Freeze-drying protective agent and application thereof in nucleic acid amplification reagent

A technology for freeze-drying protective agent and nucleic acid, applied in the field of molecular biology, can solve problems such as large freeze-drying volume, and achieve the effects of improving production efficiency, good application prospects, and improving transportation and shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

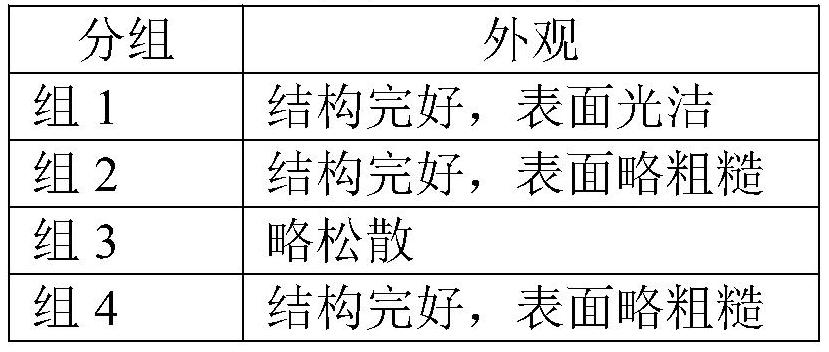

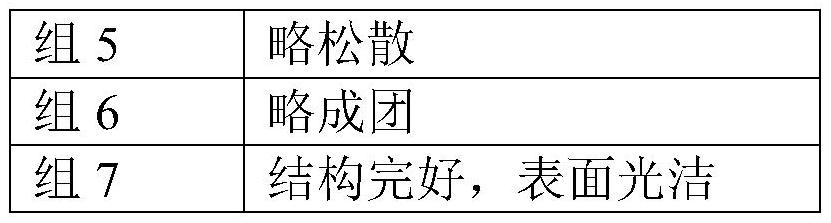

[0026] Lyoprotectant component test, the operation steps are as follows:

[0027] 1. Preparation of lyophilized preservation solution: prepare 7 groups of lyoprotectants according to Table 1, and use ddH 2 O was adjusted to 100mL.

[0028] Table 1 Formulation of lyoprotectant components

[0029] marshalling Trehalose Mannitol polyethylene glycol 8000 β-cyclodextrin 1 40g 4g 2g 1g 2 40g 2g 2g 1g 3 40g - 2g 1g 4 40g 4g 1g 1g 5 40g 4g - 1g 6 40g 4g 2g 2g 7 40g 4g 2g -

[0030] In Table 1, trehalose, mannitol, polyethylene glycol 8000, and β-cyclodextrin were purchased from Sangon Bioengineering (Shanghai) Co., Ltd. ddH 2 O was purchased from Thermo Fisher Scientific.

[0031] 2. Preparation of nucleic acid amplification reagents: Prepare nucleic acid amplification reagents according to Table 2, and the quantity is 150 for testing.

[0032] Table 2 Nucleic Acid Amplification Reagent Preparation Table ...

Embodiment 2

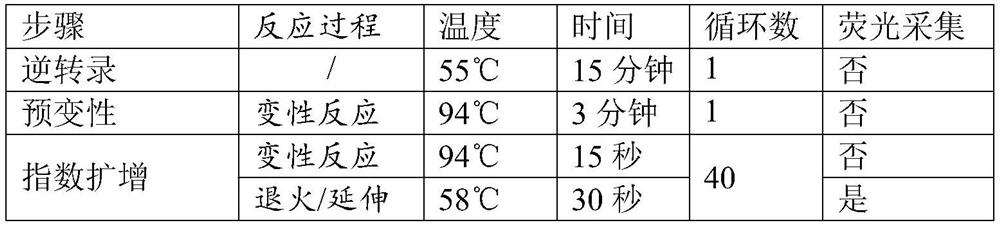

[0062] To optimize the freeze-drying process parameters, the operation steps are as follows:

[0063] 1. Prepare a lyophilized preservation solution according to the following formula: trehalose 40g, mannitol 4g, polyethylene glycol 80002g, β-cyclodextrin 1g, ddH2O to 100mL.

[0064] 2. Prepare nucleic acid amplification reagents at working concentrations according to Table 2, and the quantity is 60 for testing.

[0065] 3. Mix the nucleic acid amplification reagent prepared according to Table 2 and the lyoprotectant prepared in step 1 of Example 2 evenly at a volume ratio of 4:1 to obtain a nucleic acid amplification system mixture. The nucleic acid amplification system mixture was dispensed into PCR tubes at 5 μL / tube, and divided into 4 groups on average, with 12 PCR tubes in each group.

[0066] The above four groups of reagents were freeze-dried respectively, and the freeze-drying procedures included the pre-freezing stage, the sublimation drying stage and the analytical...

Embodiment 3

[0084] Simulated transportation test at 37°C, the operation steps are as follows:

[0085] 1. Preparation of freeze-dried storage solution: trehalose 40g, mannitol 4g, polyethylene glycol 80002g, β-cyclodextrin 1g, ddH2O to 100mL.

[0086] 2. Prepare nucleic acid amplification reagents at working concentrations according to Table 2, and the quantity is 200 for testing.

[0087] 3. Mix the nucleic acid amplification reagent prepared according to Table 2 and the lyoprotectant prepared in step 1 of Example 3 evenly at a volume ratio of 4:1 to obtain a nucleic acid amplification system mixture. The nucleic acid amplification system mixture was dispensed into PCR tubes at 5 μL / tube, and divided into 10 groups on average, with 12 PCR tubes in each group. The 5 groups of reagents were freeze-dried according to the process parameters of group 4 in Tables 6.1-6.3. The other 5 groups of reagents were temporarily stored in a -20°C freezer.

[0088] 4. Packaging: Quickly take out the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com