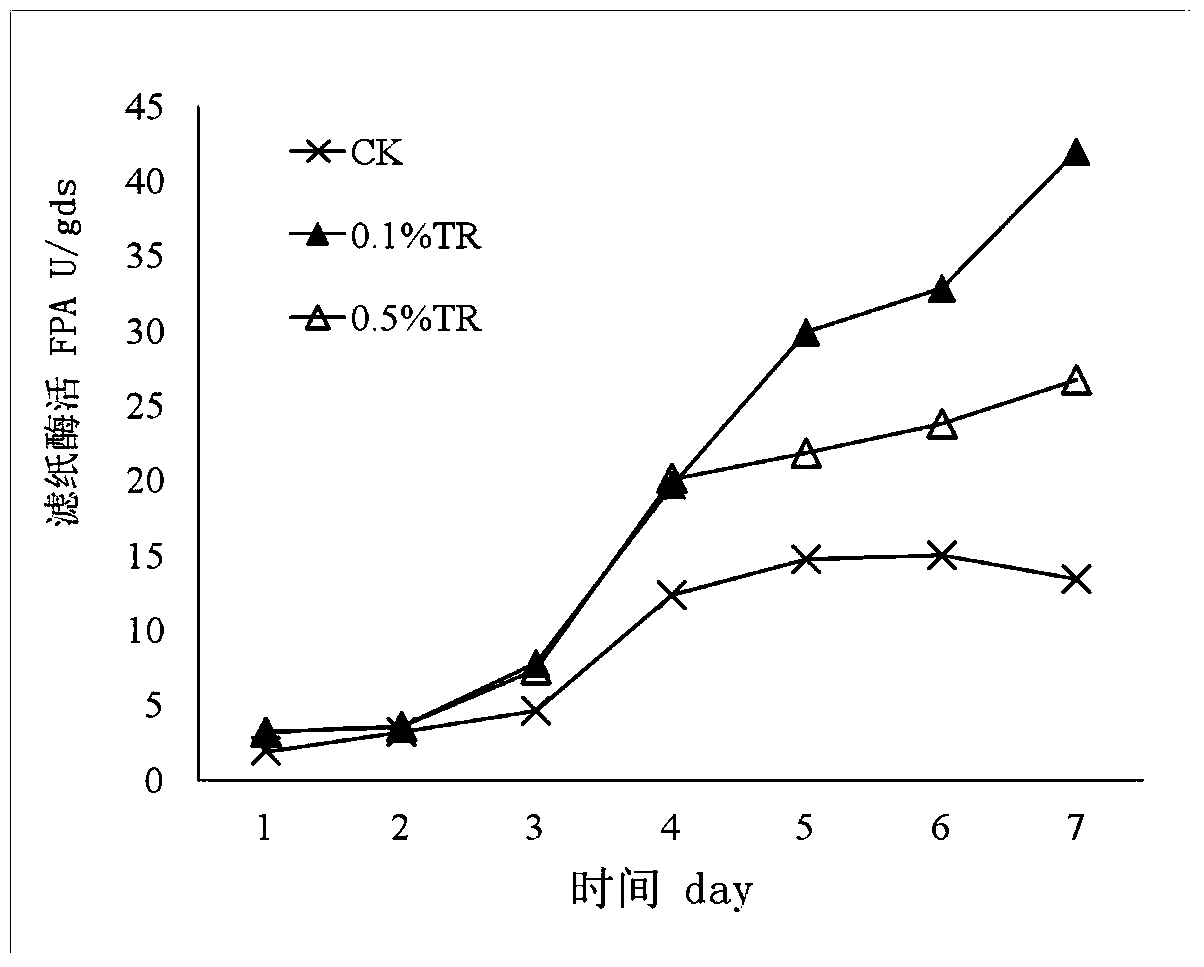

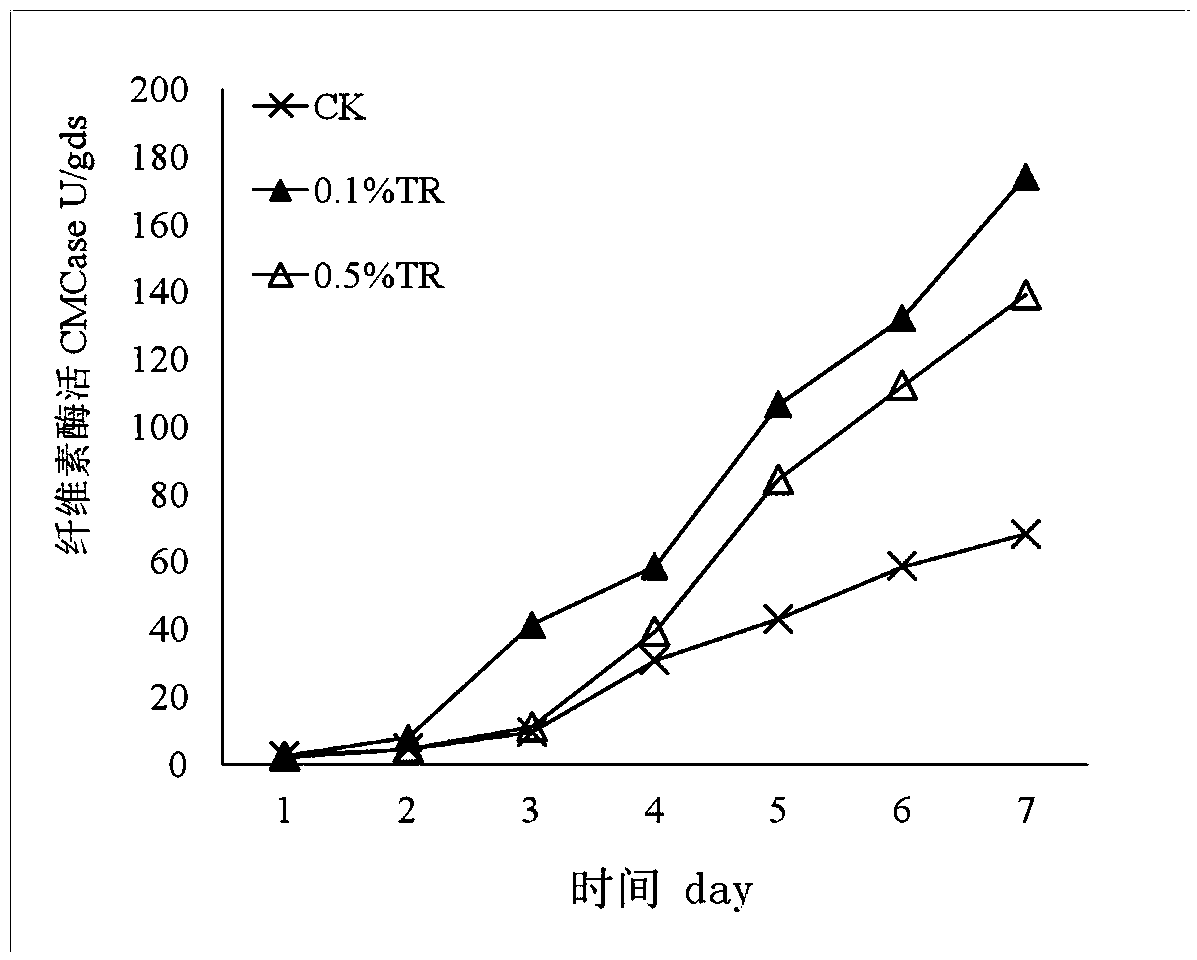

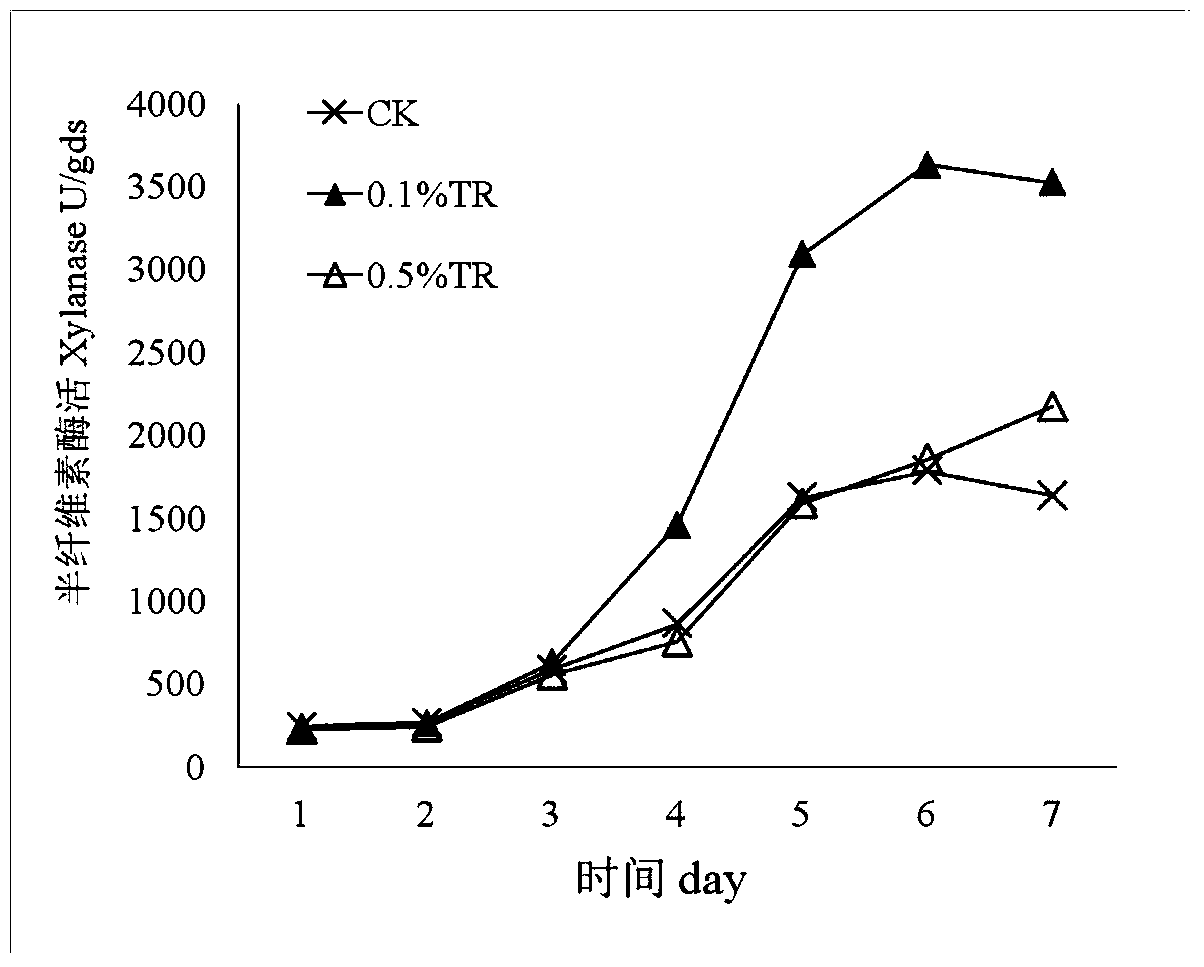

The invention belongs to the field of crop straw utilization and discloses a method of accelerating decomposition of maize straw retention. The method comprises the following steps: crushing maize straws; mixing with an assistant; inoculating a straw degrading bacterial agent; burying the straws in soil; controlling the water content of the soil to 60-80% of field water retention; and decomposing at 20-30 DEG C. Pot experiments verify that the method provided by the invention has the best decomposing effect on maize straws and the degradation rate of the straws reaches 51.9% which is improved by 14% compared with that of direct retention of the straws. The TR assistant can remarkably accelerate the straw degrading bacterial agent to generate cellulose, and the filter paper enzyme (FPA), the cellulase activity (CMCase) and the activity of hemicellulase (Xylanase) are greatly enhanced, so that the straws are directly promoted to decompose. The method disclosed by the invention promotes decomposition of maize straws and accelerates the retention process of the maize straws, can be used for conversion and utilization of straw wastes and has a wide application prospect.

Owner:NANJING AGRICULTURAL UNIVERSITY

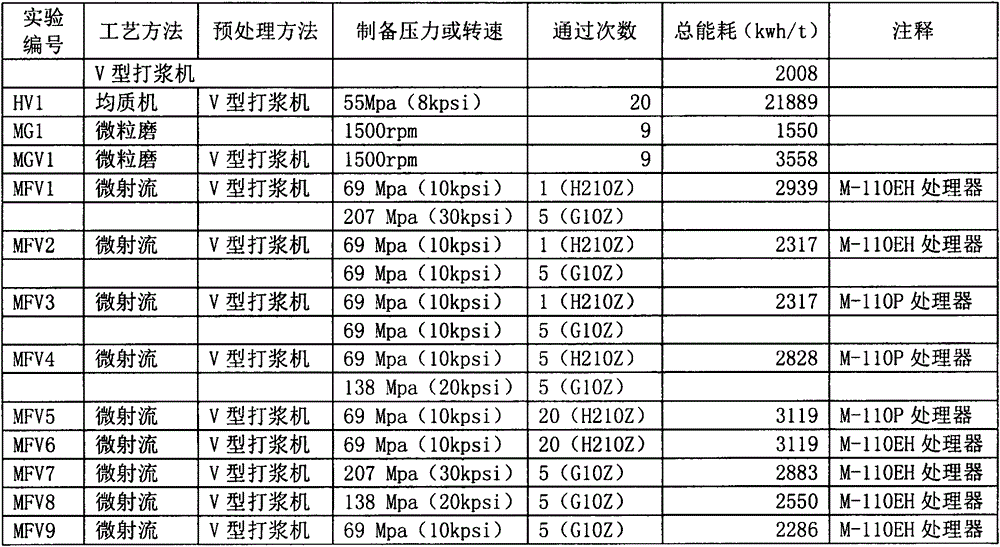

Synchronization method for preparing microfibrillated cellulose and application of microfibrillated cellulose in strengthening of paper

The invention provides a manufacturing process for an MFC (Microfibrillated Cellulose) product, which can complete the swelling of ZnCl2 and the mechanical dissociation of microfibril synchronously. The manufacturing process has the basic characteristics that the swelling and the mechanical dissociation of the cellulose microfibril in cell walls of plant fibers are completed synchronously by combining moderate mechanical pulping treatment when pulp fibers are subjected to swelling treatment by taking various types of bleaching chemical pulp, mechanical pulp and the plant fibers, such as cotton, hemp and crop straw as main treatment objects and utilizing the ZnCl2 which has a good fiber swelling effect as a main pretreatment agent; the purposes of saving energy, reducing consumption and simplifying a product preparation process flow are achieved; the MFC product can be obtained by performing subsequent treatment, such as high pressure homogenizing, on the cellulose microfibril which are subjected to the dissociation. When the product is applied to a paper production process in pulp and paper making industry, a plurality of quality indexes, such as paper strength and paper optical performance, can be effectively improved, so that the product has a good application prospect.

