Artificial graphite negative electrode material, preparation method, application and battery

An artificial graphite negative electrode and graphite crushing technology, which is applied to graphite, secondary batteries, battery electrodes, etc., can solve the problems of high cost of artificial graphite, ineffective use of by-products, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

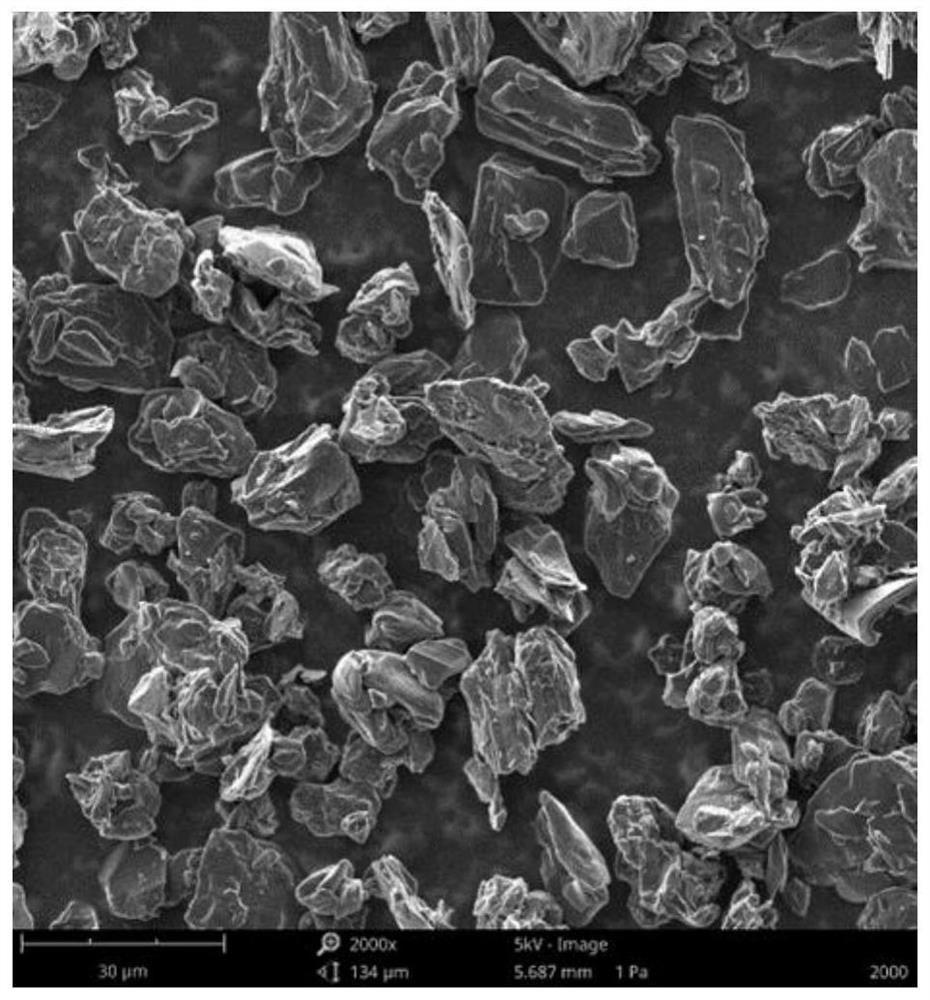

[0056](1) Grinding electrode graphite pieces with a diameter of 20 mm through a mechanical pulverizer LHJ-150, the average particle size D50 after classification is 14.0 μm, and using an electromagnetic demagnetizer ZR0709 to remove the magnetic substances in the above-mentioned graphite pieces to obtain a precursor The magnetic substance content of A is 0.4ppm;

[0057] (2) Put the precursor A and the epoxy resin into the fusion machine ZSJ-600 according to the mass ratio of 100:9, and carry out the modification treatment. The speed of the fusion machine is 800HZ, and the temperature of the modification treatment is 20°C. The modification treatment time is 4 minutes, and the precursor B is obtained;

[0058] (3) Under a nitrogen atmosphere, place the precursor B in a carbonization furnace for carbonization, raise the temperature to 1200° C. and keep it at the same temperature for 5 hours to obtain an artificial graphite anode material.

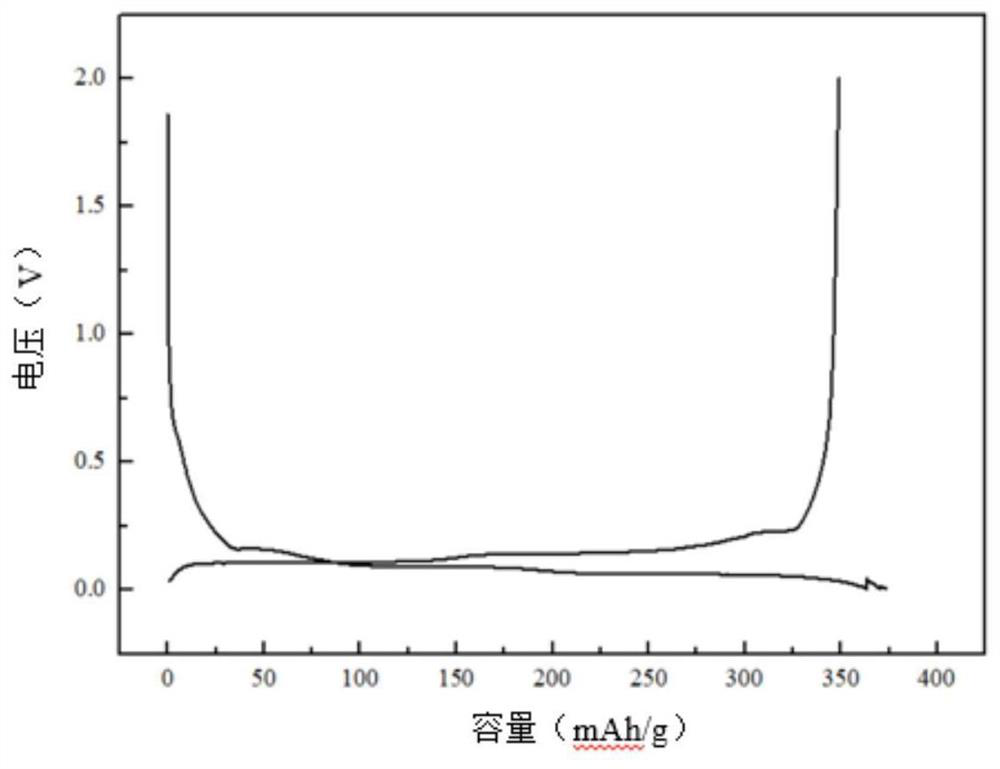

[0059] The particle diameter D50 of t...

Embodiment 2

[0061] (1) with embodiment 1 step (1);

[0062] (2) Put the precursor A and the epoxy resin into the fusion machine ZSJ-600 according to the mass ratio of 100:12, and carry out the modification treatment. The speed of the fusion machine is 800HZ, and the temperature of the modification treatment is 20°C. The modification treatment time is 4 minutes, and the precursor B is obtained;

[0063] (3) With embodiment 1 step (3).

[0064] The particle diameter D50 of the artificial graphite negative electrode material that embodiment 2 obtains is 16.9 μ m, and tap density is 0.90 g / cm 3 , the specific surface area is 1.5m 2 / g, the magnetic substance content is 1.0ppm, the discharge capacity is 348.0mAh / g, the first efficiency is 92.3%, and the 1C / 1C 500 cycle capacity retention rate is 92.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com