Patents

Literature

116results about How to "Strong production adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional device

ActiveUS20070228368A1Strong production adaptabilityUniform in-plane outputSolid-state devicesSemiconductor/solid-state device manufacturingIn planeEngineering

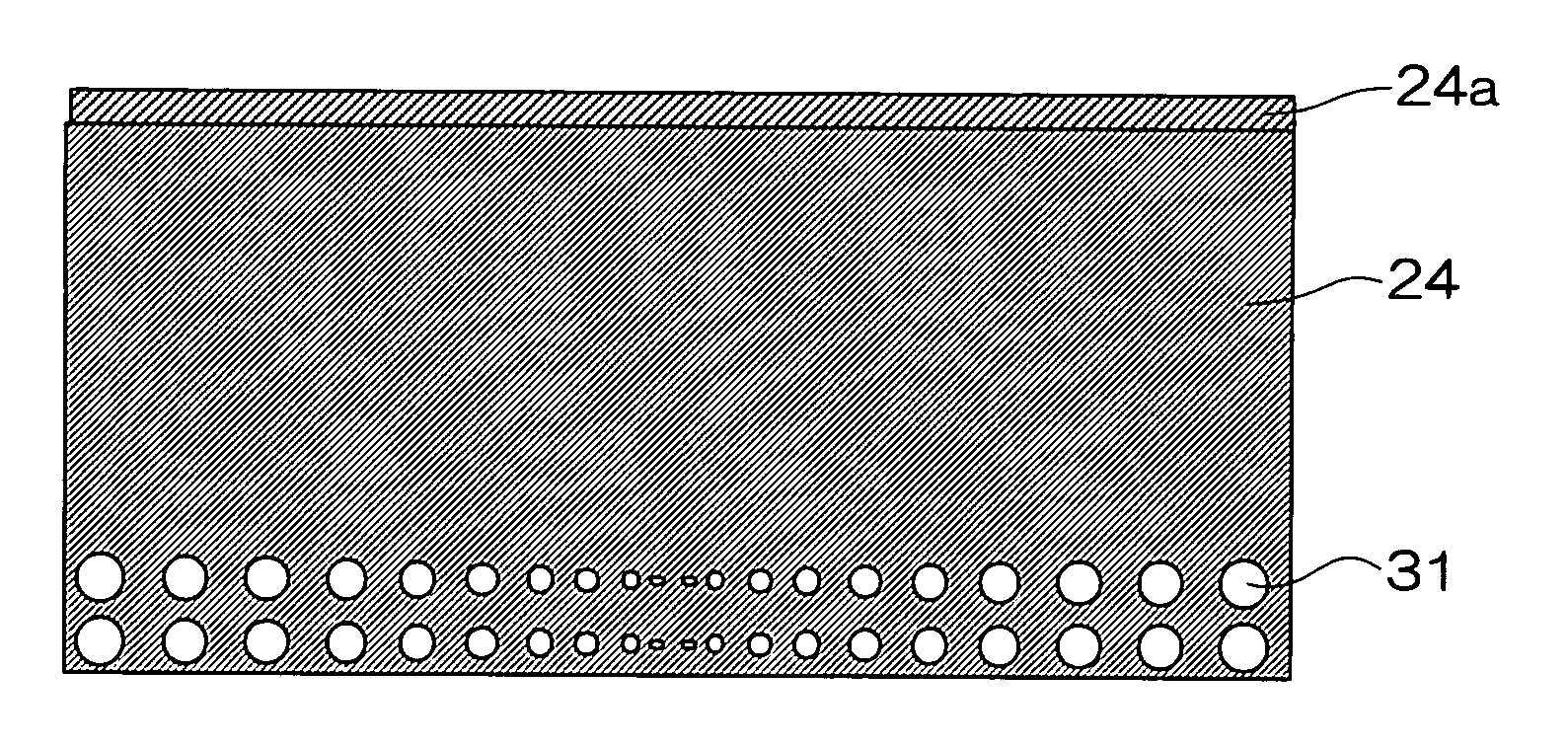

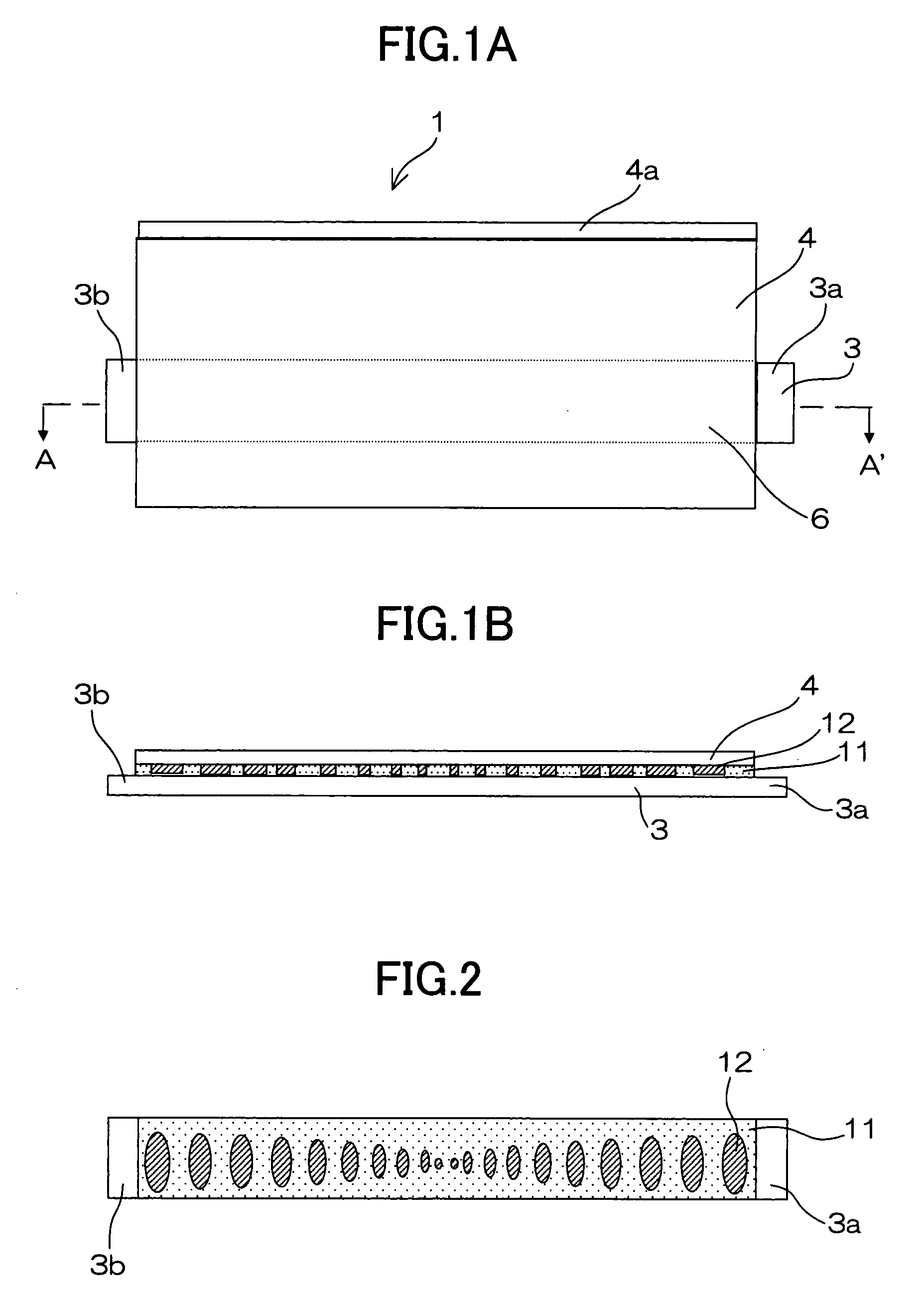

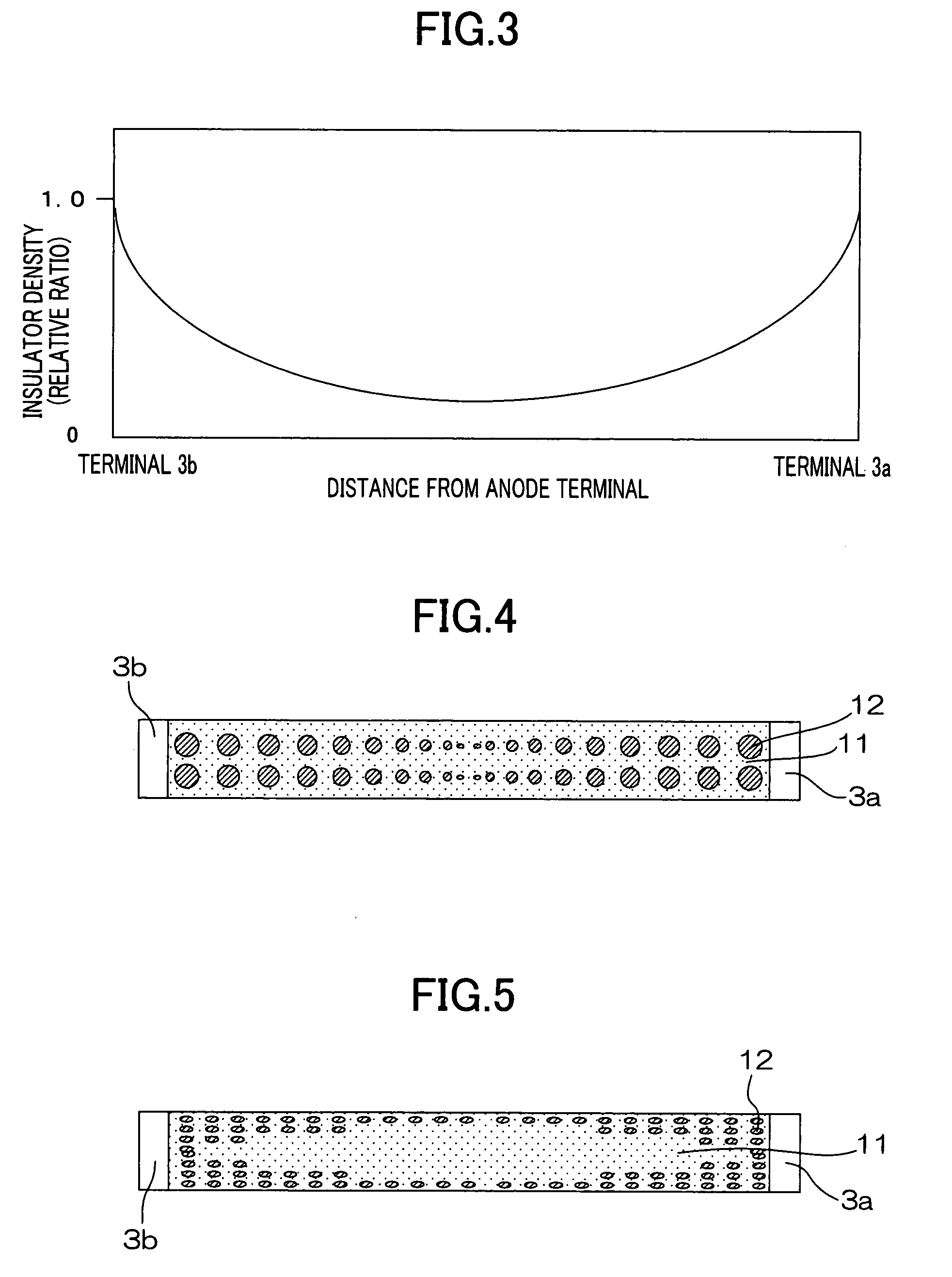

A functional device having, on a substrate, a pair of electrodes, a functional layer which is sandwiched between the electrodes and has an output that varies in accordance with an applied electric current, and a terminal arranged to apply an electric current to at least one of the electrodes, wherein an insulator is arranged between the electrodes and the density of the insulator decreases as the distance from the terminal increases, or wherein at least one of the electrodes has a notch section, and the ratio of the area of the notch section to the area of the electrode decreases as the distance from the terminal increases. This is an improved functional device which is excellent in production suitability and gives a uniform in-plane output, and can be rendered, in particular, an organic electroluminescence device.

Owner:UDC IRELAND

Sintered flux for 9Ni steel welding and preparation method thereof

ActiveCN106238965AImprove low temperature toughnessGood thermal crack resistanceWelding/cutting media/materialsSoldering mediaTO-18Crack resistance

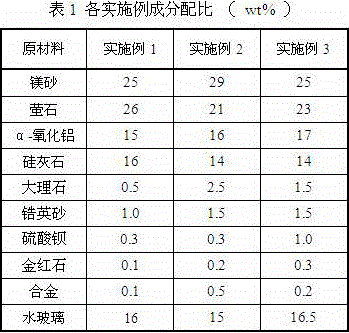

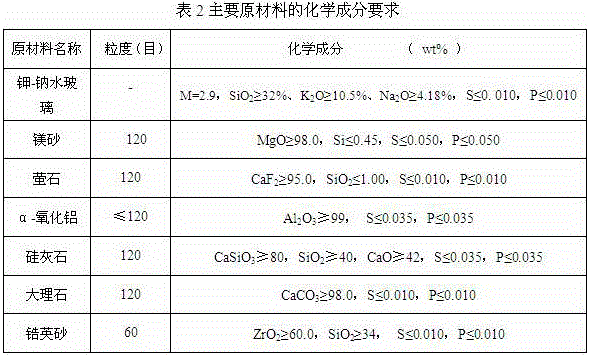

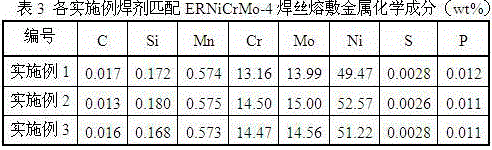

The invention discloses sintered flux for 9Ni steel welding, and relates to the technical field of welding materials. The sintered flux comprises the following components in parts by weight: 20 to 28 parts of CaF2, 23 to 33 parts of MgO, 15 to 18 parts of Al2O3, 8 to 12 parts of CaO, 4 to 10 parts of SiO2, 0.5 to 2 parts of BaO, 0.5 to 2 parts of TiO, 0.5 to 2 parts of ZrO2, 0.5 to 2 parts of alloy and 15 to 20 parts of water glass, wherein the alloy is ferrosilicon or manganese-silicon or a combination of ferrosilicon and manganese-silicon. The preparation method comprises the steps of uniformly mixing the components according to the proportion; carrying out granulation; drying at the low temperature of 300 to 400 DEG C; and sintering at the high temperature of 660 to 750 DEG C, so as to obtain a flux finished product. According to the sintered flux, the flux is matched with a solid welding wire ERNiCrMo-4, the welding manufacturability is relatively good, the mechanical property of weld joints is good, the ultra-low temperature toughness of deposited metals is stable and excellent, the hot crack resistance sensitivity is good, and the sintered flux is applicable to submerged arc flat welding and horizontal welding of 9Ni steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Solid lithium ion conducting electrolytes and methods of preparation

ActiveUS20120171562A1Low costStrong production adaptabilityMaterial nanotechnologyFinal product manufactureNanoparticleLanthanide

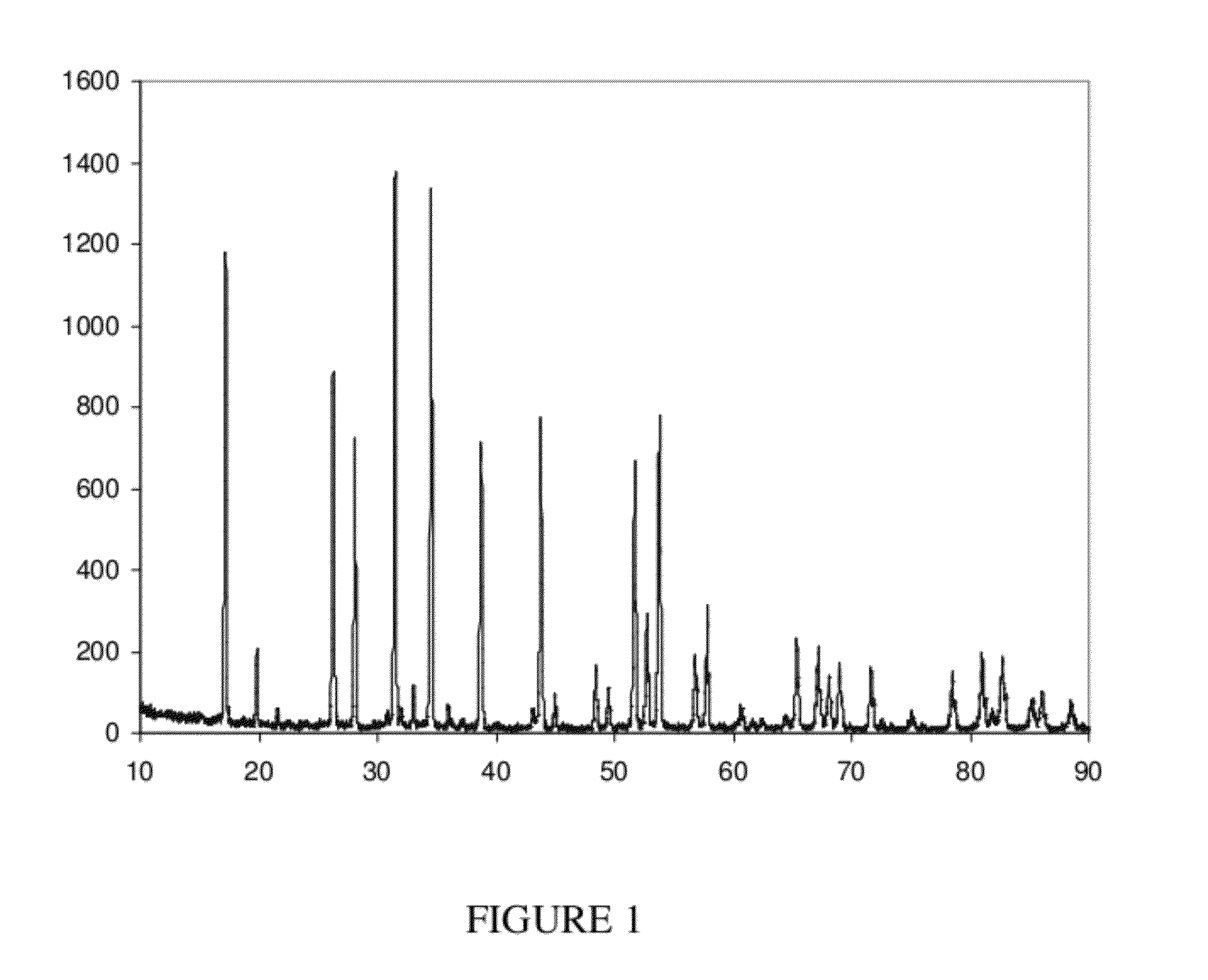

A composition comprised of nanoparticles of lithium ion conducting solid oxide material, wherein the solid oxide material is comprised of lithium ions, and at least one type of metal ion selected from pentavalent metal ions and trivalent lanthanide metal ions. Solution methods useful for synthesizing these solid oxide materials, as well as precursor solutions and components thereof, are also described. The solid oxide materials are incorporated as electrolytes into lithium ion batteries.

Owner:UT BATTELLE LLC

Sintered flux for LPG ship welding and preparation method and application thereof

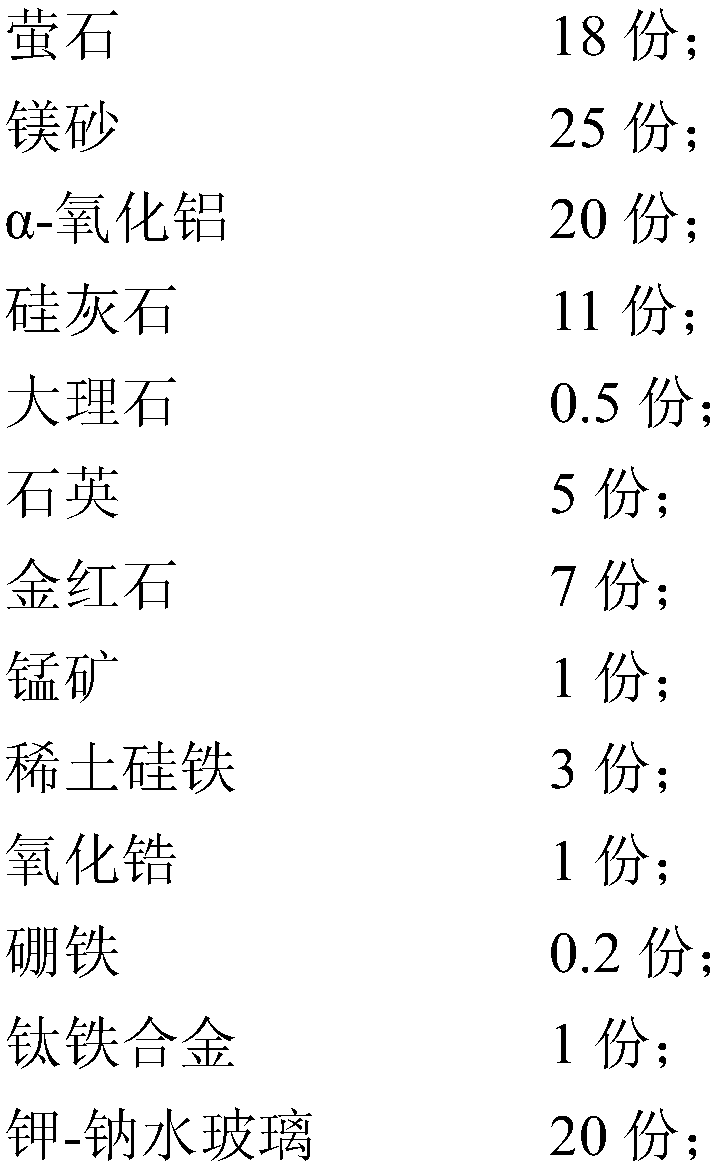

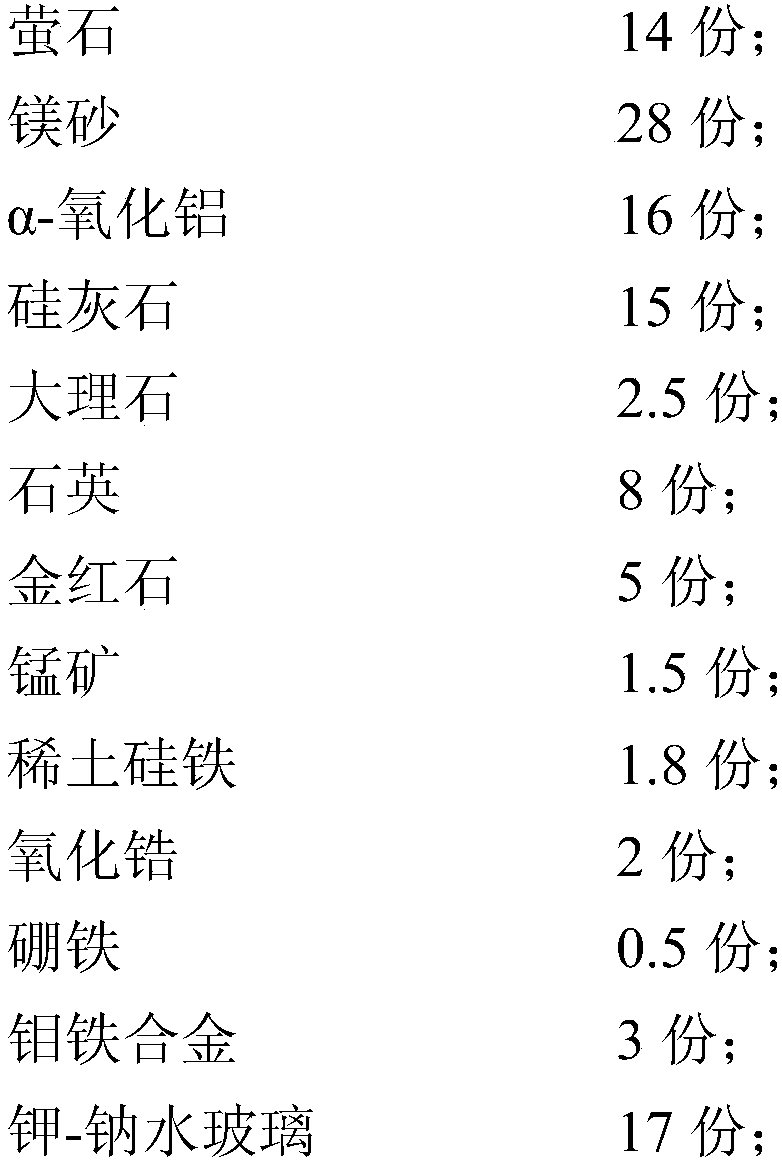

ActiveCN108581270AImprove performanceGood workmanshipWelding/cutting media/materialsSoldering mediaMetal alloyRare earth