Owner:JILIN CHENMING PAPER IND

Livestock breeding liquid dung acidifying and storing method

InactiveCN109516839AEmission reductionReduce pollutionSludge treatmentClimate change adaptationEcological environmentAnimal science

The invention discloses a livestock breeding liquid dung acidifying and storing method. The method utilizes an acidifying agent to regulate the pH value of livestock breeding liquid dung to 5.0-6.5; the liquid dung is effectively stored for no less than 60 days, and accordingly the purpose of acidifying and storing the livestock breeding liquid dung is realized. The method is easy and feasible, and low in cost; the livestock breeding liquid dung stored by utilizing the method can effectively maintain the nitrogen content, reduce ammonia volatilization and reduce emission of greenhouse gases such as methane, meanwhile, can be directly returned to the field to be applied, so as to improve the crop yield, and has good ecological environmental benefits.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Method for fabricating wheat stalk picture

InactiveCN101049791AHigh cutting accuracyUniform mass productionDecorative surface effectsOrnamental structuresLacquerEngineering

A method for making a wheat straw picture includes such steps as choosing wheat straws, rinsing, fumigating, splitting, scraping, chemical antiseptic treating, baking, splicing, ironing for smoothing, painting or printing, cutting by needed sizes, ironing, charring, coloring, sticking, and mounting. Its apparatus is also disclosed.

Owner:郝保学

Three-layer particle board and manufacture method for same

InactiveCN105965658ASave resourcesNot releasedDomestic upholsteryWood veneer joiningWood shavingsFiber

The invention relates to a particle board with a three-layer structure and a manufacturing method, belonging to the field of artificial board manufacturing. The adhesive uses isocyanate, the upper and lower surface layers use wheat straw fiber, and the middle core layer uses wood shavings. When the proportion of wheat straw fiber is ≥ 35-45%, the performance indicators of the particleboard reach the best, fully meeting the requirements of GB / T 4897.3-2003 Require. The three-layer structure particle board produced by this method has no formaldehyde release, good environmental protection performance, uses part of crop straw to replace wood, saves wood resources, and has a positive guiding effect on the manufacture of three-layer structure particle board.

