Patents

Literature

99results about How to "Not released" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Basic biomass synthetic resin and preparation method and application thereof

ActiveCN101629019AGood film formingIncrease stickinessProtein adhesivesGlue/gelatin preparationPolymer scienceAdhesive

The invention belongs to the material science field, in particular to a basic biomass synthetic resin and a preparation method and an application thereof. The basic biomass synthetic resin is prepared by the following steps: taking acidity regulator to prepare a water solution with pH value of 6.0-10.0, adding plant protein powder in the water solution under the stirring state; adding a molecular structure modifying agent under the stirring state, performing the modifying reaction for 15-240 min at 5-75 DEG C; sequentially adding modified starch and a resin assistant, performing the polymerization reaction for 15-240min at 5-90 DEG C, adding preservative in a reaction system within the last 5-20min of the polymerization reaction; adding or not adding packing after finishing the reaction, and stirring uniformly to obtain the basic biomass synthetic resin, wherein the part of the materials is taken by weight. The basic biomass synthetic resin has wide application range on the respect of preparing bonding adhesive or coating.

Owner:郑州佰沃科技发展有限公司

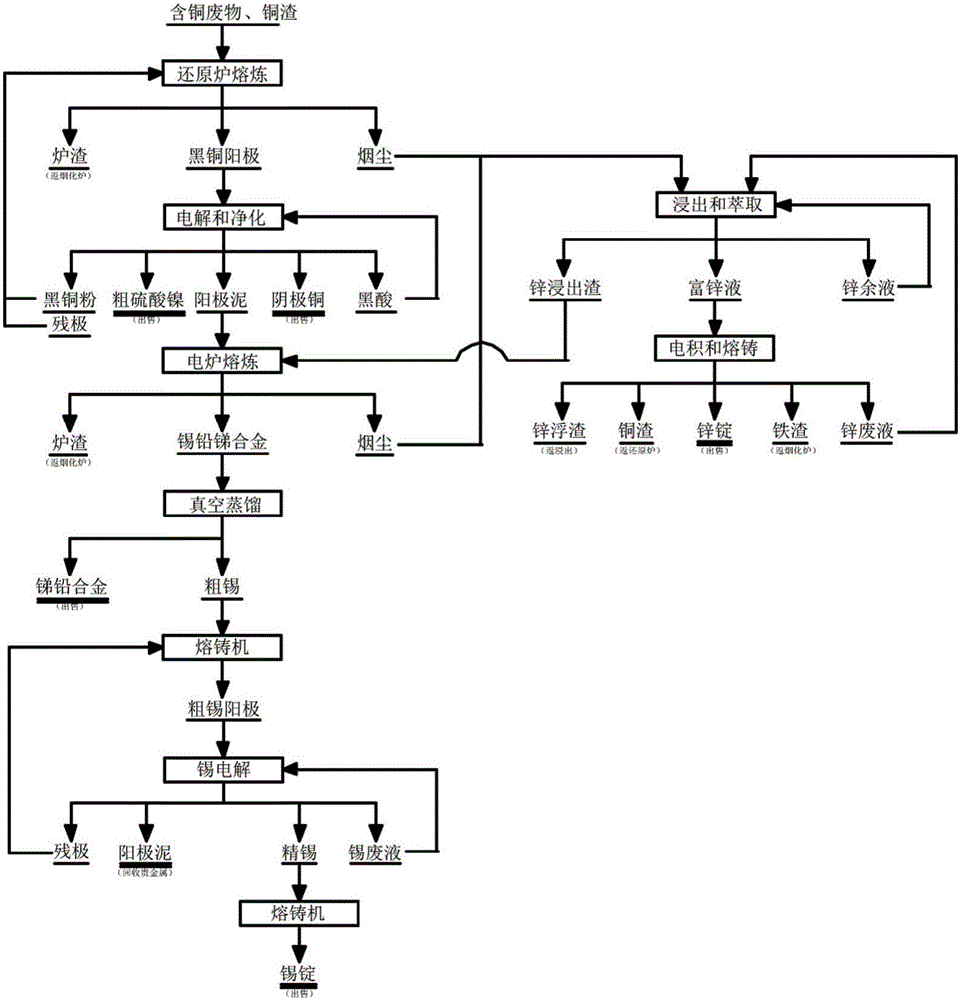

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

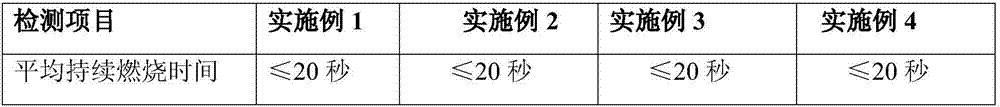

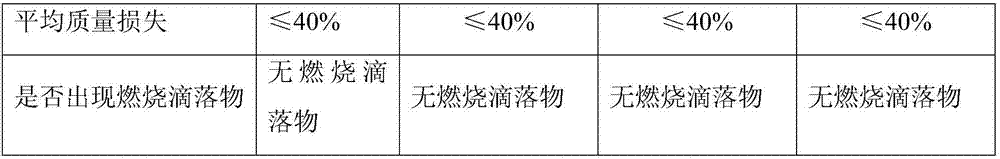

Inflaming-retarding flexible heat preservation facing material in building and preparing method thereof

The invention discloses an inflaming-retarding flexible heat preservation facing material in building and a preparing method thereof, which is prepared from the following components in part by weight: 1-50 parts of soil particles, 1-50 parts of hollow filler, 1-10 parts of reinforced fibers, 10-50 parts of flexible emulsion, 0-1 part of pigment, 1-10 parts of accessory ingredient and 10-40 parts of water, that are mixed to form slurry with appropriate viscosity, are formed in a template with decorative patterns, so as to prepare a composite material with functions of inflaming retarding, heat preservation and decoration after gradient temperature control, drying and demoulding. According to the invention, the production process is environmental-friendly, the construction process is simple, convenient and feasible, and the inflaming-retarding flexible heat preservation facing material in building is particularly suitable for external facing of high-rise buildings and old town transformation.

Owner:南通南京大学材料工程技术研究院

Waterproof environmental protective label glue

InactiveCN1613946APaste wellExcellent water resistanceUnsaturated alcohol polymer adhesivesAmmonium sulfateButyl acrylate

The invention relates to a water-resistant adhesive and its production method. It is composed of water, PVA, acryl acid, butyl acrylate, acrylamide, styrene, ammonium, persulfate, NaHCO3. It is produced by: initiating monomer with an initiator in a PVA-water solution. The process is simple and cheap. The production doesn't discharge harmful wastes.

Owner:陈平绪

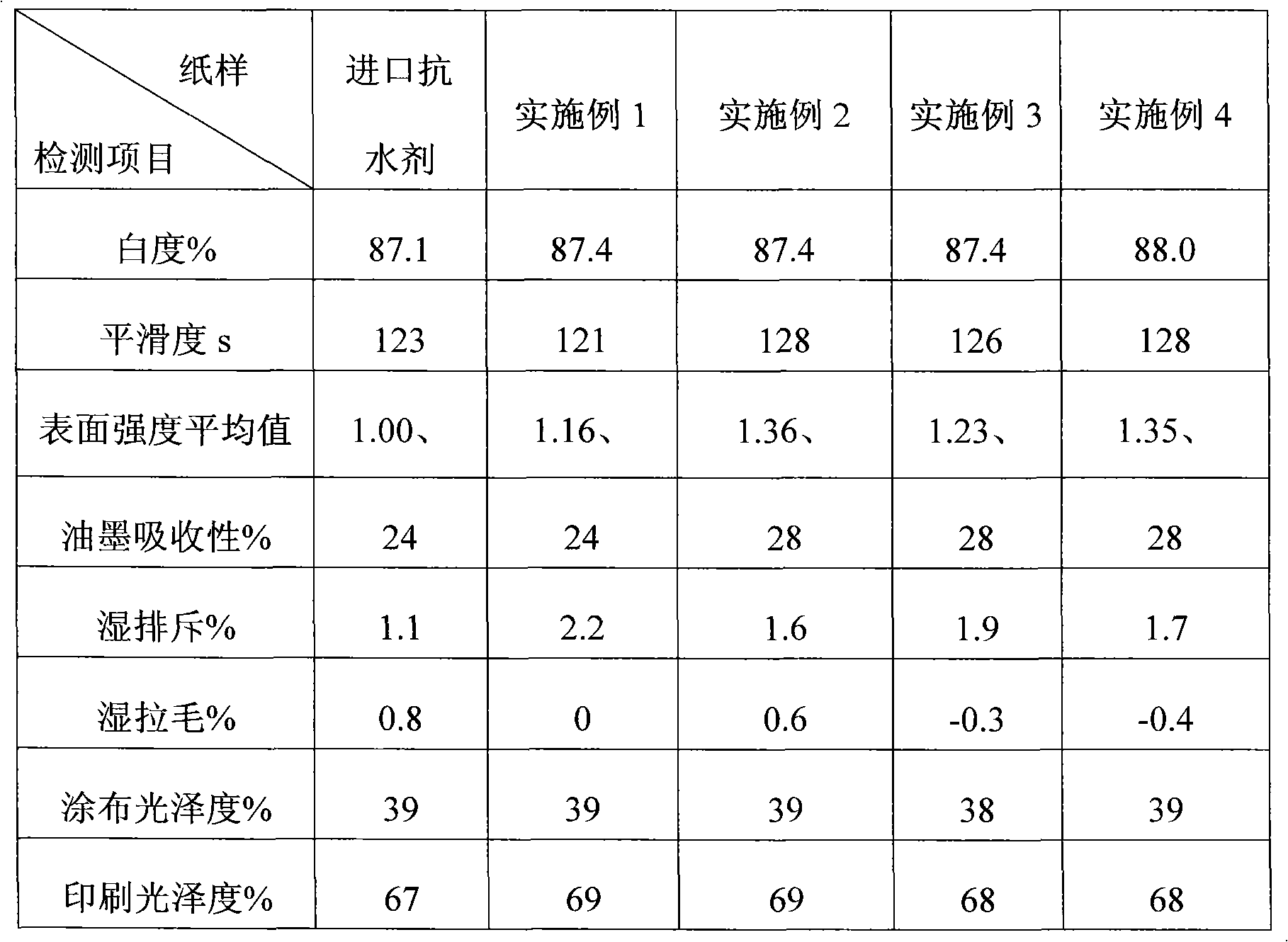

Modified coating water repellent agent and preparation method thereof

ActiveCN101831070AHigh solid contentLow viscosityWater-repelling agents additionPaper coatingThioureaPaperboard

The invention discloses a modified coating water repellent agent as well as a preparation method and application thereof. The preparation method comprises following steps of: (1) adding polybasic acid in a mixture of diethylenetriamine, diethanol amine and acidic materials, reacting for 30-60min at 120-130 DEG C firstly, and then reacting for 1-4h at 160-190 DEG C and separating produced water in a system during reaction; (2) adding water and controlling the solid content of the system to be 55-60 percent; (3) lowering the temperature of the system to 50-80 DEG C, adding thiourea in the system, reacting for 6-12h at 100-110 DEG C, adding epichlorohydrin and water for reaction for 4-10h at 20-40 DEG C, neutralizing pH value of the system to be 6-8 with acid with the weight concentration of 5-15 percent and cooling to obtain the product. The modified coating water repellent agent has high solid content by weight and good coating performance and enables produced paper and paperboards not to need curing after being applied to production.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Coating water-repellent agent and preparation method thereof

InactiveCN101403205AHigh solid contentReduce organic chlorine contentReinforcing agents additionCross-linkPolyamide

The invention discloses a coating water repellent agent and a preparation method thereof. The coating water repellent agent is a polyamide polyurea epichlorohydrin resin water solution with the solid content (mass content) of 50 percent to 60 percent, wherein, the mass percentage of organic chloride is less than 0.1 percent, the pH is equal to 6 to 8, viscosity is 150mP question mark s to 450mP question mark s. 10 percent of acid is added as a reaction additive in the reaction, which causes the product weight solid content generated at the final stage of the reaction and the coating property to be improved. Furthermore, low temperature reaction is adopted during the cross-linked reaction process with epichlorohydrin, then slight heating is carried out and ethanolamine is added for further reaction, thus reducing the organic chloride content of the generated byproduct, and reducing the organic chloride content of the whole product, which is kept at the level of less than 0.1 percent.