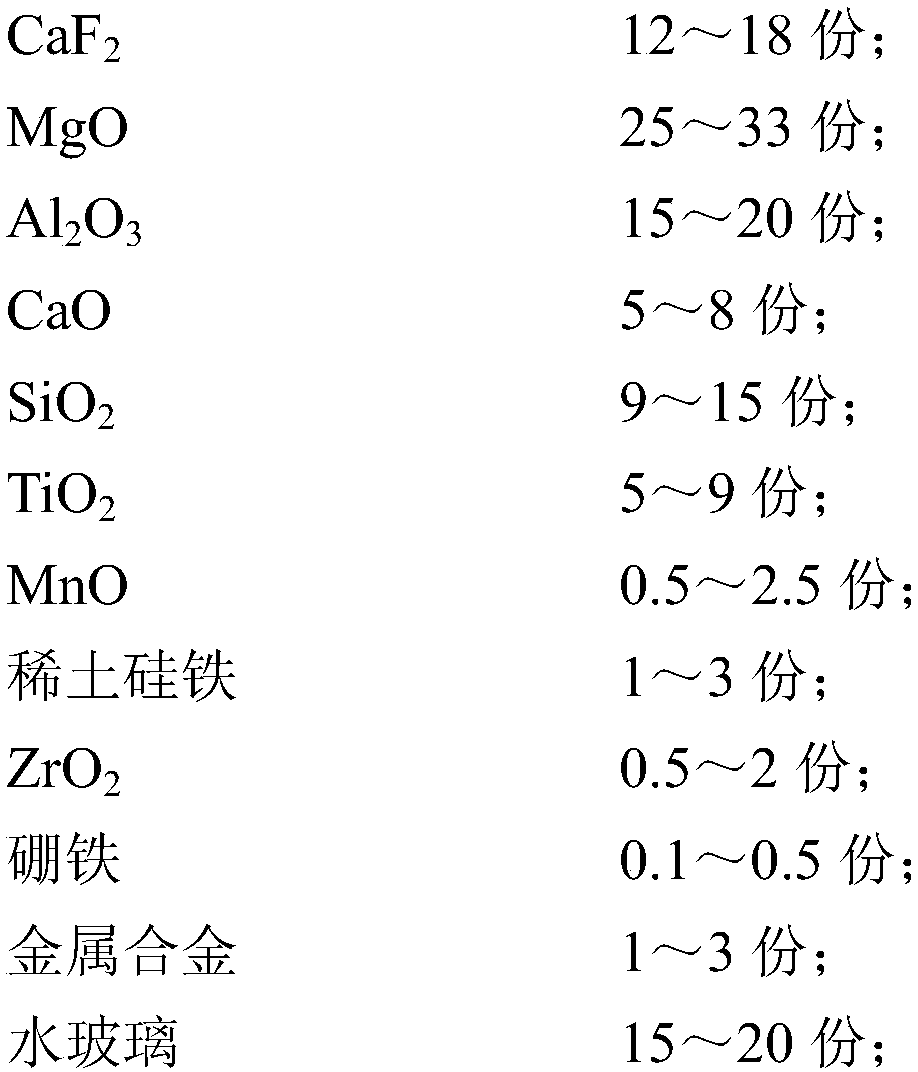

The invention belongs to the technical field of welding materials, and in particular relates to sintered flux for LPG ship welding and a preparation method and application thereof. The sintered flux for LPG ship welding is fluorine alkaline sintered flux which is prepared from the following components in parts by mass: 12-18 parts of GaF2, 25-33 parts of MgO, 15-20 parts of Al2O3, 5-8 parts of CaO, 9-15 parts of SiO2, 5-9 parts of TiO2, 0.5-2.5 parts of MnO, 1-3 parts of rare earth ferrosilicon, 0.5-2 parts of ZrO2, 0.1-0.5 part of ferroboron, 1-3 parts of metal alloy and 15-20 parts of waterglass. The flux is matched with an EH14 welding wire for submerged-arc welding, is relatively good in manufacturability, excellent in low temperature toughness, suitable for high heat input welding ofLPG ship construction, high in low temperature toughness, good in crack sensitivity and relative low in cost, and has a relatively good market promotional prospect and a good economic benefit.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

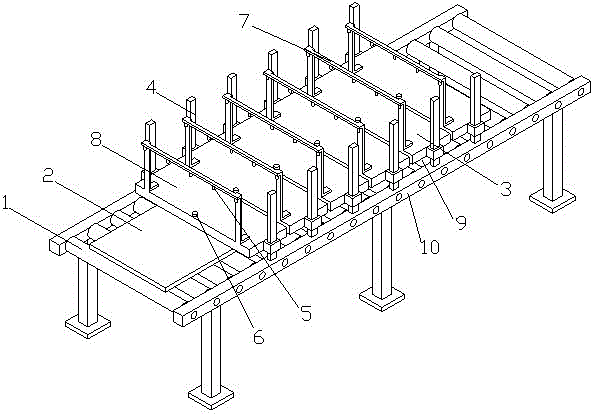

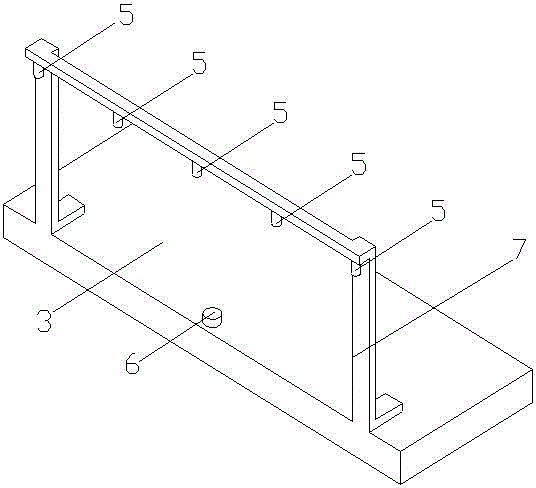

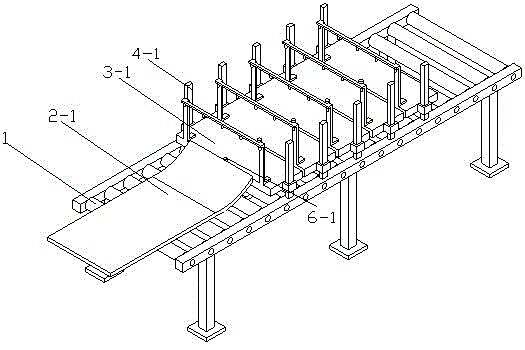

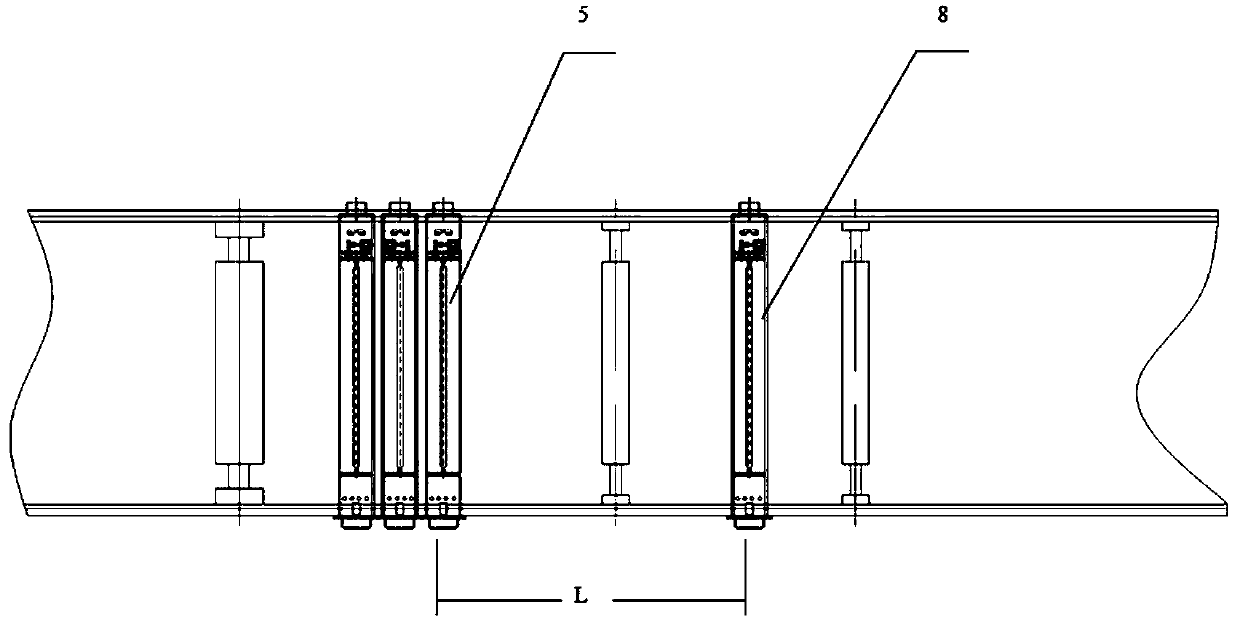

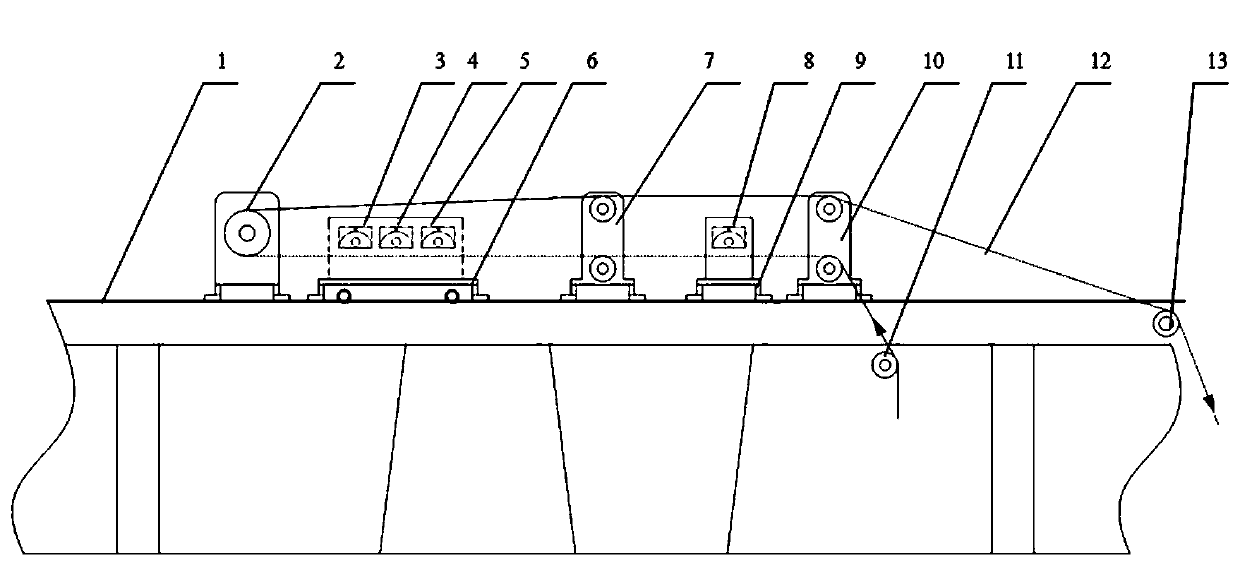

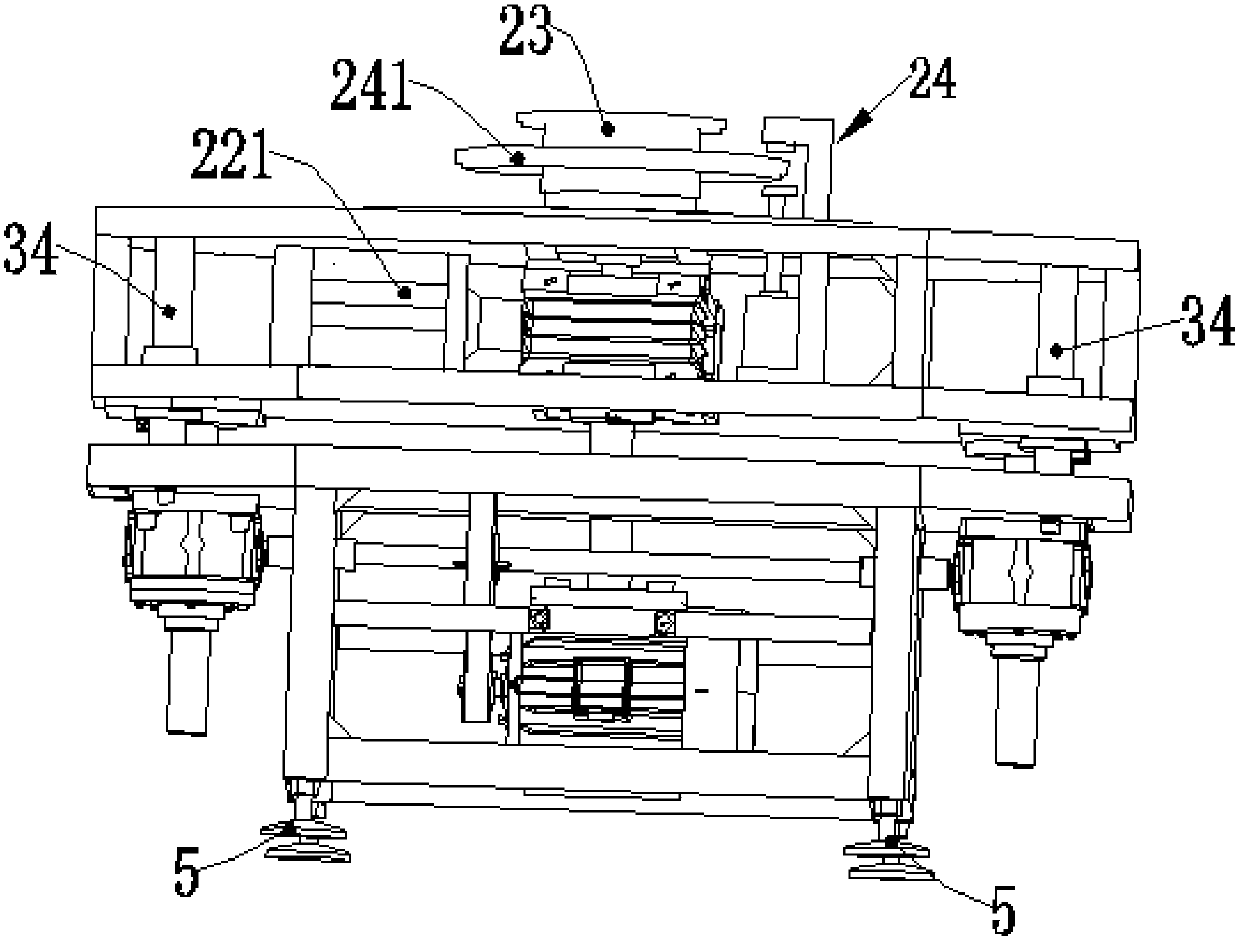

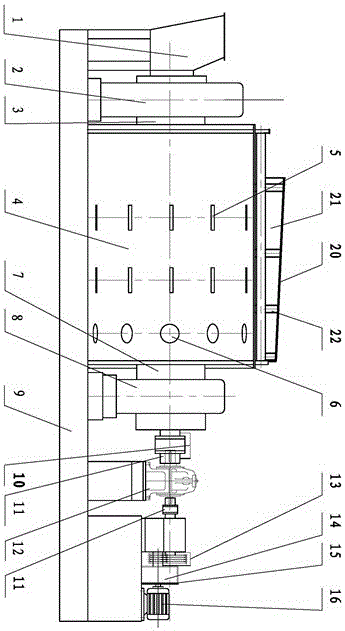

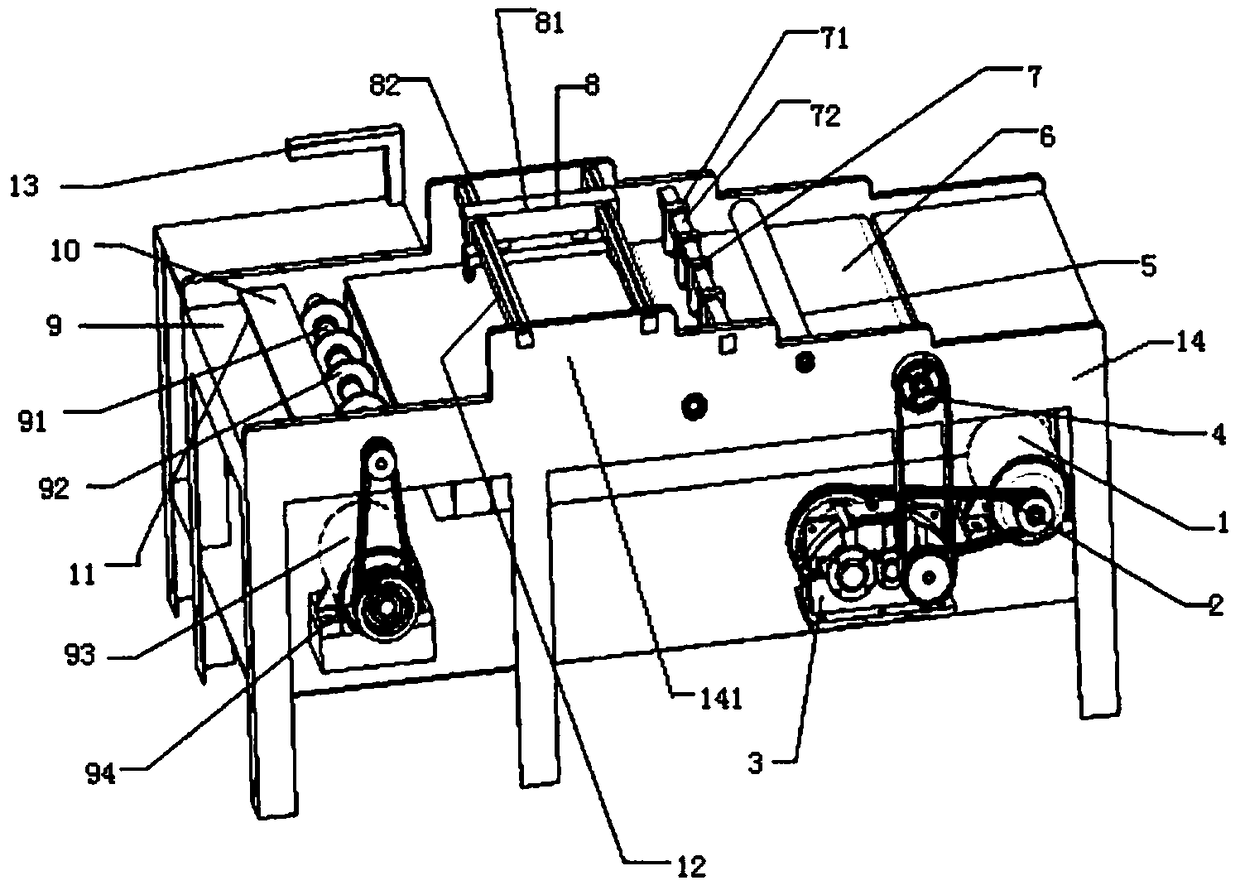

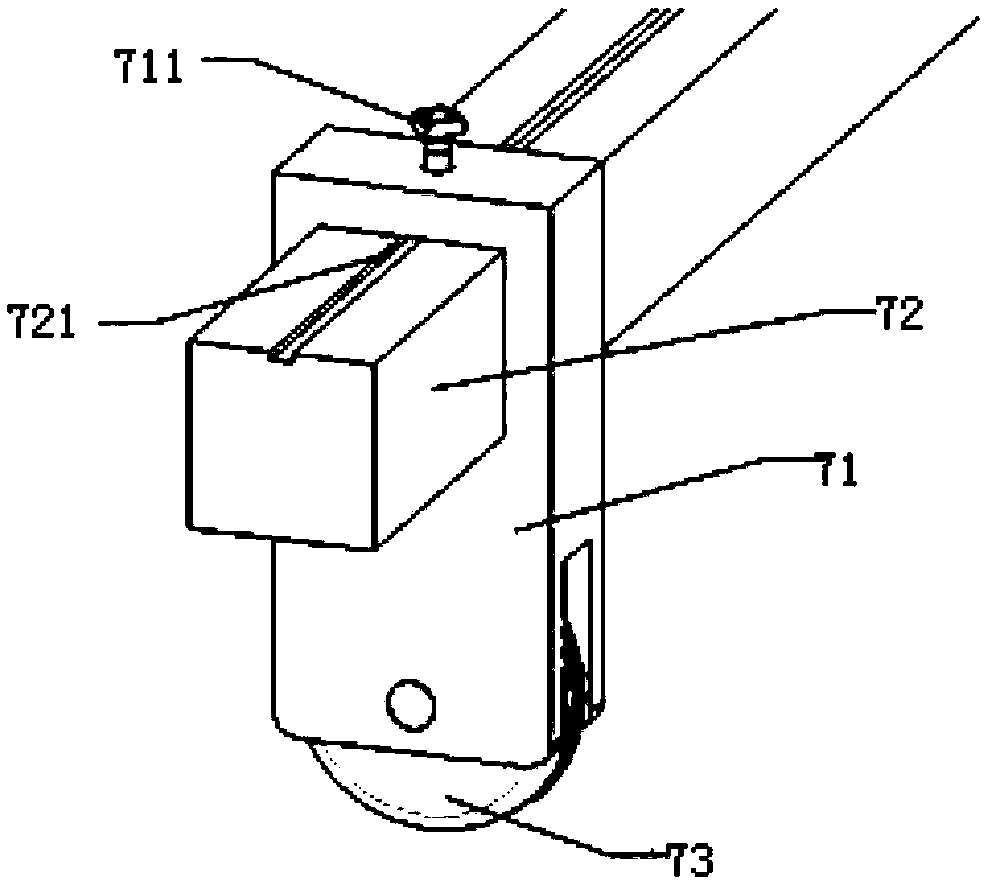

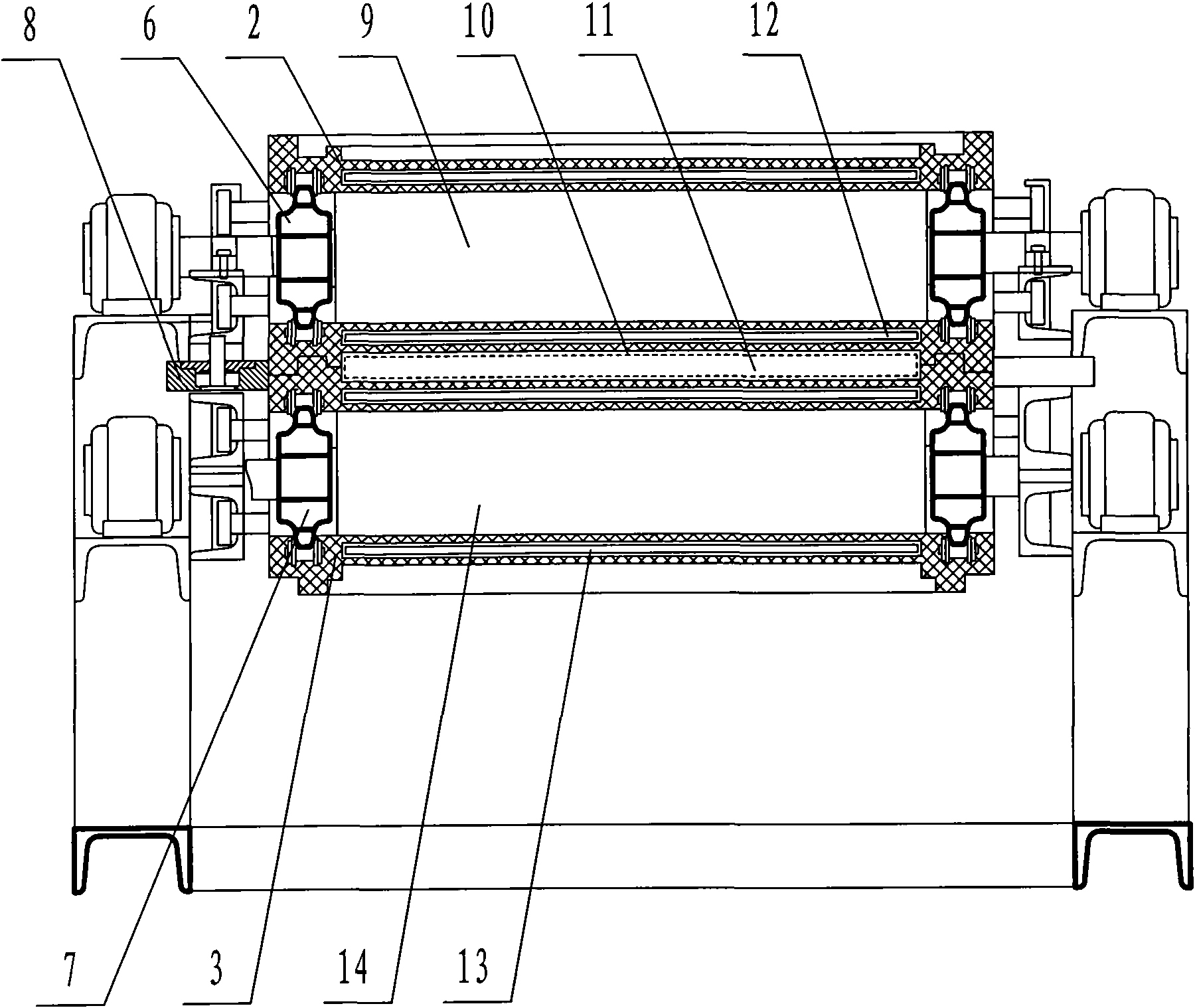

Induction heating method and device with self-adaptive distance adjusting function

