Stamp-charging coking coal blending method by adding Huangling 1/2 middle sticky coal

A coking coal and tamping coke oven technology, which is applied in coking ovens, solid fuels, special forms of dry distillation, etc., can solve the problems of failing to meet the national standard requirements of metallurgical coke, high calcium content and catalytic index, and inability to guarantee the proportioning, etc. Achieve the effects of reducing coal blending costs, good coke quality, and saving high-quality coking coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method of blending tamped coking coal into Huangling 1 / 2 medium caking coal, in which Huangling 1 / 2 medium caking coal is blended in the conventional 5.5m ramming coke oven coking coal blending scheme.

[0032] (1) The components and weight percentages of coking coal are: 1 / 3 coking coal 15%, main coking coal with caking index G≥83% 37%, medium sulfur main coke with caking index G≥85% 10%, caking index 50%≤G≤55% lean coal 10%, fat coal 17%, Huangling 1 / 2 medium caking coal 11%.

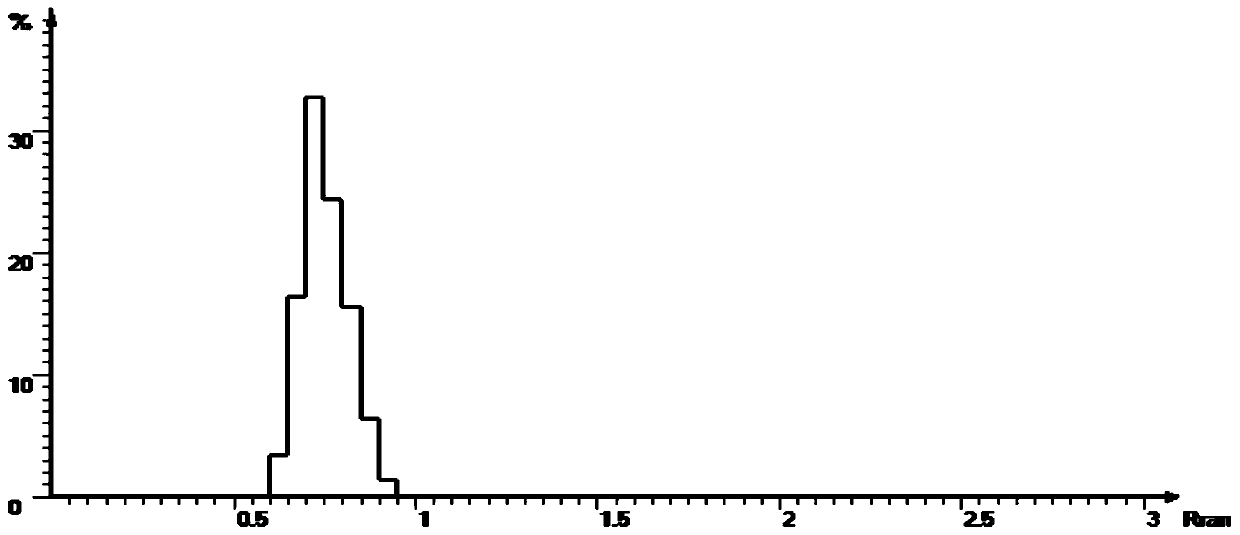

[0033] (2) Coal blending index of 5.5m tamp coke oven coking coal blended into Huangling 1 / 2 medium caking coal: ash content Ad is 10.36%, volatile content Vdaf is 26.93%, Std value is 0.87%, caking index G value is 78.8%, and the Y value is 15.5mm.

[0034] (3) As shown in Table 2, the coal quality of caking coal in Huangling 1 / 2 is as follows: the ash content Ad is 7.2%, the volatile matter Vdaf is 34.2%; Thickness Y value is 7.5mm, Std is 0.36%. The catalytic index MCI is 7.04%.

[003...

Embodiment 2

[0046] A method of blending tamped coking coal into Huangling 1 / 2 medium caking coal, in which Huangling 1 / 2 medium caking coal is blended in the conventional 5.5m ramming coke oven coking coal blending scheme.

[0047] (1) Coking coal components and weight percentages are: 1 / 3 coking coal 10%, main coking coal with caking index G≥83% 12%, lean coking coal with caking index 65%≤G≤70% 17%, caking Medium sulfur main coke with index G≥85% 12%, lean coal with caking index 50%≤G≤55%: 16%, fat coal 15%, Huangling 1 / 2 medium caking coal 18%.