Owner:CENT SOUTH UNIV

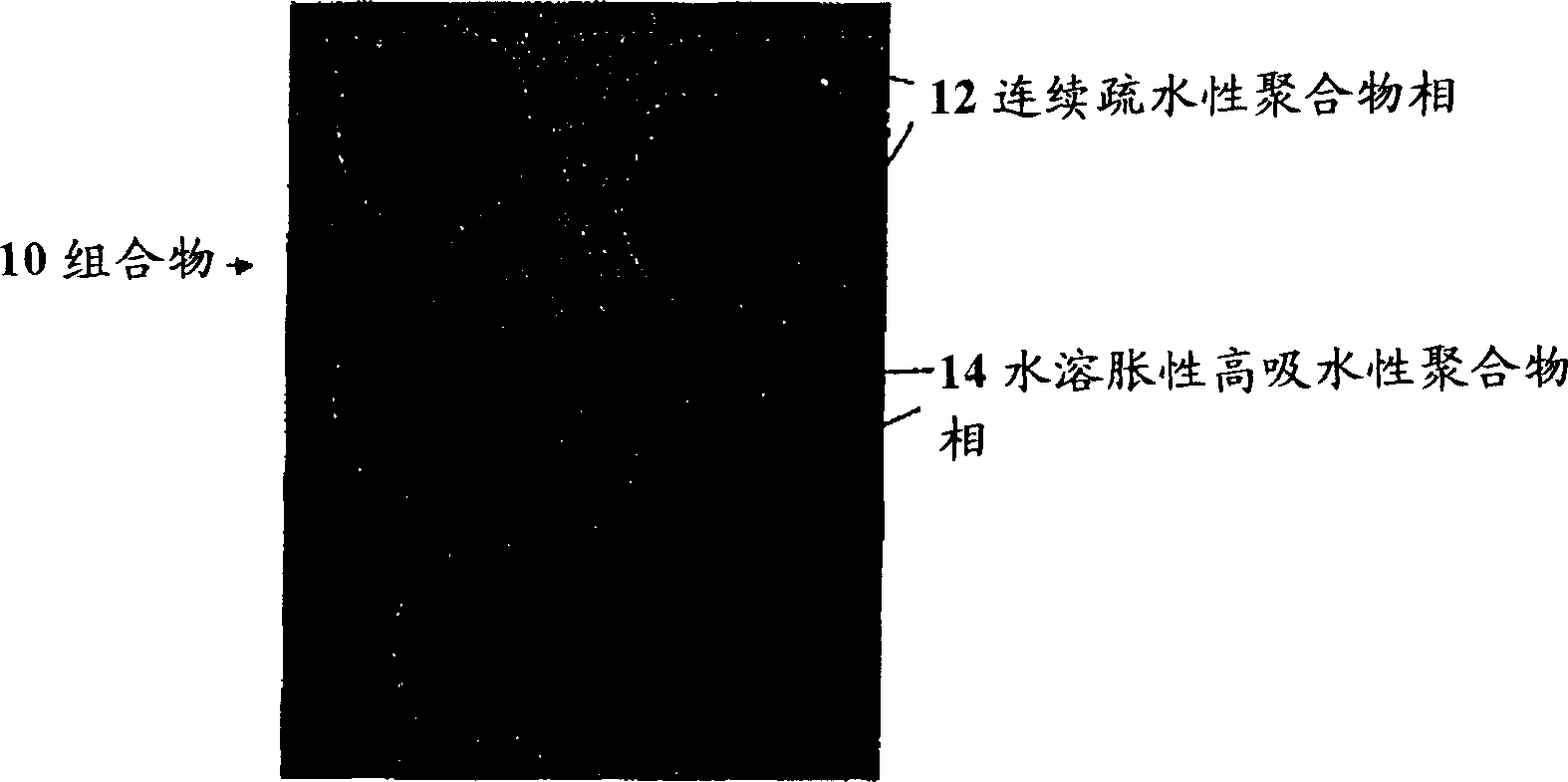

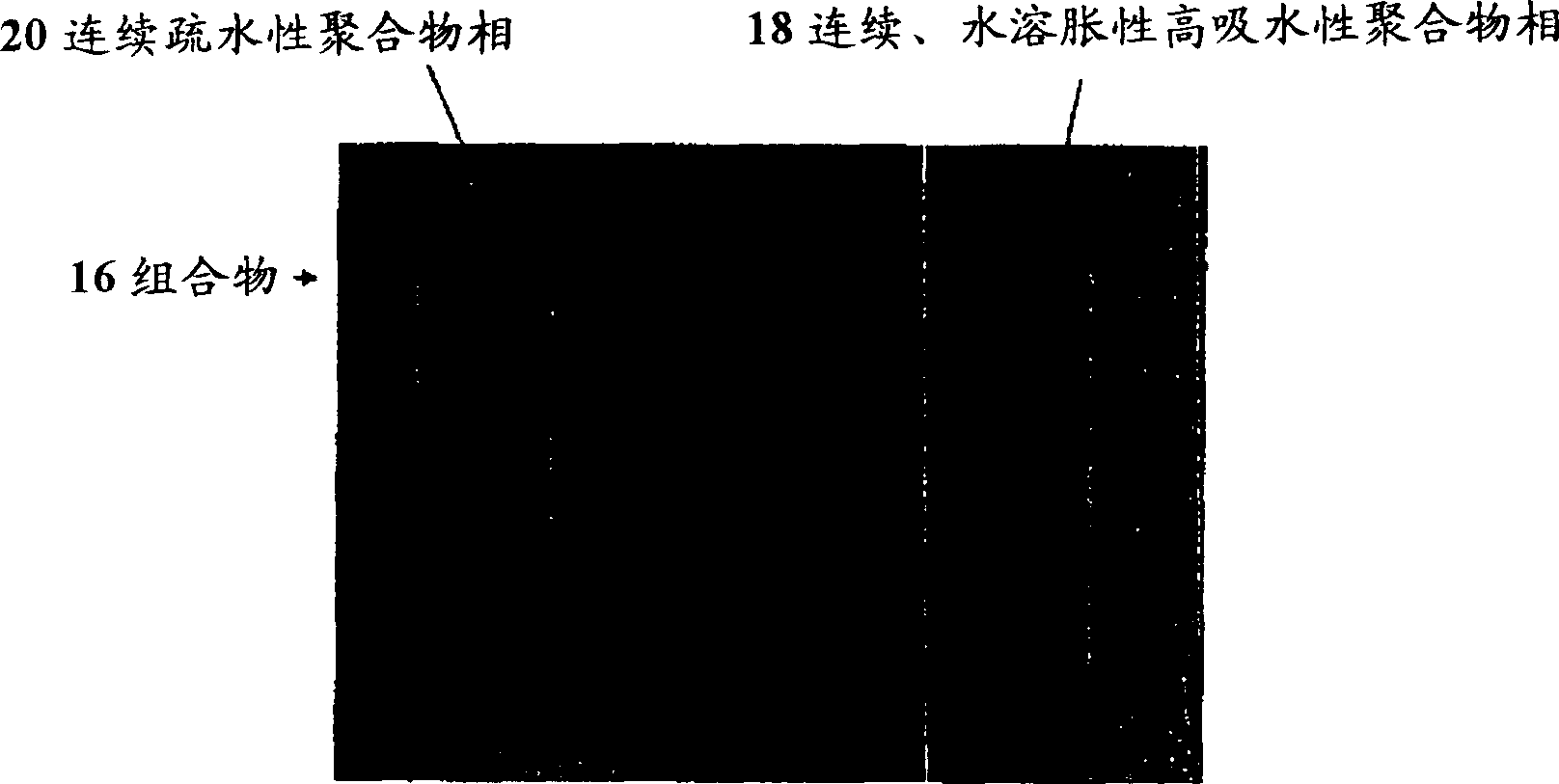

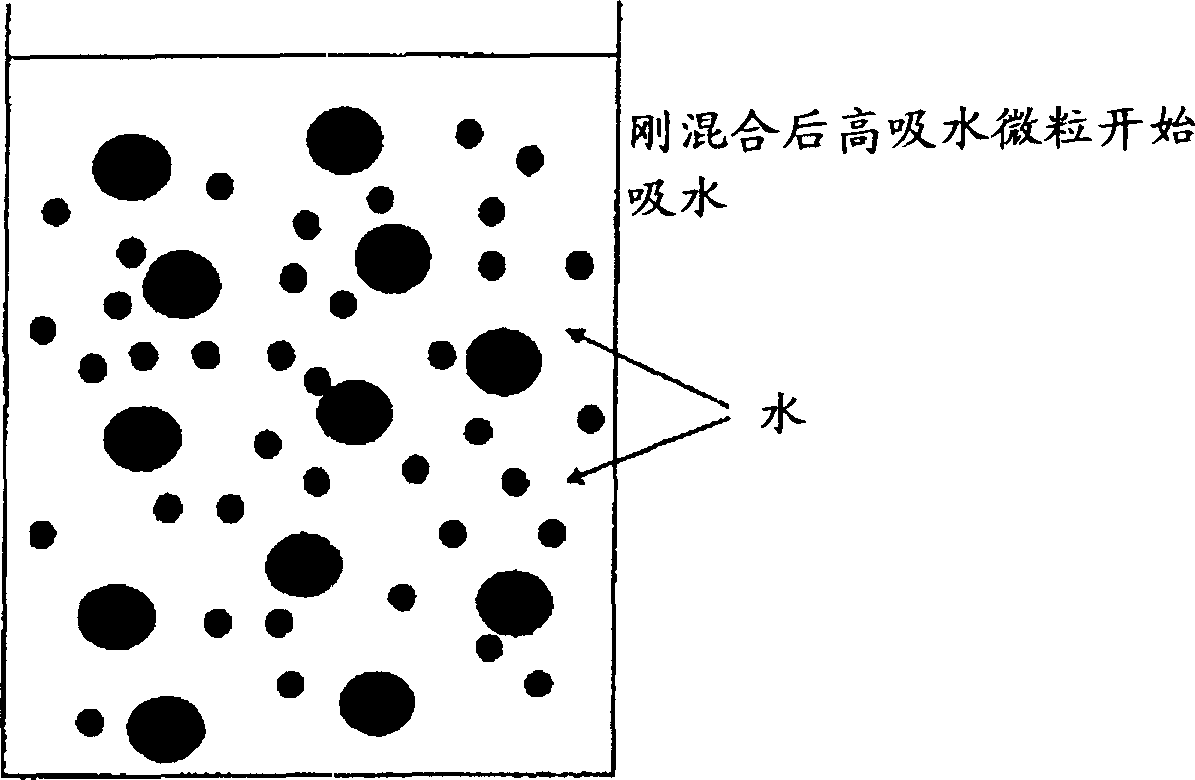

Superabsorbent-hydrophobic polymer two-phase compositions

InactiveCN1694918ANot releasedFlame retardantOther chemical processesDomestic articlesEmulsionHydrophobic polymer

Disclosed is a composition comprising a hydrophobic polymer phase and a water-swollen superabsorbent polymer phase. Also disclosed is a two component system for preparing a composition comprising a hydrophobic polymer phase and a water-swollen superabsorbent polymer phase. The first component is an emulsion of the hydrophobic polymer; the second component comprises the superabsorbent polymer; and the first and second components form the composition when mixed.