Owner:万华禾香生态科技股份有限公司

Method for producing biomass fertilizer by using straw

ActiveCN102976812ALow costIncrease beneficial microbesBio-organic fraction processingOrganic fertiliser preparationMicroorganismSoil organic matter

The invention discloses a method for producing a biomass fertilizer by using straw, which belongs to the field of biomass fertilizers. The method comprises the following steps: A) laying wheat straw on the bottom of an enclosed container and wetting the wheat straw through spraying of biogas slurry; B) laying a layer of biogas residue on the wheat straw; C) laying crop straw on the biogas residue and inserting a hollow pipe into the straw; D) introducing air into the enclosed container for 30 to 120 min through the hollow pipe by using a blower every other day; E) taking out all the materials for drying in the sun in 35 to 50 d so as to obtain a catabolite of the straw; and F) preparing the biomass fertilizer through uniform mixing of the catabolite of the straw with a fertilizer under stirring. According to the invention, decomposition of the straw can be realized through usage of a special microbial inoculums; the obtained biomass fertilizer can increase soil organic matters and beneficial microorganisms year after year and has the advantages of low cost and capacity of improving the ecological structure of soil.

Owner:SHANDONG AIFUDI BIOLOGICAL TECH

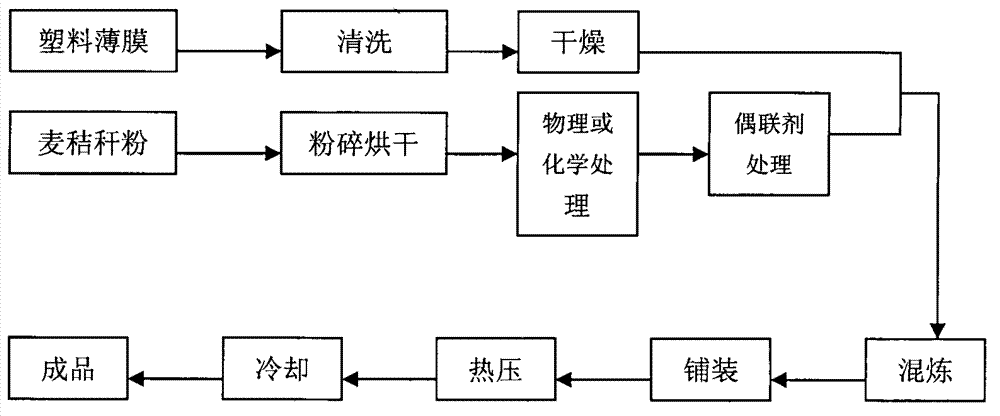

Process for preparing wheat straw/plastic film composite material

InactiveCN102863693AHigh market cost performanceSolve the shortcomings of not easy to bondRaw material divisionFiberCompression molding

The invention relates to a process for preparing a wheat straw / plastic film composite material. According to the process, a plastic film of the composite material is reinforced through wheat straw fibers, a combined treatment method (that is, wheat straw is treated through a physical or chemical method, and then a combined coupling agent is used) is used for conducting surface treatment on wheat straw fibers, the interface bonding strength between wheat straw fibers and a plastic matrix is improved, and the wheat straw / plastic film composite material can be manufactured through technologies such as melt blending and compression molding. The process has the advantages that compared with wheat straw / plastic film composite materials which are treated by a coupling agent merely, the mechanical property and the moisture-absorption water-absorption resistance of the composite material which is subjected to combined treatment are greatly improved, the frictional wear performance of the composite material is better than that of composite materials which are prepared by wheat straw and treated by the coupling agent merely. The composite material is prepared for packaging plastic films and agricultural waste and has significant realistic meaning in terms of environmental protection and resource recycling.

Owner:NANJING AGRICULTURAL UNIVERSITY

Compression molding fibre-reinforced straw plastic combined cabinet slab and preparation method thereof

The invention discloses a compression molding fibre-reinforced straw plastic combined cabinet slab which is prepared from the following raw materials according to parts by weight: 0.2-0.6 part of modified crop straw fibre or straw fibre wood powder thereof, 0.1-0.2 part of PET or nylon waste silk, 0.05-0.2 part of melamine, 0.05-0.2 part of modified talcum powder, 0.01-0.05 part of chemical assistant and 0.3-0.6 part of polyolefin thermoplastic resin. The invention also discloses a preparation method thereof. The cabinet slab of the invention is formaldehyde-free environment-protection material and has wood texture and handling characteristics, and the machinery mechanics strength thereof exceeds that of good-quality solid-wood slabs; and in addition, the cabinet slab does not adsorb water and has the functions of low coefficient of thermal expansion, moisture prevention, mildew prevention, aging prevention, combustion prevention, reuse and the like and is an ideal cabinet slab wood replacing material.

Owner:绍兴一普塑业有限公司

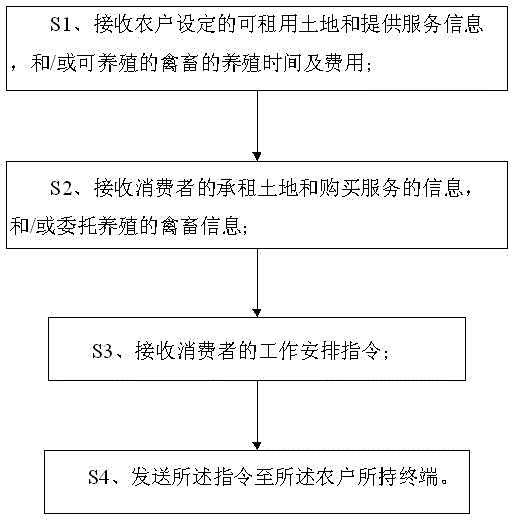

Remote farm control method and system

InactiveCN103606102AStable incomeCloser relationshipBuying/selling/leasing transactionsAgricultural scienceAgricultural engineering

Owner:甘剑文

Preparation method for environment-friendly casting material

The invention discloses a preparation method for an environment-friendly casting material. The preparation method includes the steps of wax mold preparation, surface layer coating preparation, surface sand hanging, back layer coating preparation, back sand hanging, steam dewaxing, roasting and the like. According to the preparation method, fine wood bits and crop straw fibers serve as shell manufacturing materials, so that the using amount of refractory matter is reduced, and environmental protection is facilitated; reasonable matching is adopted, so that the breathability is increased on the premise that the shell strength is guaranteed; and cellular material attapulgite is adopted, so that exhausting is facilitated, the defect of casting air holes is reduced, the rate of finished products is increased, and meanwhile the weight of the mold shell is reduced.

