Continuous casting and rolling process for producing 3005 aluminum-plastic strip blank

An aluminum-plastic strip and casting-rolling technology, which is applied in the field of aluminum processing, can solve the problems of large aluminum burning loss and high energy consumption, and achieve the effects of reducing energy consumption, improving product yield, and reducing burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

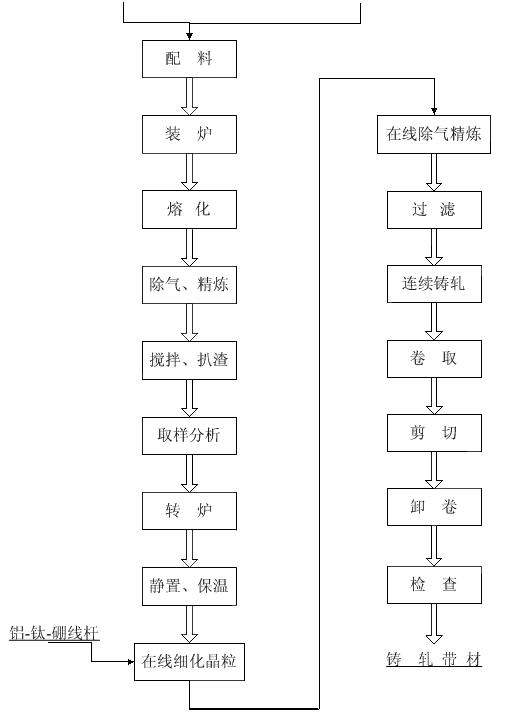

[0127] The continuous casting and rolling process for producing 3005 aluminum-plastic strip blanks includes the following steps:

[0128] 1. Melting process steps:

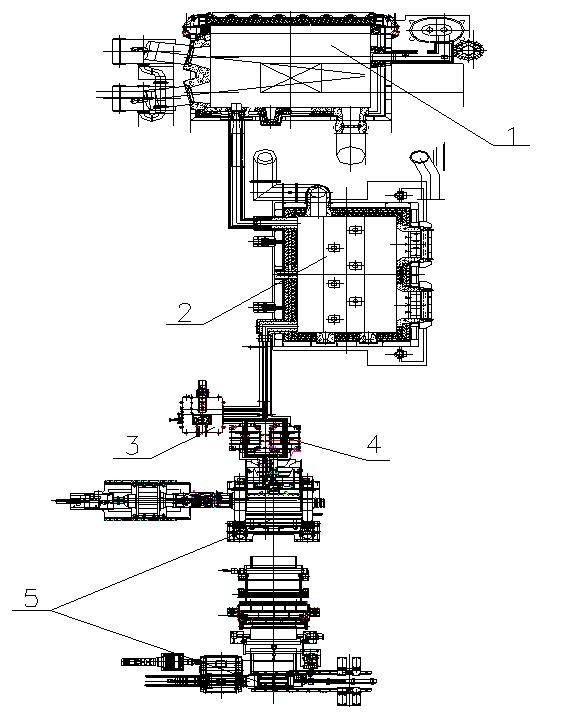

[0129] 1.1. Preparation of aluminum melting furnace 1

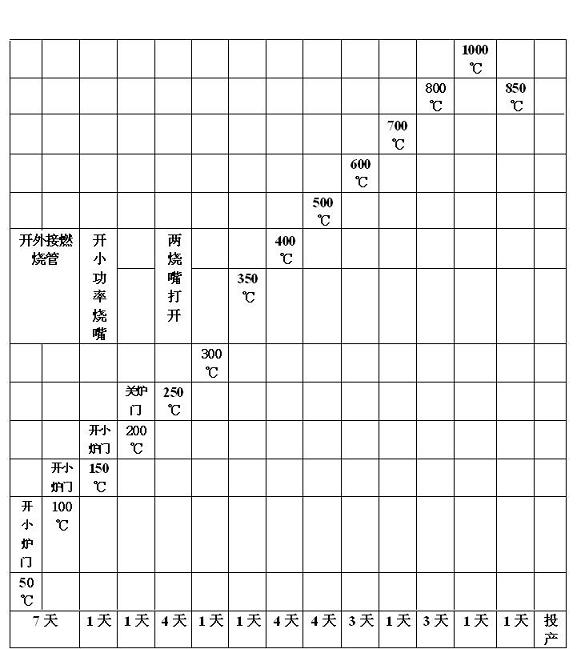

[0130] A Oven: New aluminum melting furnace 1, medium and overhauled aluminum melting furnace 1, the oven is baked according to the oven curve to drive away the moisture and ensure the use conditions of the furnace. The general oven cycle is 32 days, and the first 5 days are Open the external combustion tube to dissipate moisture, and the oven curve is as follows image 3 shown.

[0131] B Furnace washing: clean up the unqualified metal components and slag remaining in the molten pool to avoid alloy pollution in the furnace; raw aluminum can be used as the washing material for new repairs, overhauls, intermediate repairs, long-term shutdowns and alloy conversions Or the first-class waste of pure aluminum, the amount of washing material shall not be l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com