Intrinsic super-hydrophobic nano cellulose aerogel and preparation method thereof

A nanocellulose and aerogel technology, which is applied in the field of intrinsic superhydrophobic nanocellulose aerogel and its preparation, can solve the problem of increasing the thermal conductivity of pure aerogels of composite materials and limiting the application of nanocellulose aerogels. , Nanocellulose aerogel is easy to absorb moisture and other problems, to achieve the effect of integrated waterproof and moisture permeability, low density, excellent hydrophobic durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

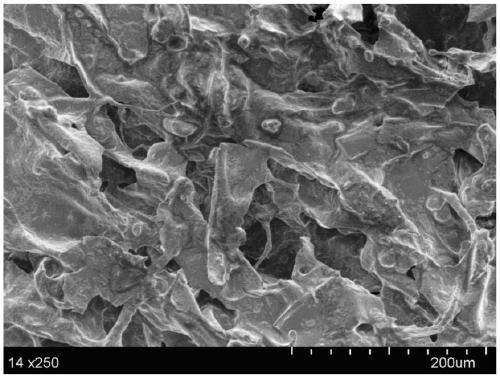

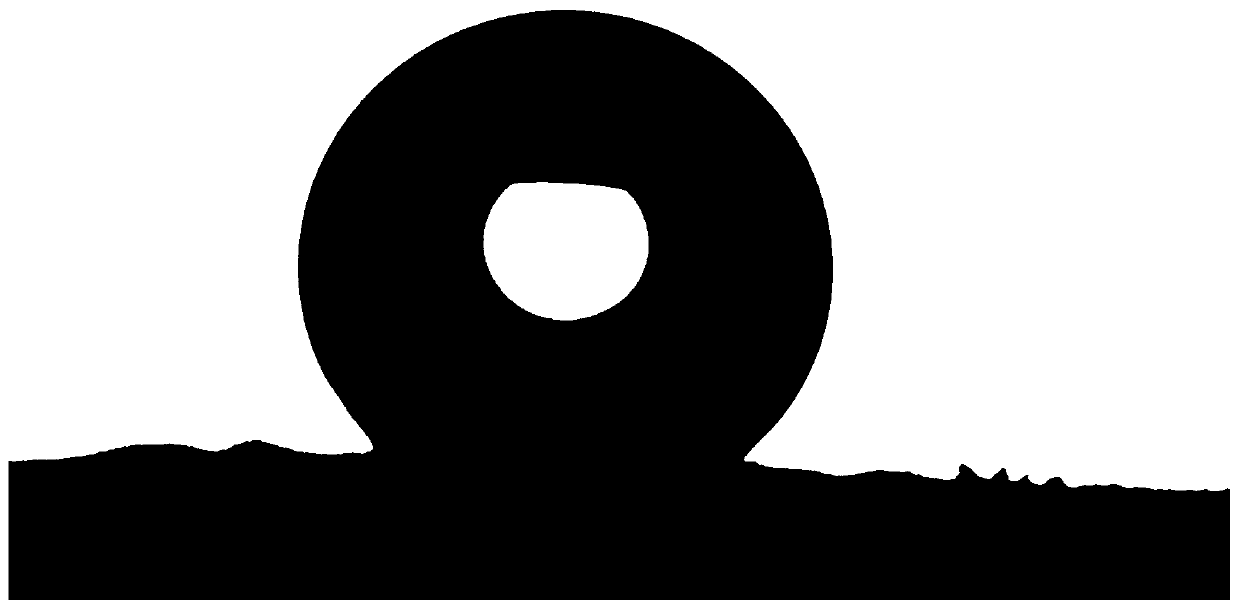

[0027] (1) Prepare 100mL of nanocellulose dispersion with a concentration of 1wt.%, add 0.5g of N,N-methylenebisacrylamide crosslinking agent, and stir mechanically for 5min to obtain a uniform precursor solution; orient the precursor solution Freeze until the precursor solution is completely frozen; freeze-dry the obtained wet gel for 48 hours, and remove the liquid to obtain nanocellulose airgel.

[0028] (2) Dissolve 4g of polydimethylsiloxane (PDMS) in 100mL of cyclohexane, configure a concentration of 4wt% low surface energy polymer solution, add 0.08g of photocuring agent 1173, and then add 3g of micronano titanium dioxide ( TiO 2 ) ratio of micron:nano 3:5, ultrasonic dispersion (100W, 40kHz) for 30min, to prepare uniform low surface energy polymer / micronano particle dispersion.

[0029] (3) Immerse (1) nanocellulose airgel in the dispersion of (2), and the intensity is 220mW / cm when the wavelength is 365nm 2 UV cured for 60s, then took it out and put it in a fume hoo...

Embodiment 2

[0031] (1) Prepare 100 mL of nanocellulose dispersion with a concentration of 2wt.%, add 1.0 g of N,N-methylenebisacrylamide crosslinking agent, and stir mechanically for 5 minutes to obtain a uniform precursor solution; orient the precursor liquid Freeze until the precursor solution is completely frozen; freeze-dry the obtained wet gel for 48 hours, and remove the liquid to obtain nanocellulose airgel.

[0032] (2) Dissolve 4g of polydimethylsiloxane (PDMS) in 100mL of cyclohexane, configure a concentration of 4wt% low surface energy polymer solution, add 0.08g of photocuring agent 1173, and then add 3g of micronano titanium dioxide ( TiO 2 ) ratio of micron:nano 3:5, ultrasonic dispersion (100W, 40kHz) for 30min, to prepare uniform low surface energy polymer / micronano particle dispersion.

[0033] (3) Immerse (1) nanocellulose airgel in the dispersion of (2), and the intensity is 220mW / cm when the wavelength is 365nm 2 UV cured for 60s, then took it out and put it in a fum...

Embodiment 3

[0035] (1) Prepare 100mL of nanocellulose dispersion with a concentration of 1wt.%, add 0.5g of N,N-methylenebisacrylamide crosslinking agent, and stir mechanically for 5min to obtain a uniform precursor solution; orient the precursor solution Freeze until the precursor solution is completely frozen; freeze-dry the obtained wet gel for 48 hours, and remove the liquid to obtain nanocellulose airgel.

[0036] (2) Dissolve 6g of polydimethylsiloxane (PDMS) in 100mL of cyclohexane, configure a low surface energy polymer solution with a concentration of 6wt%, add 0.08g of photocuring agent 1173, and then add 3g of micronano titanium dioxide ( TiO 2 ) ratio of micron:nano 4:4, ultrasonic dispersion (100W, 40kHz) for 30min, to prepare uniform low surface energy polymer / micronano particle dispersion.

[0037](3) Immerse (1) nanocellulose airgel in the dispersion of (2), and the intensity is 220mW / cm when the wavelength is 365nm 2 UV cured for 60s, then took it out and put it in a fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com