Patents

Literature

278 results about "Butyrospermol acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

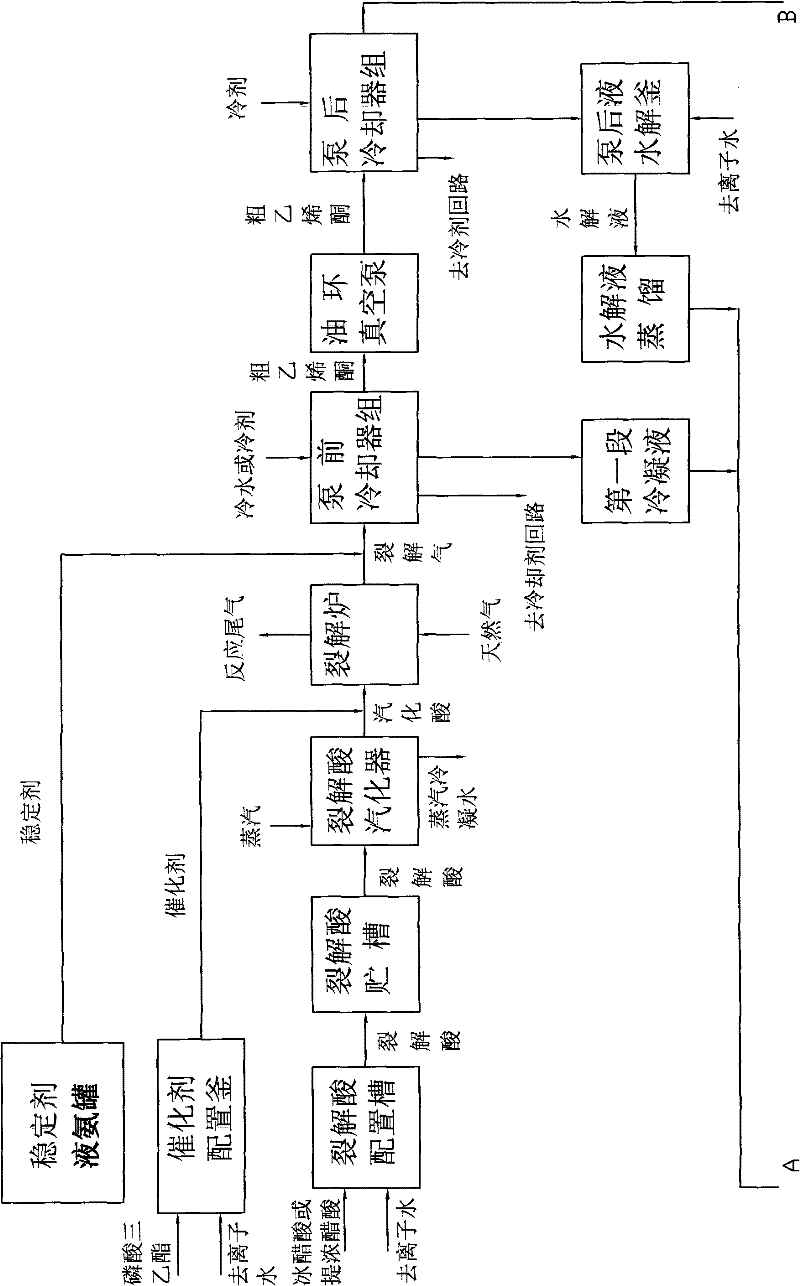

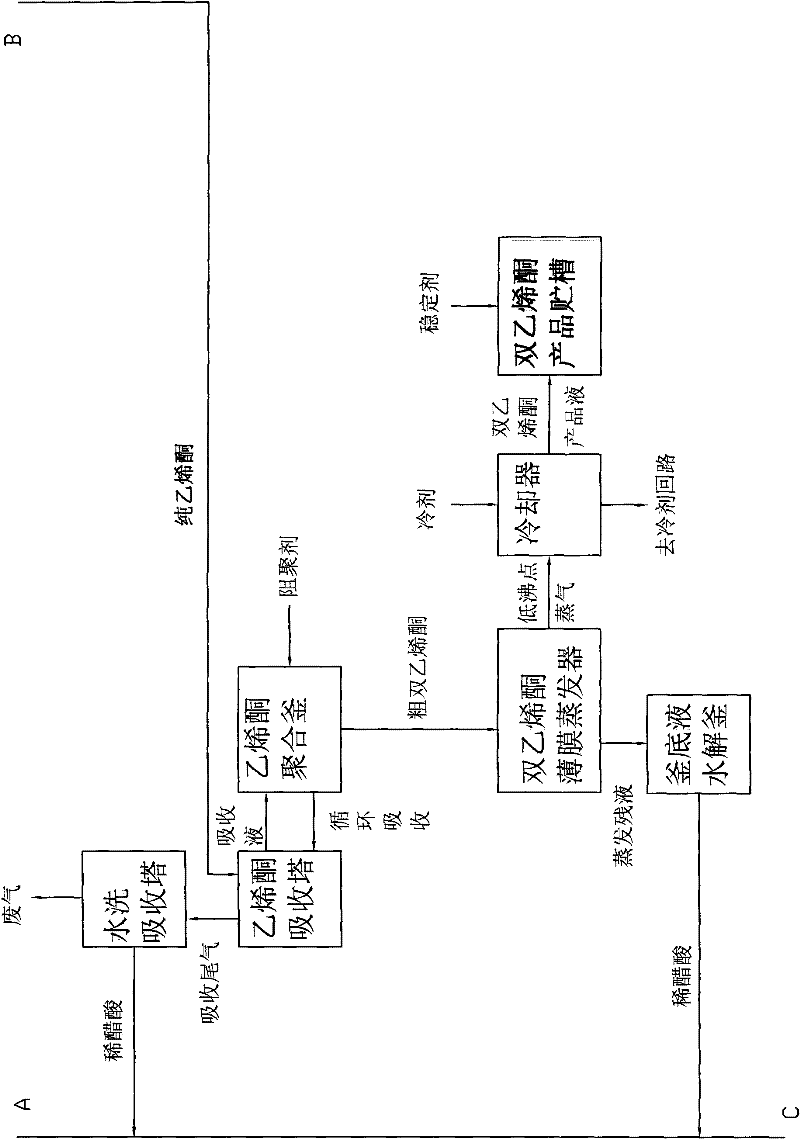

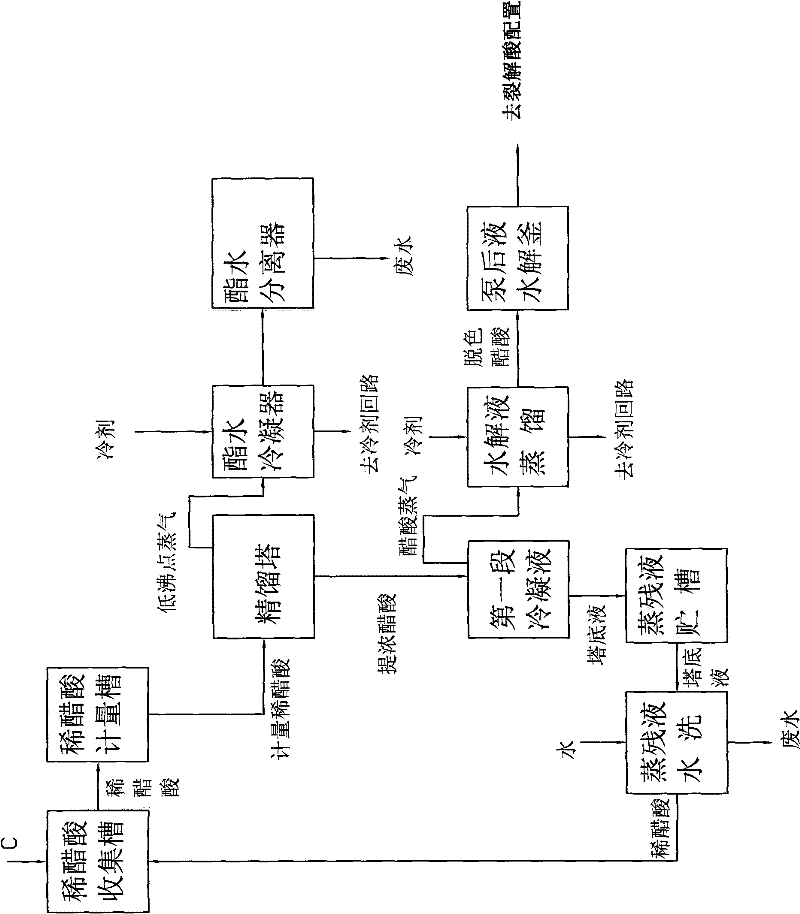

Process for preparing high-purity diketene

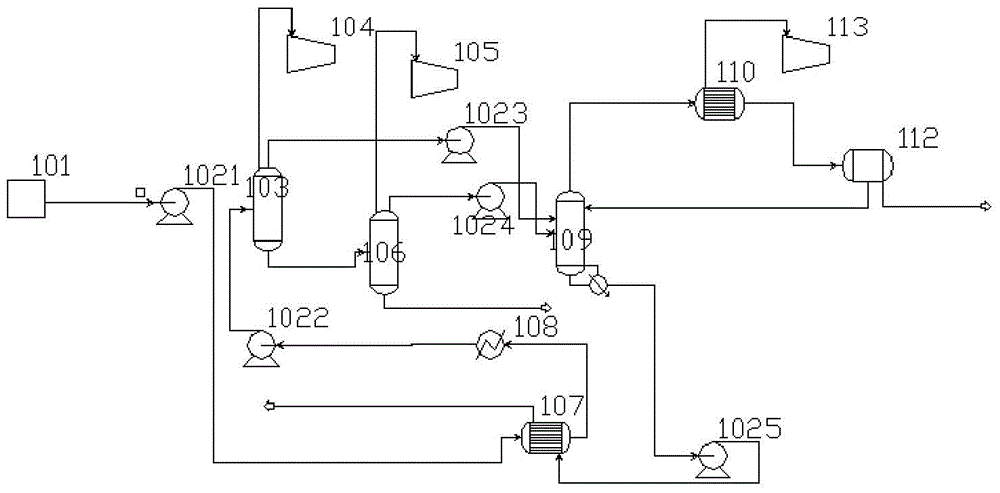

The invention relates to a process for preparing high-purity diketene, which overcomes the defects of low purity of ketene, low purity and poor safety of diketene products formed by absorbing and polymerizing ketene, as well as complex process, high cost and high acetic acid content of raffinate in the concentration recovery of dilute acetic acid. The process for preparing high-purity diketene is suitable for absorbing and polymerizing ketene dimer at low temperature on the basis of adopting stable acetic acid cracking conditions and deep refrigeration to remove impurities from cracking gas and generate pure ketene gas, adopting a film evaporator to further purify diketene products at low temperature under low pressure, and adding stabilizers after introducing polymerization inhibitor and diketene for refining during the absorption and polymerization of ketene in order to improve synthesis safety and the stability of products in storage tanks. Meanwhile, the dilute acetic acid produced in the process reasonably matches the temperature of each point of a stripping section through a sensitive plate technique, improves the water-carrying capability of butyl acetate, and greatly reduces the concentration of acetic acid in concentrated raffinate.