ActiveCN105648164ABroaden and enhance processing capabilitiesIncrease productivityFurnace typesIncreasing energy efficiencyControl systemEngineering

The invention discloses an induction heating method suitable for steel plates with any warping degree. Firstly, a steel plate (2) is moved to an inlet of inductors (8) of an induction heating furnace through a roller bed system (1), displacement sensors (5) located on the upper portion of the front end of each upper inductor (3) are used for detecting the distance between the surface of the steel plate and the sensors and sending a measurement result to an intelligent processing unit; secondly, the intelligent processing unit works out the warping degree of the steel plate and an upper inductor position adjusting mode and sends the warping degree of the steel plate and the upper inductor position adjusting mode to a PLC control system; thirdly, the PLC control system sends adjustment commands to an upper inductor position adjusting system (4), so that the distance between the steel plate and the upper inductors is kept relatively constant; and fourthly, when the steel plate enters the inductors, infrared temperature measuring units (6) mounted at the inlet ends of the upper inductors are used for detecting the temperature of the steel plate, power needed for heating the steel plate to a target temperature is worked out, and an inductor heating system is started to heat the steel plate, so that when the steel plate leaves the induction heating furnace, the temperature of the steel plate reaches the target temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

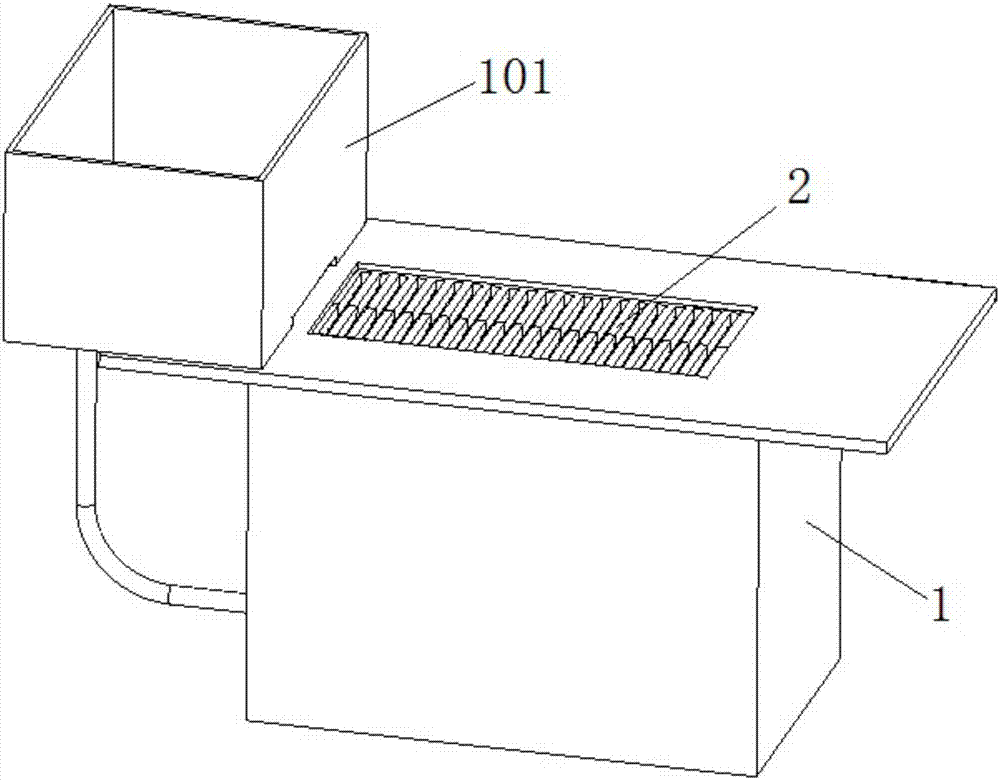

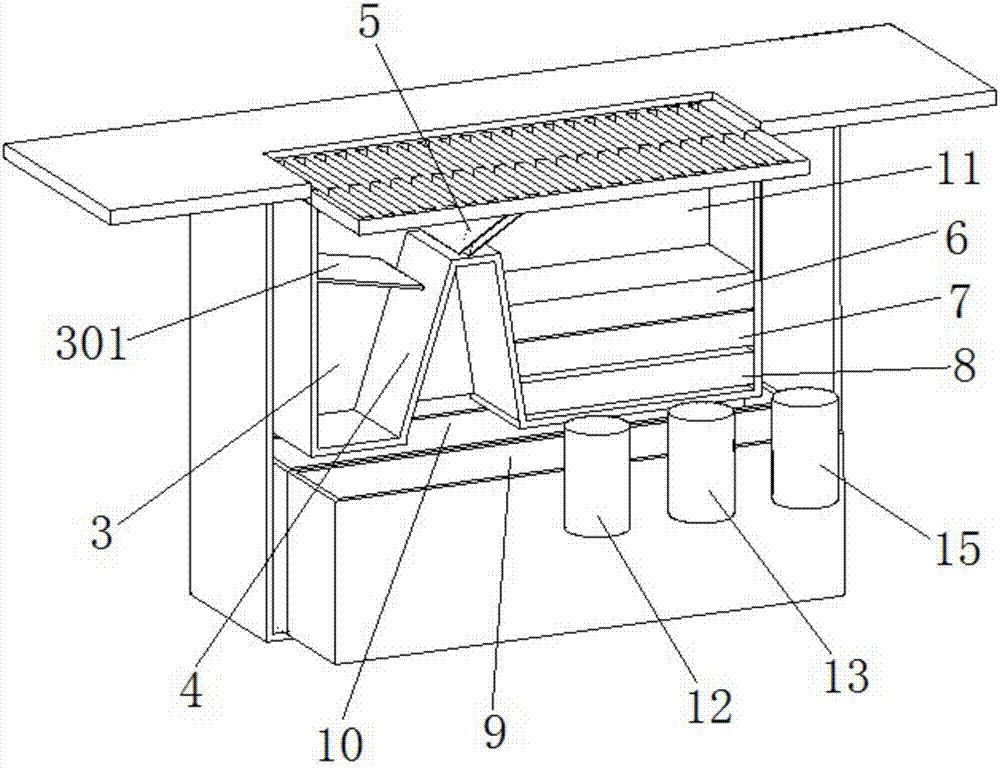

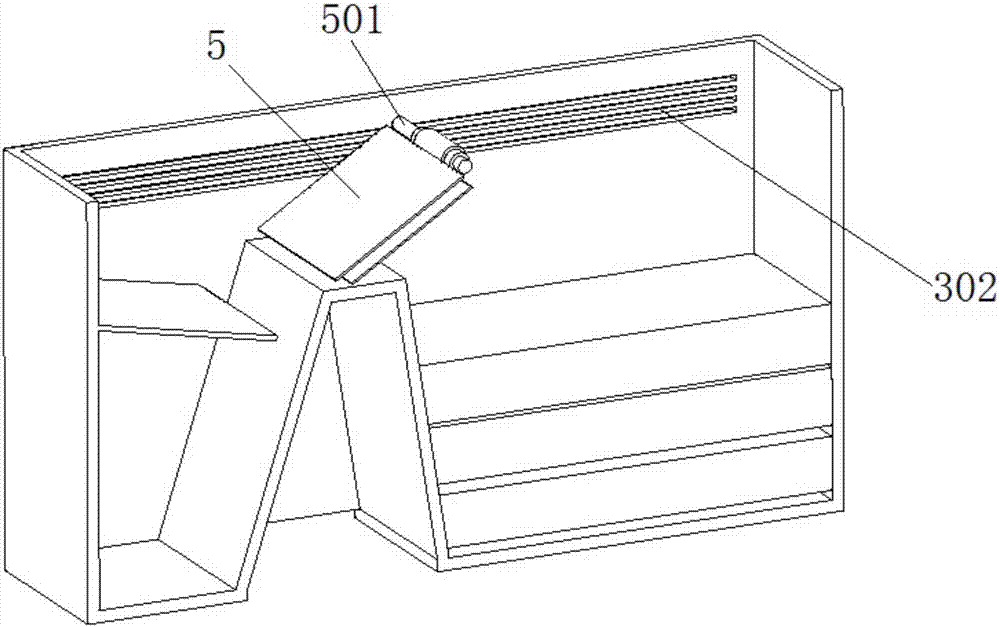

Environment-friendly waste cutting fluid circulation treatment method and purification device

InactiveCN107098505AHigh recovery rateImplement resourcesFatty/oily/floating substances removal devicesTreatment involving filtrationFiltrationNetwork density

The invention discloses an environment-friendly waste cutting fluid circulation treatment method and a purification device and belongs to the technical field of a cutting fluid. The method comprises heating a waste cutting fluid sent from a cutting fluid circulation tank to 30 to 42 DEG C, carrying out coarse filtration, then feeding the filtrate into an oil-water separation tank, carrying out primary oil-water separation through an oil scraper assembly, feeding heavy oil from an overflow port of the oil-water separation tank to an oil-water separator, carrying out secondary oil-water separation to obtain a 1-level clear liquid, filtering to remove impurities in the 1-level clear liquid through filter films having different network densities to obtain a 2-level clear liquid, conveying the 2-level clear liquid into a waste cutting liquid work tank, adjusting pH of the 2-level clear liquid to greater than or equal to 9, adding an antibacterial agent into the 2-level clear liquid to obtain a 3-level clear liquid, conveying the 3-level clear liquid into the cutting fluid circulation tank and carrying out recycling. The method has the advantages of simple processes, low energy consumption and high water recovery rate. The separated cutting liquid can be used for preparation of a cutting liquid or be conveyed into a sewage treatment system, subjected to biochemical treatment and discharged.

Owner:苏州易歌环境科技有限公司

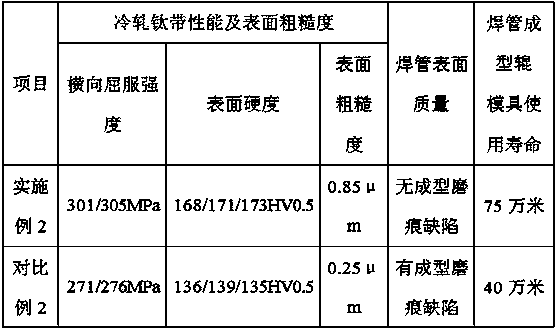

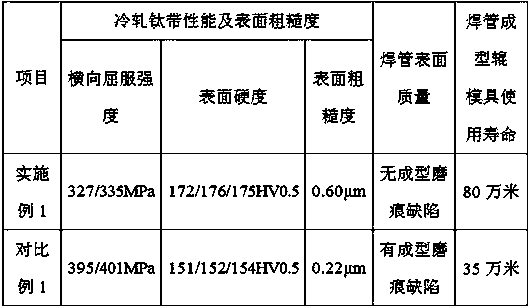

Preparation method of TA2 cold-rolled titanium strip for low-strength and easily-formed welded pipe

A preparation method of a TA2 cold-rolled titanium strip for a low-strength and easily-formed welded pipe comprises the following steps that raw material preparation, cold rolling, degreasing, continuous annealing, acid pickling, flattening and degreasing sampling are conducted, and then a finished TA2 cold-rolled titanium strip for the welded pipe is obtained. The overall content of raw materialstrengthened impurity elements is presented through [O]<dang>, an appropriate range is provided, control is conducted in the compounding process, and meanwhile subsequent cold rolling, annealing and flattening technique measures are combined, so that the transverse yield strength of the TA2 cold-rolled titanium strip for the welded pipe is controlled to be in a low level of 260-350 MPa, the forming resistance of the welded pipe is reduced effectively, and accordingly friction between the titanium strip and a welded pipe forming roller mould is reduced; and by improving the surface hardness androughness of the titanium strip, the adhesivity of the titanium strip and the forming roller mould is reduced, accordingly, the service life of a welded pipe forming roller is prolonged by a large margin, and the quality problem of forming grinding crack defects on the surface of the titanium welded pipe is solved.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

UV drying curing system added on rotogravure printing machine

InactiveCN105269949AAvoid fire and other safety accidentsStrong production adaptabilityPrinting press partsUltravioletPulp and paper industry

The invention provides an UV drying curing system added on a rotogravure printing machine. The system comprises a rotogravure printing machine. The technical scheme is that the top of a longitudinal beam of the rotogravure printing machine is provided with a water-cooling shutter type ultraviolet cold light source drying curing system. The water-cooling shutter type ultraviolet cold light source drying curing system is formed by four sets of ultraviolet cold light sources, wherein three sets are parallel together and are installed on a mobile support, and the other independent set is installed on a fixed support. The front edge and the rear edge of the fixed support are provided with dancing rolls. A paper cooling roller is arranged on the rear of the mobile support. The system enhances production adaptive capacity of an original rotogravure printing machine, realizes a connecting line gravure multiple combination process, overcomes restrictions that a rotogravure printing machine cannot print cortex oil, ice points and snowflake, widens production range of the device, and satisfies more diverse technological requirements.

Owner:桂林澳群彩印有限公司

Ultraviolet absorbent and polymer material containing the same

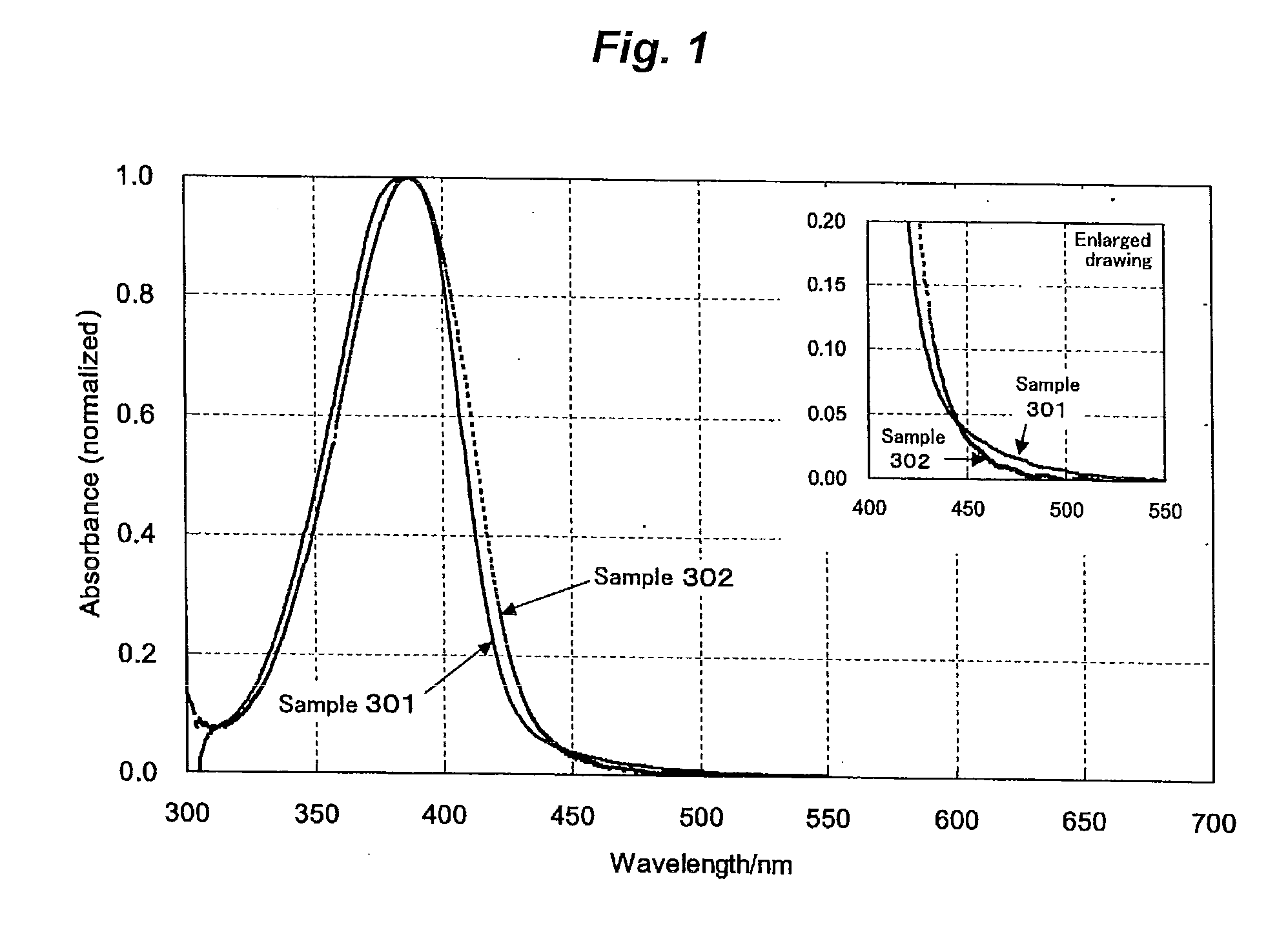

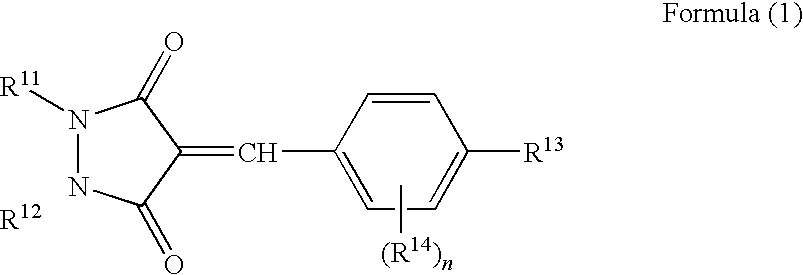

InactiveUS20100010123A1Strong production adaptabilityGood effectOrganic chemistryHydrogen atomUv absorber

An ultraviolet absorbent, containing a compound represented by formula (1) or (2); and a polymer material containing the ultraviolet absorbent:wherein R11, R12 and R14 each independently represent a monovalent substituent; R13 represents a hydrogen atom or a substituent having a Hammett substituent constant σp of −0.35 or more; and n represents an integer of 0 to 4; andwherein R21 represents a substituted or unsubstituted alkyl group having 1 to 18 carbon atoms, or a substituted or unsubstituted phenyl group; R22 represents a substituted or unsubstituted alkyl group having 1 to 18 carbon atoms; R23 represents a hydrogen atom or a substituent having a Hammett substituent constant σp of −0.35 or more; R24 represents a monovalent substituent; and m represents an integer of 0 to 4.

Owner:FUJIFILM CORP

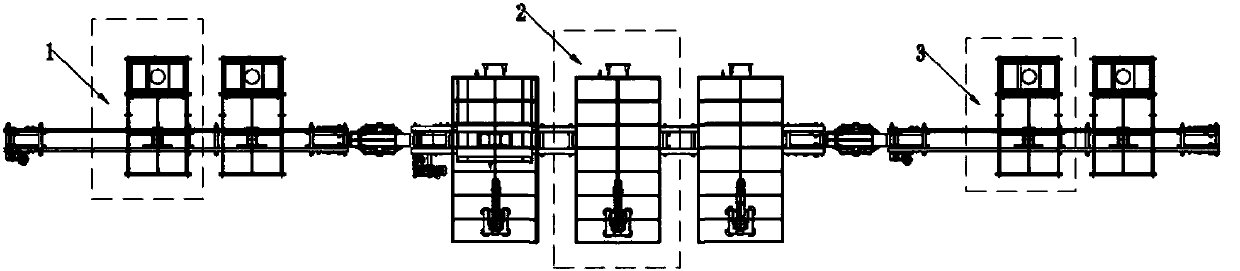

Robot automatic glaze spraying system

ActiveCN107618098AShorten the design and development cycleEasy maintenanceCeramic shaping apparatusModular compositionProduction line

The invention discloses a robot automatic glaze spraying system. The robot automatic glaze spraying system comprises a pretreatment unit, a glaze spraying unit and a posttreatment unit from upstream to downstream in sequence. The pretreatment unit comprises a plurality of pretreatment modules. Each pretreatment module comprises a blank trimming and dust collection position. The posttreatment unitcomprises a plurality of posttreatment modules. Each posttreatment module comprises a detecting and cleaning position. The glaze spraying unit comprises a plurality of glaze spraying modules. Each glaze spraying module comprises a glaze spraying conveying line, a glaze spraying robot and an air extraction and dust collection room. Each unit of the robot automatic glaze spraying system is a detachable module combination. The number of the pretreatment modules, the number of the glaze spraying modules and the number of the posttreatment modules can be set freely according to the production requirements. The production adaptability is greatly improved. The modules can be combined freely according to the production requirements. The design and development cycle of a glaze spraying production line is shortened. The number of the modules can be increased and reduced at will in the production process. The production cost is controlled flexibly.

