Patents

Literature

166results about How to "The process takes a short time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

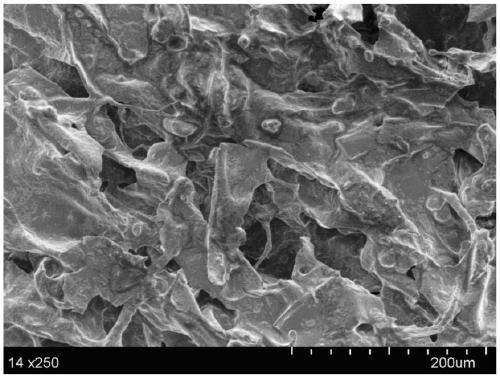

Method for preparing animal derived implantable medical biomaterial

The invention provides a method for preparing an animal derived implantable medical biomaterial. The method comprises the following steps of: pretreatment, separation and primary cleaning of an animal tissue material; virus inactivation; decellularization; sodium chloride treatment; formation; packing and sterilization. According to the animal derived decellularized extracellular cell matrix (ECM) material prepared by using the method, animal derived cell components and DNA components are completely removed, meanwhile, the components and the three-dimensional structure of the natural ECM are completely kept, active growth factors for promoting tissue regeneration can be induced, residues of endotoxin, organic solvent and toxic solvent are avoided, and products with different sizes, thicknesses and mechanical strengths can be formed according to different indications.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

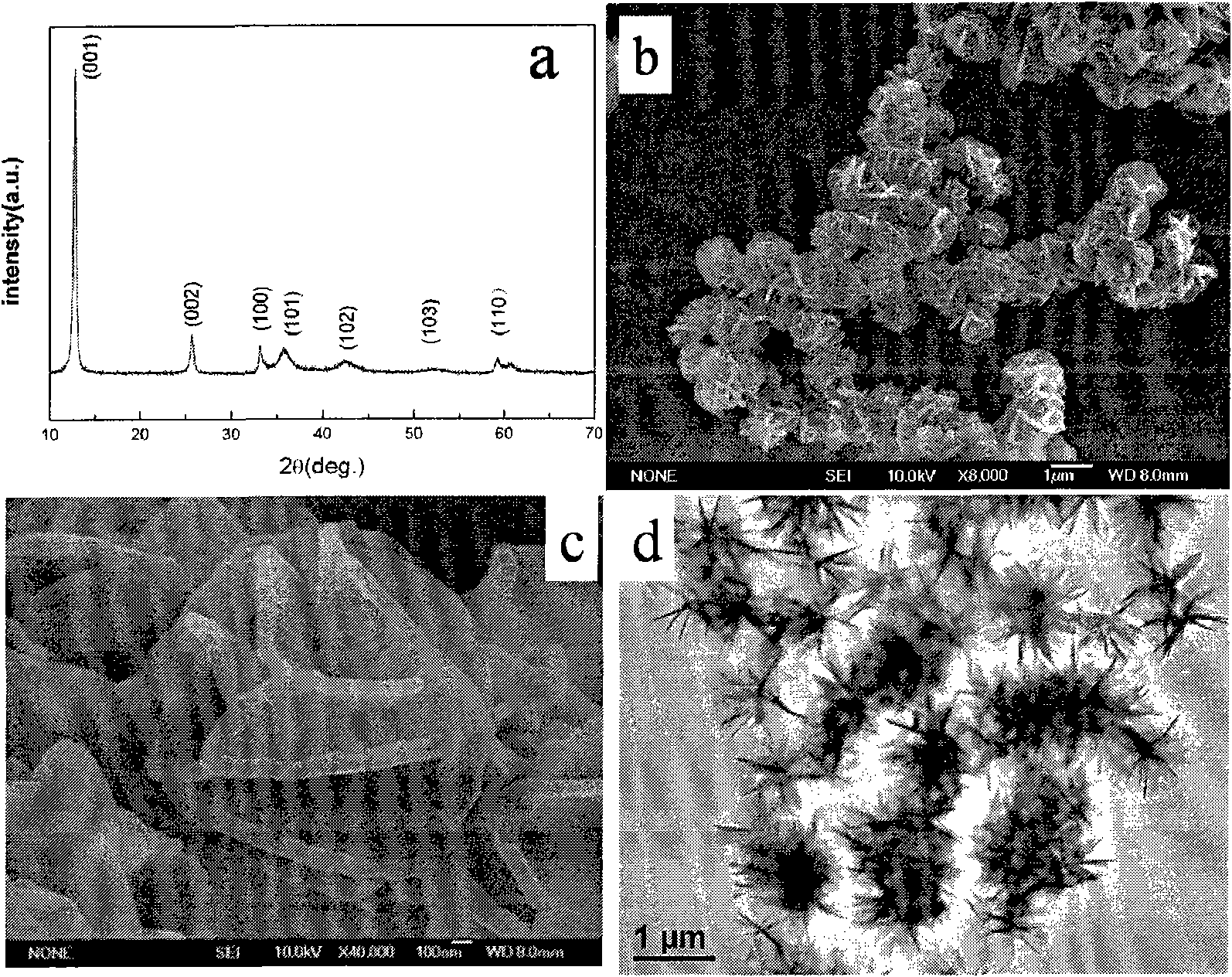

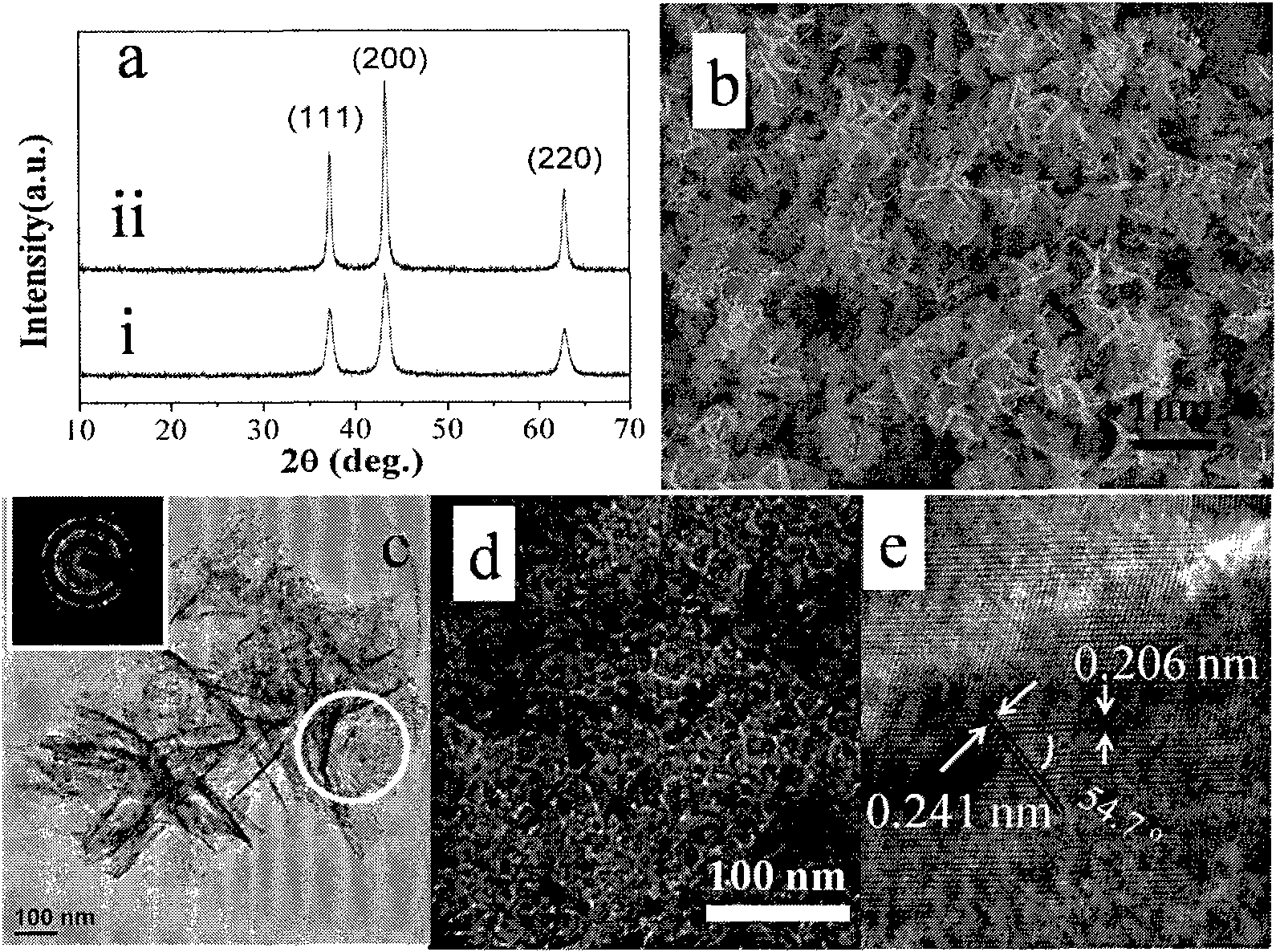

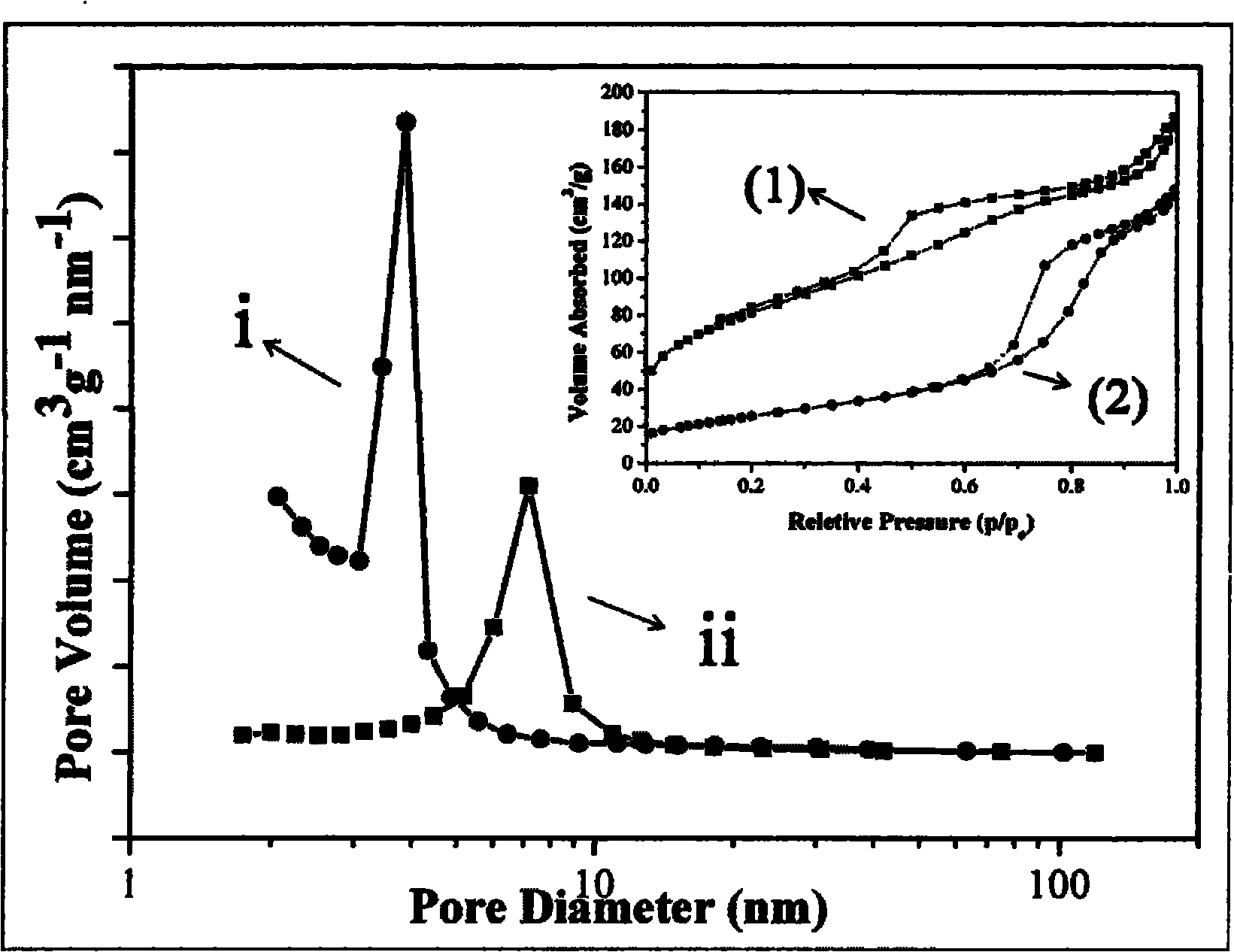

Method for preparing multilayer alpha-Ni(OH)2 or NiO nanocrystal by microwave solvothermal method

InactiveCN101985367ASimple ingredientsReduce crystallinityNickel oxides/hydroxidesReaction temperatureSolvent

The invention relates to a method for preparing multilayer alpha-Ni(OH)2 or NiO nanocrystal by a microwave solvothermal method, which is characterized by adopting any nickel salt (such as Ni(NO3)2.6H2O, Ni(Ac).4H2O, NiCl2.6H2O and the like) as a single raw material and adopting a saturated monobasic alcohol in a liquid state at room temperature as a single solvent (such as ethanol, isopropanol, normal propyl alcohol and the like), and comprising the following steps: under the conditions that the reaction temperature is 150 DEG C and the reaction time is 15min, carrying out solvothermal reaction to obtain an alpha-Ni(OH)2 multilayer nano structure with uniform size; and obtaining the porous NiO multilayer nanocrystal by a calcining process. The invention is also applicable to preparation of multilayer nanocrystals of other transition metal hydroxides and oxides. In the invention, the defect that extra soft and hard templates or an auxiliary precipitation control agent is often needed in the prior methods for preparing the multilayer NiO nanocrystal is overcome.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

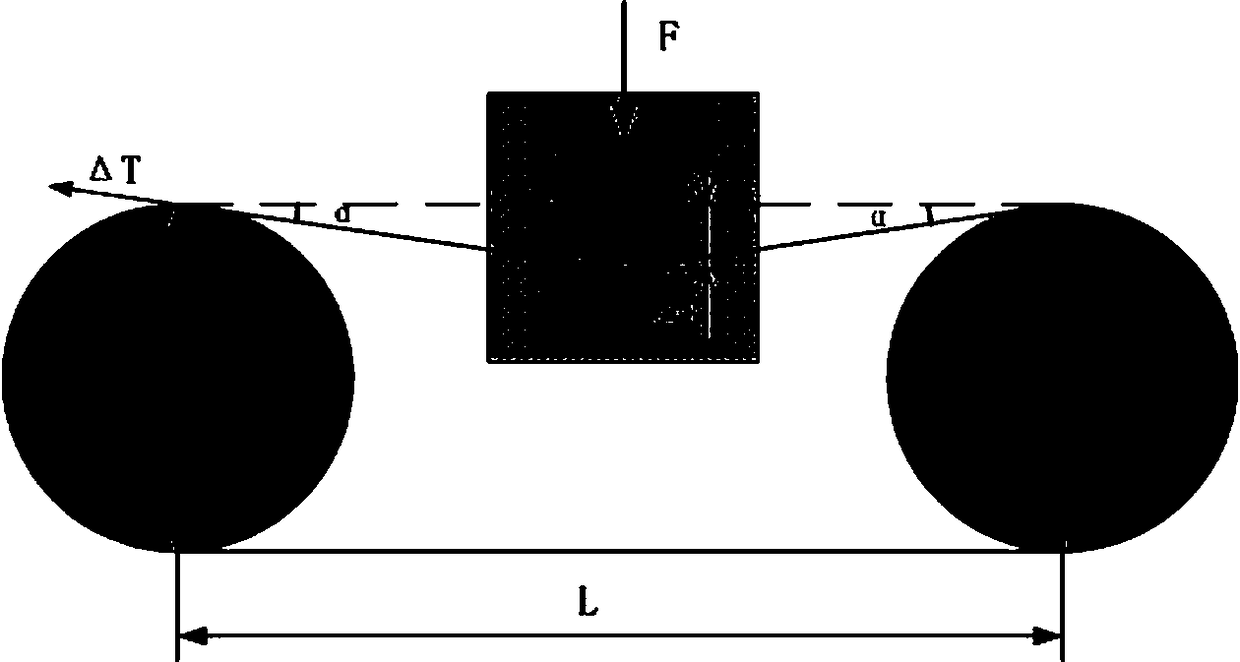

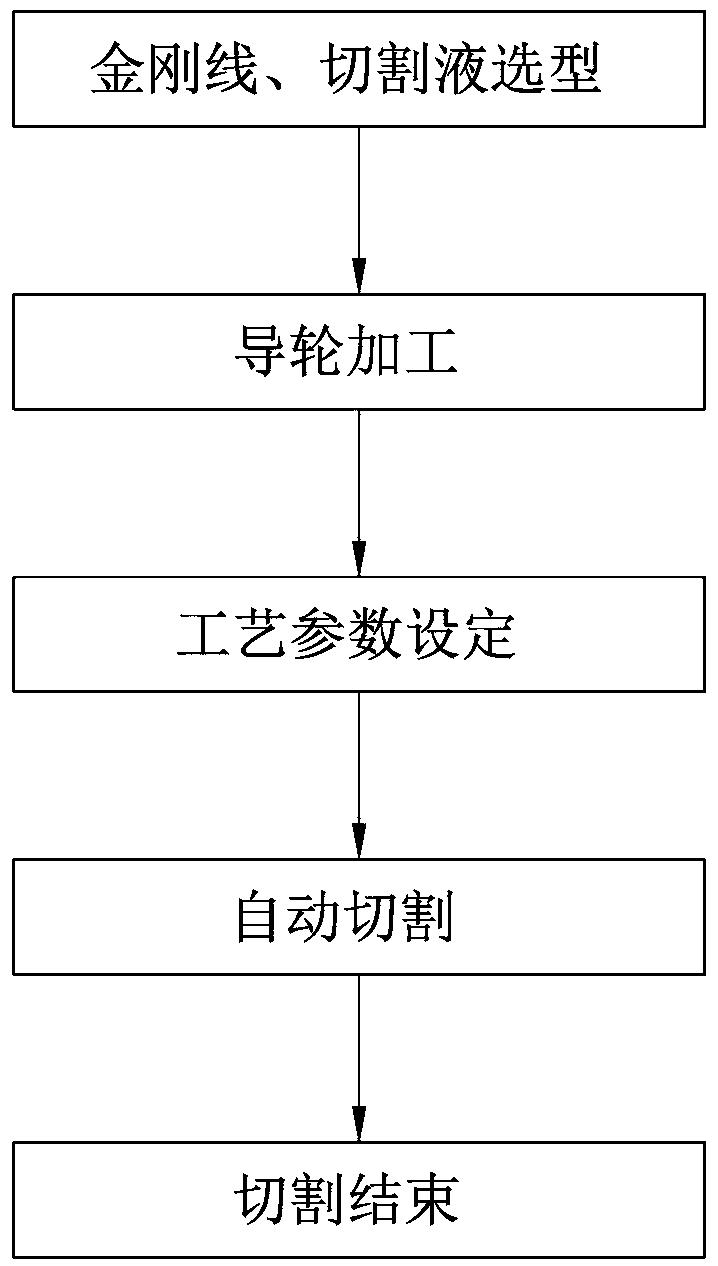

High-efficiency cutting method for crystalline silicon blocks

InactiveCN109304819AThe process takes a short timeIncrease slicing capacityFine working devicesMicrometerCrystalline silicon

