High-efficiency cutting method for crystalline silicon blocks

A cutting method and silicon block technology, which is applied in the field of silicon wafer manufacturing, can solve problems such as low yield rate, cutting speed, low efficiency, and high cost, and achieve the effects of reducing steel wire unit consumption, increasing slicing production capacity, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

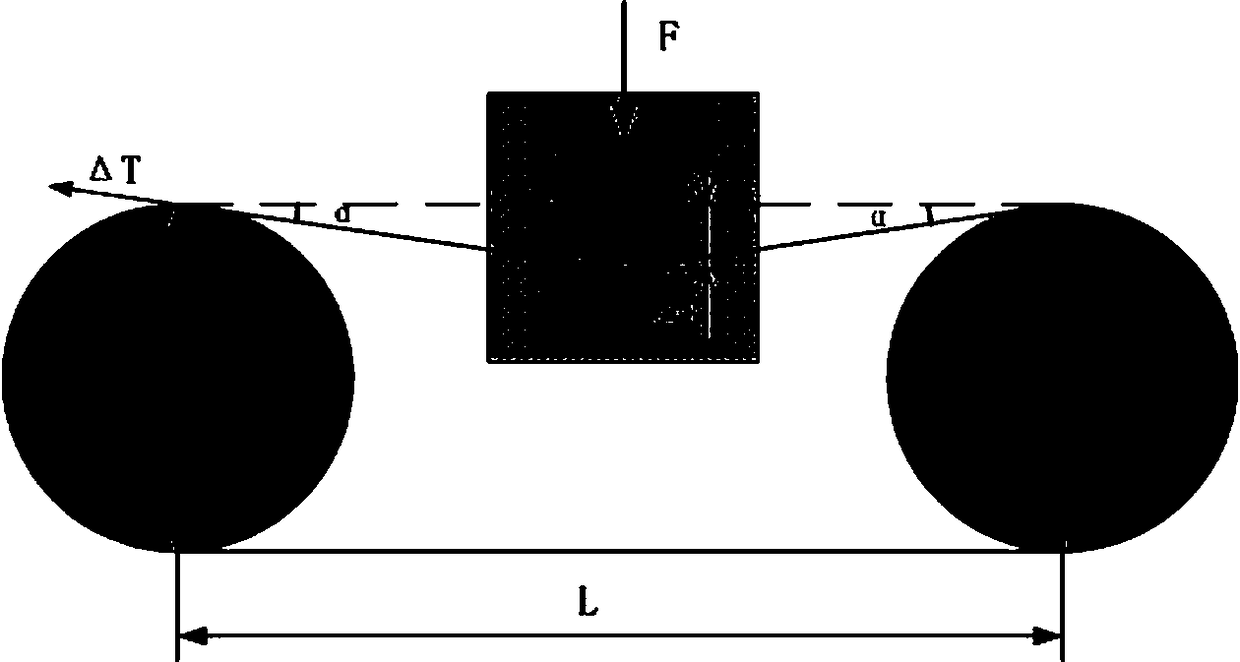

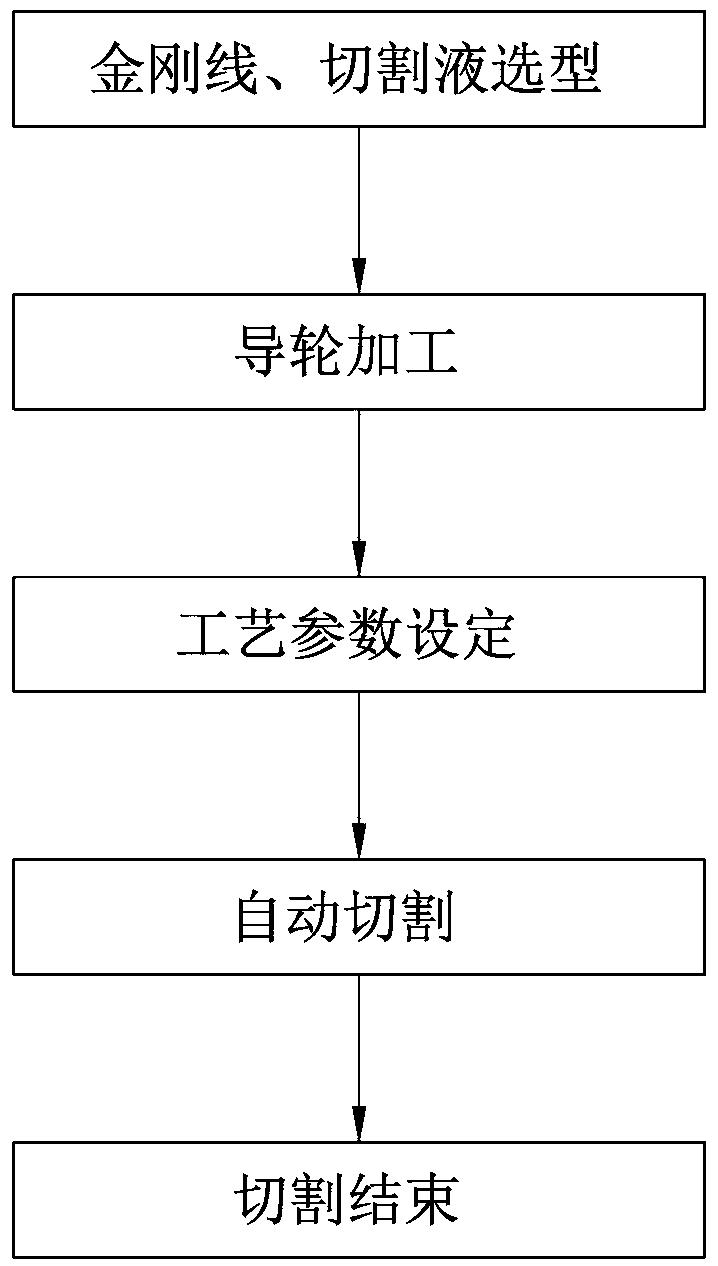

[0032] Such as figure 1 A kind of crystalline silicon block high-efficiency cutting method shown, comprises the following steps:

[0033] 1) Selection of diamond wire and cutting fluid: select single-polycrystalline mixed sand electroplated diamond wire, take 60um wire as an example, control the blade height at 5um, and control the outer diameter of the envelope at ≤81um; use low COD coolant for cutting fluid It is worth mixing with pure water, the COD of the coolant is less than 800,000 mg / L, and the surface tension is less than or equal to 35mN / m; the combination of coolant and pure water is controlled at 0.8 L / knife and added to 300L of pure water in the cylinder ;

[0034] 2) Guide wheel processing: the inclination angle of the guide wheel groove is 30°, and the groove depth is 180 μm;

[0035] 3) Process parameter setting:

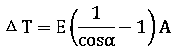

[0036] A. The cutting speed of steel wire is set to 10m / s, and the cutting ratio is a certain stage of the whole process from the zero point set b...

Embodiment 2

[0044] Such as figure 1 A kind of crystalline silicon block high-efficiency cutting method shown, comprises the following steps:

