Thinning processing method for magnesium alloy fused mass and apparatus

A treatment method and a treatment device technology, which are applied in the field of magnesium alloy refinement treatment, can solve the problems of increased alloy smelting costs, refractory melting or decomposition, etc., and achieve the effects of improving the working environment, increasing production efficiency, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

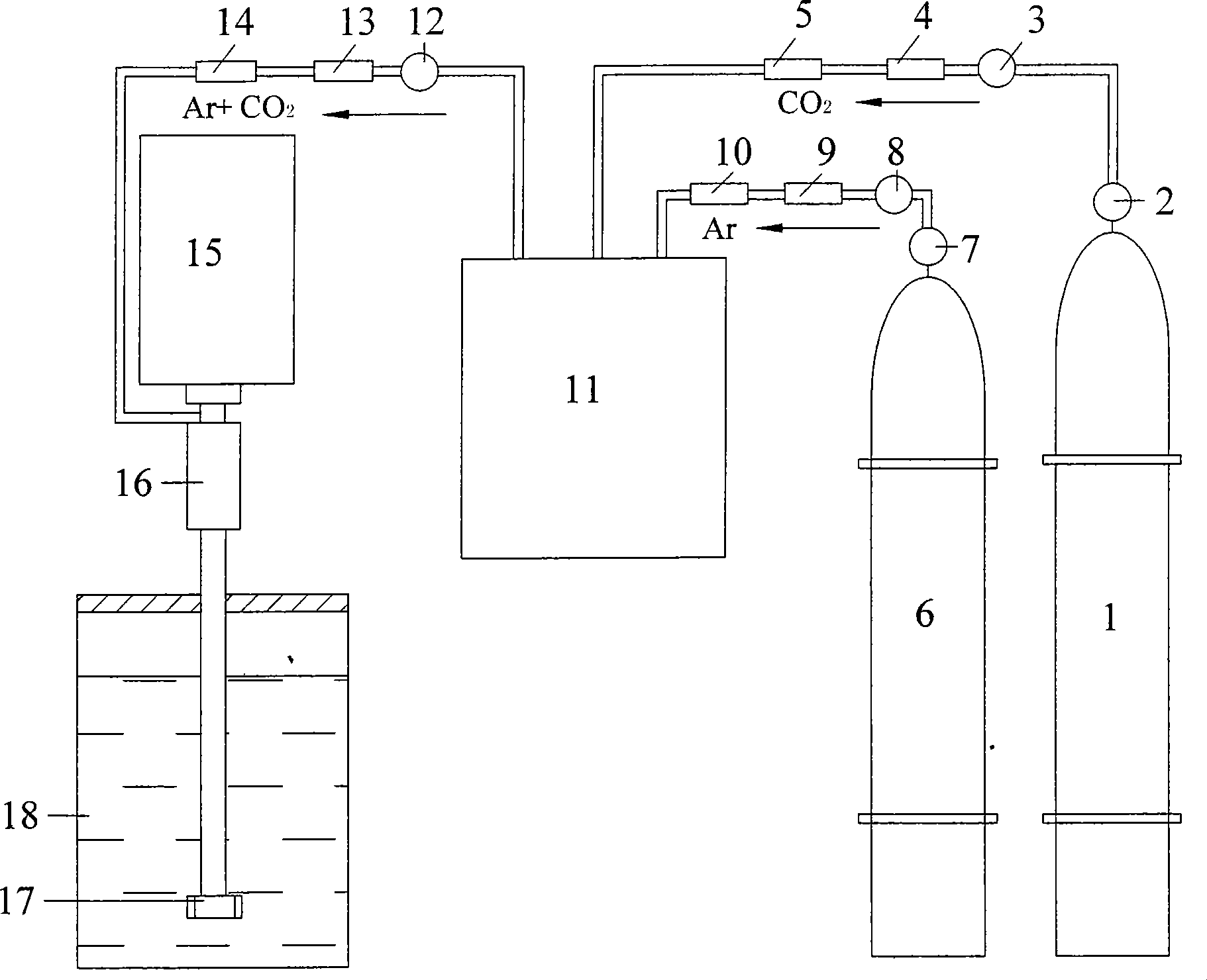

Method used

Image

Examples

Embodiment 1

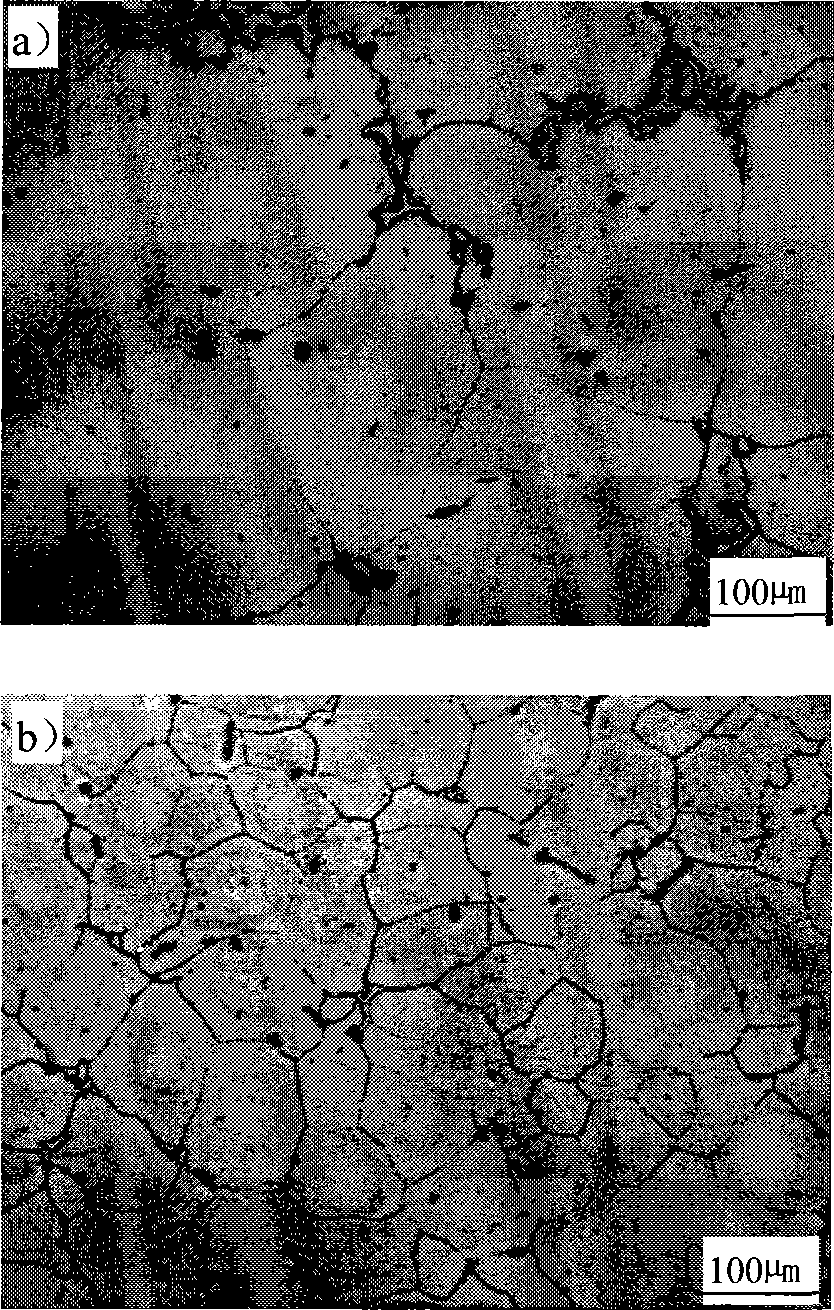

[0032] When the melt temperature is 700°C, Ar and CO 2 Mixed gas, wherein the pressure of the mixed gas is 0.3MPa, the total flow of the mixed gas is 0.5L / min, CO 2 The volume fraction is 30%, the rotational speed of the rotary nozzle is 100 rpm, the treatment time is 60 minutes, and the rest is 30 minutes. figure 2 The metallographic structures of untreated and treated AZ91 alloys are respectively. Among them (a) is the unrefined macroscopic structure (b) the refined structure. The grain size before refinement was 234 μm, and the grain size after refinement was 72 μm.