Owner:WR GRACE & CO

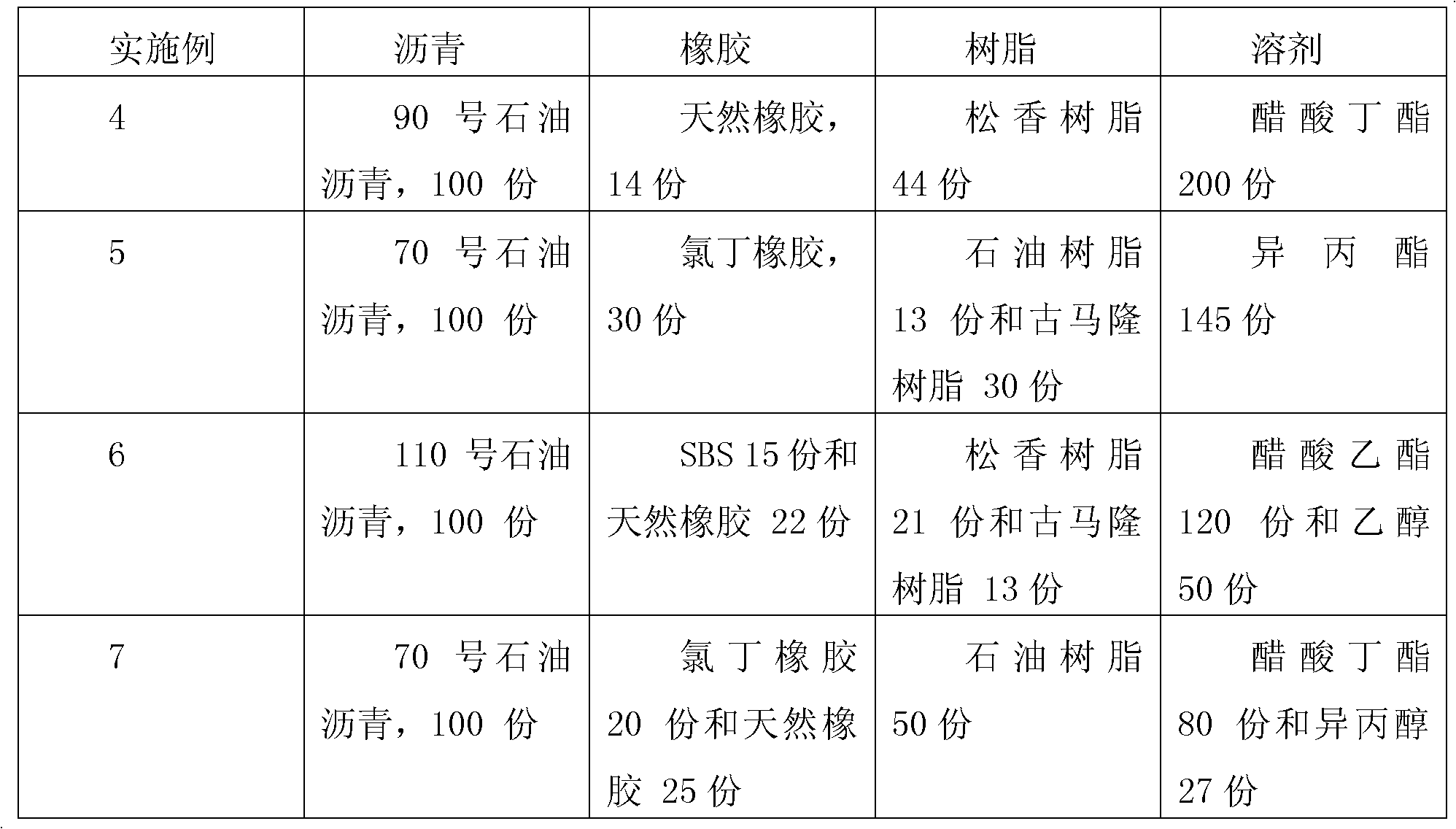

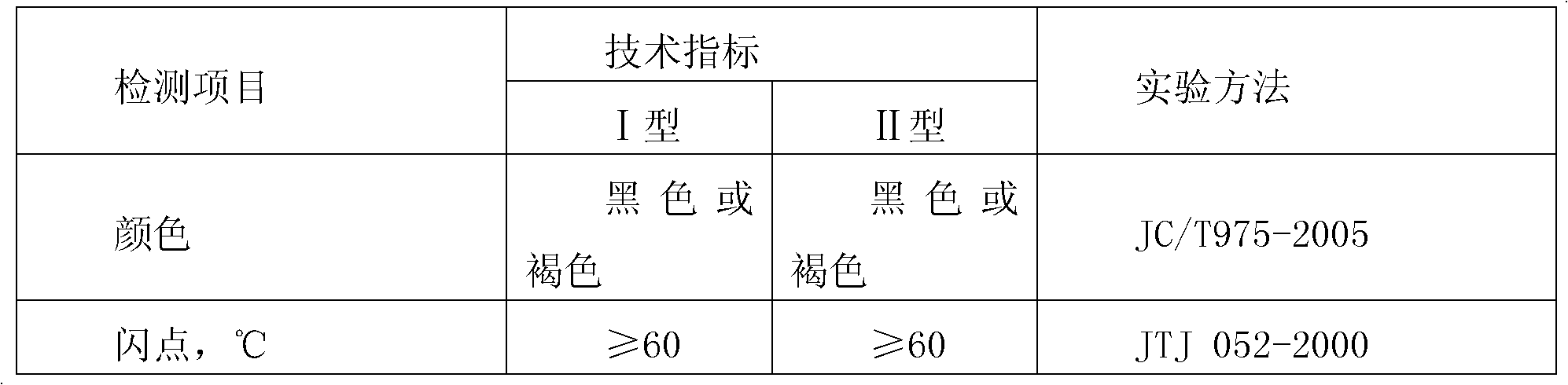

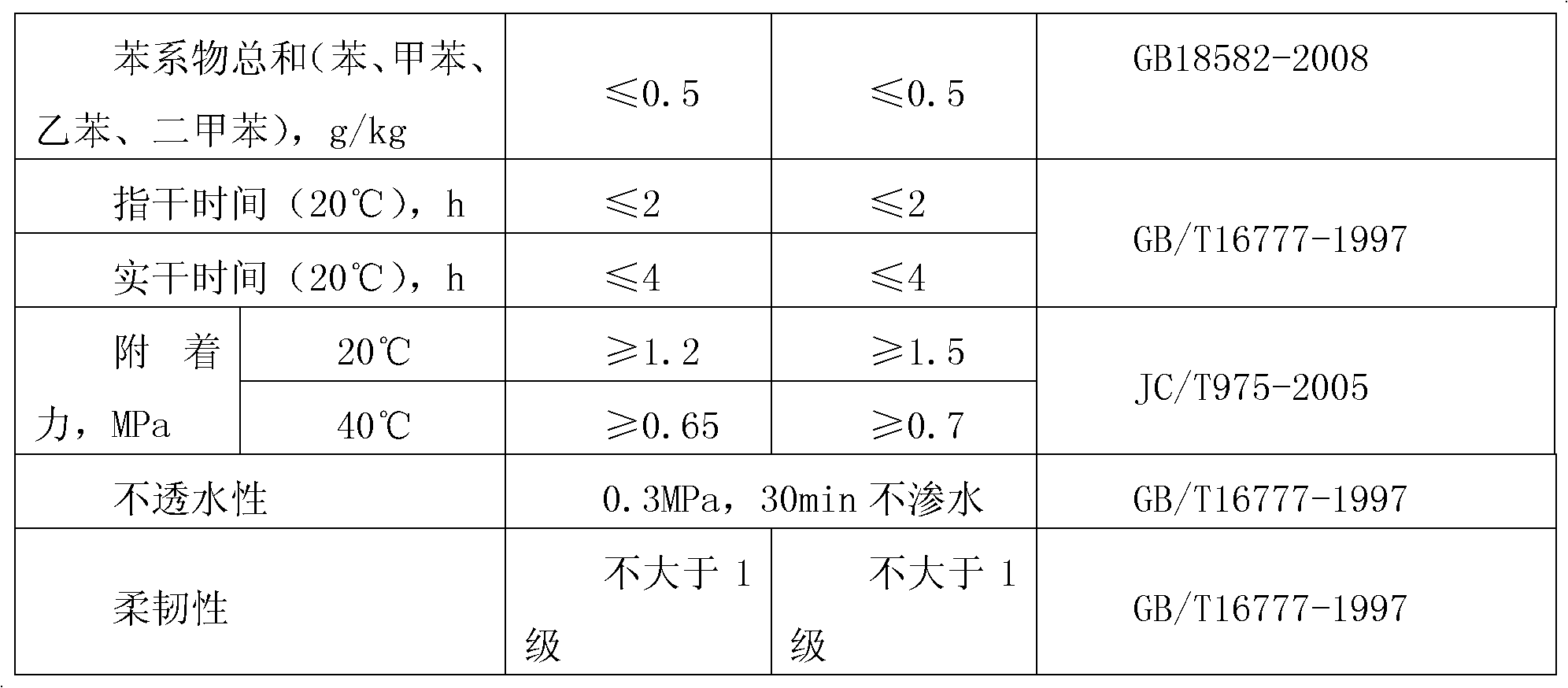

Waterproof adhesive and preparation method thereof

ActiveCN102153873ALow viscosityReduce penetrationNatural rubber coatingsBuilding insulationsPolymer sciencePetroleum

The invention discloses a waterproof adhesive, which is prepared from raw materials including 100 parts of asphalt, 10 to 50 parts of rubber, 10 to 50 parts of resin and 100 to 200 parts of solvent, wherein the asphalt is No.70, No.90 or No.110 petroleum asphalt; the rubber is natural rubber or / and synthetic rubber, and the synthetic rubber is styrene-butadiene-styrene (SBS) or / and neoprene; the resin is one or a random combination of more of petroleum resin, coumaroneindene resin and abietic resin; and the solvent is one or a random combination of more of isopropyl acetate, acetic ether, butyl acetate, isobutyl alcohol, isopropanol and ethanol. The waterproof adhesive is directly sprayed onto treated cement concrete pavement, bridge surface or steel bridge surfaces, and has low viscosity, high permeability, high waterproof performance, high adhesive force, high compatibility with and high affinity to asphalt concrete in a paved layer, the coating has high toughness and strength, the adhesive force for cement of the adhesive can reach over 1.2Mpa and the adhesive force for steel plate can reach over 1.5Mpa; meanwhile, the adhesive disclosed by the invention is nontoxic, safe and environmentally friendly, and the total content of benzene series is not more than 0.5g / kg.

Owner:重庆市智翔铺道技术工程有限公司

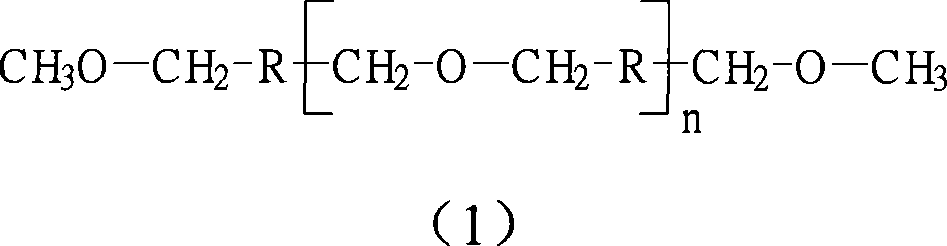

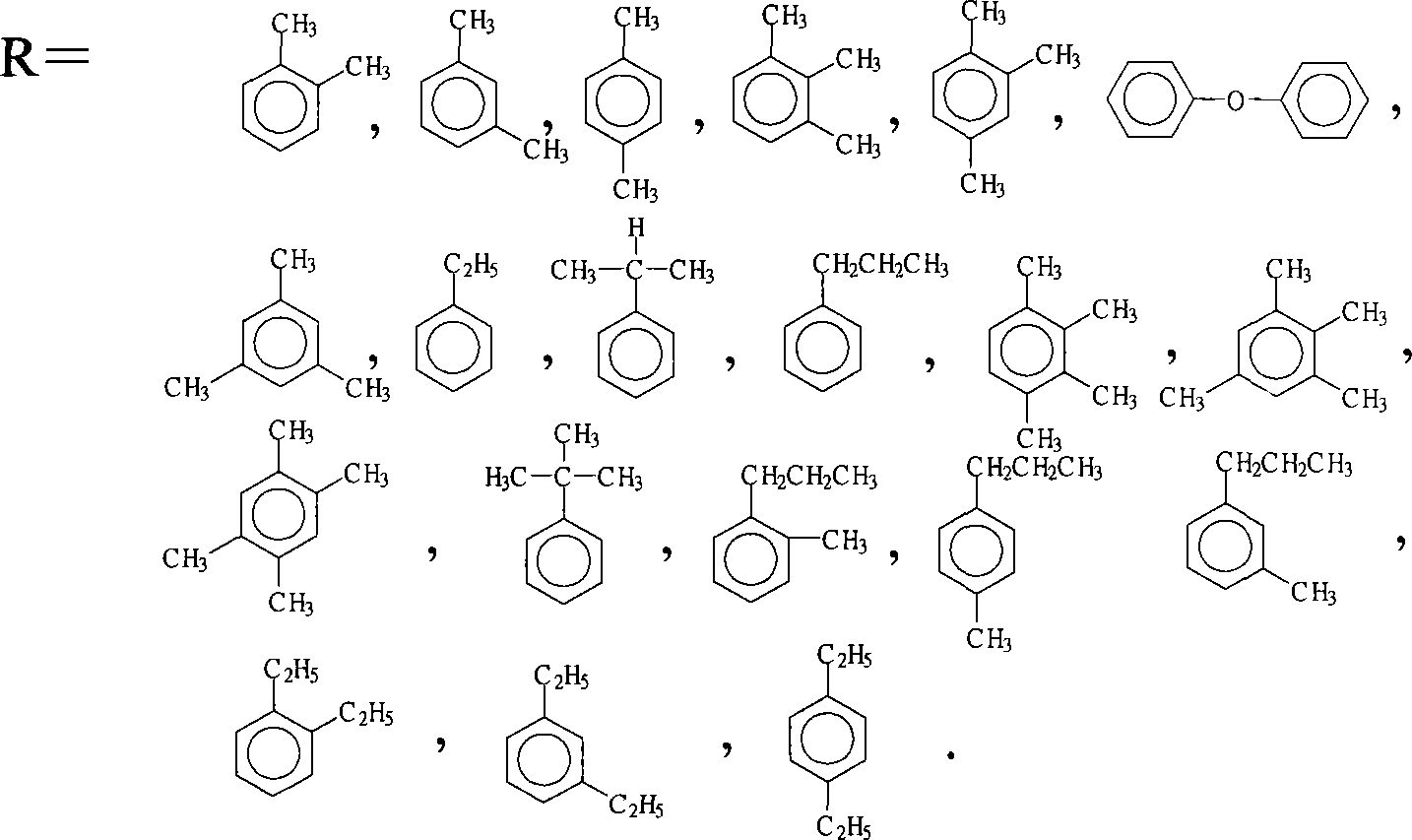

Technique for preparing methoxyl aralkyl ether oligomers

The invention relates to the technical field of thermosetting resin manufacture, in particular to a manufacturing technique of methoxy aralkyl ether oligomer. The invention obtains polymer by using methanol and formaldehyde under the condition of acid catalyst with at least one aralkyl compound and through condensation polymerization. Compared with the prior art, the invention avoids the use of catalyst of strong corrosiveness and toxicity, with few byproducts and without released corrosive substance; in addition, the method of the invention uses raw materials of low cost and has the advantages of simple manufacturing technique, good application effect and is applicable to a plurality of modified phenol-formaldehyde resin with wide development and application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

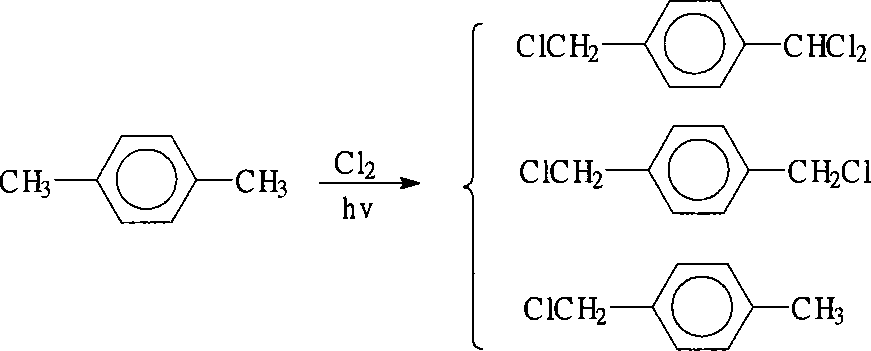

Preparation method of prevulcanization type catalyst

ActiveCN103100444ANo self-heatingNo flammability issuesCatalyst activation/preparationSimple Organic CompoundsVulcanization

The invention discloses a preparation method of a prevulcanization type catalyst. The method consists of: taking an oxidation state catalyst, adding an organic solvent and elemental sulfur, conducting heat treatment, then using an appropriate organic assistant to perform aftertreatment on the catalyst, thus obtaining the final prevulcanization type catalyst. The method enables the organic assistant and sulfur to form an organic compound, which does not decompose at low temperature, thus avoiding untimely contact of hydrogen and sulfur during startup activation, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. After high pressure air sealing, the compound of sulfur and the organic assistant decomposes. Hydrogen and sulfur react, the formed hydrogen sulfide and an active metal undergo catalyst activation in the pores of the catalyst, thus raising the initial temperature of vulcanization. After high pressure air sealing, activation oil is introduced to take away the heat generated by activation timely, thus avoiding temperature runaway of the catalyst bed and ensuring a smooth startup process. The catalyst prepared by the method involved in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environment-friendly plastic profile and its production method

The invention discloses an environment-friendly plastic profile and its production method. The production method includes: adding a filler calcium carbonate, a toughening agent chlorinated polyethylene, and an ACR aid into polyvinyl chloride resin according to proportion, then adding a lubricant stearic acid and PE wax, and then adding a whitening agent, titanium dioxide and ultramarine, finally adding lead-free calcium zinc heat stabilizer, putting the materials into a high speed mixing machine together, conducting high temperature mixing at 130-140DEG C for 8-12min, then placing the mixture into a low-speed mixing machine to cool it to 35-45DEG C, subjecting the mixture to extrusion molding, and carrying out cutting so as to obtain a finished product. The environment-friendly plastic profile solves the exceeding heavy metal problem in the prior art, does not contain chlorine, bromine or other halogens, and has high flame retardance, thus meeting the EU ROHS and the relevant IEE standards.

Owner:安徽深泰新型建材有限公司

Metal-free heterogeneous Fenton-like catalyst, and preparation method and application thereof

ActiveCN107670691AGood removal effectWon't happenWater treatment compoundsOrganic-compounds/hydrides/coordination-complexes catalystsEvaporationSolvent

The invention discloses a metal-free heterogeneous Fenton-like catalyst, and a preparation method and application thereof. The preparation method of the catalyst comprises the following steps: takingconcentrated sulfuric acid as a solvent, adding graphite powder, NaNO3 and potassium permanganate, performing a heating reaction, then adding H2O2 until the solution changes into a gold brown suspension, and performing washing, drying and grinding to obtain solid powder; and mixing 4-phenoxyphenol and the solid powder F, melting the mixture in ethanol, performing a heating reaction, removing the solvent through evaporation to obtain a solid precursor, and performing a reaction at 350-380 DEG C to obtain solid powder which is the metal-free heterogeneous Fenton-like catalyst. The metal-free heterogeneous Fenton-like catalyst disclosed by the invention is not obviously influenced by the pH value of a reaction system. The harsh condition that the pH value of the system is regulated to 2-3 isnot needed in the reaction process, and a favorable removal effect can be achieved for the degradation of nonbiodegradable toxic / harmful organic pollutants under a neutral condition at room temperature.

Owner:GUANGZHOU UNIVERSITY

Method for producing magnesium using bischofite as raw material

InactiveCN1663913AUniform particle sizeAvoid the dehydration processProcess efficiency improvementMagnesiaSolubilityMetallic materials

A method of preparing magnesium metal with bischofite, pertains to the field of metallic material. The invention is characterized in that it takes the bischofite as stock and prepare magnesium hydroxide with ammonia process under the following conditions: at the temperature between 45~55 DEG C for 20~30 minutes, with the proportion between magnesium and ammonia 1:1.2~1.5:2.2 and with the concentration of magnesium chloride about 35~55 g / L, calcinating the magnesium hydroxide under the temperature of 900~1000 DEG C for 3-4hours, getting the magnesia with the purity of more than 99.5%,in the molten salt electrolyte system of lanthanum chloride and magnesium chloride, the proportion between lanthanum chloride and magnesium chloride in moles is 10~30%, the solubility of magnesia is 5~10 mass%, thaw temperature is 700~750 DEG C, the tank voltage 4.5~6.5 volt, the current efficiency comes to 85~90%, the consumption of the direct current of magnesium is 11~12.5kWh per kilogram and the purity of magnesium is above 95%. The method avoids the dehydration process of bischofite and is characterized by the energy-saving and consumption-deducing, the highly effective and cleaning of electrolytic process, particularly for its not emitting chlorine and not polluting the environment.