Owner:NINGBO WANGLONG TECH

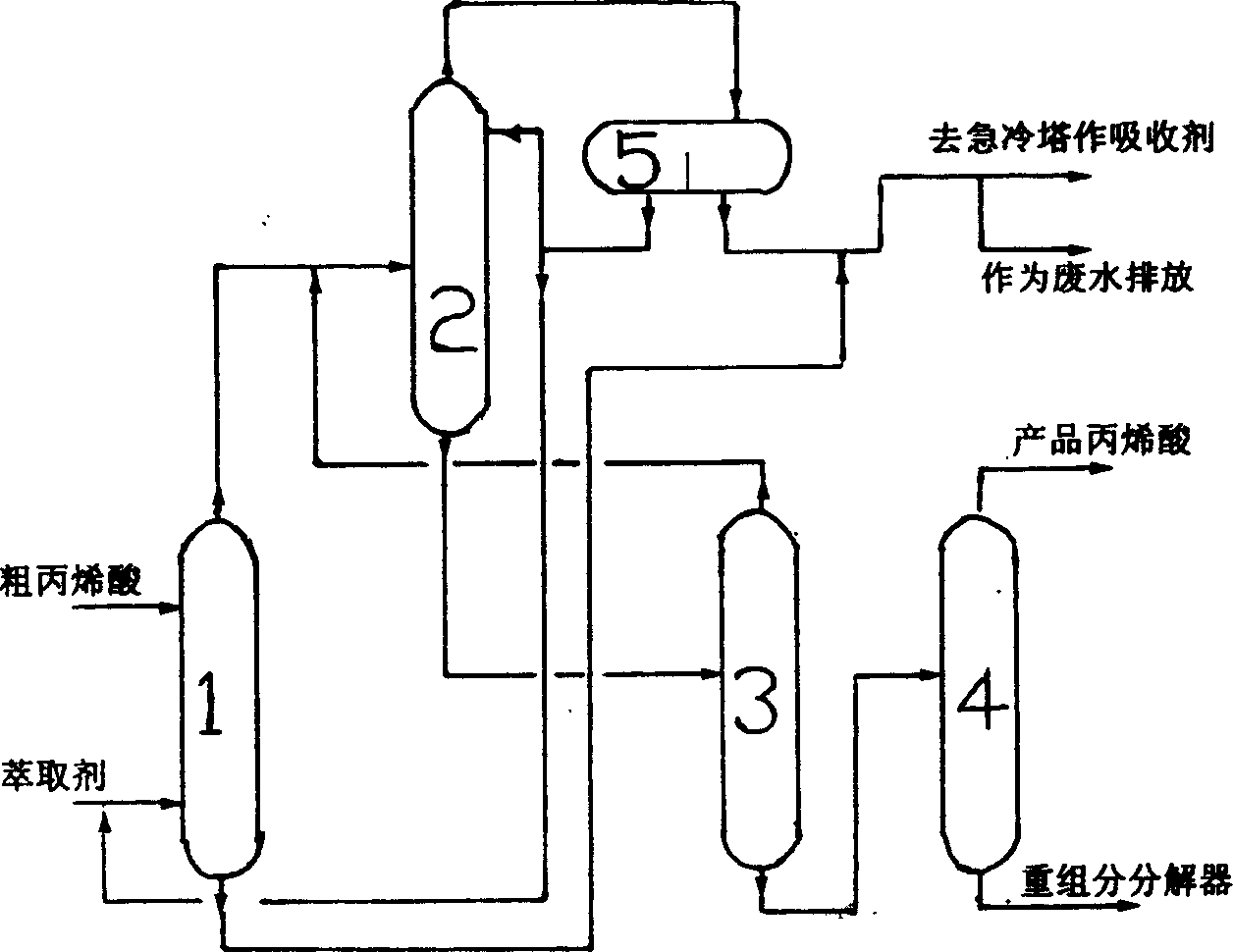

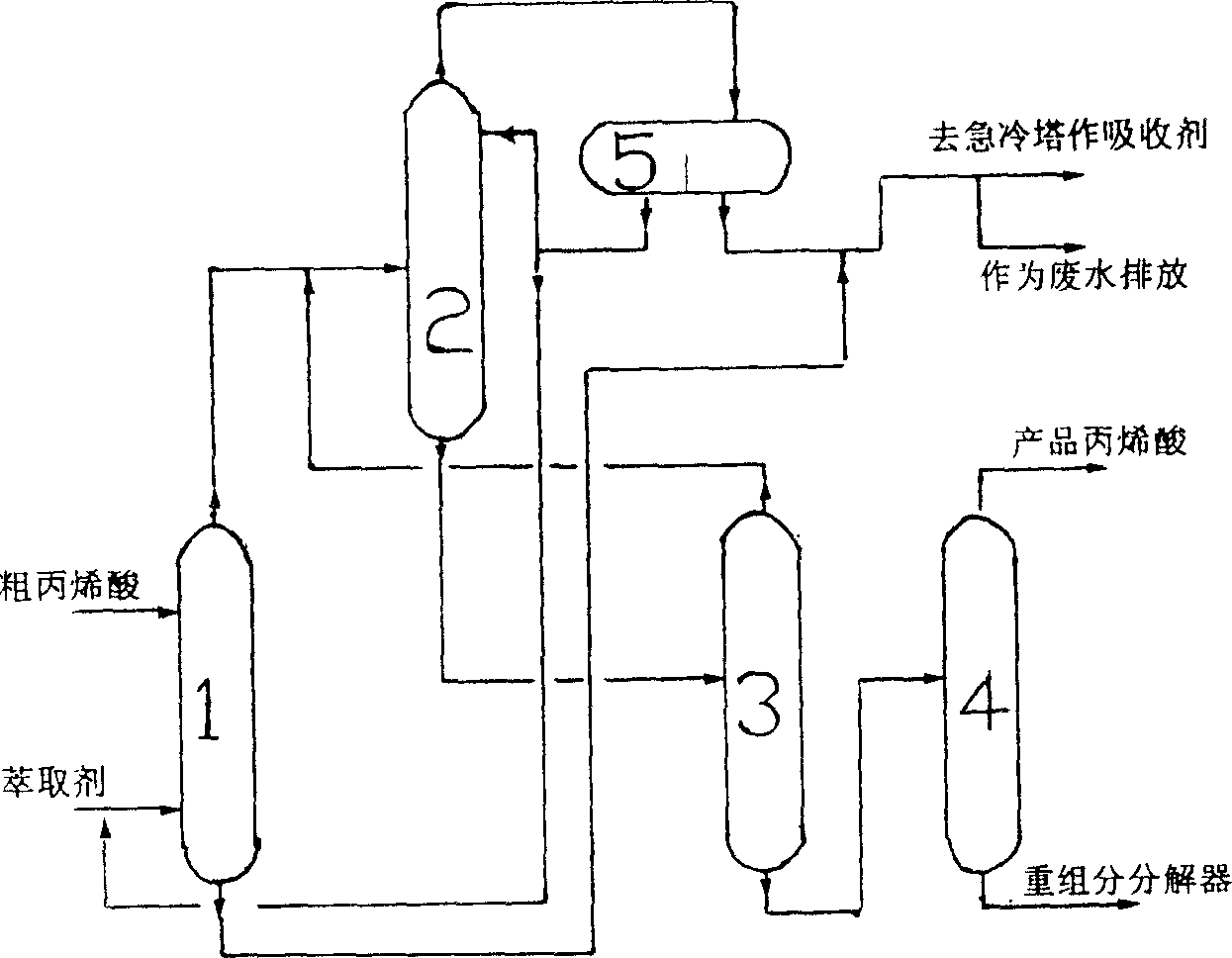

Method for purifying acrylic acid

The invention relates to the process for purifying acrylic acid which comprises using novel organic extracting agent to separate acrylic acid from its water solution, then removing light compositions such as water and acetic acid by azeotropic fractional distillation, wherein the organic extracting agent comprises toluene, acetic ether, butyl acetate, butyl acetate, propionic ether, diisobutyl ketone, isophorone, methyl phenyl ether or their mixture, preferably the composite compound of toluene with isobutyl phenylacetate, the mass ratio of toluene and isobutyl phenylacetate is between 1:1-1:50, preferably 1:2-1:12. The process according to the invention can realize high acetic acid removing ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

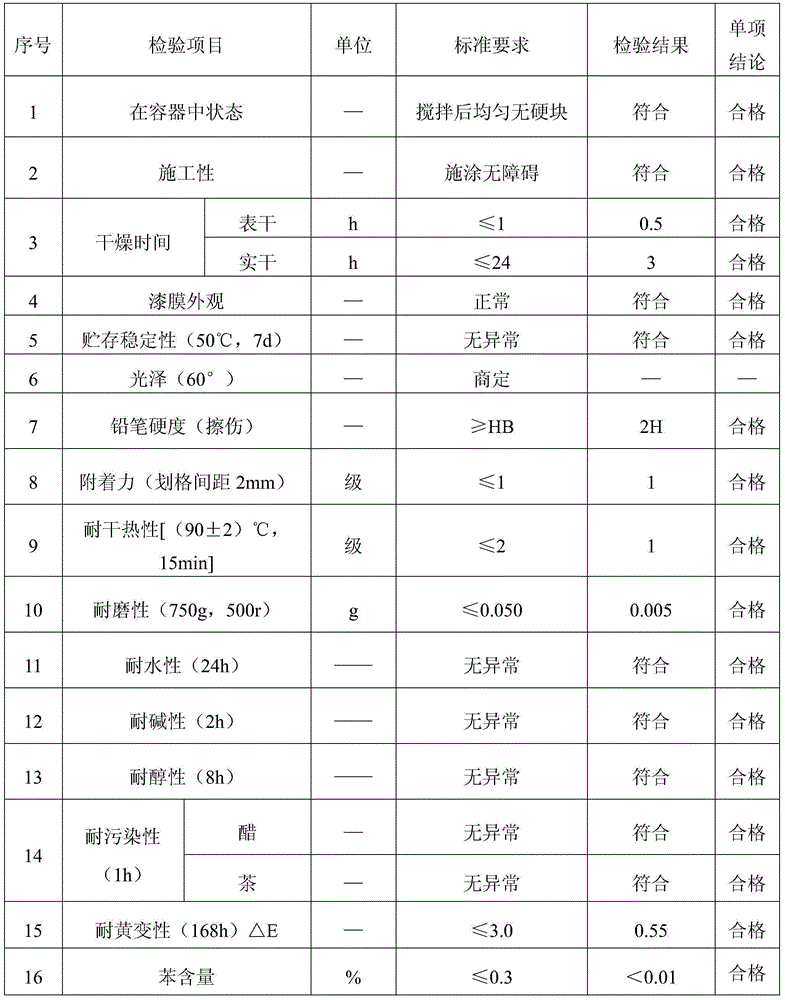

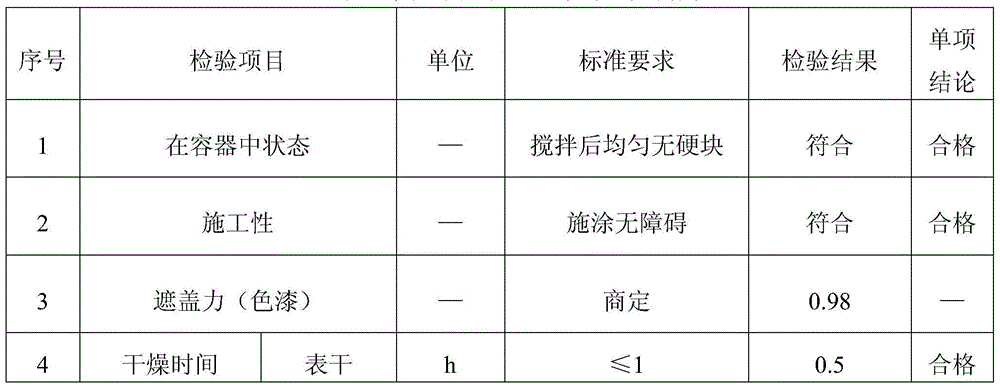

Nano SiO2-organosilicon coating and preparation method thereof

The invention relates a nanometer SiO2- organosilicon coating and preparation method. The coating comprises the 60-82% organosilicon resin, 3-10% nanometer SiO2, 5-15% dimethylbenzene, 3-8% toluene, 3-6% butyl acetate, 0.2-0.6% dispersing agent, 0.1-0.3% levelling agent, 0.2-0.4% defoaming agent, and 3-10% talcum powder. The method comprises the following steps: 1 weighing nanometer SiO2, adding dimethylbenzene, dispersing agent and butyl acetate, disperse with ultrasonic, and getting nanometer SiO2 slurry; 2 weighing organosilicon resin, adding defoaming agent and dispersing agent, then adding nanometer SiO2 sluury and talcum powder, dispersing and grinding; 3 adding left resin, solvent and adjuvant, and dispersing. The invention can improve the erosion-resisting characteristics, protect material, and extend the life.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Coating composition with ceramic imitation effect

ActiveCN102585633AWear-resistantGood mechanical propertiesPolyurea/polyurethane coatingsSpecial surfacesXylyleneEthylic acid

The invention mainly relates to the field of paint coating, in particular to a coating composition with a ceramic imitation effect. The coating comprises primer coating, middle coating and top coating. The top coating mainly comprises a main agent and a curing agent, wherein the main agent mainly comprises the following components: 5-10 parts of butyl acetate, 4-10 parts of xylene, 80-85 parts of acrylic polyol resin, 4-8 parts of propylene glycol methyl ether acetate, 0.5-2 parts of an organosilicon leveling agent, and 0.1-0.5 parts of an organosilicon antifoaming agent; and the curing agent mainly comprises the following components: 15-30 parts of butyl acetate, 15-30 parts of xylene, and 40-65 parts of an isocyanate curing agent. The coating composition provided by the invention can be used on prefabricates of plastic, glass or other materials, so that the prefabricates have a high ceramic imitation effect, and the ceramic imitating products not only have various advantages of ceramic products, but also reduces mining and use of organic soil and saves consumption of natural resources. In addition, the coating composition can be dissolved in soil, so as to reduce the pollution and destroy to the environment and reduce the harm to human bodies.