Owner:FOSHAN PRATIC CNC SCI & TECH

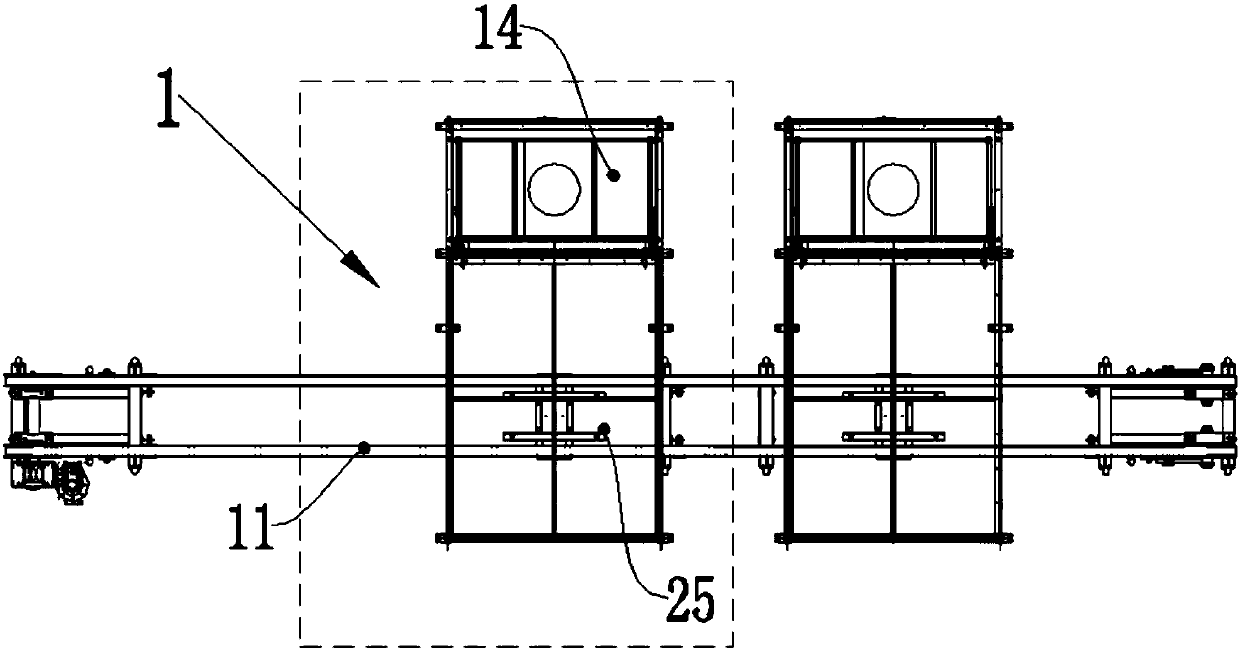

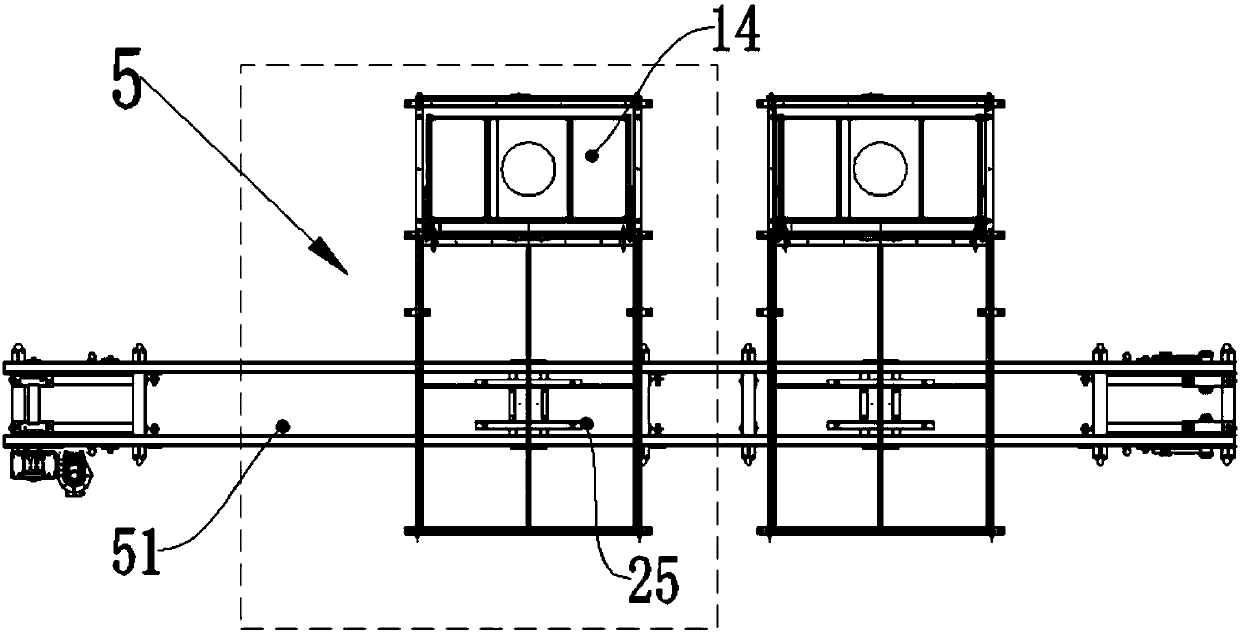

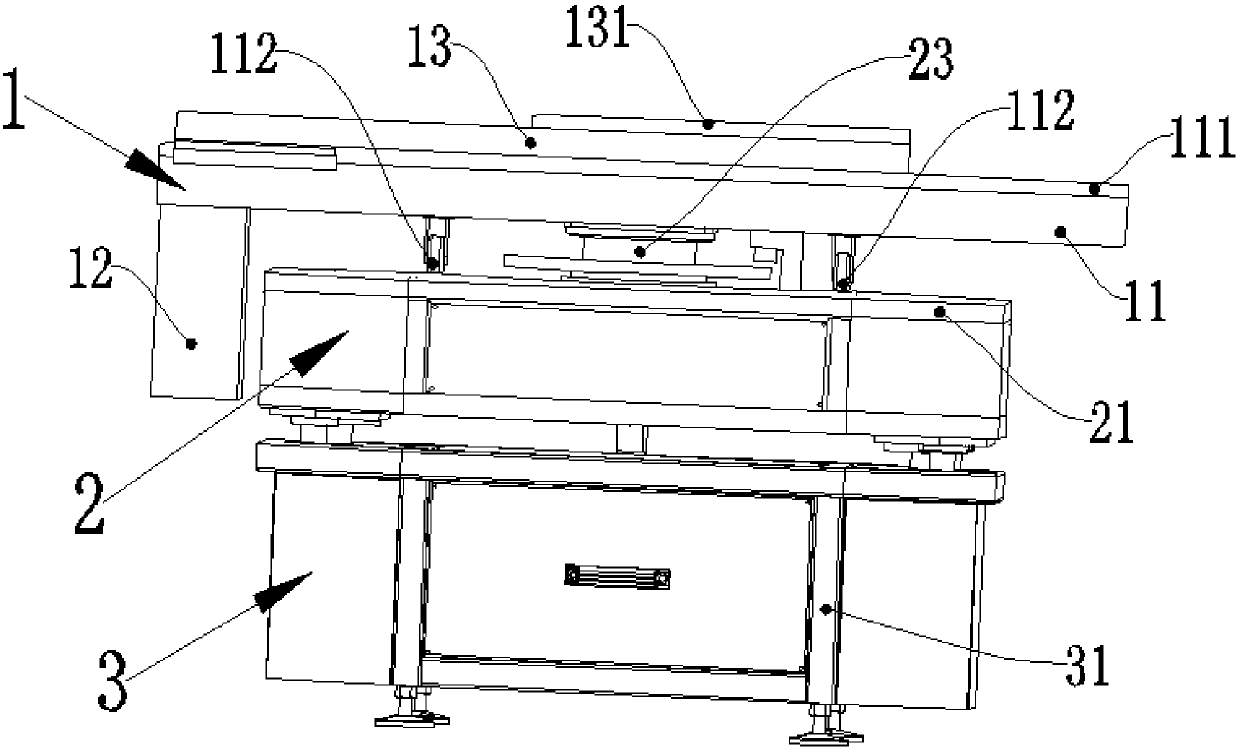

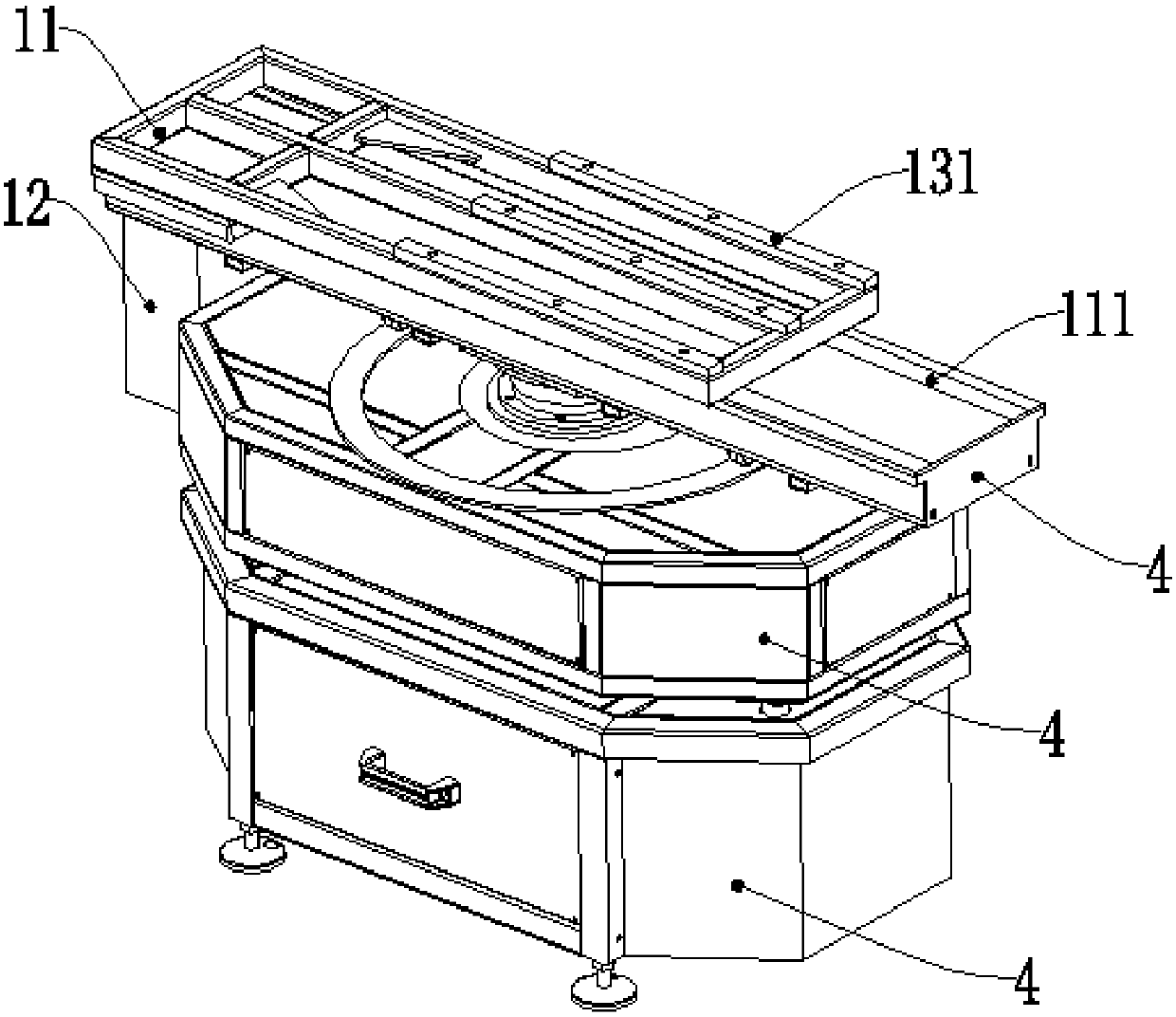

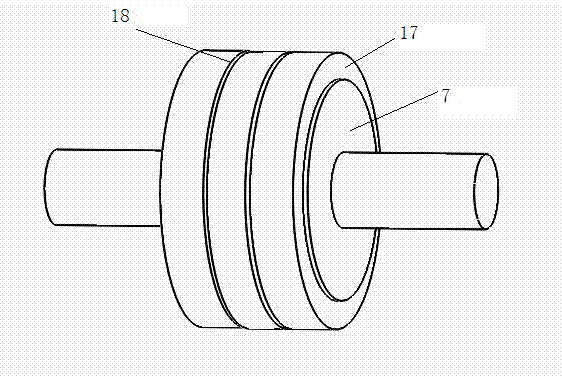

Rotational conveying device and conveying line using same

ActiveCN107618851AEasy maintenanceStrong production adaptabilityDischarging arrangementConveyor partsEngineeringMechanical engineering

The invention discloses a rotational conveying device and a conveying line using the same. The rotational conveying device comprises a sliding module, a rotating module and a lifting module. The rotating module is arranged between the sliding module and the lifting module. The lifting module comprises lifting shafts. The rotating module is connected with the lifting module through the lifting shafts. The lifting module drives the rotating module to be lifted up and down. The sliding module, the rotating module and the lifting module are of a detachable combined structure. The rotational conveying device is used for being arranged on a transfer station of a sanitary ware production conveying line, and a sanitary ware blank can be transferred onto the other production conveying line from oneproduction conveying line. The rotational conveying device of the combined structure is wide in applied range, convenient to maintain, high in production adaptability and high in operation flexibility.

Owner:FOSHAN PRATIC CNC SCI & TECH

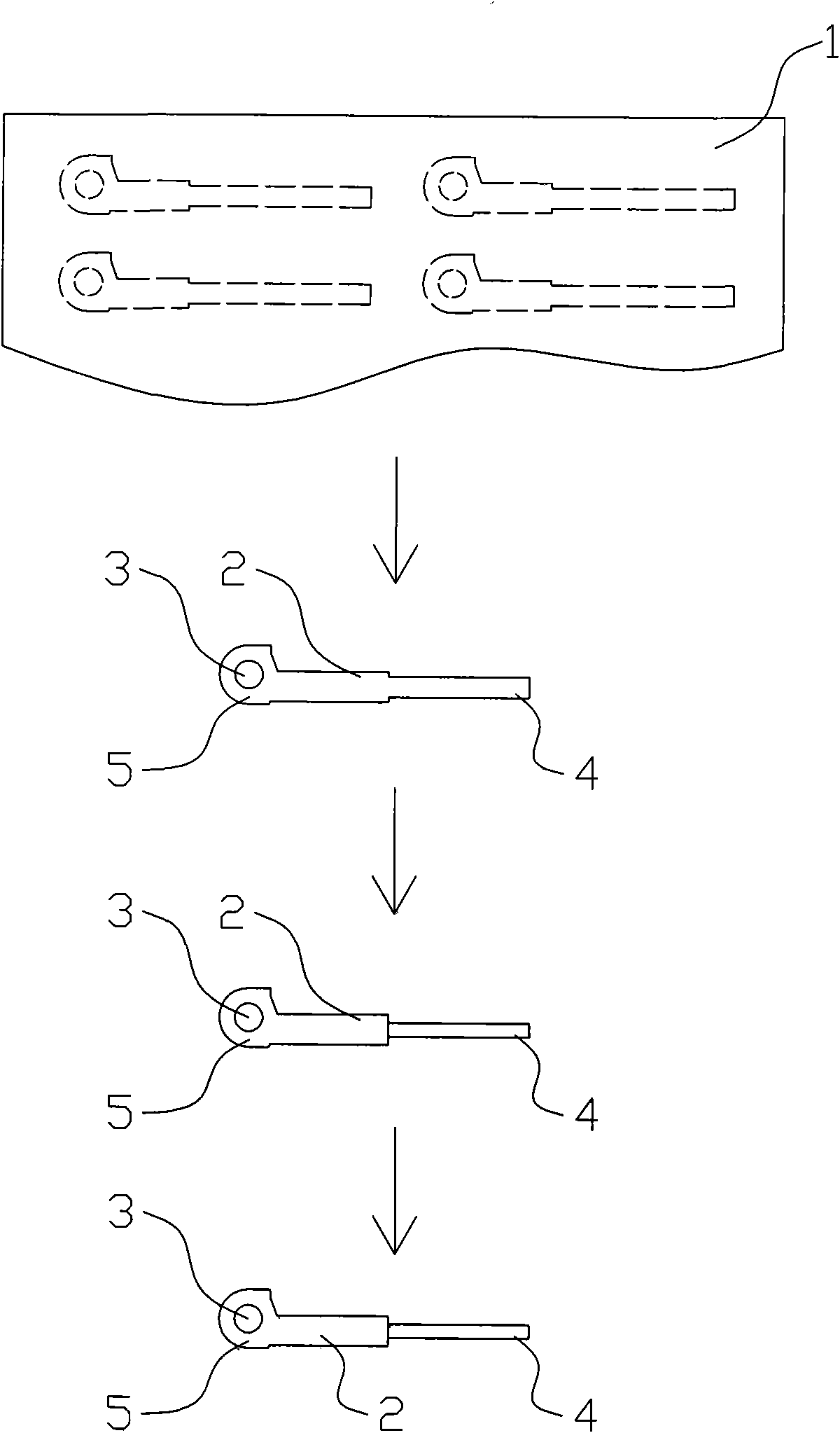

Method for manufacturing hinge shaft

InactiveCN101618496ANot easy to damageReduced tooling requirementsWelding/cutting auxillary devicesAuxillary welding devicesPunchingMetal sheet

Owner:浙江康华眼镜有限公司

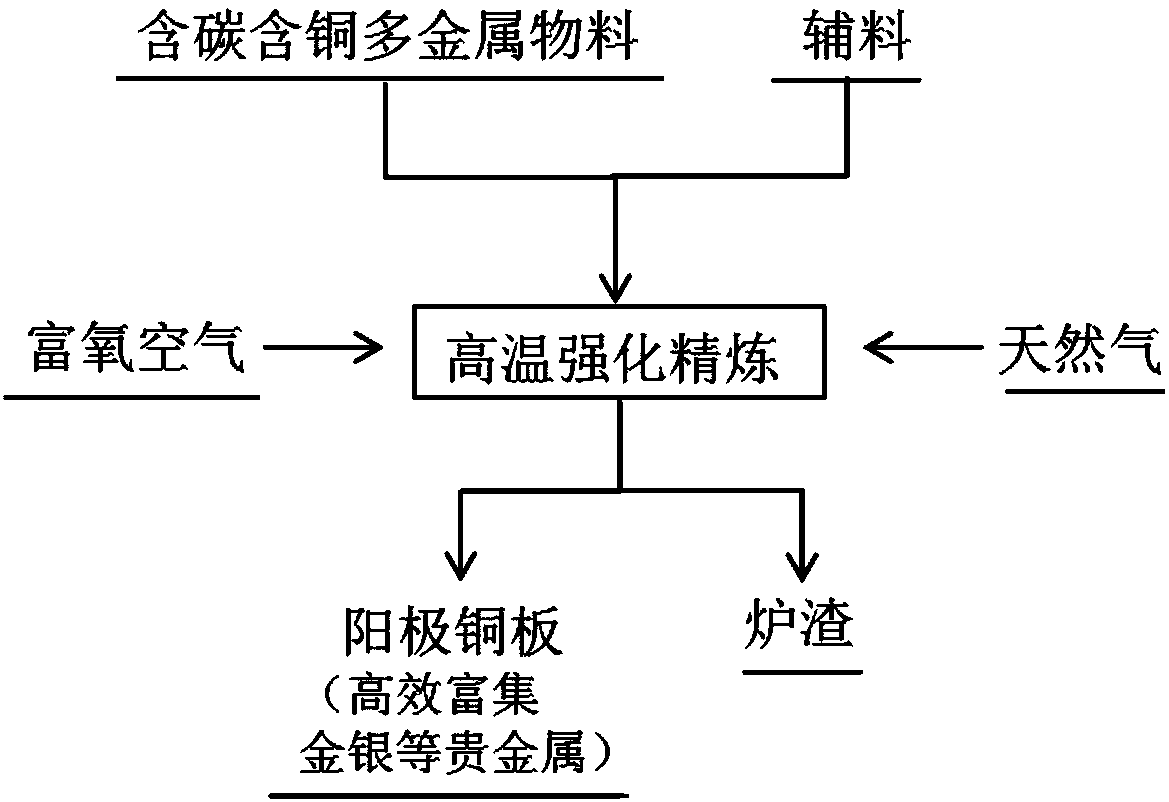

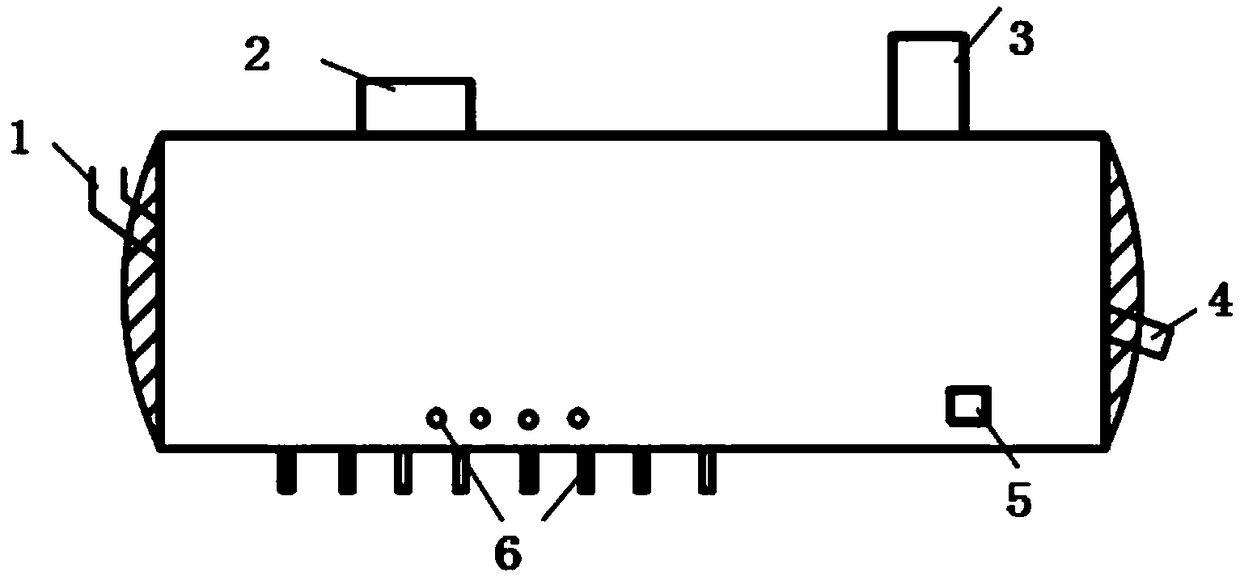

High-temperature reinforcing refining method of copper-bearing multi-metal material

ActiveCN108103319AIncrease agitation intensityGood heat and mass transfer conditionsProcess efficiency improvementSlagOxygen

The invention relates to a high-temperature reinforcing refining method of copper-bearing multi-metal material, in particular to carbon-bearing and copper-bearing material generated after processing adiscarded circuit board and other copper-bearing secondary material. The high-temperature reinforcing refining method comprises the following steps: S1, the oxidation impurity removal stage: puttingcarbon-bearing and copper-bearing multi-metal material in a high-temperature reinforcing refining furnace, and jetting oxygen-enrichement gas as an oxidizing agent, wherein caron in the material serves as fuel and is supplemented by natural gas to keep the temperature in the furnace high, and matching a slag former to realize slagging and removal of impurity elements in the material; and S2, the reduction refining stage: adding a reductant, oxygen-enrichement gas and natural gas in the furnace to carry out reduction refining on crude copper to generate qualified anode copper finally and realize efficient enrichment of precious metal. According to the high-temperature reinforcing refining method, one-step refining of the copper-bearing multi-metal material is realized to directly generate anode copper, the technological vacancy of efficient recycling of copper-bearing multi-metal material is filled, and the advantages that the processes are continuous, economical and environmentally-friendly, short in flow and high in efficiency are realized.