Embodiment 2

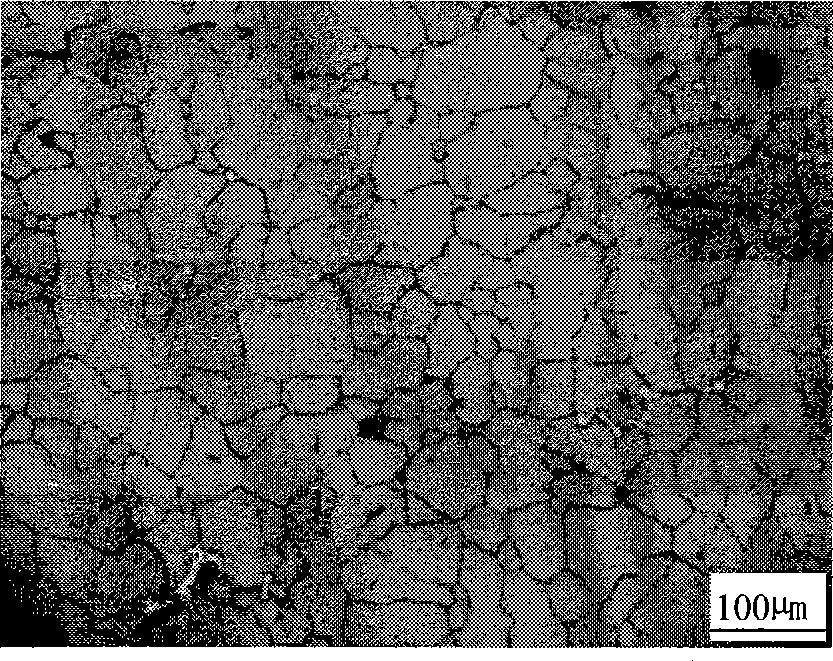

[0034] When the melt temperature is 730°C, Ar and CO 2 Mixed gas, wherein the pressure of the mixed gas is 0.2MPa, the total gas flow is 1L / min, where CO 2 The volume fraction is 20%, the rotating speed of the rotary nozzle is 280 rpm, the treatment time is 45 minutes, and the rest is 20 minutes. Finely process 45 min for macroscopic tissues such as image 3 As shown, the grain size is: 54 μm.

Embodiment 3

[0036] When the melt temperature is 770°C, Ar and CO 2 Mixed gas, the pressure of the mixed gas is 0.4MPa. The total flow rate of mixed gas is 6L / min, CO 2 The volume fraction is 40%, the rotational speed of the rotary nozzle is 400 rpm, the treatment time is 30 minutes, and the rest is 10 minutes. Finely process macroscopic tissues such as Figure 4 As shown, the grain size is about 70 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com