Method for producing abomacetin rhodanate

A technology of erythromycin thiocyanate and its production method, which is applied in the field of biomedicine, can solve problems such as biochemical treatment of difficult wastewater, and achieve the effects of low unit consumption of solvent, good product quality and easy treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

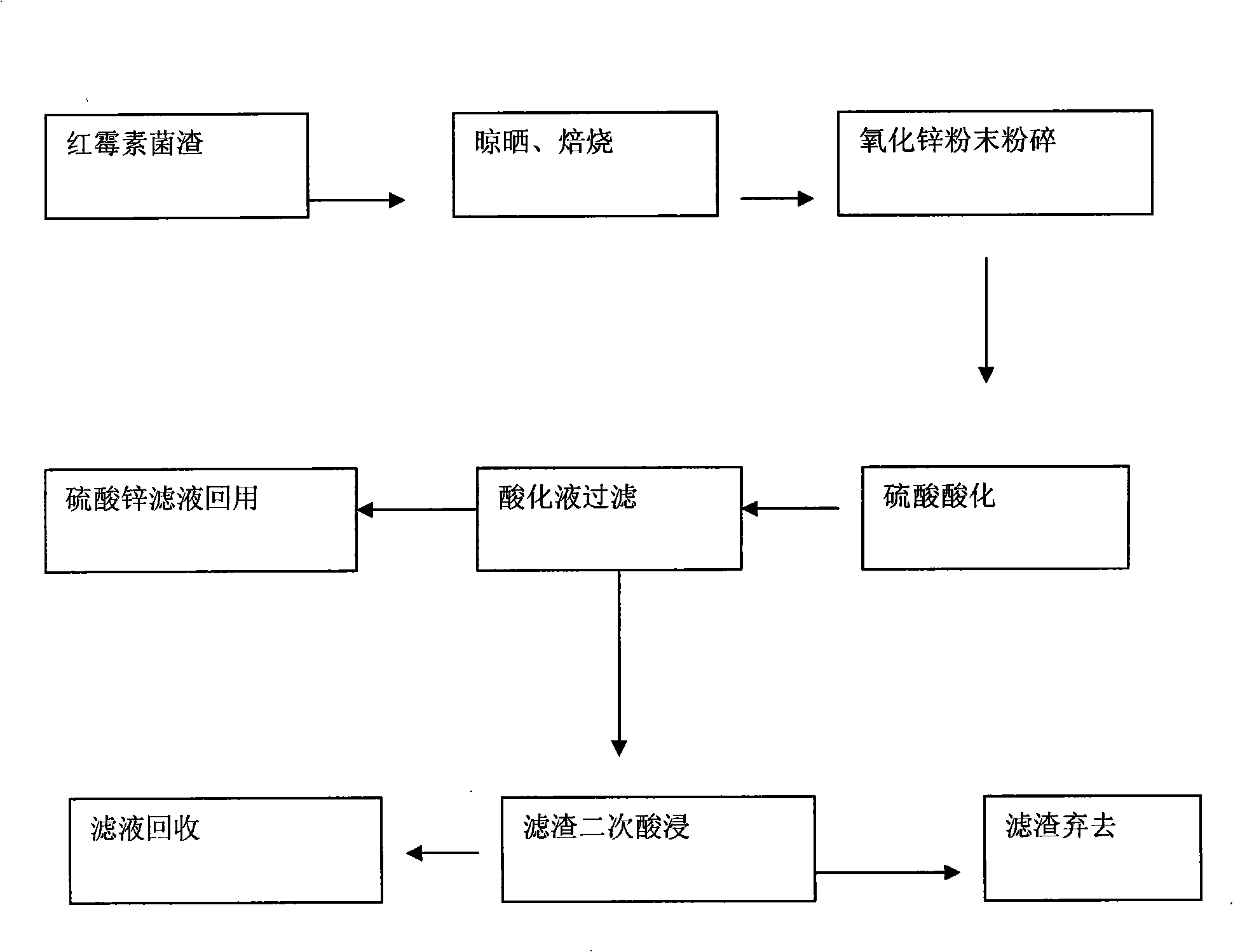

Method used

Image

Examples

Embodiment Construction

[0008] Firstly, the erythromycin filtrate is treated with a decolorizing and impurity removal resin, and then concentrated with a nanofiltration membrane with a molecular weight of 600, and concentrated to 18000u / ml~20000u / ml, and then the concentrated solution is heated to 55~56℃ and passed through Concentrated ammonia water, pH control: 9.8~10.0, ammonia flow time is 30 minutes, the crystalline solution is hot and suction filtered to obtain erythromycin base, and then erythromycin base is dissolved with butyl acetate to make it into a solution of 30,000~35000u / ml , According to the solvent extraction crystallization method for crystallization, the crystallization solution is centrifuged to obtain erythromycin thiocyanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com