Owner:DONGGUAN SUNLAND TECH CO LTD

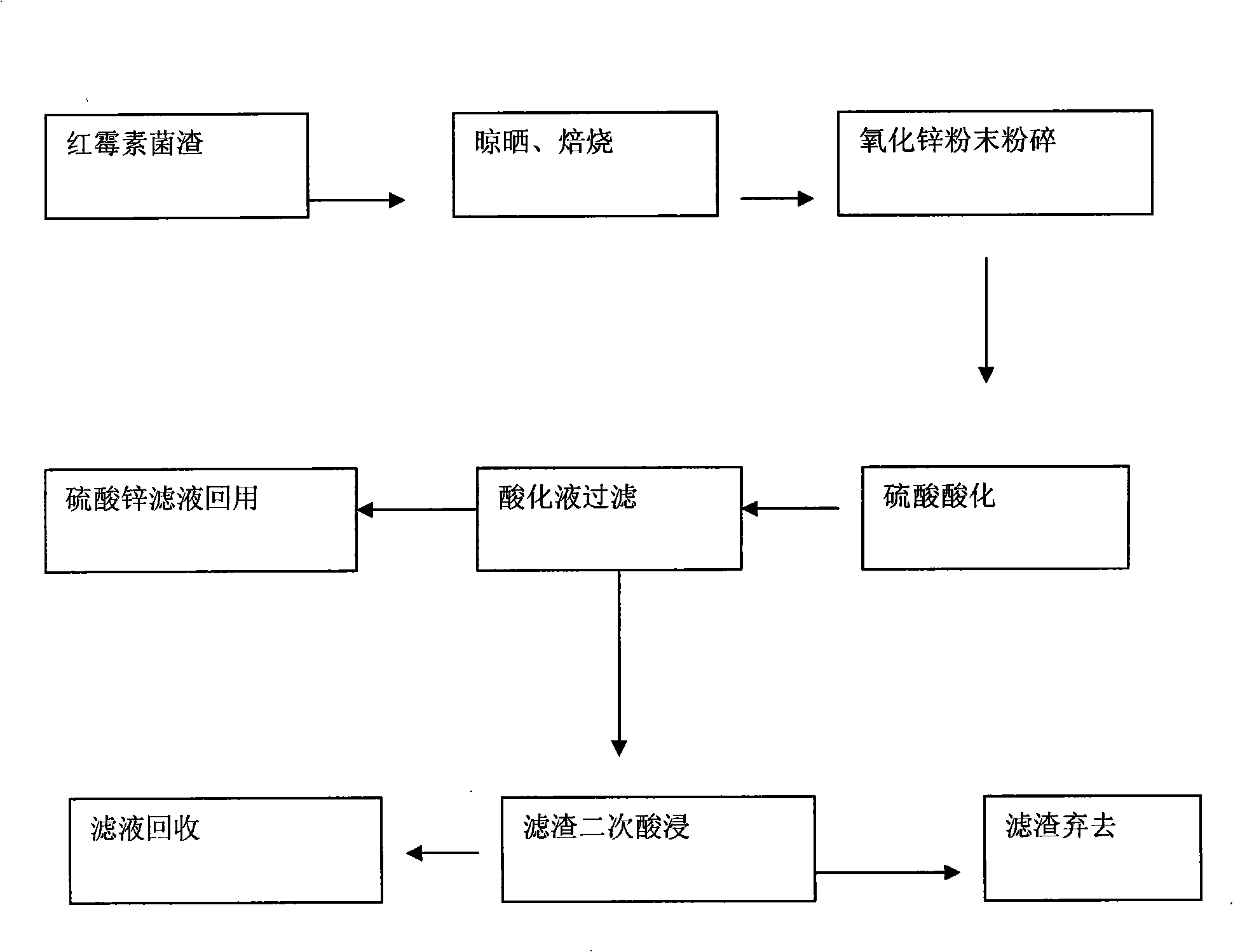

Method for producing abomacetin rhodanate

InactiveCN101407533AReduce unit consumptionEasy biochemical treatmentSugar derivativesButyl acetateAbomacetin

The invention relates to a production method of erythromycin thiocyanate, which is characterized in that erythromycin filtrate is treated by bleaching subtraction resin and condensed to 18000u / ml-20000u / ml by a nanofiltration membrane with molecular weight of 600, strong ammonia water is introduced when the condensed liquid is condensed and heated to 55DEG C to 56 DEG C, the PH value is controlled from 9.8 to 10.0, the introducing time of ammonia is 30 minutes to 45 minutes, erythromycin alkali can be obtained by extracting and filtering a crystalline liquid immediately, and then the erythromycin alkali is dissolved to be a solution of 30000u / ml to 35000u / ml by butyl acetate, crystallization is carried out according to a method of solvent extraction crystallization, and then the thiocyanate erythromycin can be obtained by centrifugal separation. The production method of the erythromycin thiocyanate uses the method of water-phase crystallizing the erythromycin and then transferring salts by the solvent, the product quality is good, the unit consumption of the solvent is low, the yield is similar to the solvent method, moreover, the production wastewater realizes removing contamination and shunt, is easy to treat, and has good environmental benefit.

Owner:NINGXIA QIYUAN PHARMA

High transparency scratch-resisting matt clear paint

ActiveCN103131321AImprove the decorative effectImprove protectionPolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses high transparency scratch-resisting matt clear paint which is composed of a host agent, a curing agent and a diluent agent. The host agent comprises 65.5 % - 75.5% of short oil alkyd resins, 16 % - 25 % of solvent, 0.1 % - 0.3 % of antifoaming agents, 0.1 % - 0.3 % of flatting agents, 0.1 % - 0.5 % of anti-settling agents, 0.1 % - 0.3 % of dispersing agents, 1 % - 3 % of scratch-resisting assistant agents, and 4 % - 8 % of delustering agents. The curing agent comprises 40 % - 50 % of toluene diisocynate (TDI) trimer, 10 % - 20 % of TDI- hexamethylene diisocyanate (HDI) mixed trimer, 20 % - 30 % of TDI- trimethylolpropane adduct, and 20 % - 30 % of butyl acetate. The diluent agent comprises 40 % - 50 % of butyl acetate, 20 % - 30 % of dimethylbenzene, and 20 % - 30 % of propylene glycol methyl ether acetate. The high transparency scratch-resisting matt clear paint is good in transparency and scratch-resisting performance, and is easy to process.

Owner:安徽名士达新材料有限公司

Invisible coating material and preparation method thereof

ActiveCN103013256AImprove absorbing performanceLow areal densityCoatingsAcrylic resinCarbon nanotube

The invention discloses an invisible coating material and a preparation method thereof. The invisible coating material comprises a component A and a component B in a weight ratio of (10-15): 1, wherein the component A is prepared from the following raw materials in weight percentage: 40-60% of hydroxyl acrylic resin, 10-15% of carbon nanotube, 5-10% of ceramic powder, 5-8% of vacuum glass microbead, 1-5% of siloxane coupling agent, 1-10% of nano-sized barium sulphate, 1-10% of nano-sized titanium dioxide and 5-10% of dimethylbenzene and butyl acetate mixture; and the component B is prepared from the following raw material in weight percentage: 100% of biuret. The invention provides the invisible coating material with good invisible effect, high wave-absorbing capacity, small surface density, light weight and high bonding strength and the preparation method thereof.

Owner:山东孚日宣威新材料科技有限公司

Preparation method of nitrolacquer

The invention discloses nitrate cellulose with 11.7-12.2% nitrogen, which comprises the following parts: 19-13wt% modified alkide resin with 70% coconut oil, 5-10wt% dye, 0.1-0.3wt% fatty butyl ester composite plasticizer and 67-50% composite solvent with butyl acetate and butanol or alcohol. The main index of paint reaches environmental protective request, which contains not more than 0.1% phthalandione ester.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

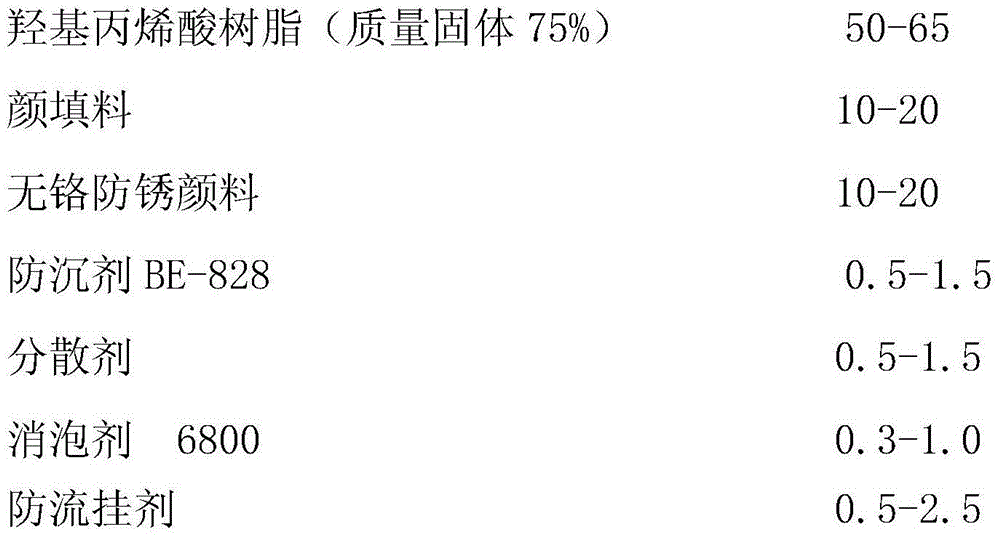

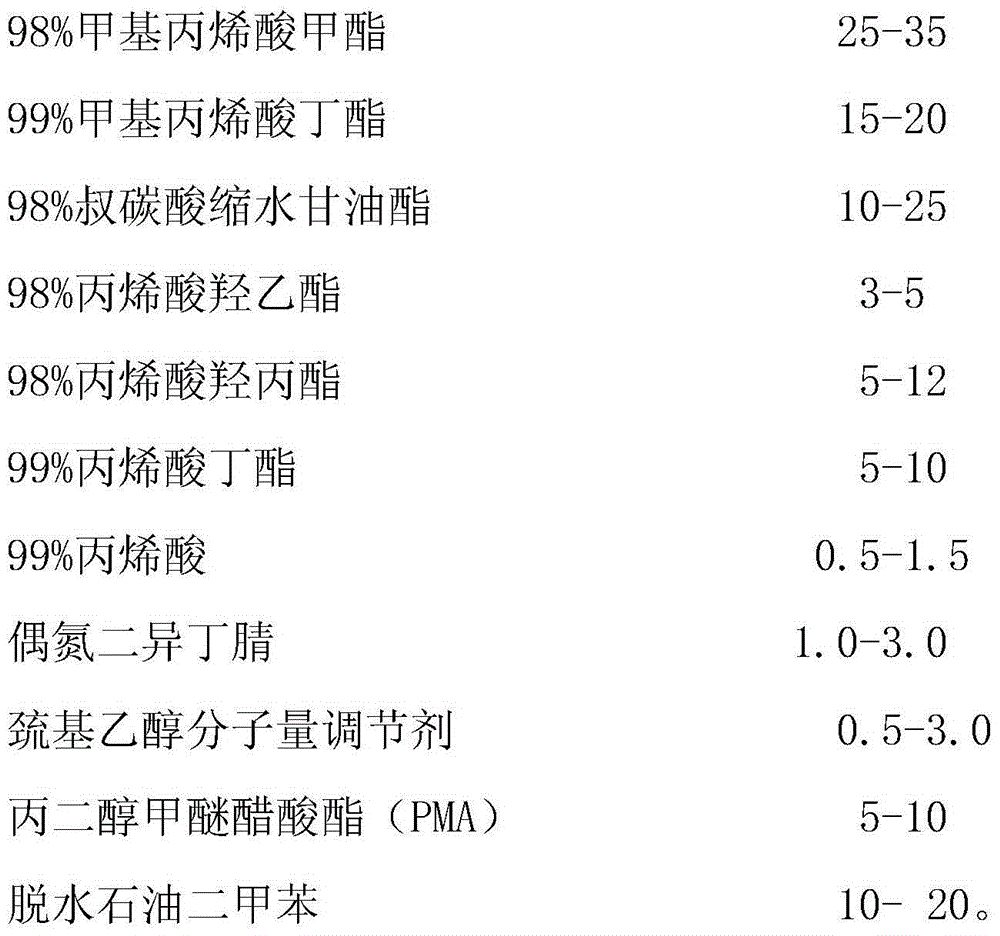

High-solid chrome-free acrylic polyurethane finish paint

InactiveCN103555178AImprove the decorative effectLight colorPolyurea/polyurethane coatingsButyl acetateWeather resistance

The invention relates to a high-solid chrome-free acrylic polyurethane finish paint consisting of two components A and B which are mixed together according to a ratio of 100:25. The component A comprises the following components in parts by weight: 50-65 parts of self-made tert-carbonic glycidyl ester modified hydroxylated acrylic resin (with 75 mass percent of solids), 10-20 parts of a color filler, 10-20 parts of a chrome-free anticorrosive pigment, 0.5-1.5 parts of an anti-setting agent BE-828, 0.5-1.5 parts of a dispersant, 0.3-1.0 part of a defoaming agent, 0.5-2.5 parts of an anti-sagging agent, 0.3-0.5 part of a leveling agent and 5-10 parts of a solvent. The component B comprises the following components in parts by weight: 50-70 parts of fat diisocyanate and 30-50 parts of butyl acetate. The high-solid chrome-free acrylic polyurethane finish paint disclosed by the invention has relatively high requirements for overall properties including weather resistance, fullness, salt fog resistance, adhesive force, chemical resistance and the like.

