Silver-zinc crust wet process comprehensive recovery method

A technology of silver-zinc shell and wet method, which is applied in the field of comprehensive recovery of silver-zinc shell by wet method, can solve the problems of affecting metal recovery rate, lack of smelting slag recovery instructions, and production cycle affecting enterprise capital backlog, etc., to achieve short process time, Strong production adaptability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

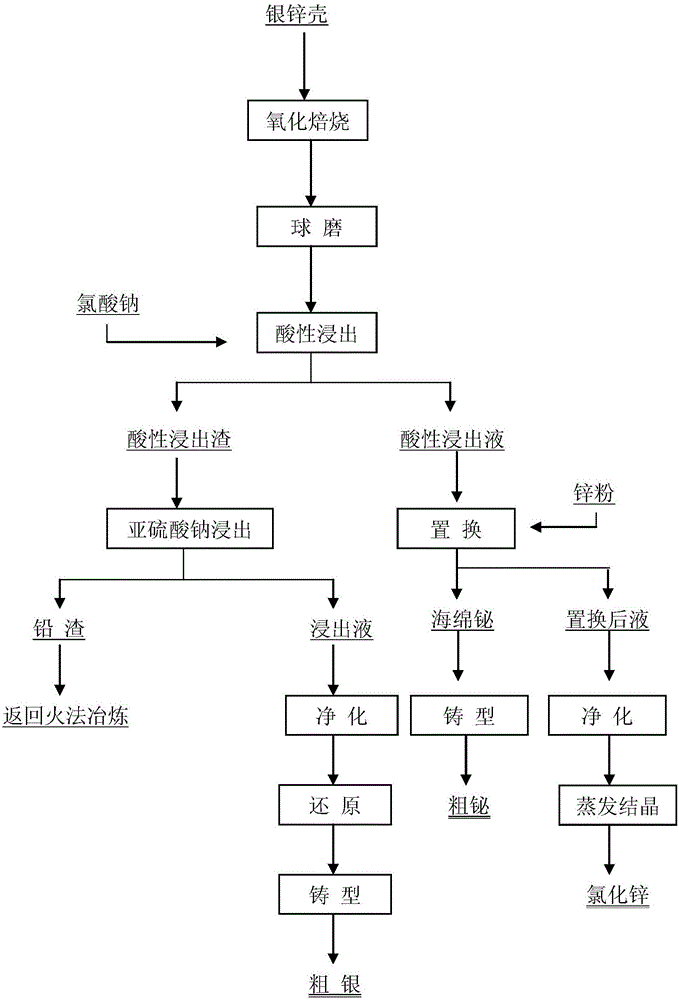

[0030] The flow chart of the production method of the comprehensive recovery of silver-zinc shell by wet method in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0031] Take 2000g of silver-zinc shell and add 200g of calcium oxide for oxidative roasting. The oxidative roasting is divided into three stages. The first stage of roasting is roasting at a roasting temperature of 700°C for 2 hours, and then the second stage of roasting is carried out at a roasting temperature of 800°C. Roasting at low temperature for 2 hours, and finally the third stage of roasting, roasting at 1000°C for 1 hour, rolling continuously throughout the roasting process to make it evenly roasted; then crushing and mixing the roasted silver-zinc shells in a ball mill, 150 mesh sieve, now the element composition content in the silver-zinc shell is (fully roasted and ball milled): lead: 4.14%, silver: 10.49%, bismuth: 20.39%, zinc: 25.67, particle size: 150 mesh.

[0...

Embodiment 2

[0039] The flow chart of the production method of the comprehensive recovery of silver-zinc shell by wet method in this embodiment is as follows figure 1 As shown, the specific steps are as follows:

[0040] Take 2000g of silver-zinc shell and add 60g of calcium oxide for oxidative roasting. The oxidative roasting is divided into three stages. The first stage of roasting is roasting at a roasting temperature of 400°C for 6 hours, and then the second stage of roasting is carried out at a roasting temperature of 700°C. Roasting at low temperature for 4 hours, and finally the third stage of roasting, roasting at 800°C for 3 hours, rolling continuously throughout the roasting process to make it evenly roasted; then crushing and mixing the roasted silver-zinc shells in a ball mill, 200 mesh sieve, at this time the elemental composition content in the silver-zinc shell is (fully roasted and ball milled): lead: 10.32%, silver: 15.46%, bismuth: 25.49%, zinc: 30.16, particle size: 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com