The invention discloses a high-efficiency cutting method for crystalline silicon blocks in the field of solar energy application. The high-efficiency cutting method comprises the following steps of 1)diamond wire and cutting liquid selection, wherein a single-polycrystalline mixed sand electroplating diamond wire (the diamond wire diameter ranges from 50 micrometers to 70 micrometers is adopted,the cutting fluid is selected from a low COD coolant and pure water mixture; 2) guide wheel processing; 3) process parameter setting, wherein the diamond wire, the cutting fluid and a guide wheel arematched, after a cutting machine is assembled, the feeding speed of the working table is adjusted to be 800-3000micrometers per minute, the cutting fluid process flow is 110-180 KG / Min, the cutting liquid cooling temperature is 17-23 DEG C; 4) automatic cutting, wherein after the machine is started for warming up by 5-10 minutes, when it is known that the parameters are normal through spot check,automatic cutting starts; and 5) ending of cutting, wherein a rod is lifted to complete silicon block cutting. The high-efficiency cutting method effectively improves the cutting speed and the cuttingefficiency, improves the yield rate, reduces the cost of auxiliary materials like the diamond wire consumption, improves the slice profitability, and can be used for silicon wafer production.

Owner:YANGZHOU RONGDE NEW ENERGY TECH

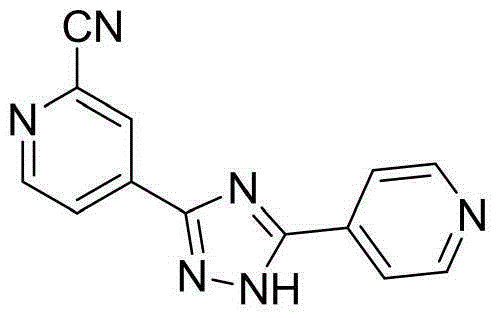

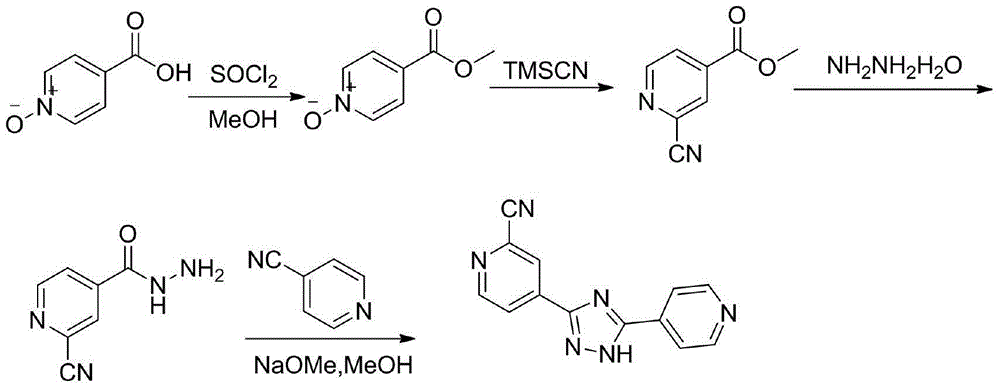

Preparation technology for 5-(2-cyano4-pyridyl)-3-(4-pyridyl)-1,2,4-troazole

InactiveCN105130958ARelieve pressureSimple processOrganic chemistryHydrazine compoundOne-pot synthesis

The invention belongs to the field of medicine and chemical engineering, and particularly discloses a preparation technology for 5-(2-cyano4-pyridyl)-3-(4-pyridyl)-1,2,4-troazole (topiroxostat). The preparation technology is characterized in that methyl isonicotinate serving as a compound II is used as a starting raw material, the compound II, phosphorus oxychloride, N,N-dimethyl formamide, iodine and 28% ammonium hydroxide form a compound III which is 2-cyano methyl isonicotinate in a one-pot synthesis mode, then a compound IV which is 2-cyano isonicotinyi hydrazine is formed through synthesis, a topiroxostat crude product Ia is prepared through condensing the compound IV which is 2-cyano isonicotinyi hydrazine and 4-cyanopyridine, salifying is performed on the crude product Ia and para-toluenesulfonic acid to form topiroxostat tosilate Ib, and finally the topiroxostat finished product I is obtained through desalting in a refined mode. The number of reactions steps is reduced, the yield of the finished product is increased, the reaction process is low in toxin and has small influences on environment, the reaction route is short, the cost is greatly lowered, the product purity is larger than 99.7%, the net contamination is smaller than 0.1%, and standard requirements are met.

Owner:JINAN KANGHE MEDICAL TECH

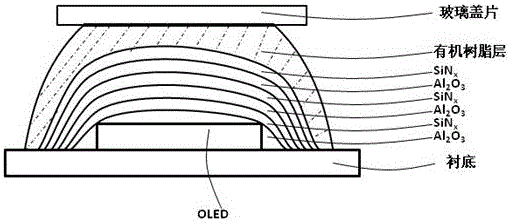

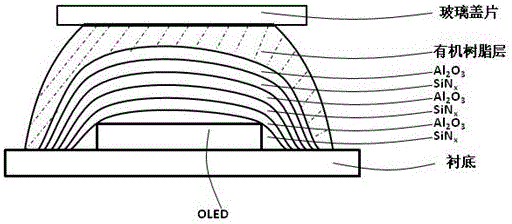

Organic light-emitting device (OLED) packaging structure and method

InactiveCN105679964AImprove compactnessMake up for the shortcomings of not being able to cover dust particles wellSolid-state devicesSemiconductor/solid-state device manufacturingGlass coverThin membrane

The invention discloses an organic light-emitting device (OLED) packaging structure and a method. The packaging structure is characterized by comprising a substrate, the OLED, a thin film packaging layer, an organic resin layer and a glass cover sheet, wherein Al2O3 thin films and SiNx thin films are sequentially overlapped to form the thin film packaging layer. In the packaging method, the Al2O3 thin film is prepared by using an atomic layer deposition technology, the SiNx thin film is prepared by using a plasma chemical vapor deposition or sputtering technology, and thus, the thin film packaging layer has high compactness, water vapor can be prevented from corroding the OLED, and the thin film packaging layer making efficiency is also improved. As the organic resin layer and the glass cover sheet are arranged on the thin film packaging layer, by using the full covering effects of the organic resin layer and the protection effects of the glass cover sheet, the service life of the device is further improved.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

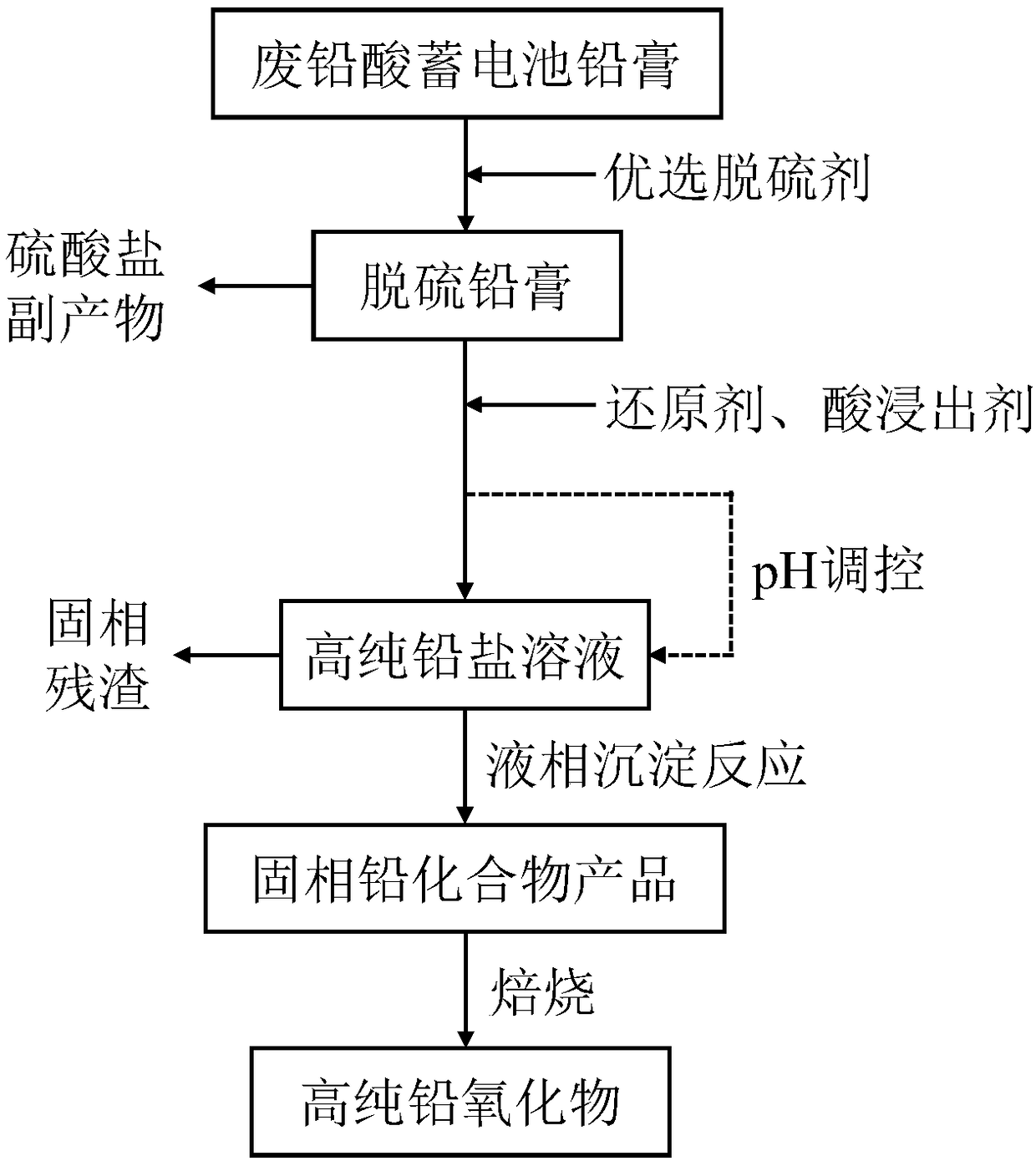

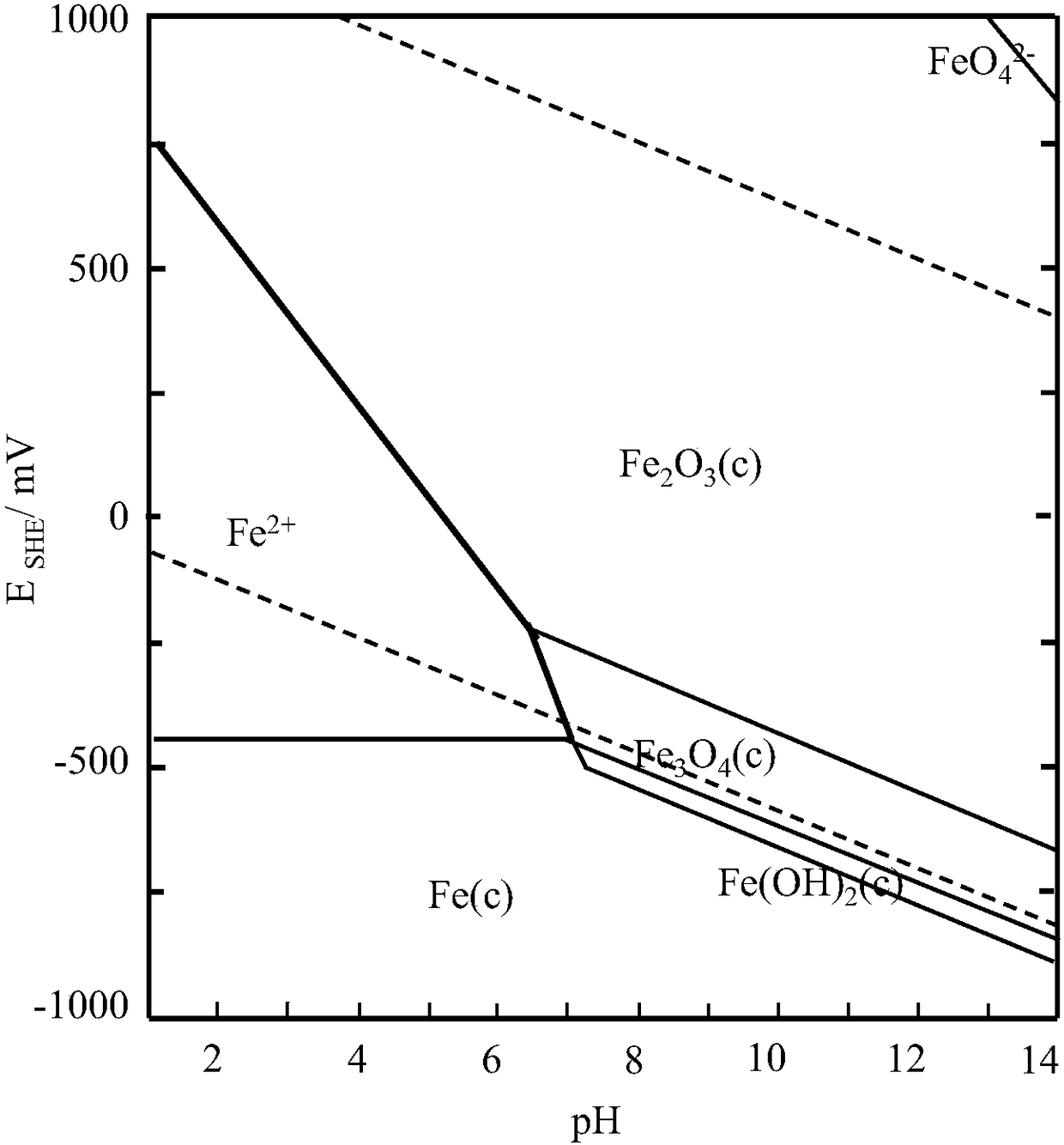

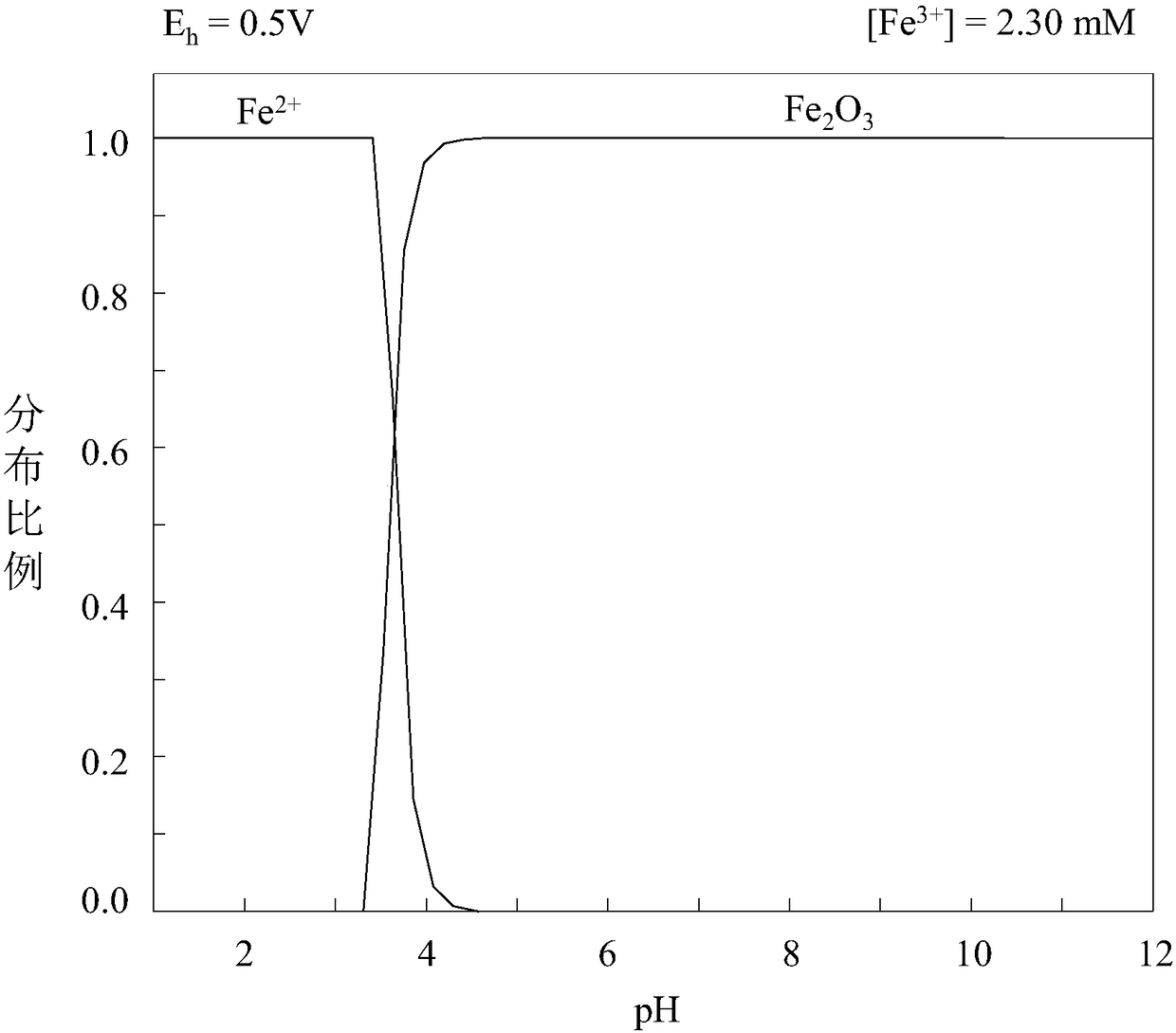

Method for preparing high-purity lead compound through wet recovery and impurity removal of waste lead plaster

The invention discloses a method for preparing a high-purity lead compound through wet recovery and impurity removal of waste lead plaster. The method comprises the following steps that 1, strong basecontaining Na and K elements is used as a basic desulfurizer for carrying out normal-temperature desulfuration on waste lead paster, the obtained desulfurated lead paster reacts with an acid leachingagent mixed with a hydrogen peroxide reducing agent, after reaction is finished, a lead salt solution is obtained by adjusting the pH value and carrying out filtration according to the variety of theacid leaching agent, or the lead salt solution is obtained through direct filtration; 2, the lead salt solution is subjected to liquid phase reaction conversion to prepare a solid phase lead compound, and lead oxide and other products can also be produced through follow-up roasting. By means of the whole process technological set of wet recovery and parameter conditions adopted by key technologysteps are improved and optimized, the high-purity lead compound (and high-purity lead oxide) can be prepared from waste lead paster through an acid leaching wet recovery method, and the problems thattwo impurity elements Ba and Fe are high in content and not likely to be removed are solved.