Owner:青岛博泰美联化工技术有限公司

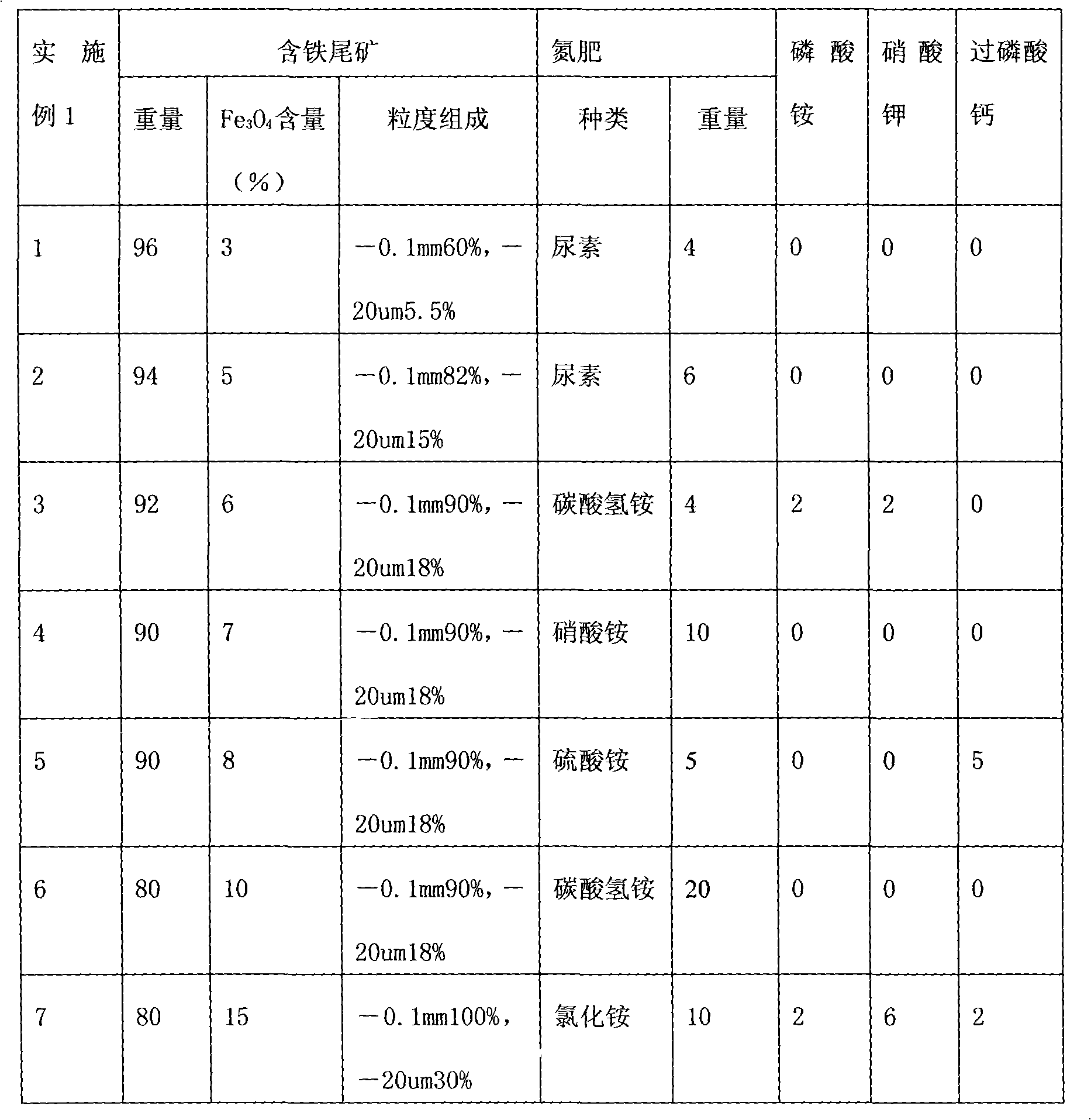

Magnetized tailings composite soil modifier

InactiveCN101265409ASimple componentsSimple preparation processOrganic fertilisersSoil conditioning compositionsGranularityPhosphor

The invention discloses a magnetized iron tailing compound soil amendment, which is prepared by iron-containing tailing, nitrogen fertilizer or nitrogen, phosphor and kalium compound fertilizer through the processes of mixing, magnetizing treatment, bagging and so on. The magnetized iron tailing compound soil amendment has the components according to the content ranges as follows: the iron-containing tailing 80%-96% (weight), the nitrogen fertilizer or the nitrogen, phosphor and kalium compound fertilizer 4%-20% (weight); and the ferriferrous oxide content in the iron-containing tailing 3%-15%(weight). The particle size of the iron-containing tailing is minus 0.1 mm, and the content occupies 60 to 100 percent (weight), wherein minus 20 um content is less than or equal to 30 percent. The magnetized iron tailing compound soil amendment has the advantages that the components are simple, the cost is low, the magnetized effect is good, the tailing used amount is large, and the soil hardening can not be caused during long use, and the agriculture crop wealth effect is obvious after application.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

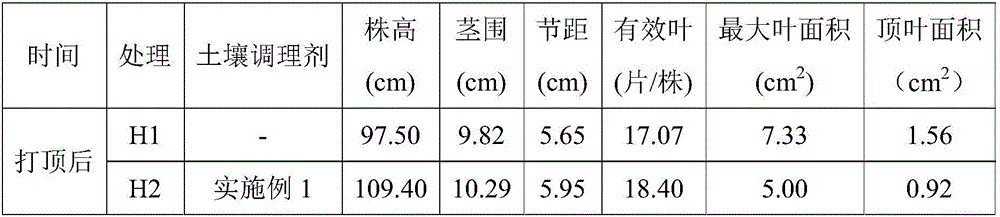

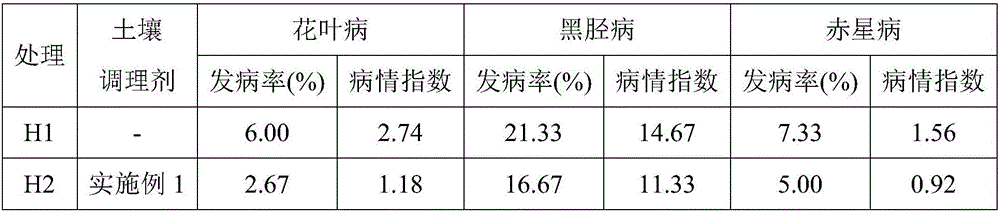

Crop continuous-cropping soil improver and preparation method of same

InactiveCN106554240AEasy to operateLow costAgriculture tools and machinesExcrement fertilisersContinuous croppingPlant disease

The invention relates to a crop continuous-cropping soil improver and a preparation method of same and belongs to the technical field of production of agricultural fertilizers. The soil improver is mainly produced from, by weight, 4-6 parts of a microorganism fermentation inoculant, 30-50 parts of dried cow dung, 4-6 parts of straws, 30-48 parts of weathered coal, 8-12 parts of a microorganism beneficial composite inoculant, and 1.5-2.5 parts of nano carbon. By means of wastes in breeding industry and agriculture as raw materials, a decomposed organic fertilizer is prepared through fermentation by the microorganism inoculant, and then the weathered coal and the soil beneficial inoculant are added to perform secondary fermentation, and finally, the nano carbon is added and mixed with the fermentation product to produce the soil improver. The soil improver, in a bio-improvement manner, has excellent soil improvement effect on the basis of continuous-cropping obstacle formed by continuous cropping, and also can effectively inhibit soil-borne diseases and also supplies nutrients to soil. The soil improver is harmless to environment. By means of the wastes in breeding industry and agriculture as raw materials, the soil improver is low in cost, turns wastes into resources and is suitable for being promoted and applied.

Owner:ZHENGZHOU UNIV +3

Production method of sweet potato sprout

The invention discloses a production method of a sweet potato sprout, and belongs to the technical field of culture of seedling of crops. The production method comprises the steps of: (1) seeding potato seeds and culturing seedlings; (2) preparing a paper micro nutrition bowl; (3) cutting the seedlings and performing cottage; (4) rooting; and (5) binning, transporting and selling, etc. By adopting the production method of the sweet potato sprout, the seedling output per unit area is greatly increased, the quality of cutting seedlings is ensured, the effective seedling rate is up to 97 to 98%, the working intensity in culture of the seedlings and the cost of seedling are obviously reduced, the production efficiency is improved, and therefore the industrial production is realized; in addition, the sprout in the paper bowl has the advantages of being small in size, light in weight, convenient to transport, flexible in planting season and high in survival rate, and extending the shelf life to be up to 15 to 20 days. The production method of the sweet potato sprout can be popularized and applied in sweet potato production areas and seed and seedlings companies.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Bentonite organic fertilizer

A bentonite organic fertilizer is composed of, by weight, 30 parts to 60 parts of bentonite mineral powder, 20 parts to 70 parts of animal dung, 20 parts to 80 parts of Chinese medicine residues, 1 part to 2.5 parts of EM biological agents and 10 parts to 25 parts of straw ash. The bentonite serves as base carriers and absorbs and gathers organic matter and microelements in the animal dung and the Chinese medicine residues, organic fertilizer base materials are produced through fertilization of the EM biological agents, the potassium-enriched straw ash is added to the organic fertilizer base materials to form ideal mineral potassium-enriched organic fertilizers, the requirement of crops for nutrients is met, soil is improved, and the drought resisting capacity and the water retaining capacity of soil are improved. Practices show that by means of the bentonite organic fertilizer, the problems of soil hardening and crop quality reduction caused by utilization of a large quantity of fertilizers are solved.