Owner:TIANHENG PAINT CO LTD

Sprayed and coated odorless polyurethane floor paint

InactiveCN104403553AGood solvent releaseImprove mechanical propertiesPolyurea/polyurethane coatingsMethyl carbonateToluene diisocyanate

The invention relates to sprayed and coated odorless polyurethane floor paint which consists of a main agent, a solidifying agent and a diluent, wherein the main agent comprises the following components in percentage by weight: 64-70 percent of odorless alkyd resin, 19.0-25.0 percent of a solvent, 0.5-1.0 percent of a de-foaming agent, 0.1-0.5 percent of a flatting agent, 2-5 percent of a anti-settling agent, 0.5-1 percent of a dispersing agent and 3.0-8 percent of a matting agent; the solidifying agent comprises the following components in percentage by weight: 40.0-50.0 percent of a toluene diisocyanate trimer, 20.0-30.0 percent of 6-hexamethylene diisocyanate trimer and 20.0-30.0 percent of butyl acetate; the diluent comprises the following components in percentage by weight: 30.0-40.0 percent of butyl acetate, 20.0-30.0 percent of dimethyl carbonate, 30.0-40.0 percent of propylene glycol monomethyl acetate. A product construction way of the sprayed and coated odorless polyurethane floor paint adopts machine spraying and coating, and after construction, floors are free from odor after one night.

Owner:上海展辰涂料有限公司 +4

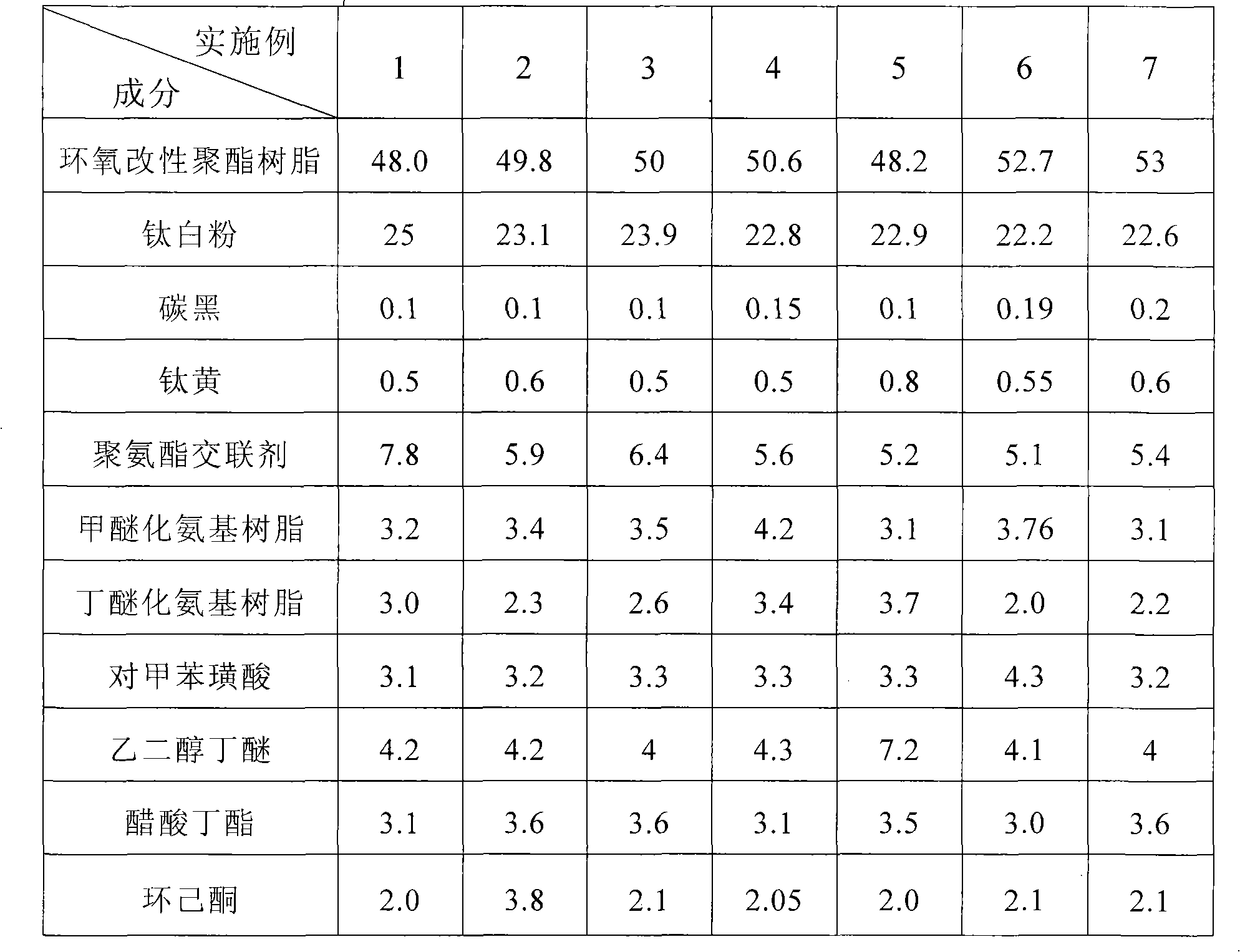

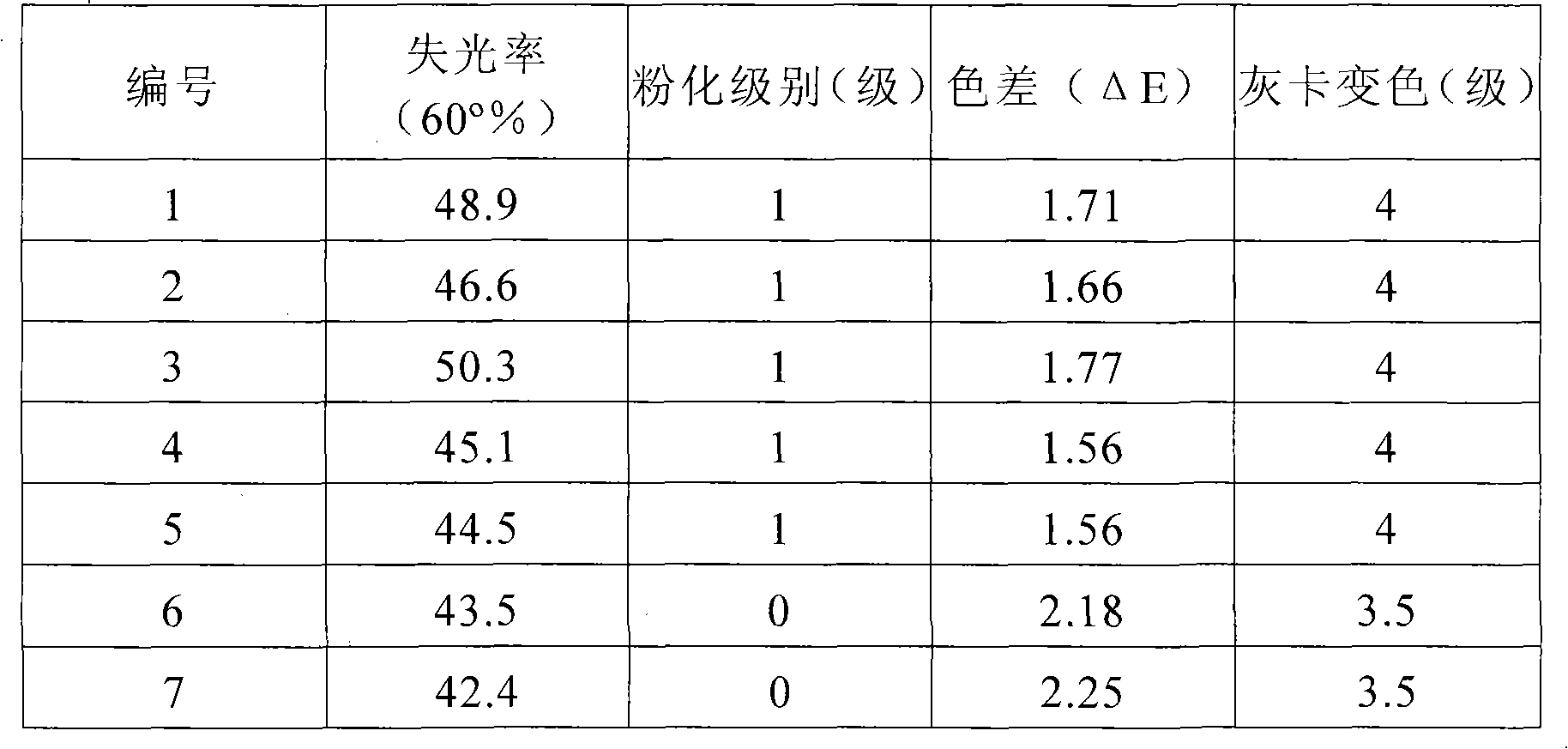

Coating for sandwich panel and board two-used colorful steel plates and method of use thereof

InactiveCN101289594AImprove performanceUniform coatingLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention discloses a coating material used in a sandwich board-veneer double use color-coated steel plate and a method for using the same. The compositions in percentage by mass of the coating material are: 48 to 53 percent of epoxy modified polyester resin, 22.9 to 25.6 percent of pigment powder, 5 to 8 percent of polyurethane crosslinking agent, 3 to 4.5 percent of methanol-etherized amino resin, 2 to 4 percent of butanol-etherized amino resin, 3 to 5 percent of p-toluenesulfonic acid, 4 to 8 percent of butyl glycol ether, 3 to 4 percent of butyl acetate and 2 to 4 percent of cyclohexanone. The coating material adopts a modified epoxy system and a back coating adopts double layer coating mode in order to meet the requirements of product durability; meanwhile, the comprehensive adjustment of viscosity, speed and pressure during primary / fine coat back coating process is carried out to ensure the coating effect of a product; therefore, the surface rigidity (i.e. the scratch resistant performance) of the product can reach to 1,200 g; meanwhile, the crosslinking density after coating material curing is higher and the corrosion resistant performance of the product is stronger (reaching to the zero grade after 500-hour salt spray test).

Owner:BAOSHAN IRON & STEEL CO LTD

High-solid low-VOC (volatile organic compound) benzene-free solvent-type acrylic resin

The invention relates to a 3C paint, particularly a high-solid low-VOC (volatile organic compound) benzene-free solvent-type acrylic resin. The high-solid low-VOC (volatile organic compound) benzene-free solvent-type acrylic resin is a benzene-free system and is composed of a component A, a component B and a component C. The component A is composed of butyl acetate and propylene glycol methyl ether acetate. The component B is composed of methyl methacrylate, styrene, 2-hydroxypropyl acrylate, butyl methacrylate, butyl acrylate, acrylic acid and tert-butyl peroxybenzoate. The component C is composed of tert-butyl peroxybenzoate and butyl acetate. When being used as a finish paint matched with the primer for 3C electronic products, the resin has the advantages of favorable matching property, higher hardness, higher wear resistance, excellent alcohol resistance, excellent chemical resistance, excellent artificial sweat resistance, excellent cold / heat shock resistance, excellent high-temperature / high-dampness resistance, excellent artificial aging resistance and the like. The resin has high solid content, low viscosity and lower VOC, is more environment-friendly when being used as a benzene-free system, and has higher market competitiveness.

Owner:NANXIONG RISING CHEM IND

Method for producing anti-shatter coating for glass and application method thereof

InactiveCN101724340AHas diffuse transmission propertiesGood anti-shatter functionCoatingsFirming agentEthyl acetate

The invention relates to methods for producing anti-shatter coating for glass and an application method thereof. The method comprises the following steps of: (1) mixing CaSb2O6 powder or silica powder and butyl acetate according to the proportion of 1 to 0.9 to 1 to 1.1by weight, grinding for 10 to 36 hours by a ball mill and taking the mixture A out; (2) weighing 15 to 30 parts by weight of organic silicon resin, 1 to 2 parts by weight of silicon flatting agent prepared by a vapor phase method, 5 to 15 parts by weight of 120 solvent oil or butyl acetate or ethyl acetate or toluene, 0.1 to 0.5 part by weight of the mixture prepared in the process (1), 0.1 to 0.5 parts by weight of organic silicon resin firming agent and 0.1 to 0.5 part by weight of inorganic pigment, mixing all the materials at normal temperature and placing the materials into a dispersion machine for 1 to 2 hours, wherein the revolution speed of the dispersion machine is set at 500 to 1000 rpm, filtering out impurities through a filter, and standing for 10 to 36 hours to obtain the white gelatinous anti-shatter coating.