Owner:CENT SOUTH UNIV

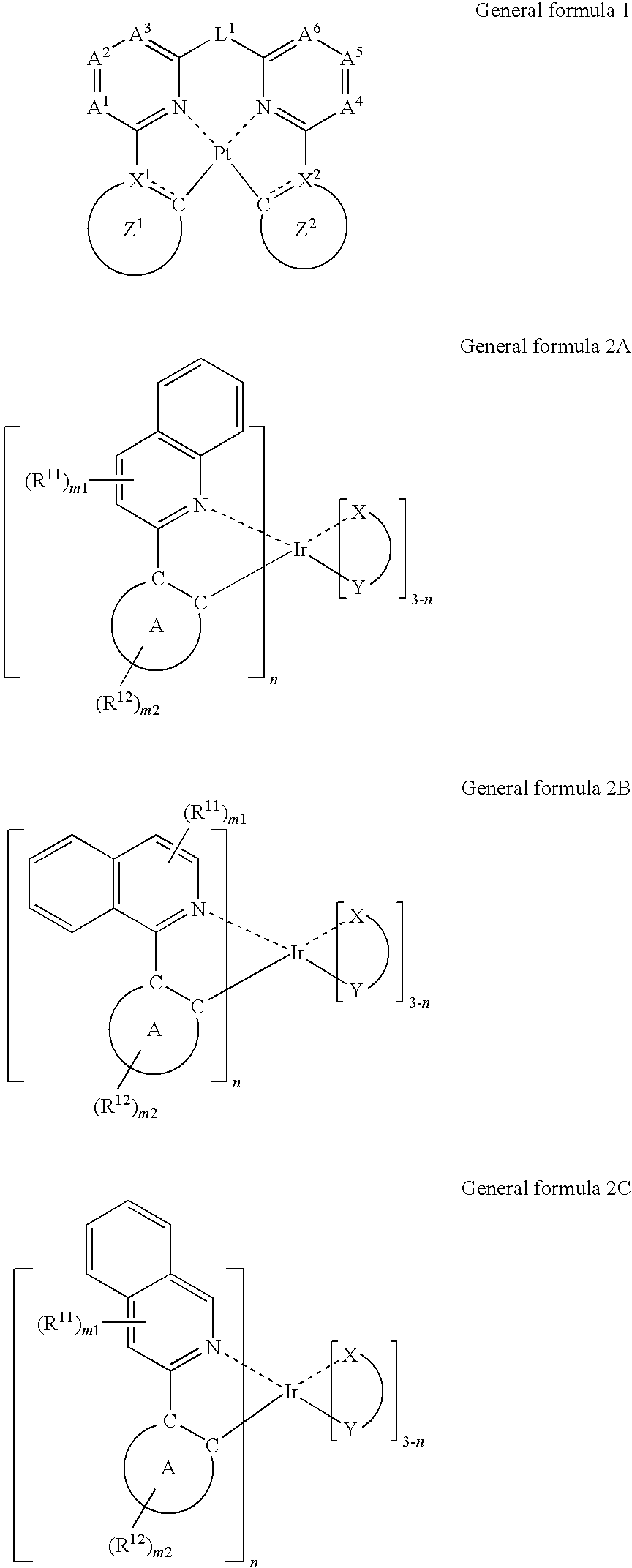

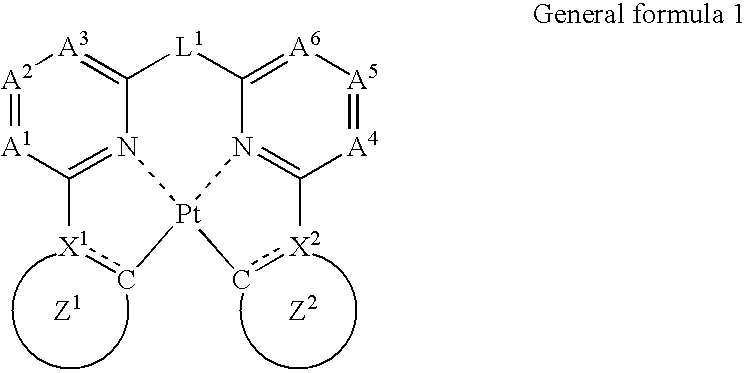

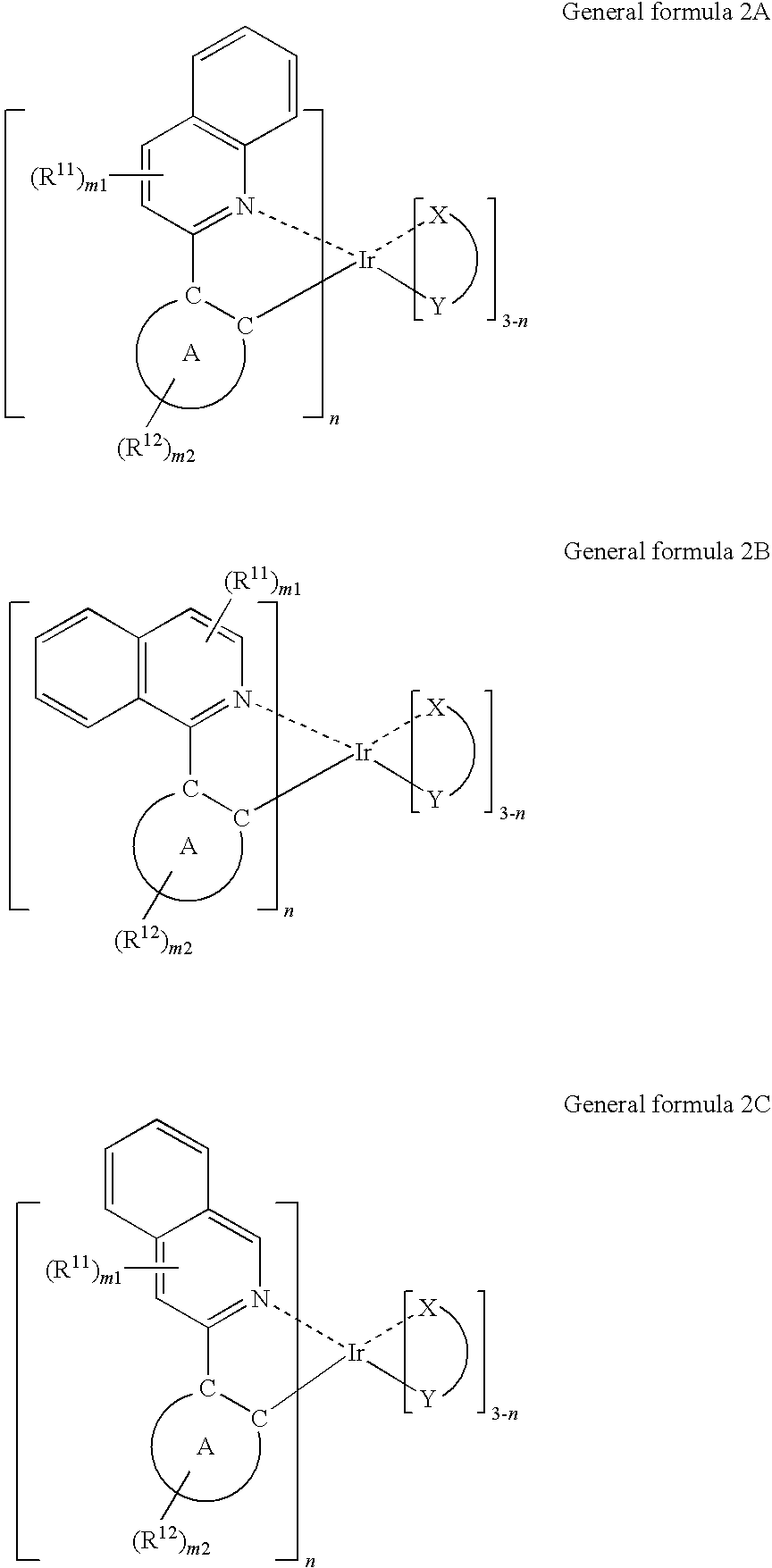

Organic electroluminescence element

ActiveUS20100314613A1High and excellent enduranceStrong production adaptabilitySolid-state devicesSemiconductor/solid-state device manufacturingPlatinum complexOrganic electroluminescence

To provide an organic electroluminescence element, containing: at least one pair of electrodes; at least one organic light-emitting layer disposed between the electrodes, the organic light-emitting layer comprising two phosphorescent light-emitting materials and a charge-transporting material, wherein the organic light-emitting element is a white organic light-emitting element, and the charge-transporting material is a hole-transporting material, and wherein one of the two phosphorescent light-emitting materials is a platinum complex expressed by the following general formula 1, and the other is an iridium complex expressed by any one of the following general formulae 2A to 2C:

Owner:UDC IRELAND

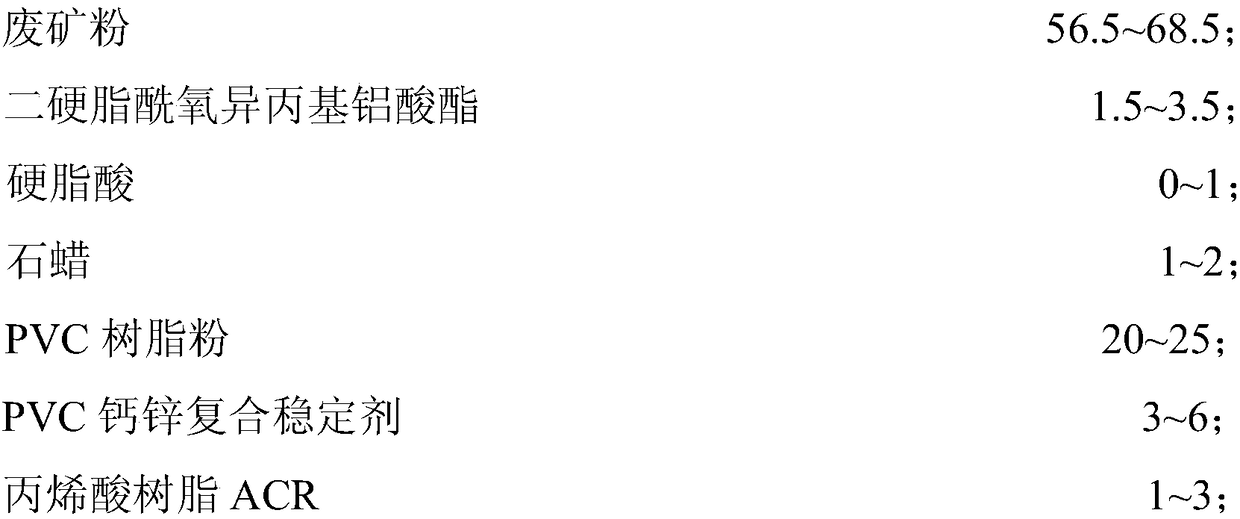

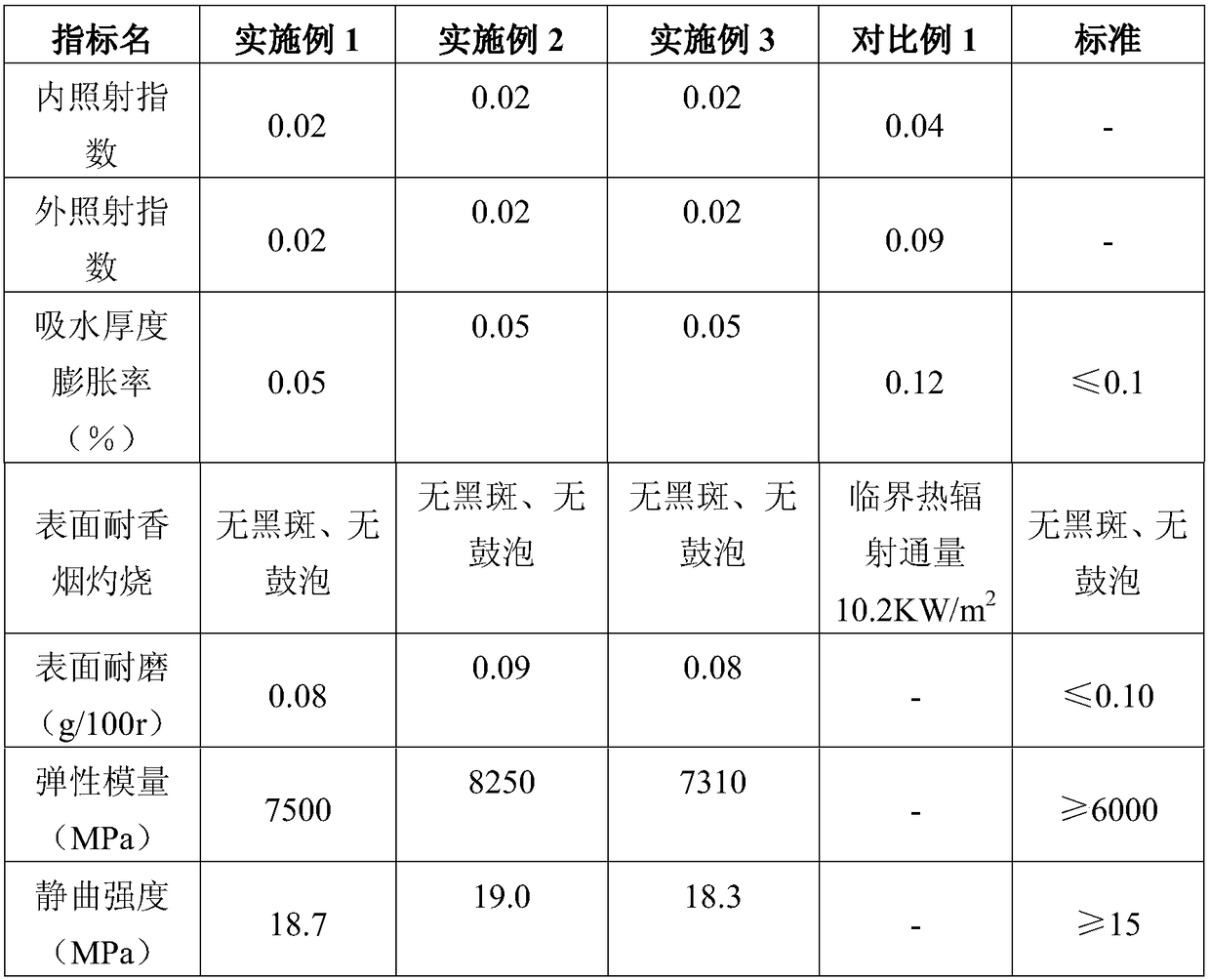

Stone-plastic composite floor production line

The invention discloses a stone-plastic composite floor production line, which includes steps of material preparation, extrusion, finishing, coating, quality detection, and packaging. The material preparation includes two steps of pre-treating waste ore powder and preparing a PVC composite material; the extrusion includes steps of material loading, extrusion, vacuum shaping, track drawing and cutting; the finishing includes steps of heavy sanding thickness fixation, dedusting, double-end-milling and four-side planing; the coating workshop includes work steps of: two times of putty paint, one time of sanding paint, three times of priming paint, three times of finishing coat, one time of varnish, one time of wear-resistant paint and three times of sanding and dedusting treatment. The production line achieves high-additional-value and full-automatic recovery of waste ore powder. The stone-plastic composite floor is super-water-resistant, flame-retarding and heat-insulation and is high instrength and toughness, is free of formaldehyde release and can be recycled by 100%. The production line is low in investment and is quick to work, has good production adaptability, and has extensivepromotion and application prospect.

Owner:SHAANXI SCI TECH UNIV +1

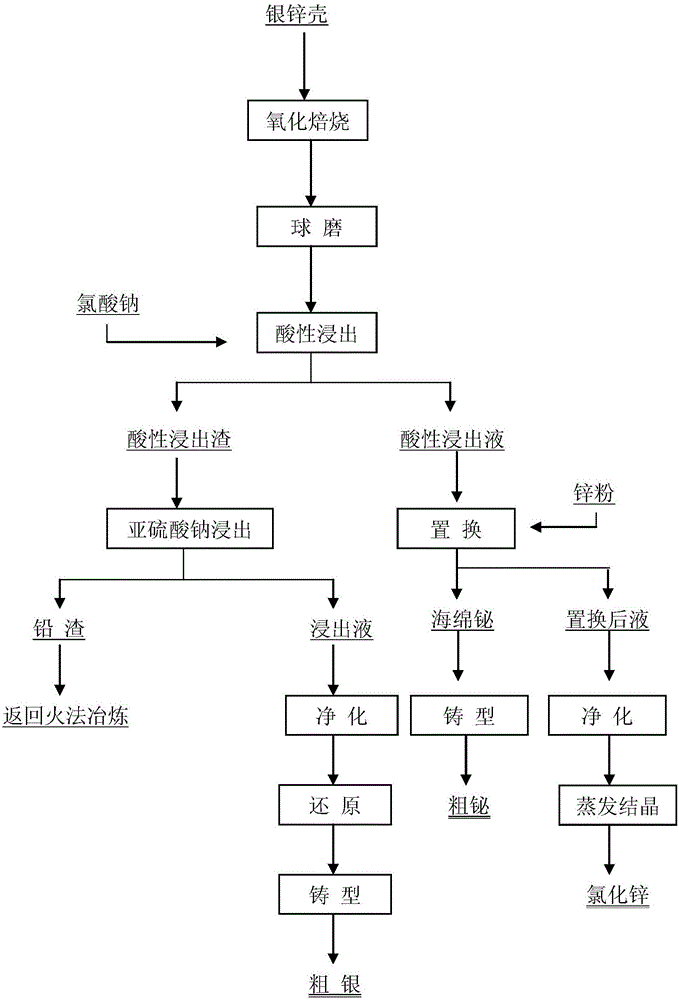

Silver-zinc crust wet process comprehensive recovery method

ActiveCN106011474ASolve the backlogSimple processProcess efficiency improvementRecovery methodSulfite salt

The invention discloses a silver-zinc crust wet process comprehensive recovery method which is characterized in that that silver-zinc crusts are subjected to thorough roasting and ball milling sieving; then through an acid leaching condition, an acid extract and acid leaching residues are obtained; after the acid leaching residues are leached by sodium sulfite, lead residues and an extract are obtained; the lead residues can return to a pyrogenic process smelting system, the extract is purified and then is reduced by formaldehyde, and crude silver is finally obtained after casting; the acid extract can be replaced by zinc powder and sponge bismuth is obtained; liquid after replacement is purified and then is subjected to evaporative crystallization, and zinc chloride is obtained; and direct recovery rates of silver, bismuth and zinc respectively reach above 95.7%, 94.1% and 88.9%. The silver-zinc crust wet process comprehensive recovery method is applicable to recovery of valuable metals, such as silver, bismuth and zinc, from the silver-zinc crusts rich in lead, silver, bismuth and zinc; the lead residues can return the pyrogenic process smelting system; the direct recovery rates are high; separation is thorough; and rapid recovery of valuable metals, especially silver, of the pyrogenic process smelting system is facilitated more.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

