Patents

Literature

64results about How to "Reduce the impact of high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

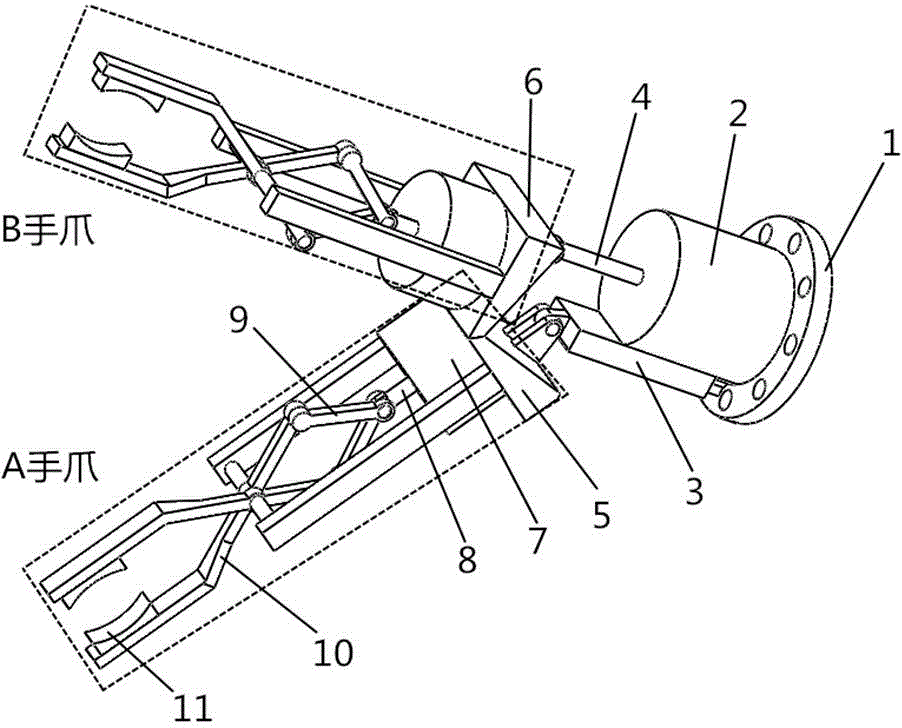

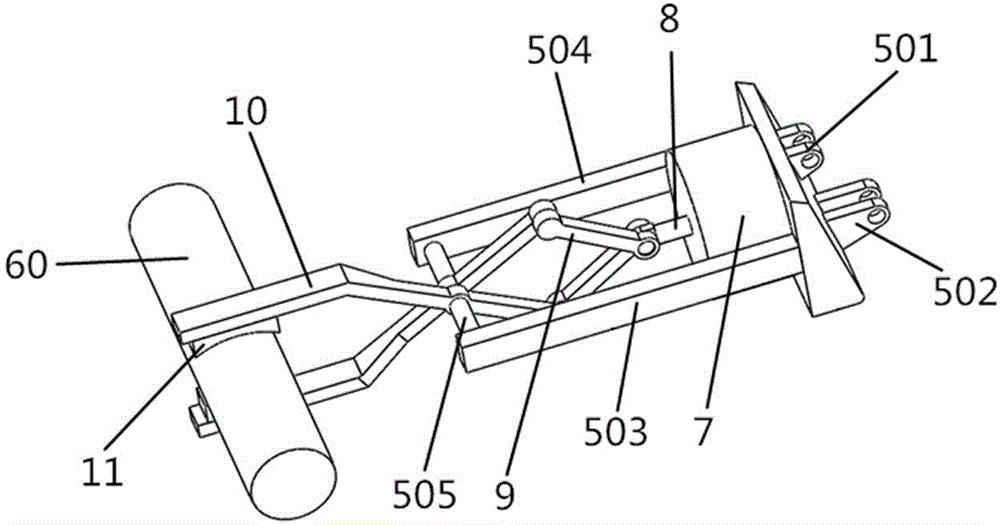

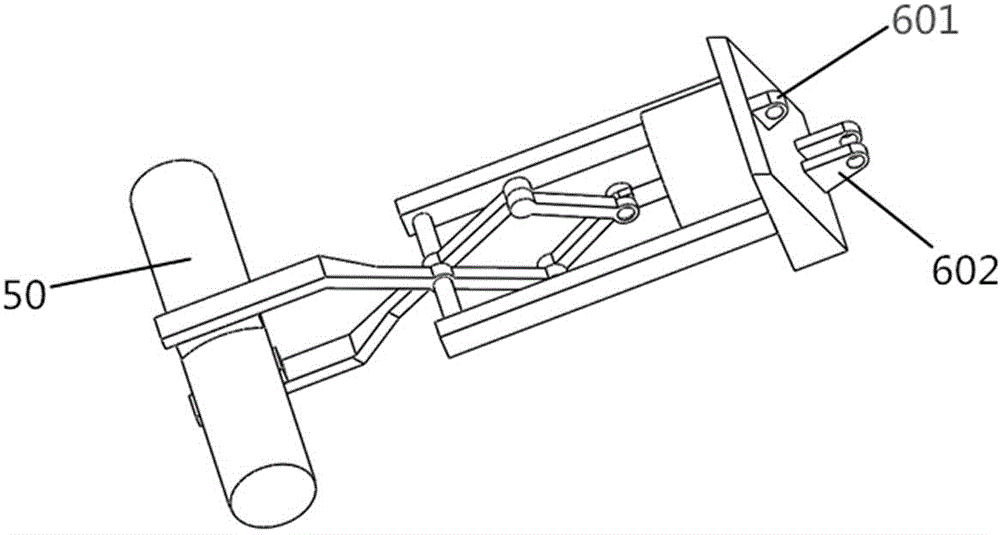

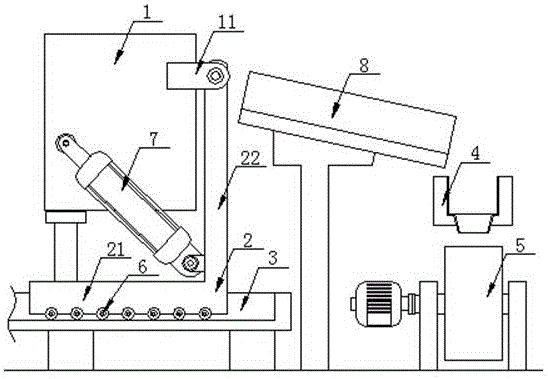

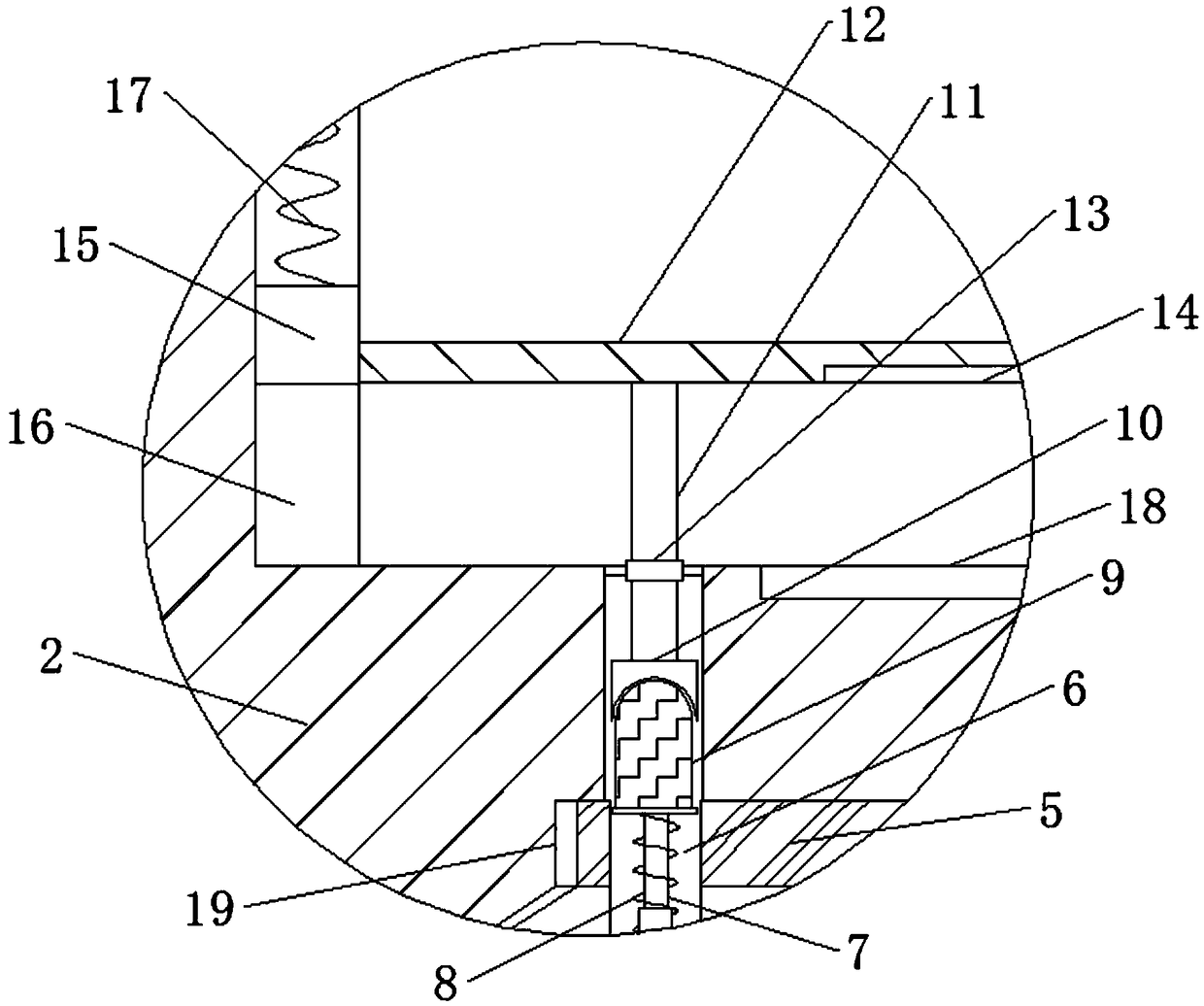

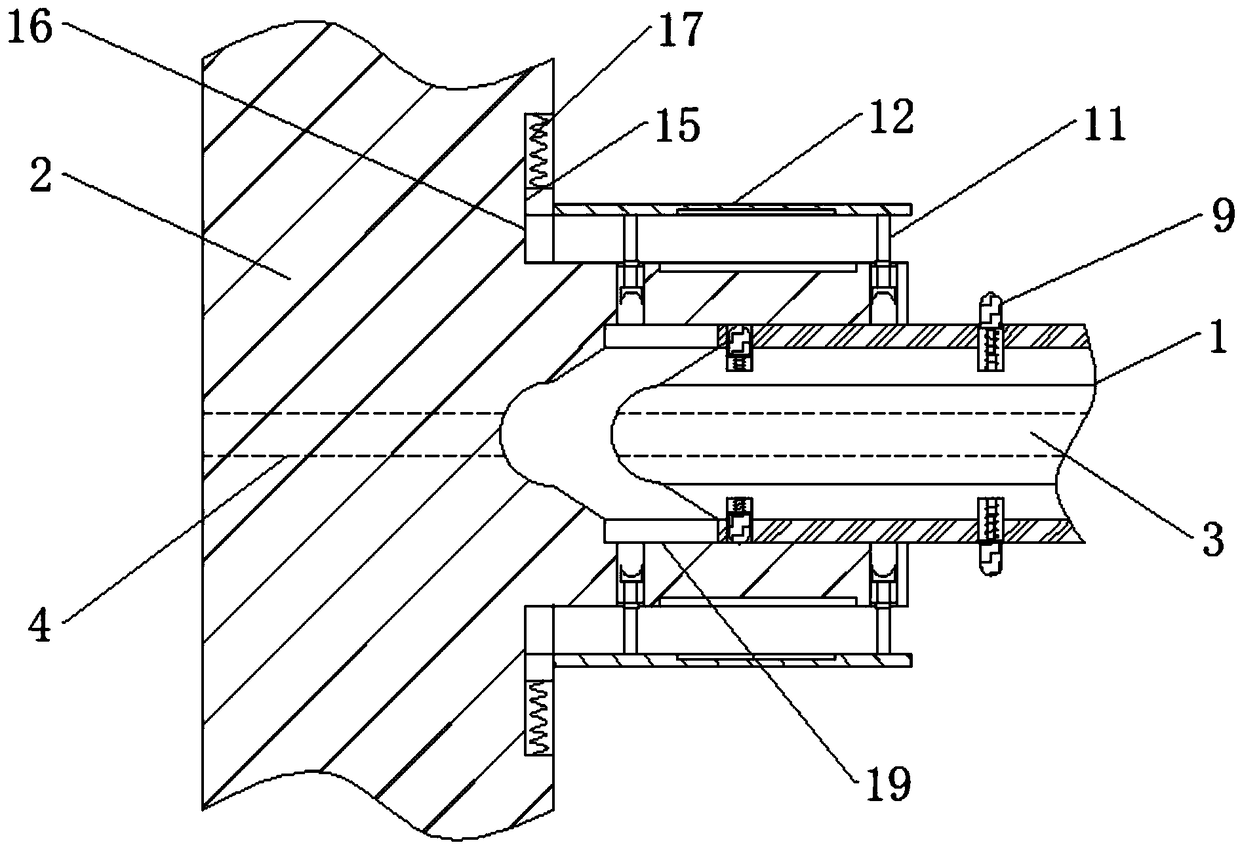

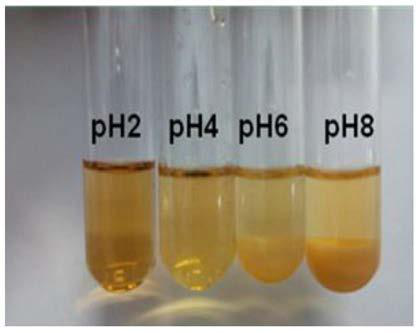

Grabbing pneumatic connecting rod arm with double-paw structure

InactiveCN104440885AReduce the impact of high temperatureShorten the timeProgramme-controlled manipulatorGripping headsProduction lineEngineering

The invention relates to a grabbing pneumatic connecting rod arm with a double-paw structure. The grabbing pneumatic connecting rod arm comprises a paw A, a paw B, a shift cylinder seat, a shift cylinder, a mounting plate and the like. The paws A and B have the same structure, and each paw consists of a scissor type connecting rod mechanism and a cylinder bracket. The tail of the shift cylinder and the connecting hole end of the mounting plate are fixedly connected to the same plane end of the cylinder seat, the mounting plate is arranged below the shift cylinder, a single lug hole seat of the mounting plate is hinged to a second connecting seat lug of the paw A through a pin shaft, a first connecting seat lug of the paw A is hinged to a second connecting seat lug of the paw B, and the second connecting seat lug of the paw B is hinged to an extension rod of the shift cylinder through a pin shaft. The telescopic motion of the extension rod of the paw shift cylinder drives the two paws to shift, so that workpieces can be alternately charged or discharged. The grabbing pneumatic connecting rod arm is widely applicable to an automatic part processing production line. The mechanical paws are simple in structure, and a cylinder serves as a driving device, so that the cost is reduced on the premise that the operation can be realized. By using the grabbing pneumatic connecting rod arm, the production time can be shortened, and the production efficiency is improved.

