In situ leaching injection process

A technology of in-situ leaching and liquid injection, which is applied to the improvement of process efficiency, mining fluids, drilling equipment and methods, etc., can solve problems such as poor stability, achieve strong adaptability, improve rare earth leaching rate, and reduce waste leaching. mineral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

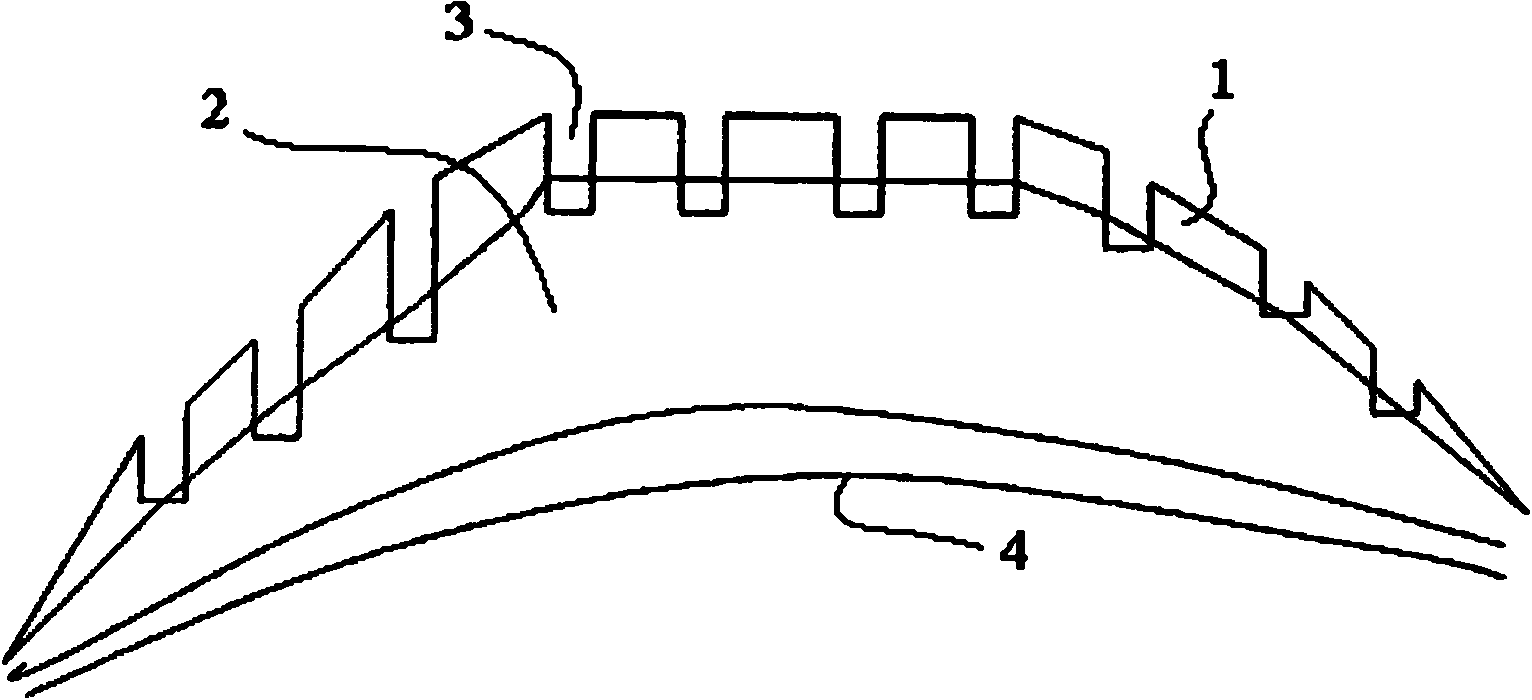

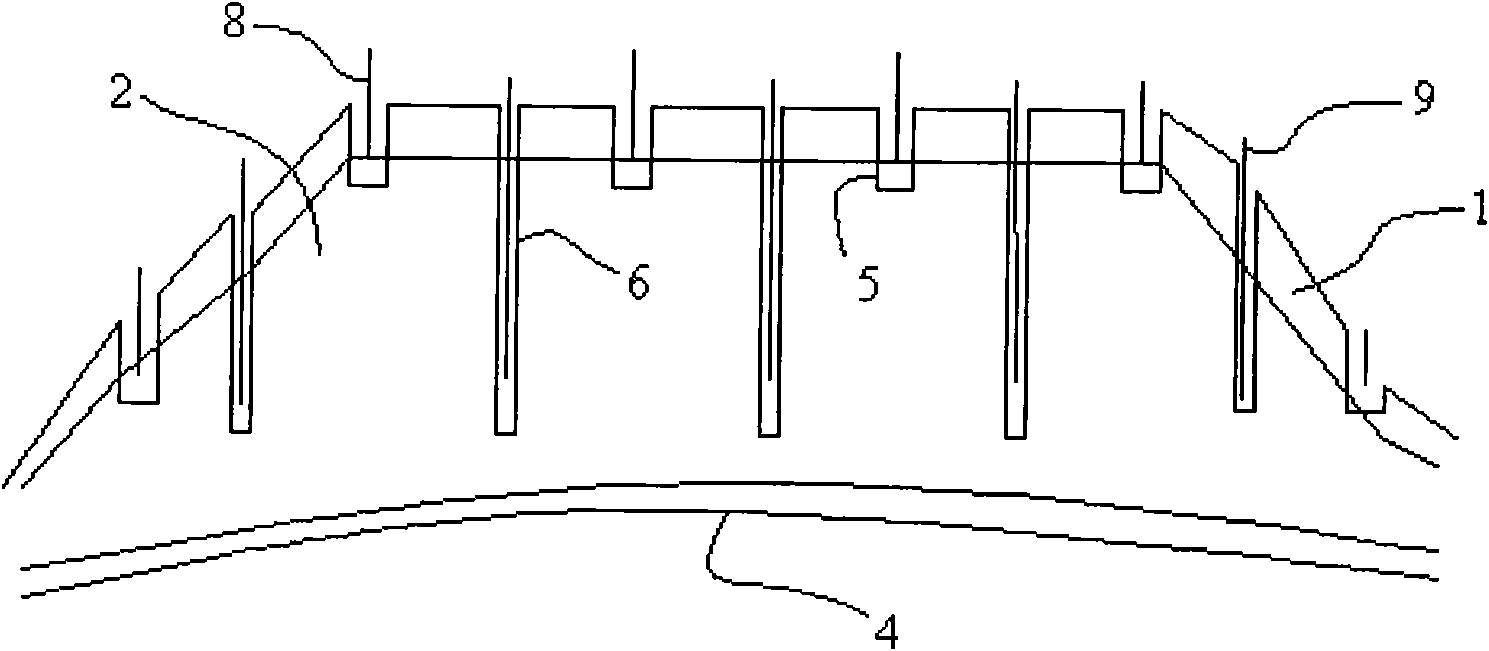

[0038] Referring to the accompanying drawings, the specific implementation method of the technical solution of the present invention is as follows:

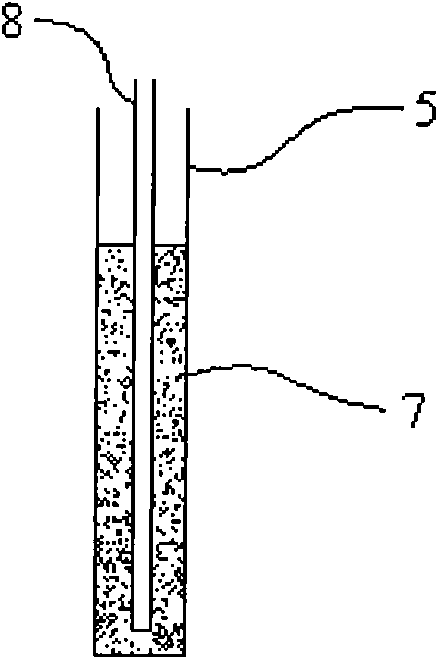

[0039] Such as figure 2 As shown, according to the spatial distribution of the ore body, the change of the thickness of the ore body, the permeability of the ore soil, and the engineering layout of the liquid collection system, etc., the special Luoyang shovel is used to set the static pressure liquid injection shallow well 5 and the general Luoyang shovel is used to set the closed well 5. Pressure deep well 6, forming a liquid injection network distributed at intervals; the distance between liquid injection wells is generally 2.5×2.5 meters, but if the ore soil is medium-coarse sand structure, it can be adjusted to 3×3 meters, and it can be adjusted to 3 meters if it is mainly clay and silt. 2 x 2 meters. The well depth of the shallow well 5 directly reaches 1 to 2 meters below the ore layer 2, and the well depth of the deep w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com