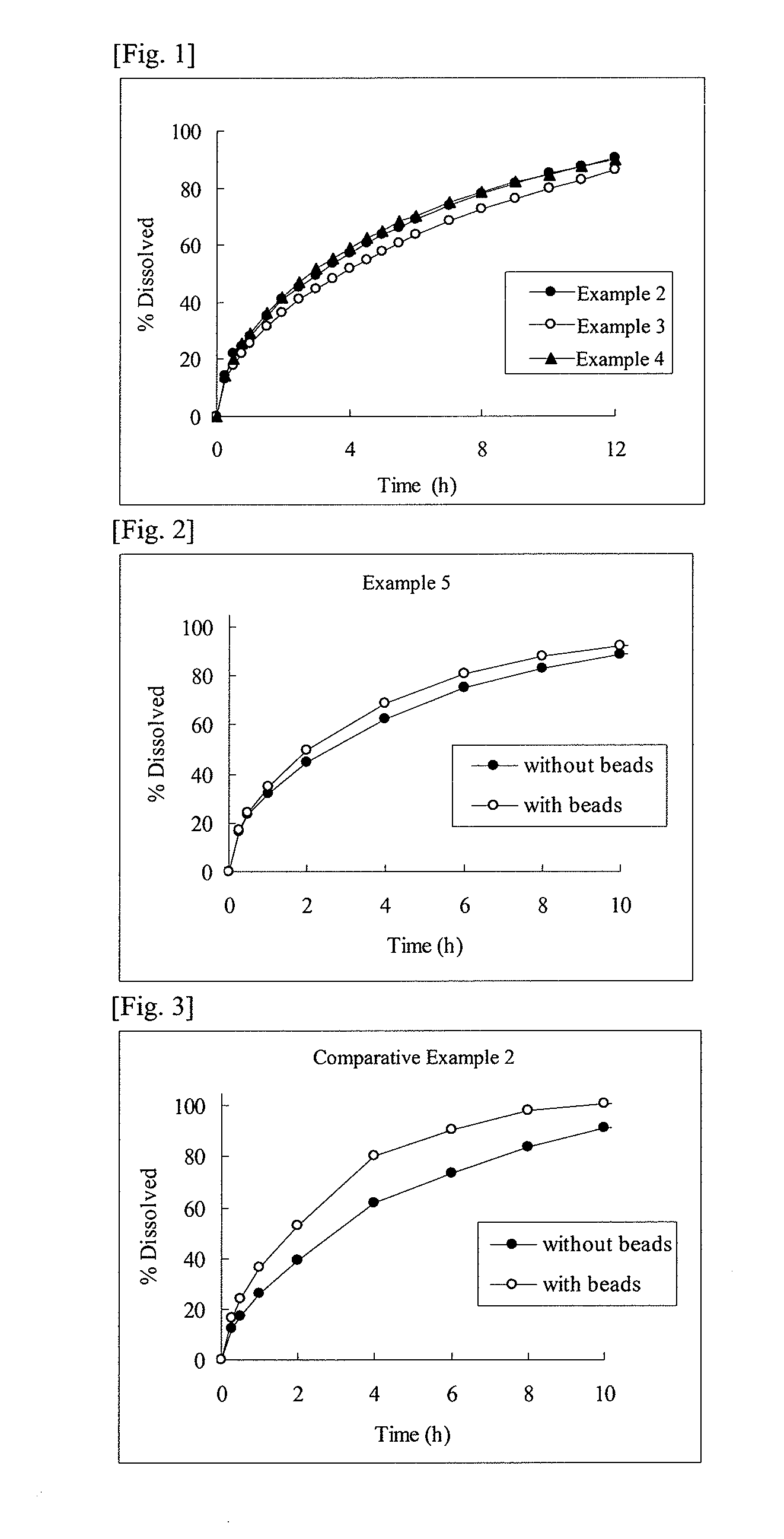

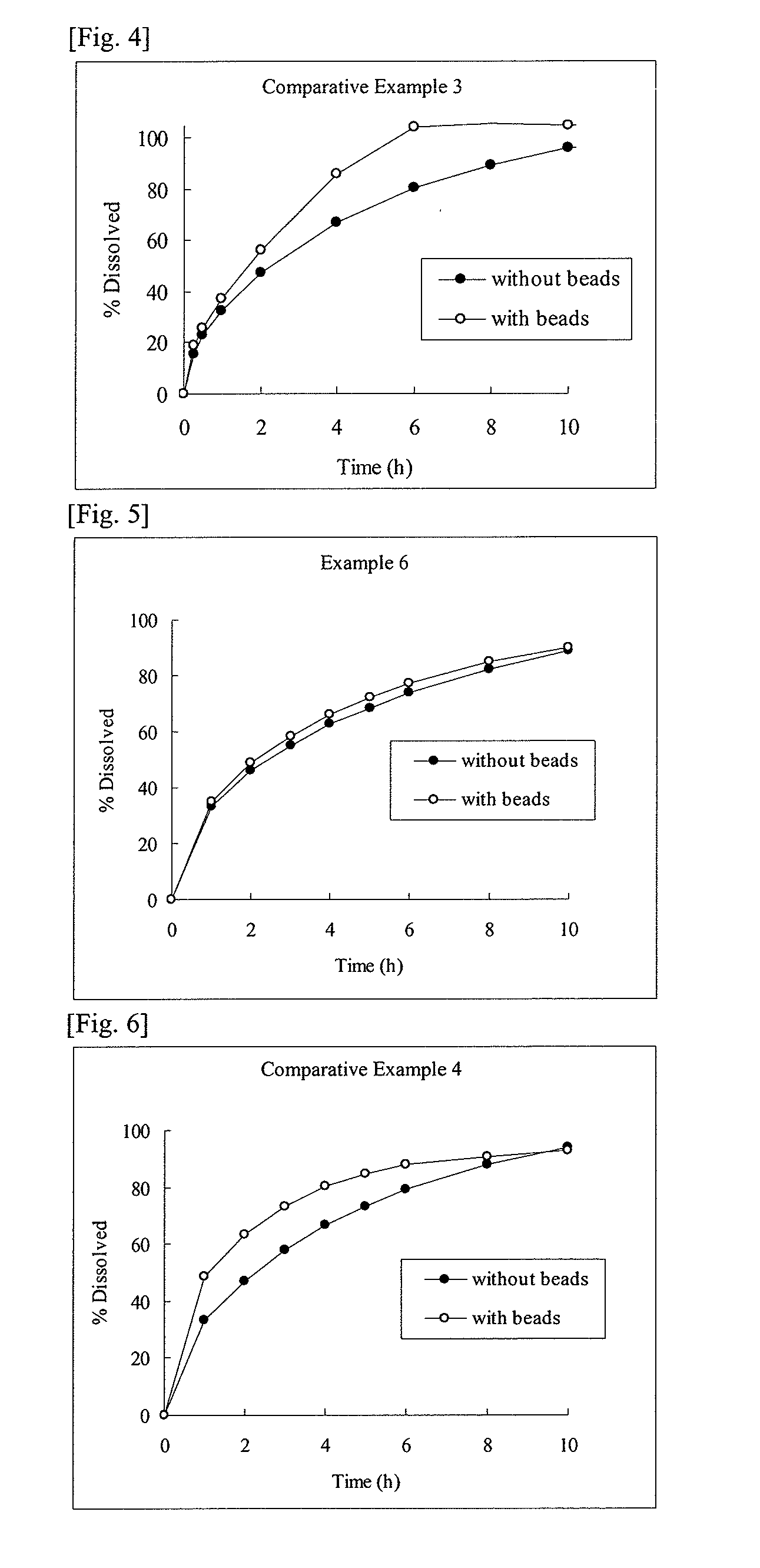

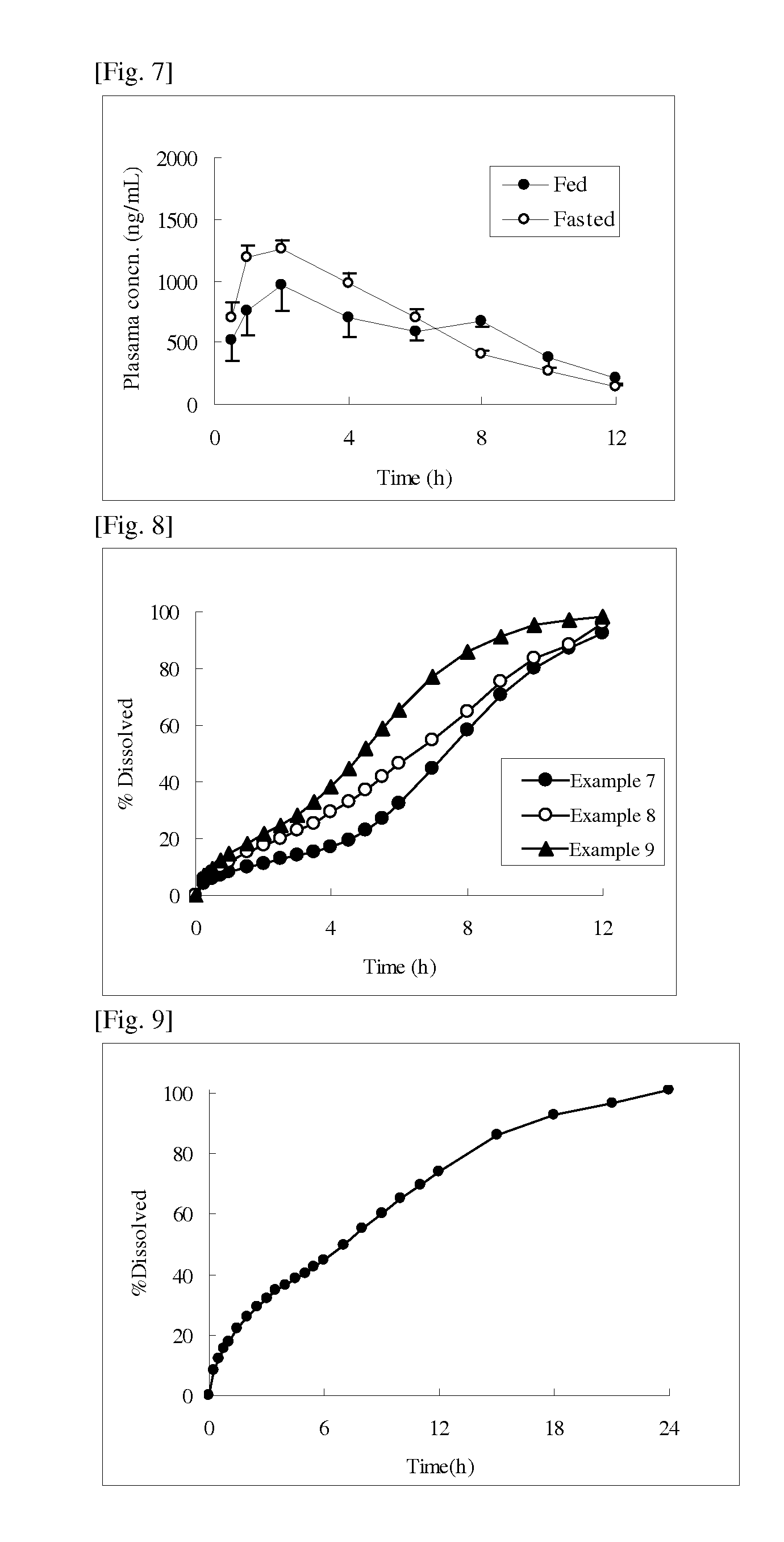

Sustained-release preparation and method for producing the same

InactiveUS20100221335A1Not easily disintegrateEliminate side effectsBiocideMetabolism disorderWater soluble drugWater soluble

The present invention provides a preparation which is a sustained-release preparation capable of providing a dissolution profile that permits once-daily administration even in the case of a highly water-soluble drug, and which can exhibit stable drug dissolution behavior and can be reduced in its size; and a method for producing the same. A preparation containing a highly water-soluble drug, a gel-forming polymer, and a low-melting lipophilic substance is usable as a sustained-release preparation that permits once-daily administration, and enables reduction in its size and simple production thereof, and thus, the objects have been achieved.

Owner:DAIICHI SANKYO CO LTD

Energy-saving and environment-friendly milling screening machine

The invention relates to the technical field of grinding equipment, in particular to an energy-saving and environment-friendly milling screening machine. The energy-saving and environment-friendly milling screening machine comprises a material feeding portion, a barrel body and a driving device, wherein a lining plate is arranged in the barrel body, the material feeding portion is connected with the barrel body through a hollow shaft, the barrel body is connected with the driving device through a transmission shaft, a barrel opening, away from the material feeding portion, of the barrel body is in a sealed shape, a material discharging hole is formed in the barrel body, a screen is arranged outside the barrel body, surrounds the outside of the barrel body, and is arranged in a barrel shape, a screening portion is formed between the screen and the barrel body, one end of the screening portion is open, the other end of the screening portion is closed, and the closed end of the screening portion and the closed end of the barrel body are connected with each other, and are located at the same side. According to the energy-saving and environment-friendly milling screening machine disclosed by the invention, milling and screening integrated production is realized without arranging a plurality of sets of equipment; energy consumption of equipment for screening and conveying can be reduced; the accumulation of materials can be effectively avoided as a strong exhaust hole is formed, and therefore the yield and production efficiency are increased, finer grinding phenomena can be reduced, and the pick-up rate of finished products is increased; moreover, the milling and screening in both dry and wet manners can be realized, so that production adaptability is enhanced, and the wet-type operation can also solve the problem of flying dust.

Owner:樊日宏 +1

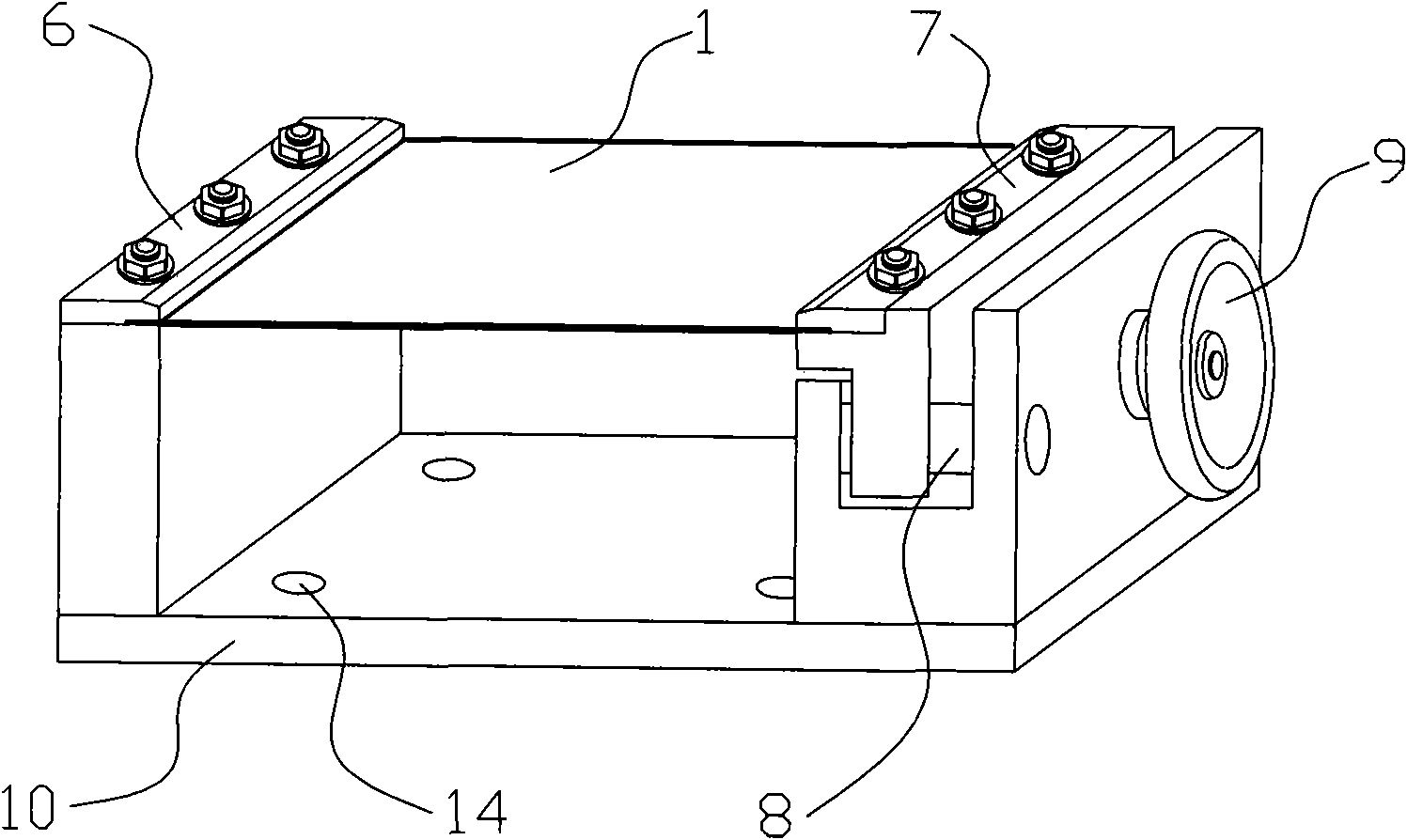

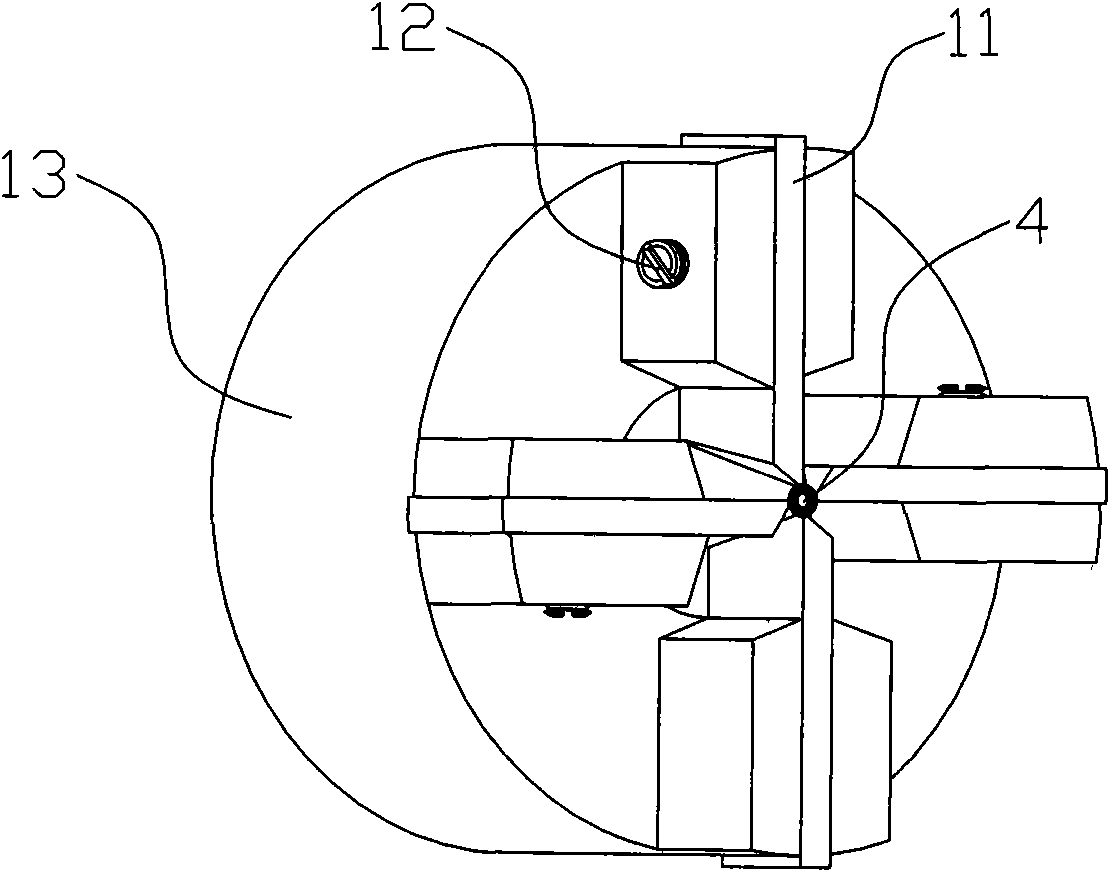

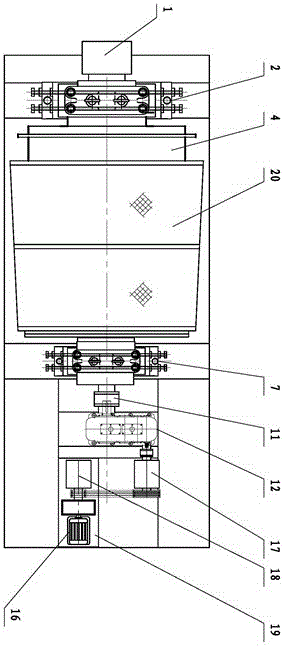

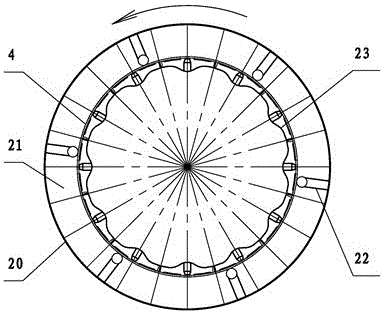

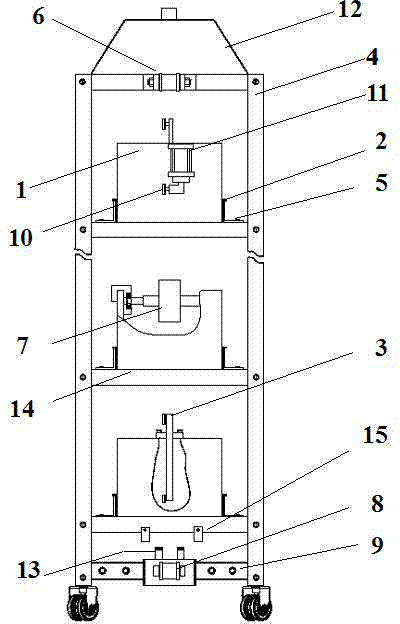

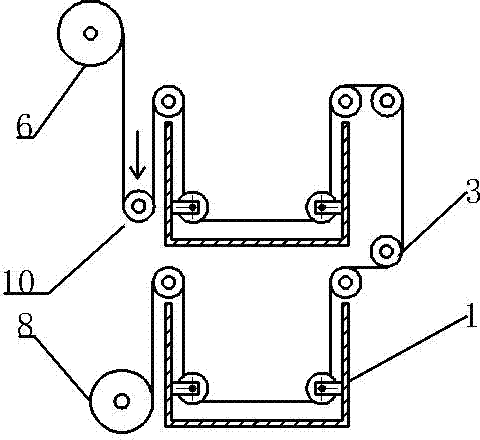

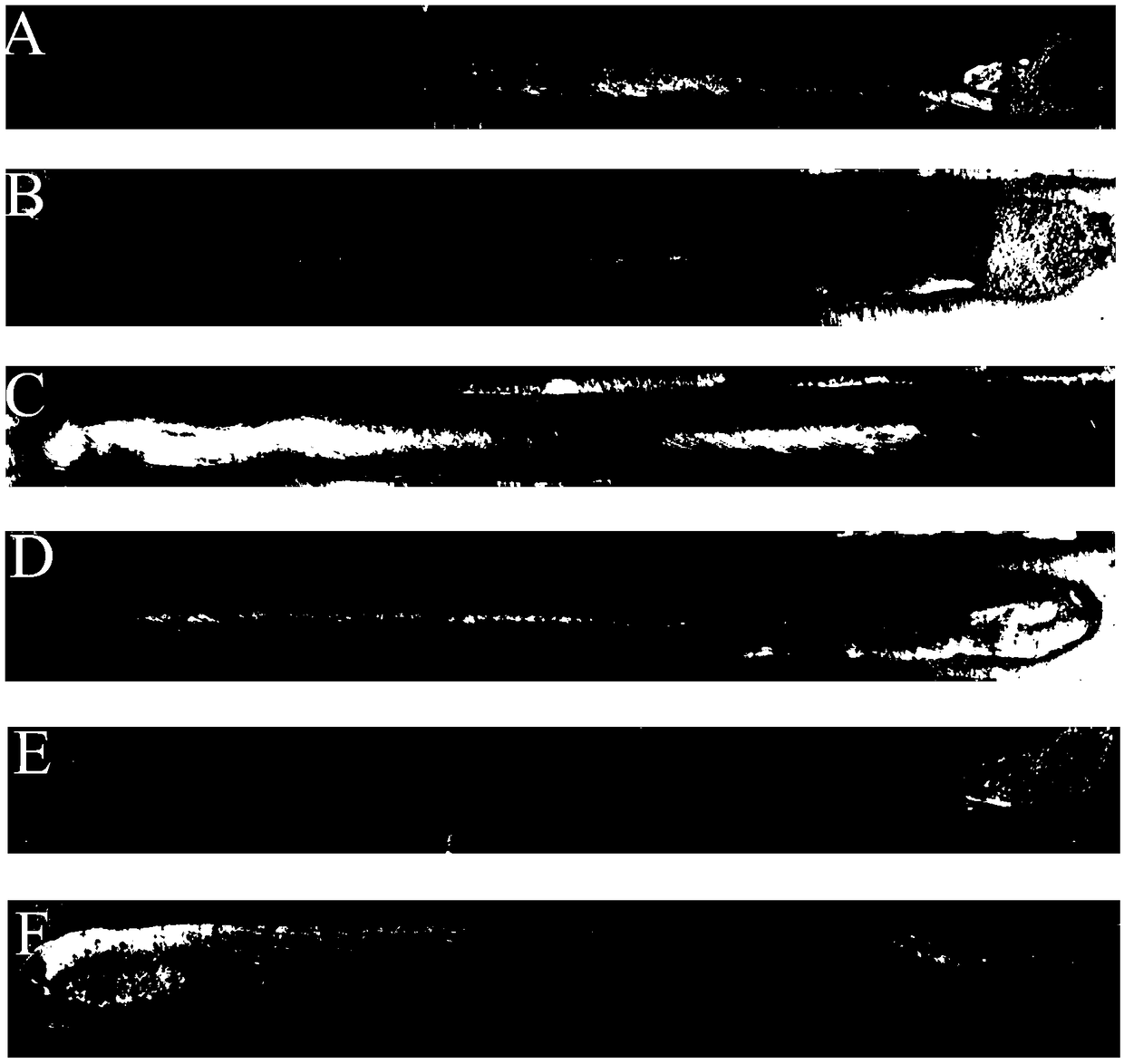

Spatial three-dimensional layout type quickly-composite brush electroplating diamond wire saw device

ActiveCN102828212AImprove the lack of a large area occupied by the plane distributionSmall footprintCellsTanksHorizontal distributionDiamond wire saw

The invention discloses a spatial three-dimensional layout type quickly-composite brush electroplating diamond wire saw device, which comprises at least three electroplating baths (1) and a bracket (4). The spatial three-dimensional layout type quickly-composite brush electroplating diamond wire saw device is characterized in that each electroplating bath (1) is arranged on the bracket (4) in a three-dimensional mode; the top of the bracket (4) is provided with a pay-off wire wheel (6); the bottom of the bracket (4) is provided with a take-up wire wheel (8) capable of preventing coiling wires; a silk wire between the pay-off wire wheel (6) and the take-up wire wheel (8) is provided with a wire guide wheel (3) and a tensioning wheel (10); the tensioning wheel (10) is driven by a cylinder (11); the cylinder (11) is installed on the bracket (4) or the electroplating baths (1); and a graphite felt brush (7) is rotated on the electroplating baths (1). According to the spatial three-dimensional layout type quickly-composite brush electroplating diamond wire saw device disclosed by the invention, the deficiency of big horizontal distribution land occupation of the traditional electroplating equipment is improved, the structure is flexible and variable and has a strong applicability, continuous and composite electric brush processing is realized, a plurality of brush electroplating steps can be continuously finished, a plurality of slots are arranged on the graphite felt brush to realize multi-wire composite brush electroplating processing, and the processing efficiency is effectively improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

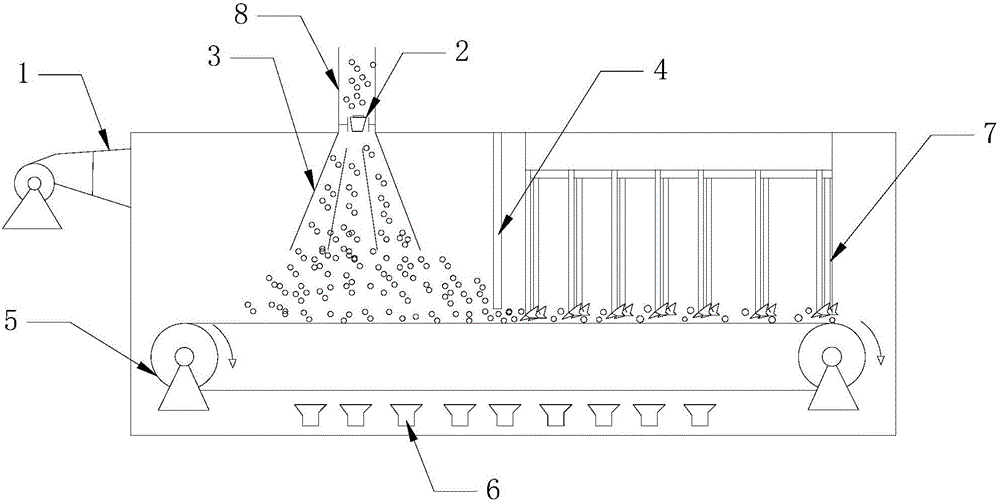

Microwave dryer for polyacrylamide colloidal particles and microwave drying method

InactiveCN105841468AReduce noiseReduce the impact of high temperatureDrying solid materials with heatGranular material dryingRotary valveProcess engineering