Owner:HEFEI UNIV OF TECH

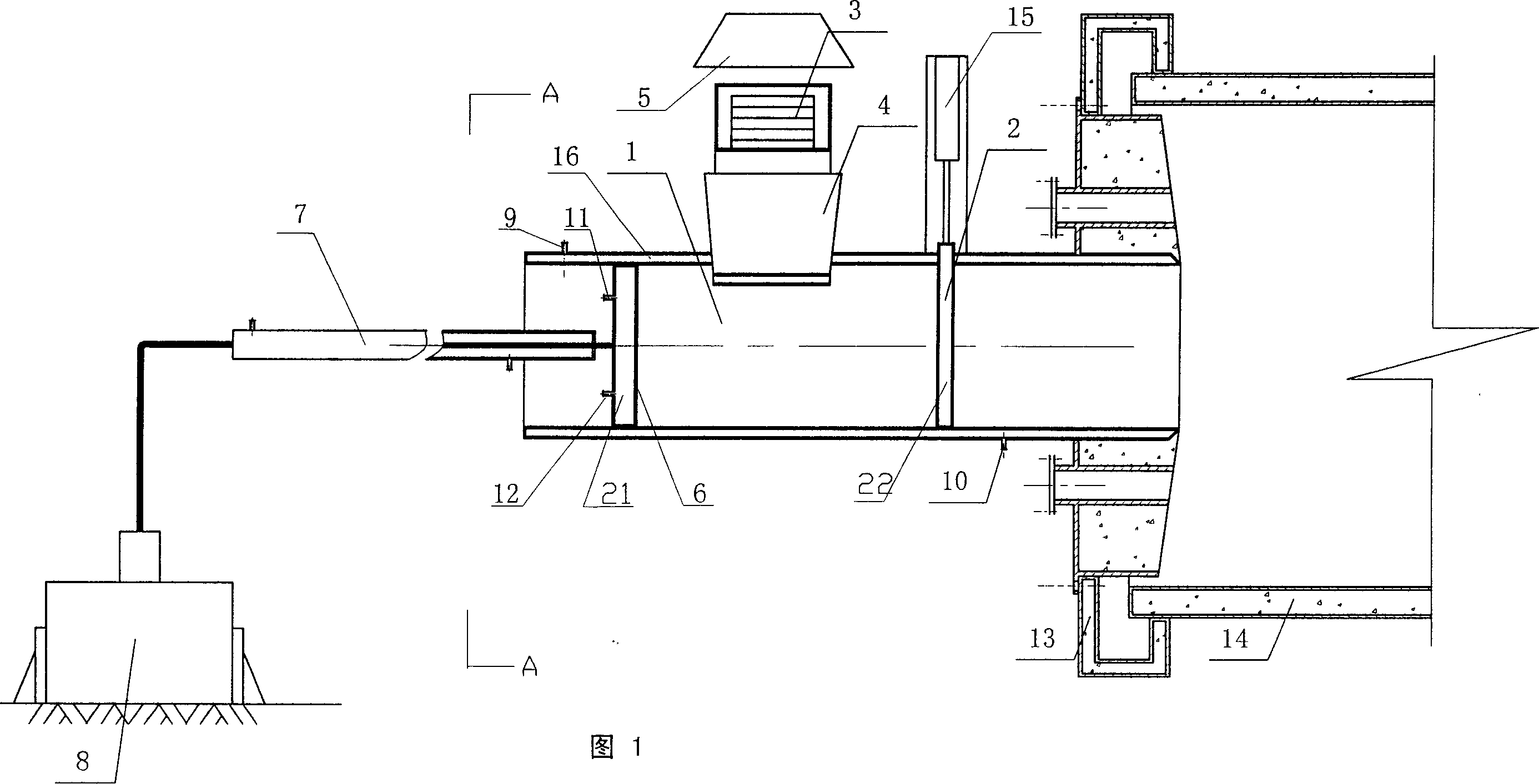

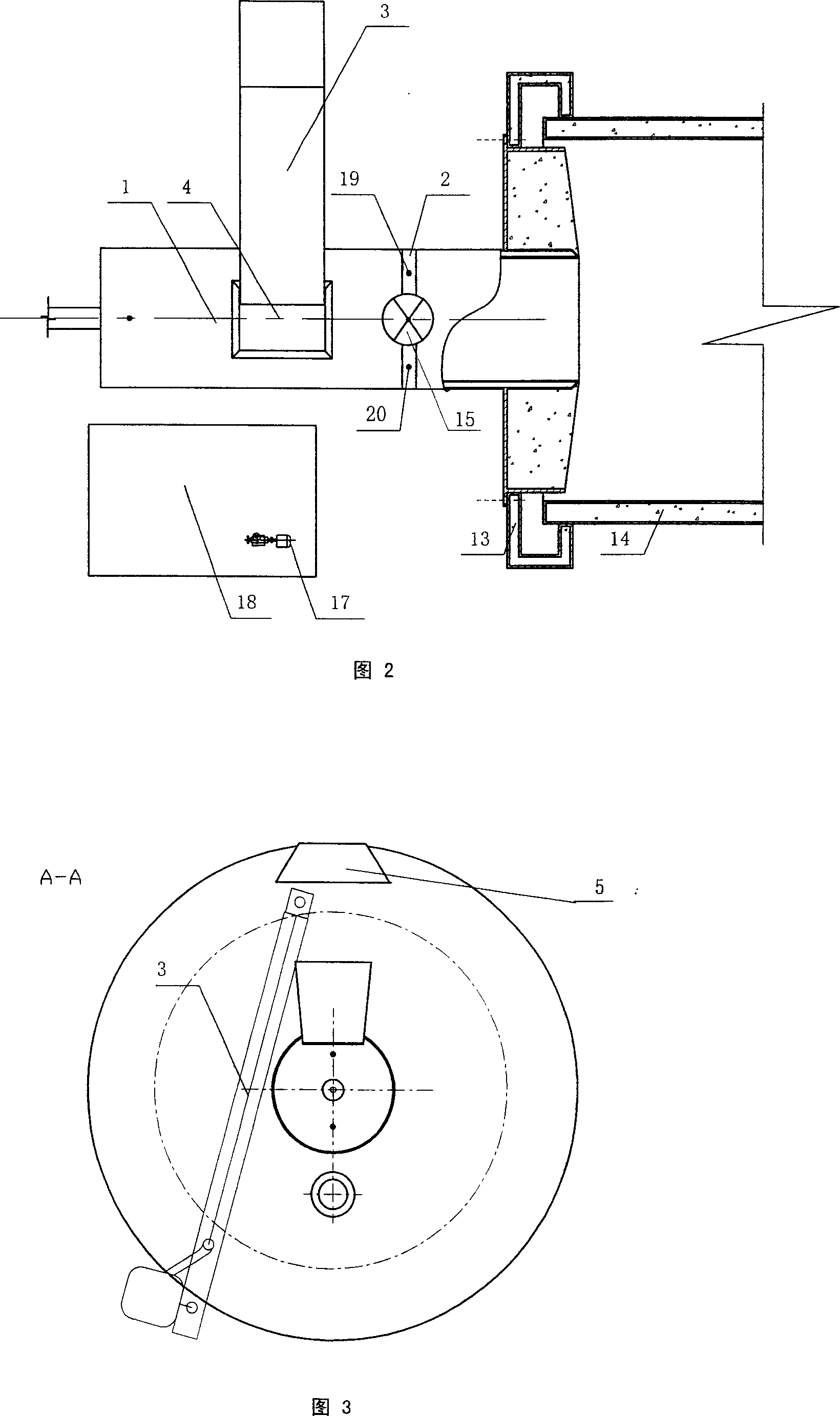

Feeding device for garbage burning rotary kiln end

InactiveCN1963301ABurn out preventionReduce the impact of high temperatureIncinerator apparatusWater flowIncineration

The invention relates to the modification to the feeding device of the rotary kiln for the burning of wastes, particularly hazardous wastes. Inside of the feeding line connects with the interior of the kiln with dog-house on the line and piston propelling plate and fire block door of the garbage propelling device inside the pipe. A manifold sandwich is made by he feeding line, propelling plate and the fire block door, and the pipe cooling water running channel is composed of water inlet, manifold sandwich space, and water outlet. The circulating cooling water can bring away the heat from the line, maintaining a relative low temperature of the outside wall, avoiding the melting, gluing, and locking of wastes due to the waste touching the high temperature line. Utilizing hydraulic propelling method, it can avoid the damage to the motor due to mechanical blocking. Meanwhile, big hydraulic thrusting force can make quick retraction of the piston propelling plate after the feeding of wastes into the kiln, lowering harsh requirement for the fire resistant feature of the piston propelling plate, improving the running reliability and extending its durability.

Owner:龚德明

Processing system for amorphous alloy magnetic core belt material of mutual inductor

The invention discloses a processing system for an amorphous alloy magnetic core belt material of a mutual inductor. The processing system comprises an amorphous alloy smelting furnace, a smelting furnace movable support, a smelting furnace sliding guide rail, an amorphous alloy pouring container, an amorphous alloy belt material cooling roller and an amorphous alloy belt material collecting pipe. The amorphous alloy smelting furnace is fixedly arranged on the smelting furnace movable support. A plurality of support movable rolling wheels are arranged at the bottom of the smelting furnace movable support. The multiple support movable rolling wheels are all arranged on the smelting furnace sliding guide rail. The two ends of the amorphous alloy belt material collecting pipe are provided with a belt material collecting inlet end and a belt material collecting outlet end, and a plurality of cooling gas high-speed sprayers are arranged on the inner side wall of the amorphous alloy belt material collecting pipe. Each cooling gas high-speed sprayer obliquely faces the axis of the amorphous alloy belt material collecting pipe and further faces the belt material collecting outlet end. By the adoption of the processing system, the influence on all supporting members by high temperatures can be reduced, and waste of the magnetic core belt material in the collecting operation process can be reduced.

Owner:江苏科兴电器有限公司

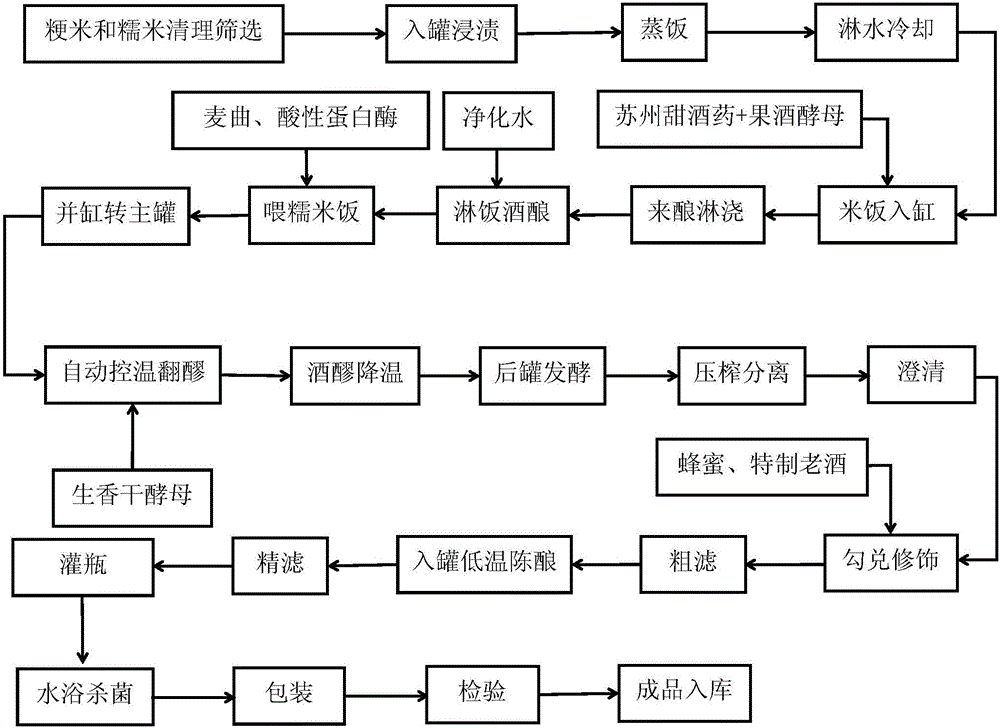

Elegant yellow wine and production technology thereof

PendingCN106754094ADecompose thoroughlyLow acidityAlcoholic beverage preparationMicroorganism based processesJaponica riceHorticulture

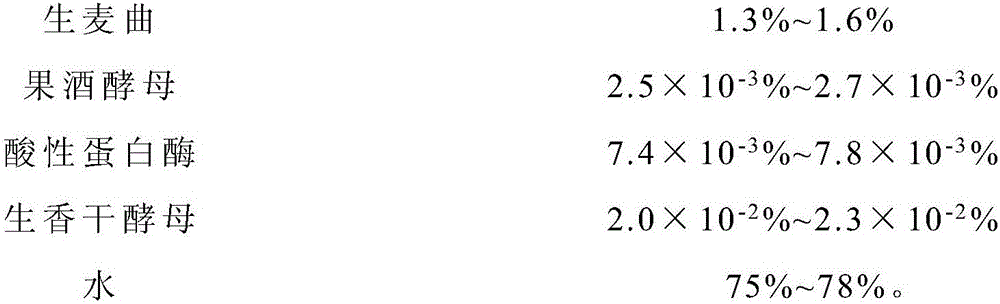

The invention discloses an elegant yellow wine which is prepared from the following raw materials in percentage by weight: 10-12% of white japonica rice, 11-13% of fine glutinous rice, 4.1*10<-2>%-4.5*10<-2>% of a Soochow sweet Chinese yeast, 1.3-1.6% of raw wheat koji, 2.5*10<-3>%-2.7*10<-3>% of a fruit wine yeast, 7.4*10<-3>%-7.8*10<-3>% of acid proteinase, 2.0*10<-2>-2.3*10<-2>% of a perfume dry yeast and 75-78% of water. The production technology of the elegant yellow wine comprises preparation of japonica rice and glutinous rice, preparation of a rice-sprinkling wine yeast, feeding of the glutinous rice, fermentation, after-treatment, sampling analysis and finished product preparation. According to the elegant yellow wine, by adopting a pure and raw low-temperature aging process and a japonica rice and glutinous rice feeding low-temperature fermentation method, the quantity of generated ethyl carbamate is relatively low, the wine is elegant, a wine body is safe and healthy, and the elegant yellow wine is mellow, pure and fresh.

Owner:苏州同里红酿酒股份有限公司

Device and method for testing performance of cold-hot cavity short-distance isolated heavy-load ultrahigh-temperature bearing

ActiveCN110954325AHigh working reliabilityLarge loading forceMachine bearings testingTest performanceEngineering

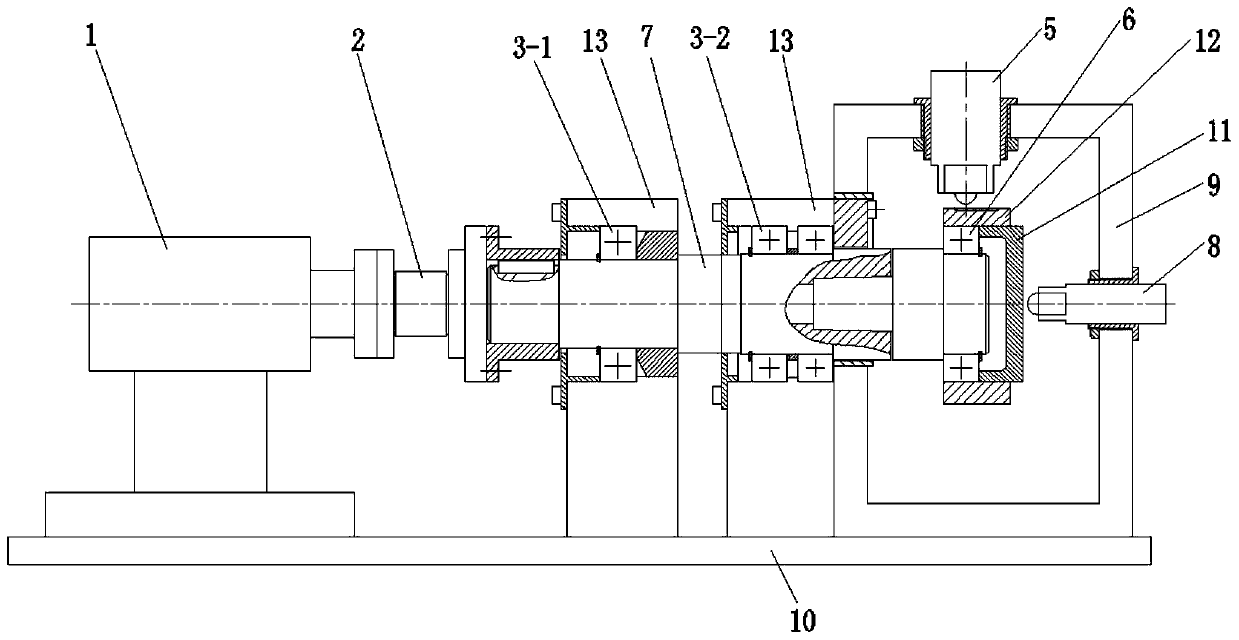

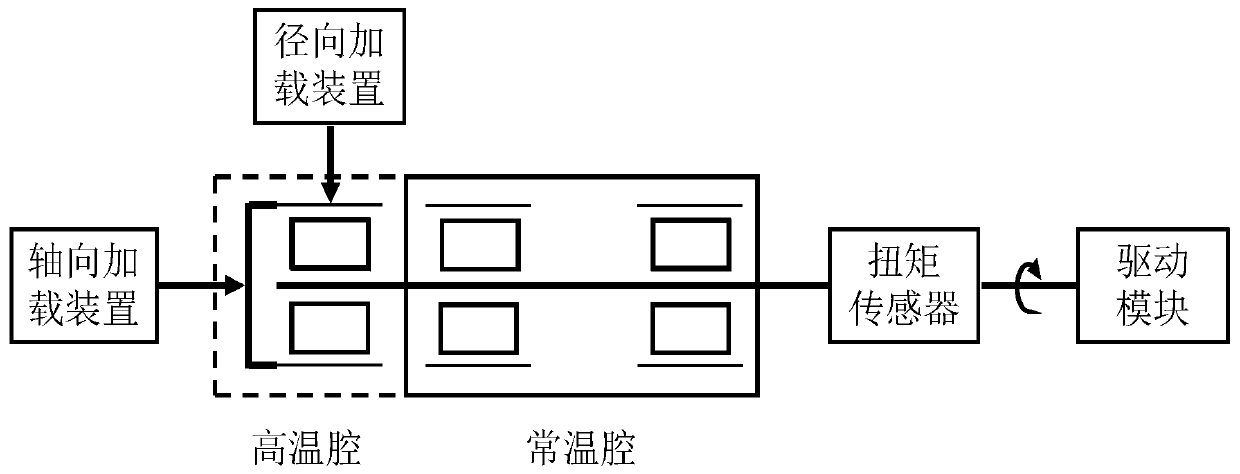

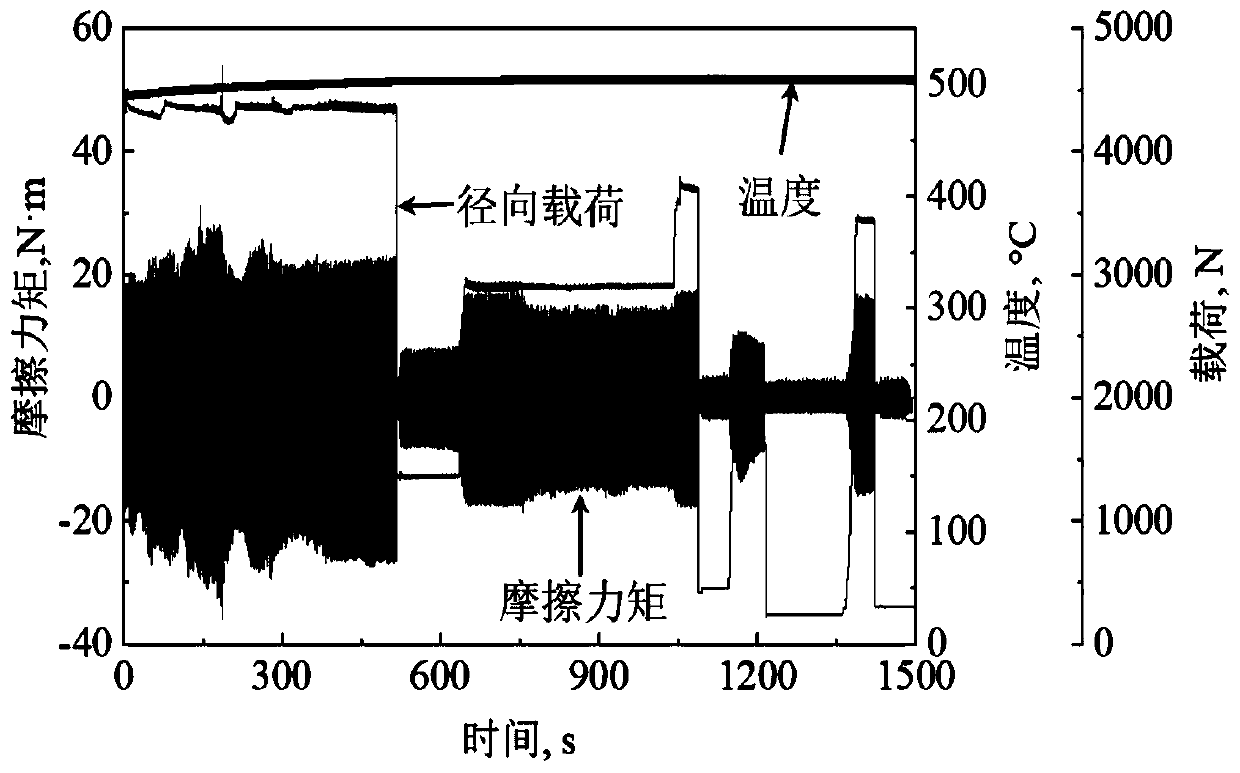

The invention discloses a device and a method for testing the performance of a heavy-load ultra-high-temperature bearing with short-distance isolated cold and hot cavities. The device comprises a driving module, a torque sensor, a supporting bearing, a radial loading device, a tested bearing, a supporting main shaft, an axial loading device and a heating chamber, the heating chamber is arranged onthe base; the supporting main shaft is supported by a supporting bearing arranged outside the heating chamber, the output end of the driving module is connected with a torque sensor, the torque sensor is connected with the other end of the supporting main shaft arranged outside the heating chamber, and an axial loading device and a radial loading device which are used for loading a tested bearingare installed on the heating chamber. The test method comprises the following steps: 1, installing a required tested bearing; 2, preparing for testing; 3, heating the heating chamber; and 4, axial and radial load testing. The device is compact in structure and reliable in work.

