Method of preparing silver nanowire by utilization of hydrothermal method

A technology of silver nanowires and hydrothermal method, which is applied in the direction of nanotechnology, can solve the problems of unsuitable for large-scale production of reaction liquid, small amount of reactants, low efficiency, etc., achieves huge application potential, low sensitivity of process parameters, Good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

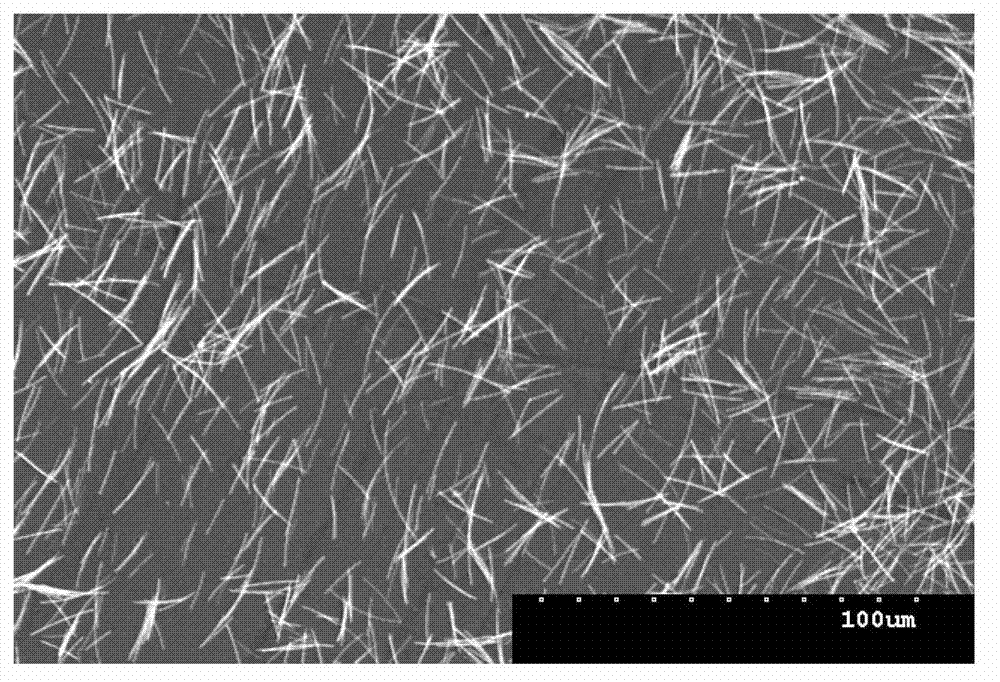

Embodiment 1

[0021] 1) Add 34g of silver nitrate to 20L of ethylene glycol, stir and dissolve at room temperature to obtain a solution of silver nitrate in ethylene glycol with a concentration of 0.01M;

[0022] 2) Add 66.6g of PVP and 22mg of sodium chloride into 4L of ethylene glycol, stir and dissolve at room temperature to obtain an ethylene glycol PVP solution with a PVP concentration of 0.15M and a sodium chloride concentration of 0.09mM;

[0023] 3) Pour the ethylene glycol PVP solution into the ethylene glycol silver nitrate solution, stir until evenly mixed, and obtain the reaction mother liquor.

[0024] 4) Put the reaction mother liquor into a self-heating reactor with a capacity of 30L, raise the temperature to 160°C, and react for 3 hours;

[0025] 5) After the reaction is completed, centrifuge the reaction solution at 2000rpm, remove the supernatant, add acetone to wash, then centrifuge at 2000rpm, then add ethanol to wash, and centrifuge at 4000rpm after washing to obtain ab...

