Pipeline unloading and transporting device, system and method

A technology for fixing pipelines and pipelines, which is used in lifting devices, transportation and packaging, and transportation of objects, etc., can solve the problems of cumbersome unloading and adjustment of pipelines, large labor costs, and pipelines are easily collided, so as to improve the efficiency of transportation and unloading. , reduce labor costs, improve convenience and rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

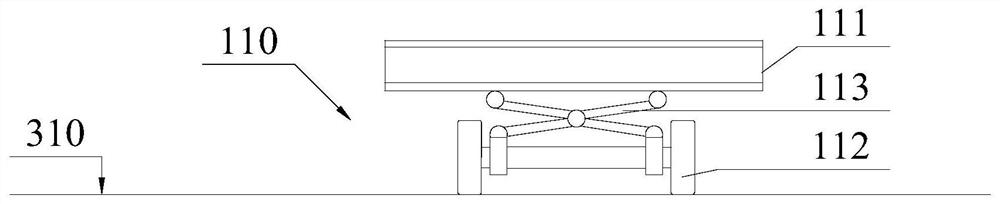

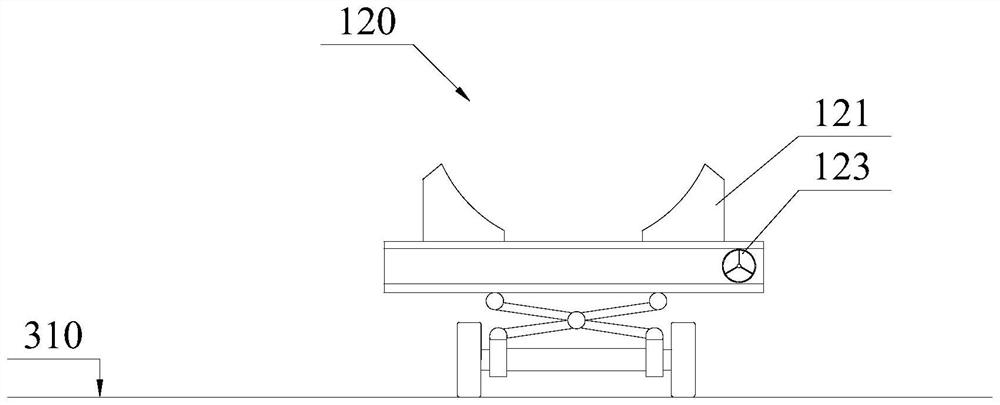

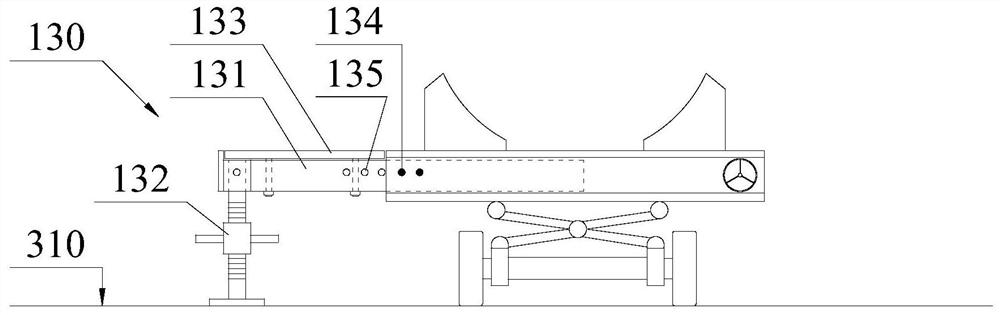

[0057] Please refer to Figure 1 to Figure 8 , Embodiment 1 of the present invention provides a pipeline unloading device 100, including:

[0058] The pipeline transportation vehicle 110 includes a vehicle frame 111 and a wheel assembly 112 , a lifting mechanism 113 is arranged between the vehicle frame 111 and the wheel assembly 112 , and the lifting mechanism 113 can adjust the height of the vehicle frame 111 . Wherein the lifting mechanism 113 may include a shear frame 1131 and a hydraulic cylinder 1132 . Of course, the lifting mechanism 113 can also be in other forms known in the art. The lifting mechanism 113 can adjust the height of the vehicle frame 111 relative to the wheel assembly 112, wherein the lifting mechanism 113 can be a hydraulic lifting mechanism. The wheel assembly 112 includes an axle and wheels mounted on the axle. Wherein the length of the vehicle frame 111 may not be greater than 5 meters, and the width may not be greater than 1.5 meters. It can be we...

Embodiment 2

[0073] Please refer to Figure 1 to Figure 8 with Figure 10 to Figure 13 , Embodiment 2 of the present invention also provides a pipeline unloading system, including multiple sections of the pipeline unloading device 100 and the power vehicle 400 in the first embodiment above, and between the pipeline unloading devices 100 and between the pipeline unloading device 100 and the power vehicle. The vehicles 400 are connected through the traction device 150 . The pipeline unloading system also has a multi-section pipeline unloading device 100, each section of the pipeline unloading device 100 can transport at least one pipeline, and the pipeline unloading device 100 is pulled by a power vehicle 400, which can save manpower and improve transportation efficiency. Wherein the traction device 150 includes but not limited to a traction member 151 and a traction lock 152 . Wherein the traction member 151 can be a traction rod, and can also be a traction rope or a traction chain. The ...

Embodiment 3

[0075] Please refer to Figure 1-13 Embodiment 3 of the present invention also provides a pipeline unloading method, using the pipeline unloading device 100 of the above-mentioned embodiment 1 or the pipeline unloading system of the second embodiment, used for pipeline transportation and unloading on the pipeline support 320 of the tunnel 300 Operation, may include the following steps:

[0076] Step 501 , hoisting the pipeline 200 onto the pipeline transportation vehicle 110 of the pipeline fixing mechanism 120 .

[0077] Step 502 , restrain the pipeline 200 on the pipeline transportation vehicle 110 by the pipeline fixing mechanism 120 .

[0078] Step 503 , transport the pipeline 200 to the location of the pipeline support 320 by the pipeline transportation vehicle 110 .

[0079] Step 505 , using the brake device of the pipeline transportation vehicle 110 to keep the pipeline transportation vehicle 110 parked at the location of the pipeline support 320 .

[0080] Step 506 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com