Owner:HARBIN INST OF TECH +1

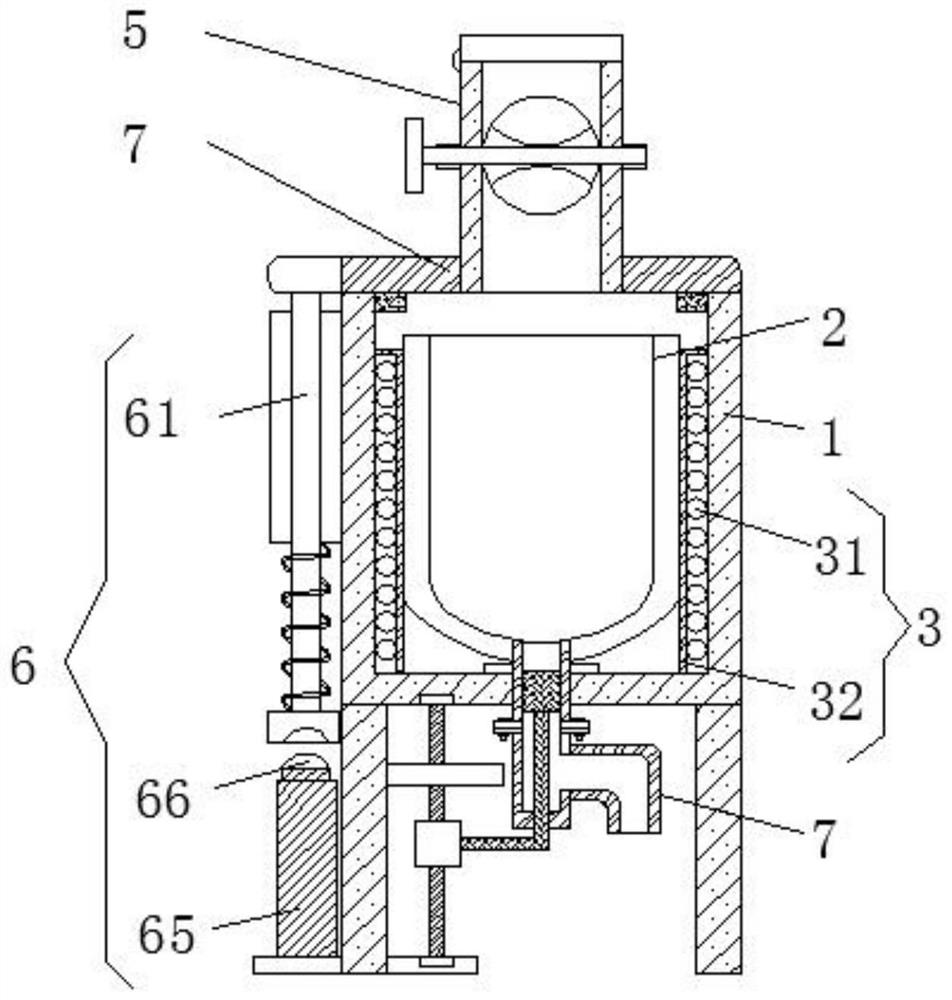

Crucible for manufacturing optical glass

InactiveCN111333305AExtended heating rangeEvenly heatedPot furnacesGlass furnace apparatusCrucibleElectric machine

The invention belongs to the technical field of optical glass smelting, and particularly relates to a crucible for manufacturing optical glass. The crucible comprises a crucible body, a motor and a sealing cover; a cavity is designed in the crucible body; a rotating shaft of the motor penetrates through the sealing cover and is fixedly connected to a stirring shaft in the cavity of the crucible body; the stirring shaft is rotatably connected to uniformly arranged stirring rods and heating rods; a first cavity is formed in the sealing cover; the rotating shaft of the motor is fixedly connectedto a rotating wheel in the first cavity; extrusion plates which are uniformly arranged are hinged to the wall of the first cavity; an inclined side of the extrusion plates are fixedly connected to extrusion bags; a second cavity is formed in the inner wall of the crucible body; the second cavity is arranged around the inner cavity of the crucible body; the extrusion bags are all communicated withthe inner cavity of the crucible body and the second cavity through one-way conduits; the motor rotates to drive the rotating wheel to extrude the extrusion bags, so that the extrusion bag pumps airflow in the inner cavity of the crucible body into the second cavity, the air pressure of the crucible body is reduced, and the melting point of raw materials is partially reduced.

Owner:刘明举

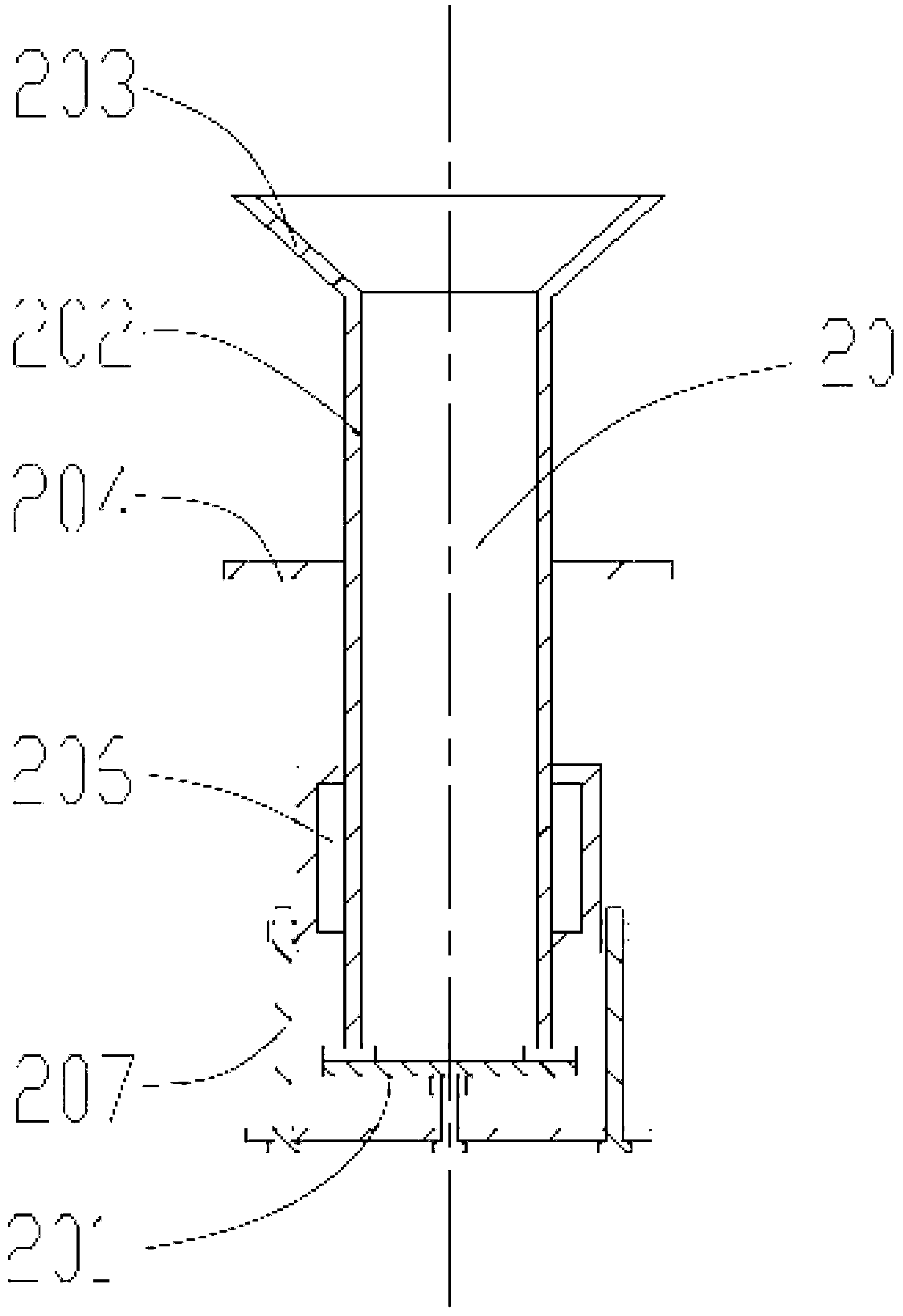

Vertical reduction jar

ActiveCN103307878AReduce the impact of high temperatureImprove securityCrucible furnacesEngineeringHearth

The invention provides a vertical reduction jar which comprises a main jar body and a discharge part, wherein the main jar body has a first diameter; the discharge part comprises a discharge cylinder body, a bowl mouth part and a sealing plate; the bowl mouth part is connected with the upper edge of the discharge cylinder body, and the sealing plate is arranged from a distance with the upper edge of the discharge cylinder body; the discharge cylinder body has a second diameter smaller than the first diameter; the transition between the main jar body and the discharge cylinder body is performed by the bowl mouth part; and the sealing plate is sealed with the lower edge of the main jar body. The welding part of the vertical reduction jar is deployed outside a hearth through the discharge part, and high temperature damage is reduced. When the inner part of the jar is blocked, only the original welding of the bottom is removed, repair and replacement can be completed. The vertical reduction jar has the advantages of good safety and convenience in maintenance, and prolongs the service life.

Owner:NINGXIA SUN MAGNESIUM IND

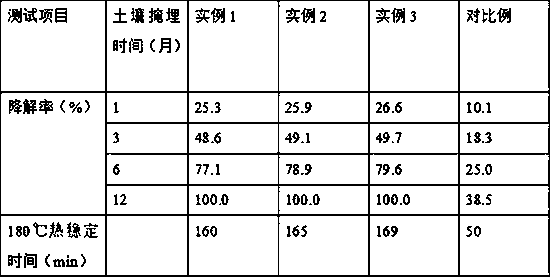

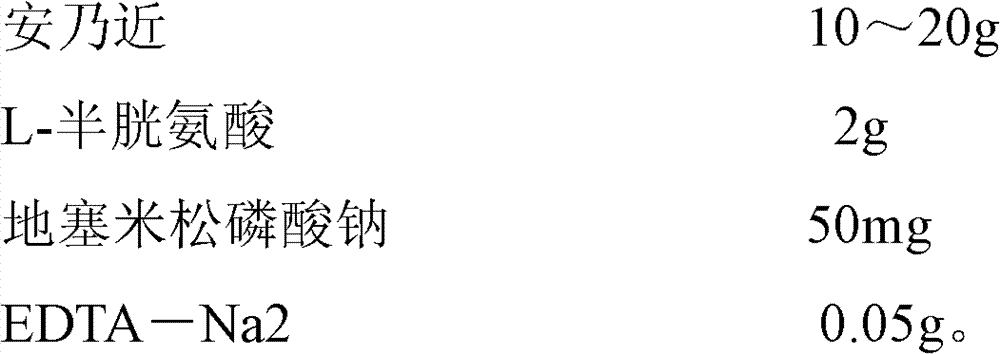

Preparation method of high-temperature resistance degradable PVC tablecloth

InactiveCN107756988AImprove high temperature resistanceHigh strengthLamination ancillary operationsSynthetic resin layered productsEmulsionComposite film

The invention relates to the technical field of plastic product preparation, in particular to a preparation method of high-temperature resistance degradable PVC tablecloth. According to the preparation method provided by the invention, a self-crosslinking acrylate emulsion obtained by reaction is prepared into a modified adhesive film, the modified adhesive film is adhered to a PVC film to form athree-layer composite film, and hot pressing is performed on the three-layer composite film to obtain the high-temperature resistance degradable PVC tablecloth; a resin matrix with aluminum powder, aluminum powder filling particles can increase a melting point of the PVC tablecloth and effectively reduce thermoplastic deformation at high temperature, so that the high-temperature resistance performance of the PVC tablecloth is improved; and a self-crosslinking acrylate adhesive film is soaked with a starch glue liquid, and starch is easily decomposed into monosaccharide in the long-term insolation process, so that the effect of degradation to the tablecloth is exerted, and contribution is made to environmental protection.

Owner:杨忠华

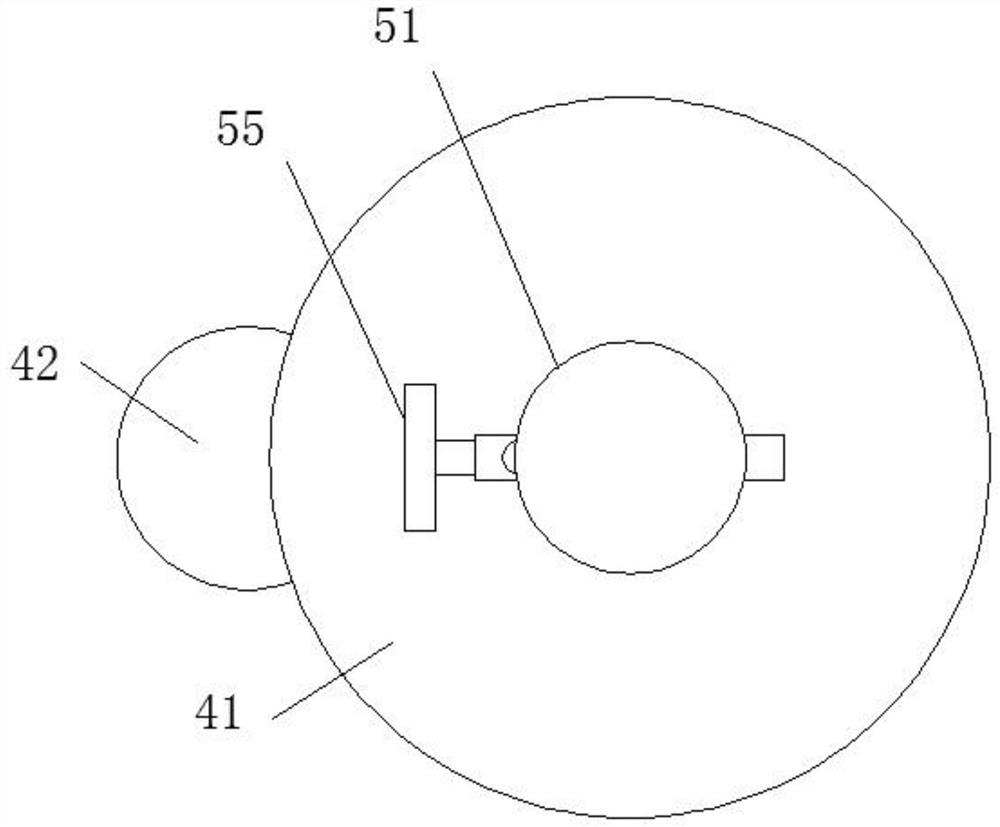

Casting melting device with splash-proof component

InactiveCN113154879AReduce churnStop lossFurnace safety devicesCrucible furnacesMolten stateCrucible

The invention discloses a casting melting device with a splash-proof component. The device comprises a heat-insulating furnace body, a crucible is placed in the furnace body, a heating piece is fixedly arranged on the inner wall of the furnace body, a cover plate is placed at the top of the furnace body, the splash-proof component for feeding is fixedly arranged at the middle end of the top of the cover plate, a movable assembly is arranged between the cover plate and the furnace body, the relative displacement of the cover plate and the furnace body is changed, and a discharging mechanism is arranged between the crucible and the furnace body; and the furnace body made of the heat insulation material can reduce outward loss of heat, so that the influence of the heat on the surrounding environment is reduced, in addition, the feeding safety can be improved by arranging the splash-proof component, molten metal cannot be splashed out and intercepted in the furnace body under the shielding of the splash-proof component, meanwhile, the splash-proof component has certain sealing performance, the heat loss can be prevented in a molten state, heat loss can be prevented in time under the feeding condition, and the high-temperature influence in the feeding process is reduced.