Owner:UNIV OF SCI & TECH BEIJING

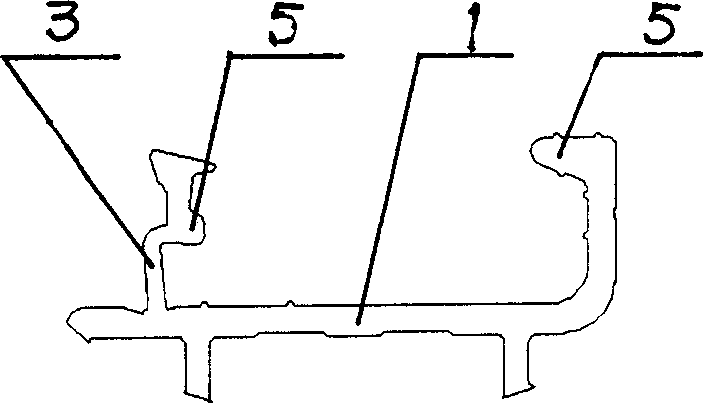

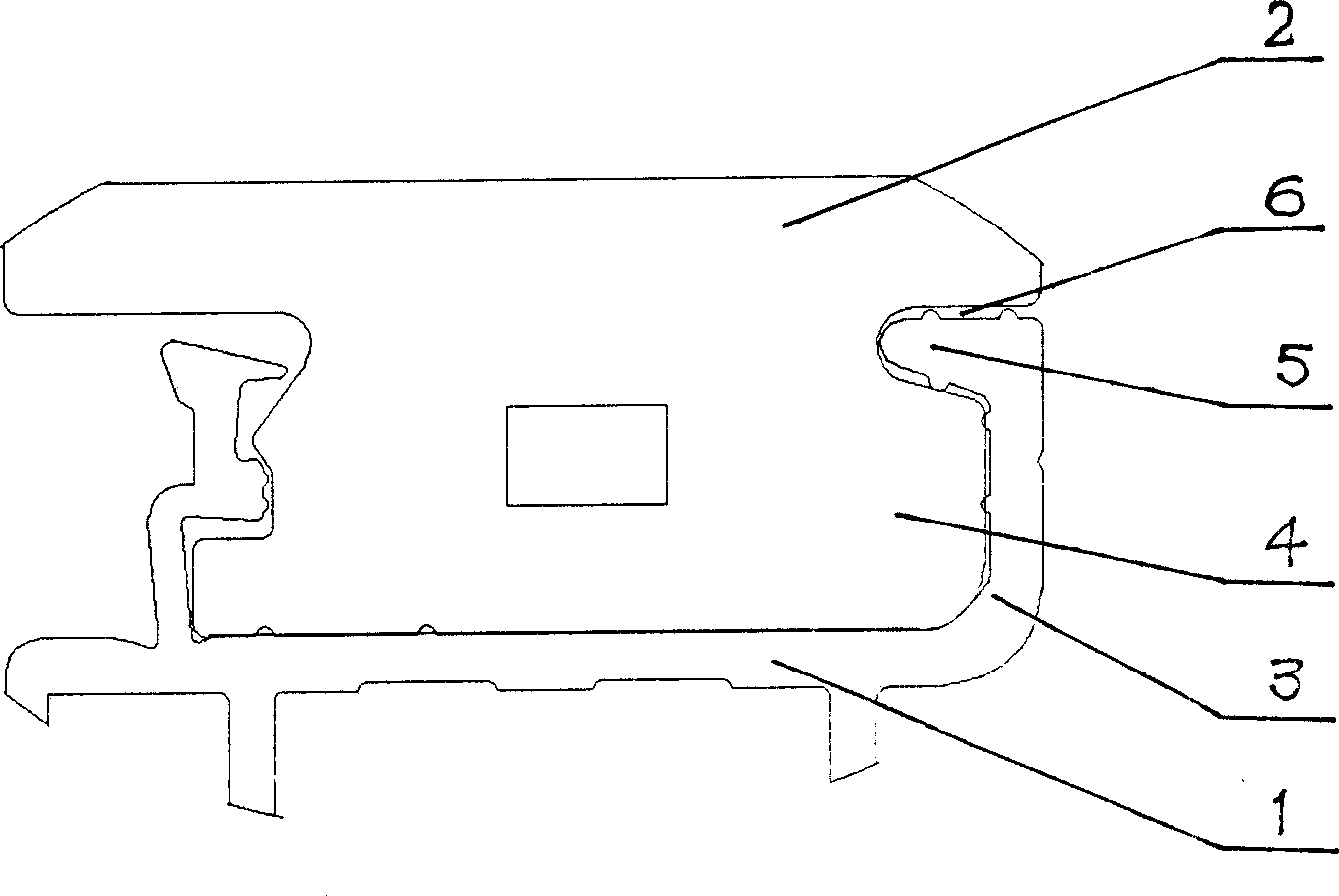

Pulling on press type composite shape bar of aluminum and wood, and fabricating method

InactiveCN1916341ADifficult to form mass productionShape extrusion stabilityWallsWing framesHigh volume manufacturingEngineering

The present invention discloses a through-pressed aluminium-wood composite section material. It is made up by connecting aluminium section material with wood section material. It is characterized by that the connection end of said aluminium section material is equipped with connection mouth, and the connection end of said wood section material is equipped with connection head, the form of said connection mouth is matched with the form of said connection head, the connection of said aluminium section material and wood section material can be implemented by making the connection head of the wood section material be passed through the connection mouth of aluminium section material and making them be compressed together. Besides, said invention also discloses a production process of said through pressed aluminium wood composite section material.

Owner:叶鹏智

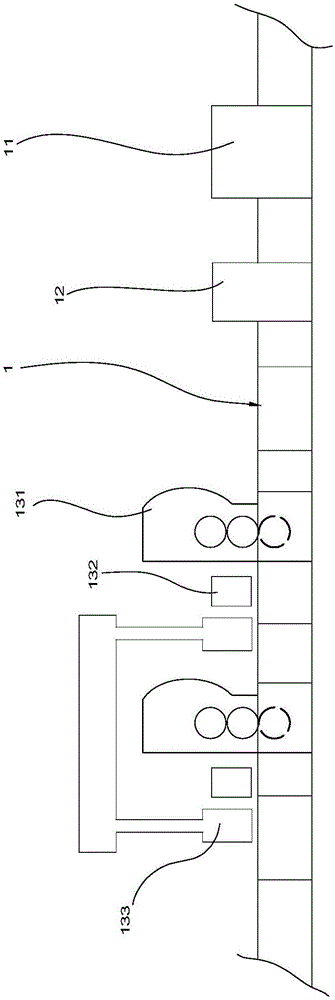

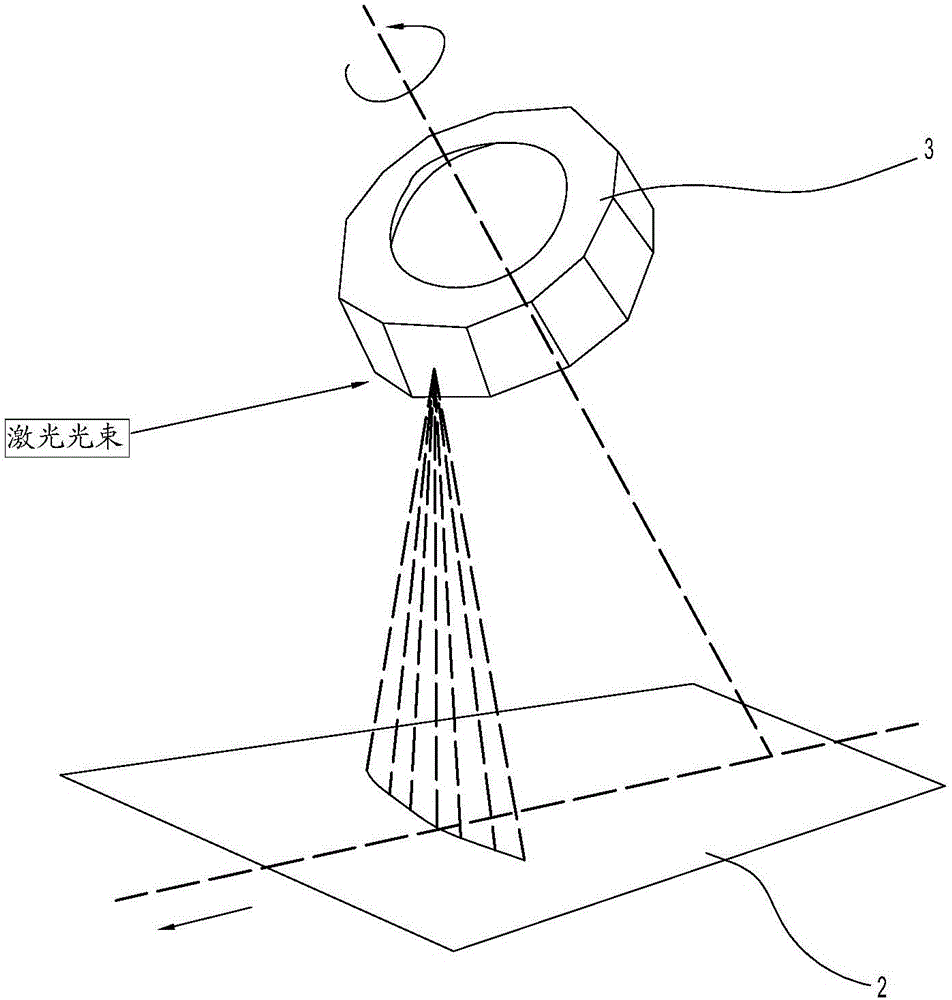

Method for printing by adopting iron printing machine and environment-friendly coating

ActiveCN106113959AEasy to cutFacilitates high frequency weldsChemical industryInksEnvironmental resistanceLaser processing

The invention discloses a method for printing by adopting an iron printing machine and an environment-friendly coating. The method is characterized by comprising the steps of substrate surface treatment and UV printing; in substrate surface treatment, the feeding section of the iron printing machine is additionally provided with a laser processor, a substrate surface treatment process is directly built in a printing line to form a continuous online surface treatment and printing production integrated process, and laser produced by the laser processor rapidly moves on a substrate surface; and in UV printing, the iron printing machine is connected in series with a plurality of UV printing units, each UV printing unit comprises a printing assembly, a UV lamp bank and an exhaust gas recovery assembly, the printing assembly in each UV printing unit adopts UV environment-friendly ink to realize printing of local patterns on the substrate surface subjected to laser processing, and each exhaust gas recovery assembly comprises a cooling hood and a suction fan and is used for recovering exhaust gases and waste heat which are generated by UV printing.