Owner:清远市华榕农业发展有限公司

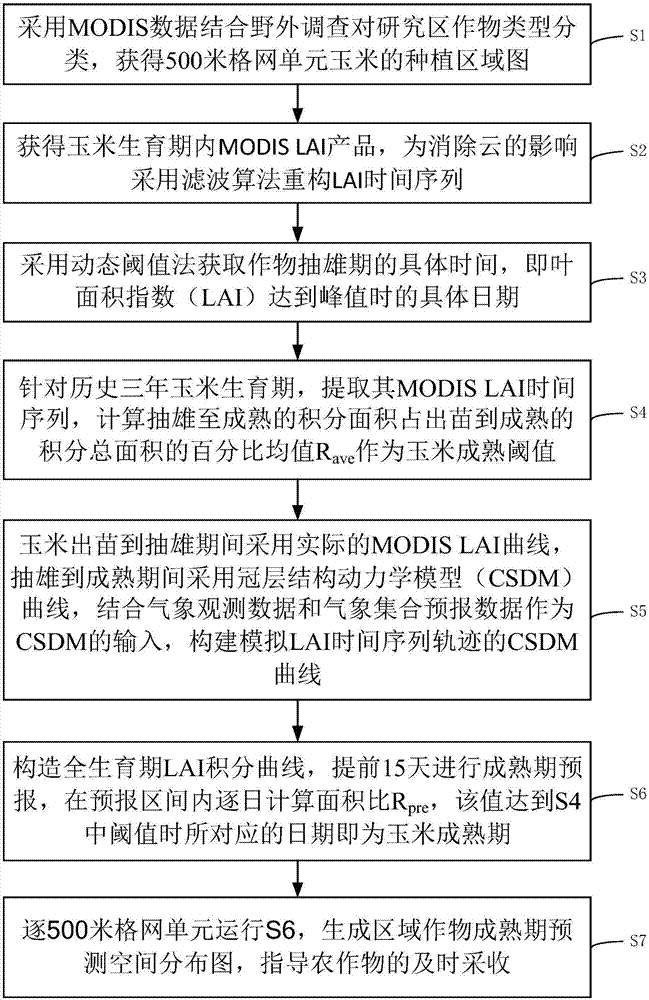

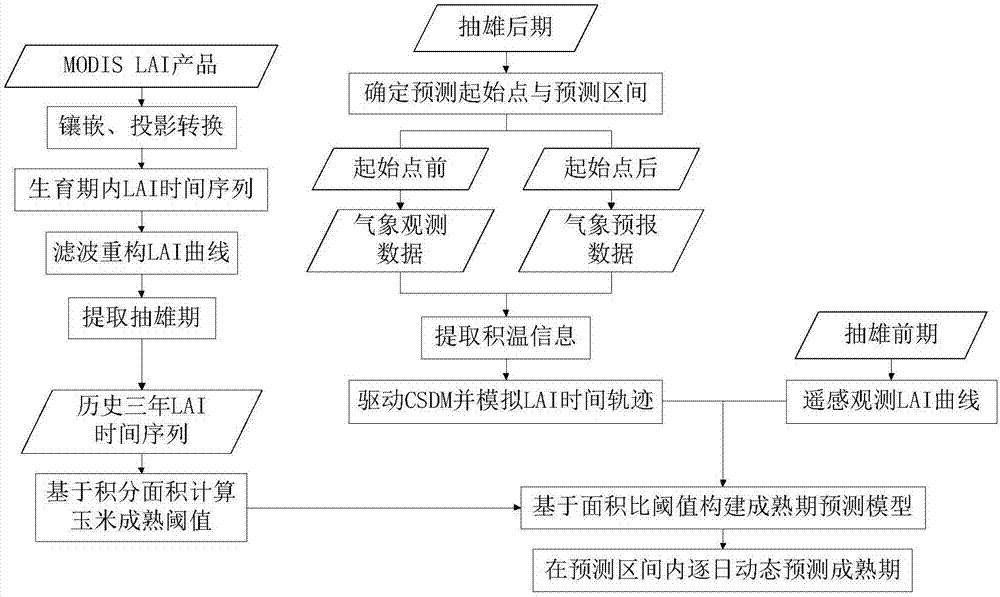

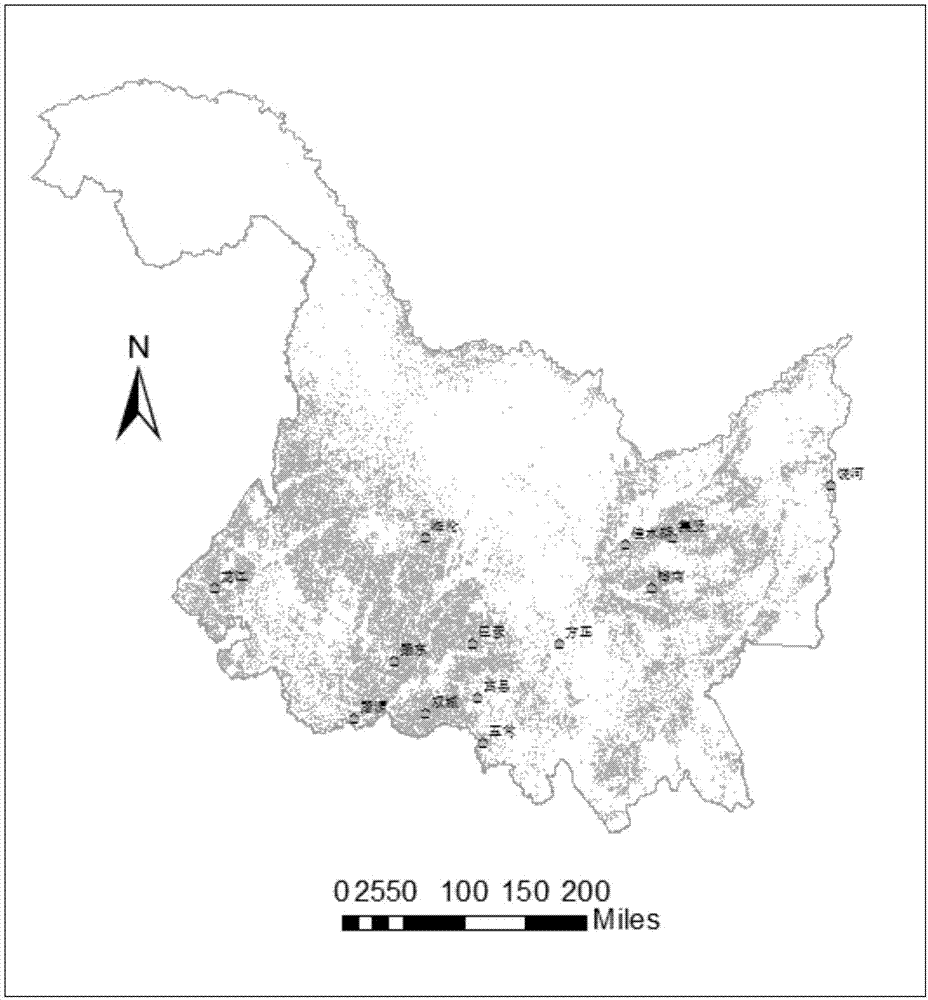

Regional corn mature period prediction method based on time sequence LAI curve integral area

ActiveCN107423850AOvercome limitationsAvoid emergenciesForecastingColor/spectral properties measurementsPredictive methodsFilter algorithm

The invention belongs to the field of agricultural remote sensing and discloses a regional corn mature period prediction method based on a time sequence LAI curve integral area. The method comprises the steps of (S1) obtaining a planting area map of corns of a 500-meter grid unit, (S2) reconstructing a LAI time sequence by using a filtering algorithm with MODISLAI products in a corn growth period, (S3) using a dynamic threshold method to obtain a specific date of a tasseling stage, (S4) calculating corn growth periods of past three years, and calculating a percentage average value Rave of an integral area from the tasseling stage to a mature stage in an integral total area from seedling emergence to matureness, (S5) forming a whole growth period LAI integral curve, (S6) calculating an area ratio Rpre day by day in a forecast interval, and taking a corresponding date as a corn mature period when Rpre is larger than or equal to Rave, and (S7) predicting a mature period by a 500-meter grid unit, generating a regional corn mature period prediction spatial distribution map, and guiding the timely harvest of crops.