Owner:HUAZHONG UNIV OF SCI & TECH

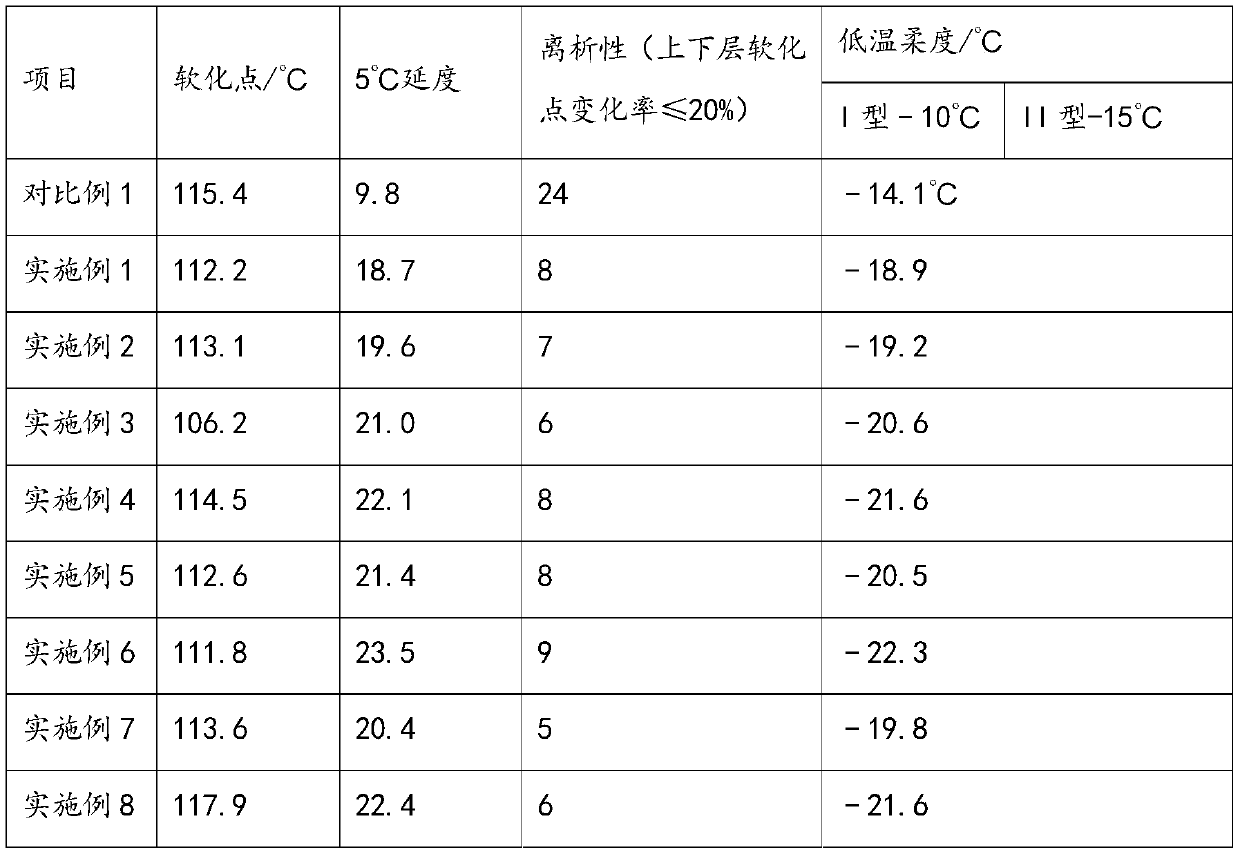

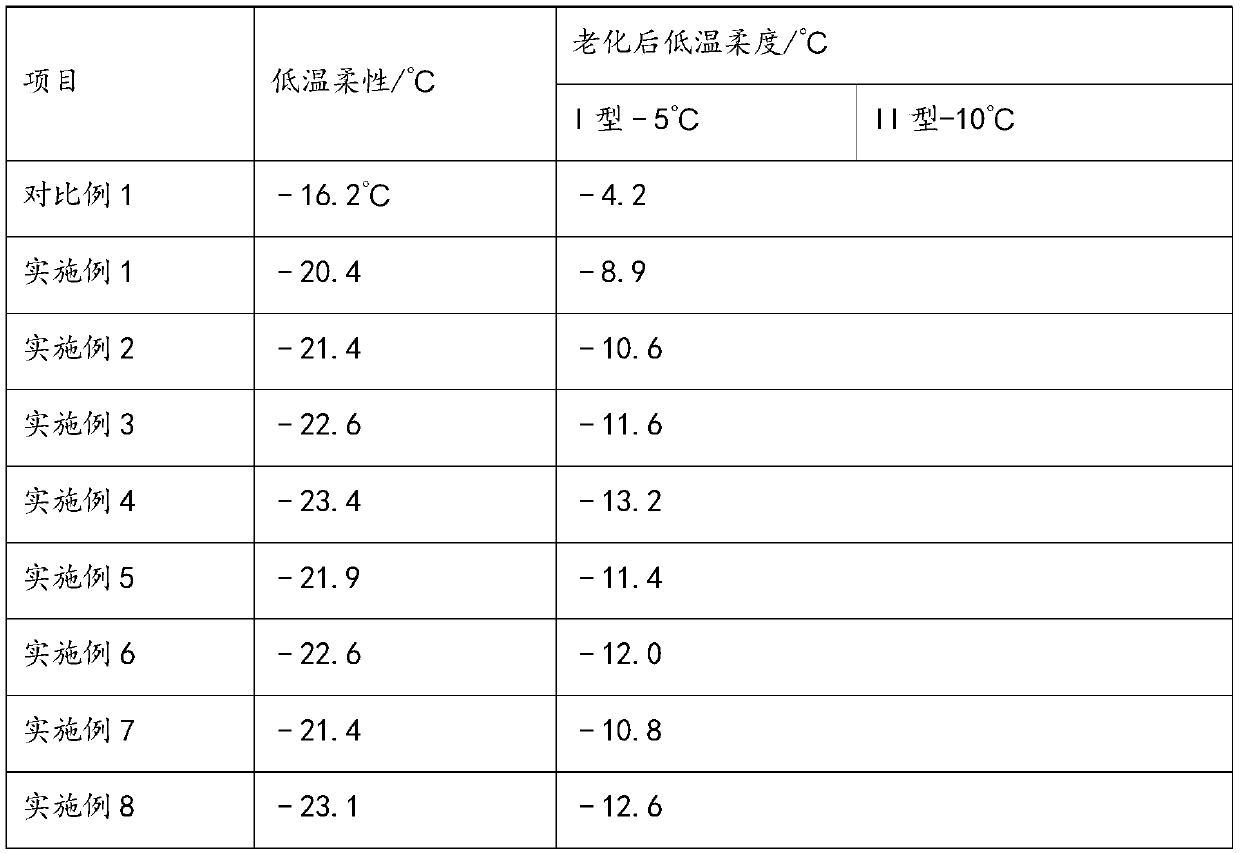

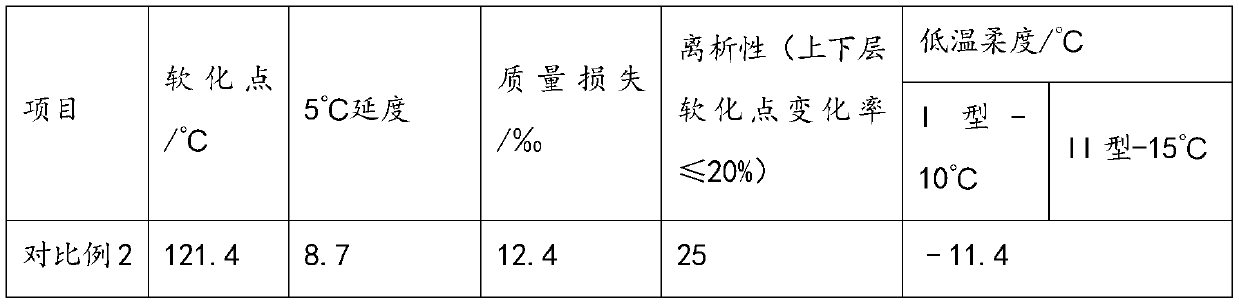

Efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and preparing method

InactiveCN110042670AFast swelling rateGood compatibilitySynthetic resin layered productsConstructions elementsEnvironmental resistanceBituminous waterproofing

The invention relates to an efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material and a preparing method. The preparing method comprises the steps of mixing anduniformly stirring 34-54 parts of matrix asphalt and 1.5-15 parts of softening oil, increasing the temperature to 150-170 DEG C, starting to add 10-15 parts of waste rubber powder and 0.01-0.03 part of an activating agent, increasing the temperature, maintaining the temperature at 170-180 DEG C, conducting development for 60-80 minutes at the rotation speed of 20-200 r / min, afterwards, adding 4-15parts of waste rubber powder, conducting stirring development for 10-20 minutes, conducting cutting and grinding once through a colloid mill, adding 15-30 parts of a filler, and then conducting stirring development for 30-60 minutes to obtain a modified asphalt coating material; conducting coating and cladding technologies on the prepared modified asphalt coating material, and then conducting cooling rolling to prepare the rubber-powder-modified asphalt waterproof coiled material. According to the efficient and environment-friendly rubber-powder-modified asphalt waterproof coiled material andthe preparing method, by adding the activating agent, all technology parameters of the batching period are greatly adjusted, the technology time can be shortened, the technology temperature and stirring speed can be lowered, and the prepared product also has better performance indexes, has excellent storage stability and application performance, and is an efficient, energy-saving and environment-friendly product.

Owner:YUZHONGQING WATERPROOF MATERIALS CO LTD

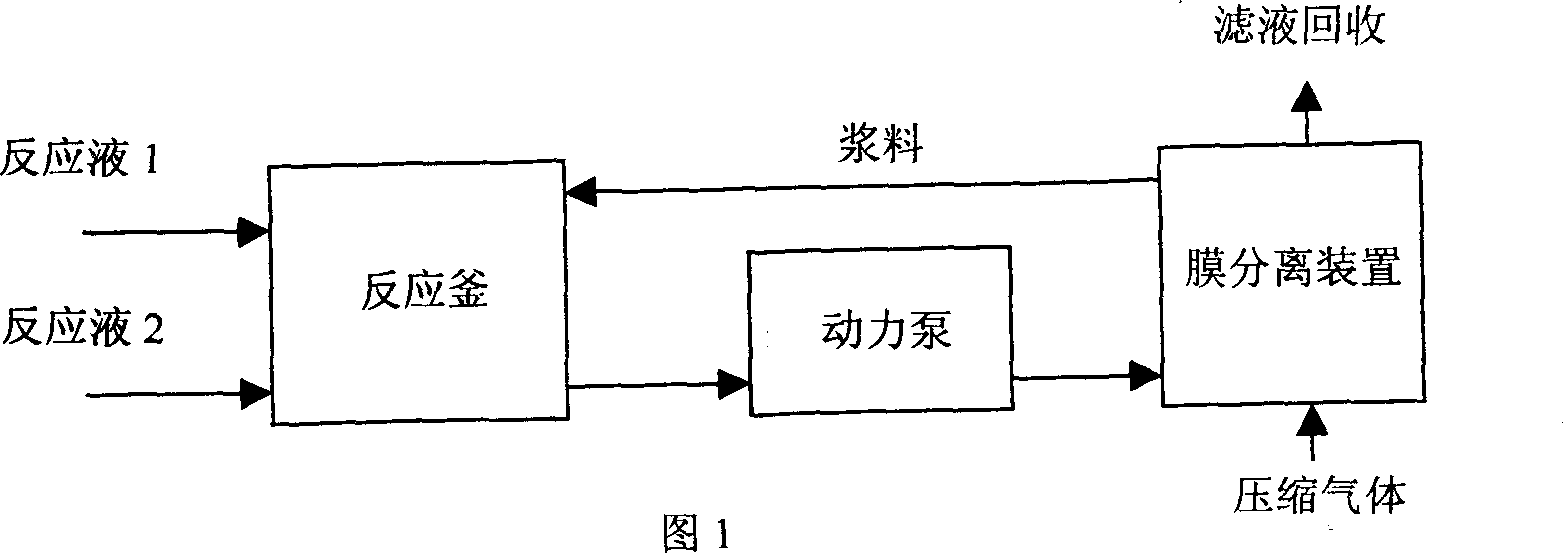

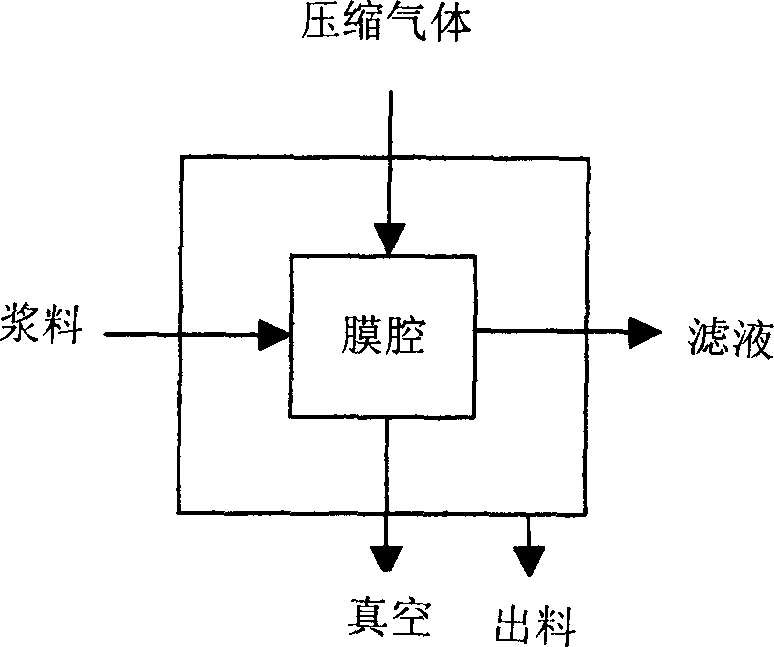

Process for continuously preparing double metal cyanide complex catalyst

InactiveCN1457928AHigh yieldThe process takes a short timeOrganic-compounds/hydrides/coordination-complexes catalystsCyanidePolyol

The continuous process of preparing double metal cyanide catalyst includes the steps of: mixing reaction of the materials, filtering and washing, replacement of water, concentration and addition of functional polymer. The catalyst is used in synthesis of polyether polyol and has high reaction activity and short inducing period. The prepared polyether polyol has very low unsaturation degree. The present invention has a technological period within 36 hr.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

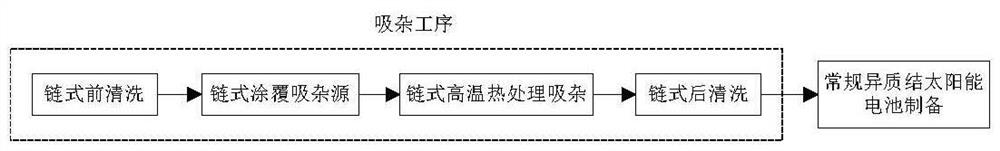

Efficient heterojunction solar cell and preparation method thereof

InactiveCN112289894ALow content of metal impuritiesImprove conversion efficiencyFinal product manufactureSemiconductor devicesElectrical batteryPhysical chemistry