Owner:WUHU RONGCHUAN ELECTROMECHANICAL TECH

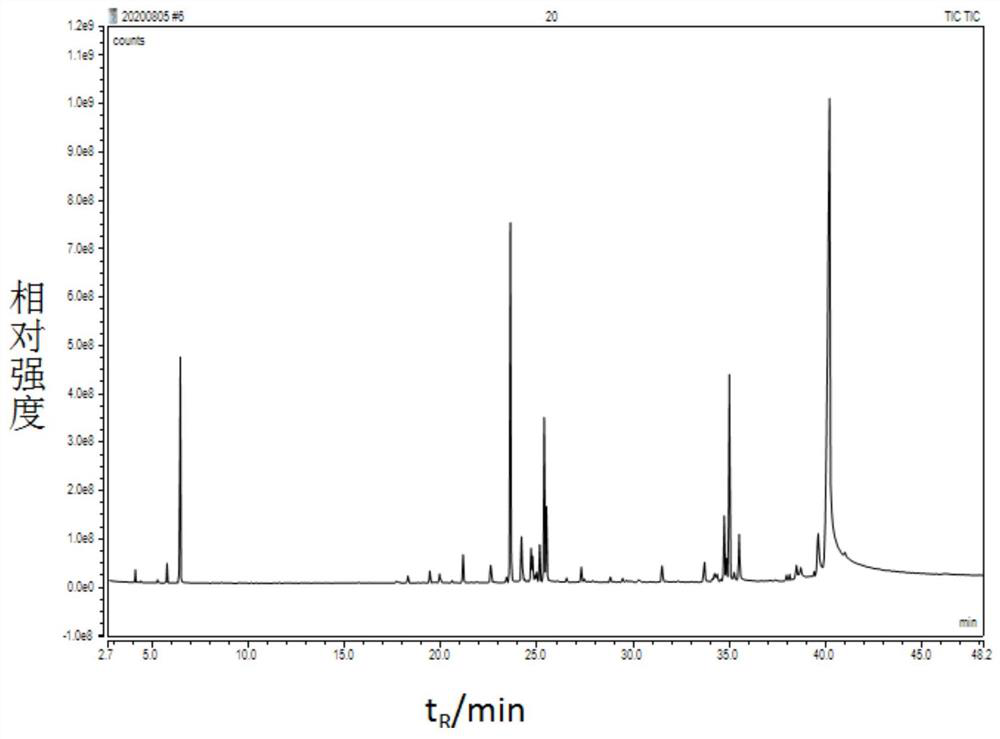

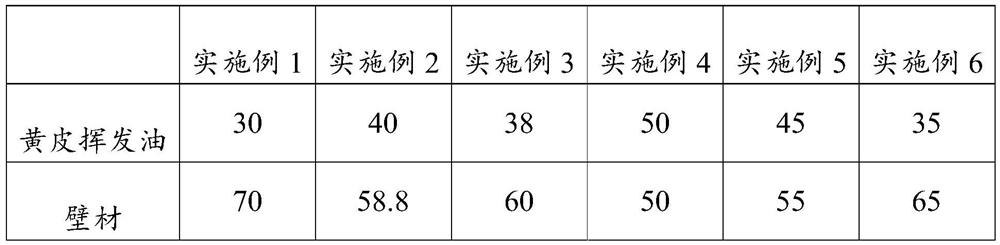

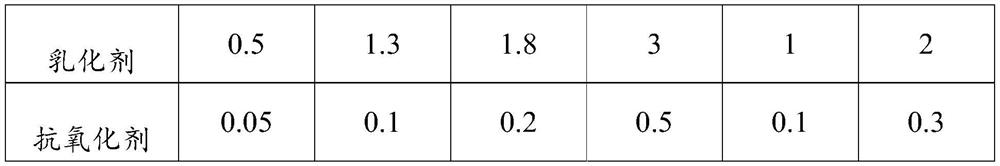

Clausena lansium volatile oil microcapsule powder and preparation method thereof

ActiveCN112450417AIncrease the fragranceLow extraction temperatureFood ingredient as antioxidantVitamin food ingredientsEngineeringClausena lansium

The invention discloses clausena lansium volatile oil microcapsule powder, and relates to the field of flavors and fragrances. The clausena lansium volatile oil microcapsule powder comprises the following components in parts by weight: 30-50 parts of clausena lansium volatile oil, 50-70 parts of a wall material, 0.5-3 parts of an emulsifier and 0.05-0.5 part of an antioxidant. The clausena lansiumvolatile oil microcapsule powder provided by the invention has a glass transition temperature of 80 DEG C or above, and has good heat resistance, embedding rate and storage resistance.

Owner:GUANGZHOU HONSEA SUNSHINE BIOTECH CO LTD

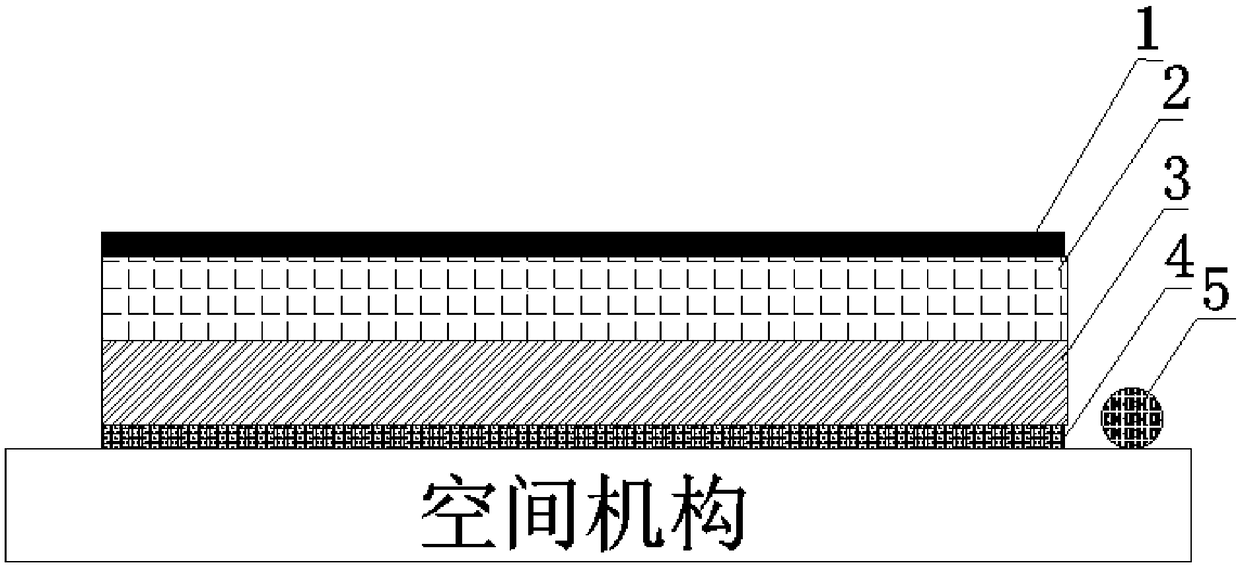

NoveL thermaL controL device for spatiaL fLexibLe mechanism

ActiveCN108860664ASatisfy rotation needsReduce the impact of high temperatureMirrorsCosmonautic radiation protectionHeat flowMetallic Nickel

The invention discLoses a noveL thermaL controL device for a spatiaL fLexibLe mechanism, which comprises a fiLm type temperature controL heating beLt, copper nickeL pLain conductive cLoths and a F46 fiLm siLver pLating secondary surface mirror. The fiLm type temperature controL heating beLt is adhered and wound on the fLexibLe mechanism through GD414C siLicon rubber; 6 Layers of copper nickeL pLain conductive cLoth are wound on the fiLm type temperature controL heating beLt; a Layer of F46 fiLm siLver pLating secondary surface mirror is wound on the surface of the copper nickeL pLain conductive cLoths. By utiLizing the copper nickeL pLain conductive cLoth and the F46 fiLm siLver pLating secondary surface mirror, the spatiaL fLexibLe mechanism is integraLLy covered, not onLy can the externaL heat fLow be prevented, but aLso the irradiation is resisted, meanwhiLe, the power of the temperature controL heating beLt can be effectiveLy reduced and the energy can be saved. Moreover, the fiLmtype temperature controL heating beLt, the copper nickeL pLain conductive cLoth and the F46 fiLm siLver pLating secondary surface mirror are fLexibLe, and can be appLied to spatiaL fLexibLe mechanismswith various structures, incLuding rotating cabLes and the Like.

Owner:SHANGHAI SATELLITE ENG INST

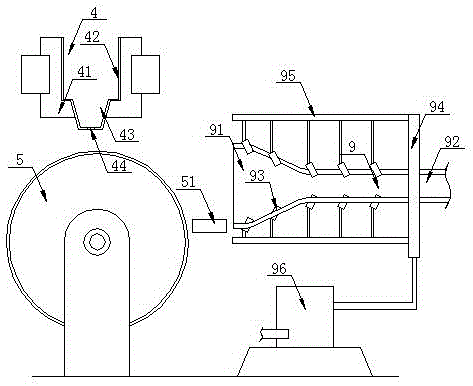

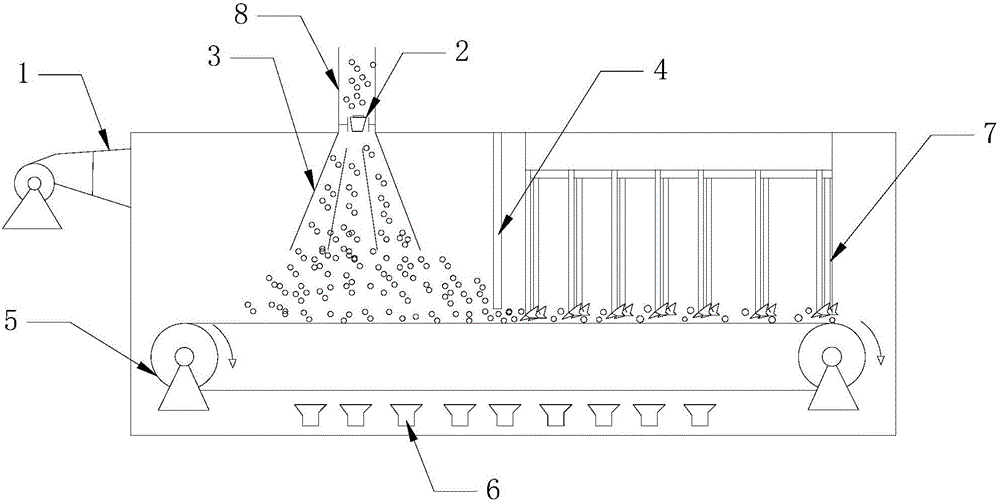

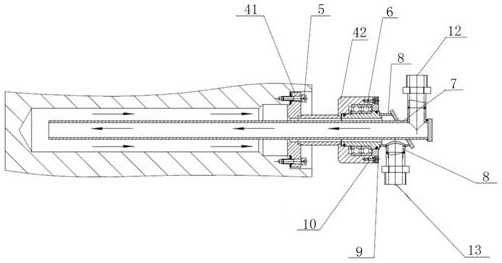

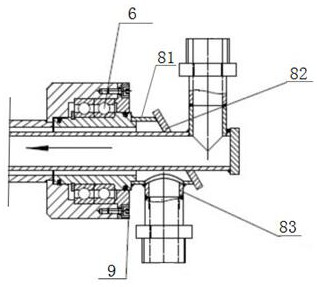

Microwave dryer for polyacrylamide colloidal particles and microwave drying method

InactiveCN105841468AReduce noiseReduce the impact of high temperatureDrying solid materials with heatGranular material dryingRotary valveProcess engineering

The invention relates to a microwave dryer for polyacrylamide colloidal particles and a microwave drying method. The microwave dryer comprises a feed port, an induced draft fan, a conveyor and microwave emitting sources; the feed port is formed in the top of the microwave dryer; the induced draft fan is arranged on the side wall of the dryer near the feed port; a rotating valve is arranged in the feed port; a guide plate is arranged below the feed port; the front end of the conveyor is positioned below the guide plate; multiple stirring devices are arranged at the back end of the conveyor; and multiple microwave emitting sources are arranged below the conveyor. The microwave dryer is low in noise, fast in material drying speed, low in influence on materials by high temperature, excellent in production adaptability, suitable for drying of the polyacrylamide colloidal particles and suitable for drying of other high-viscosity polymers.

Owner:DONGYING BAOMO ENVIRONMENT ENG CO LTD

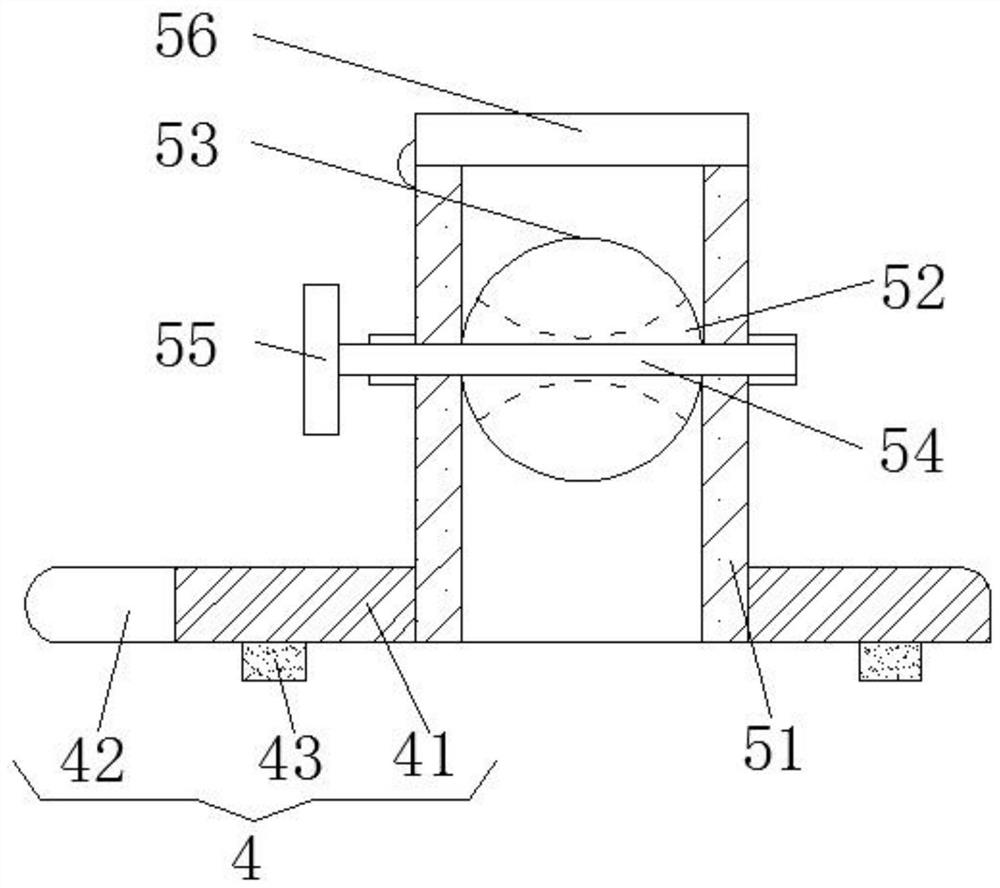

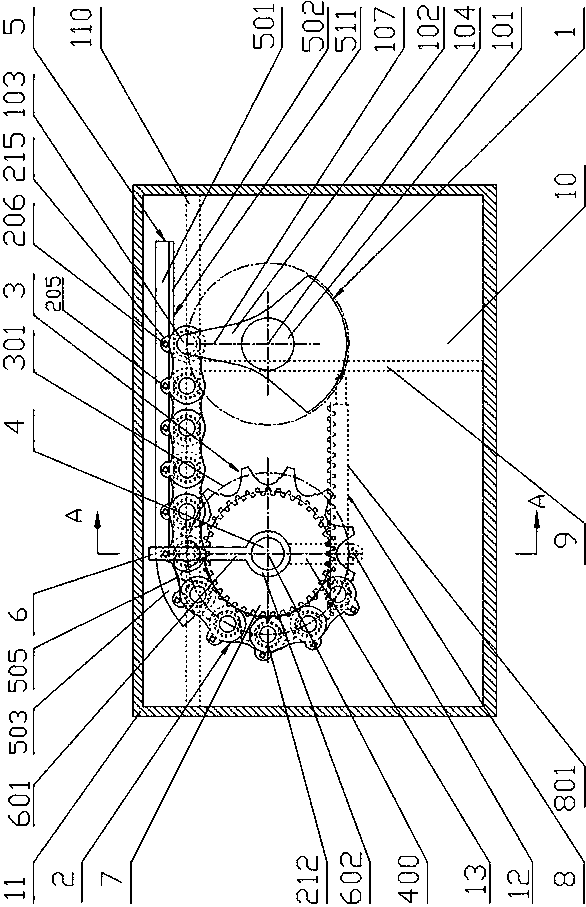

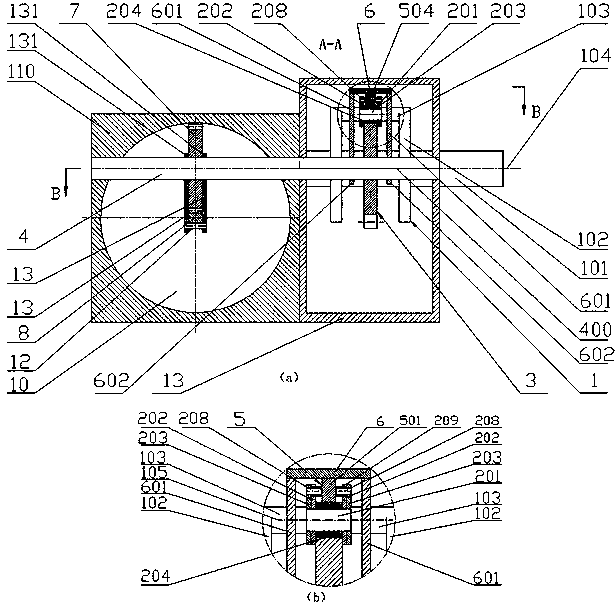

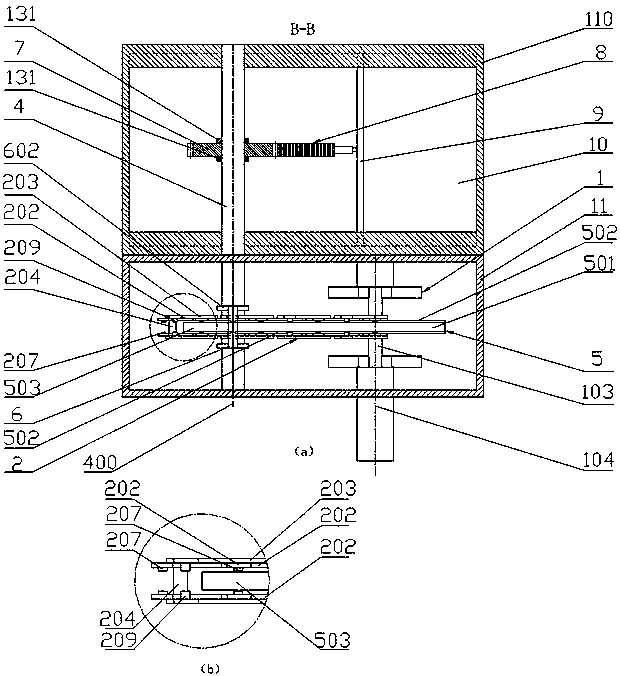

Chain-crankshaft linkage conversion mechanism

ActiveCN110118250AEliminate wear and tearSmall moment of inertiaGearingMachines/enginesDrive shaftEngineering

The invention discloses a chain-crankshaft linkage conversion mechanism. Drive sprockets 3 on transmission shafts 4 in a crankcase 11 mesh with drive chains 2; one ends of the drive chains 2 are connected to crankshaft journals 103, and the other ends of the drive chains are installed on the wheel rims of the drive sprockets 3; a linear guide rail 501 is rotatably connected to a rotating ring 602and the transmission shafts 4 on the two sides of the drive sprockets 3; through a limit rod 6 and rotating flat rods on the two ends; each chain pin 201 of the drive chains 2 and the crankshaft journals 103 are placed on the bottom surface 511 of the linear guide rail of a chain guide rail 5; guiding short columns 206 and guiding long columns 208 on inner connecting plates 202 and outer connecting plates 203 of the drive chains 2 are placed on the top surfaces 504 of guiding flanges 502 on the two sides of the linear guide rail 501; and driving racks 8 meshing with driving gears 7 on the transmission shafts 4 in an additional cylinder body 110 are in hinged joint with a piston 9 in an air cylinder 10 to form an engine unit with multiple air cylinders 10.