Owner:李苏辉

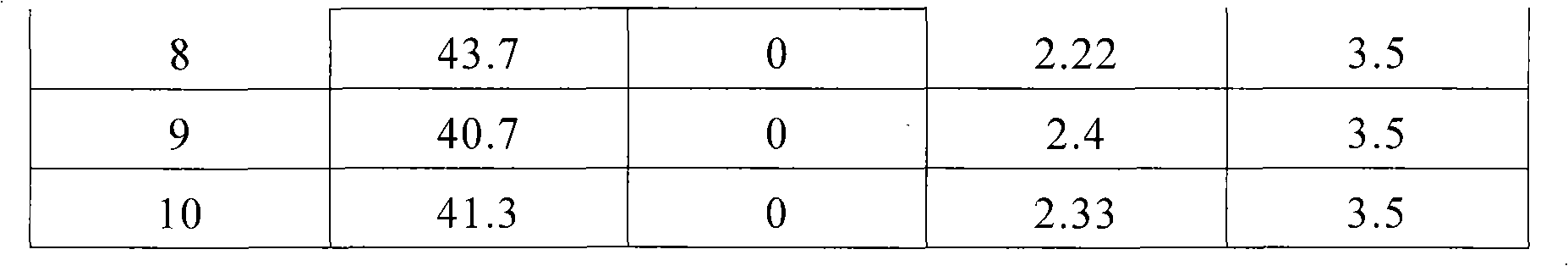

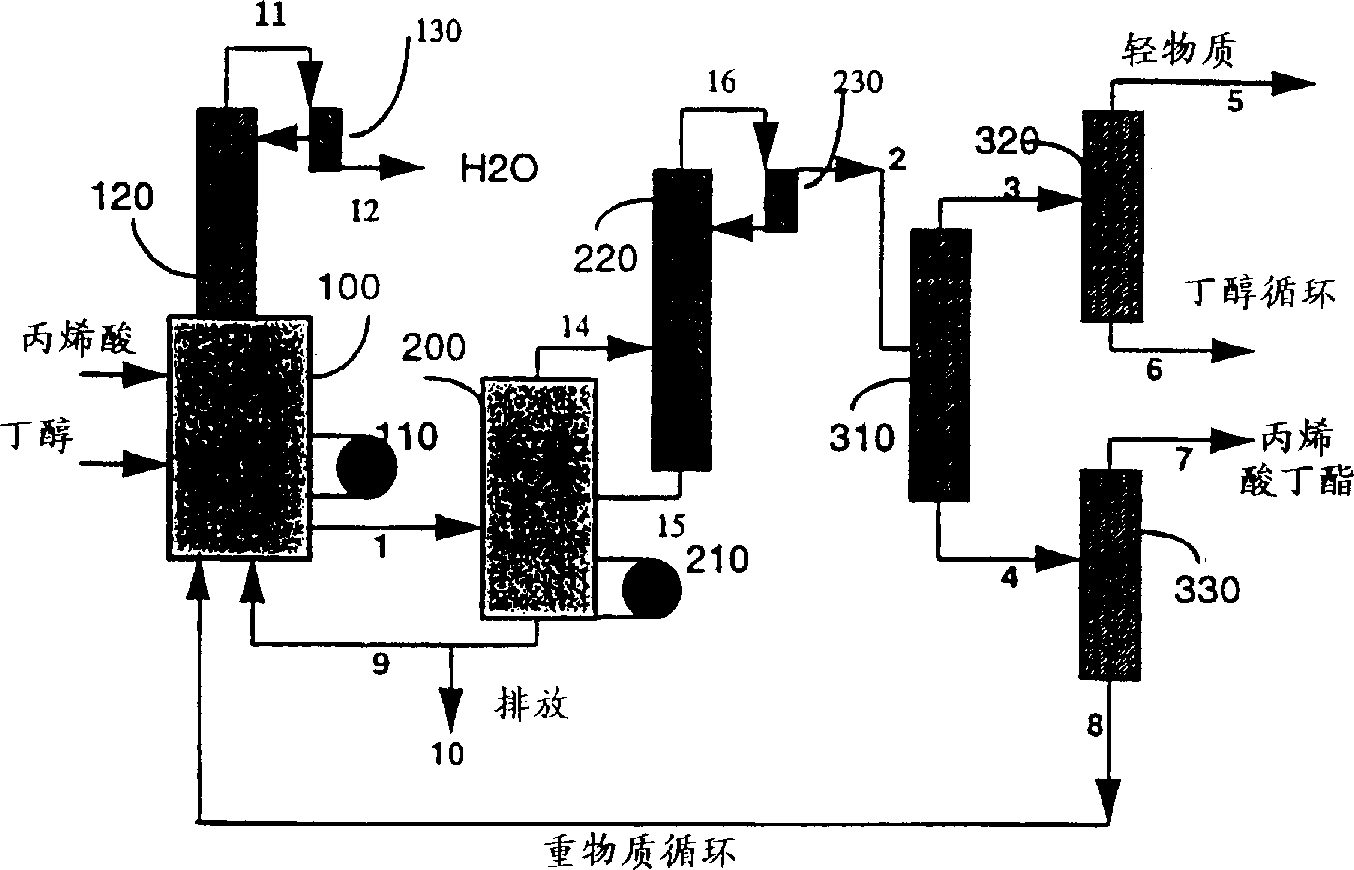

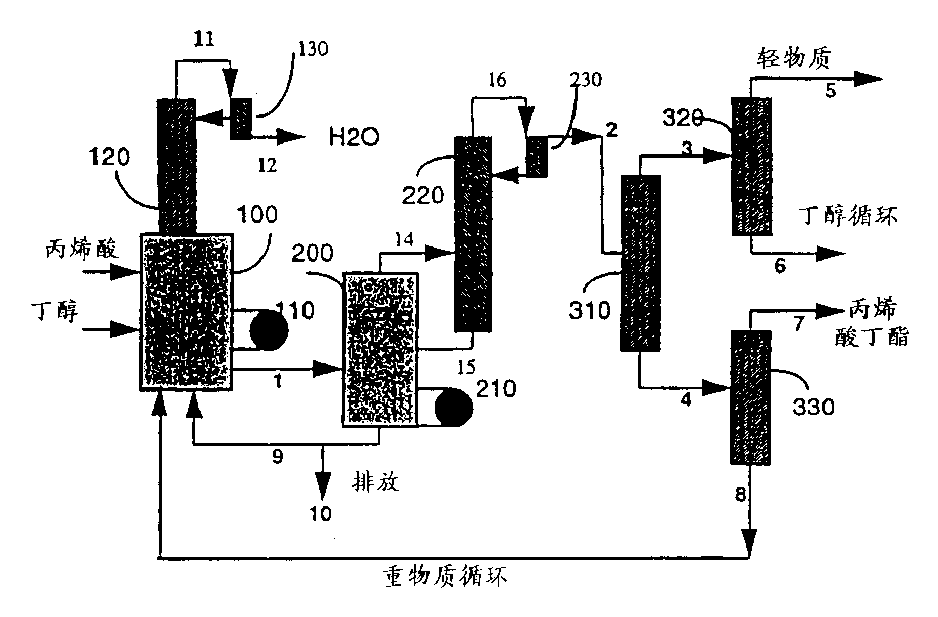

Process for refining butylacrylate

InactiveCN1254331AOrganic compound preparationCarboxylic acid esters preparationPolymer scienceEthylic acid

Crude butyl acrylate streams, e.g., from the reaction of butanol and acrylic acid, are refined using a splitter distillation column to yield a butyl acrylate- and heavies-containing bottoms fraction and an overhead fraction containing dibutyl ether, butyl acetate, butanol and butyl acrylate. The bottoms fraction is then subjected to separation, e.g., by distillation, to separate heavies from the bottoms fractions and to recover butyl acrylate. A process for the production of butyl acrylate is also disclosed, which process comprises not only the above-mentioned refining steps but also includes the steps of withdrawing from the splitter distillation column the overhead fraction and distilling the overhead fraction to recover a bottoms stream containing butanol and butyl acrylate, at least a portion of which could be recycled for reaction with acrylic acid to make butyl acrylate, and recovering the separated heavies, at least a portion of which could be recycled to a reaction zone for the production of butyl acrylate. At least 10,000 lb(avoir) quantities of a butyl acrylate product comprising at least 99.8% by weight of butyl acrylate and containing not more than about 200 ppm butyl ether and not more than about 200 ppm butyl acetate are producible.