Owner:萍乡市时代工艺包装有限公司

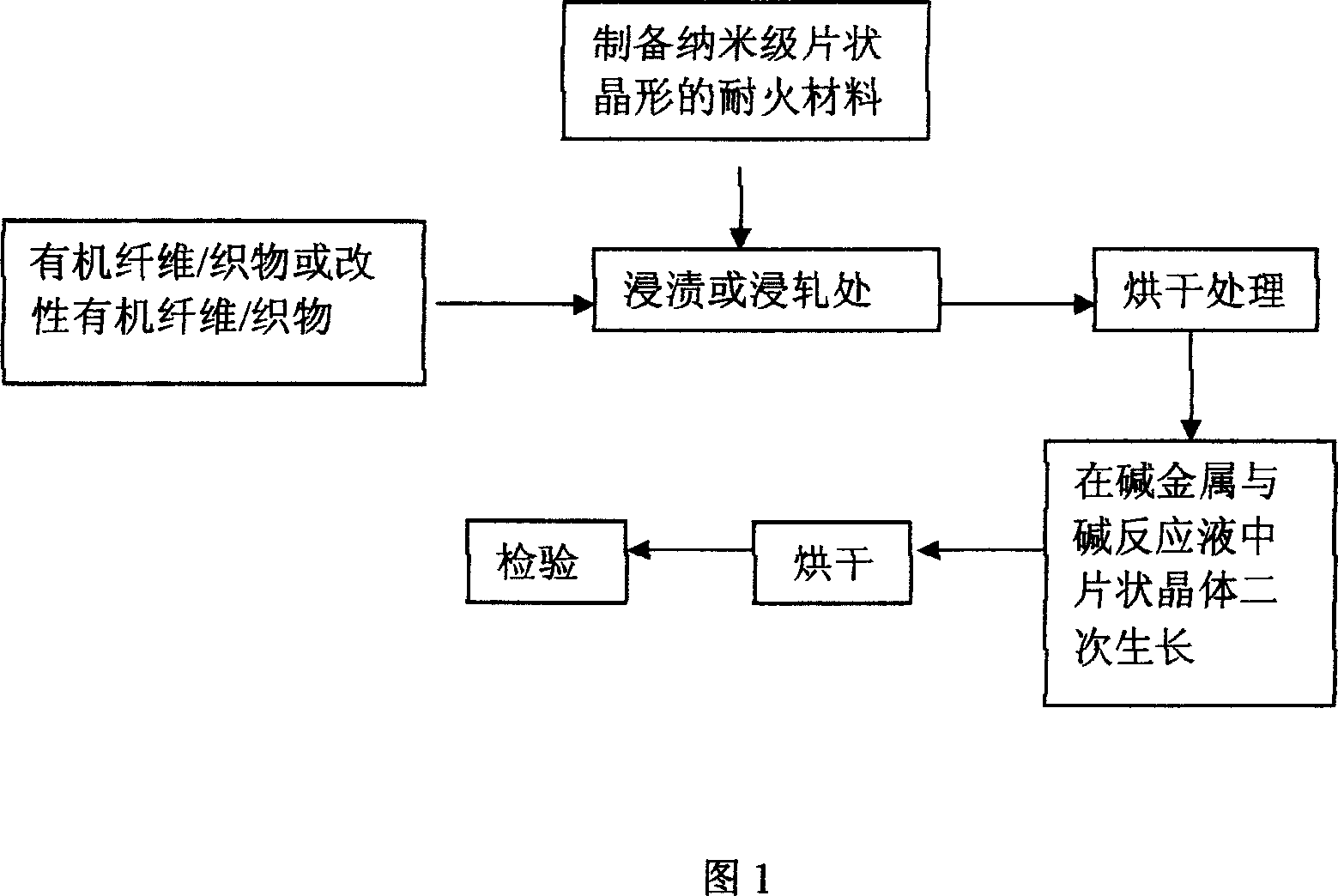

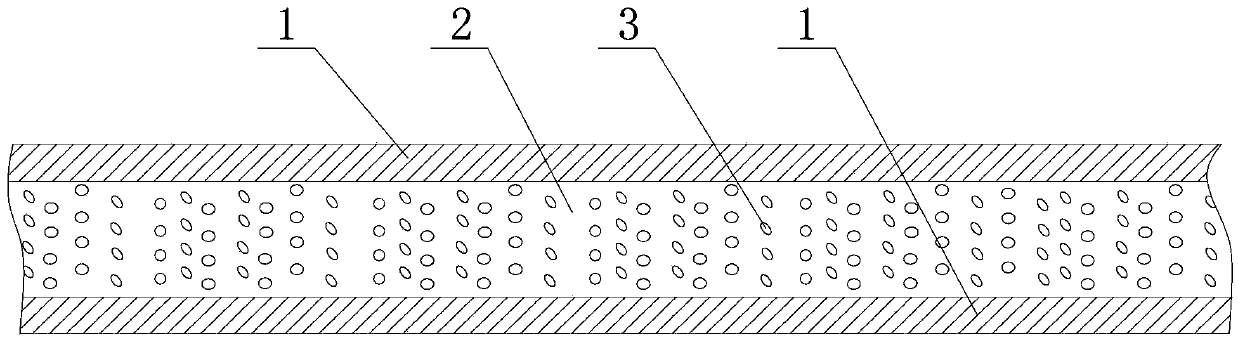

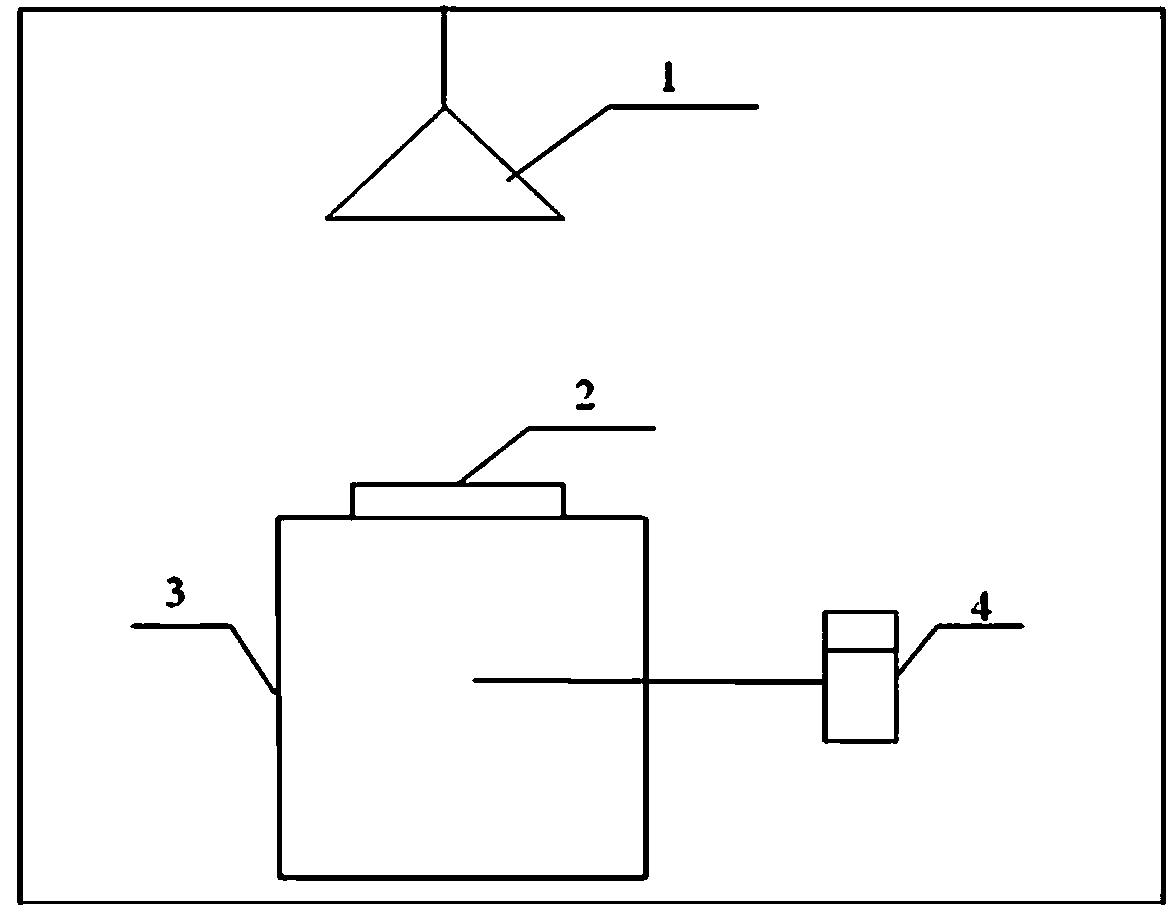

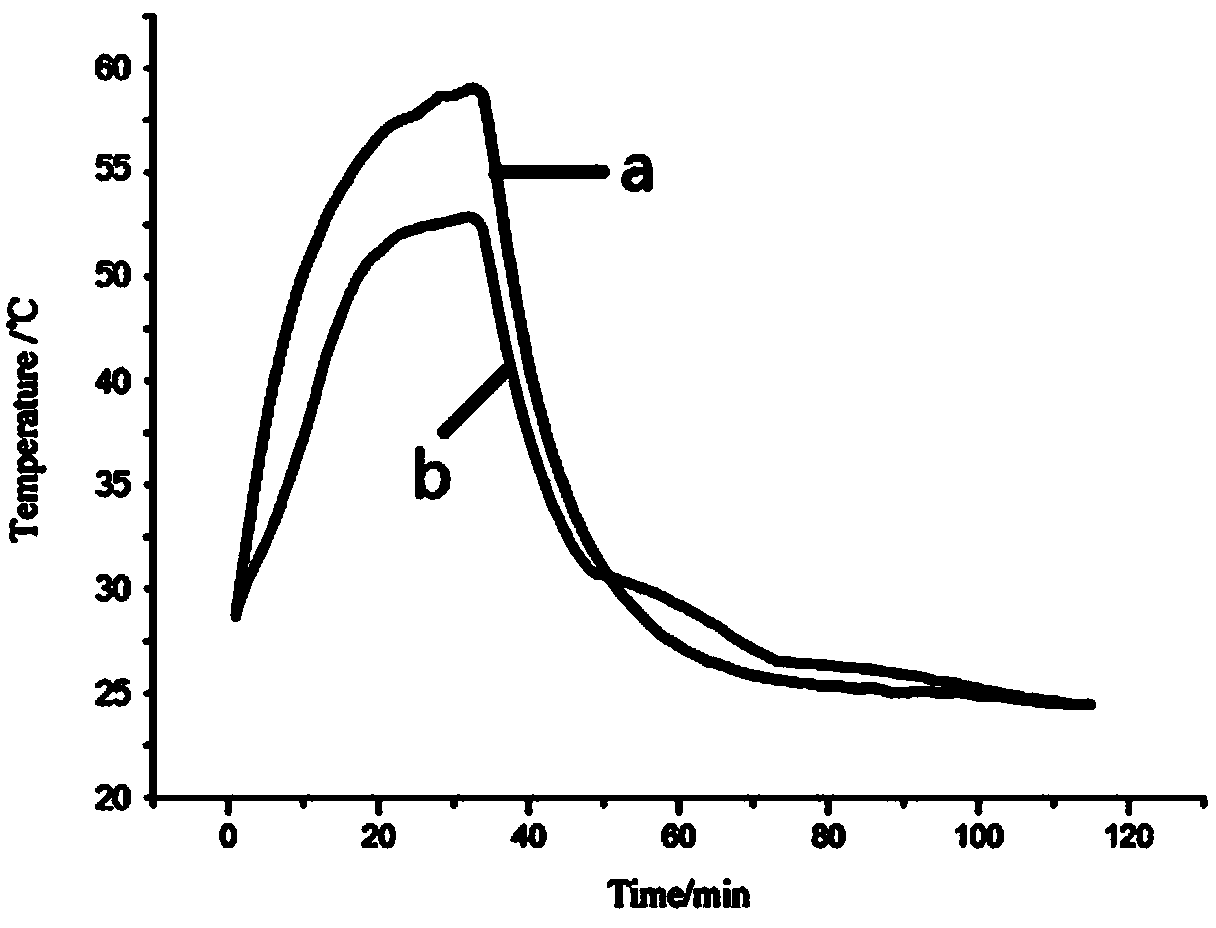

Flame resisting heat insulating conditioning method for orgainic fiber fabric

InactiveCN1932135AAchieve wrappingNo pollution in the processFibre treatmentFiberAgricultural engineering

The present invention discloses a finishing method for raising heat-insulating and flame-proofing performance of organic fibre fabrics. Said method is characterized by forming a continuous protective film made of sheet hydroxide on the surface of organic fibre or fabrics so as to raise flame-proofing and heat-insulating performance of organic fibre fabrics.

Owner:DONGHUA UNIV

Novel green fireproof door core board and process for manufacturing same

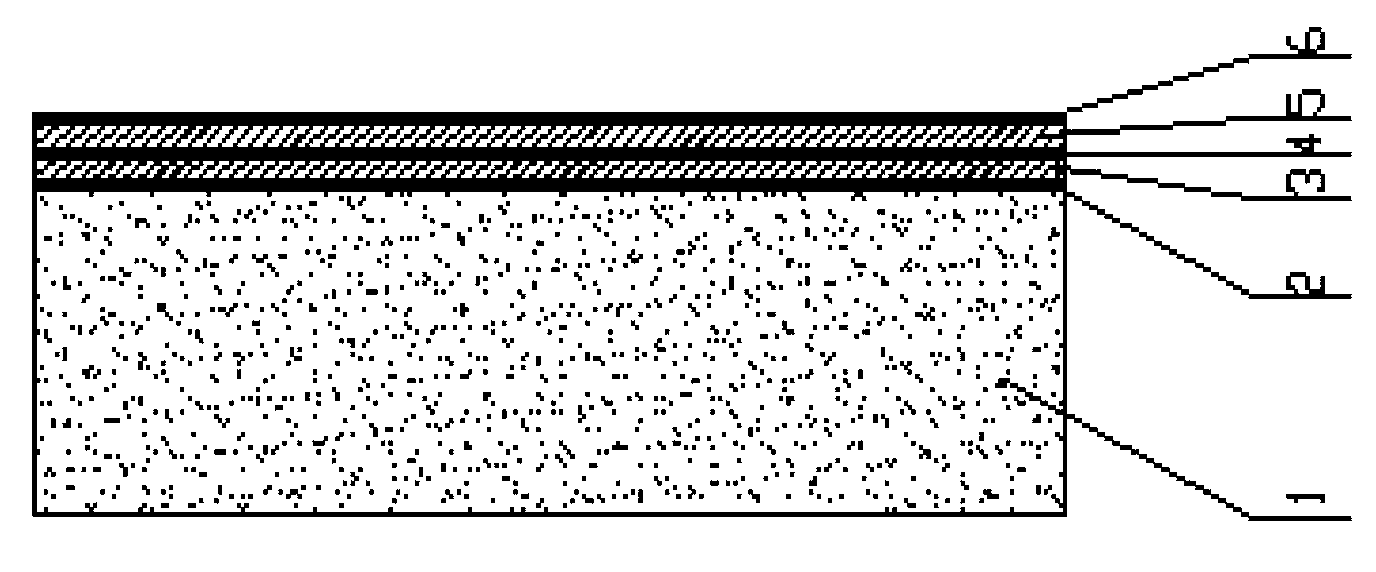

InactiveCN103422792AMeet fire resistance requirementsMeet insulation needsFireproof doorsSurface layerEmulsion

The invention discloses a novel green fireproof door core board. The novel green fireproof door core board is characterized in that the novel green fireproof door core board comprises a core board body and the thickness of the core board body is 2-5cm; a surface layer with the thickness being 0.5-1.5cm is respectively arranged on the upper surface of the core board body and the lower surface of the core board body and the core board body is a fireproof layer; the fireproof layer is made of cement, expansion particles, short filaments, bentonite, light calcium powder, melt glass, water, foaming agents and acrylic acid emulsion. As further improvement, the expansion particles are EPS foam particles. The novel green fireproof door core board is low in weight, easy to carry, convenient to cut and easy to construct, lowers building cost and is long in service life and especially, the load of the novel green fireproof door core board is lightened.

Owner:张家港市盛港绿色防火建材有限公司

Composite powder binding agent containing gelatinized phosphate starch and kaolin and preparation method thereof

The invention provides a preparation method of a composite powder binding agent containing gelatinized phosphate starch and kaolin, and belongs to the technical field of binding agents for casting. The preparation method comprises the following steps of: firstly preparing the phosphate starch through a dry method; and combining and gelatinizing the obtained phosphate starch and coupling agent modified kaolin to obtain the composite powder binding agent containing the gelatinized phosphate starch and the kaolin for casting. After tapioca is esterified, a part of hydroxyls are converted into ester groups, and the function of hydrogen bonds between starch molecular chains is weakened; therefore, the sand flowability and the damp absorption resistance of the binding agent are obviously improved. Due to the adding of organic kaolin, the flowability of core sand is increased, and the high temperature resistance of the core sand is improved. The core sand prepared from the binding agent product has the characteristics of high tensile strength, good damp absorption resistance and excellent high temperature resistance, can be used for replace combined resin sand and a part of resin sand to produce level II mud cores, has the advantages of needing low cost, being environment-friendly, being convenient to transport and the like, has obvious economic benefit, and can be widely applied in the casting field.

Owner:FUZHOU UNIVERSITY

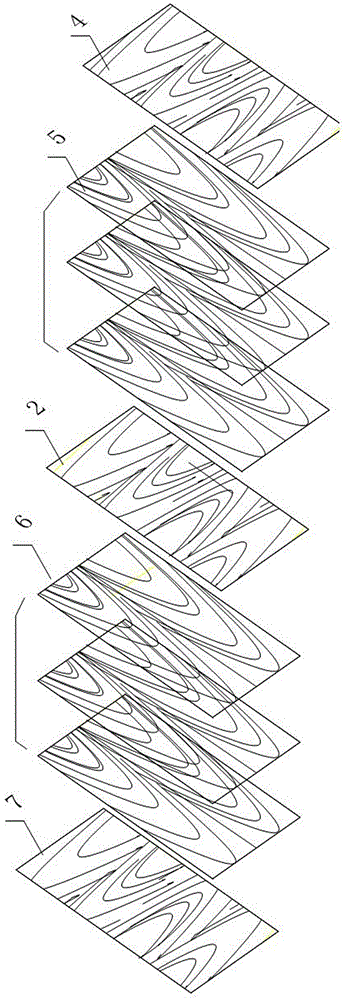

Phase-change insulating flexible facing material and preparation method thereof

The invention discloses a phase-change insulating flexible facing material and a preparation method thereof. A specific embodiment is as follows: the phase-change insulating flexible facing material is prepared by the preparation method comprising the following steps: coating mud powder, phase change microcapsules, an adhesive and a cross-linking agent which serve as main raw materials on a template, and baking and molding under gradient temperature, wherein the raw materials include the following components in parts by mass: 30-50% of mud powder, 5-10% of phase change microcapsules, 15-30% of adhesive, 3-6% of organic bentonite, 0.5-1% of emulsifier, 1-5% of auxiliaries, 1-5% of cross-linking agent and 10-20% of water. Compared to an existing flexible facing material, the phase-change insulating flexible facing material disclosed by the invention has the following advantages that on the premise of preventing advantages of an existing flexible high polymer facing material from losing, functions of insulating and decorating are integrated, a construction process is simplified, an application scope of the material is widened and a broad market prospect is guaranteed; the facing material disclosed by the invention does not require high temperature sintering and is beneficial for energy conservation and emission reduction; in addition, the material, in production and use, is free from release of toxic gas, and is harmless to environment and human health.