The invention discloses an efficient heterojunction solar cell and a preparation method thereof, and the preparation method is characterized in that a gettering process is added before a conventionalheterojunction solar cell preparation process, and the gettering process is completed through a full-chain process; the full-chain process comprises the following steps: coating a gettering source ona silicon wafer in a chain manner; and performing chained high-temperature gettering. According to the preparation method, the conversion efficiency of the efficient heterojunction solar cell is improved by reducing the metal impurity content of the N-type silicon wafer; the efficiency distribution of the prepared efficient heterojunction solar cell is more centralized, and the product consistencyis greatly improved; the battery edge electric leakage rate is reduced, and the battery yield is improved; the full-chain gettering process shortens the circulation time of the silicon wafer in the manufacturing process, reduces the pollution probability of the silicon wafer, improves the conversion efficiency of the battery to a certain extent, and is short in time consumption, low in energy consumption, high in automation degree and beneficial to industrial popularization and application.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

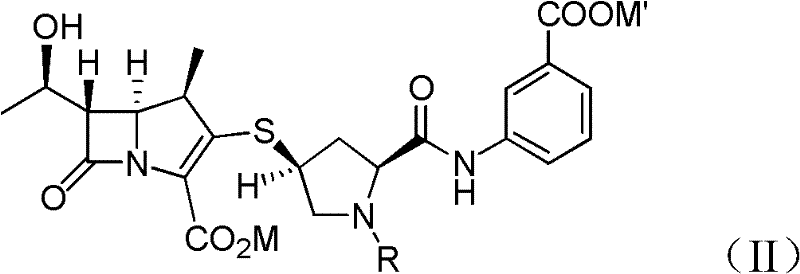

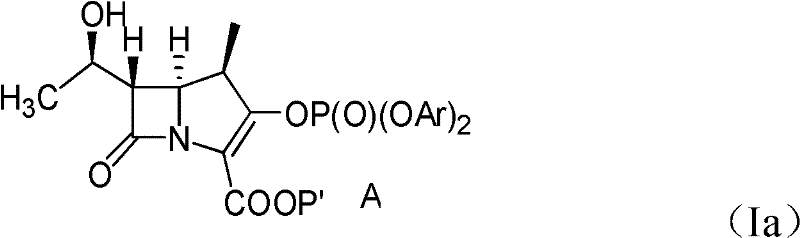

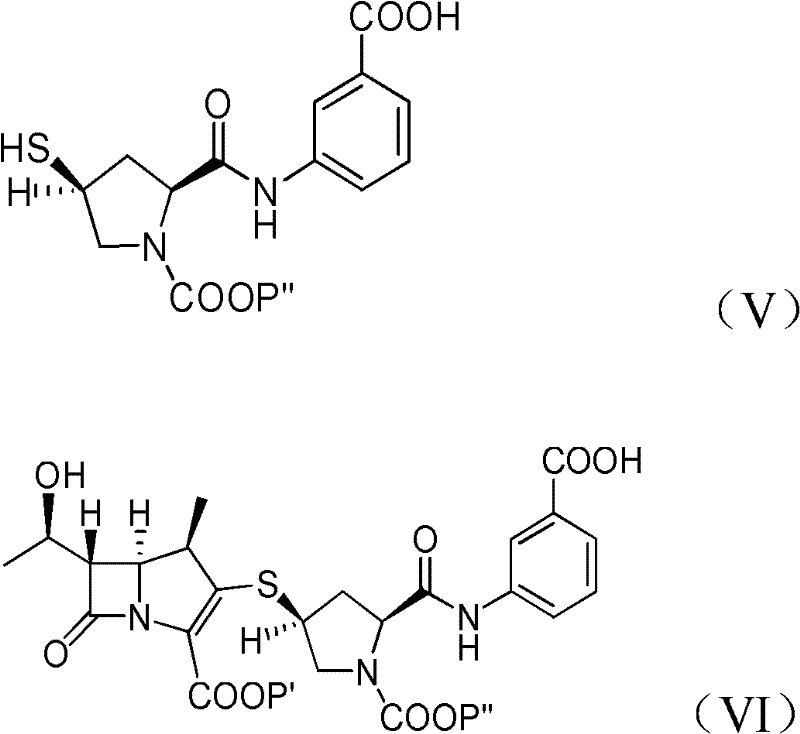

Process for the preparation of carbapenem using cabapenem intermediates and recovery of cabapenem

InactiveCN102250145AReduce generationNovel preparation methodOrganic active ingredientsGroup 5/15 element organic compoundsErtapenemMedicinal chemistry

The present invention aims to prepare carbapenem intermediates which can effectivly produce Ertapenem, Meropenem and Doripenem; and provides an effective process for recovering ertapenem compounds.

Owner:SAVIOR LIFETEC CORP

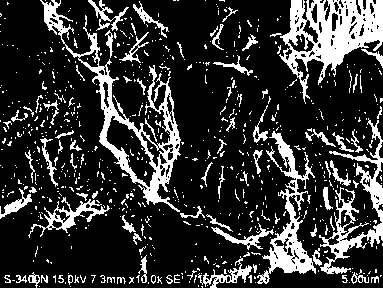

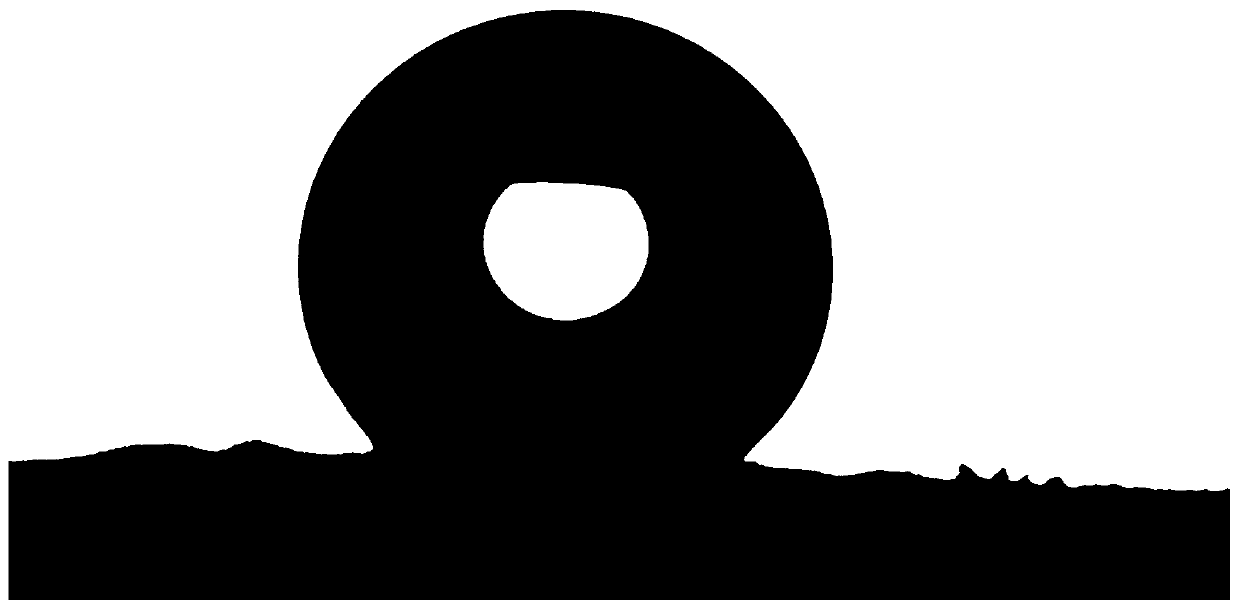

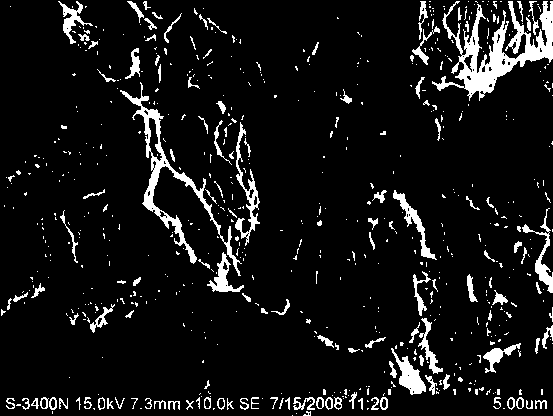

Intrinsic super-hydrophobic nano cellulose aerogel and preparation method thereof

The invention discloses intrinsic super-hydrophobic nano cellulose aerogel and a preparation method thereof. The preparation method comprises the following steps: adding a cross-linking agent into a nano-cellulose dispersion liquid to obtain a precursor solution, and carrying out oriented freezing and drying on the precursor solution to prepare three-dimensional ordered nano-cellulose aerogel; anddipping the aerogel into a low-surface-energy polymer / micro-nano inorganic particle dispersion liquid, and curing and drying to prepare the intrinsic super-hydrophobic nano cellulose aerogel. According to the preparation method, the nano-cellulose fiber dispersion liquid is used as a precursor, ice crystals are used as a template, the nucleation and growth speed and direction of the ice crystalsare regulated and controlled by changing the temperature gradient, and the ice template is removed by freeze drying, so that the three-dimensional ordered nano cellulose aerogel material is prepared;by adding polydimethylsiloxane and micron / nano titanium dioxide particles, the super-hydrophobic aerogel with a low-surface-energy polymer / micro-nano coarse structure is constructed. The prepared nanocellulose aerogel has excellent hydrophobic performance and can be applied to the fields of heat preservation, cold prevention and oil absorption.

Owner:DONGHUA UNIV

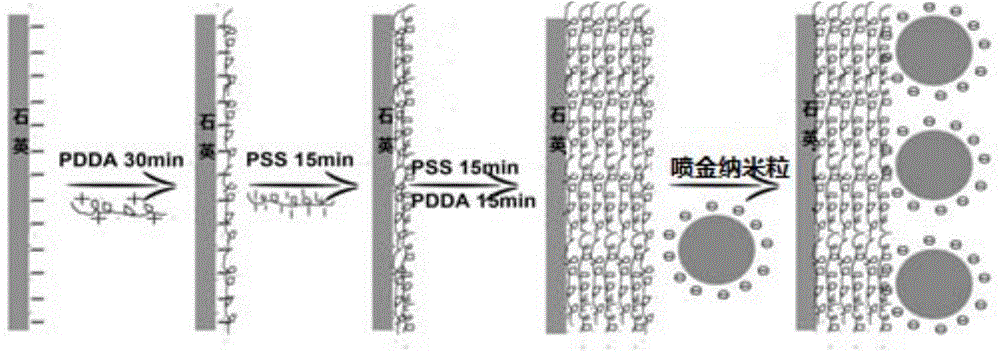

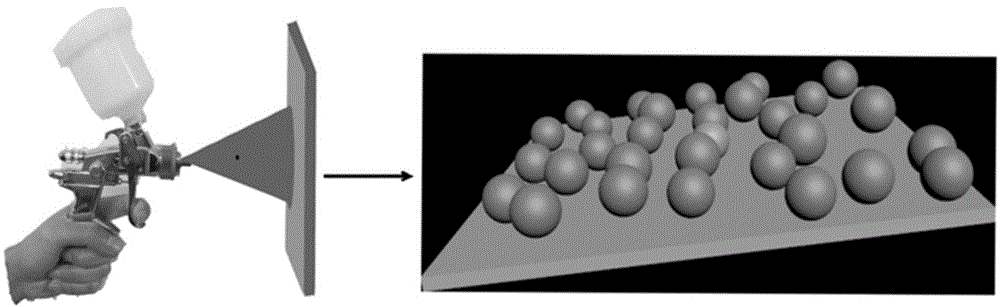

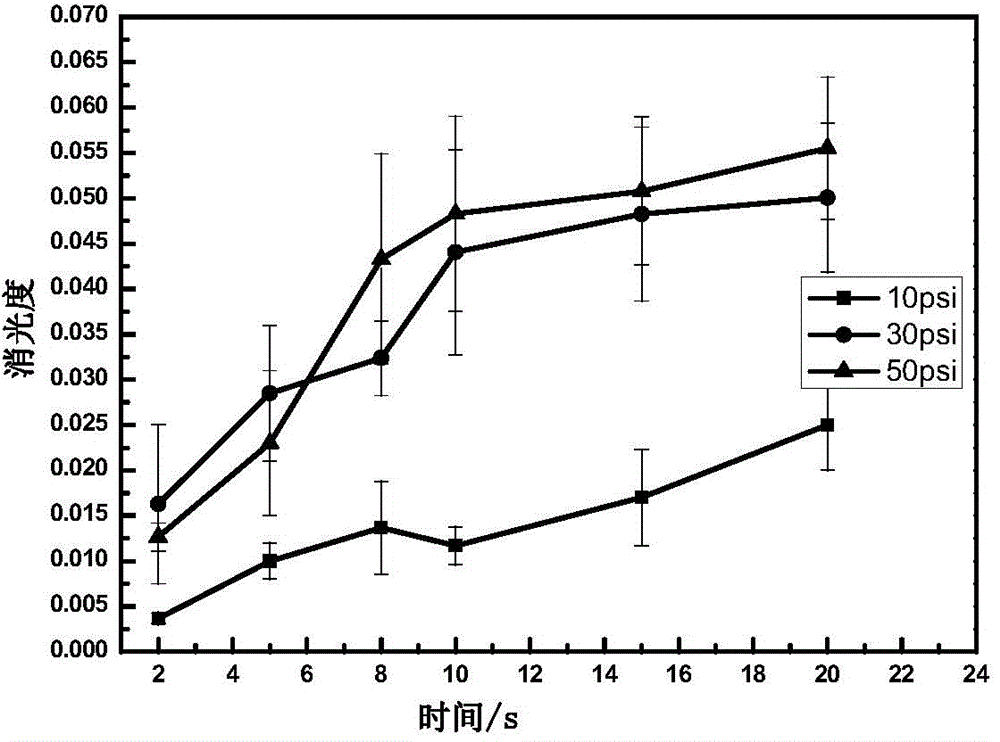

Fluorescent enhancement nano thin film and preparation method thereof

The invention discloses a fluorescent enhancement nano thin film and a preparation method thereof. The preparation method includes the steps of: 1) pre-treating a substrate to enable the surface of the substrate to be charged, and then forming a single-layer or a multi-layer film, of which the surface has positive charges, on the substrate; and 2) spray-coating the surface of the single-layer or a multi-layer film with metal nano particles, removing physical adsorption, and blow-drying the material. The spray-coating pressure is 5-60 psi, the spraying time is 2-30 s, and the distance between a nozzle of a spray gun for spray coating and the substrate is 10-30 cm. The preparation method is simple, is short in time consumption, is free of limit on substrate size and is suitable for large-scale production. The nano particles are sprayed onto the pre-treated substrate through spray coating to form the thin film with appearance and distance of metal nano particles being adjustable.