Owner:CHINA AGRI UNIV

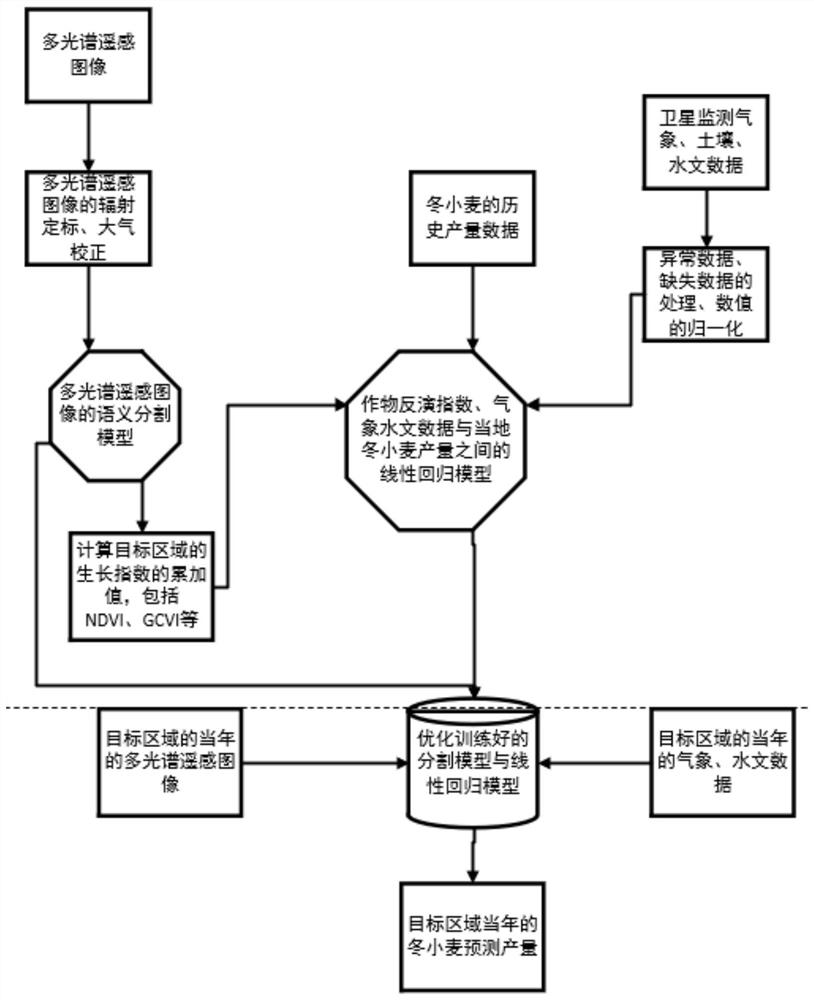

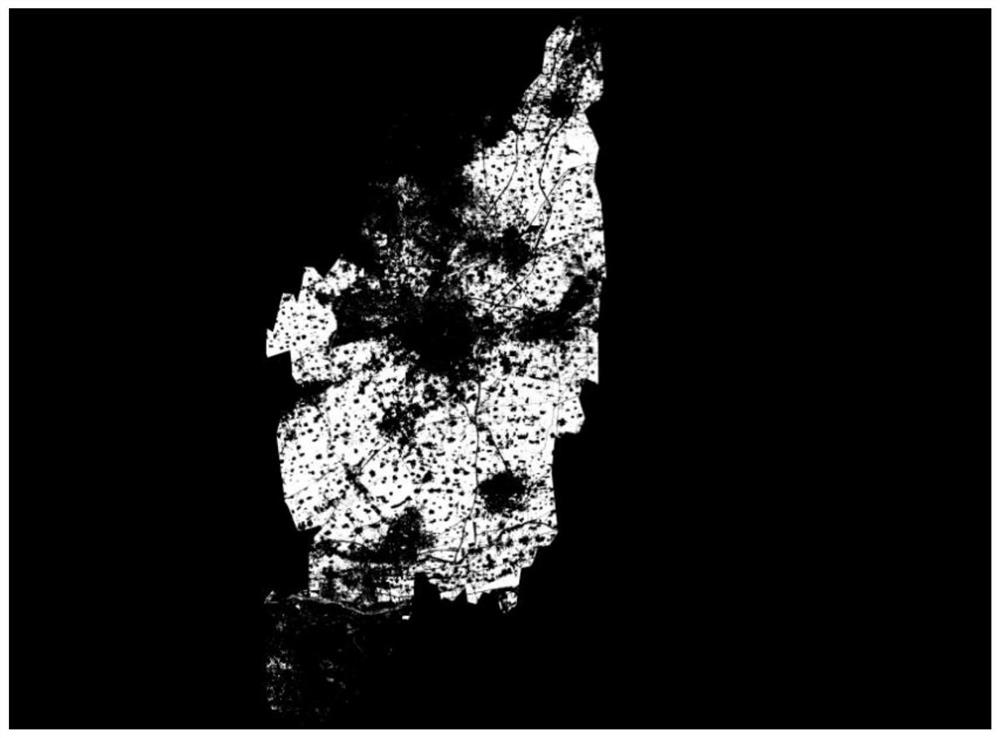

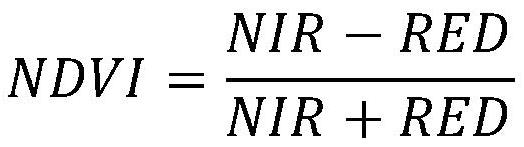

Wheat planting region segmentation and yield prediction method

InactiveCN112183428AImprove accuracyAvoid misjudgmentForecastingCharacter and pattern recognitionSensing dataSoil science

The invention discloses a wheat planting area segmentation and yield prediction method, and existing open multispectral remote sensing data and satellite monitoring meteorological environment data areused to realize the accurate segmentation of a winter wheat planting area and a scientific yield estimation method. Therefore, the time, labor and financial costs caused by large-scale on-site surveying and mapping and meteorological monitoring are avoided. Meanwhile, the model has good mobility, can be applied to the segmentation of a planting area of winter wheat and the prediction of the yieldand can also be effectively applied to other crops, and agricultural modernization and business become possible.