[0045] 1) Selection of diamond wire and cutting fluid: choose single-polycrystalline mixed sand electroplated diamond wire, take 60um wire as an example, control the blade height at 5.5um, and control the outer diameter of the envelope at ≤81um; use low COD cooling for cutting fluid It is worth mixing liquid and pure water, the COD of the cooling liquid is less than 800,000 mg / L, and the surface tension is less than or equal to 35mN / m; middle;

[0046] 2) Guide wheel processing: the inclination angle of the guide wheel groove is 35°, and the groove depth is 200μm;

[0047] 3) Process parameter setting:

[0048] A. The cutting speed of steel wire is set to 20m / s, and the cutting ratio is a certain stage of the whole process from the zero point set by the slicer to the end of cutting;

[0049] B. Tension setting, select the tension according to t...

Embodiment 3

[0056] Such as figure 1 A kind of crystalline silicon block high-efficiency cutting method shown, comprises the following steps:

[0057] 1) Selection of diamond wire and cutting fluid: select single-polycrystalline mixed sand electroplated diamond wire, take 60um wire as an example, control the blade height at 6um, and control the outer diameter of the envelope at ≤81um; use low COD coolant for cutting fluid It is worth mixing with pure water, the COD of the coolant is less than 800,000 mg / L, and the surface tension is less than or equal to 35mN / m; the combination of coolant and pure water is controlled at 1.5 L / knife, and it is added to 350L of pure water in the cylinder ;

[0058] 2) Guide wheel processing: the inclination angle of the guide wheel groove is 40°, and the groove depth is 220μm;

[0059] 3) Process parameter setting:

[0060] A. The cutting speed of steel wire is set to 30m / s, and the cutting ratio is a certain stage of the whole process from the zero point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com