Owner:HAIAN INST OF HIGH TECH RES NANJING UNIV

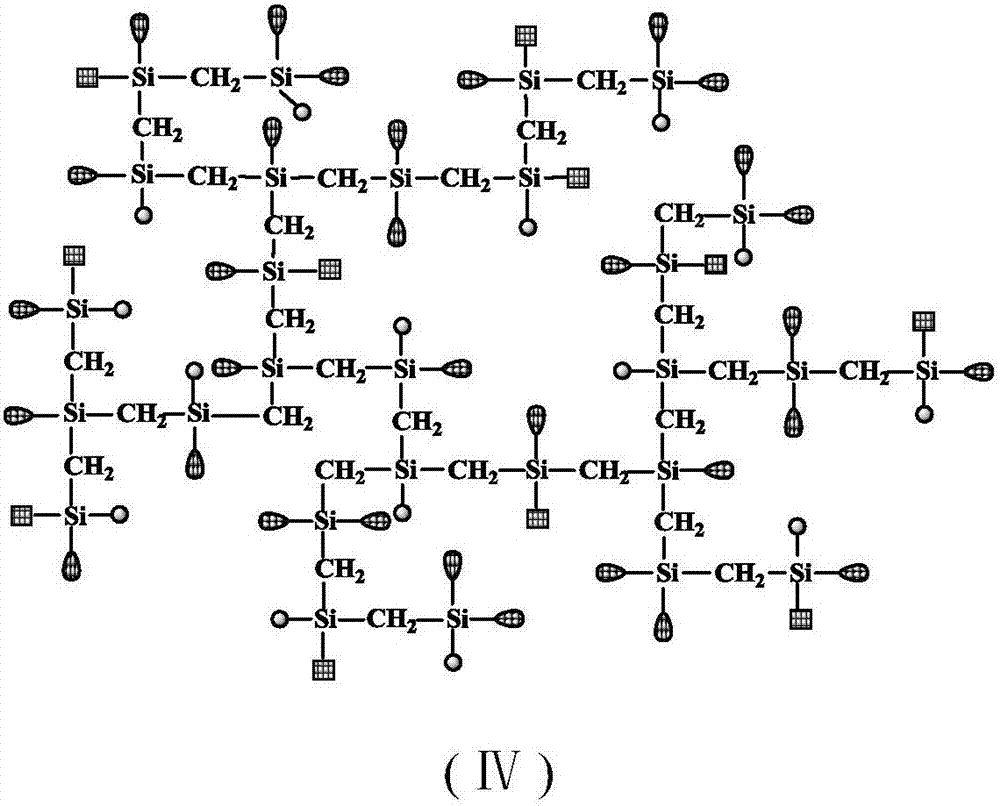

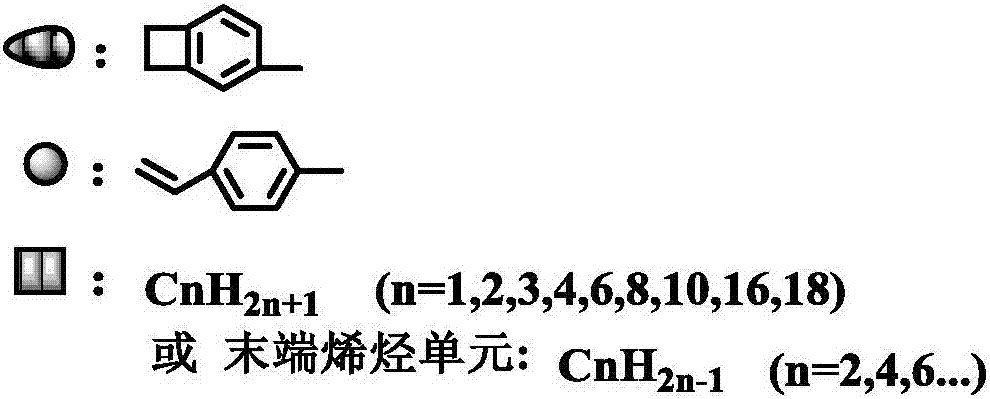

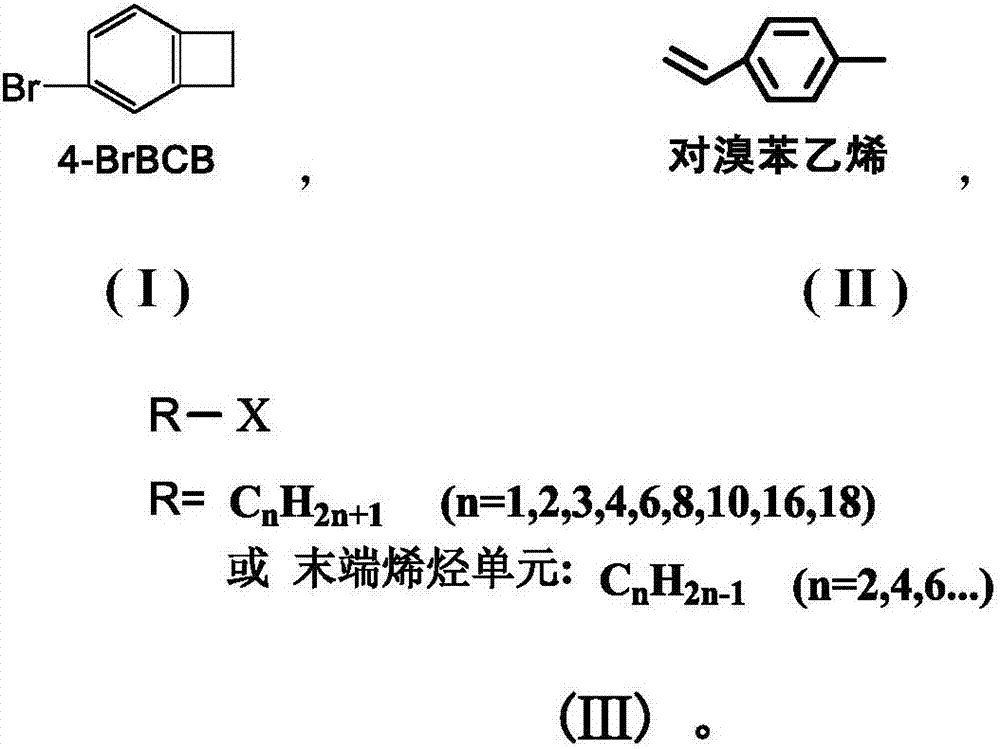

Light/heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin and preparation method thereof

The invention discloses light / heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin as shown in a formula (IV) and a preparation method thereof. The preparation method of the hyperbranched polycarbosilane benzocyclobutene resin comprises the following steps: generating a Grignard reagent from chloromethyltrichlorosilane under the action of magnesium; then performing a coupling reaction with Si-Cl to further form a hyperbranched Si-Cl bond-containing hyperbranched polycarbosilane polymer; adding 4-bromobenzocyclobutene to react; adding p-bromostyrene to react; then adding alkyl (alkenyl) halide to react; performing cooling; adding distilled water (deionized water) into the system for a quenching reaction; and performing solvent extraction, concentration, and purification steps such as distillation or column chromatography on silica gel to obtain the light / heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin. The light / heat double crosslinked hyperbranched polycarbosilane benzocyclobutene resin prepared by the method is excellent in thermal, electrical and photosensitive properties and is suitable for being used as a high performance dielectric film material or a packaging material in the field of microelectronics industry, space flight and aviation and national defense and the like. The formula (IV) is as shown in the specification.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Cement-based polystyrene material and insulation board production process based thereon

InactiveCN104119046AMeet fire resistance requirementsImprove fire resistancePolymer scienceThermal insulation

The invention discloses a cement-based polystyrene material, which comprises the following components: (1) according to a dry powder ratio (by mass percentage): 65-85 of portland cement; 10-25 of fly ash; 0.15-0.25 of polypropylene fiber; 0.2-0.4 of a concrete admixture; and 0.15-0.25 of an emulsion; and (2) the volume ratio of the dry powder to expanded polystyrene particles being 1:4-1:6. The production process for preparation of a composite insulation board based on the cement-based polystyrene material includes the steps of proportioning, stirring, molding transportation, curing and molding packaging, and a final product can be obtained thereby. The composite insulation board obtained on the basis of the formula and the preparation process has the advantages of high fire resistance, high thermal insulation, high strength, light weight, high bonding strength, and no toxicity or harm, etc.

Owner:江苏省苏安能节能建材科技有限公司

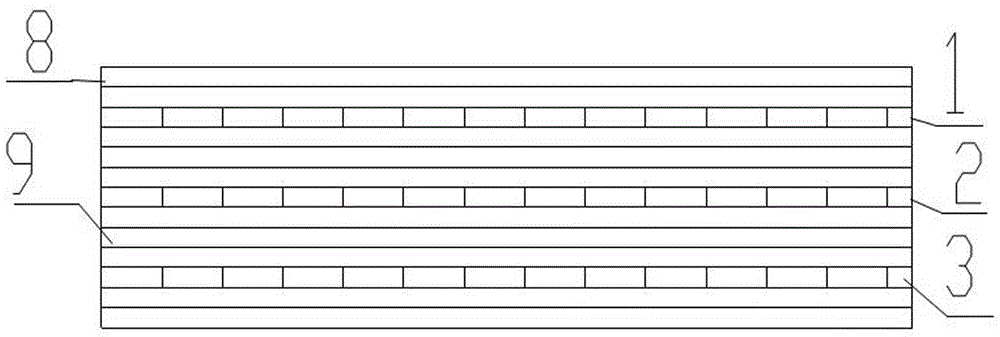

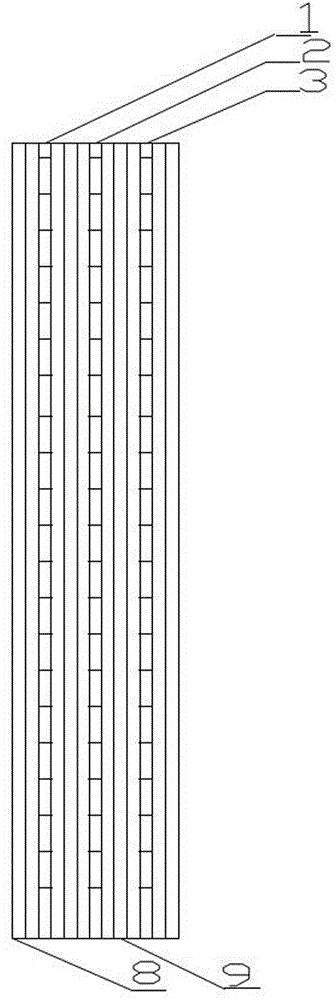

Flexible veneer overlaid cement particle board

The invention discloses a flexible veneer overlaid cement particle board. The flexible veneer overlaid cement particle board comprises a base board, an upper flexible veneer layer which is steeped with melamine; one side of the base board, a balanced layer and the upper flexible veneer layer which is steeped with melamine are fixedly pressed to be adhered to form into a whole; flexible veneers are performed solidification and steeping through the melamine adhesive which is used for low temperature solidification and steeping to form into the soft veneer layer which is steeped with the melamine under the low temperature condition; the soft veneer layer which is steeped with the melamine is pasted on the surface of the base board through the balanced layer; harmful substances such as VOC (Volatile Organic Compounds) are not released after solidification. The flexible veneer overlaid cement particle board can be used as roofs, ceilings, floors, non-bearing internal and external walls, roofing sheathings, sound insulation boards, fire protection boards, building templates and the like and can overcome the disadvantages of secondary pollution and stable size caused by the painting processing during the utilization process of the existing block boards, density boards and other artificial boards. The melamine soft veneer which is fixed on the flexible veneer overlaid cement particle board can well glued with artificial boards through the balanced payer under the lower temperature condition.

