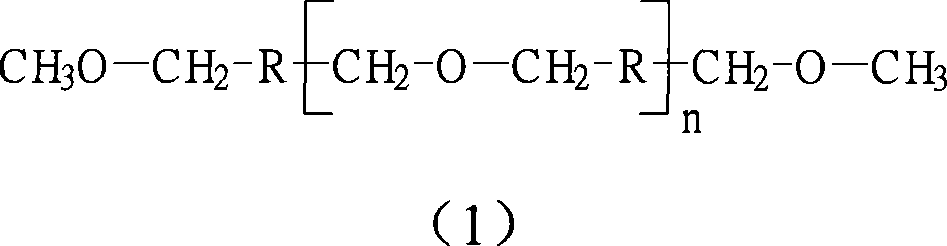

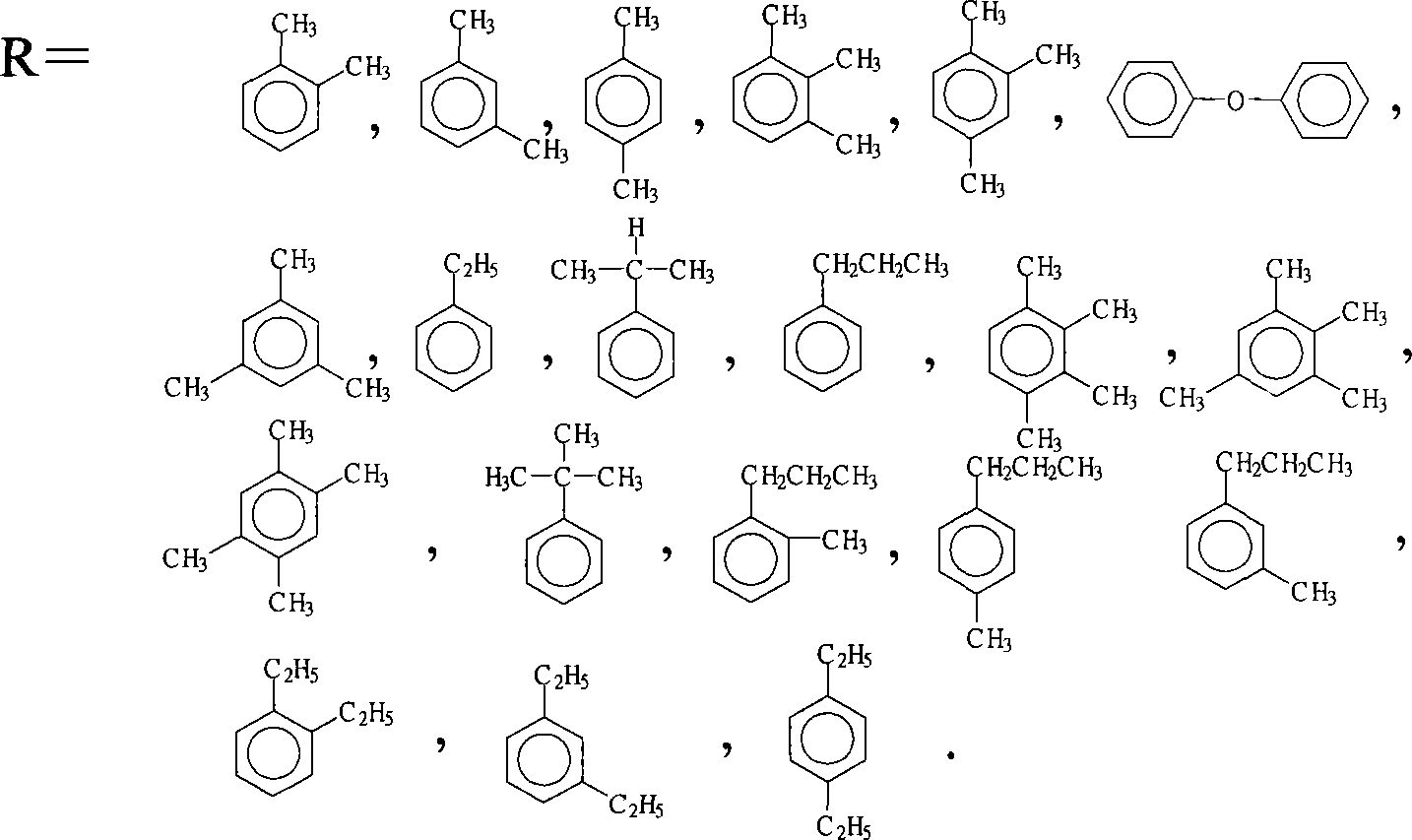

Technique for preparing methoxyl aralkyl ether oligomers

A methoxy aralkyl ether and manufacturing technology, which is applied in the field of thermosetting resin manufacturing, can solve problems such as difficulty in realizing large-scale industrial production, and achieve excellent application effects, broad development and application prospects, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

