A process for manufacturing composite ceramic covered with a photocatalyst membrane

A production process and membrane composite technology, which is applied in the field of ceramics, can solve problems such as high cost, complex production process, and unstable product performance, and achieve the effects of improving the environment, efficient and clean air, and simple production process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

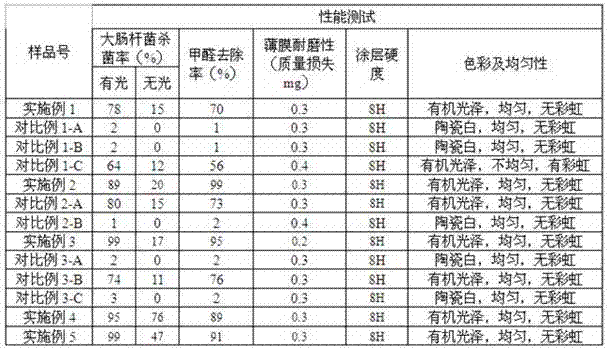

Examples

Embodiment 1

[0026] The ceramics were washed 3 times with absolute ethanol to remove surface oil stains, and then washed 3 times with distilled water, and dried in a drying oven to obtain ceramics with a dry and clean surface. The starting material is diluted with distilled water to a peroxotitanic acid concentration of 0.1wt.%, to obtain a peroxotitanic acid aqueous solution, and polyether-modified polydimethylsiloxane is added to the peroxotitanic acid aqueous solution, and the polyether-modified polydimethylsiloxane is Dimethylsiloxane accounts for 0.5% of the total aqueous solution, and it is made into a spraying liquid; control the spraying pressure to 0.6MPa, the spraying distance from the nozzle to the ceramic surface is 200mm, the spraying speed is 20cm / s, and the overlap width between one spraying and the previous one 1 / 3, coating amount 200ml / m 2, Spraying at room temperature (20°C), the humidity of the environment is controlled at 40-50%, there is no oil and water in the air, an...

Embodiment 2

[0032] Add 30% hydrogen peroxide (analytical pure) to 1mol / L titanium hydroxide aqueous solution to make peroxotitanium complex system, the volume ratio of titanium hydroxide aqueous solution and 30% hydrogen peroxide is 1:1, complexing Add 10 times the mass of distilled water to dilute the substance system to obtain an aqueous solution of the peroxotitanium complex system, and add 0.5wt.% of the total mass of polyether-modified polydimethylsiloxane to the aqueous solution to make a spray solution ;Spray the spray liquid evenly on the dry and clean ceramic surface, control the spray pressure 0.8MPa, spray distance 200mm, spray speed 20cm / s, lap width 1 / 3, coating amount 400ml / m 2 , Spraying under the conditions of ambient temperature 15°C and humidity 30-40%, there is no oil and water in the air, the air cleanliness is 10000, the measurement shows that the wet film thickness is 0.3mm, dry at room temperature for 30min, and the sprayed liquid film is dry on the surface, that is,...

Embodiment 3

[0037] Wash the ceramic plate once with absolute ethanol to remove surface oil, then wash it three times with distilled water, and dry it in a drying oven to obtain a ceramic plate with a dry and clean surface. When the concentration of peroxotitanic acid is 5wt.%, an aqueous solution of peroxotitanic acid is obtained, and a polyether-modified polydimethylsiloxane accounting for 2wt.% of the total mass is added to the aqueous solution of peroxotitanic acid to make a spraying liquid; Spray the spray liquid evenly on the surface of the dry and clean ceramic plate, control the spraying pressure to 0.8MPa, the spraying distance to 300mm, the spraying speed to 10cm / s, the lap width to 1 / 3, and the coating amount to 100ml / m 2 , Spraying under the conditions of ambient temperature 15°C and humidity 30-40%, there is no oil and water in the air, the air cleanliness is 10,000, the measurement shows that the wet film thickness is 0.2mm, dry at room temperature for 30min, and the sprayed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com