Owner:DOW GLOBAL TECH LLC

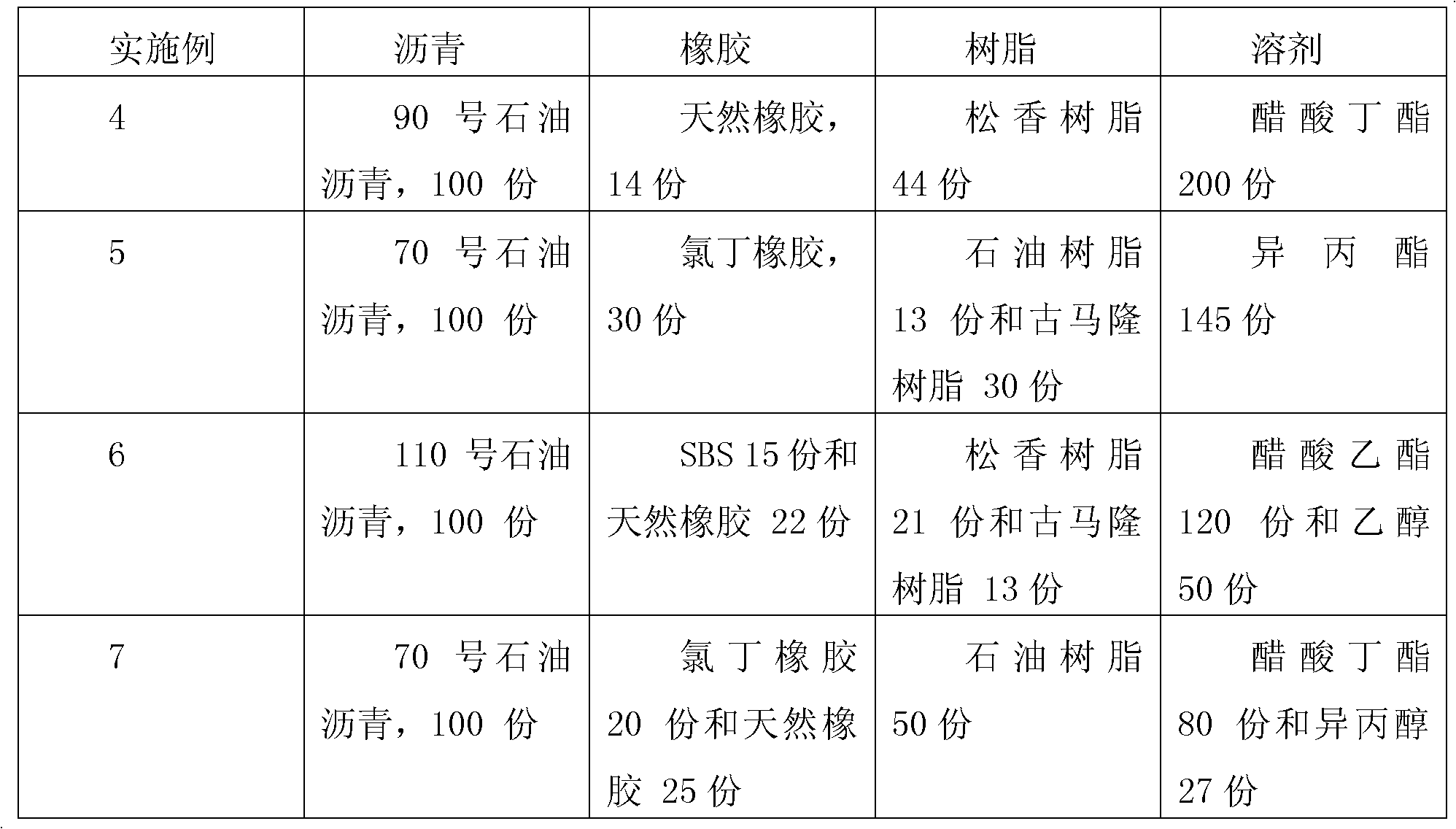

Waterproof adhesive and preparation method thereof

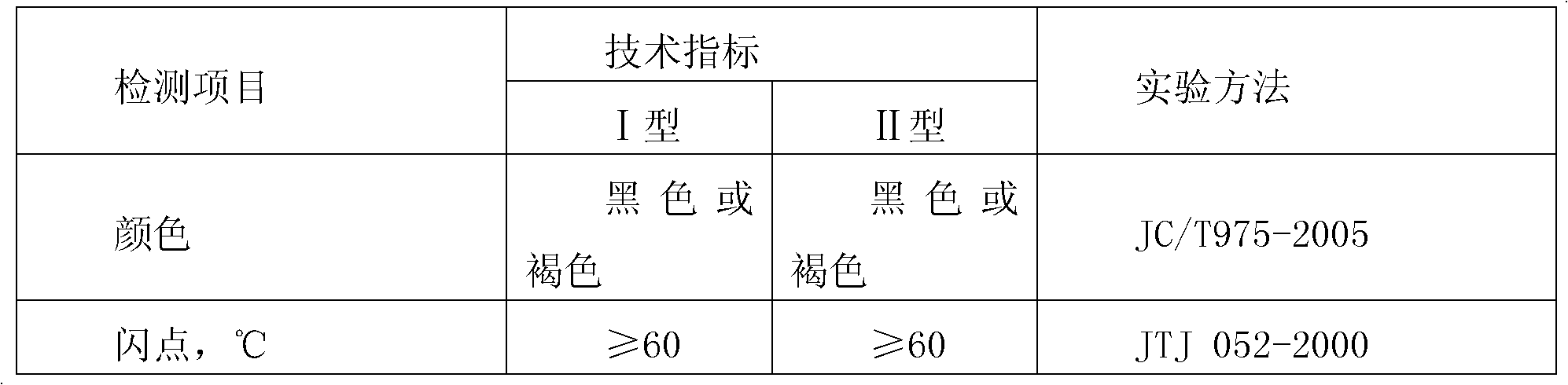

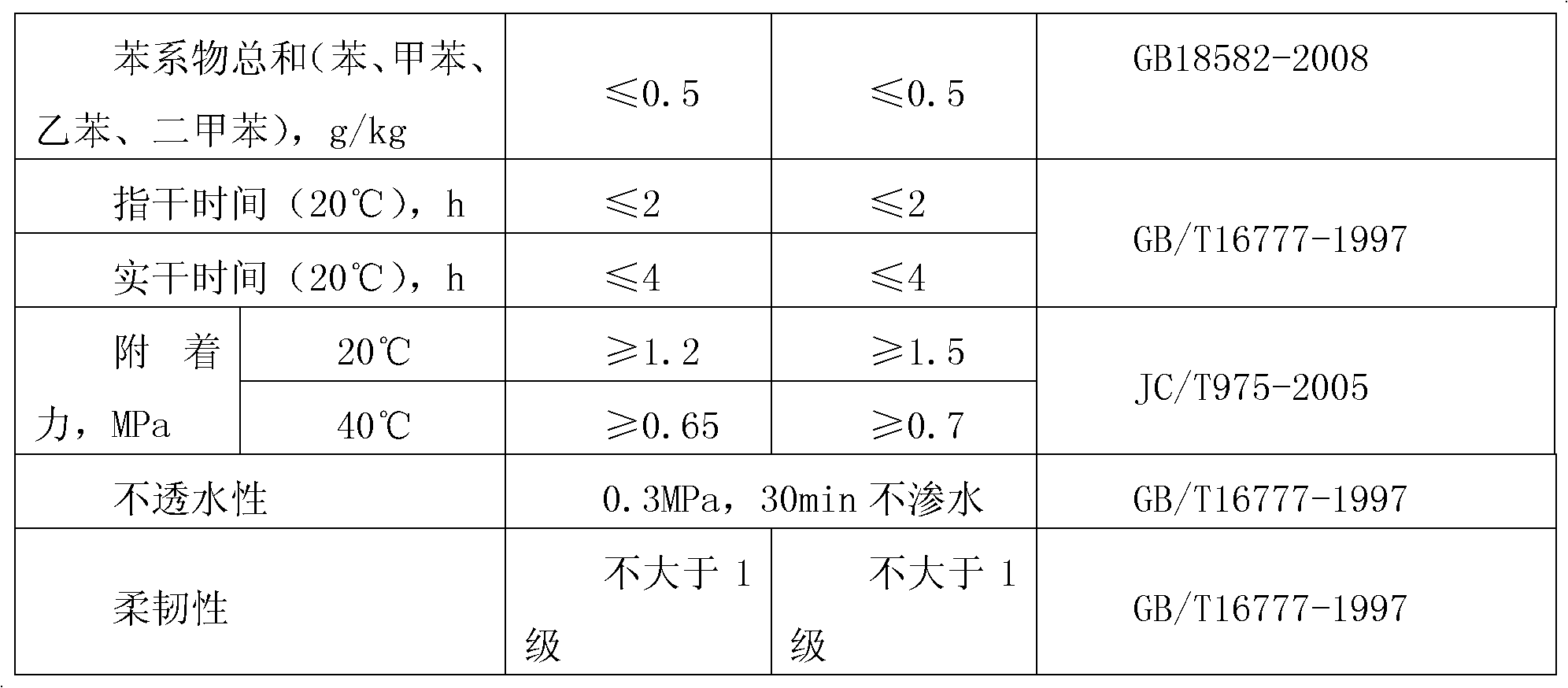

ActiveCN102153873ALow viscosityReduce penetrationNatural rubber coatingsBuilding insulationsPolymer sciencePetroleum

The invention discloses a waterproof adhesive, which is prepared from raw materials including 100 parts of asphalt, 10 to 50 parts of rubber, 10 to 50 parts of resin and 100 to 200 parts of solvent, wherein the asphalt is No.70, No.90 or No.110 petroleum asphalt; the rubber is natural rubber or / and synthetic rubber, and the synthetic rubber is styrene-butadiene-styrene (SBS) or / and neoprene; the resin is one or a random combination of more of petroleum resin, coumaroneindene resin and abietic resin; and the solvent is one or a random combination of more of isopropyl acetate, acetic ether, butyl acetate, isobutyl alcohol, isopropanol and ethanol. The waterproof adhesive is directly sprayed onto treated cement concrete pavement, bridge surface or steel bridge surfaces, and has low viscosity, high permeability, high waterproof performance, high adhesive force, high compatibility with and high affinity to asphalt concrete in a paved layer, the coating has high toughness and strength, the adhesive force for cement of the adhesive can reach over 1.2Mpa and the adhesive force for steel plate can reach over 1.5Mpa; meanwhile, the adhesive disclosed by the invention is nontoxic, safe and environmentally friendly, and the total content of benzene series is not more than 0.5g / kg.

Owner:重庆市智翔铺道技术工程有限公司

Novel alkyd resin containing titanium and preparation method of alkyd resin

The invention discloses novel alkyd resin containing titanium. A preparation method of the novel alkyd resin includes the following steps that 1, polyatomic acid anhydride, monobasic acid, polyhydric alcohol, vegetable oleic acid and antioxidant are mixed in a reaction kettle, a reaction is conducted at the temperature of 150-250 DEG C till the acid value is smaller than 15, and then the temperature is lowered to 30-100 DEG C; 2, then organic solvent and organic titanium are added and stirred to be uniform, and a reaction is conducted for 4-8 hours at the temperature of 80-120 DEG C; the organic solvent is one or more of fat hydrocarbon solvent oil, n-butyl acetate, acetic ether and acetic acid methyl ester; the weight ratio of polyatomic acid anhydride to monobasic acid to polyhydric alcohol to vegetable oleic acid to antioxidant to organic solvent to organic titanium is (130-150): (18-25): (125-145): (240-260): (1-2): (480-510): (38-46). The alkyd resin containing titanium prepared through the preparation method is high in drying speed, lustrousness and hardness, good in adhesive force and free of toxic or harmful substance.

Owner:CHENGDU SUPPON CHEM IND CO LTD

Method for purifying acrylic acid

The invention relates to the process for purifying acrylic acid which comprises using novel organic extracting agent to separate acrylic acid from its water solution, then removing light compositions such as water and acetic acid by azeotropic fractional distillation, wherein the organic extracting agent comprises toluene, acetic ether, butyl acetate, butyl acetate, propionic ether, diisobutyl ketone, isophorone, methyl phenyl ether or their mixture, preferably the composite compound of toluene with isobutyl phenylacetate, the mass ratio of toluene and isobutyl phenylacetate is between 1:1-1:50, preferably 1:2-1:12. The process according to the invention can realize high acetic acid removing ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

Matte varnish and preparation method thereof

The invention relates to wood furniture coatings, and discloses a matte varnish with high yellowing resistance and high hardness. The matte varnish is prepared by mixing a component A, a component B and a component C in the weight ratio of 1:0.5:0.5-0.6. The component A is prepared from 75-85 wt% of acrylic resin, 0.6-1 wt% of a dispersant, 1-1.5 wt% of polyethylene wax liquor, 0.5-1% of polyamide wax liquor, 0.5-1% of a leveling agent EFKA-3777, 0.05-0.2% of a leveling agent EFKA-3600, 0.05-0.1% of an anti-foaming agent, 2-3% of methyl isobutyl ketone, 0.3-0.5% of wax powder, 2.5-4.2% of a matting agent, 1.5%-2.5% of butyl acetate, 0.5-1% of an ultraviolet light absorber, 0.5-1% of a light stabilizer and 5-8% of cellulose acetate solution; the component B is a curing agent; and the component C is a diluent. The invention also discloses a preparation method of the matte varnish. The matte varnish provided by the invention has high hardness and high yellowing resistance.

Owner:广东花王涂料有限公司

Process method for recycling butanol-butyl acetate from antibiotic production wastewater

ActiveCN104151136AIncrease relative volatilityLow quality scoreOrganic compound preparationWater contaminantsButyl acetatePhase splitting

The invention relates to a process method for recycling butanol-butyl acetate from antibiotic production wastewater. The process method comprises the following steps: preheating wastewater of which the content of butanol-butyl acetate is 1-5 percentage by mass by using a tower bottom of a rectifying tower; further heating to 80-85 DEG C by using a heat exchanger, feeding into a flash column; feeding distillate from the top of the flash column into the rectifying tower; and separating the distillate. As a tubular type heat exchanger on the top of the rectifying tower is connected with a pressure reducer so that the shell pass of the rectifying tower and the tubular type heat exchanger is maintained to be less than 35kPa. The steam on the top of the tower is condensed and fed into a phase splitting tank, the light phase is fed into a tank to be detected, the heavy phase flows back, and the tower bottoms are cooled to 30-35 DEG C and discharged. By adopting the process method, the recycling rates of butanol and butyl acetate are greatly increased; by comprehensive utilization of pressure-reduced distillation and heat, the energy consumption can be reduced and remarkable practicability and economical efficiency are achieved.

Owner:HEBEI UNIV OF TECH

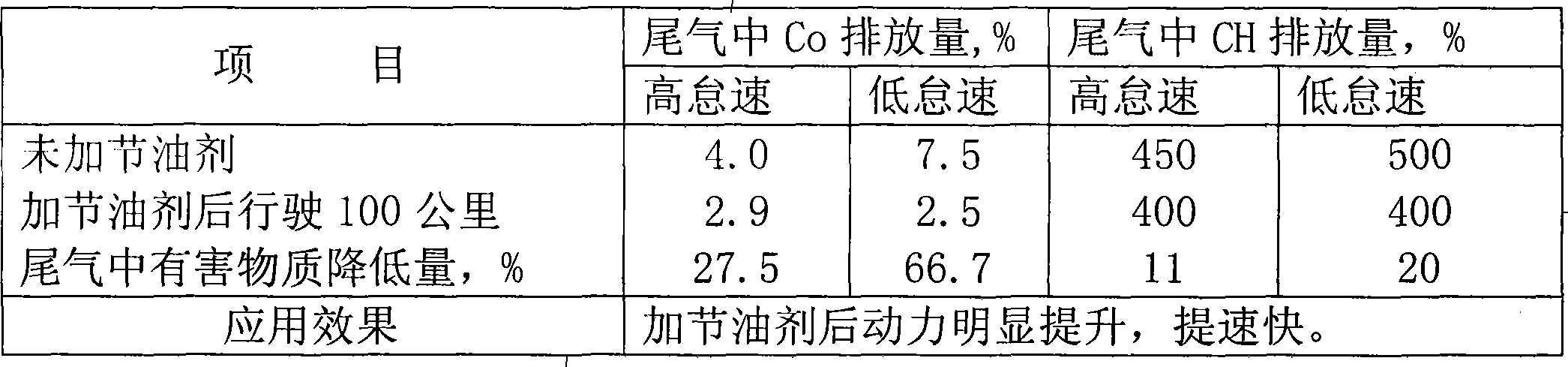

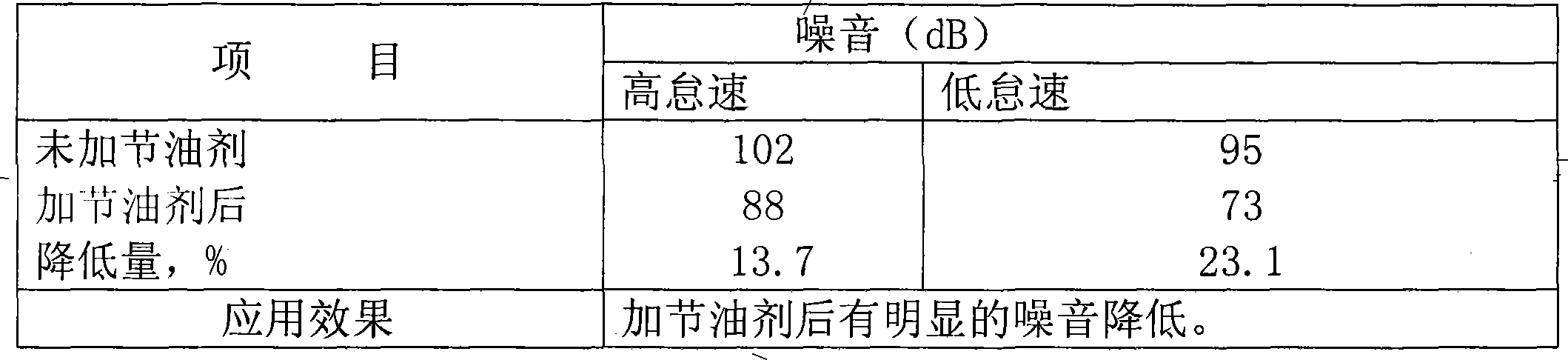

Gasoline and diesel oil additive with power-increasing and energy-saving function

The invention relates a motor fuel addictive, specifically relates to an engine fuel petrol or diesel fuel additive, belonging to biological chemical industry area. The components of the addictive include hydrogenated vegetable oil triglyceride, biological lipase, dimethyl formamide and butyl acetate. The preparation method of the butyl acetate is that: at room temperature, 1-8 portions hydrogenated vegetable oil triglycerides, 0.2-0.9 portions of biological lipases, 15-30 portions of dimethyl formamides and 55-82 portions of butyl acetates are mixed, and are agitated at the temperature of 15-25 DEG C to be uniform, so that the product is obtained. The motor fuel addictive can be directly added into petrol or diesel fuel by volume of 1:1000, has the function of enhancing motivation and saving petrol, and also can decrease exhaust pollution, protect engines and prolong service life.