Owner:BEIHUA UNIV

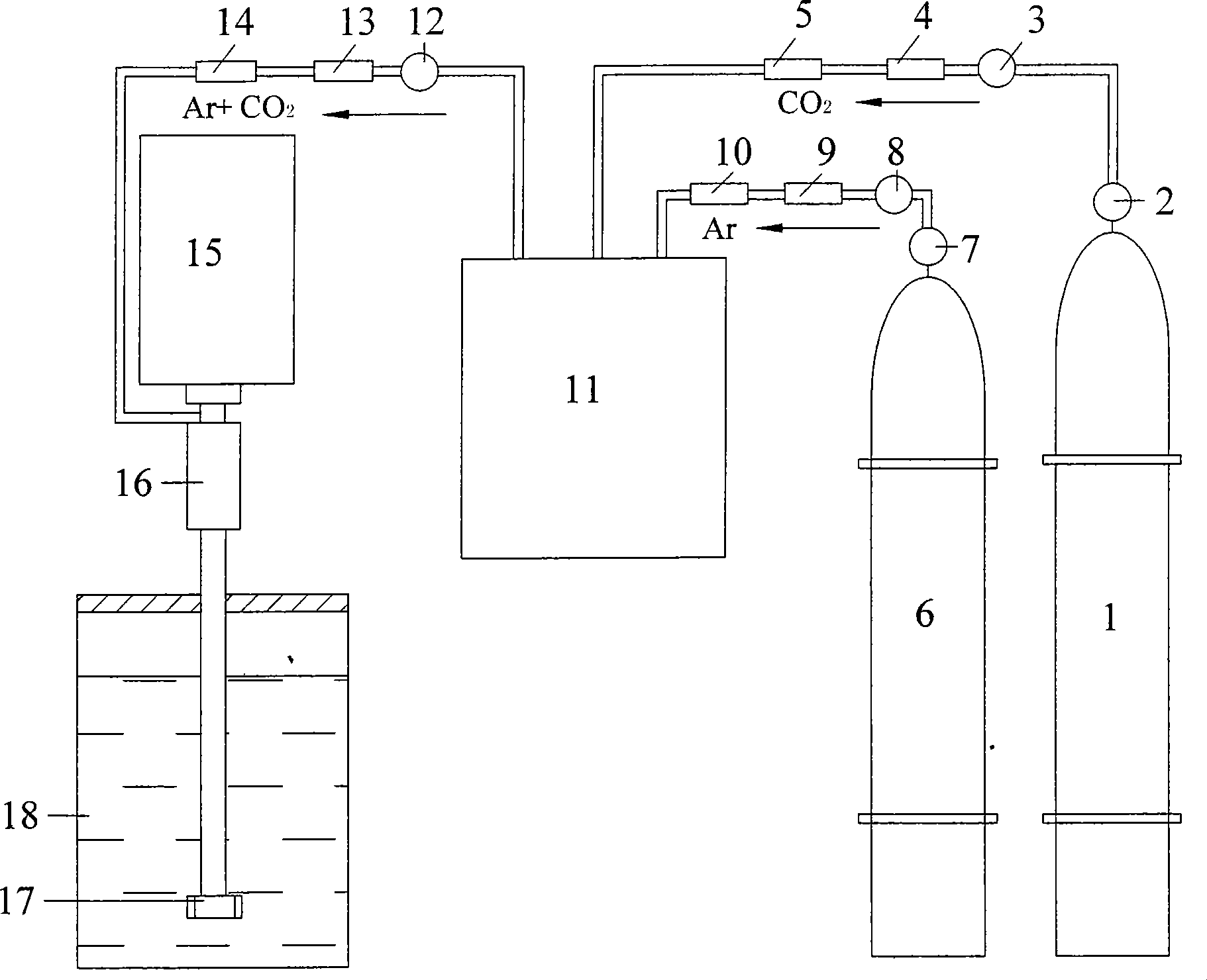

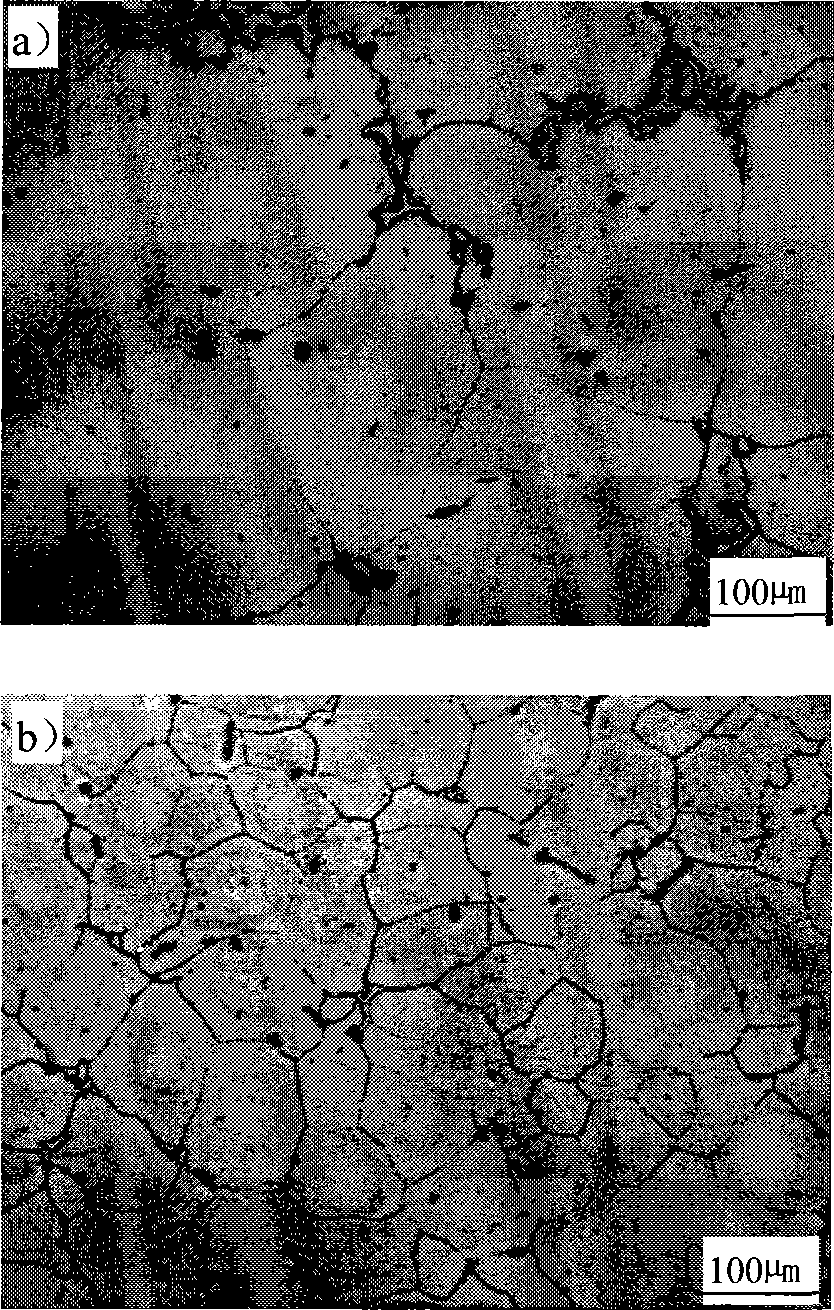

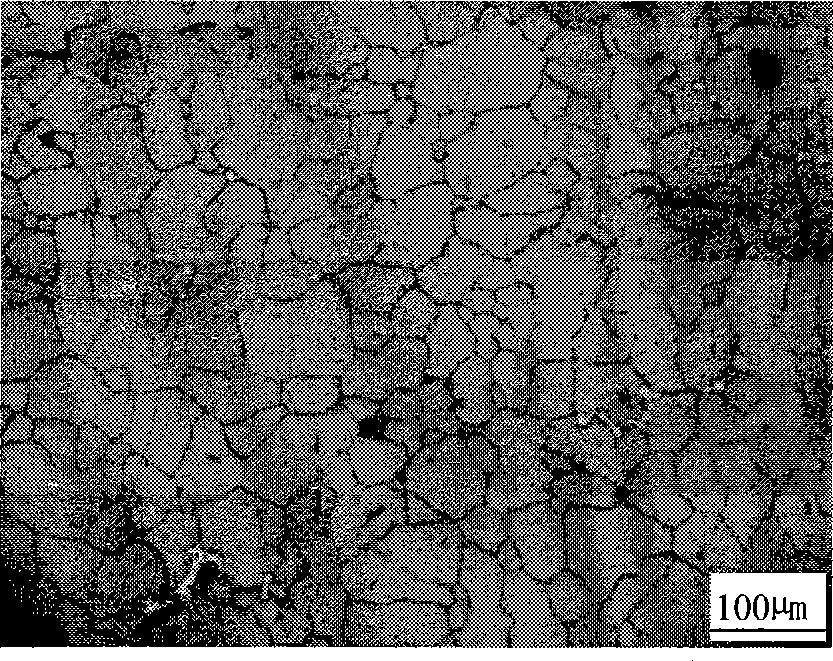

Thinning processing method for magnesium alloy fused mass and apparatus

The invention relates to a thinning treatment technology which can be used for a magnesium alloy melt containing aluminum, and a special device thereof. The thinning treatment technology is that mixed gas of protective gas and carbon dioxide gas is blown into a magnesium-aluminum alloy melt by adopting a rotary blowing manner at 700 DEG C to 790 DEG C, the process is stopped after being carried out for 15min to 60min, and pouring is carried out after stillness for 10 min to 30 min, thus realizing the aim of thinning. The pressure of the mixed gas is 0.15MPa to 0.5MPa, the volume percentage of the carbon dioxide gas in the mixed gas is 20 percent to 40 percent, the flow of the mixed gas is 0.5ml / min to 10ml / min, and the rotary blowing speed is 100 to 500 revolutions per minute. The special device used for the technology is realized by that a gas bottle is connected to a nozzle by a gas mixer, and the pressure and the flow of the mixed gas introduced to the melt are adjusted by adjusting the reducing valve and the flow meter of the mixer. The invention can improve the purity of the magnesium alloy melt while thinning the magnesium alloy crystal grains, enhance the performance quality of casting products greatly, improve production conditions and increase labor production efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Glucose-phenol resin adhesive for foundry and a preparation method of same

The invention discloses a glucose-phenol resin adhesive for foundry and a preparation method of the glucose-phenol resin adhesive. Glucose and phenol are co-condensed under the action of catalyst and then compounded after organic bentonite is added, so that the glucose-phenol resin adhesive for foundry is prepared; and the mass fraction of the organic bentonite in the adhesive is 1% to 10%. Compared with the prior art, the invention solves the problems of high cost, heavy pollution, poor recyclability and poor performance of the conventional adhesive for foundry and have the advantages of simple preparation technology, high strength of prepared adhesive, good technological performance, high adhesion strength, excellent storage stability and the like.

Owner:FUZHOU UNIV

Method for manufacturing environmental-protection anti-deformation board at low carbon

InactiveCN104552496AResolves variable crackingSolve environmental problemsWood veneer joiningBattenMechanical engineering

The invention discloses a method for manufacturing an environmental-protection anti-deformation board at low carbon; timber resources are not inexhaustible resources, so the timber resources have the problems of high demand and high cost. The method comprises the following steps: S1, performing rotary cutting on logs into veneers by a rotary cutter; grading the veneers; drying the veneers until moisture content is lower than 12 percent; coating surface layers and a middle layer with glue, pressing to manufacture a composite board, and cutting into battens which are equal in specification; selecting three layers of cross grain arranged battens; putting one of the three layers of cross grain arranged battens in the middle, and putting the remaining two layers of cross grain arranged battens on the surface layers or inner layers of the surface layers; pressing the three layers of cross grain arranged battens into an anti-deformation board by a hot press; standing for more than 15 days for curing; cutting into broad battens according to fixed length, coating with the glue, and manufacturing an anti-deformation board by an automatic board jointing machine; cutting off the redundant four sides, and sanding with a sanding belt. According to the manufacturing method disclosed by the invention, valuable timber resources are replaced by fully utilizing common timber resources, and therefore the resources are saved; waste is turned into treasure, forest resources are protected strongly, and the cost is reduced.

Owner:HEILONGJIANG HUAXIN FURNITURE

Odor removal formaldehyde-resistant liquid granite-imitated coating and preparation method thereof

PendingCN110437693AEfficient and durable anti-formaldehyde to remove VOCRich pore structureAntifouling/underwater paintsPaints with biocidesEmulsionDefoaming Agents

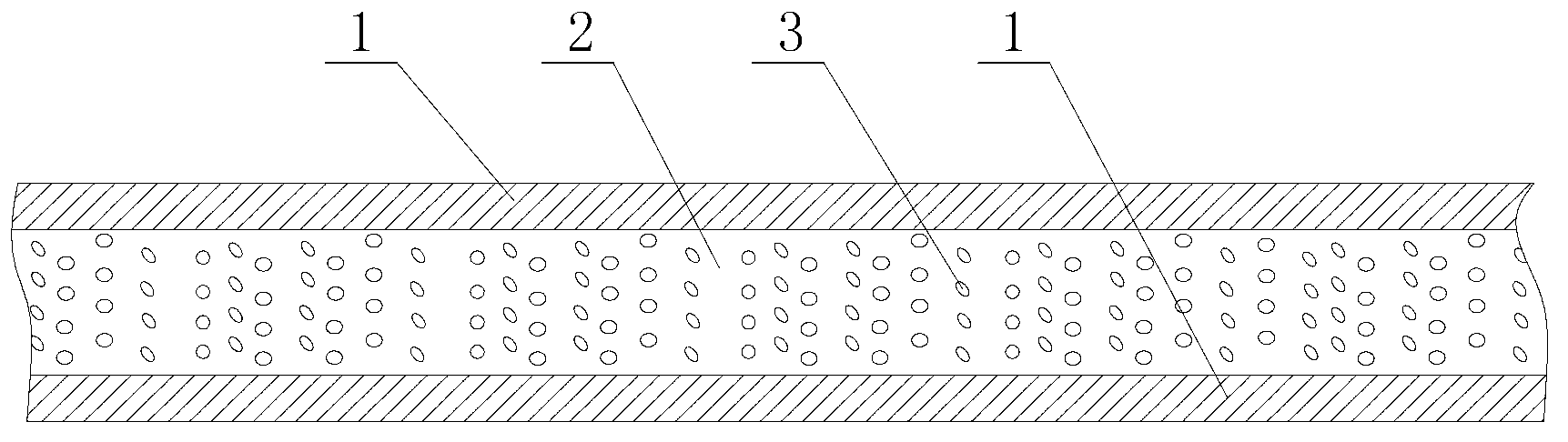

The invention discloses an odor removal formaldehyde-resistant liquid granite-imitated coating and a preparation method thereof. The coating is prepared from a protective adhesive, color matching basepaint and a continuous phase, wherein the protective adhesive is prepared from deionized water, a dispersant, a viscosity reducer, a mildew preventive, a sterilizing agent, protective rubber powder and a pH modifier, the color matching base paint is prepared from deionized water, a mildew preventive, a dispersant, cellulose, a filler, formaldehyde-resistant powder, a defoaming agent, a pH modifier, an odor removal emulsion, a coalescing agent, an antifreezing agent, a sterilizing agent, a thickener and a protective adhesive, and the continuous phase is prepared from deionized water, organbentonite, water-soluble anion powder, an odor removal emulsion, a coalescing agent, an antifreezing agent, a pH modifier and a thickener. According to the odor removal formaldehyde-resistant liquid granite-imitated coating, the environment-friendly odor removal emulsions are used as base materials, the water-soluble anion powder and the formaldehyde-resistant powder are added, the environment-friendly odor removal emulsions, the water-soluble anion powder and the formaldehyde-resistant powder are subjected to the synergistic action, thus formaldehyde is effectively decomposed, and a product has the outstanding formaldehyde purification efficiency and lasting efficiency.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

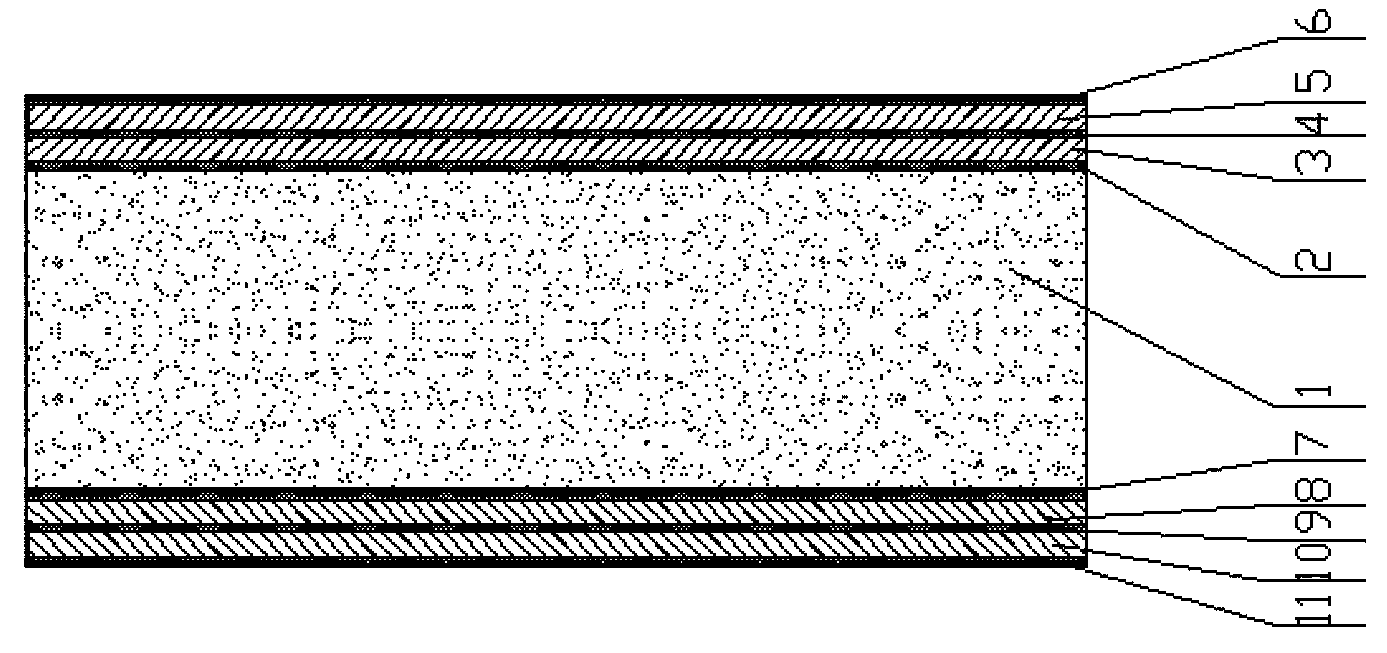

Cement-based fiber-reinforced fireproof heat-preservation plate and preparation process thereof

InactiveCN102839758AImprove fire resistanceMeet fire resistance requirementsHeat proofingCeramicwareFire resistanceStrong binding

The invention discloses a cement-based fiber-reinforced fireproof heat-preservation plate. The cement-based fiber-reinforced fireproof heat-preservation plate is characterized by comprising a core layer, wherein the upper surface and the lower surface of the core layer are respectively provided with surface layers; the core layer is a cement gelatinizing layer; and furthermore, the cement gelatinizing layer contains non-uniformly distributed expanded granules. The invention also provides a preparation process of cement-based fiber-reinforced fireproof heat-preservation plate, comprising the following steps of: measuring raw materials; stirring materials; carrying out extrusion forming; and adhering a gridding cloth. The invention completely meets the requirement for fire resistance of an outer wall heat-preservation plate, has low heat transfer, can meet the requirements for heat preservation and heat insulation of buildings and has high anti-crush anti-breaking strength; the raw materials can not be combusted at high temperature without releasing poisonous gases, belong to safe environmental-friendly materials and are all from the nature without corrosivity or radioactivity; and the cement-based fiber-reinforced fireproof heat-preservation plate disclosed by the invention has the advantages of light weight, easy carrying, good cutting, easy construction, good compatibility and strong binding power of a wall body.

