Fluorescent enhancement nano thin film and preparation method thereof

A technology of fluorescence enhancement and nano-film, applied in the field of fluorescence-enhanced nano-film and its preparation, can solve the problems of unsuitability for large-scale production, uncontrollable shape, distance, complicated equipment, etc. The effect of limited and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

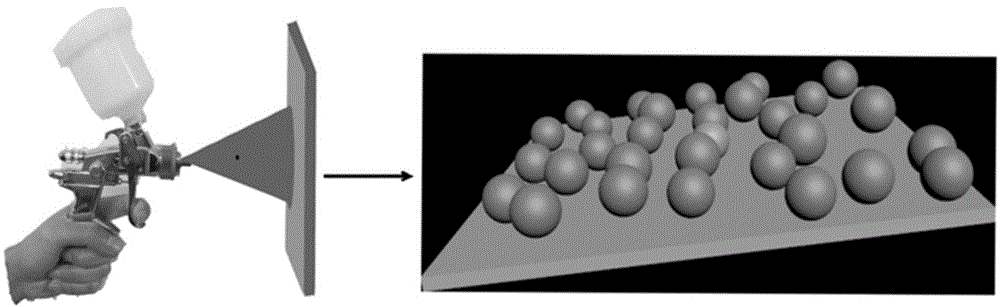

Method used

Image

Examples

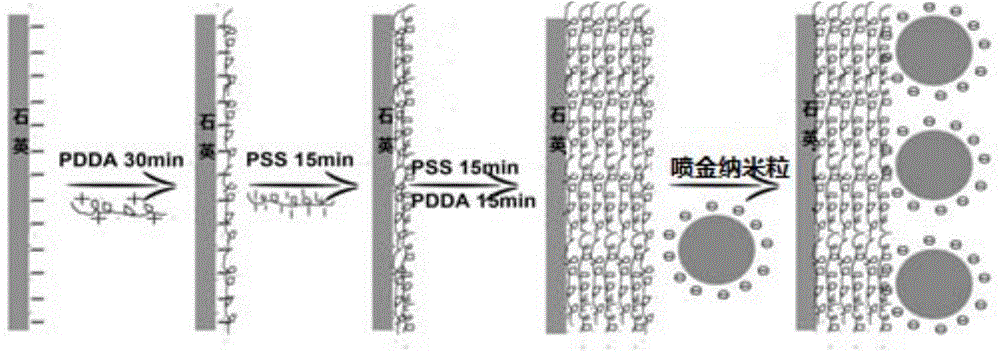

Embodiment 1

[0044] (1) Preparation of gold nanoparticles

[0045] Gold nanoparticles with a diameter of about 13nm are obtained by reducing chloroauric acid with sodium citrate. The specific method is as follows: 200mL of 1mM HAuCl 4 Heat 3H2O to boiling under vigorous stirring, quickly add 20mL of 38.8mM sodium citrate solution, continue stirring, keep boiling for half an hour, take out the solution and stir to cool to room temperature, and store the synthesized gold nanoparticles in the dark in a refrigerator at around 4°C.

[0046] (2) Pretreatment of quartz substrate

[0047] Sonicate with toluene, acetone, chloroform, ethanol and deionized water for 10 minutes respectively to remove various impurities attached to the surface of the substrate, and then in a mixed solution of 98% sulfuric acid and 30% hydrogen peroxide (v:v=7:3) Heat and boil for 20 minutes until no bubbles overflow. Rinse with a large amount of distilled water after cooling, then blow dry with nitrogen, and set as...

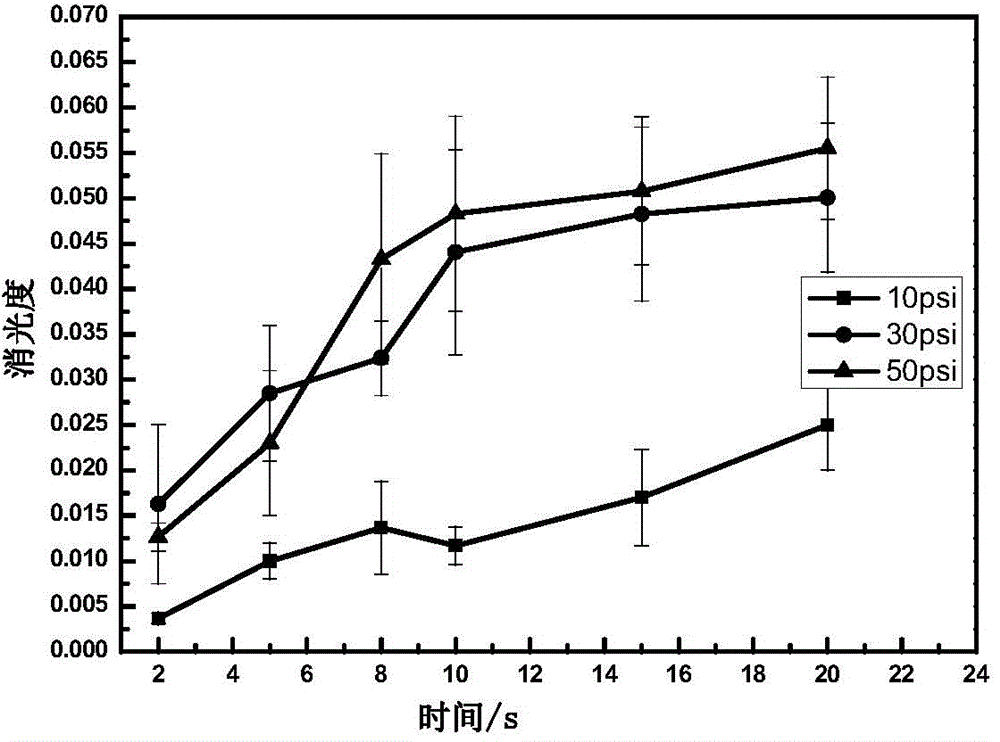

Embodiment 2

[0053] In this embodiment, the spraying pressure is 10 psi, and the other control conditions of the experiment are the same as in Embodiment 1, and a gold nano film is prepared.

Embodiment 3

[0055] In this embodiment, the spraying pressure is 50 psi, and the other control conditions of the experiment are the same as in Embodiment 1, and a gold nano film is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com