Assembling type optical cable cross-connecting cabinet

An optical cable junction box and an assembled technology, which is applied in the field of assembled optical cable junction boxes, can solve the problems such as the relatively large limitation of the optical fiber junction box, the inability to flexibly adjust the capacity of the optical fiber junction box, and the difficulty in the work of the optical fiber line, etc., so as to achieve good capacity expansion, Improve the flexibility and adaptability of use, the effect of flexible and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

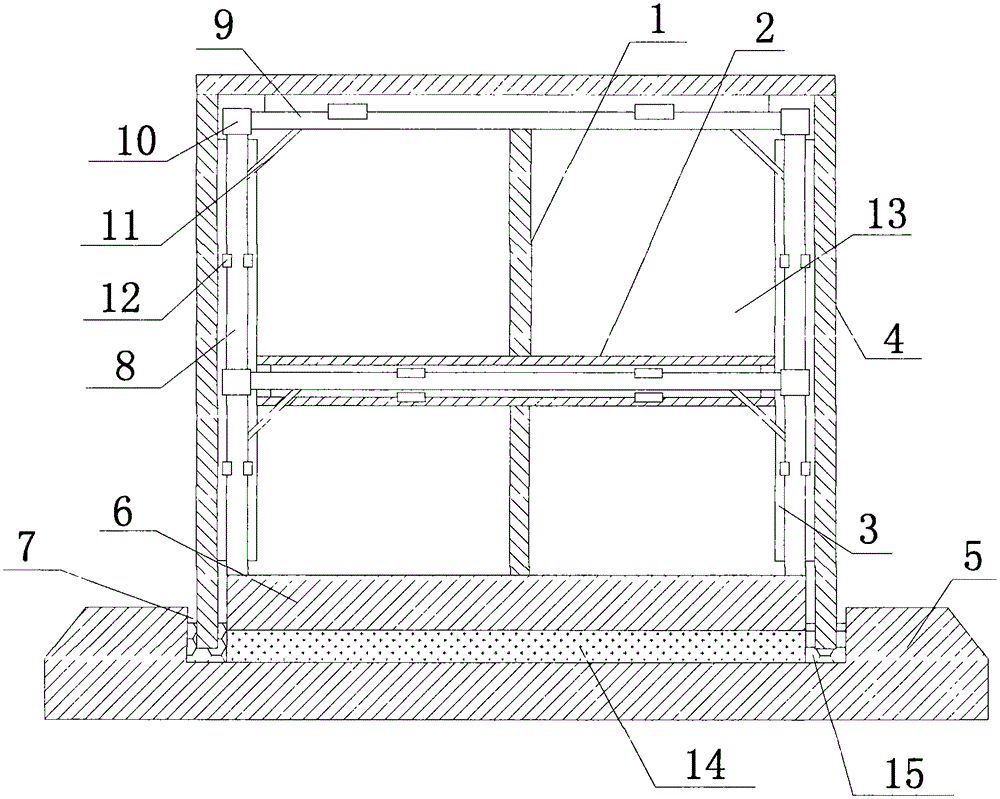

[0014] like figure 1 The described assembled optical cable connection box includes a positioning base, a bearing frame, a bearing plate 1, a partition 2, a guide rail 3 and a protective plate 4, and the positioning base includes a base 5 and a bearing seat 6, wherein the bearing seat 6 is embedded. A positioning groove 7 with a width of 1-5 mm is left on the upper surface of the base 5 and between the base 5. The bearing frame includes a column 8, a beam 9, a shaft sleeve 10 and a reinforcing rib 11, of which at least four columns 8 surround the bearing. The axis of the seat 6 is vertically installed on the upper surface of the bearing seat 6, a number of beams 9 are slidably connected with the column 8 through the shaft sleeve 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com