Owner:张家港市盛港绿色防火建材有限公司

Low-smoke halogen-free flame-retardant glass fiber-enhanced polyolefin cable material

InactiveCN108314835ASelf-extinguishingImprove flame retardant performancePlastic/resin/waxes insulatorsEpoxyAlkane

The invention relates to a low-smoke halogen-free flame-retardant glass fiber-enhanced polyolefin cable material. The low-smoke halogen-free flame-retardant glass fiber-enhanced polyolefin cable material is prepared from the following raw materials in parts by weight: 100 parts of polyolefin substrate, 10 to 30 parts of maleic anhydride-modified polyolefin, 40 to 100 parts of filler, 5 to 10 partsof glass fiber, 5 to 10 parts of phosphor-containing flame-retardant agent, 5 to 10 parts of nitrogen-containing flame-retardant agent, 0.1 to 5 parts of epoxy-based silane coupling agent, 2 to 5 parts of direct-chain alkane containing monoamine, and 0.5 to 2 parts of processing additive. The prepared low-smoke halogen-free flame-retardant glass fiber-enhanced polyolefin cable material has good flame-retardant effect, good physical and mechanical properties, and a great application prospect.

Owner:李嘉顺

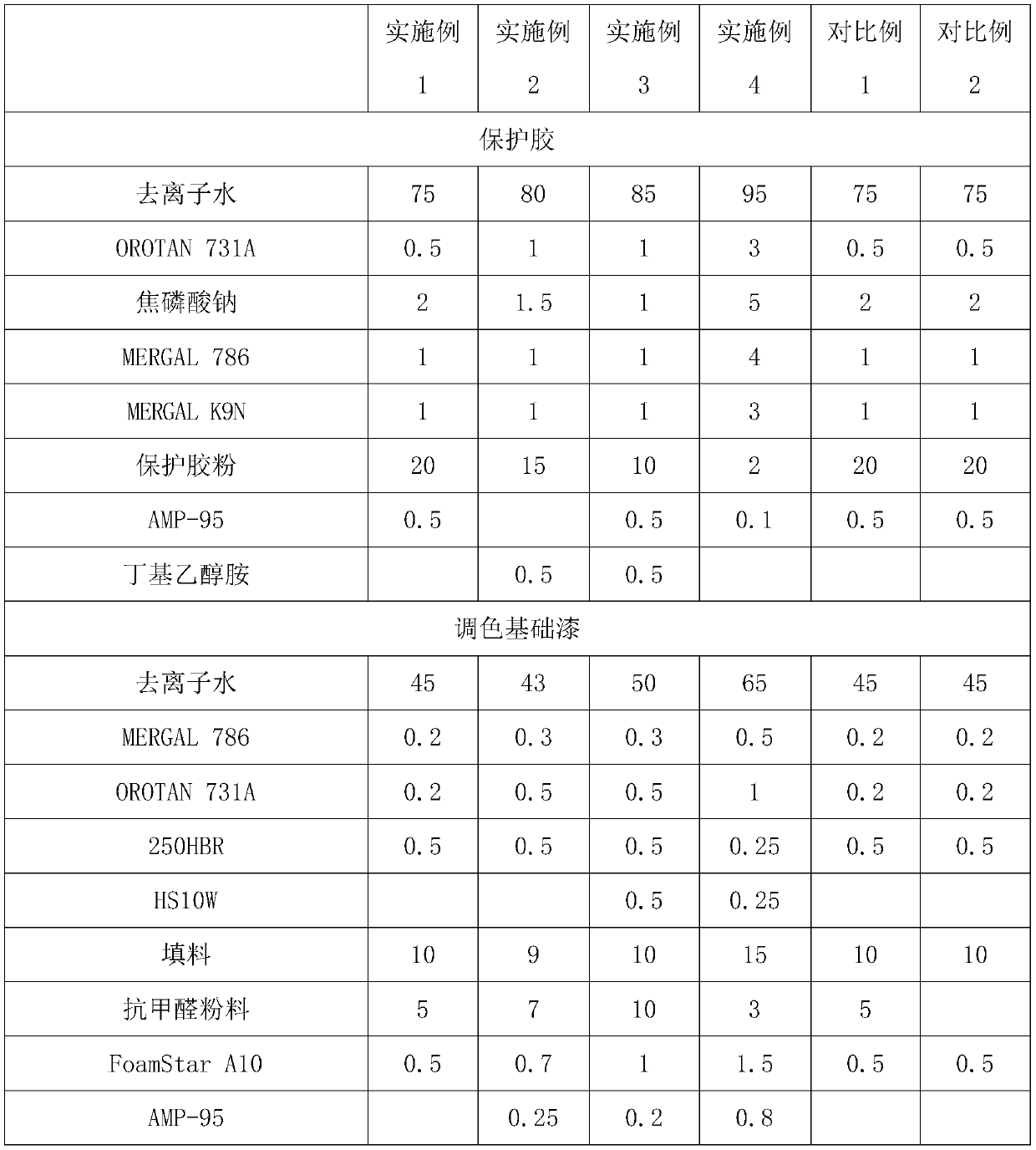

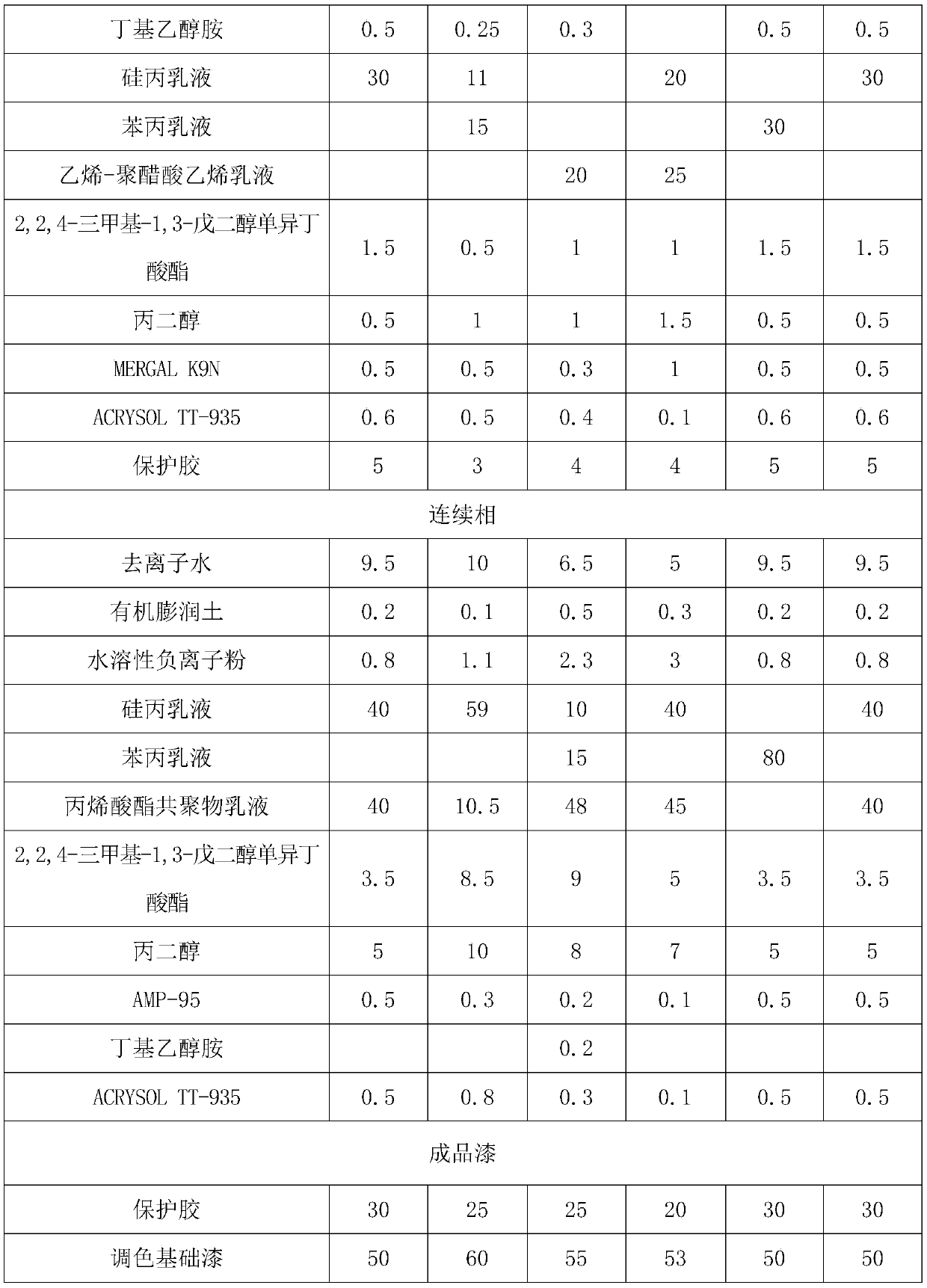

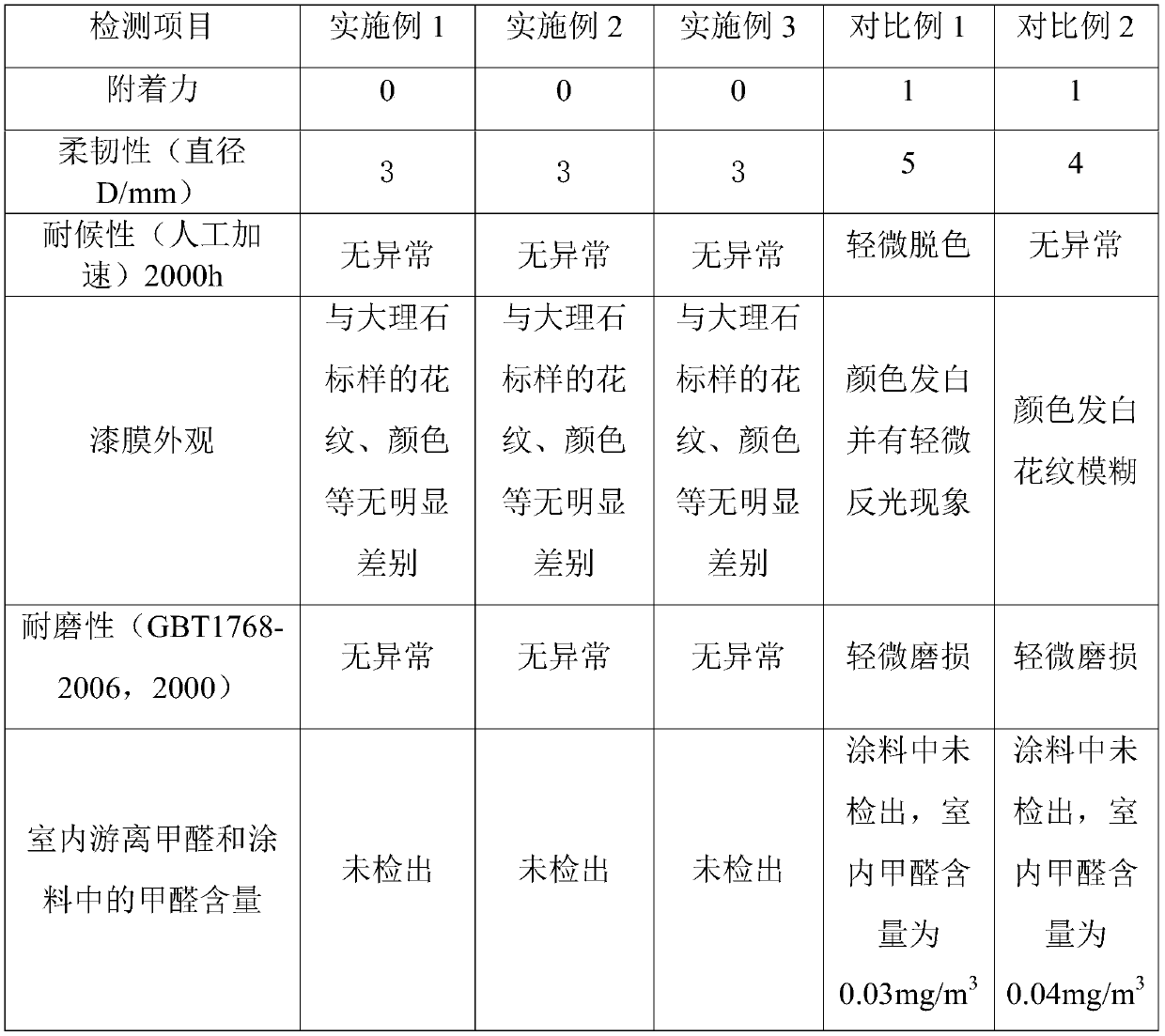

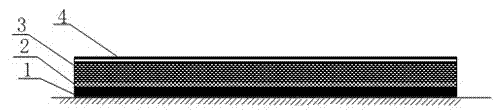

Sand-in-water coating and preparation method thereof

The invention relates to the technical field of coatings, and particularly discloses a sand-in-water coating and a preparation method thereof. The sand-in-water coating comprises, by weight, 20-30 parts of a protective glue, 50-60 parts of a toning base paint and 15-25 parts of a continuous phase. The sand-in-water coating has the advantages of strong adhesive force, high toughness, good wear resistance and good weather resistance, and a film formed by the coating can achieve the natural effect and beauty of marble textures.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Fireproof silicon rubber wallpaper

PendingCN107288282AImprove smoothnessStain resistantCovering/liningsCoatingsPolymer scienceSilicon rubber

The invention belongs to the technical field of decorative materials, and particularly relates to fireproof silicon rubber wallpaper. The fireproof silicon rubber wallpaper comprises a base layer and a silicon rubber layer, wherein the base layer is attached to a wall face, and the silicon rubber layer is attached to the outer part of the base layer. The base layer is fireproof cloth with the thickness of 0.1 mm-0.5 mm, and the thickness of the silicon rubber layer is 0.2 mm-2.0 mm; a bridging agent layer with the thickness of 0.01 mm-0.1 mm is evenly sprayed between the base layer and the silicon rubber layer, and the top face of the base layer and the bottom face of the silicon rubber layer are fully bonded by the bridging agent layer; and an ink layer is sprayed on the top face of the silicon rubber layer, and ink used in the ink layer is oil with the silicone hand feeling or silicone PU ink. The fireproof silicon rubber wallpaper has flame resistant and high-temperature resistant performance, corrosion resistance, damp prevention and stain resistance and is easy to scrub; and the fireproof cloth of the base layer and the main silicon rubber layer are made of environmental-friendly materials, gas harmful to human health is not generated, and the fireproof silicon rubber wallpaper is well suitable for indoor decoration using.

Owner:东莞市火矽硅橡胶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com