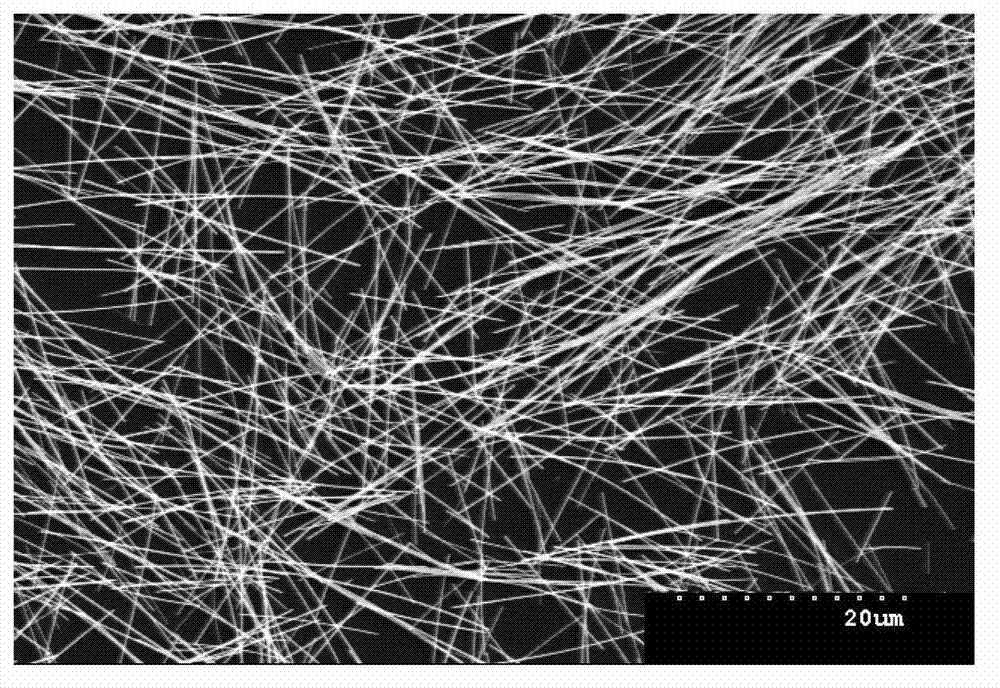

Embodiment 2

[0029] 1) Add 1.7Kg of silver nitrate to 100L of ethylene glycol, stir and dissolve at room temperature to obtain a solution of silver nitrate in ethylene glycol with a concentration of 0.1M.

[0030] 2) Add 5Kg of PVP and 0.745g of potassium chloride into 100L of ethylene glycol, stir and dissolve at room temperature to obtain an ethylene glycol PVP solution with a PVP concentration of 0.45M and a potassium chloride concentration of 0.1mM.

[0031] 3) Pour the ethylene glycol PVP solution into the ethylene glycol silver nitrate solution, stir until evenly mixed, and obtain the reaction mother liquor.

[0032] 4) In a hydrothermal reactor with a capacity of 200L, heat the mixed reaction mother liquor to 180°C for 2.5h.

[0033] 5) After the reaction was completed, the reaction solution was centrifuged at 2000 rpm, the supernatant was removed, washed with acetone, and centrifuged at 2000 rpm; finally, ethanol was added to wash and centrifuged at 4000 rpm to obtain about 1000 g ...

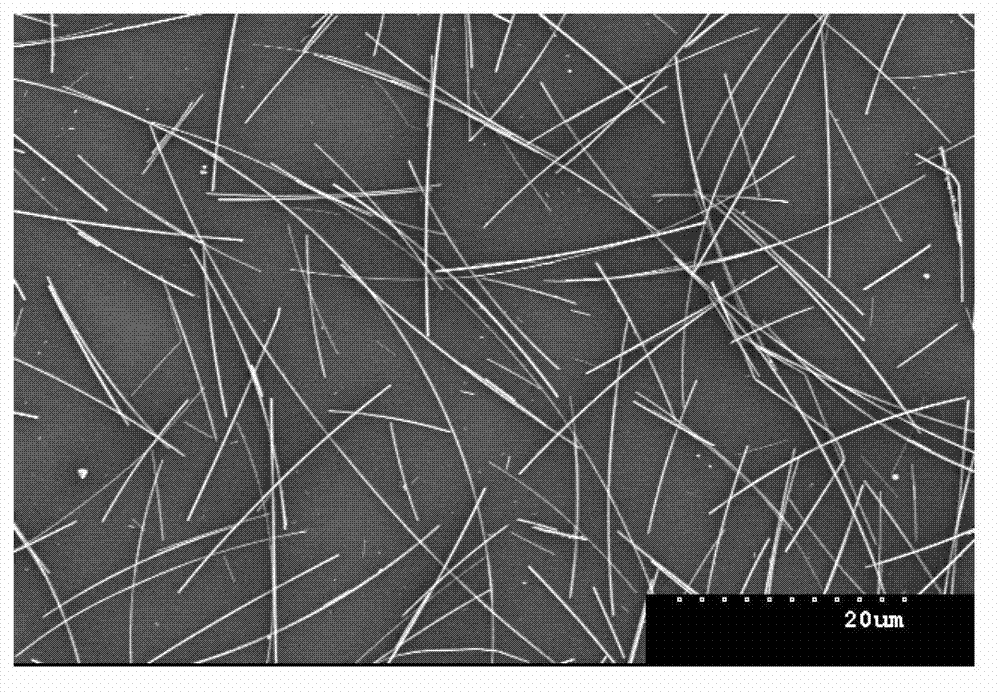

Embodiment 3

[0037] 1) Add 6.8Kg of silver nitrate to 200L of ethylene glycol, stir and dissolve at room temperature to obtain a solution of silver nitrate in ethylene glycol with a concentration of 0.2M.

[0038] 2) Add 6.66Kg of PVP and 2.69g of copper chloride to 200L of ethylene glycol, stir and dissolve at room temperature to obtain an ethylene glycol PVP solution with a PVP concentration of 0.3M and a copper chloride concentration of 0.1mM.

[0039] 3) Pour the ethylene glycol PVP solution into the ethylene glycol silver nitrate solution, stir until evenly mixed, and obtain the reaction mother liquor.

[0040] 4) In a hydrothermal reactor with a capacity of 500L, heat the mixed reaction mother liquor to 170°C for 5h.

[0041] 5) After the reaction is completed, the reaction solution is centrifuged at 2000 rpm, the supernatant is removed, washed with acetone, and centrifuged at 2000 rpm. Finally, ethanol was added for washing and centrifuged at 4000 rpm to obtain about 4000 g of silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com