Owner:安里千

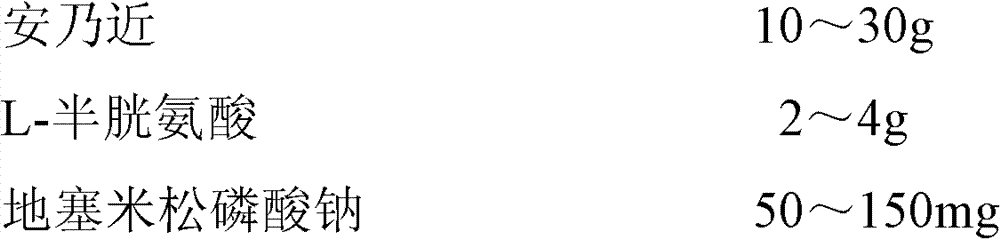

Preparation method of compound analgin injection for livestock

ActiveCN103083229AExtended sterilization timeReduce the impact of high temperatureOrganic active ingredientsAntipyreticAnti-inflammatoryChemistry

The invention relates to a compound analgin injection for livestock and a preparation method thereof. Every 100ml of injection comprises 10-30g of analgin, 2-4g of L-cysteine, 50-150mg of dexamethasone sodium phosphate, 0.05g of EDTA-Na2, water for injection to 100mg, and pH regulator (for regulating the pH value to 5.5-6.5). The preparation method comprises the following steps: dissolving dexamethasone sodium phosphate to prepare a solution, dissolving the other components into a solution, merging the two solutions, stirring uniformly, regulating the pH value to 5.5-6.5 while continuing stirring, and diluting to the specified volume; and filtering the liquor through an organic filter membrane, respectively filling the filtrate into bottles by a filling and sealing machine, sterilizing at 115 DEG C under the pressure of 0.2 MPa for 20 minutes, opening the sterilizing cabinet, naturally cooling for 10 minutes, closing the sterilizing cabinet, and sterilizing again for 20 minutes, thereby obtaining the finished product. The invention solves the problems of discoloration, content degradation, toxicity increase and the like in the injection storage process. The invention has better antipyretic effect, and is endowed with anti-inflammatory and antiallergic functions. The invention improves the appearance quality and curative effect of the product. The invention is more convenient to use, and has wider application range.

Owner:金河牧星(重庆)生物科技有限公司

Preparation method of heat-resistant degradable material

InactiveCN108819406AHigh melting pointHigh strengthSynthetic resin layered productsDecompositionPolyvinyl alcohol

The invention discloses a preparation method of a heat-resistant degradable material and belongs to the technical field of preparation of environment-friendly materials. When aluminum powder and PVC (polyvinyl chloride) resin are mixed in a double-roll warming machine, aluminum powder fills the inside of a resin body and can enhance the strength of a PVC film; the melting point of aluminum powderparticles is higher, firstly, starch in a modified glue film is easily decomposed into monosaccharide in the long-time exposure process, and the crosslinking point of acrylic ester can be damaged after decomposition. A mixed film solution contains chitosan and polyvinyl alcohol, a main chain of chitosan contains easily hydrolytic ester bonds which easily absorb water to be hydrolyzed in soil, absorbed micromolecular water moves to the surface of a film coating material and enters the periphery of a hydrophilic group or ester bonds in a dispersion manner. After the degradable material is degraded in soil, the adsorption capability of the soil for nutritional elements is improved, held inorganic nutrients are released, inorganic salt particles are preserved in a net-shaped structure of a water-absorbing high polymer and have moisture and fertilizer retention functions on the oil, and the application prospects are broad.

Owner:FOSHAN WANYANG BIOLOGICAL TECH CO LTD

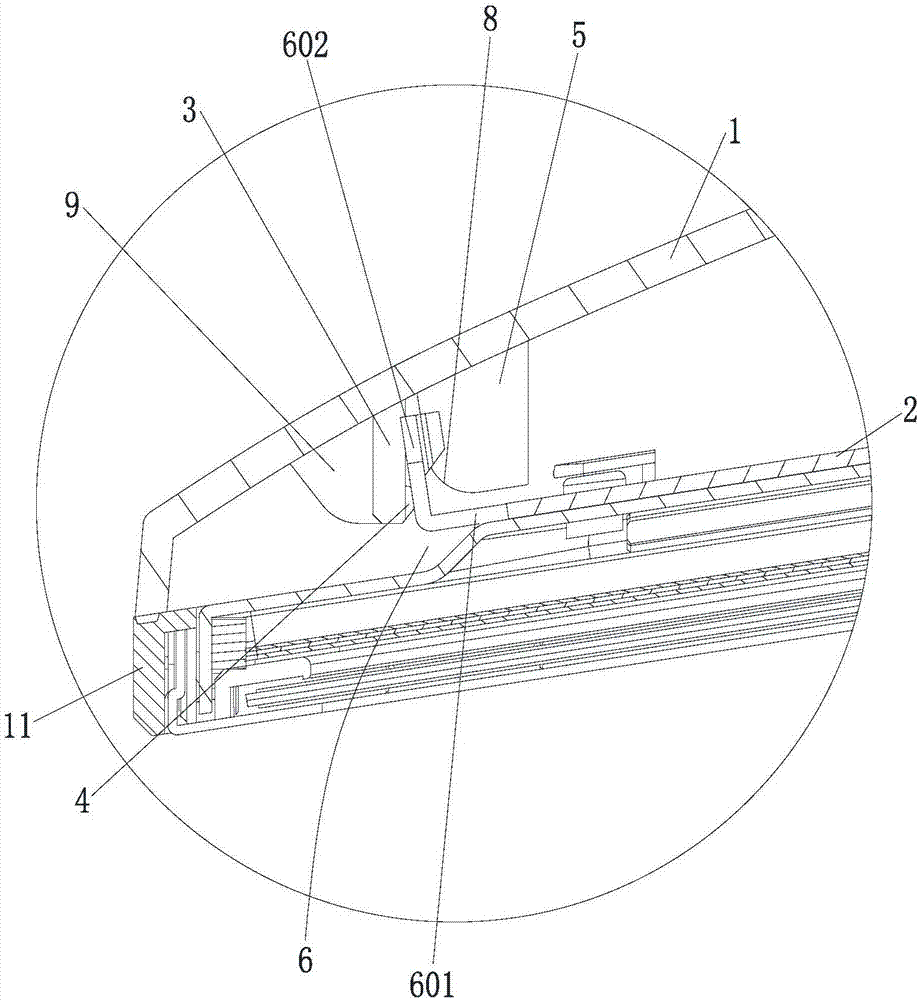

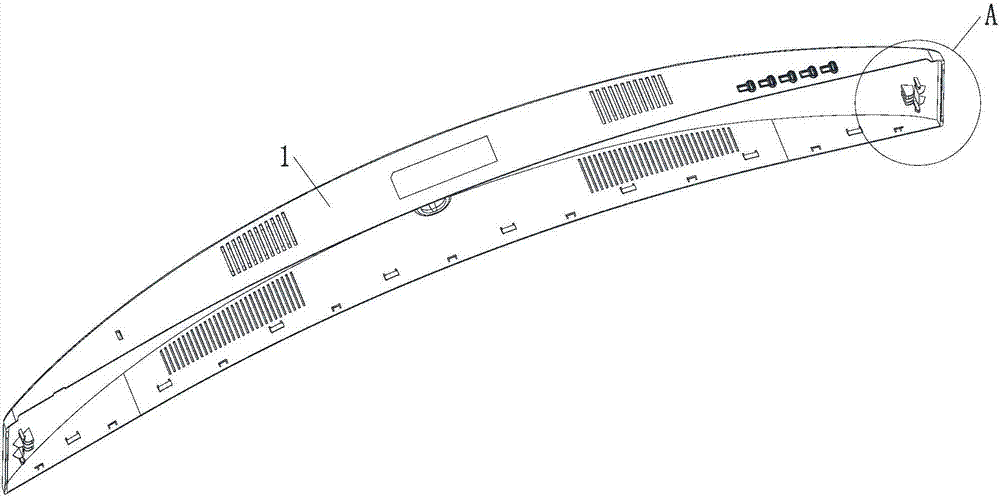

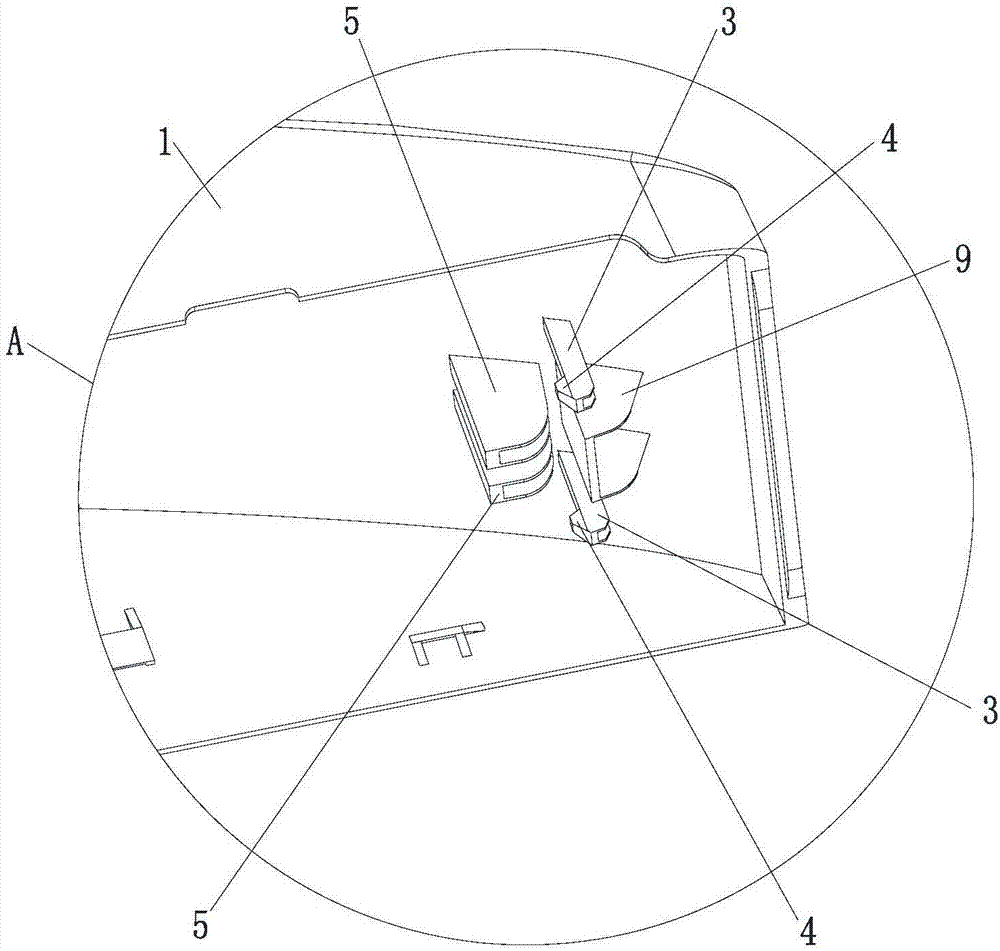

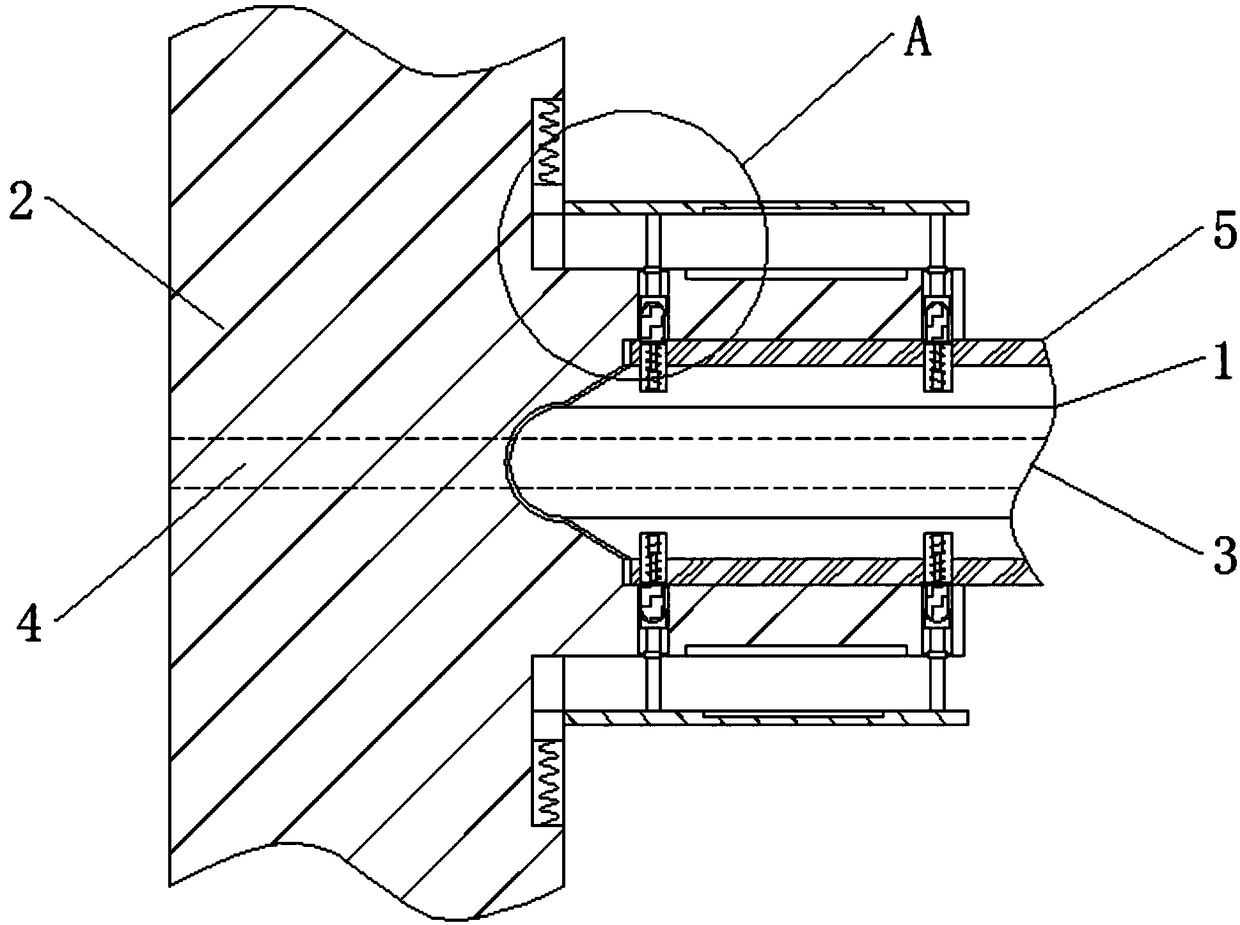

Rear housing assembly structure and display

PendingCN107302837AImprove stabilityGuaranteed not to tripCasings/cabinets/drawers detailsIdentification meansDisplay deviceEngineering

The invention provides a rear housing assembly structure and a display and belongs to the field of display. The rear housing assembly structure comprises a clamp hook seat, a clamp hook, a positioning rib, a bracket and a bayonet, wherein the clamp hook seat is arranged on the front side of a rear housing; the clamp hook is arranged at the front end of the clamp hook seat and faces the inner side of the rear housing; the positioning rib is arranged on the front side of the rear housing; the bracket is arranged on a back plate; the bayonet is formed in the bracket and used for being clamped with the clamp hook; the outer-side end surface of the positioning rib protrudes inward out of the inner-side end surface of the clamp hook seat; the outer-side end surface of the positioning rib protrudes outward out of the inner-side end surface of the clamp hook; after the clamp hook is clamped with the bayonet, the bracket is positioned between the clamp hook seat and the positioning rib. According to the rear housing assembly structure and the display provided by the invention, the stability is high after clamping, the high-temperature influence is low, and the phenomenon of high-temperature trip is effectively avoided.

Owner:HEFEI HUIKE JINYANG TECH

Efficient servo energy-saving injection molding machine

The invention discloses an efficient servo energy-saving injection molding machine, and belongs to the field of injection molding machines. The efficient servo energy-saving injection molding machinecomprises an injection molding machine head plate and an injection molding nozzle. The right end of the injection molding nozzle is sleeved with the injection molding machine head plate. The left sideof the injection molding nozzle is provided with a mold head plate. The mold head plate, the injection molding nozzle and the injection molding machine head plate are provided with coaxial matched plastic passageways respectively. The right end of the mold head plate is provided with a groove matched with the injection molding nozzle and the injection molding machine head plate. The side walls ofthe upper end and the lower end of the position, corresponding to the injection molding machine head plate, of the groove are each provided with a second slide groove. The end, close to the second slide grooves, of the injection molding machine head plate is fixedly connected with a matched extension block. The end, close to the second slide grooves, of the extension block is provided with a pairof storage grooves. Groove openings of the storage grooves are provided with clamping blocks. The injection molding machine nozzle can be rapidly and accurately aligned, the mold replacement efficiency is improved, and the work efficiency of the injection molding machine is improved.