The invention relates to a microwave dryer for polyacrylamide colloidal particles and a microwave drying method. The microwave dryer comprises a feed port, an induced draft fan, a conveyor and microwave emitting sources; the feed port is formed in the top of the microwave dryer; the induced draft fan is arranged on the side wall of the dryer near the feed port; a rotating valve is arranged in the feed port; a guide plate is arranged below the feed port; the front end of the conveyor is positioned below the guide plate; multiple stirring devices are arranged at the back end of the conveyor; and multiple microwave emitting sources are arranged below the conveyor. The microwave dryer is low in noise, fast in material drying speed, low in influence on materials by high temperature, excellent in production adaptability, suitable for drying of the polyacrylamide colloidal particles and suitable for drying of other high-viscosity polymers.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

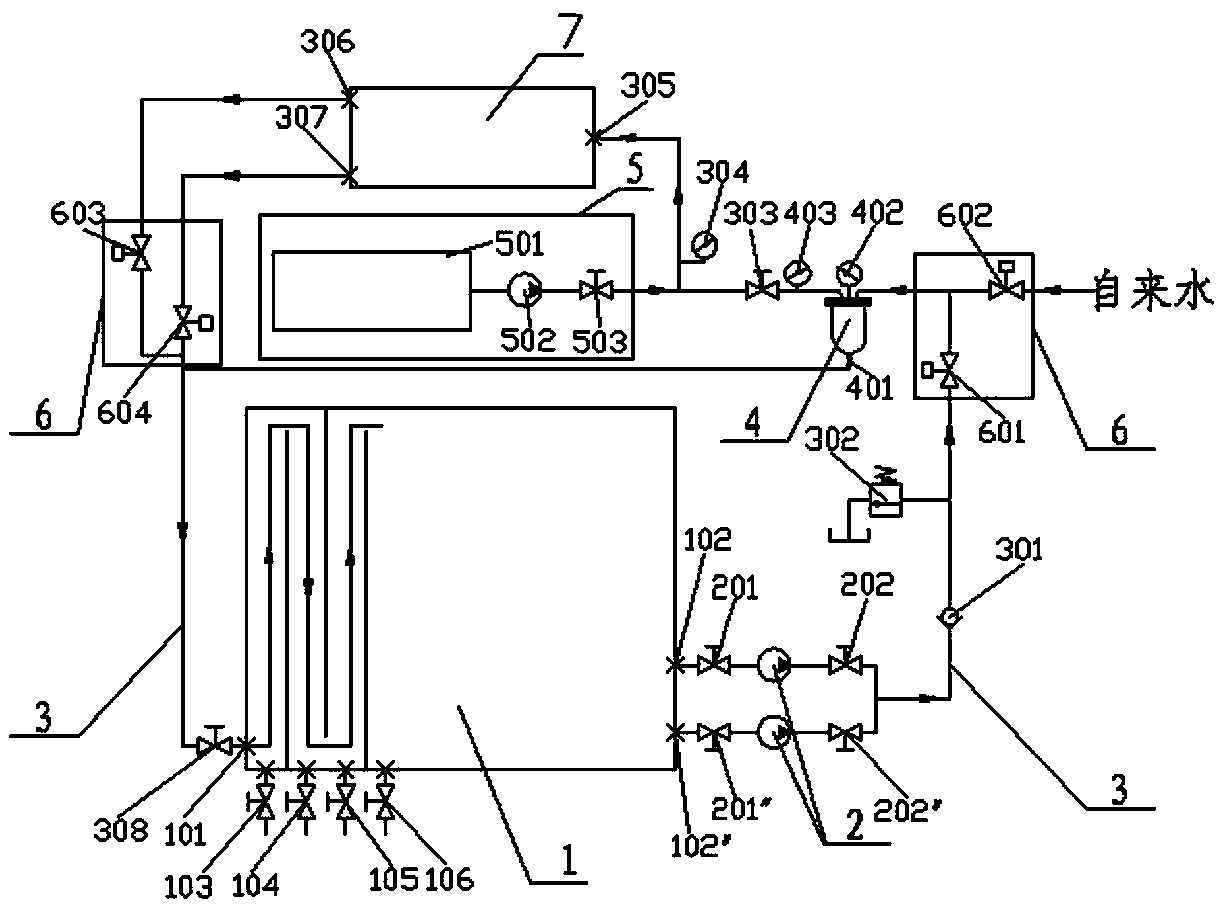

Nitric acid recycling system

The invention relates to the recycling of acidic liquid and particularly relates to a nitric acid recycling system. At present, a waste acid solution passing through nitric acid cleaning and ceramic filtering equipment still has certain acidity and is needed to be neutralized by adding an alkaline solution, and then, the waste liquid is discharged. The process has the defects that the resource is wasted, the cost is increased, the process is complex and not easy to control, and the discharged waste liquid can not be up to the standard frequently and pollutes the environment. The system is composed of a dilute nitric acid recovering, depositing and storing tank, a stainless steel magnetic pump device, a stainless steel delivery and recovery pipeline device, a stainless steel filter device, an automatic concentrated nitric acid liquid replenishing device and an automatic electrical control device; the waste acid solution is mixed with 50% nitric acid output by the automatic concentrated nitric acid liquid replenishing device to be up to the concentration of 3-5% after being deposited and filtered, and then, the waste acid solution is utilized.

Owner:HEBEI PROVINCE FANSHAN PHOSPHORITE CO LTD

Low-alloy steel welding rod capable of achieving postweld heat treatment

ActiveCN107088719AImprove stabilitySolve crackingWelding/cutting media/materialsSoldering mediaManganesePotassium/sodium ratio

The invention provides a low-alloy steel welding rod capable of achieving postweld heat treatment. An H08E carbon steel welding core is used as a welding core. A flux cover comprises, by weight, 42-55 parts of marble, 18-24 parts of fluorite, 0,5-2 parts of rutile, 3-9 parts of quartz, 0.3-0.8 part of sodium carbonate, 0.3-0.8 part of CMC, 0.2-0.5 part of graphite, 3-9 parts of silicon iron, 3-9 parts of manganese, 9-18 parts of alloy, and 20-25 parts of water glass. Alloy powder comprises, by weight, 25-35 parts of nickel powder, 5-15 parts of ferromolybdenum, 5-15 parts of ferrotitanium and 90-110 parts of iron powder. Potassium-sodium water glass with the modulus M being 3.4 and the potassium-sodium ratio being 1 / 2-3 / 4 is adopted to serve as the water glass. According to the low-alloy steel welding rod capable of achieving postweld heat treatment, the manufacturability is good; and under the wide technological specification, electric arcs are stable, deslagging is easy, and weld beads are formed uniformly and are attractive.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

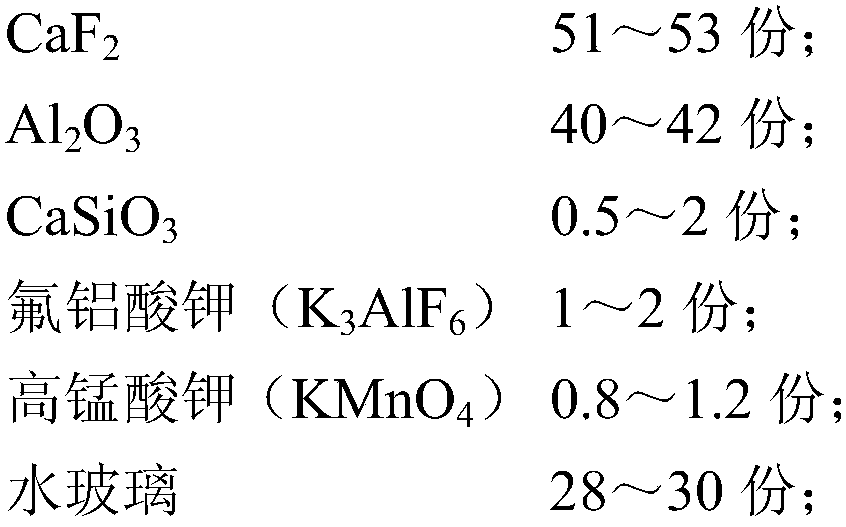

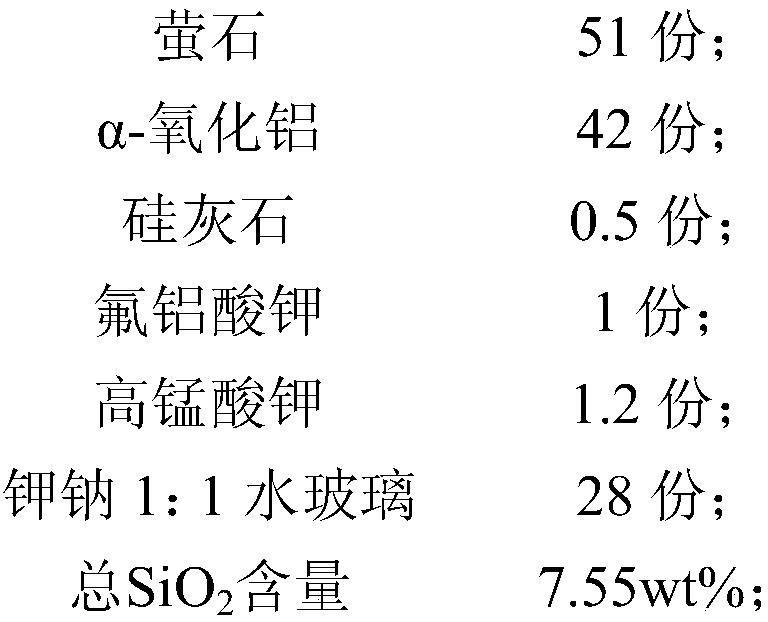

Sintered flux for stainless steel welding wire containing niobium and titanium, and preparation method and application thereof

ActiveCN108723638AEnsure submerged arc welding does not stick to slagWell formed weldWelding/cutting media/materialsSoldering mediaEconomic benefitsSodium silicate

The invention belongs to the technical field of welding materials and particularly relates to sintered flux for a stainless steel welding wire containing niobium and titanium, and a preparation methodand application thereof. The sintered flux for the stainless steel welding wire containing niobium and titanium comprises the following components of, by mass, 51-53 parts of CaF2, 40-42 parts of Al2O3, 0.5-2 parts of CaSiO3, 1-2 parts of K3AlF6, 0.8-1.2 parts of KMnO4 and 28-30 parts of sodium silicate. The sintered flux is prepared through the steps of compounding, dry mixing, wet mixing, pelletizing, drying, sintering, sieving and the like, the flux is matched with ER321 and ER34 submerged arc welding wires which conform to the standard of AWS A5.9, and the weld bead deslagging property, the weld bead forming property and the deposited metal property are good; and the flux is simple in component and low in cost, and has large market promotion prospects and good economic benefits with continuous expanding of the field of intercrystalline corrosion resistance application of austenitic stainless steel.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Environment-friendly automatic carton manufacturing machine

PendingCN109016660AStrong production adaptabilityReduce capital investmentPaper-makingBox making operationsEngineeringCarton

The invention discloses an environment-friendly automatic carton manufacturing machine which comprises an impressing device and a cutting device. The impressing device comprises a transverse impressing device and a longitudinal impressing device; a conveying structure, the longitudinal impressing device, the transverse impressing device and the cutting device are sequentially mounted on a mountingbase from left to right; the longitudinal impressing device comprises a longitudinal pressing wheel bracket, a pressing wheel shaft and a longitudinal pressing wheel; the transverse impressing devicecomprises a transverse pressing wheel bracket, a supporting shaft and a transverse pressing wheel; the cutting device comprises a cutting shaft, cutting wheels, a motor II and a belt wheel II; the two ends of the cutting shaft are mounted on a side baffle; the multiple cutting wheels are mounted on the cutting shaft; and one end of the cutting shaft penetrates through the side baffle and is connected with the motor II through the belt wheel II at the tail end. According to the carton manufacturing machine, all processes are integrated on one equipment, production working hours are greatly shortened, the production efficiency is effectively improved, and the labor intensity of workers is lowered.

Owner:TIANJIN CHENGJIAN UNIV

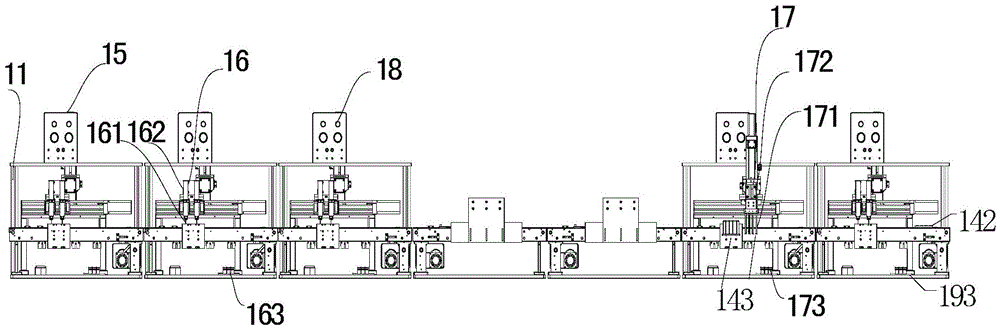

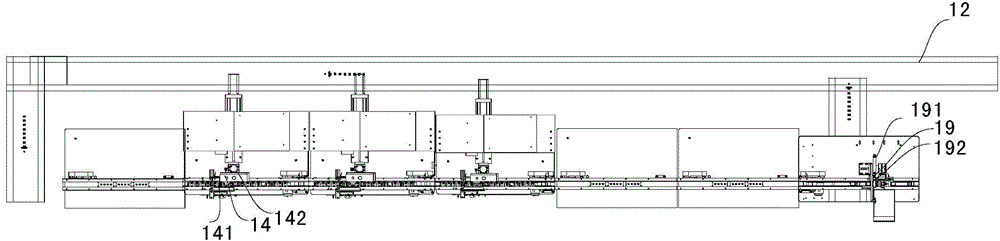

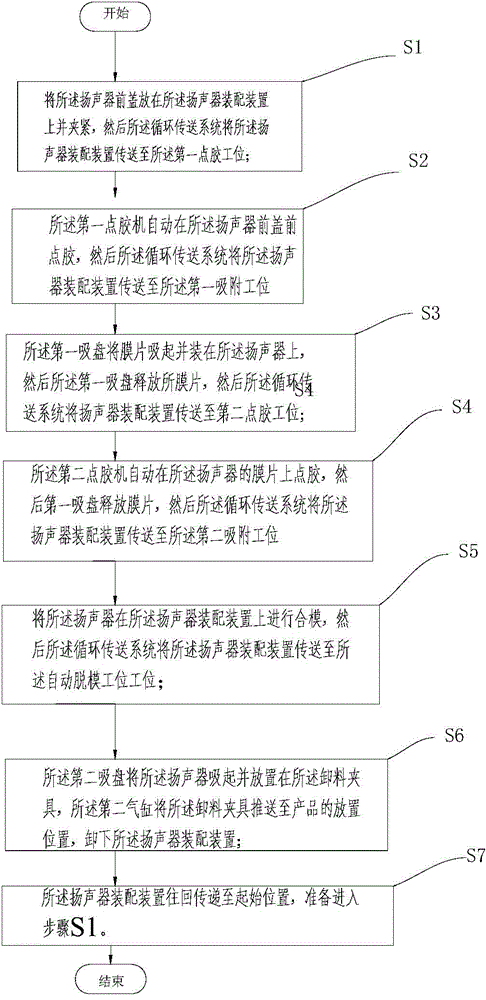

Speaker automatic production line and production line control method

ActiveCN105282675AStrong production adaptabilityIncrease productivityElectrical transducersProduction lineTransfer system

The present invention discloses a speaker automatic production line which comprises a production line frame body, a circulation transfer system arranged on the production line frame body, a tool structure for circulation transfer system transfer and a control structure which controls the automatic operation of an automatic production line. The speaker automatic production line also comprises a first dispensing station for automatically dispensing a speaker front cover glue, a first taking and placing station for taking and placing a diaphragm, a second dispensing station for dispensing a speaker diaphragm center glue, and an automatic diaphragm removing station for automatically removing a speaker from a speaker assembly device. The stations of the production line are orderly arranged forward, thus the speaker automatic dispensing and diaphragm loading can be carried out by the production line, the production efficiency of the speaker is greatly improved, the labor consumption is small, the production cost is reduced, and the product pollution is small. The invention provides a production line control method for running the automatic production line.

Owner:DONGGUAN NASHENG ELECTRONICS EQUIP

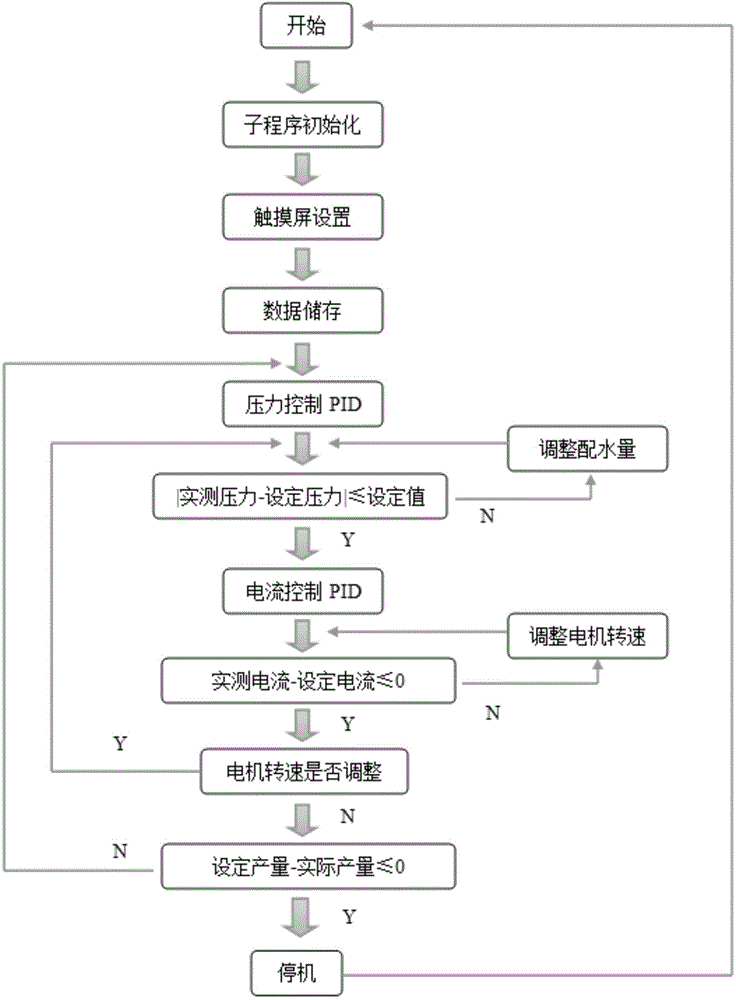

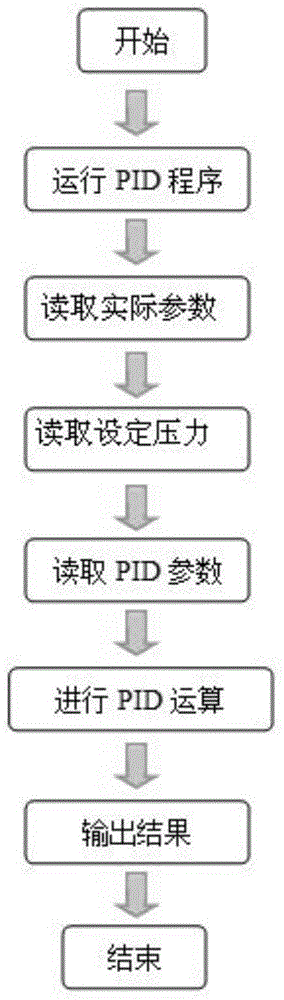

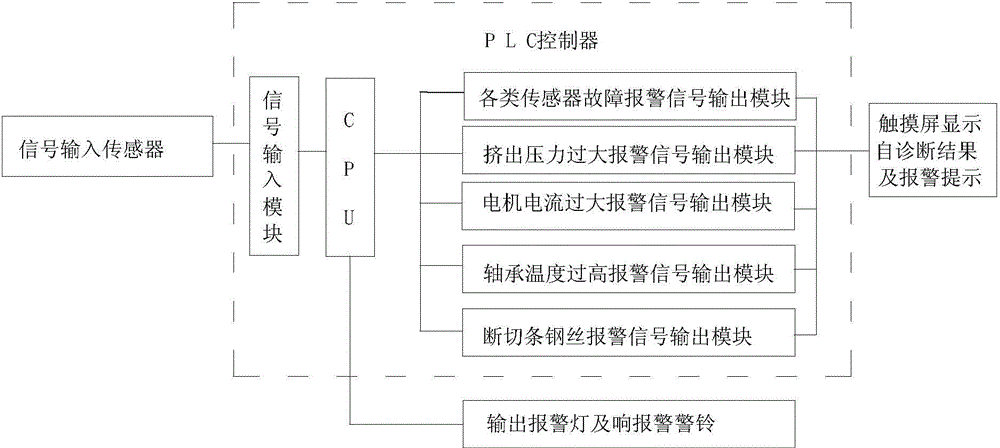

Fully automatic cutting and forming intelligent control system for brick and tile industry

InactiveCN105629912AExtrusion Pressure ControlEasy to controlTotal factory controlProgramme total factory controlHuman–machine interfacePower flow

The invention relates to a fully automatic cutting and forming intelligent control system for a brick and tile industry. The system comprises an extruder operation control system consisting of an extruder control device and an extruder program control part. The extruder program control part comprises a main program, a parameter setting sub program, a data storage sub program, an extruder pressure PID control sub program, an extruder current PID control sub program, and an extruder production control sub program. The intelligent control system further comprises an extruder slitting self-diagnosis system. The invention can accurate control the extruding pressure of an extruder, is small in fluctuation range of the extruding pressure, high in forming quality, and good in production adaptability to different products, also has a self-diagnosis function and an alarm function, and can carry out self-diagnosis analysis of reasons why a program cannot continue to operate and display the analysis result and fault solution on a human-machine interface. In addition, when a slitting steel wire breaks, the diagnosis system can automatically alarm and stop the operation of an extruder host.

Owner:LIUZHOU ZHIMA BRICK TILE MACHINERY +1

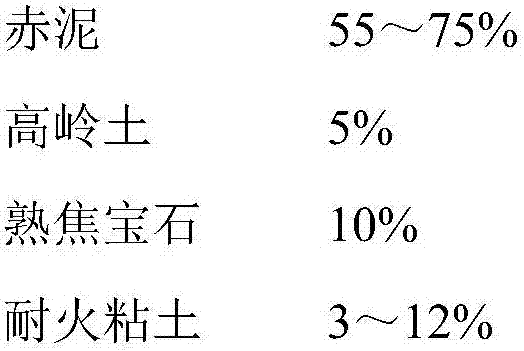

Antistatic ceramic prepared from large admixing amount red mud taken as raw material and sintered in roller kiln and preparation method thereof

ActiveCN107285736ASolve stacking problemsEasy to adjust anti-static indicatorsCeramic materials productionClaywaresRed mudRefractory

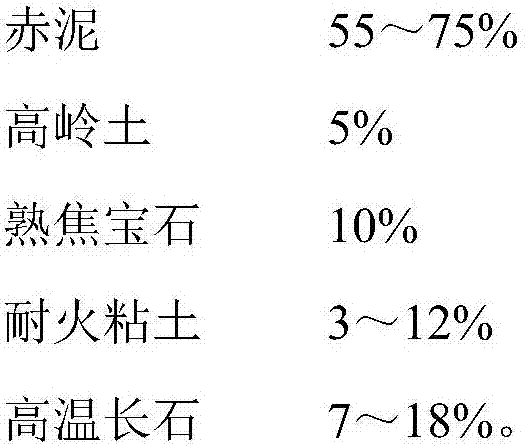

The invention relates to an antistatic ceramic prepared from large admixing amount red mud taken as the raw material and sintered in a roller kiln and a preparation method thereof, and belongs to the technical field of ceramic preparation. The antistatic ceramic is prepared from the following raw materials in percentage by weight: 55 to 75% of red mud, 5% of kaolin, 10% of cooked flint clay, 3 to 12% of refractory clay, and 7 to 18% of high temperature feldspar. The preparation method comprises the following steps: evenly mixing the raw materials according to the ratio mentioned above, then adding water according to a ratio of water to raw materials of 35:65, mixing, grinding, drying, grinding again to obtain dry powder, preparing ceramic powder by a balling machine or a manual mode, carrying out compression moulding under a pressure of 200 MPa, drying obtained mould for 1 hour at a temperature of 150 DEG C, then placing the mould in a roller kiln, and burning the mould at a temperature of 1150 to 1160 DEG C to obtain the antistatic ceramic. The using amount of red mud is large, by adjusting the using amount of red mud, the antistatic indexes of the antistatic ceramic are controlled conveniently; the antistatic ceramic is sintered in a roller kiln at a time, the deformation amount is little, no foam is generated, the production efficiency is high, and the preparation method is suitable for large scale industrial production.

