Waterproof adhesive and preparation method thereof

A waterproof adhesive and adhesive technology, used in building components, coatings, building insulation materials, etc., can solve the problem that the quality of waterproof construction does not form unified operating procedures and acceptance standards, threatens the health of production and construction personnel, and lacks bridge engineering. Waterproof construction team and other problems, to achieve the effect of excellent shear resistance and bonding performance, easy to popularize and apply, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

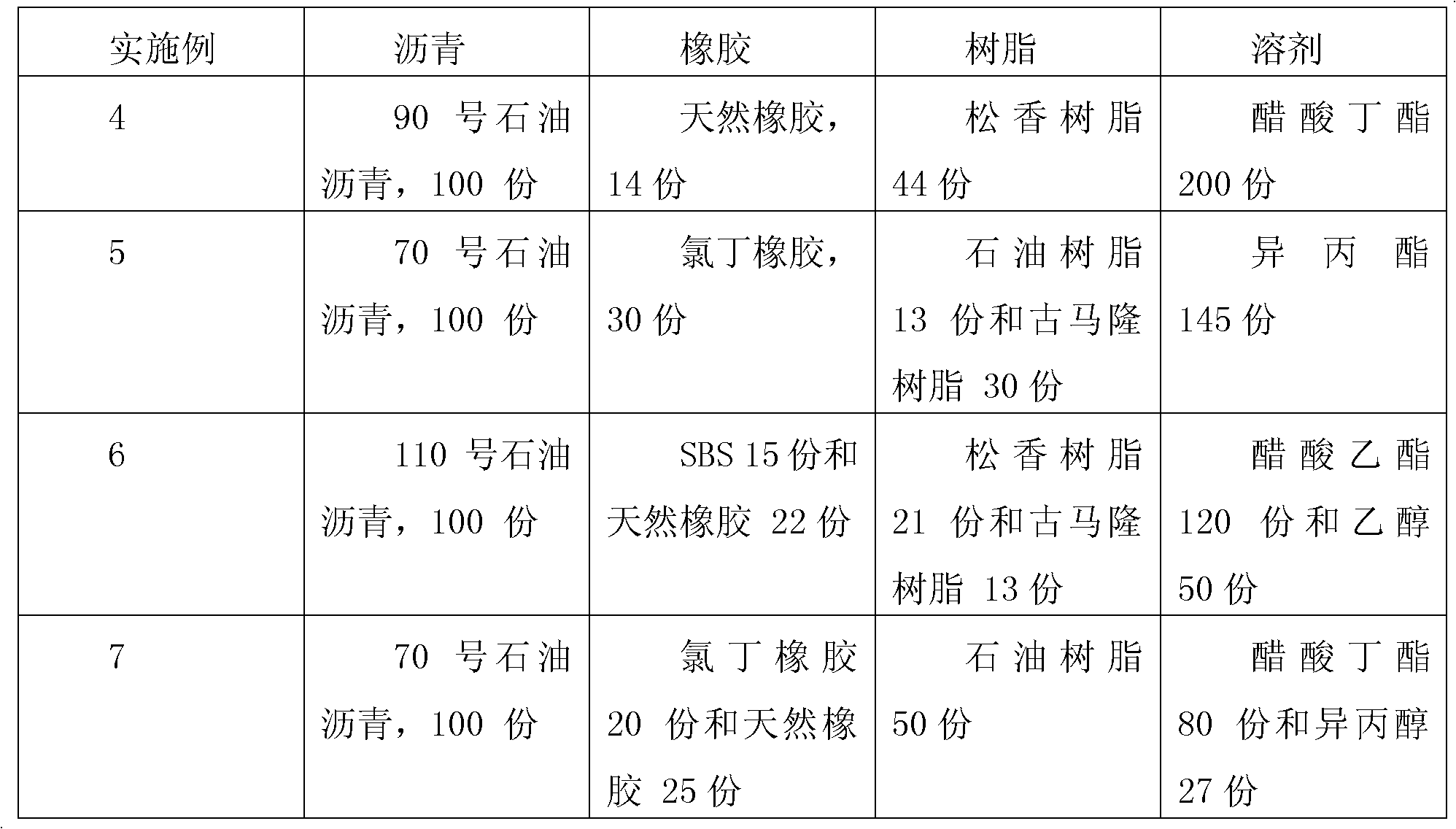

Examples

Embodiment 1

[0026] A waterproof adhesive is prepared as follows:

[0027] ① Weigh the raw materials according to the following ratio

[0028] No. 70 petroleum asphalt 300Kg,

[0029] SBS 100Kg,

[0030] Natural rubber 20Kg,

[0031] Petroleum resin 144Kg,

[0032] Isopropyl acetate 370Kg,

[0033] Isobutanol 230Kg.

[0034] ②Preparation process

[0035] 1. Add 370Kg of isopropyl acetate and 230Kg of isobutanol into a 2000L jacketed stirring reaction pot respectively, add 100Kg of SBS, 20Kg of natural rubber, and 144Kg of petroleum resin under stirring; heat up to 40°C, keep stirring at 40°C for 1.5 h.

[0036] 2. No. 70 petroleum asphalt is stored in a storage tank with a constant temperature of 100°C. Pump 300Kg of No. 70 petroleum asphalt into a jacketed stirring reaction pot, control the reaction temperature at 40°C, and stir and dissolve for 2 hours.

[0037] 3. Cooling water is passed through the jacketed stirring reaction pot. When the temperature of the material is lowered ...

Embodiment 2

[0039] A waterproof adhesive is prepared as follows:

[0040] ① Weigh the raw materials according to the following ratio

[0041] No. 90 petroleum asphalt 100Kg,

[0042] Natural rubber 50Kg,

[0043] Rosin resin 25Kg,

[0044] Ethyl acetate 148Kg.

[0045] ②Preparation process

[0046] 1. Add the above-mentioned ethyl acetate into the jacketed stirring reaction pot, add the above-mentioned natural rubber and rosin resin under stirring; raise the temperature to 22°C, keep the temperature at 22°C and stir for 2 hours.

[0047] 2. No. 90 petroleum asphalt is stored in a storage tank with a constant temperature of 100°C. Pump the No. 90 petroleum asphalt into the jacketed stirring reaction pot, control the reaction temperature at 50°C, and stir and dissolve for 2 hours.

[0048] 3. Cooling water is passed through the jacketed stirring reaction pot, and when the temperature of the material is lowered to 25°C, the material is discharged and packaged.

Embodiment 3

[0050] A waterproof adhesive is prepared as follows:

[0051] ① Weigh the raw materials according to the following ratio

[0052] No. 110 petroleum asphalt 100Kg,

[0053] SBS 28Kg,

[0054] Neoprene 15Kg,

[0055] Coumarone resin 10Kg,

[0056] Butyl acetate 120Kg,

[0057] Ethanol 36Kg.

[0058] ②Preparation process

[0059] 1. Add the above-mentioned ethyl acetate into the jacketed stirring reaction pot, add the above-mentioned natural rubber and rosin resin under stirring; raise the temperature to 57°C, keep the temperature at 57°C and stir for 1h.

[0060] 2. No. 110 petroleum asphalt is stored in a storage tank with a constant temperature of 100°C. Pump the No. 110 petroleum asphalt into the jacketed stirring reaction pot, control the reaction temperature at 57°C, and stir and dissolve for 0.5h.

[0061] 3. Cooling water is passed through the jacketed stirring reaction pot, and when the temperature of the material is lowered to 20°C, the material is discharged and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com