Owner:山东国弘能源科技有限公司

Heat dissipation coating and preparation method

The invention provides a heat dissipation coating used for LED lights and a preparation method. The coating is characterized by comprising the following raw materials by weight parts: 40-45 parts of organic silicone resin, 18-22 parts of butyl acetate, 24-26 parts of ethyl acetate, 12-14 parts of nano-silica, 8-10 parts of nanometer titanium dioxide, 20-22 parts of aluminium nitride powder, 5-7 parts of emery powder, 1-2 parts of dibutyltin dilaurate, 2-3 parts of tributyl tin trichloride, 8-10 parts of vinyl acetate, 12-14 parts of nano bauxite, 3-5 parts of isopropyl tri(dioctyl pyrophosphate acyloxy) titanate, 1-2 parts of tetraethylenepentamine, 1-2 parts of salicylic acid, and 4-5 parts of a film forming agent. The emery powder provided in the invention is relatively high in melting point, thereby improving a high temperature resistance performance of the heat dissipation coating; the nanometer titanium dioxide has self-cleaning property, thereby helping to maintain a clean coating.

Owner:TIANCHANG JINLING ELECTRONICS

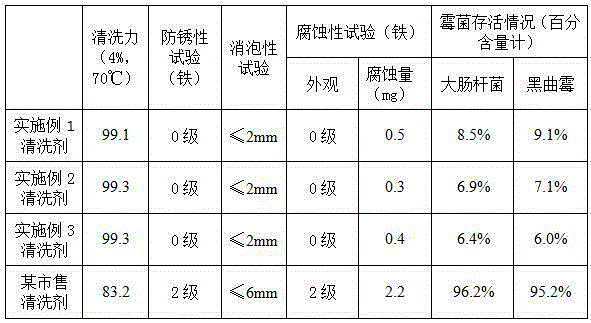

Computer electronic display screen cleaning agent and preparation method thereof

InactiveCN105238579AThe preparation process is simpleEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBenzoic acidPhosphoric Acid Esters

The present invention relates to a computer electronic display screen cleaning agent, which comprises, by mass, 52-56 parts of biochemical fulvic acid, 54-58 parts of benzotriazole, 50-54 parts of 1-hydroxyethylidene-1,1-diphosphonicacid, 54-58 parts of alkanol phosphate ester, 50-54 parts of hydroxyethylenediamine, 54-58 parts of sodium ligninsulfonate, 50-54 parts of caprylic / capric triglyceride, 56-60 parts of benzoic acid, 50-54 parts of potassium dihydrogen phosphate, 54-58 parts of polyacrylamide, 50-54 parts of polyethylene glycol stearate, 54-58 parts of sodium humate, 50-54 parts of polyepoxysuccinic acid, 54-58 parts of mercaptobenzothiazole, 50-54 parts of isothiazolinone, 54-58 parts of cyclic silicone oil, 50-54 parts of lecithin, 54-58 parts of permethrin, 50-54 parts of butyl acetate, 54-58 parts of dodecyl dimethyl benzyl ammonium chloride, 50-54 parts of benzimidazole allyl thioether, 54-58 parts of aliette, 50-54 parts of a silver ion antibacterial agent, and 1000-2000 parts of water. The cleaning agent of the present invention has good cleaning ability.

Owner:龚灿锋

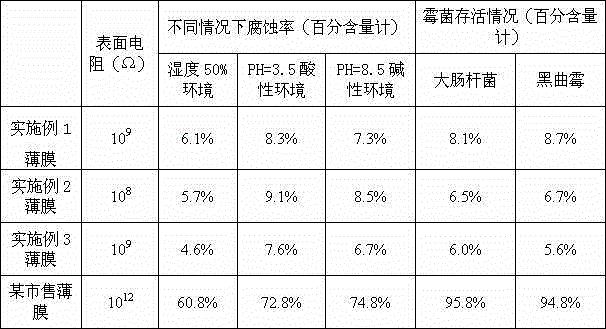

Anti-static multifunctional thin film and preparation method thereof

InactiveCN105153597AReduce frictional resistanceSlow lubricating mediumPhosphorous acidPolymer science

The invention relates to an anti-static multifunctional thin film which comprises the following ingredients by mass: 36 to 40 parts of PC resin, 38 to 42 parts of polyvinyl chloride resin, 34 to 38 parts of polythiophene, 38 to 42 parts of polyethylene glycol, 34 to 38 parts of polyphenylene vinylene, 34 to 38 parts of 2-hydroxyethyl methyl terephthalate, 40 to 44 parts of permethrin, 34 to 38 parts of polythene grafted maleic anhydride, 38 to 42 parts of triphenyl phosphite, 34 to 38 parts of poly-methylene-ether-diol, 38 to 42 parts of anti-static master batch, 34 to 38 parts of tetra-thio-naphthacene, 38 to 42 parts of polyaryl ether nitrile, 34 to 38 parts of octenyl succinic starch ester, 38 to 42 parts of polylactic acid, 34 to 38 parts of a Ca-Zn composite stabilizer, 38 to 42 parts of erucamide fluorescent powder, 34 to 38 parts of butyl acetate, and 38 to 42 parts of a lubricant. The anti-static multifunctional thin film is relatively corrosion-resistant, antistatic, anti-bacterial, and mildew-proof; the thin film product prepared according to the invention is suitable for various fields.

Owner:SHAOXING XIANGYU GREEN PACKING CO LTD

Matte white paint and preparation method thereof

The invention relates to a wooden furniture paint, and discloses a matte white paint having high yellowing resistance and high hardness. The matte white paint is formed by mixing a component A, a component B and a component C with the weight ratio of the component A to the component B and the component C to be 1:0.4-0.5:0.6. The component A is prepared from the following components in percentage by weight: 55-65% of titanium dioxide starch, 18.6-25% of acrylic resin, 0.6-1% of a dispersing agent, 1.5-2% of polyamide wax starch, 0.5-1% of a flatting agent EFKA-3777, 0.05-0.1% of a flatting agent EFKA-3600, 0.05-0.1% of an antifoaming agent, 1-2.5% of methyl isobutyl ketone, 0.3-0.5% of wax powder, 2.5-4.2% of delustering powder, 1-1.5% of butyl acetate, and 6-10% of an acetic acid cellulose solution; the component B is a curing agent component; the component C is a diluent component. The invention further discloses the matte white paint and the preparation method thereof. The matte white paint disclosed by the invention has high hardness and high yellowing resistance.

Owner:广东花王涂料有限公司

Abamectin emulsion in water and preparation method thereof

The invention provides abamectin emulsion in water. The emulsion in water is composed of the following components in percentage by weight: 1-7% of abamectin, 3-15% of an organic solvent, 2-6% of a macromolecular emulsifying agent, 4-10% of an anti-freezing agent and the balance of water, wherein the macromolecular emulsifying agent is obtained by three types of monomers including an acrylic acid type acid or ester, alkenyl ammonium chloride and allyl amide at the mol ratio of 1 to (0.05-0.5) to (0-0.5) through inverse emulsion polymerization, wherein the pH value of the polymer is 5-9 at 25 DEG C, the viscosity of 1% de-ionized water dispersion liquid is 100mPa*s to 10000mPa*s and the relative molecular weight is 500000-20000000; and the organic solvent is one or more of toluene, xylene, kerosene, ethanol, acetone, cyclohexanone, methyl ethyl ketone, isopropanol, butanol, acetic ether, butyl acetate and solvent gasoline. By virtue of the emulsion in water, abamectin, which has extremely low solubility in the water, oil or organic solvent, can form a stable and efficient water emulsion system. The invention further provides a preparation method of the abamectin emulsion in water.

Owner:SHANTOU SHENTAI NEW MATERIAL TECH DEV CO LTD

Environment-friendly organosilicone pressure-sensitive adhesive and preparation method thereof

The invention provides an environment-friendly organosilicone pressure-sensitive adhesive and a preparation method thereof. PMA, DBE, EGDA, n-butyl acetate and other environment-friendly solvent are adopted, are free of toxin to human bodies, and avoid the environment pollution; in addition, through the cooperation of PMA, DBE, EGDA and n-butyl acetate, the combination of high-boiling-point solvent and low-boiling-point solvent is formed, the solubility of the organosilicone pressure-sensitive adhesive is better, the proper volatile gradient of the solvent is formed when the adhesive is applied and cured in the adhesive tape manufacturing process, and the prepared pressure-sensitive adhesive tape is more smooth in surface and more excellent in transparency and prevents adhesive residues.

Owner:湖北新四海化工股份有限公司

Insulating coating special for high-voltage lines

InactiveCN103773138AImprove wear resistanceImprove insulation performanceAnti-corrosive paintsGlycerolEthylic acid

The invention provides an insulating coating special for high-voltage lines. The insulating coating is prepared from the following raw materials in parts by weight: 55-60 parts of polytetrafluoroethylene emulsion, 20-25 parts of silica powder, 10-13 parts of titanium dioxide, 0.5-1 part of polyethylene wax, 0.6-0.8 part of defoamer, 15-20 parts of glycerol, 16-18 parts of n-butyl acetate and 80-90 parts of water. The insulating coating has excellent non-corrosibility and high and low temperature resistance in addition to excellent insulation property, and the coating has excellent wear resistance.

Owner:NANTONG TIANMING PHOTOELECTRIC TECH

PU smell removing polyurethane coating as well as preparation and application thereof

ActiveCN103881551AImprove fullnessFast dryingPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