Owner:DONGHUA UNIV

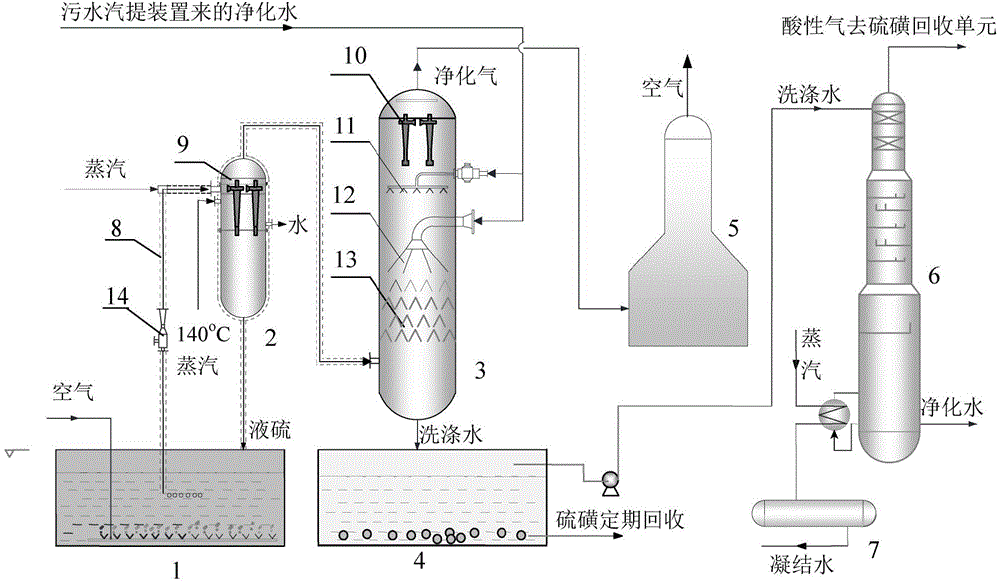

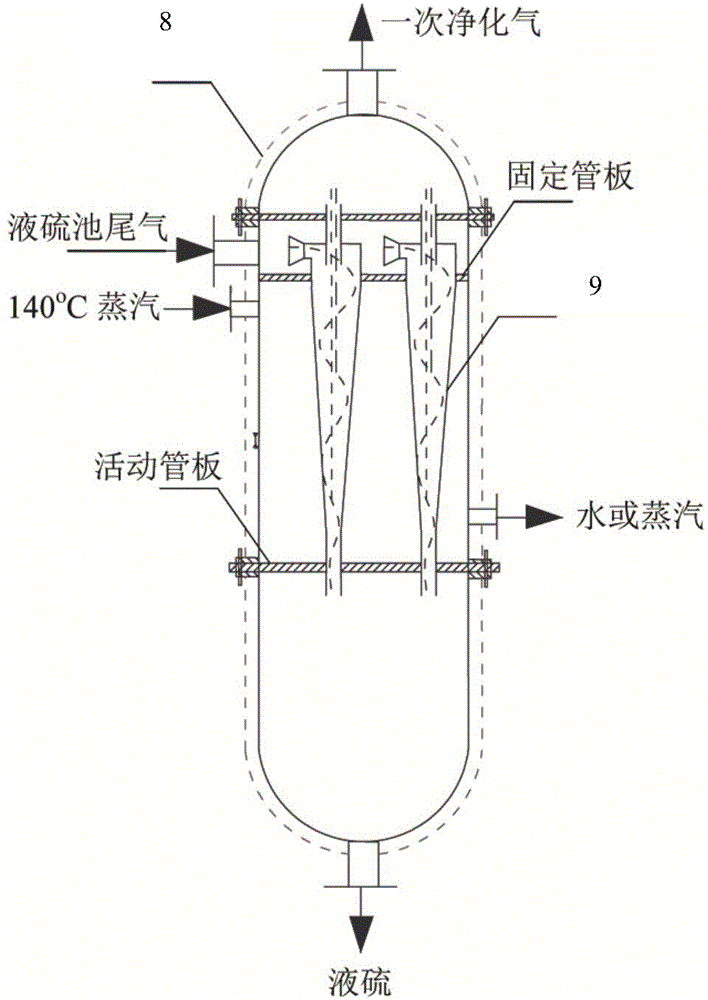

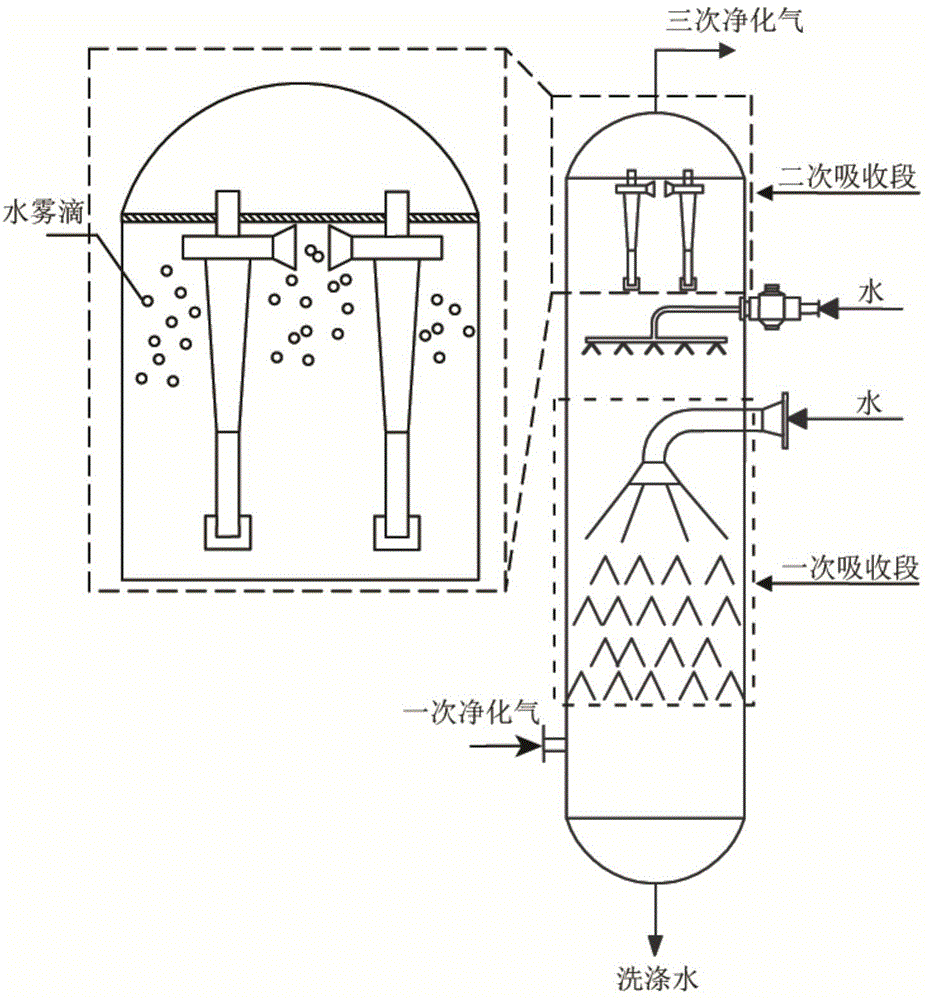

Method and device for treating liquid sulfur tank tail gas

ActiveCN104474850ASolve the blockageSolving Corrosion ProblemsDispersed particle filtrationIncinerator apparatusCouplingAtomizer nozzle

The invention relates to a method and a device for treating liquid sulfur tank tail gas, and in particular provides the method for treating the liquid sulfur tank tail gas. The method comprises the following steps: (a) delivering the liquid sulfur tank tail gas into a heat exchange rotational flow tank provided with a steam jacket, and removing liquid sulfur drops entrained in the tail gas by using a heat exchange and rotational flow separation coupling technology, thereby obtaining a primary purified gas; (b) delivering the obtained primary purified gas into a rotational flow absorbing tower, and washing the liquid sulfur drops and absorbing H2S and SO2 in the rotational flow absorbing tower, thereby obtaining a secondary purified gas; and (c) mixing the obtained secondary purified gas with frog drops sprayed out by an atomizer nozzle arranged in the rotational flow absorbing tower, and then delivering the mixture into a rotational flow absorber arranged in the rotational flow absorbing tower so as to absorb sulfur-containing gases, thereby obtaining a tertiary purified gas. The invention also provides the device for treating liquid sulfur tank tail gas.

Owner:SHANGHAI HUACHANG ENVIRONMENT PROTECTION

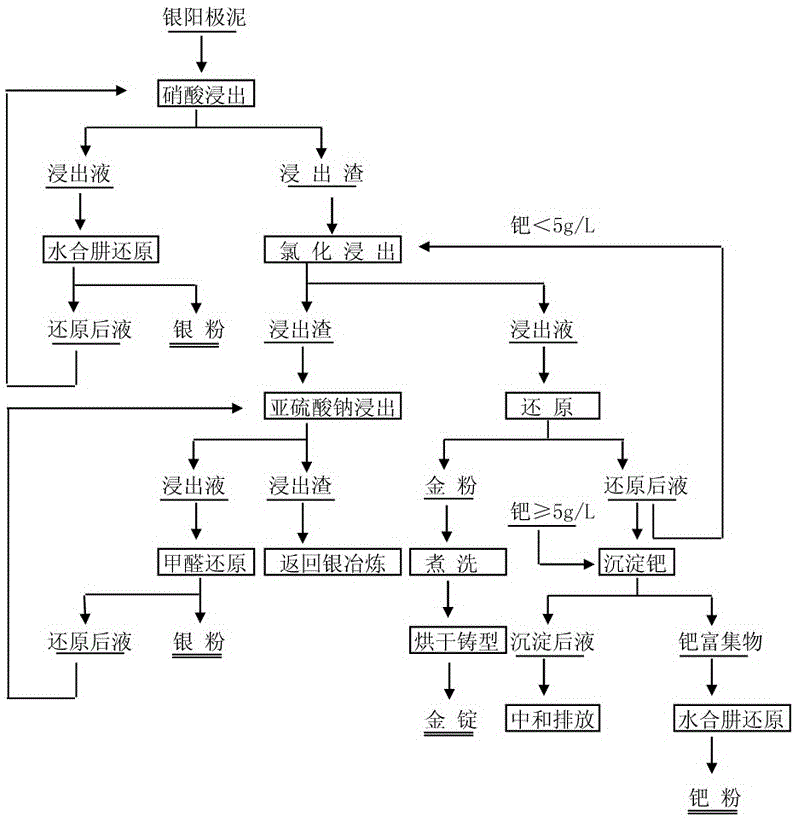

Method for directly purifying gold from silver anode slime through wet method comprehensive recovery

ActiveCN106065434AThe process takes a short timeImprove product qualityProcess efficiency improvementPrecious metalPalladium

The invention relates to a method for directly purifying gold from silver anode slime through wet method comprehensive recovery. After an outer layer silver chloride wrappage of the silver anode slime is leached out through nitric acid, gold and palladium are leached out through chlorination, silver is leached out from leaching residues through sodium nitrite, and the silver and a former nitrate leachate are subjected to formaldehyde reduction together to obtain silver powder. A chlorination leachate is subjected to reduction to obtain 99.99% gold powder, and after-reduction liquid can be cycled to chlorination leaching or dissolution reduction after replacement to obtain palladium powder. The direct recovery rates reach 99% and 98% or above. The method is suitable for directly purifying the gold from the silver anode slime rich in gold and silver, the silver and palladium precious metals in the silver anode slime are recycled, and the problem of accumulation of a large number of funds due to an overlong production cycle in the recovery process of the silver anode slime of the gold and silver smelting industry is solved well.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

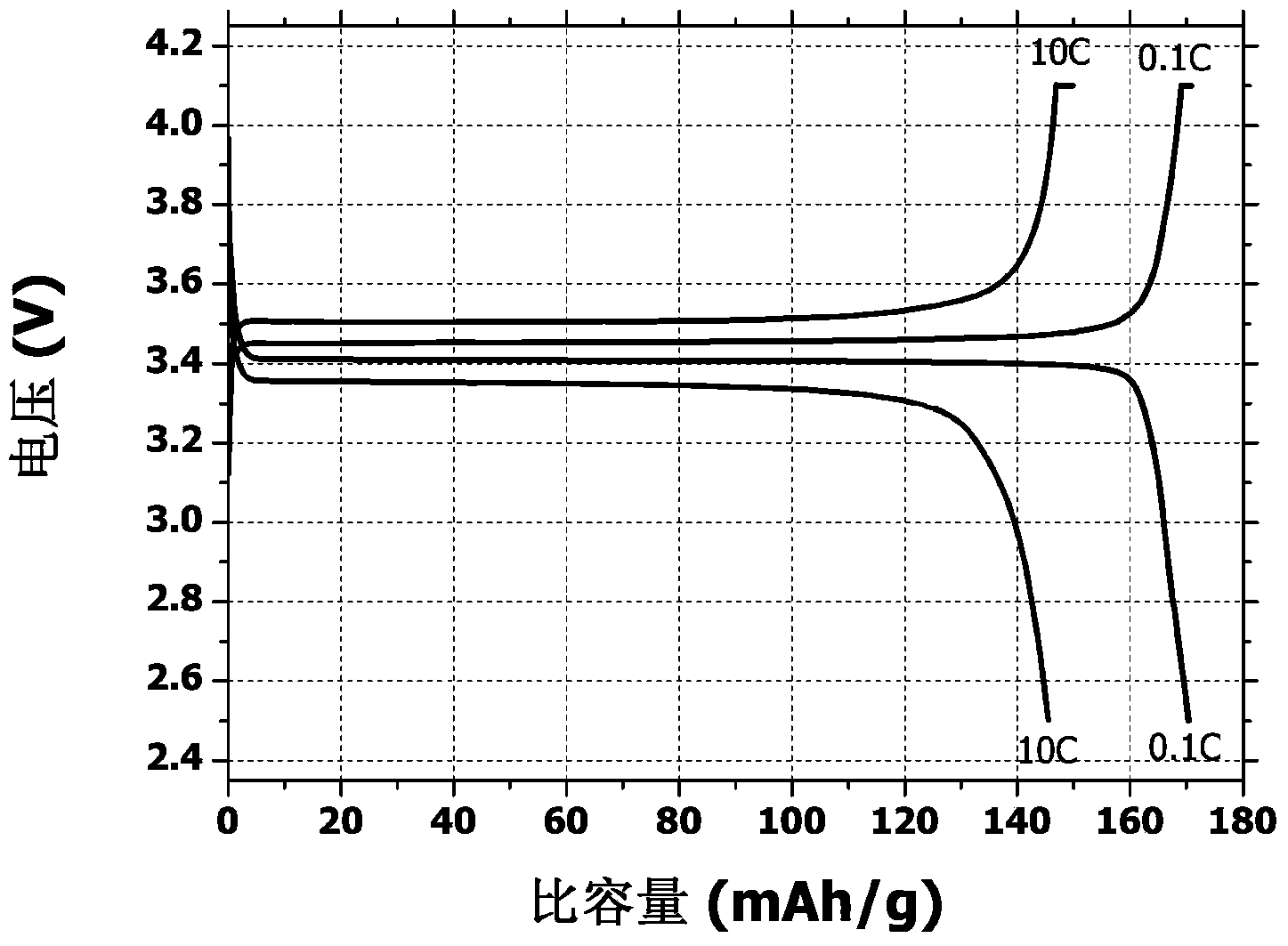

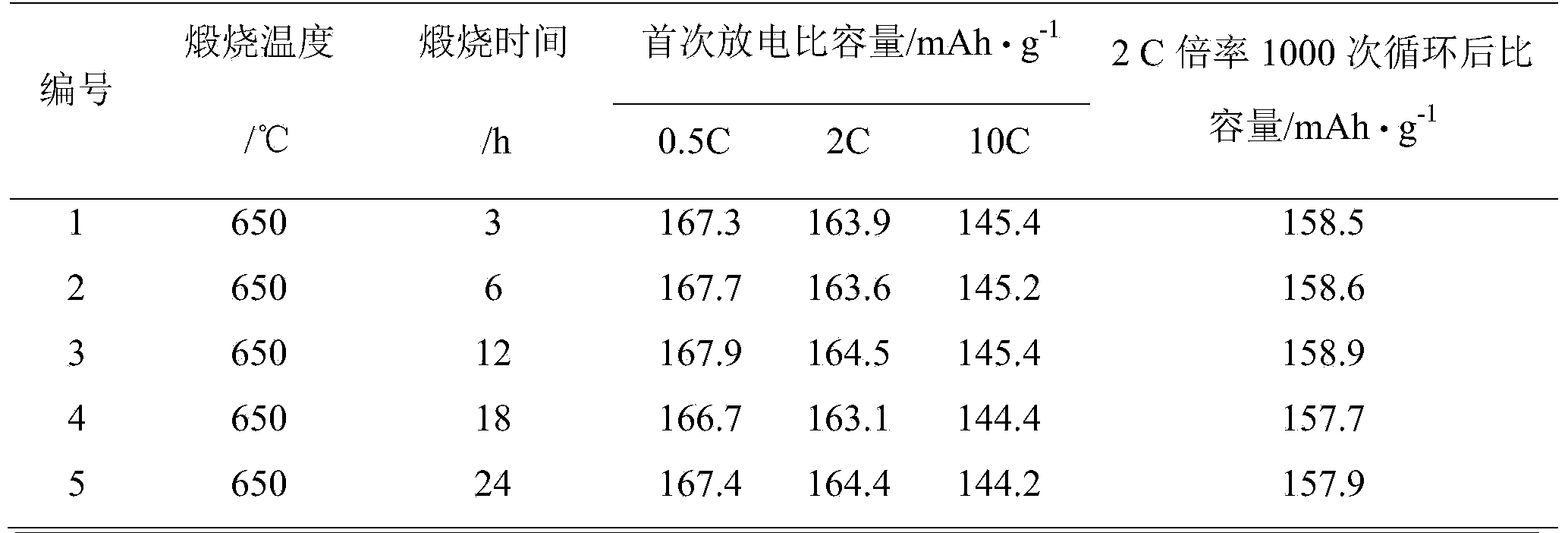

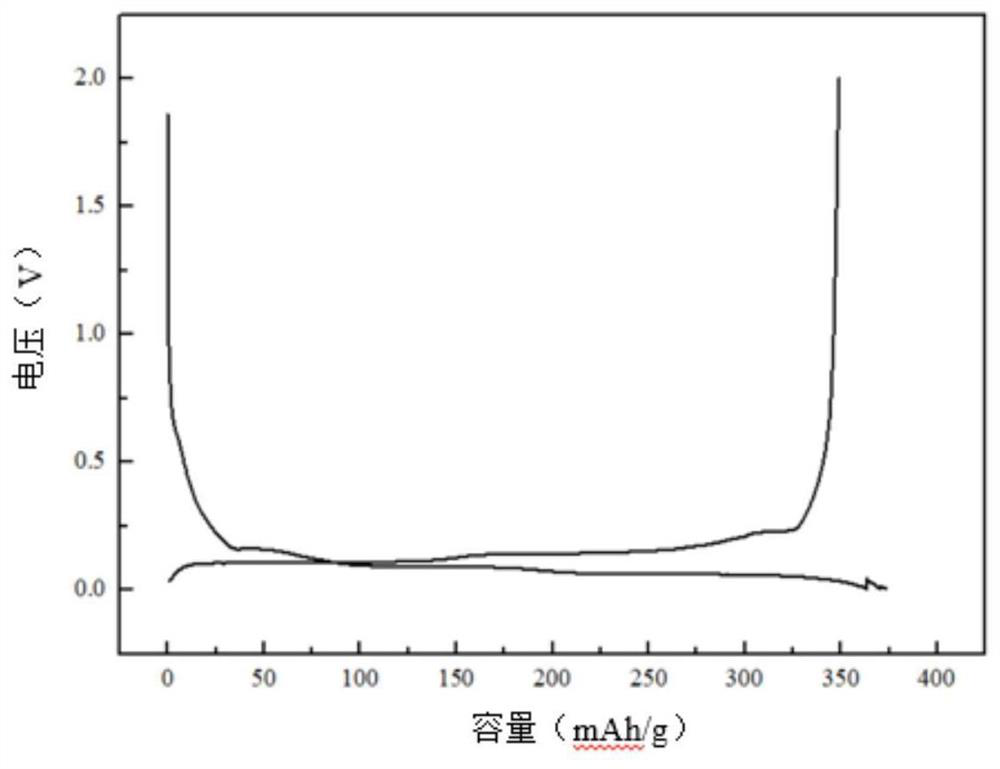

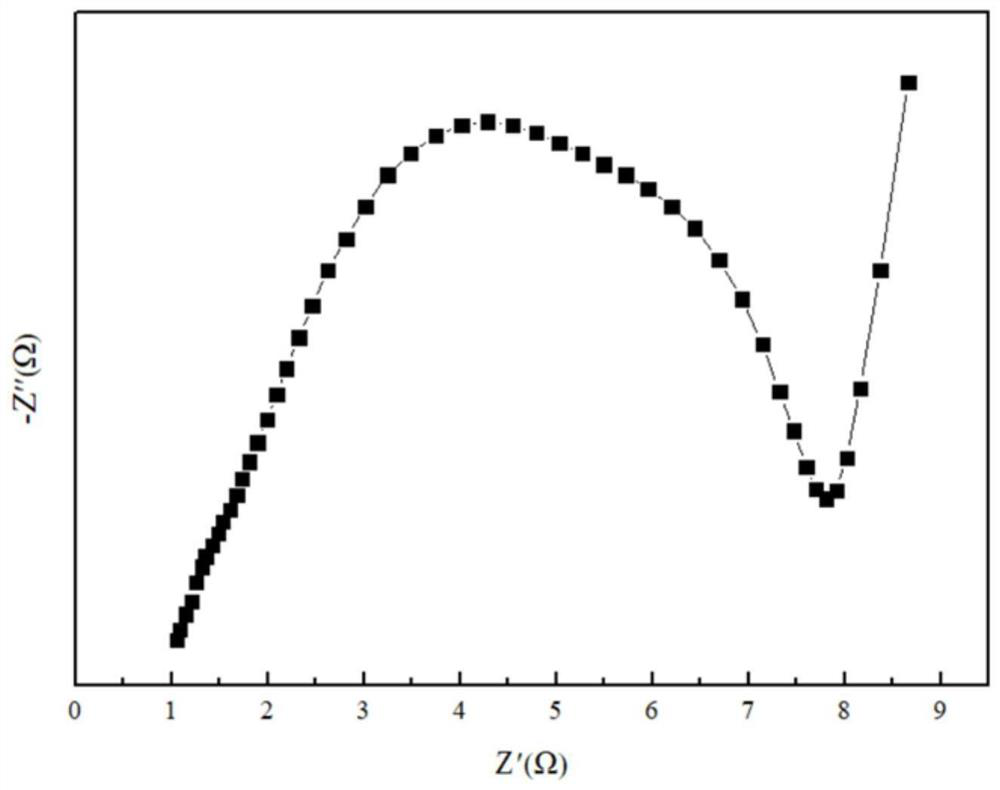

Lithium iron phosphate-based composite positive electrode material as well as preparation method and application thereof