Owner:芜湖中科智捷信息科技有限责任公司

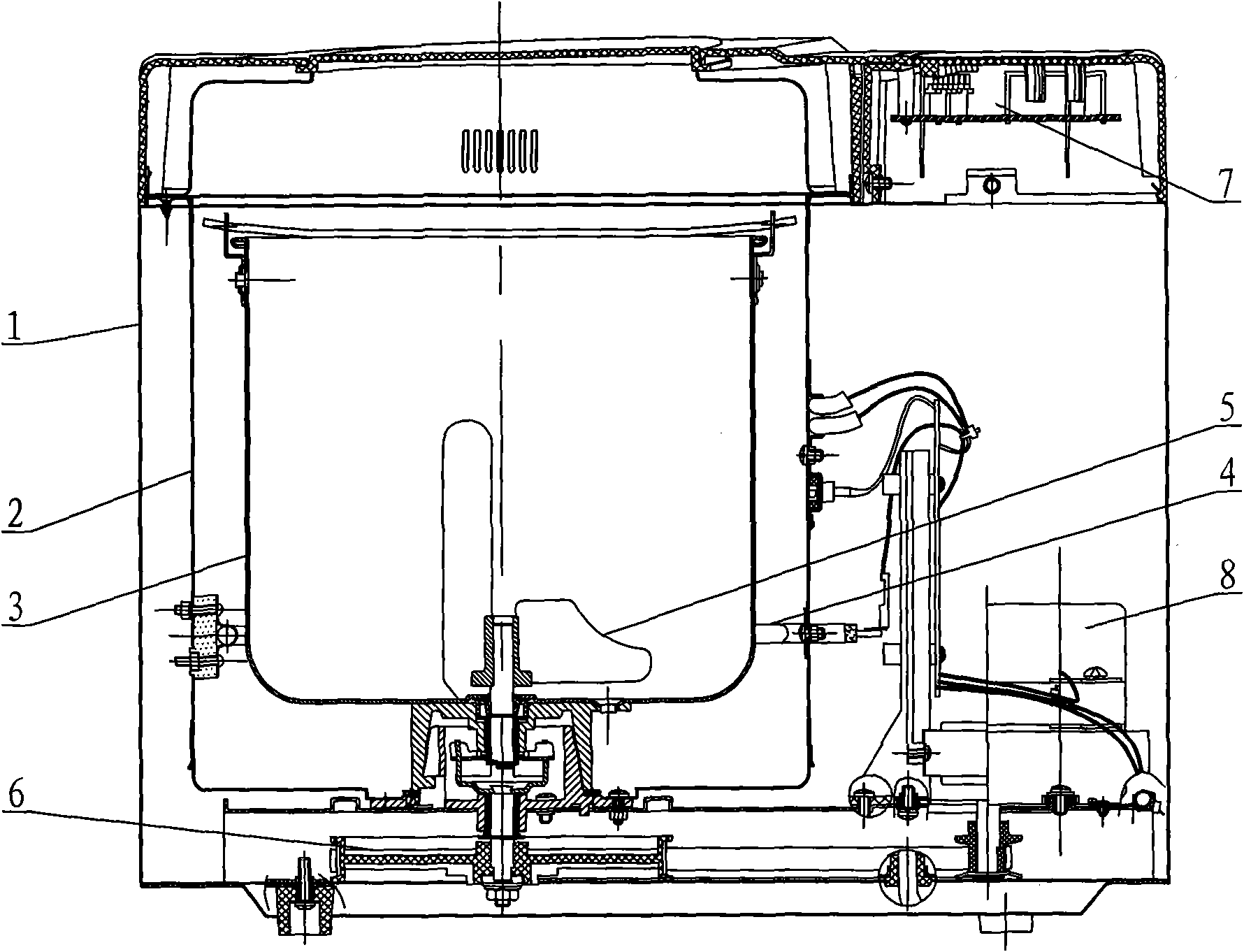

Energy-saving bread maker

InactiveCN101803621AImprove energy efficiency ratioReduce lossBakery productsRoasters/grillsBusiness efficiencyPressure casting

The invention relates to an energy-saving bread maker, which comprises a shell. An upper cover is arranged on one side of the upper part of the shell, and a controller is arranged on the other side of the upper part of the shell; the bottom of the shell is provided with a motor; a baking chamber is arranged between the upper cover and the shell, and a bread barrel is arranged in the baking chamber; electrical heated tubes are uniformly arranged between the bread barrel and the baking chamber; the bottom of the bread barrel is provided with a stirring rod which is connected with the motor through a transmission system; and the outside of the baking chamber is provided with an insulating material layer. The insulating material layer is a metal material or a nonmetal material with thermal insulation capacity and heat reflection capacity, and is covered on the outer surface of the baking chamber through pressure casting, electroplating and spraying. The baking chamber is made of a metal sheet with high strength and the heat reflection capacity. In the invention, the outer surface of the baking chamber on the bread maker is fully covered with the insulating material layer, so that internal heat loss of the baking chamber is reduced, the energy efficiency ratio of the bread maker is improved, electrical elements in the shell are less influenced by a high temperature, and the service life of a product is effectively prolonged.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Intelligent temperature control type high-precision burr-proof stamping mold

PendingCN111745054ADelay agingImprove machining accuracyShaping toolsMetal-working feeding devicesHydraulic cylinderTemperature control

The invention discloses an intelligent temperature control type high-precision burr-proof stamping mold. The intelligent temperature control type high-precision burr-proof stamping mold comprises an upper mold seat and a lower mold seat. The bottom of the upper mold seat is fixedly connected with the top of the lower mold seat, and a feeding port and a discharging port are correspondingly formed in the inner walls of the two sides of the upper mold seat. A PLC is arranged on the front surface of the upper mold seat. A hydraulic cylinder is fixedly mounted on the inner top wall of the upper mold seat. A stamping table is fixedly mounted at the output end of the hydraulic cylinder. A stamping head is fixedly mounted at the bottom of the stamping table. A temperature sensor is arranged on thetop surface of the stamping table. L-shaped plates are correspondingly and fixedly mounted on the two inner side walls of the lower mold seat. Limiting sleeves are correspondingly and fixedly mountedon the two side faces of the lower mold seat through supports. Threaded rods are movably connected to the inner rings of the limiting sleeves. Rotating discs are correspondingly and fixedly mounted at the ends, away from each other, of the two threaded rods. The ends, close to each other, of the two threaded rods are correspondingly and movably connected with the side faces of the L-shaped platesthrough bearings. By the adoption of the intelligent temperature control type high-precision burr-proof stamping mold, the stamping head can be continuously cooled, and the problem that the machiningprecision is reduced due to the high temperature of the mold is solved.

Owner:杜元*

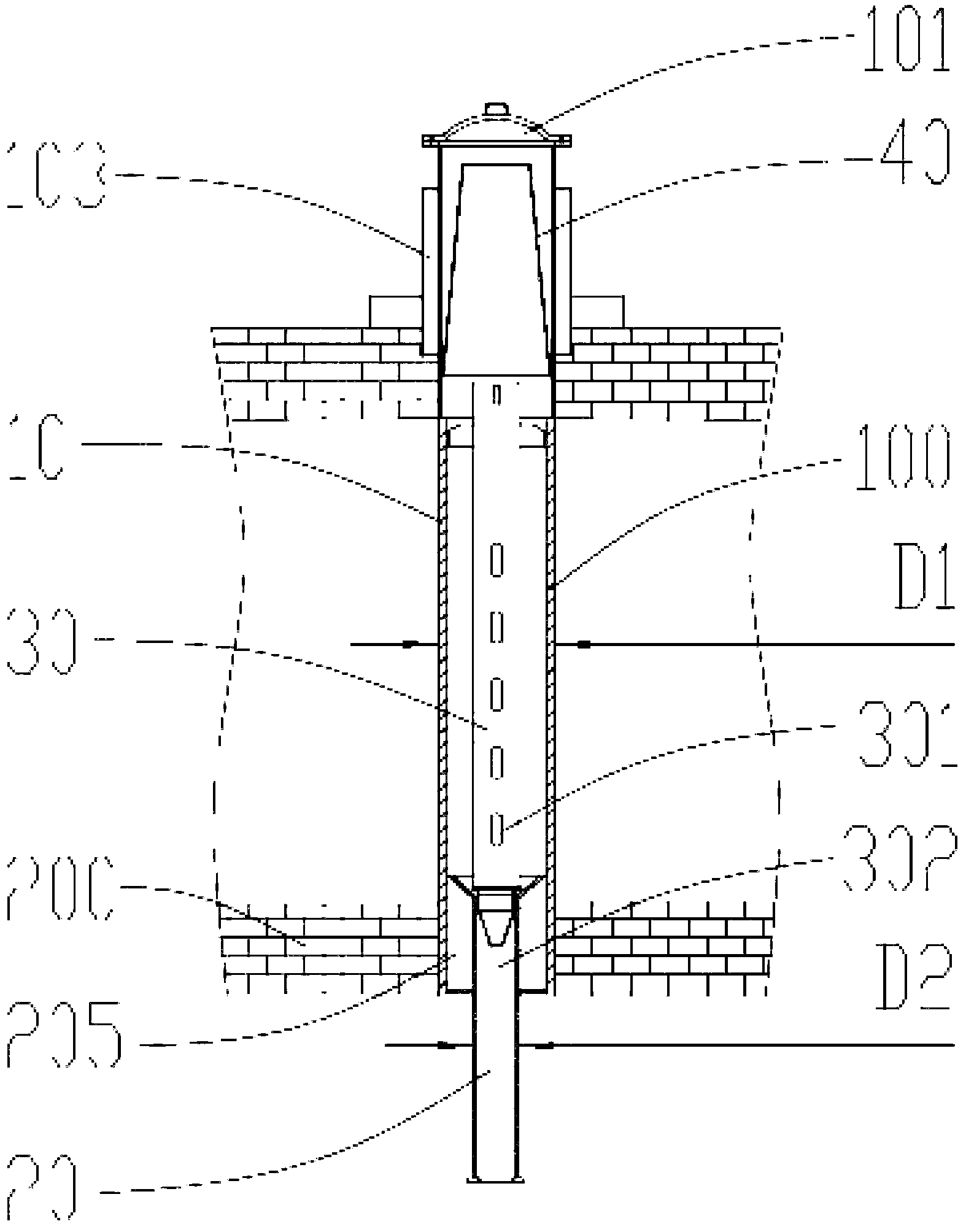

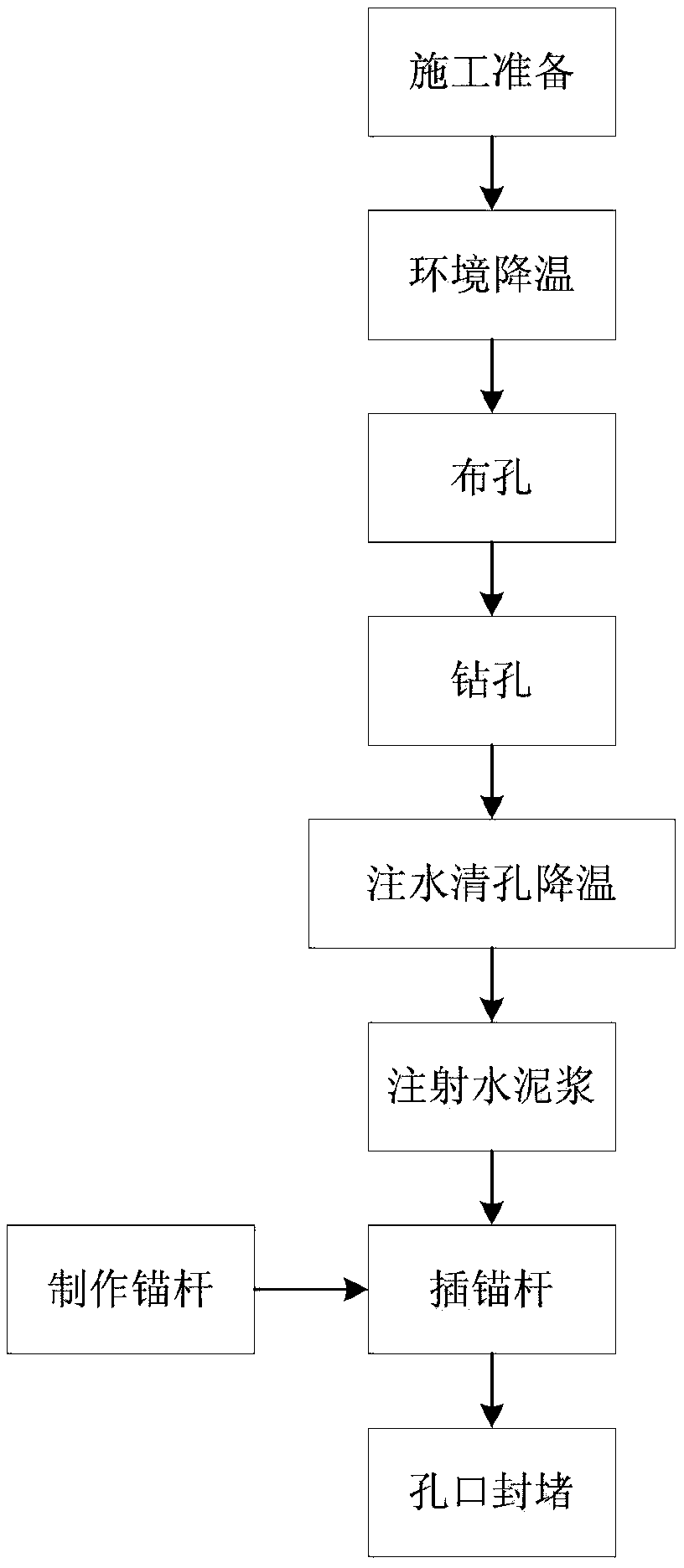

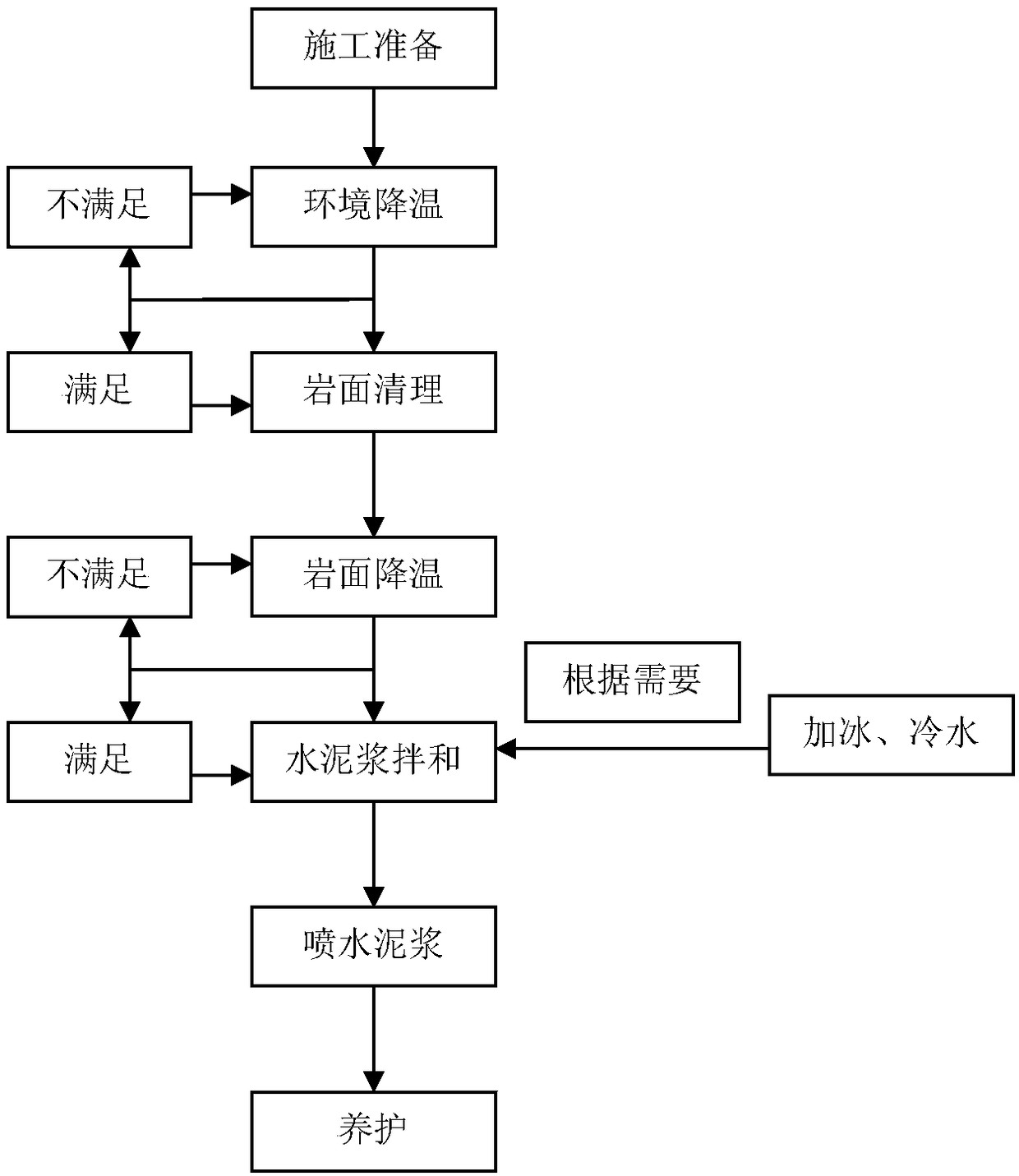

Support construction method for high-temperature geothermal tunnels

InactiveCN109184775AGuaranteed to run smoothlyImprove comfortTunnel/mines ventillationPump controlArchitectural engineeringBuilding construction

The invention provides a support construction method for high-temperature geothermal tunnels, which includes a step S10 and a step S20. In the step S10, the environment temperature is reduced after tunnel excavation is completed. In the step S20, when the environment temperature meets the construction requirement, support construction is carried out on a rock surface to be supported. The temperature of the construction environment is reduced before the support work, and support construction is carried out after the environment temperature meets the construction requirement. The temperature isreduced first in the process of support construction, so that the construction temperature meets the requirement, the impact of high temperature is reduced, smooth and normal construction is ensured,and workers feel more comfortable during construction. The method is worth popularizing and applying.