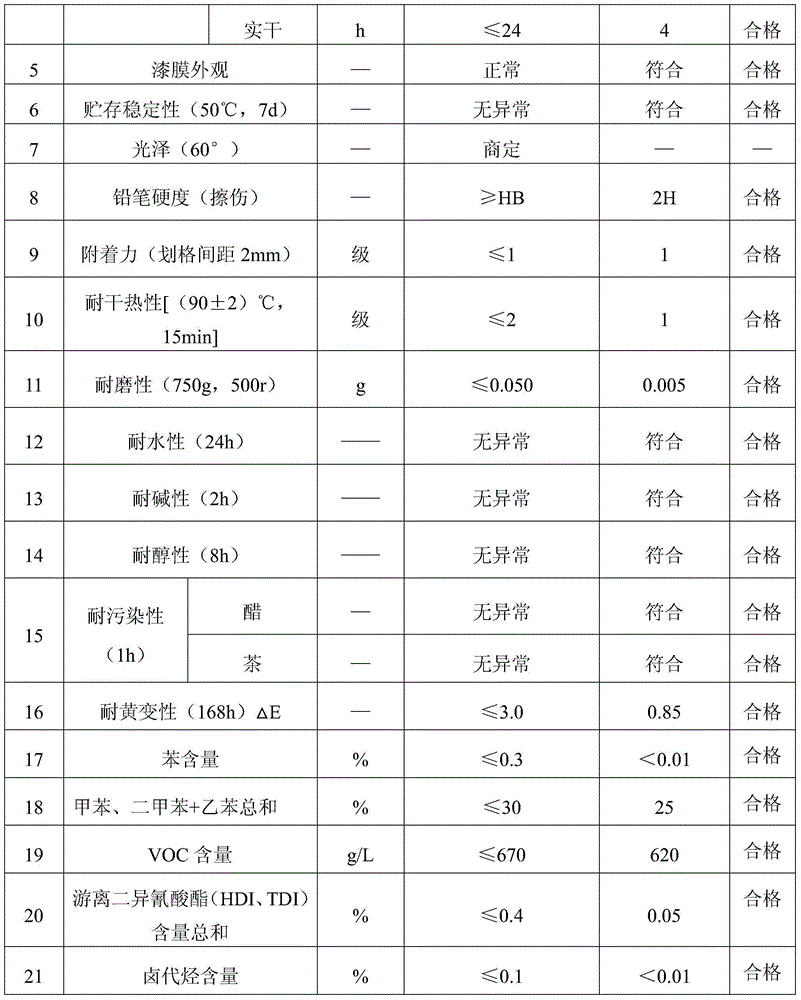

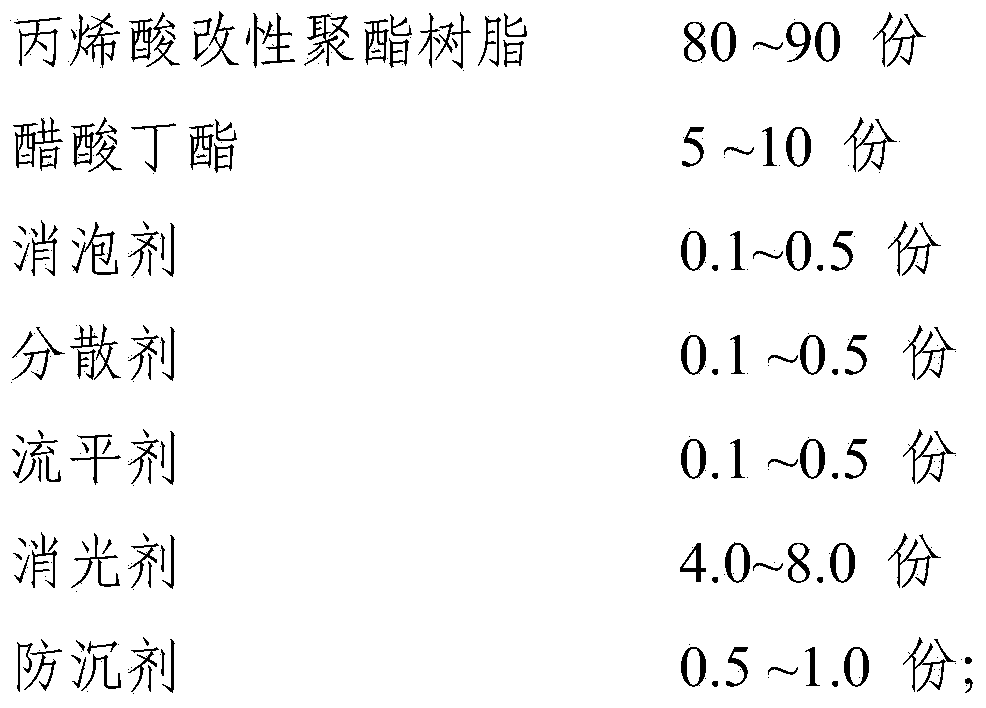

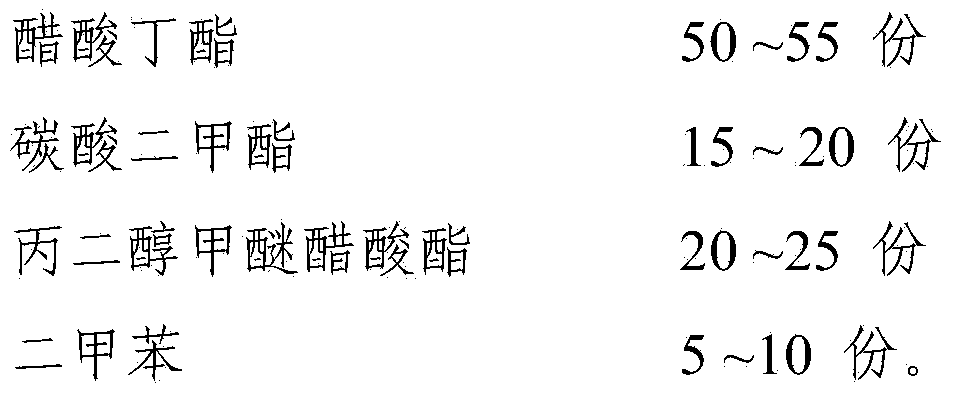

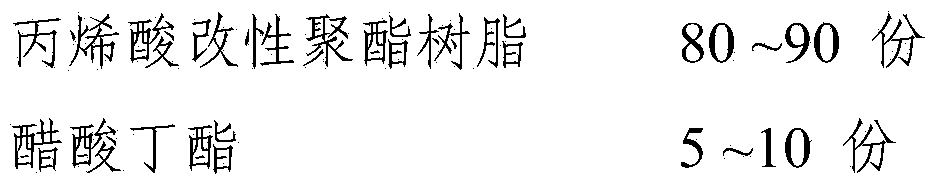

The invention provides a PU smell removing polyurethane coating which consists of a component A, a component B and a component C, wherein the component A comprises a crylic acid modified polyester resin, n-butyl acetate, a defoaming agent, a dispersing agent, a leveling agent, a delustering agent and an anti-settling agent; the component B comprises polyisocyanates, a co-polymer and n-butyl acetate; the component C comprises n-butyl acetate, dimethyl carbonate, propylene glycol monomethyl ether acetic ester and dimethylbenzene. According to the PU smell removing polyurethane coating, by modifying the double-component hydroxy acrylic resin, the characteristic that the hydroxy acrylic resin is rapid in releasing a solvent is maintained, and the fullness of the hydroxy acrylic resin is remarkably improved; the PU smell removing polyurethane coating provided by the invention not only has the characteristics of rapid drying speed, high hardness and excellent fullness, but also is small in smell. A good synergistic effect of various components of the coating is brought into play, and particularly through interaction and balancing of the resin, the solvent and the hardening agent, the coating is free of conspicuous smell after the coating is constructed and dried for 48 hours.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

Rubber composition and preparation method thereof

The invention discloses a runner composition. The rubber composition is characterized by being prepared from the following materials in parts by weight: 100-110 parts of ethylene-propylene-diene rubber, 30-40 parts of nitrile rubber, 0.5-1.5 parts of stearic acid, 0.02-2 parts of paraffins, 2-4 parts of anti-ageing agent MB, 5-10 parts of titanate coupling agent, 15-20 parts of calcium carbonate, 0-1.5 parts of antioxidant and 5-10 parts of butyl acetate. The rubber composition, which is prepared by utilizing ethylene-propylene-diene rubber and nitrile rubber, disclosed by the invention has the advantages of being excellent in oil resistance, wear resistance, ozone ageing resistance, low temperature resistance and the like.

Owner:WUJIANG DEZUO DAILY CHEM PROD

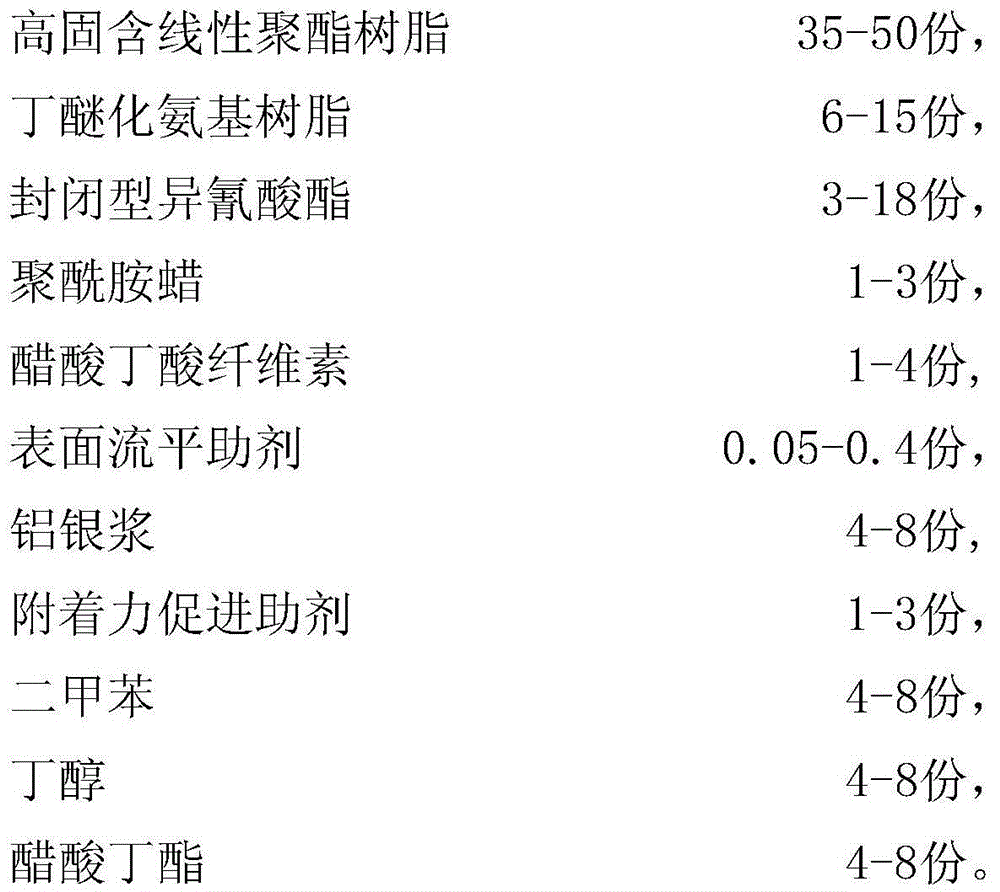

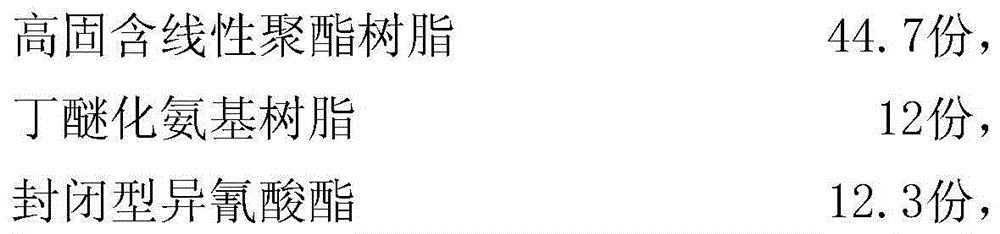

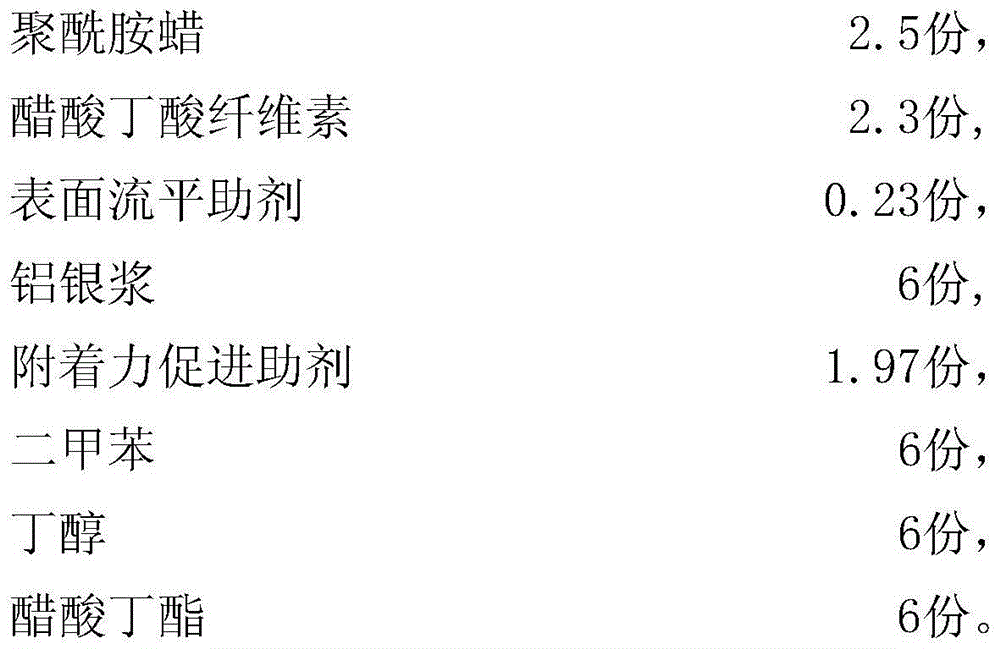

Metallic flashing lacquer capable of resisting machining and cutting, and preparation method thereof

ActiveCN103555181AReduce volatilityEmission reductionPolyurea/polyurethane coatingsLacquerPliability

The invention relates to a formula of a metallic flashing lacquer capable of resisting machining and cutting, and a preparation method of the metallic flashing lacquer. The formula comprises the following components in parts by weight: 35-50 parts of high-solid-content linear polyester resin, 6-15 parts of butylated amino resin, 3-18 parts of blocked isocyanate, 1-3 parts of polyamide, 1-4 parts of cellulose acetate butyrate, 0.05-0.4 part of surface leveling aid, 4-8 parts of aluminum paste, 1-3 parts of adhesion promoter aid, 4-8 parts of dimethylbenzene, 4-8 parts of butanol, and 4-8 parts of n-butyl acetate. The metallic flashing lacquer is less in environmental pollution, and lower in VOC content, and has excellent flexibility, surface decoration effect and finish turning and machining resistance properties.

Owner:上海金力泰化工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com