Pulling on press type composite shape bar of aluminum and wood, and fabricating method

A composite profile and processing technology, applied in the processing technology of aluminum-wood composite profiles and the field of aluminum-wood composite profiles, can solve problems such as the degree of connection firmness, affecting the deep development and application of aluminum-wood composite profiles, and the inability to form a standard bonding structure. , to achieve good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

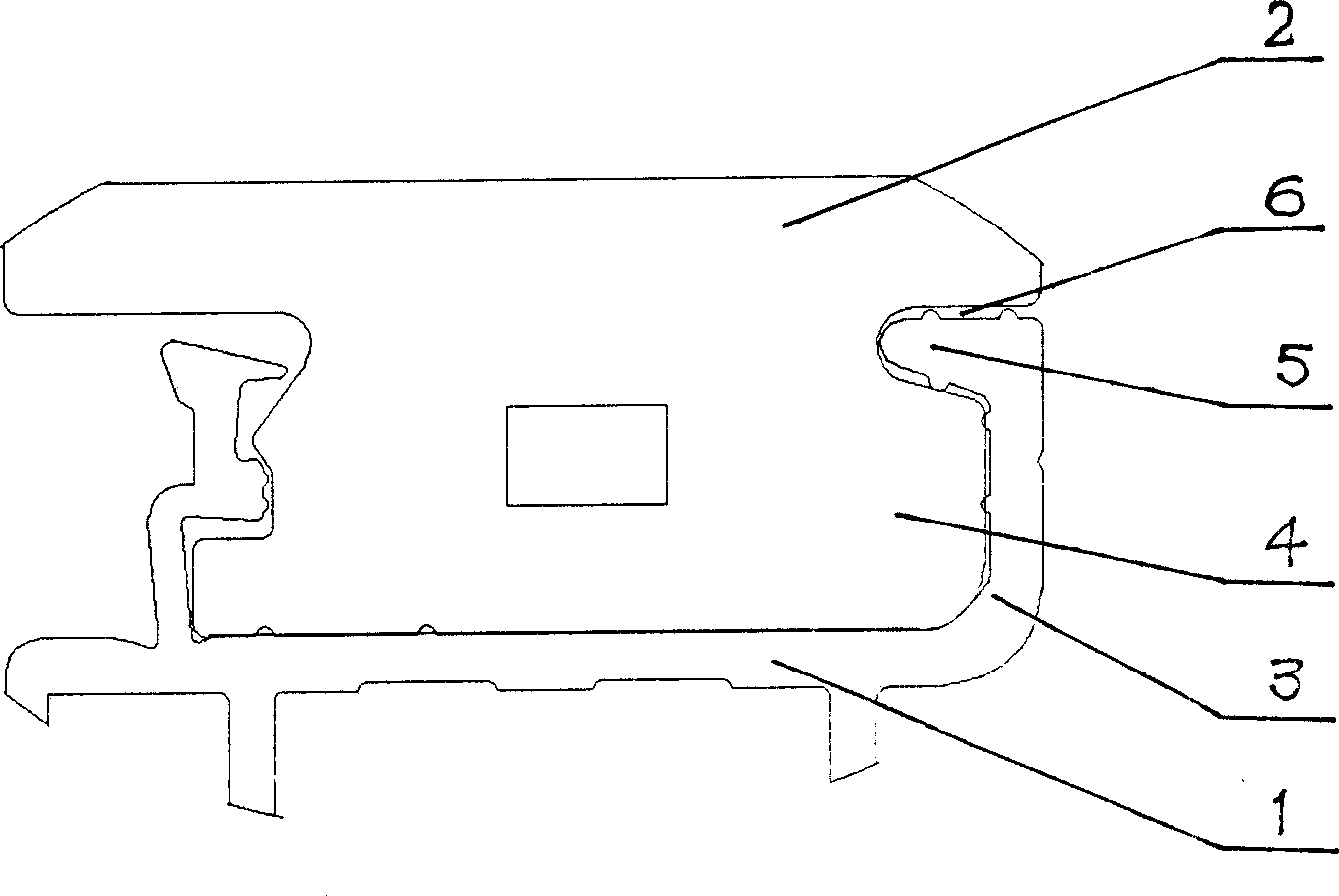

[0023] Such as Figure 5 As shown, the piercing type aluminum-wood composite profile of the embodiment of the present invention is formed by connecting an aluminum profile 1 and a wooden profile 2, the connecting end of the aluminum profile 1 is provided with an interface 3, and the connecting end of the wooden profile 2 is provided with a joint 4, The shape of the interface 3 and the joint 4 are matched, and the connection between the aluminum profile 1 and the wood profile 2 is formed by the joint 4 of the wood profile being fitted in the interface 3 of the aluminum profile and pressed.

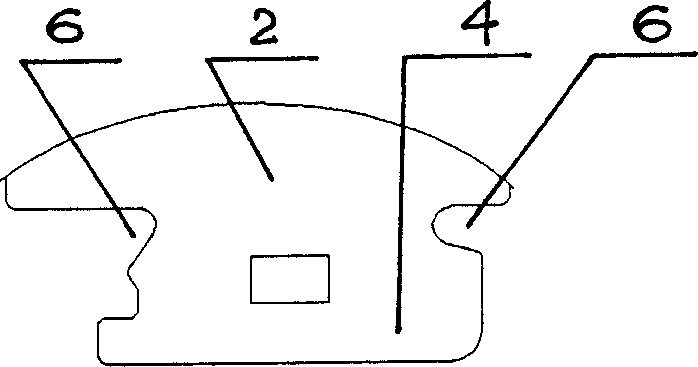

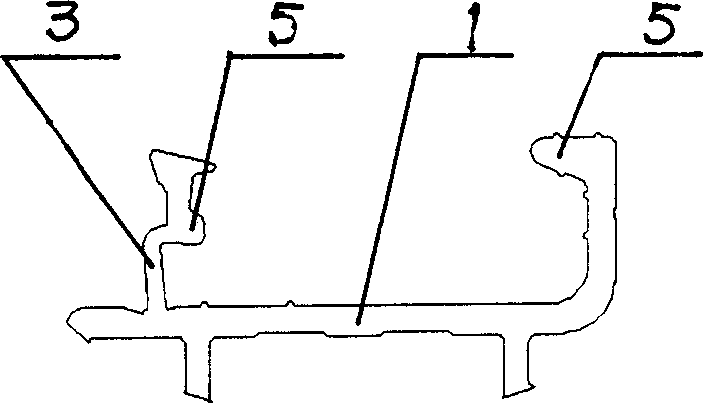

[0024] As an embodiment of the present invention, the two inner sides of the interface 3 of the aluminum profile are provided with protrusions 5, such as figure 2 As shown; the two outer sides of the joint 4 of the wood profile are provided with grooves 6 corresponding to the protrusions 5, as figure 1 Shown; the protrusion 5 snaps into the groove 6, as image 3 shown. The shapes of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com