Owner:浙江大学中原研究院 +1

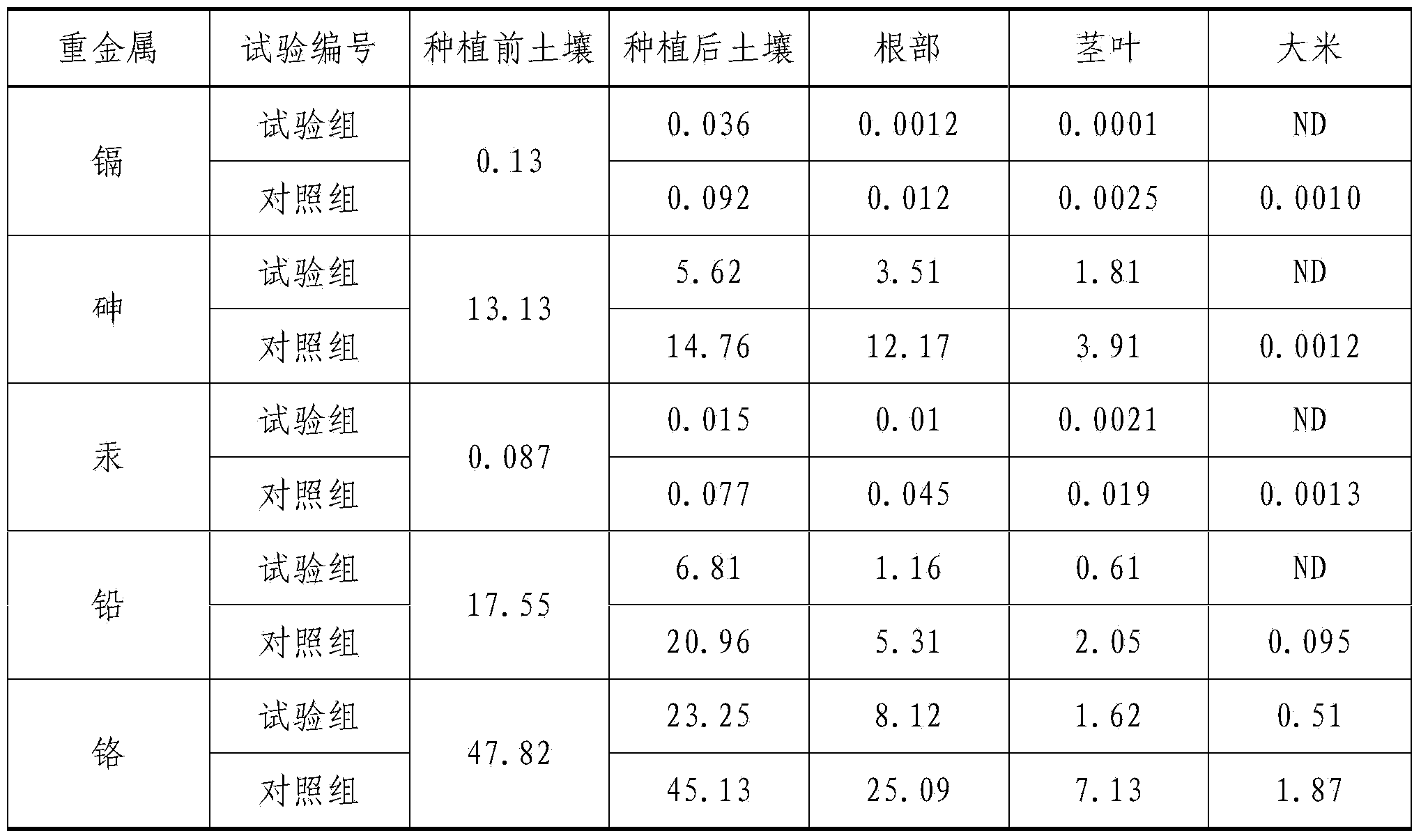

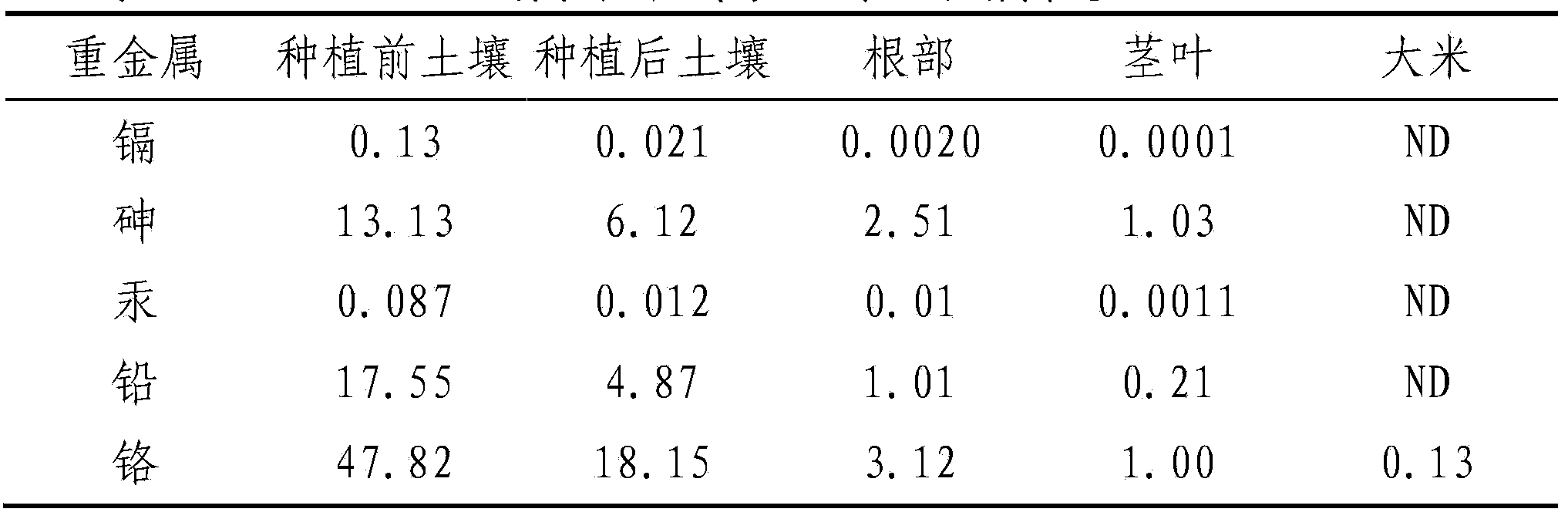

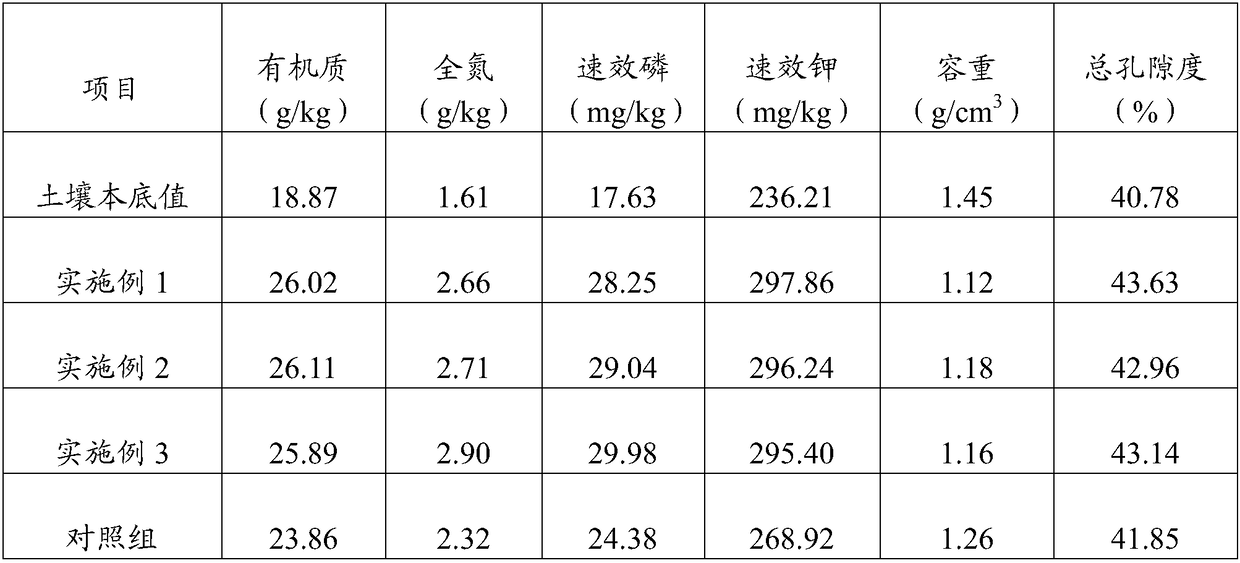

Rice cultivation method capable of reducing content of heavy metal in rice

ActiveCN103918517AReduce heavy metal contentAvoid absorptionRice cultivationPest controlCrop cultivation

The invention discloses a rice cultivation method capable of reducing the content of heavy metal in rice and relates to the technical field of crop cultivation. The method comprises the following steps of seed rice disinfection, germination accelerating, preparation of a rice field, sowing and seedling growth, arrangement of land for growing field rice, rice transplanting, fertilization, irrigation, pest control and harvesting. The method has the advantages of reducing the content of the heavy metal in the rice and the content of the heavy metal in soil, restoring the soil polluted by the heavy metal, and being applicable to the areas where soil is polluted by the heavy metal, and the use amount of pesticide and fertilizers can be reduced when the rice cultivation method is applied to the unpolluted areas.

Owner:HUNAN XINJINHAO TEA OIL

Method used for producing biological organic fertilizer through conversion of straw and breeding industry manure with agricultural probiotics

PendingCN108314585AOvercome limitationsFast start-up of fermentationCalcareous fertilisersExcrement fertilisersBiotechnologyPotassium

The invention discloses a method used for producing biological organic fertilizer through conversion of straw and breeding industry manure with agricultural probiotics. The method comprises followingsteps: straw pretreatment; breeding industry manure pretreatment; primary fermentation of straw and breeding industry manure which are obtained via pretreatment; secondary fermentation of straw and breeding industry manure which are obtained via pretreatment; and obtaining of biological organic fertilizer. According to the method, crop straw and breeding industry manure are mixed and fermented toprepare the biological organic fertilizer, so that the limit of single raw material is avoided; compared with single raw material fermentation of crop straw or breeding industry manure, the method possesses following advantages: fermentation starting speed is faster, fermentation time is short, and comprehensive cost is lower. The prepared biological organic fertilizer is capable of increasing thecontents of soil organic matters and nutritional elements such as phosphor and potassium, increasing nutrient conversion rate and the amount of beneficial microorganisms in products, promoting soil restoration, realizing betterment of land fertility, reducing chemical fertilizer using amount, improving crop disease resistance, improving crop quality, reducing investment, increasing yield, and promoting income increase.