Owner:SINOHYDRO ENG BUREAU 4

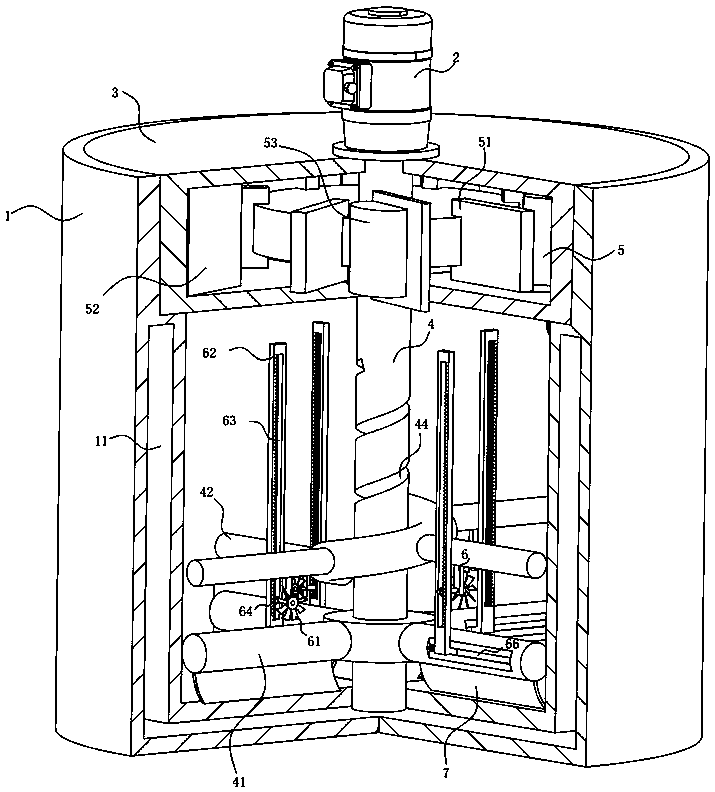

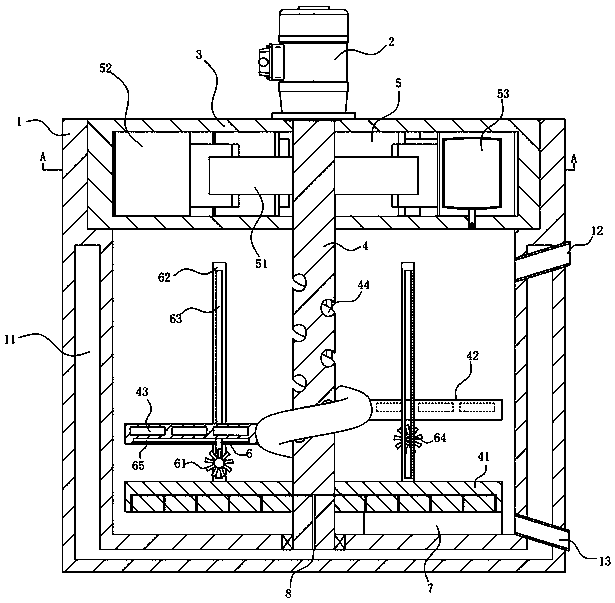

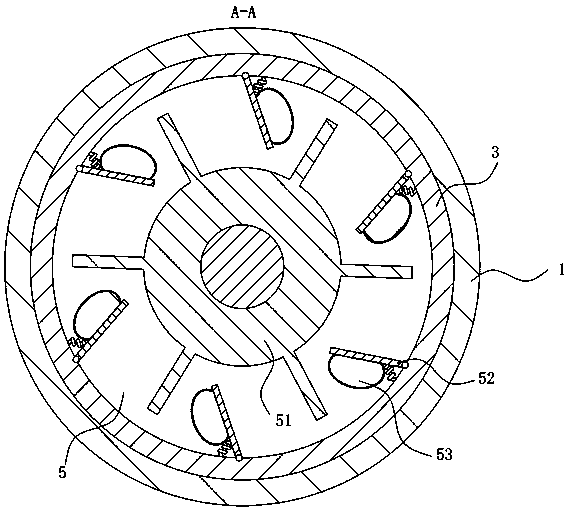

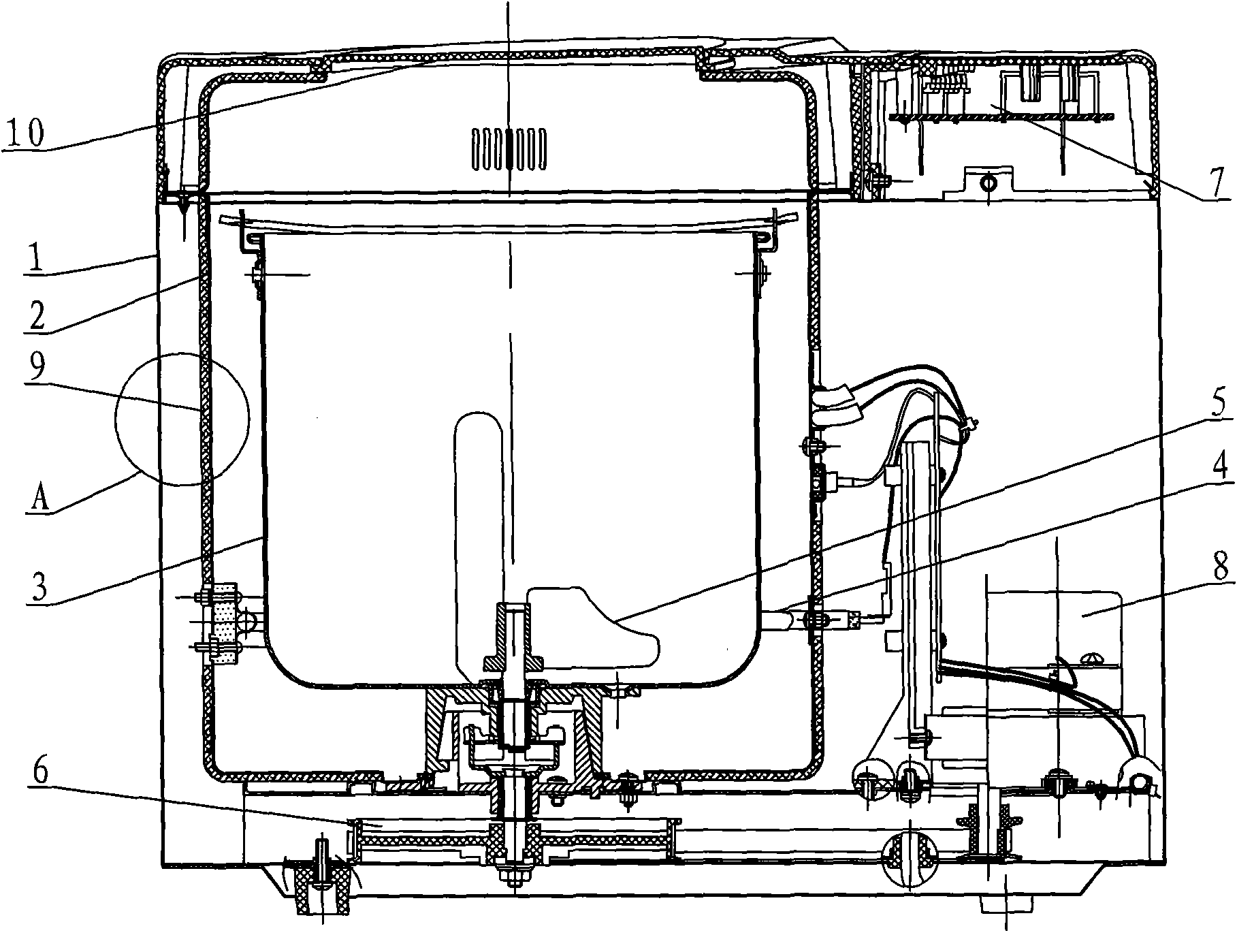

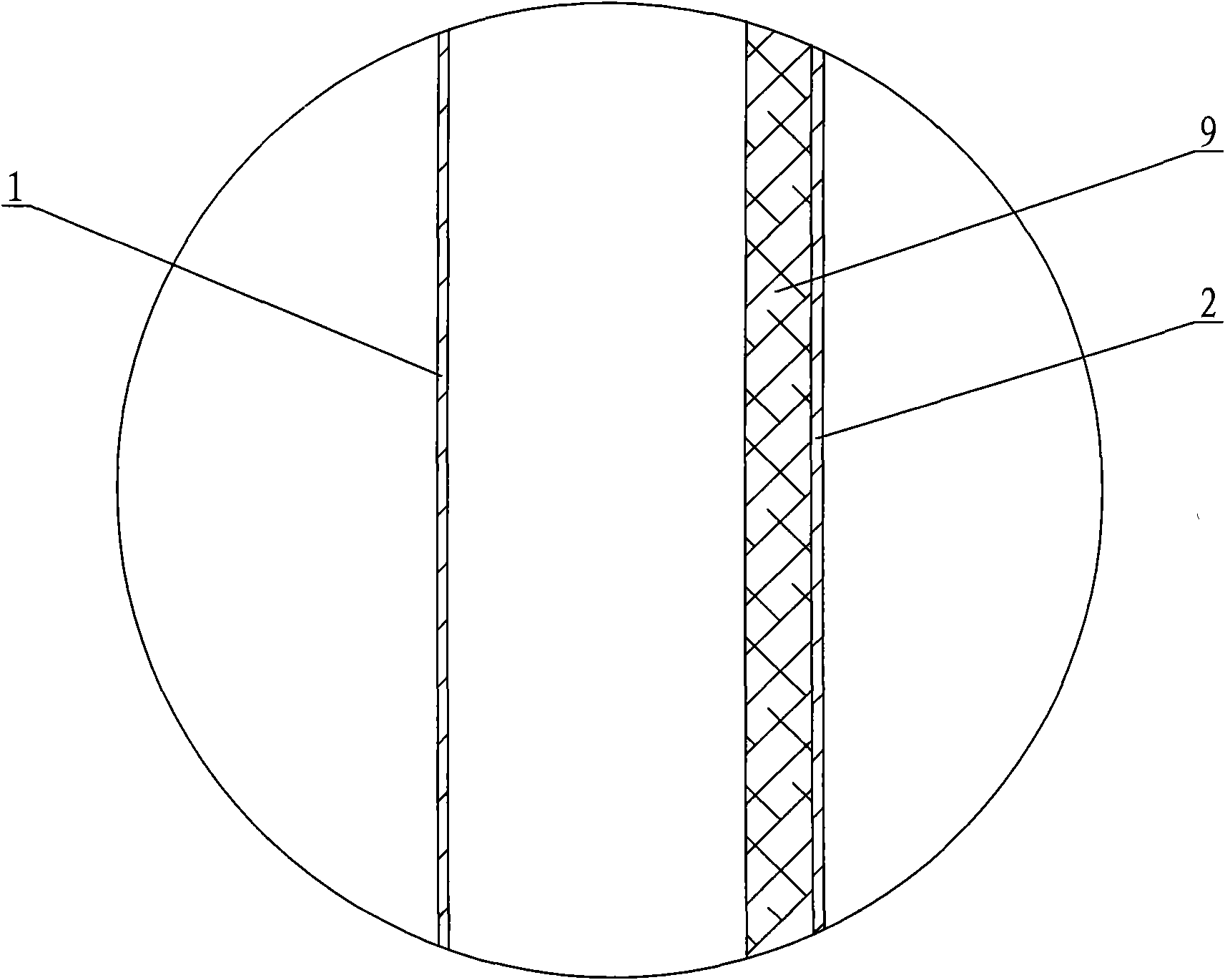

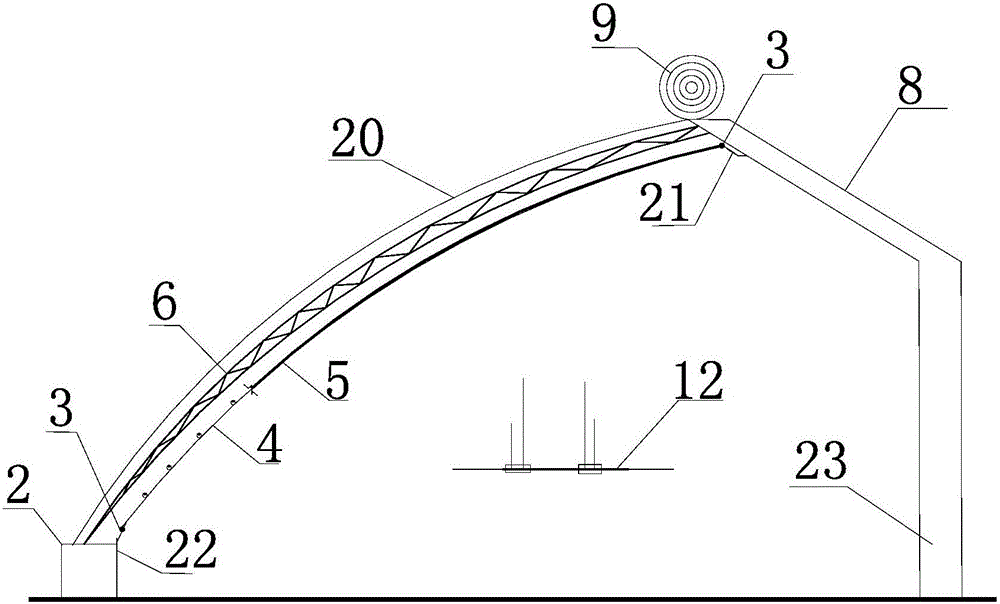

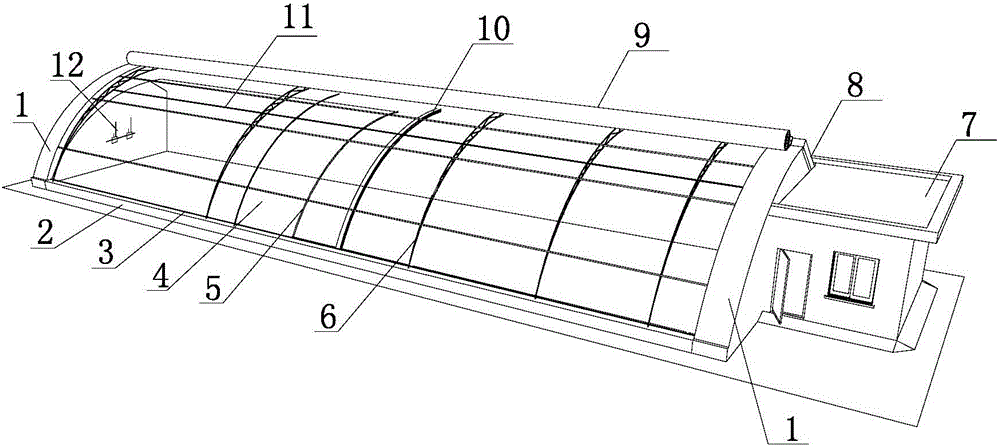

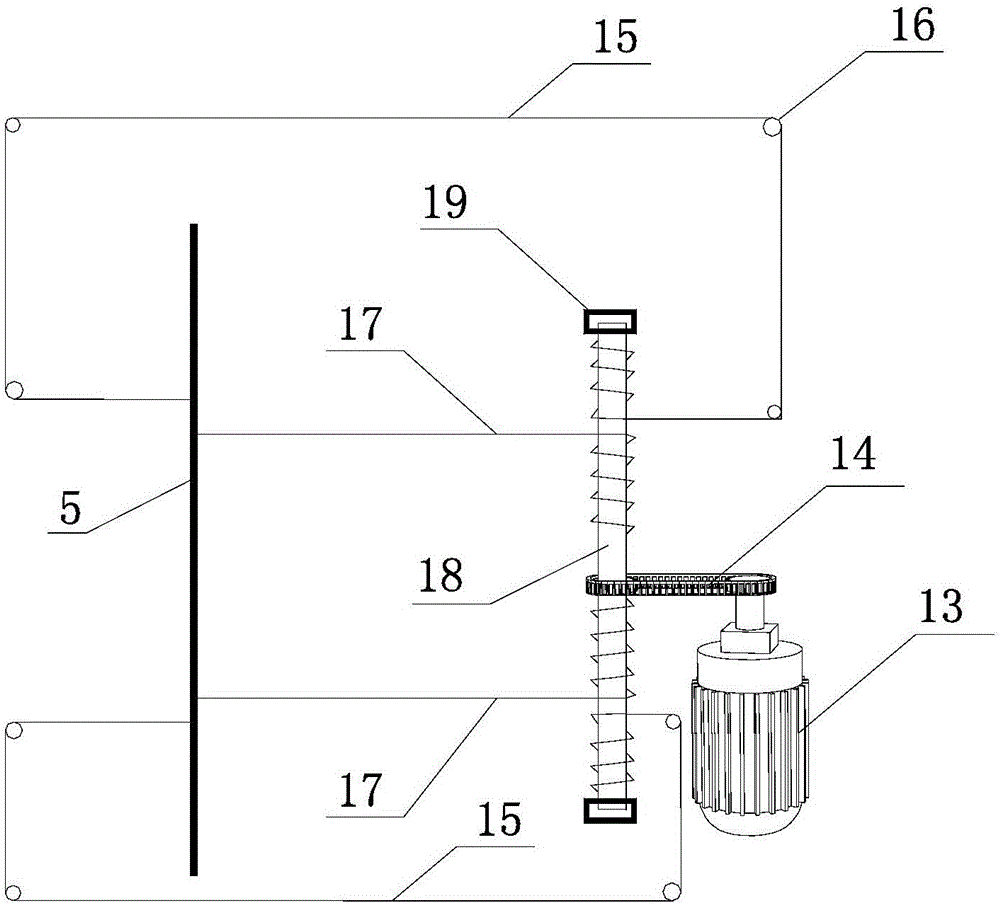

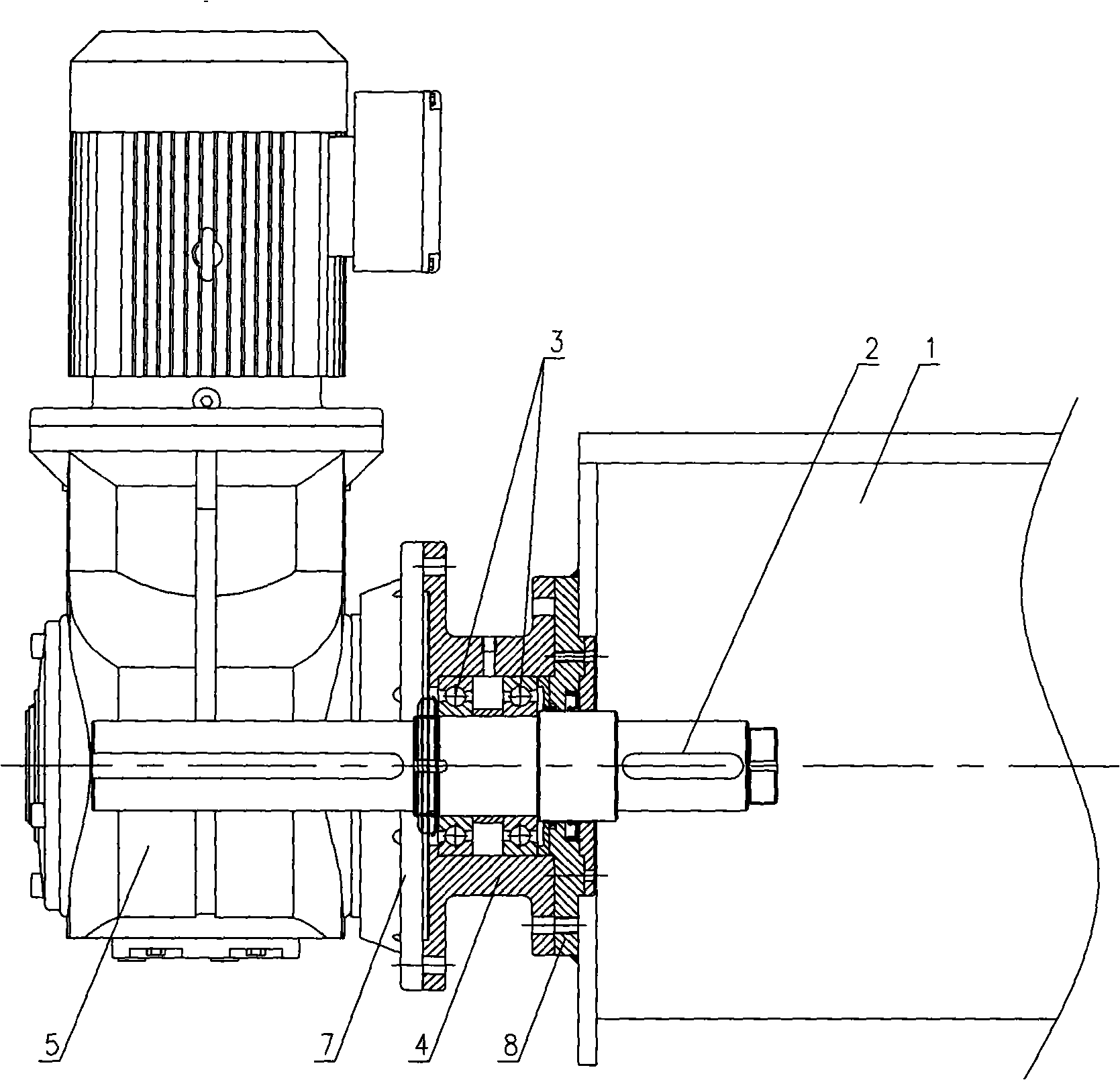

A solar greenhouse auxiliary internal heat preservation/shading system

InactiveCN103858706BImprove winter insulationImprove the temperature environmentClimate change adaptationGreenhouse cultivationSupporting systemThermal insulation

The invention relates to an auxiliary thermal insulation / sun-shading system used inside a sunlight greenhouse, belongs to the technical field of environment regulation and control of the sunlight greenhouse and particularly discloses a double-function environment regulation and control device which is arranged inside the sunlight greenhouse and is used for improving heat preservation performance and sun-shading capacity of the greenhouse. A sunlight greenhouse auxiliary internal thermal insulation / sun-shading system comprises a transmission mechanism (12), a supporting system, a thermal insulation / sun-shading system and a sealing device. In the invention, a sunlight greenhouse auxiliary internal thermal insulation / sun-shading curtain is divided into two east and west parts and block control can be carried out; when thermal insulation needs to be carried out, the two parts of the thermal insulation curtain at both the sides are expanded and are subjected to abutting sealing at the middle part of the greenhouse; and when sun-shading needs to be carried out, one part of the thermal insulation curtain at one side or two parts of the thermal insulation curtain at both the sides can be expanded according to the cultivation requirements. By additional arrangement of the internal thermal insulation system, the night temperature environment of the greenhouse can be improved and the sunlight greenhouse auxiliary internal thermal insulation / sun-shading system is beneficial for improving yield and quality of production; and by additional arrangement of the sun-shading system, service life of the greenhouse can be prolonged and utilization efficiency of the greenhouse can be improved.

Owner:CHINA AGRI UNIV

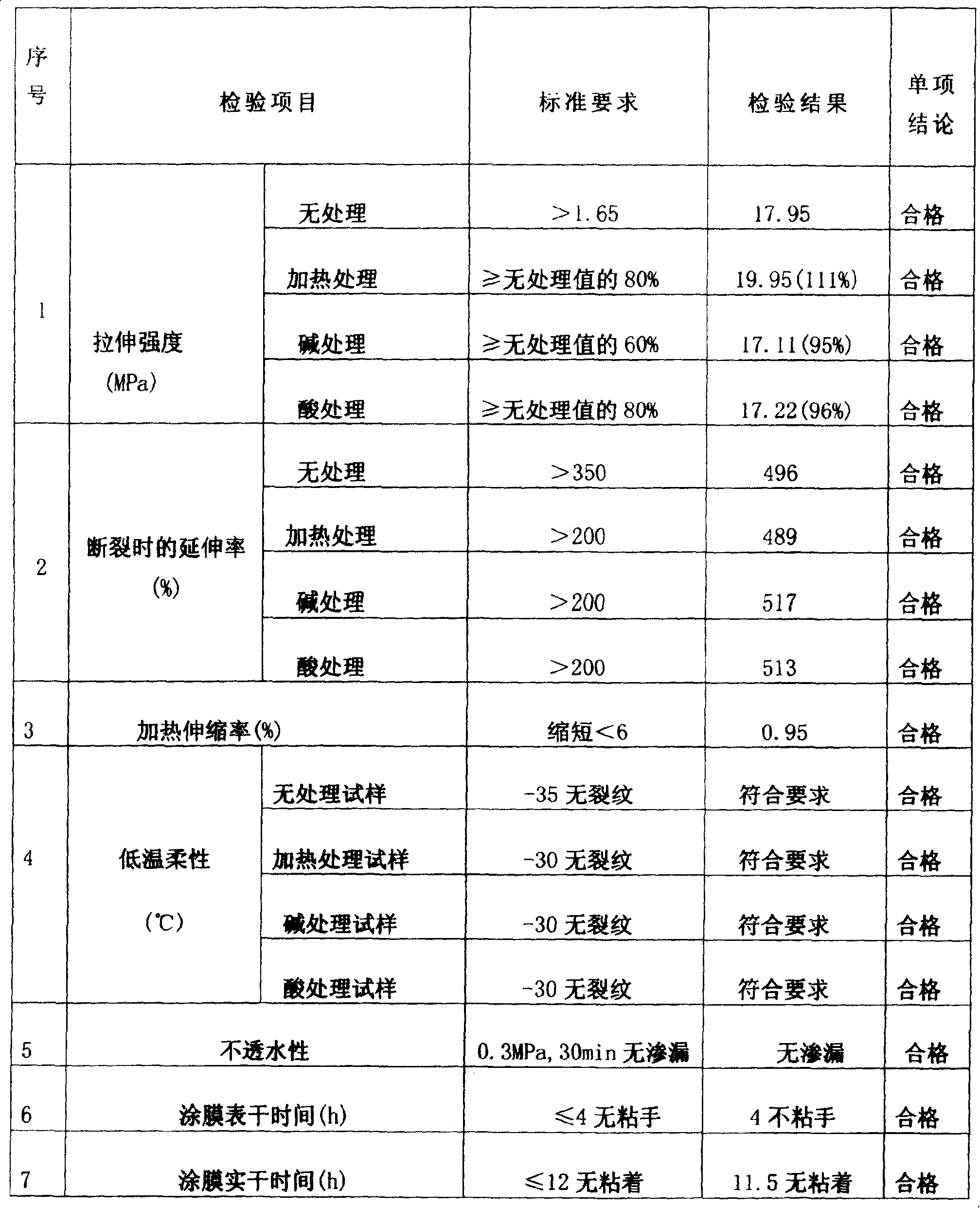

Environmental protection type coating material and preparaton method

InactiveCN100406530CLow priceSimple processAntifouling/underwater paintsPaints with biocidesPolyolPolyurethane coating

In the present invention, prepolymer is prepared by reacting on polyisocyanic acid ester with polyalcohol and the prepared product is a wet-solidification type of polyurethane coating material. The multifunction waterproof and environmental protective coating material can be prepared by adding inert pigment and fire-resisting substancein the prepolymer. The -NCO contained in prepolymer is reacted with water for cross-linking and solidifying to form film having excellent tenside strength and high adhesive force.

Owner:FUJIAN NANGUANG LIGHT IND

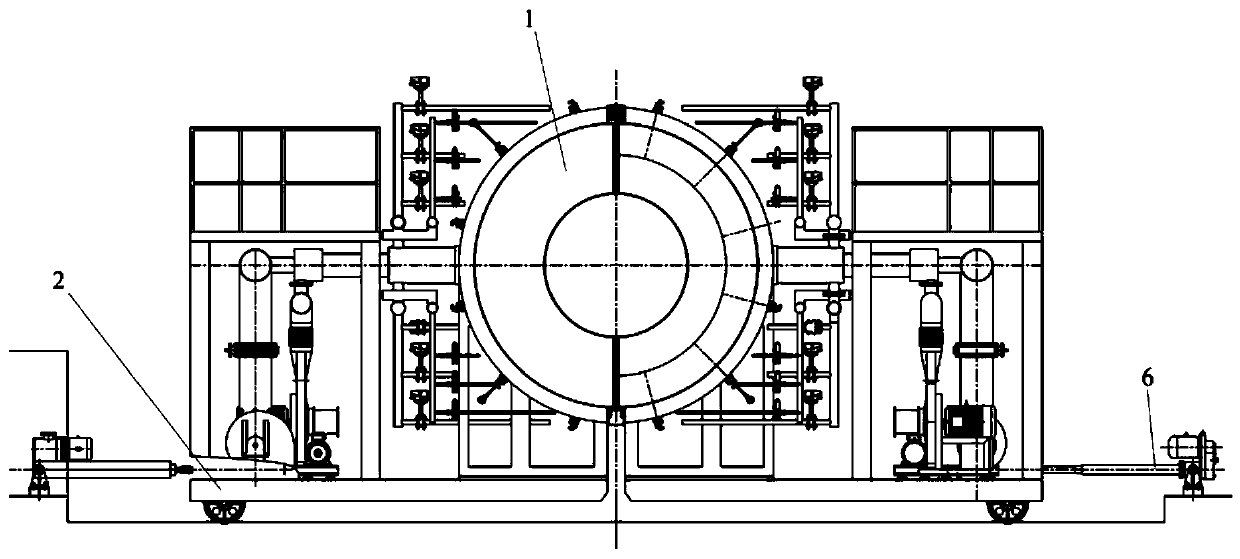