ActiveCN103943864AEvenly distributedImprove electrochemical performanceCell electrodesSecondary cellsLithium iron phosphateHigh energy

The invention discloses a lithium iron phosphate-based composite positive electrode material. The lithium iron phosphate-based positive electrode material comprises lithium iron phosphate and graphene, wherein a thin film made of the grapheme uniformly wraps a lithium iron phosphate nanocrystal, the lithium iron phosphate is obtained by converting a lithium iron phosphate precursor, and the lithium iron phosphate precursor and the graphene are simultaneously synthesized through one-time reaction. The preparation method of the composite positive electrode material comprises the following steps: mixing a lithium source, an iron source and phosphate according to a stoichiometric ratio, adding nanoscale flake graphite and the like, carrying out high-energy ball milling so as to obtain the precursor, heating the obtained precursor in an inoxidizability atmosphere, and carrying out heat preservation, thus obtaining the lithium iron phosphate-based composite positive electrode material disclosed by the invention. The lithium iron phosphate-based composite positive electrode material disclosed by the invention can be applied as the lithium battery positive electrode material. The first specific discharge capacity of the lithium battery at the 2C rate can reach above 163mAh g<-1>, and after the battery cycles 1000 times at the 2C rate, the retention rate of the specific capacity of the battery is greater than 95%.

Owner:CENT SOUTH UNIV

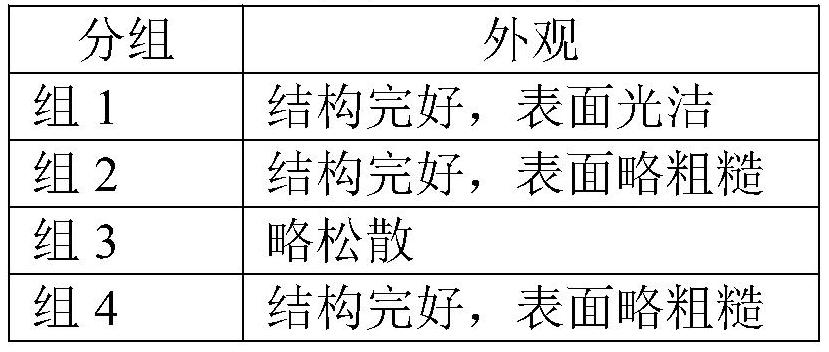

Biological repair tablet for endocranium and preparation method thereof

The invention provides a biological repair tablet for endocranium and a preparation method thereof. The repair tablet uses small intestine submucosa tissues of inbred line animals without cell and DNA (deoxyribonucleic acid) components as the raw material, completely reserves the extracellular matrix component and structure, and has a micropore structure. The preparation method of the repair tablet comprises the following operation steps: determination of animal source, pretreatment and rough cleaning of small intestine tissues, virus inactivation, cell removal, DNA removal treatment, formation, packaging and sterilization. The biological repair tablet for endocranium prepared by the method uses an inbred line animal as an animal source, and thus, the hereditary features are pure, stable and uniform, thereby radically ensuring the stability and uniformity of different batches of products; and the biological repair tablet for endocranium has fewer animal source DNA residues, completely reserves the three-dimensional structure of natural ECM, and has the advantages of low immune source property and high infection resistance.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

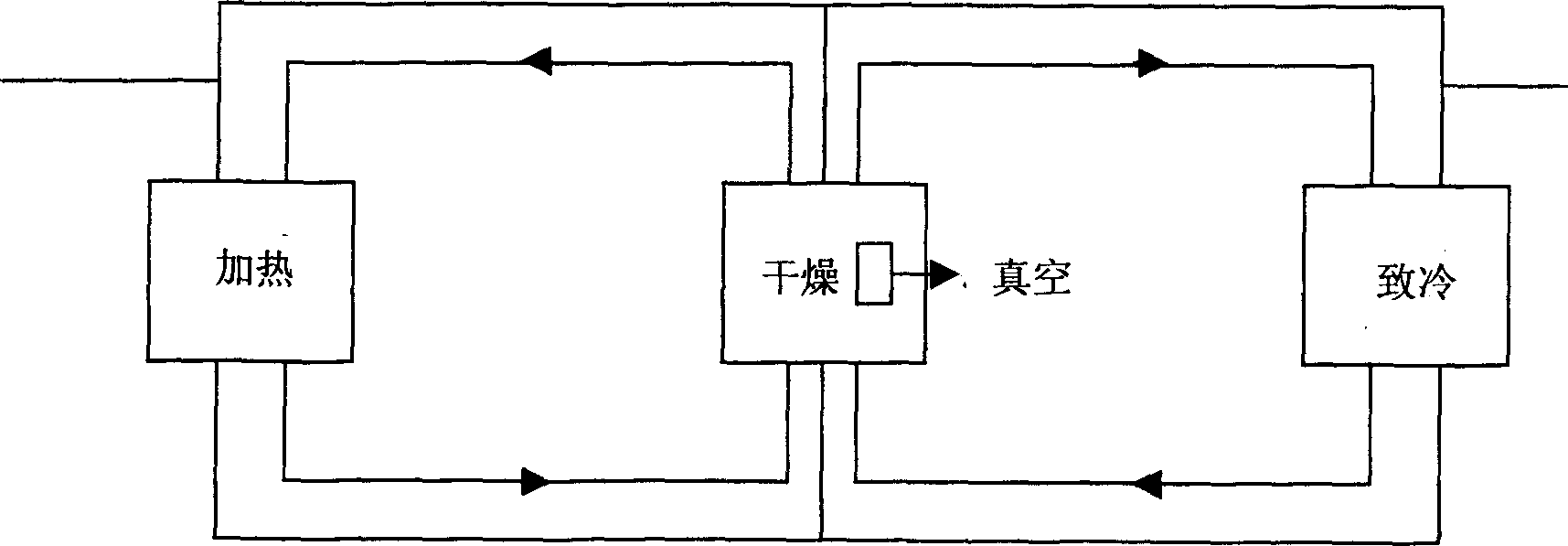

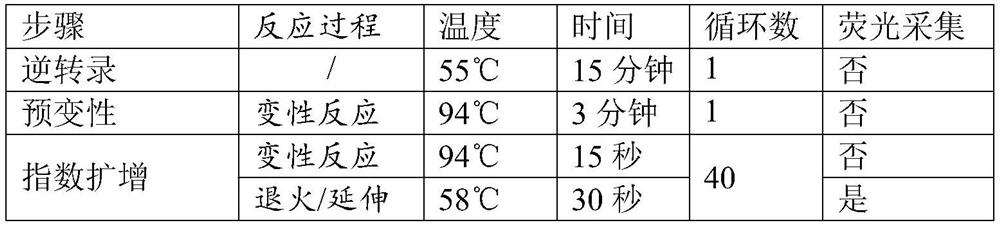

Freeze-drying protective agent and application thereof in nucleic acid amplification reagent

InactiveCN111662902AImprove transportationExtended shelf lifeMicrobiological testing/measurementDNA preparationFreeze-dryingPolyethylene glycol

The invention discloses a freeze-drying protective agent and application thereof in a nucleic acid amplification reagent. The freeze-drying protective agent contains the following substances, including trehalose, mannitol, [beta]-cyclodextrin, polyethylene glycol 8000 and water. The freeze-drying protective agent can obviously improve the transportation and storage life of the nucleic acid amplification freeze-drying reagent under a room temperature condition. In addition, the volume of the reagent is reduced to shorten freeze-drying technical time consumption, production efficiency is improved, and the freeze-drying protective agent has a good application prospect.

Owner:诺迦(杭州)生物工程有限公司

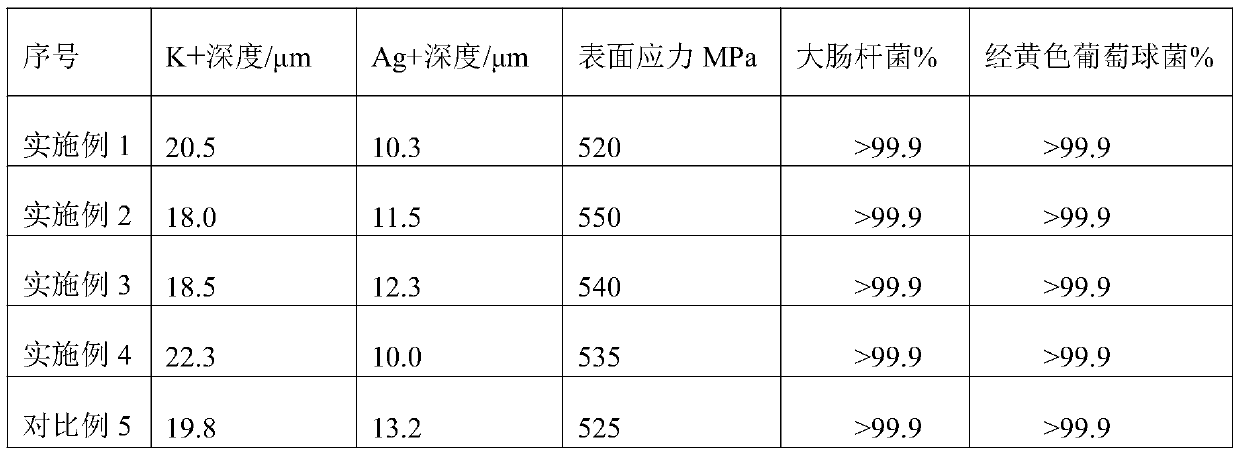

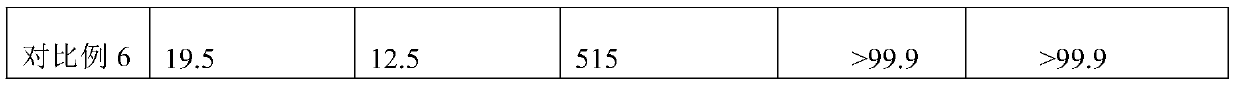

Manufacturing method of high-tempered antibacterial glass cup

The invention discloses a manufacturing method of a high-tempered antibacterial glass cup. The manufacturing method comprises the following steps: (1) cleaning: cleaning a semi-finished product high-silicon-boron glass cup; (2) spraying a toughening agent, namely atomizing and spraying a KNO3 solution to the inner surface and the outer surface of the glass cup, and drying; (3) annealing and tempering: heating the dried glass cup to an annealing temperature, and carrying out annealing treatment; (4) spraying an antibacterial agent, namely atomizing and spraying an AgNO3 solution on the surfaceof the annealed glass cup, and drying; (5) antibacterial treatment: heating the dried glass cup containing the antibacterial agent to a high temperature, and carrying out antibacterial treatment; (6)ultrasonic cleaning: subjecting the glass cup to ultrasonic cleaning after antibacterial treatment and drying the same. According to the manufacturing method, tempering and antibiosis of the high-silicon-boron glass cup can be achieved at the same time, the technological process is short in consumed time, and the production efficiency is high; the prepared high-tempered antibacterial glass cup ishigh in strength and good in impact resistance, and has good resistance to escherichia coli and staphylococcus aureus.

Owner:JIANGSU XINUO INDAL

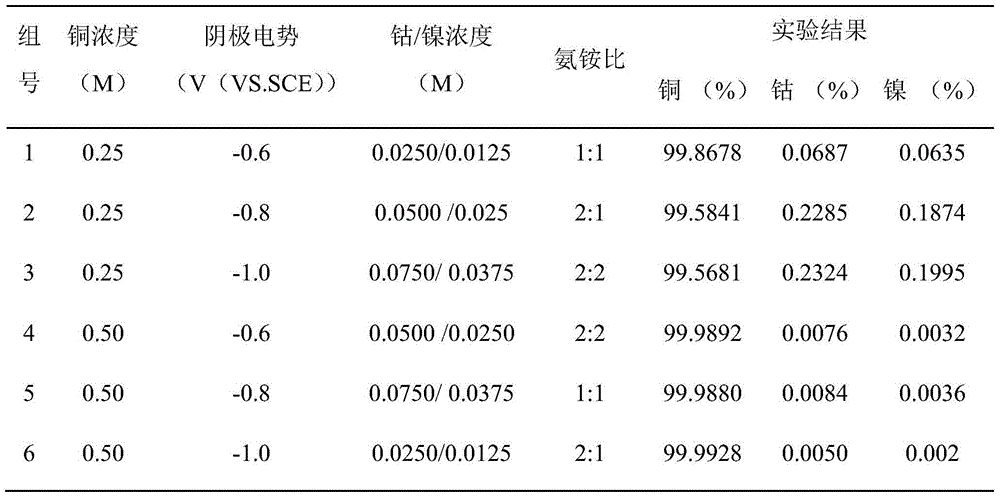

Electrolysis method for separating copper from cobalt and nickel in chloride ion ammoniacal system and application of products thereof

The invention discloses a method for separating copper from cobalt and nickel in a chloride ion ammoniacal system. The method mainly adopts an electrolysis separation technology, which comprises the following steps: dissolving a proper amount of at least one of copper salt, cobalt salt and nickel salt in a leached liquid of an analogue mineral sample containing copper, cobalt and nickel, adding ammonium chloride and a proper amount of active metal chloride into the solution, finally adding concentrated ammonia water so as to obtain an electrolytic system; carrying out electrolysis on the electrolytic system by taking graphite as the positive electrode and a stainless steel plate as the negative electrode, controlling the voltage to carry out electrolysis separation, and carrying out deposition to obtain the copper powder with high copper content and low nickel and cobalt content and electrolysis residual liquid with enriched nickel and cobalt. The electrolysis method has the advantages of simple and efficient steps, low cost, environmental friendliness, and good resource comprehensive utilization rate.

Owner:CENT SOUTH UNIV

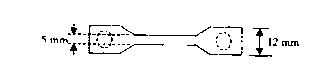

Anal fistula suppository and preparation method thereof

The invention provides an anal fistula biological suppository and a preparation method thereof. The anal fistula biological suppository uses small intestine submucosa tissues of inbred line animals without cell and DNA (deoxyribonucleic acid) components as the raw material, completely reserves the extracellular matrix component and structure, and has a micropore structure. The preparation method of the anal fistula biological suppository comprises the following operation steps: determination of animal source, pretreatment and rough cleaning of small intestine tissues, virus inactivation, cell removal, DNA removal treatment, formation, packaging and sterilization. The anal fistula biological suppository prepared by the method uses an inbred line animal as an animal source, and thus, the hereditary features are pure, stable and uniform, thereby radically ensuring the stability and uniformity of different batches of products; and the anal fistula biological suppository has fewer animal source DNA residues, completely reserves the three-dimensional structure of natural ECM, and has the advantages of low immune source property and high infection resistance.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

High-frequency induction selective tempering heat treatment method for high-nitrogen stainless bearing steel

ActiveCN112708732AImprove efficiencyOrganizational structure improvementIncreasing energy efficiencyTemperingToughness

The invention discloses a high-frequency induction selective tempering heat treatment method for high-nitrogen stainless bearing steel, and belongs to the technical field of material heat treatment. The high-nitrogen stainless bearing steel comprises the components in percentage by weight: 0.3-0.65% of C, less than or equal to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.015% of S, less than or equal to 0.025% of P, 14.5-16.0% of Cr, 0.85-1.10% of Mo, 0.2-0.5% of N, and the balance Fe, except unavoidable impurity elements. The high-nitrogen stainless bearing steel is subjected to overall quenching and tempering as well as high-frequency induction selective tempering, so that the thread part of a high-nitrogen stainless bearing steel part is locally softened after heat treatment, the hardness requirement of 38-42 HRC is met, meanwhile, the high hardness of 58 HRC or above is kept on the raceway working face, and the use requirement of the bearing part is met. The high-frequency induction selective tempering heat treatment method has the advantages that the problem of integral hardening of the high-nitrogen stainless bearing steel is solved, the high hardness of the raceway working surface is ensured, and the thread part has good strength and toughness in a matching mode.