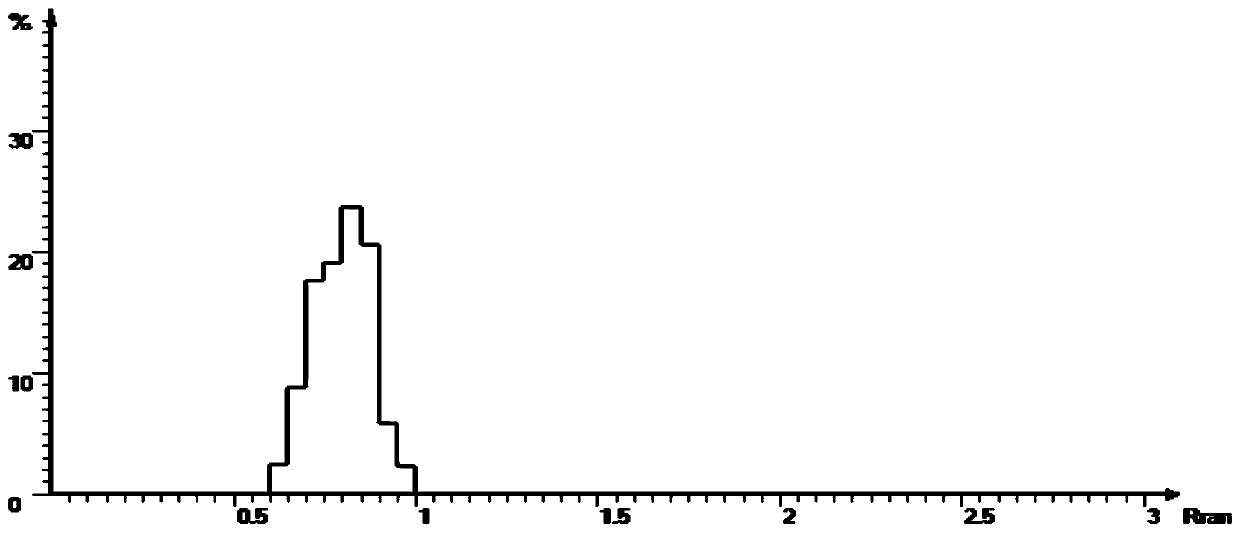

[0048] (2) Coal blending index of 5.5m tamp coke oven coking coal blended into Huangling 1 / 2 medium caking coal: ash content Ad is 10.17%, volatile content Vdaf is 26.7%, Std value is 0.86%, caking index G value is 77.4%, and the Y value is 14.2mm.

[0049] (3) As shown in Table 4, the coal quality of caking coal in Huangling 1 / 2 is as follows: the ash content Ad is 7.6%, the volatile matter Vdaf is 34.6%; Thickness Y value is 8.6mm, Std is 0...

Embodiment 3

[0060] A method of blending tamped coking coal into Huangling 1 / 2 medium caking coal, in which Huangling 1 / 2 medium caking coal is blended in the conventional 5.5m ramming coke oven coking coal blending scheme.

[0061] (1) Coking coal components and weight percentages are: 1 / 3 coking coal 10%, main coking coal with caking index G≥83% 30%, lean coal with caking index 50%≤G≤55% 9%, caking The index G is 15%, lean coal is 8%, fat coal is 18%, and Huangling 1 / 2 medium caking coal is 25%.

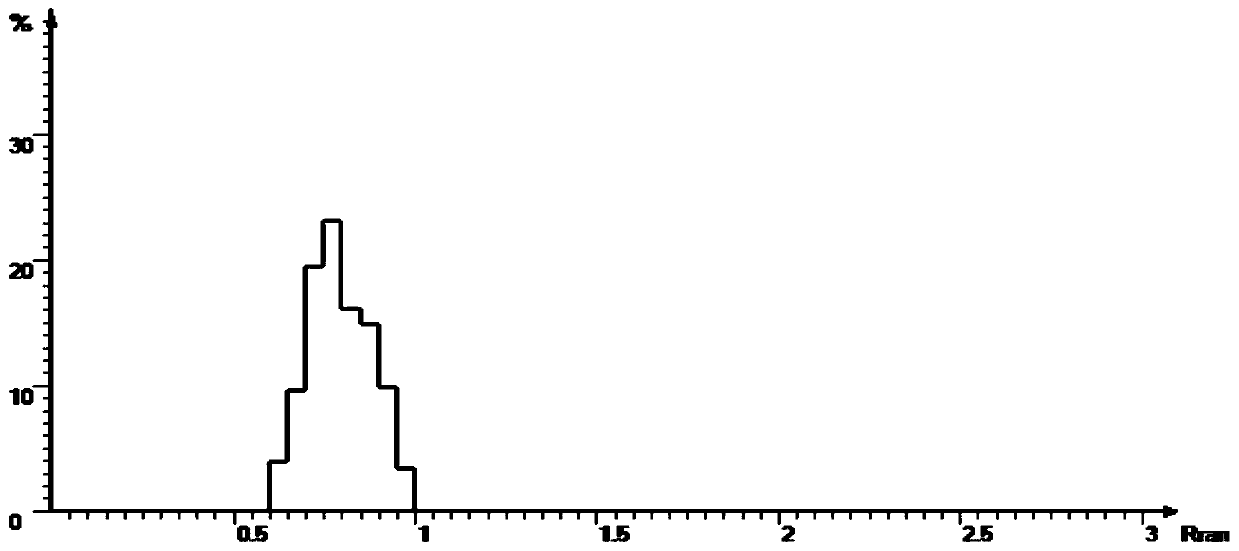

[0062] (2) Coal blending index of 5.5m tamp coke oven coking coal blended into Huangling 1 / 2 medium caking coal: ash content Ad is 10.13%, volatile content Vdaf is 29.32%, Std value is 0.85%, caking index G value is 74.7%, and the Y value is 14.59mm.

[0063] (3) As shown in Table 6, the coal quality of caking coal in Huangling 1 / 2 is as follows: the ash content Ad is 7.1%, the volatile content Vdaf is 33.6%; The thickness Y value is 9.8mm, and the Std value is 0.38%. The catalytic index MCI...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com