Owner:HUANGHUAI UNIV

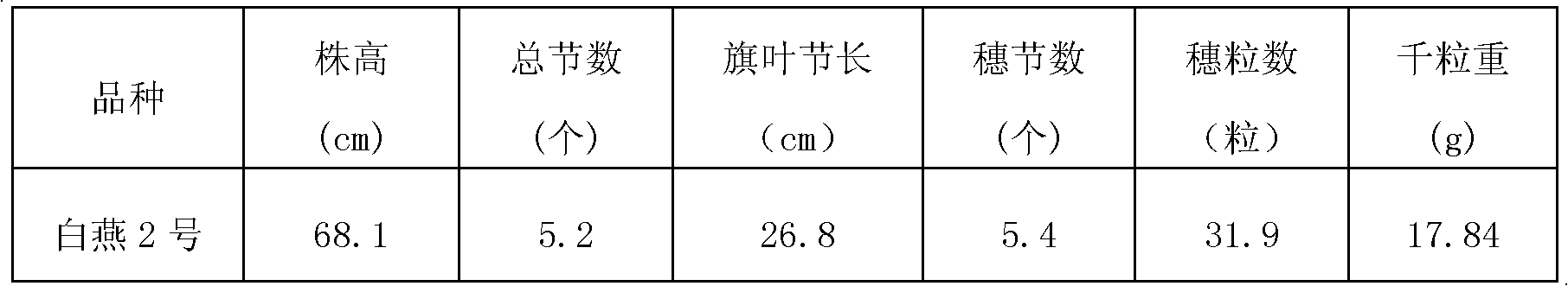

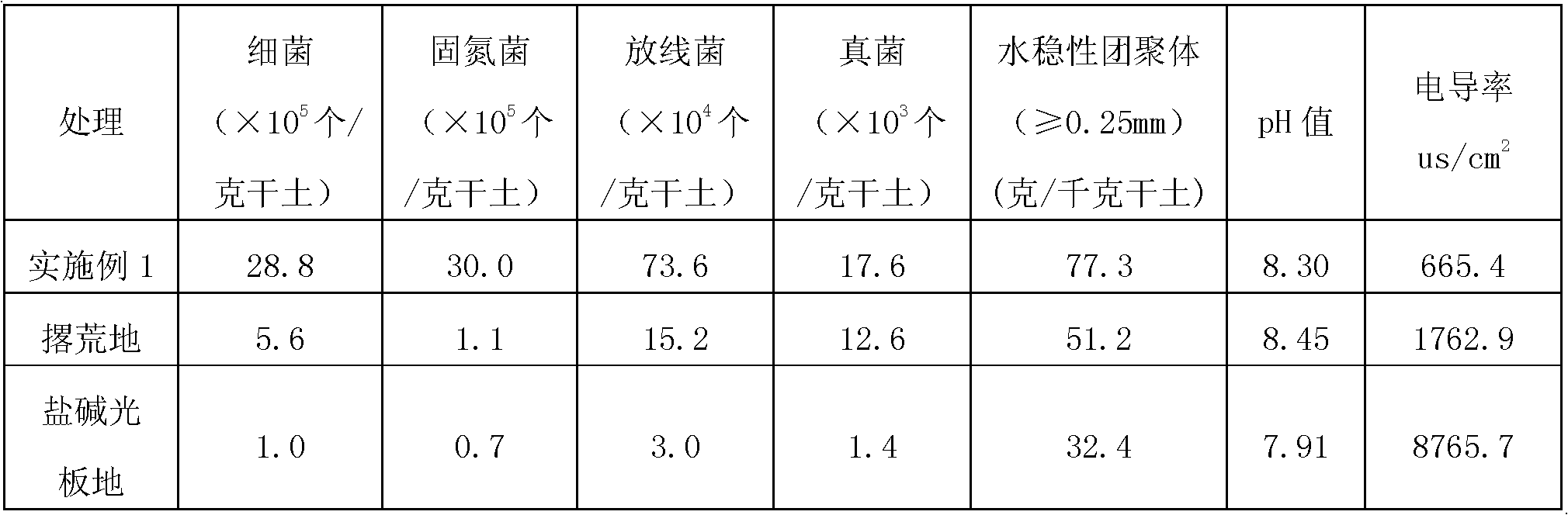

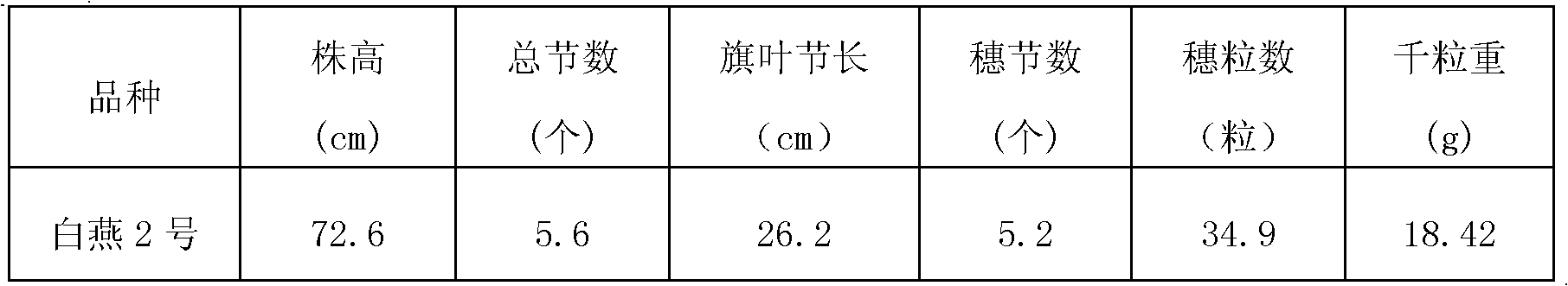

Method for planting oat by utilizing yellow river delta coast salinized soil

InactiveCN102630458AGood biological foundationHigh organic contentHorticultureEconomic benefitsPest control

The invention relates to a method for planting oat by utilizing yellow river delta coast salinized soil. The method comprises the following steps of: (1) applying crop straws and thoroughly decomposed farm manure onto the surface of the yellow river delta coast salinized soil, deeply ploughing and leveling; (2) irrigating deeply land ploughed and leveled in the step (1) before seeding; (3) uniformly spreading a soil ecological modifying agent and the compound fertilizer at the same time after all surface water permeates into soil, and carrying out rotary tillage; and (4) ridging after rotary tillage, seeding oat from the last ten days of March to the beginning of April, and compacting after seeding; and (5) carrying out childbearing period irrigation, fertilization, pest control, weed control and harvesting. The method disclosed by the invention has the advantages of low investment, can continuously improving the soil structure and can realize certain economic benefit.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

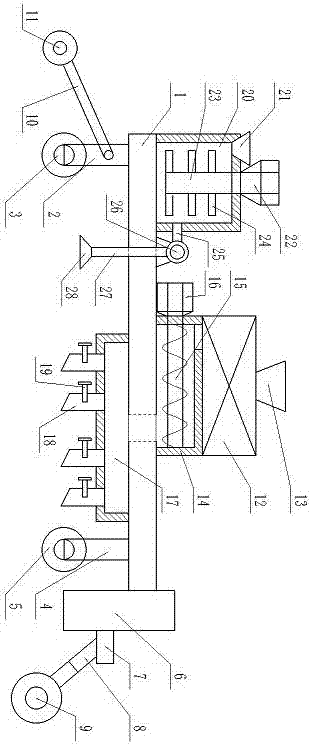

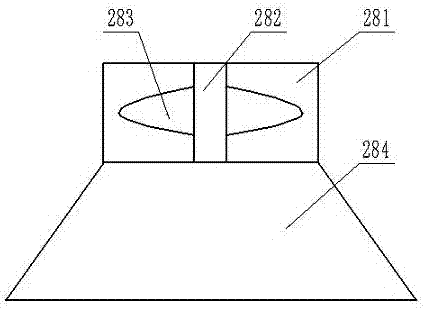

Automatic root fertilizer distributor special for crops

InactiveCN106922267AStir wellSimple structureFertiliser distributersPressurised distribution of liquid fertiliserAgricultural engineeringAgriculture crops

The invention discloses an automatic root fertilizer distributor special for crops. The automatic root fertilizer distributor special for crops has the advantages of simple and reasonable structure, low production cost, convenience in mounting and complete function. An automatic manner is adopted for applying fertilizer, so that the working efficiency is greatly increased, and meanwhile, water fertilizer and solid fertilizer are applied together with each other. In a use process, a slotting wheel is used for slotting, the solid fertilizer enters into a transportation chamber from a solid fertilizer chamber, and then enters into a solid fertilizer pipe and lastly leaves from a fertilizer applying pipe, and a valve is used for controlling the fertilizer flow in the fertilizer applying pipe, so that the solid fertilizer application for the root is realized; a stirring rod is used for uniformly stirring the water fertilizer in a water fertilizer chamber; after the water fertilizer is pumped by a fertilizer pump, the water fertilizer is irrigated by a nozzle; when the water fertilizer passes by a blade in the nozzle main body, the water fertilizer is atomized under an impact effect, so that the application of the water fertilizer for the root is realized; after the fertilizer is applied, a soil covering wheel is used for covering the slot.

Owner:杨成梅

Method for cultivating cotton in saline-alkali soil

The invention discloses a method for cultivating cotton in saline-alkali soil, and relates to the field of technologies for cultivating crops. The method is characterized by comprising steps of plowing the soil to press salt; pressing the salt by the aid of water; additionally applying organic fertilizers to the saline-alkali soil; sowing seeds in due time; covering the soil by mulching films; placing seedlings in the soil in due time; reducing branches of cotton and pruning the cotton; uncovering the mulching films timely, watering the cotton and applying additional fertilizers to the cotton; performing reasonable chemical control; timely performing insect disease prevention on the cotton. The method has the advantages of simplicity, clear steps and good cultivation effect.

Owner:固镇县淮鸿灰天鹅养殖专业合作社

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com