Owner:CENT IRON & STEEL RES INST

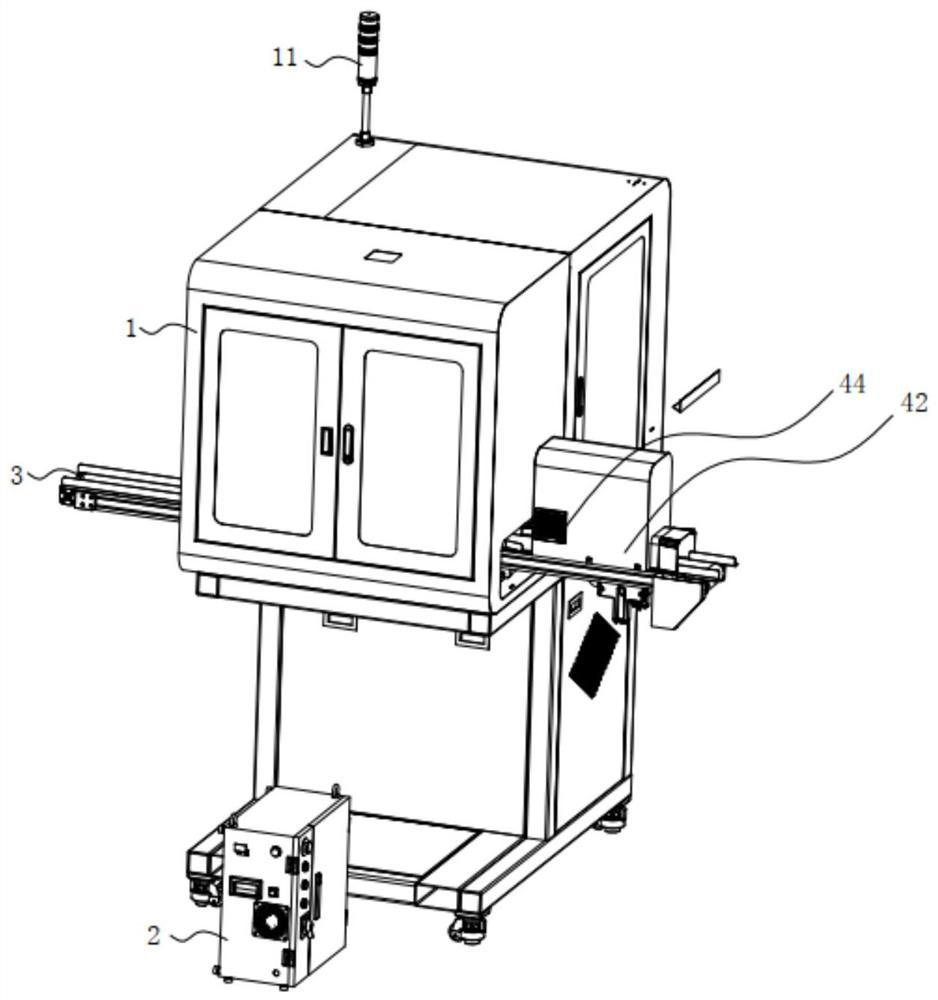

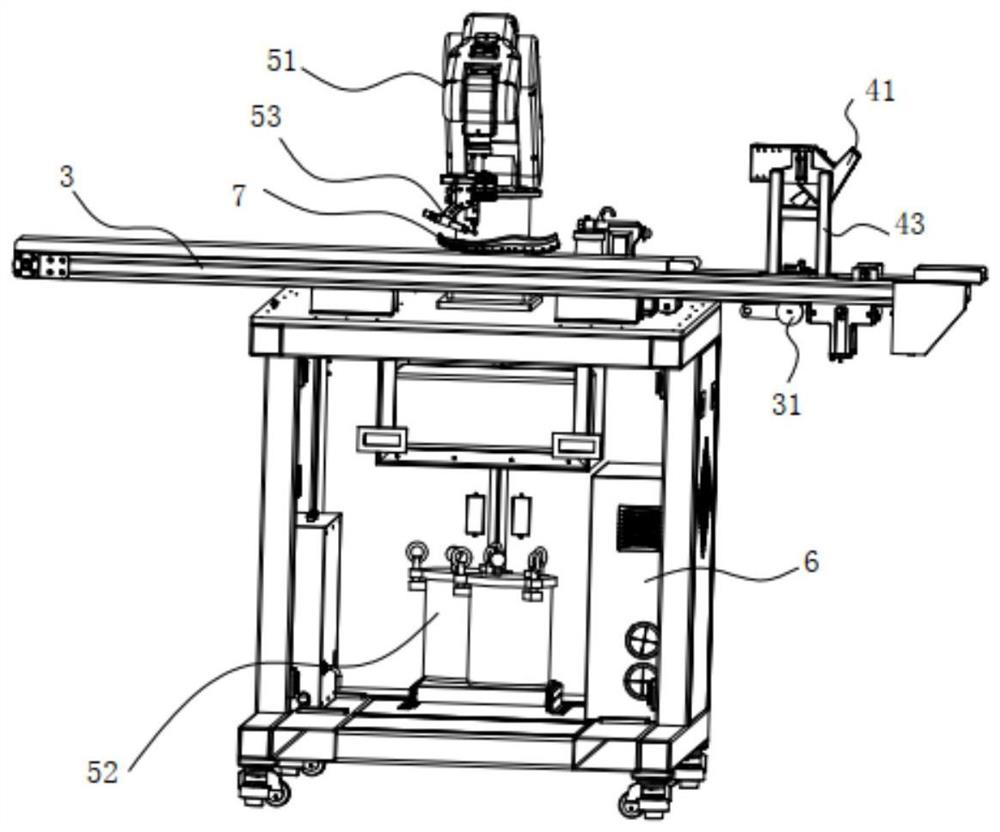

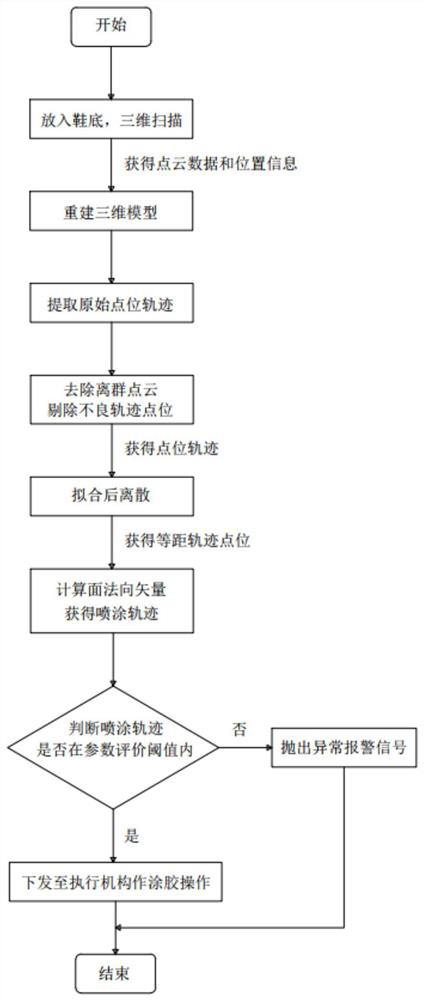

Shoe sole dynamic following glue spraying method and system

PendingCN113303564AEliminate waiting time to sprayThe process takes a short timeImage enhancementImage analysisThree dimensional modelPoint location

The invention provides a shoe sole dynamic following glue spraying method which comprises the following steps: performing three-dimensional scanning on a shoe sole product needing glue spraying, and reconstructing a three-dimensional model of the product according to point cloud data and position information; extracting an original point location track according to the three-dimensional model; removing outlier cloud of the original point location track, and eliminating bad track point locations to obtain a point location track; after a point location track curve is fitted, dispersing the point location track curve into equidistant track point locations; calculating a surface normal vector of the track on the sole point cloud through the point cloud data and the equidistant track point locations; and calculating point position information followed by a mechanical arm in real time according to the obtained spraying track and the position information of a conveying belt. A transmission following module is introduced and combined with an industrial camera to obtain three-dimensional data of a shoe sole, and dynamic following glue spraying of the shoe sole is achieved through the space movement capacity of a multi-joint robot, following movement of the conveying belt and glue spraying equipment according to the extracted information. The invention further provides a shoe sole dynamic following glue spraying system.

Owner:QUANZHOU HUAZHONG UNIV OF SCI & TECH INST OF MFG +1

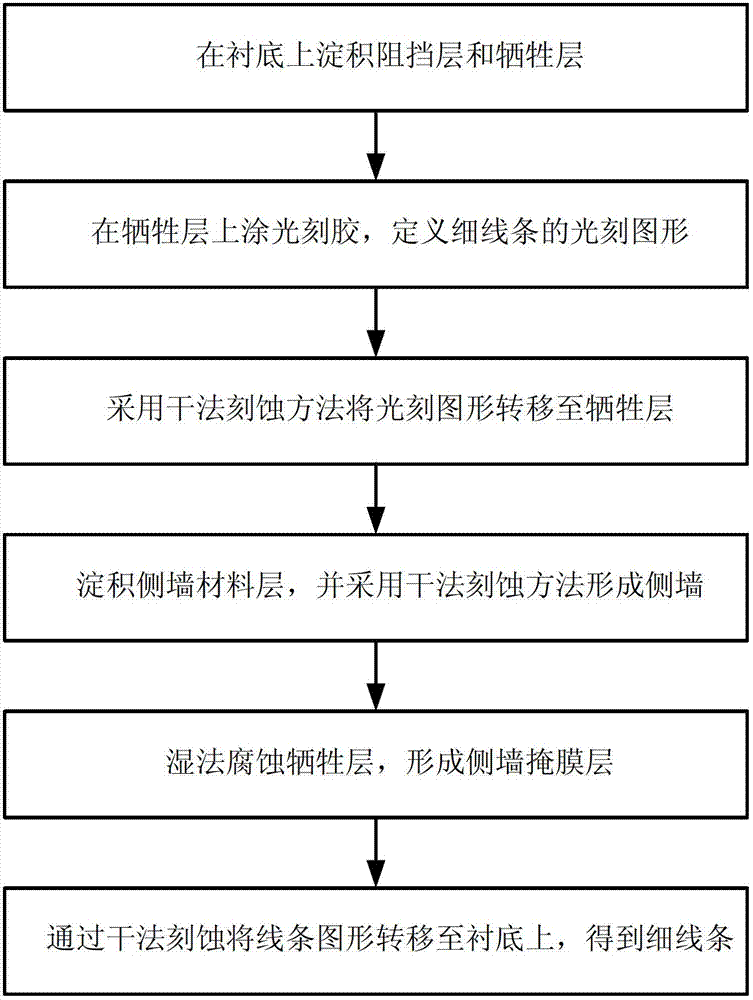

Method for manufacturing thin line with relatively small edge roughness

InactiveCN102768956AReduce roughnessRough causedSemiconductor/solid-state device manufacturingElectron-beam lithographyThin line

The invention provides a method for manufacturing a thin line with relatively small edge roughness, comprising the following steps of depositing a blocking layer and a sacrificial layer on a substrate; coating photoresist on the sacrificial layer, and defining a photoetching graph of the line; transferring the photoetching graph to the sacrificial layer by using a dry etching method; depositing a side wall material layer, and forming a side wall by using the dry etching method; carrying out wet etching on the sacrificial layer in the side wall to form a side wall mask layer; and transferring the line graph to the substrate by using the side wall mask layer and through the dry etching method, so as to obtain the thin line. The method disclosed by the invention is combined with the side wall technology and the wet etching technology; electron-beam lithography, high-temperature oxidation and the like are not used; and the thin line with small edge roughness can be obtained.

Owner:PEKING UNIV

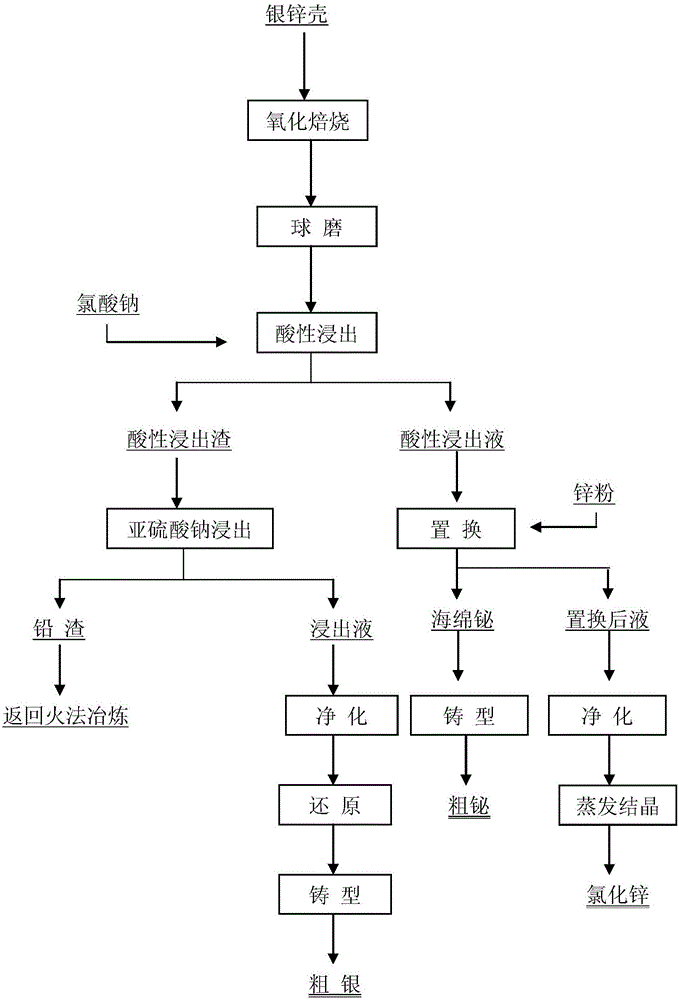

Silver-zinc crust wet process comprehensive recovery method

ActiveCN106011474ASolve the backlogSimple processProcess efficiency improvementRecovery methodSulfite salt

The invention discloses a silver-zinc crust wet process comprehensive recovery method which is characterized in that that silver-zinc crusts are subjected to thorough roasting and ball milling sieving; then through an acid leaching condition, an acid extract and acid leaching residues are obtained; after the acid leaching residues are leached by sodium sulfite, lead residues and an extract are obtained; the lead residues can return to a pyrogenic process smelting system, the extract is purified and then is reduced by formaldehyde, and crude silver is finally obtained after casting; the acid extract can be replaced by zinc powder and sponge bismuth is obtained; liquid after replacement is purified and then is subjected to evaporative crystallization, and zinc chloride is obtained; and direct recovery rates of silver, bismuth and zinc respectively reach above 95.7%, 94.1% and 88.9%. The silver-zinc crust wet process comprehensive recovery method is applicable to recovery of valuable metals, such as silver, bismuth and zinc, from the silver-zinc crusts rich in lead, silver, bismuth and zinc; the lead residues can return the pyrogenic process smelting system; the direct recovery rates are high; separation is thorough; and rapid recovery of valuable metals, especially silver, of the pyrogenic process smelting system is facilitated more.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

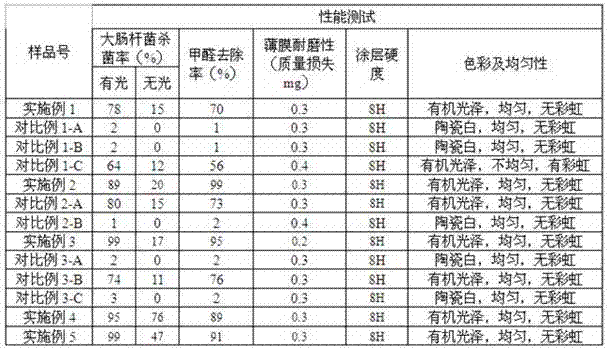

A process for manufacturing composite ceramic covered with a photocatalyst membrane

ActiveCN107473770AEnsure safetyEnsure hygieneWater closetsWash-standsProduction lineComposite ceramic

The invention provides a process for manufacturing composite ceramic covered with a photocatalyst membrane, and belongs to the technical field of ceramic. An adopted technical scheme is the process for manufacturing the composite ceramic covered with the photocatalyst membrane. The process includes preparing an aqueous solution of a peroxy-titanium system, with the concentration of the solution being 0.1-5 wt%; adding a surfactant into the aqueous solution to prepare a spraying solution; evenly coating clean and dry ceramic with the spraying solution; drying the surface; performing high-temperature calcination, with the calcination temperature being controlled to be 300-900 DEG C and the calcination time being 10-120 min; cooling the product to room temperature to obtain the composite ceramic. Beneficial effects of the process are that the process has simple and concise steps, is short in consumed time, high in efficiency and low in investment, and can be widely applied in various production lines of manufacture factories; and a product has excellent wear resistance, antibacterial performance and formaldehyde degrading performance, can efficiently clean air, can improve the environment, has beautiful gloss like organic precious stone, and is high-grade, elegant and beautiful.