Owner:ZIBO GOLD LION KING TECH CERAMICS CO LTD

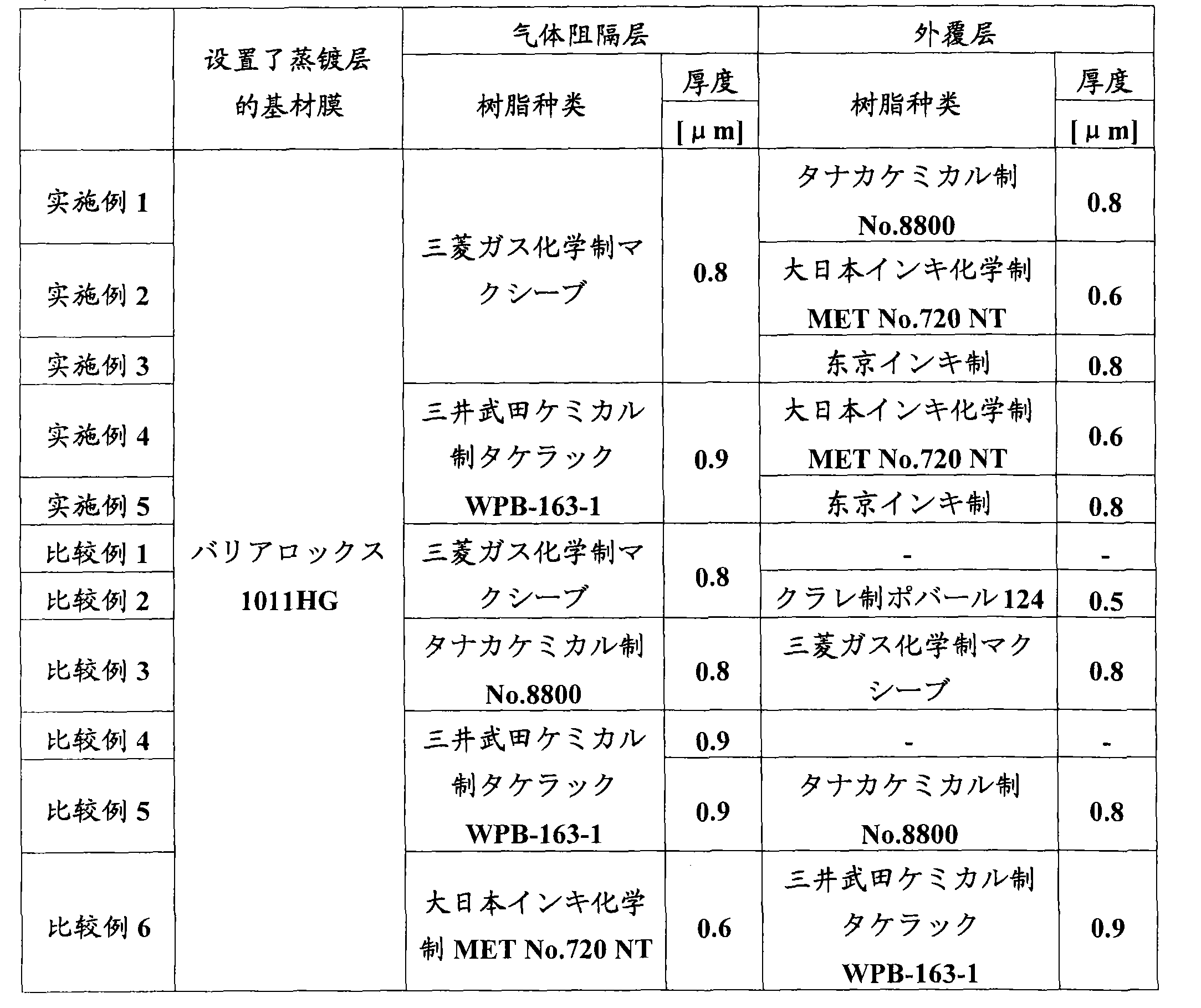

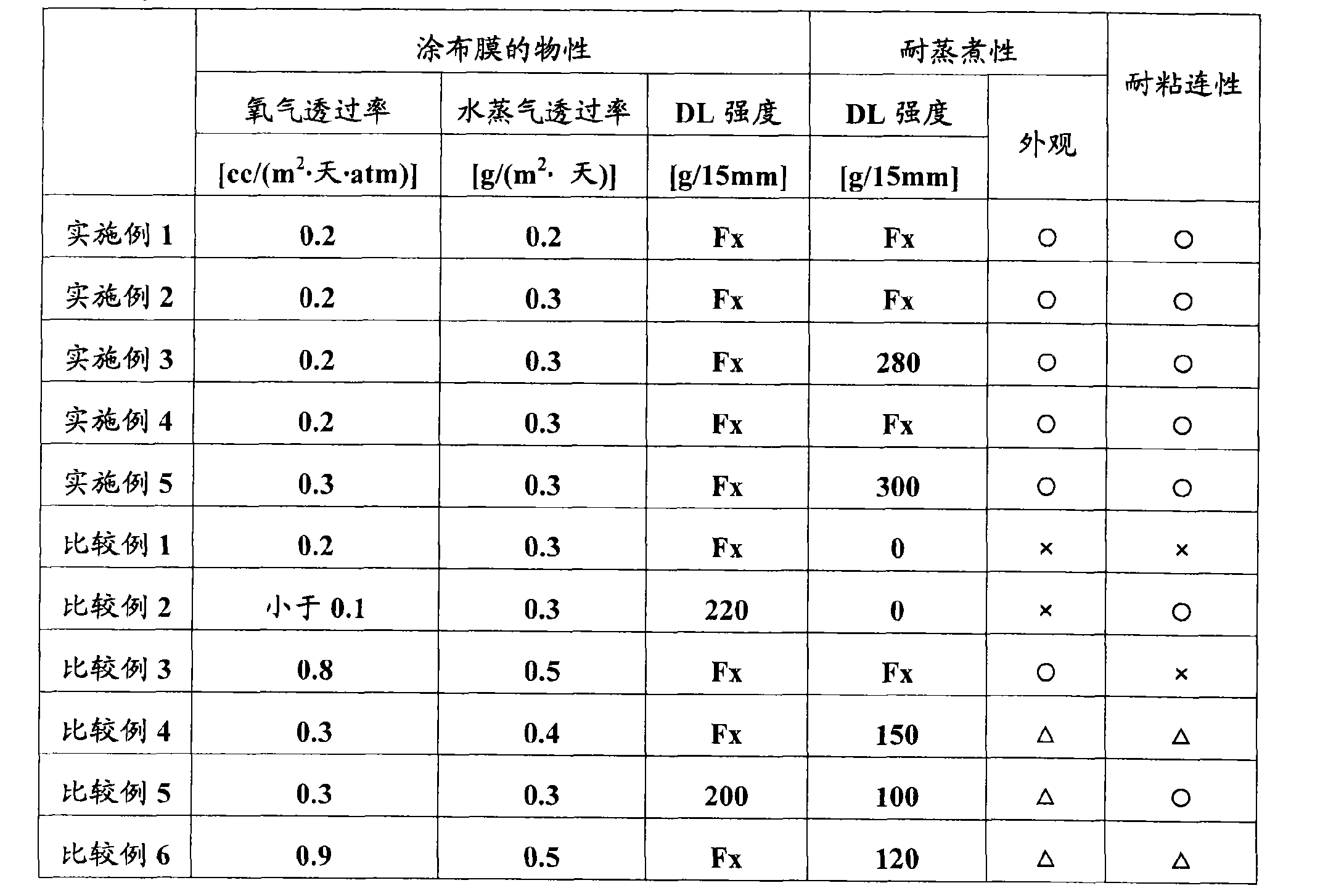

Gas barrier film

InactiveCN101421105AStrong production adaptabilityImprove barrier propertiesFlexible coversLiquid surface applicatorsEpoxyWater vapor

Disclosed is a gas barrier film exhibiting excellent oxygen and water vapor blocking performance, while having resistance to heat sterilization treatments such as a boiling / retorting treatment. A gas barrier film as a first embodiment of the present invention is characterized by having a structure wherein a deposition layer of an inorganic compound is formed on one side of a base film, a gas barrier layer of a polyepoxy cured product having a skeleton represented by the formula (1) below is formed on the deposition layer, and an overcoat layer made of at least one resin selected from the group consisting of polyepoxy resins, polyester resins and polyacrylic resins is formed on the gas barrier layer. A gas barrier film as a second embodiment of the present invention is characterized by having a structure wherein a deposition layer of an inorganic compound is formed on one side of a base film, a gas barrier layer of a polyurethane resin is formed on the deposition layer, and an overcoat layer made of a polyester resin and / or a polyacrylic resin is formed on the gas barrier layer.

Owner:TORAY IND INC

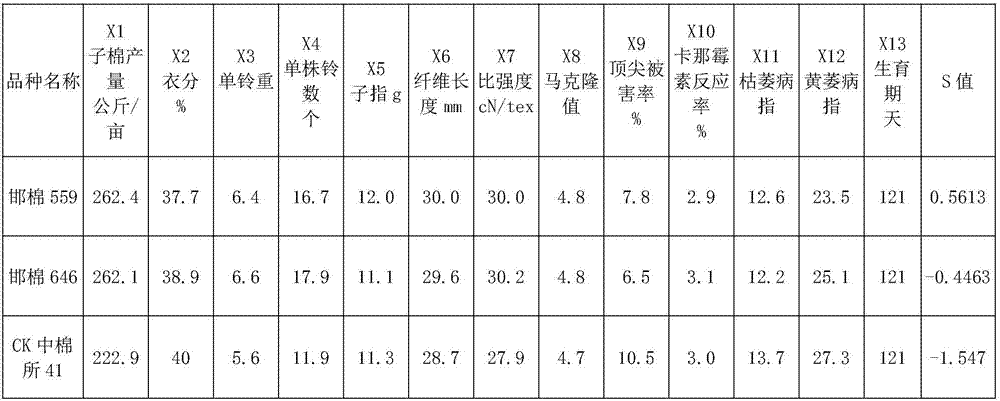

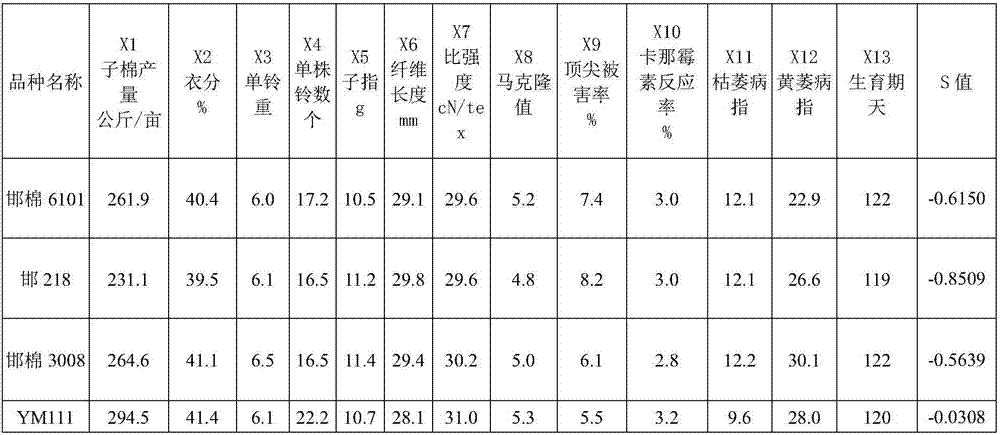

Structural comprehensive evaluation breeding method for cotton line

InactiveCN107389871AQuick filterStrong production adaptabilityTesting plants/treesHorticultureTarget lineAgricultural science

The invention provides a structural comprehensive evaluation breeding method for a cotton line. The method comprises the following steps: classifying thirteen representative characters of the cotton line, comparing, and carrying out comprehensive analysis, wherein the thirteen characters cover related characters such as yield, fiber quality and stress resistance of the cotton line, investigating and comparing index values of different characters, and comprehensively applying correlation coefficients between the index values of different characters and lint yield, so that different index characteristic values (S) which can represent, evaluate and breed the cotton line are obtained; and then comprehensively comparing the selected cotton line yield, quality and stress resistance results, and screening out a harmonized and unified cotton line with strong productive adaptability and better stability. The structural comprehensive evaluation breeding method for the cotton line can accurately and rapidly screen out a target line and objectively reflect comprehensive performance of the target line.

Owner:邯郸市农业科学院

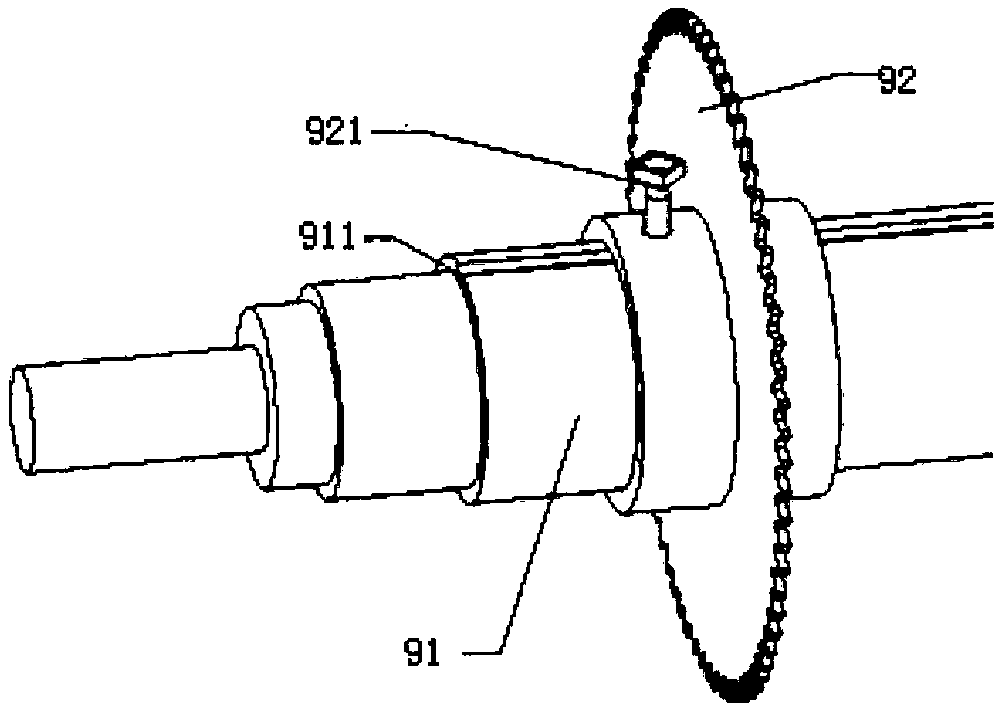

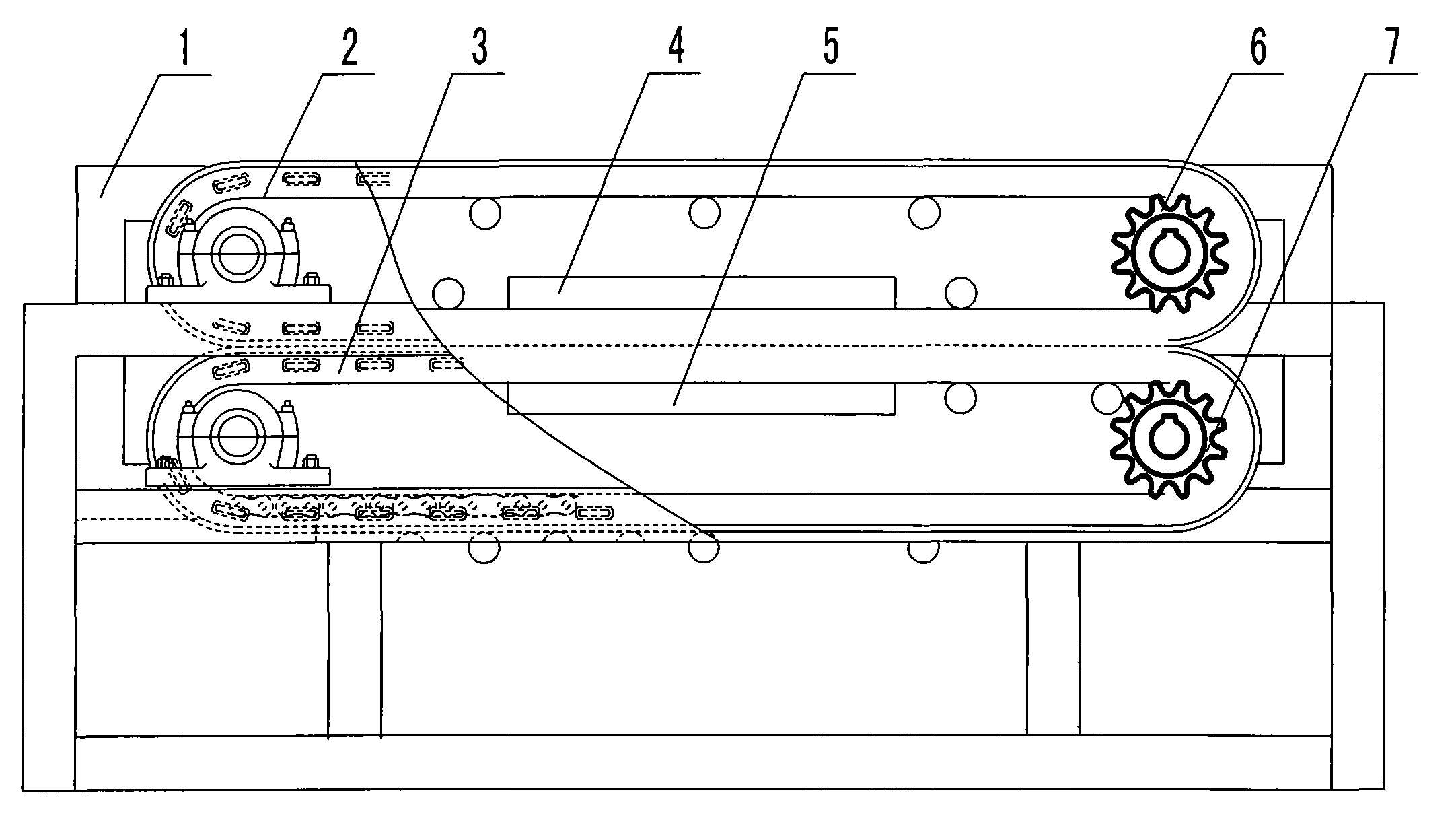

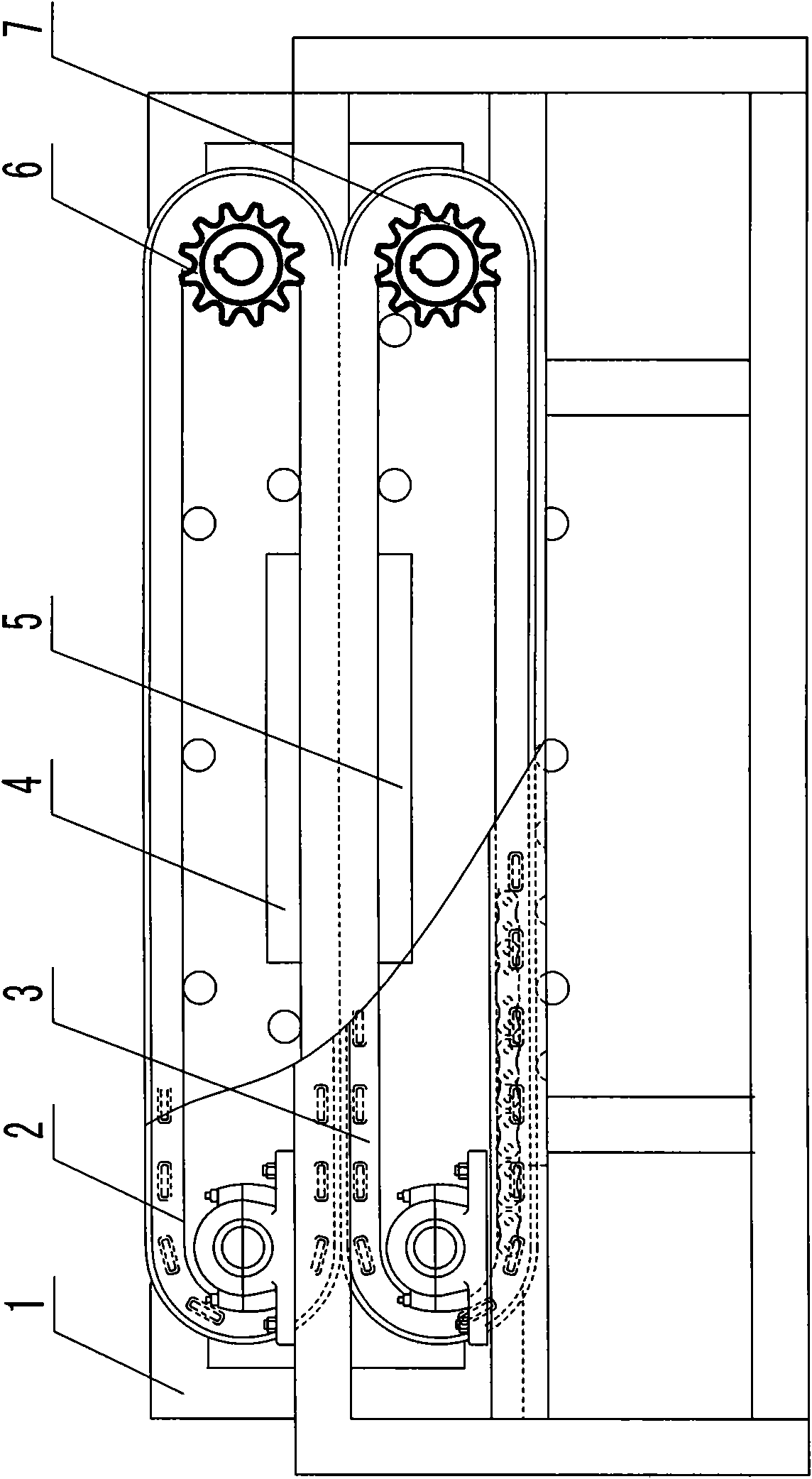

Chain plate-type tailing squeezer

InactiveCN101810966AEasy to separateStrong production adaptabilityMoving filtering element filtersWorking environmentSprocket

The invention discloses a chain plate-type tailing squeezer, comprising a slurry conveying device, a rack, an upper chain wheel roller and a lower chain wheel roller, an upper chain wheel and a lower chain wheel, an upper rubber press belt and a lower rubber press belt, wherein the upper and lower rubber press belts are in a hollow structure, a plurality of upper and lower water sucking square tubes are arranged in the hollow structure and provided with water sucking ports; an upper water sucking box and a lower water sucking box are arranged in the middle part of the upper and lower rubber press belts; the upper and lower water sucking square tubes are connected with the upper and lower water sucking box; two ends of both the upper and lower rubber press belts adopt a concave-convex-shaped connection structure, a filter fabric is arranged on the inner wall of a seal cavity formed in the middle part; the discharge end of the rack is provided with a sealing pinch roller, the feeding end is provided with a rubber closing plate, and a slurry pipe is arranged in the center of the rubber closing plate and is communicated with the seal cavity. In the invention, production is carried out in a closed work environment, thus having good sealing effect, large filter-pressing force, continuous production, stable and reliable operation, small influence caused by plasticity and viscosity of slurry, strong adaptability to various slurry production, high production efficiency and large yield in unit time, avoiding pollution, improving material-water separation effect.

Owner:柳有根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com