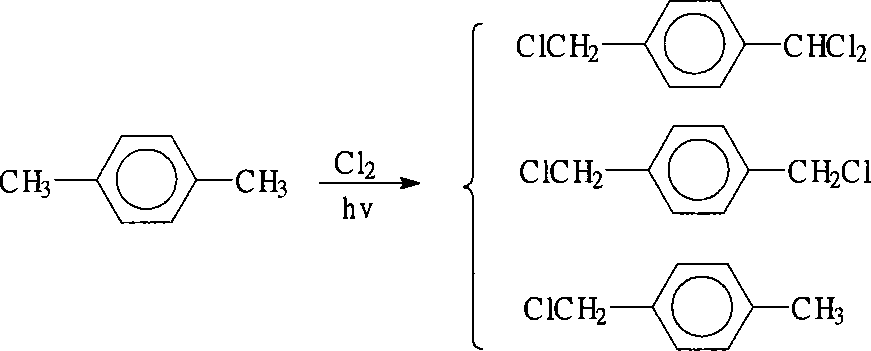

Method used

Image

Examples

Embodiment 1

[0025] 2000ml three-necked bottle, equipped with constant pressure funnel, mechanical stirring and condensing device. First put 420g (14mol) of formaldehyde into the three-necked bottle. Add 588g (6mol) of concentrated sulfuric acid into the separatory funnel, and drop it into the three-necked flask. After the dropwise addition, pour 212g (2.00mol) of m-xylene and 192g (6mol) of methanol into a three-necked flask, keep stirring, and raise the temperature of the water bath to 60-70°C. React for 1 hour. Afterwards, the temperature was raised to make the reaction temperature reach 78-80° C., and a reflux phenomenon occurred, and the reaction was carried out in this state for 6 hours. After the reaction was completed, the system was cooled to room temperature and separated into layers, and the liquid in the lower layer was removed. The collected upper liquid was washed with 10% Na 2 CO 3 Wash with aqueous solution, and then wash with hot water at 60-70°C until neutral. The r...

Embodiment 2

[0030] 2000ml three-necked bottle, equipped with constant pressure funnel, mechanical stirring and condensing device. First put 420g (12.23mol) of formaldehyde into the three-necked bottle. Add 176g (1.8mol) of concentrated sulfuric acid into the separatory funnel, and dropwise into the three-necked flask. After the dropwise addition, 340 g (2.00 mol) of diphenyl ether and 256 g (8 mol) of methanol were poured into a three-necked flask, stirred continuously, and the temperature of the water bath was raised to 60-70°C. React for 1 hour. Afterwards, the temperature was raised to make the reaction temperature reach 78-80° C., and a reflux phenomenon occurred, and the reaction was carried out in this state for 6 hours. After the reaction was completed, the system was cooled to room temperature and separated into layers, and the liquid in the lower layer was removed. The collected upper liquid was washed with 10% Na 2 CO 3 Wash with aqueous solution, and then wash with hot wat...

Embodiment 3

[0034] 2000ml three-necked bottle, equipped with constant pressure funnel, mechanical stirring and condensing device. First put 120g (4mol) of formaldehyde into the three-necked bottle. Add 78.4g (0.8mol) of concentrated sulfuric acid into the separatory funnel, and dropwise into the three-necked flask. After the dropwise addition is complete, pour 240g (2.00mol) of 1,2,3-trimethylbenzene, 1,2,4-trimethylbenzene, a mixture of mesitylene and 128g (4mol) of methanol into a three-necked flask and keep stirring , and raise the temperature of the water bath to 60-70°C. React for 1 hour. Afterwards, the temperature was raised to make the reaction temperature reach 78-80° C., and a reflux phenomenon occurred, and the reaction was carried out in this state for 6 hours. After the reaction was completed, the system was cooled to room temperature and separated into layers, and the liquid in the lower layer was removed. The collected upper liquid was washed with 10% Na 2 CO 3 Wash w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com