Owner:唐山佐仑环保科技有限公司

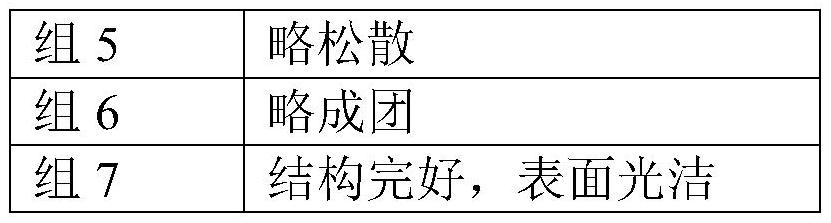

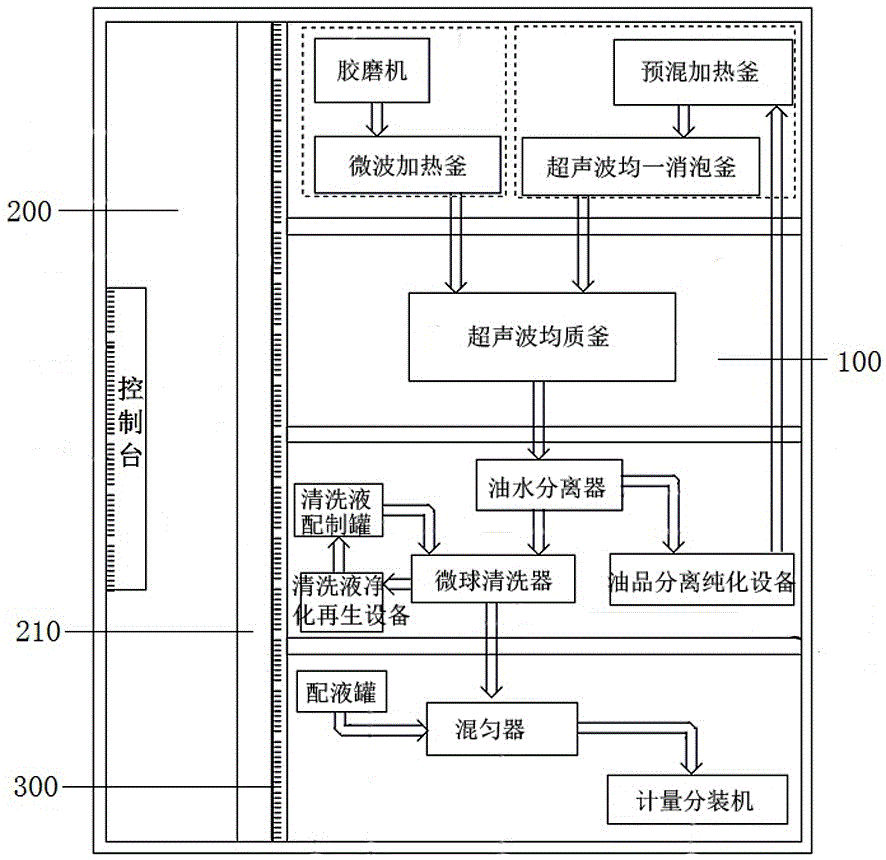

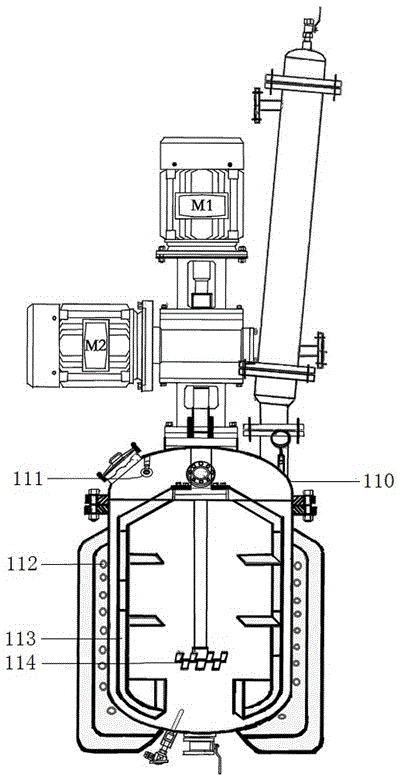

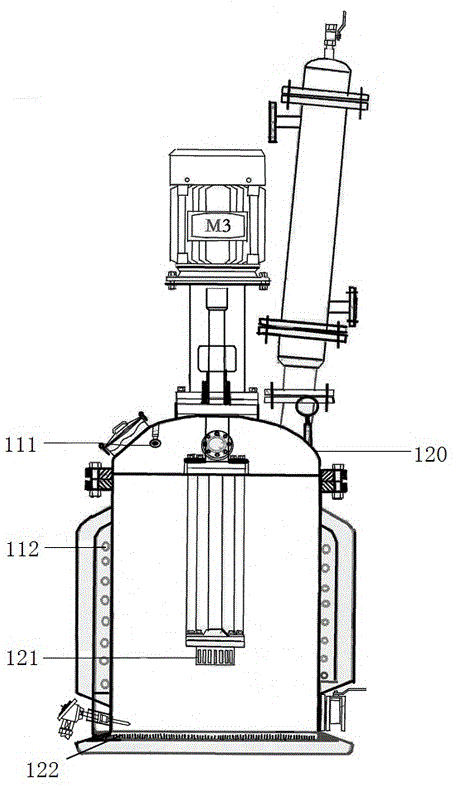

Uniform-grain-size agarose gel microsphere production system and production process thereof

The invention relates to a uniform-grain-size agarose gel microsphere production system and a production process thereof. The system comprises a production area and a control area positioned beside the production area, a gel mill and a premix heating kettle are arranged in the production area, the gel mill is connected with a microwave heating kettle, the premix heating kettle is connected with an ultrasonic uniform defoaming kettle, both the microwave heating kettle and the ultrasonic uniform defoaming kettle are connected with an ultrasonic homogenizing kettle, a high-frequency ultrasonic homogenizing kettle is connected with an oil-water separator, a water-phase outlet of the oil-gas separator is connected with a microsphere cleaning device which is connected with a mixer, and the mixer is connected with a metering subpackaging machine. Large-scale production of agarose gel microspheres uniform in grain size, smooth in sphere form and free of impurities is realized, and the system plays a certain role in promoting development of biomedicine industry of China and has good social and economic benefit.

Owner:厦门三冀科技有限公司

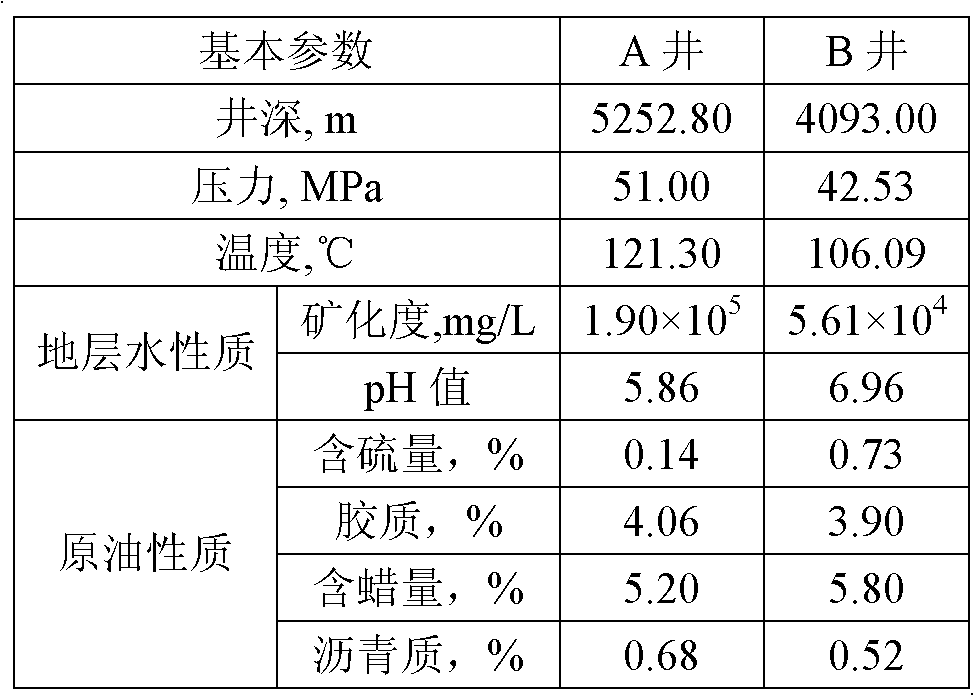

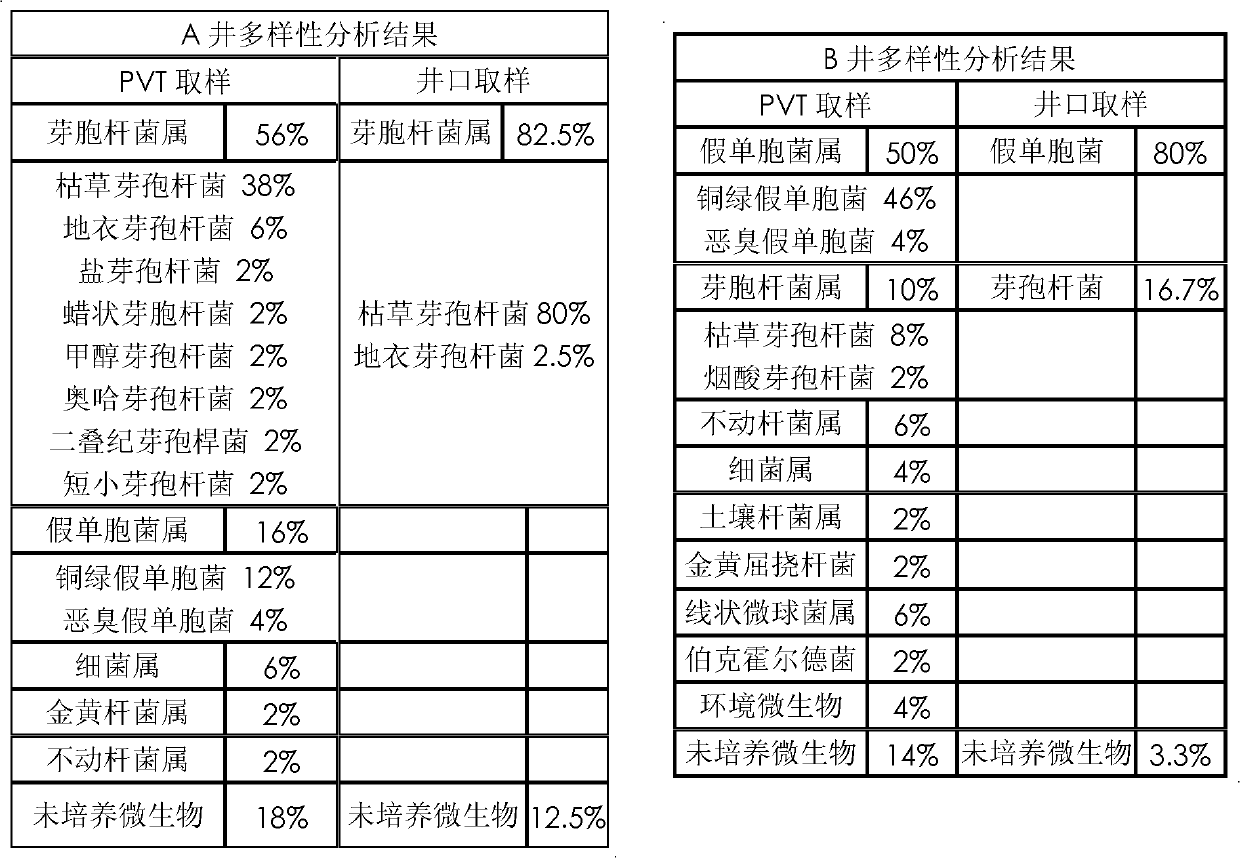

Oil-reservoir endogenous microbe in-situ recovery method

ActiveCN102952846AStrong targetingAccurate environmental informationMicrobiological testing/measurementRecovery methodMicrobial enhanced oil recovery

The invention relates to an oil-reservoir endogenous microbe in-situ recovery method. The method comprises the following steps: 1, well ore data analysis: collecting and organizing base data of a target well; 2, value simulation: determining microbial recovery environment adaptability requirements based on a concrete design scheme required by the microbial enhanced oil recovery; 3, determining a sample burying depth through the well ore analysis data; 4, in-situ recovery: recovering required endogenous microbial resources on the scene, and recovering an oil sample or an oil water sample fluid at a specific oil reservoir target burying depth through a PVT (pressure, volume and temperature) instrument according to the value stimulation result; and 5, carrying out subsequent microbial diversity analysis and screening. The method is suitable for the endogenous microbial recovery under various temperature, pressure, pH, mineralization, burial depth oil-reservoir geology conditions, is especially suitable for the deep-well microbial recovery of high-temperature and high-pressure oil reservoirs, and has uses comprising the trace monitoring of oil-reservoir harmful microbes, the endogenous / exogenous microbial diversity analysis before and after the action of the microbial enhanced oil recovery, and the like.

Owner:PETROCHINA CO LTD

High-temperature manganese phosphating process

ActiveCN109082657AReduce corrosionReduce roughnessMetallic material coating processesManganeseHeavy load

The invention discloses a high-temperature manganese phosphating process which comprises the following steps that a, a workpiece is electrically de-oiled to obtain a A product.; b, the product A is washed with hot water to obtain a B product; c, the product B is washed with cold water to obtain a C product; d, the C product is washed with acid to obtain a D product; e, the D product is cleaned with cold water to obtain a E product; f, the E product is surface-adjusted by immersing the E product in the first surface conditioning liquid containing the saponifier surface conditioning agent to obtain a F product; g, the F product is surface-adjusted by immersing the F product in a second surface conditioning liquid containing a manganese phosphate surface conditioning agent to obtain a G product; h, the G product is phosphated to obtain a H product; i, the H product is washed with cold water to obtain a product I; j. the product I is washed with hot water to obtain a J product; k, and theproduct J is dried to obtain a finished product. The high-temperature manganese phosphating process has the advantages of short process time and small mechanical fit tolerance, and the phosphating workpiece can withstand high speed, heavy load and large impact.

Owner:AVIC LIYUAN HYDRAULIC

Method for performing dyeing by utilizing glucose generated by enzymolysis

The invention discloses a method for performing dyeing by utilizing glucose generated by enzymolysis. Glucoamylase is used for further treating desizing fluid to finally convert starch into glucose and disaccharide, the glucose and the disaccharide are directly used as reducing agents, and the use of sodium sulfide or the re-addition of the glucose is avoided, so that raw materials are saved, the using amount of water is reduced, sewage treatment cost is lowered, steps are simplified, and process time consumption is reduced.

Owner:BEIJING RICH TARGET LEATHER CLOTH

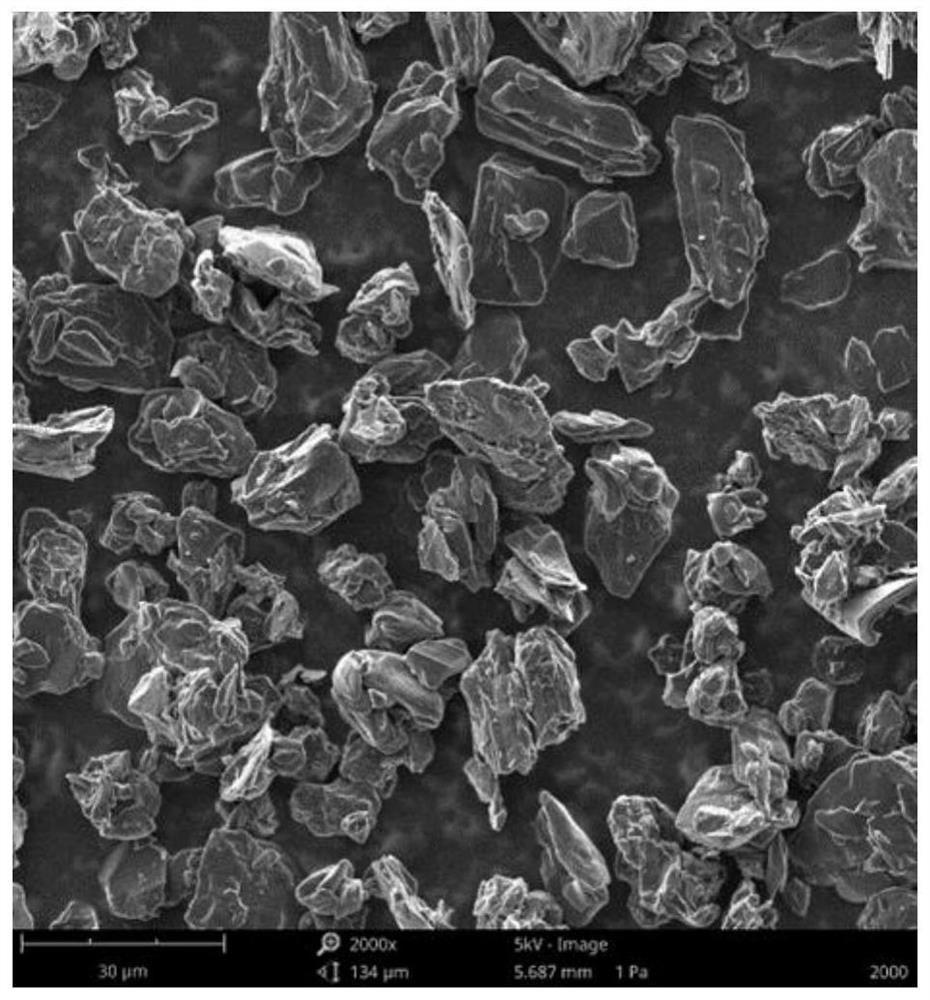

Artificial graphite negative electrode material, preparation method, application and battery

PendingCN112713264AHigh tap densityImprove efficiencyGraphiteCell electrodesElectrical batteryGraphite

The invention discloses an artificial graphite negative electrode material, a preparation method, application and a battery. The preparation method of the artificial graphite negative electrode material comprises the following steps of (1) carrying out electric demagnetization on graphite fragments with the particle size D50 of 13.5-17.5 microns to obtain a precursor A; (2) the precursor A and a coating agent being modified to obtain a precursor B, and the curing temperature of the coating agent being 80-150 DEG C; and (3) carrying out heat treatment on the precursor B to obtain the artificial graphite negative electrode material. The preparation method of the artificial graphite negative electrode material is simple, short in process time consumption and easy for mass production, the raw materials are common industrial products, and the raw material graphite scraps are low in cost and stable in source; compared with the prior art, the artificial graphite negative electrode material prepared by using the crushed graphite can ensure relatively high tap density, initial efficiency, rate capability and cycle capacity retention ratio, and meets the use requirements of the artificial graphite negative electrode material.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com