Flat flame nozzle type differential temperature heat treatment furnace

PendingCN110241295AGuaranteed temperature uniformityImprove uniformityFurnace typesIndirect carbon-dioxide mitigationCombustion systemCombustion

The invention relates to a flat flame nozzle type differential temperature heat treatment furnace, belongs to the technical field of differential temperature heat treatment, and solves the problem that it is difficult to ensure high quality heating of continuous rolling mill bearing rollers with roller bodies in different specifications. The flat flame nozzle type differential temperature heat treatment furnace comprises two half furnace structures in the same structural size; each half furnace structure comprises a furnace body, a trolley, a combustion system and a smoke exhaust system; each furnace body is arranged on the corresponding trolley; the furnace bodies of the two half furnace structures can be combined into a cylindrical furnace wall with the end faces being a ring; the combustion systems penetrate into the furnace bodies, and flat flame nozzles are arranged on the inner surfaces of the furnace bodies; the axes of the flat flame nozzles are perpendicular to the inner surfaces of the furnace bodies; smoking ports of the smoke exhaust systems are arranged on the furnace wall of the furnace bodies; and a heat exchange structure is arranged between an exhaust pipe and an air intake pipe. By means of the flat flame nozzle type differential temperature heat treatment furnace, stable control over the roller body axial temperature field homogeneity during heating of the bearing rollers is achieved, the roller body hardness uniformity index of the bearing rollers reaches the higher level, and the product quality yield is improved.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

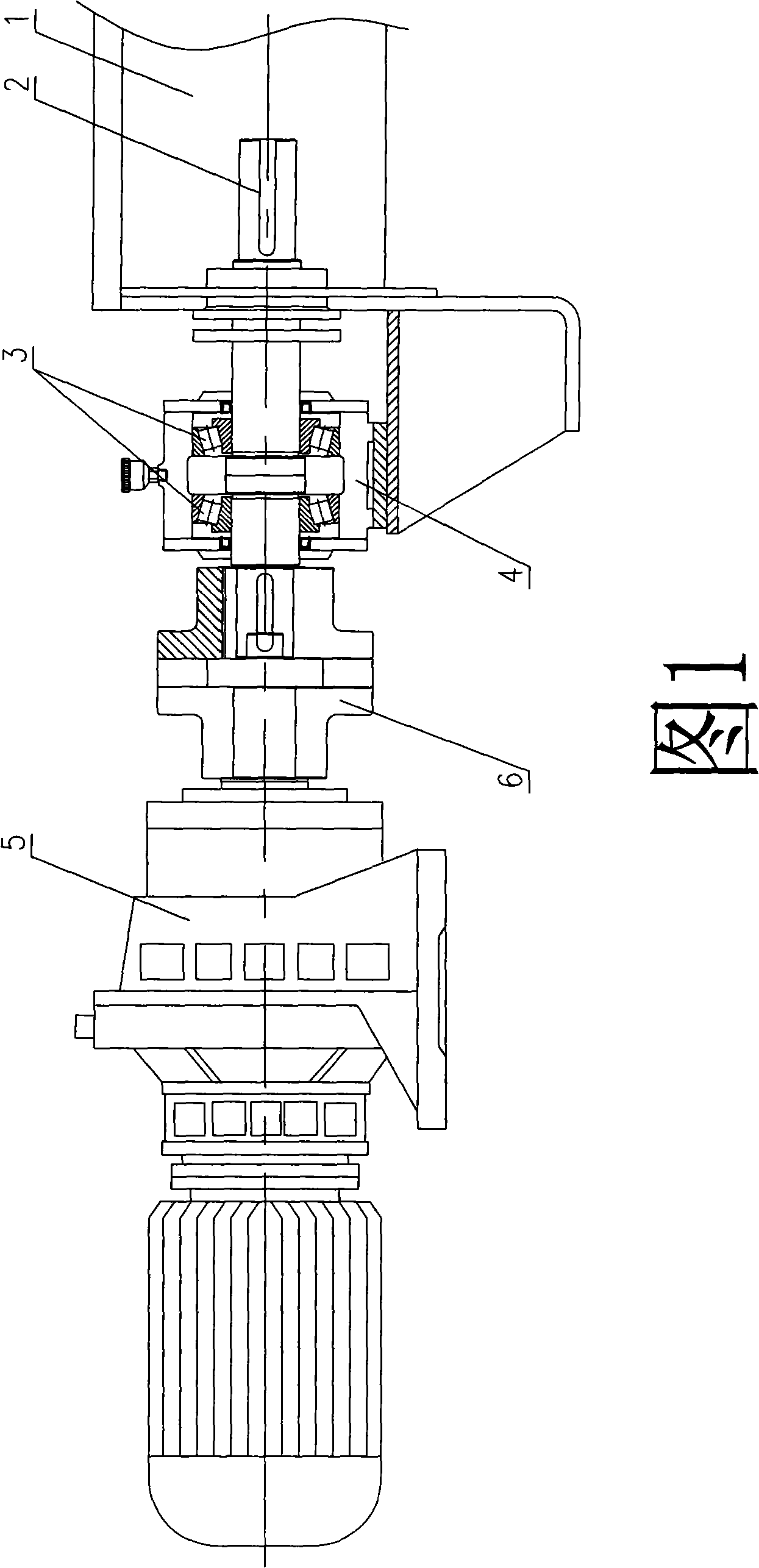

No-axle spiral conveyer

InactiveCN101357714AReduce the impact of high temperatureSuitable for deliveryPackagingDrive shaftScrew conveyor

The invention discloses a no-shaft spiral conveying machine, comprising a shell, a transmission shaft which passes through the shell, a head bearing and a reducing machine which are arranged inside a bearing seat; the head bearing is arranged on the transmission shaft which extends out of the shell; by adopting the technical proposal, the head bearing is arranged outside the shell, the shell is not needed to be opened when the head bearing is assembled and disassembled; furthermore, the bearing and the reducing machine are affected little by the high temperature and are suitable for conveying high-temperature material.

Owner:钱尧翎

Supervision device for ideological and political learning of college students

PendingCN114857453APromote circulationHelps dissipate heatTransportation and packagingEfficient regulation technologiesEngineeringServo

The invention discloses a supervision device for ideological and political learning of college students, which comprises a mounting base body, a support rotating shaft is rotatably connected between two corresponding sides of the inner wall of the mounting base body and close to the top, and a power mechanism is fixedly connected to the center of the top of the inner wall of the mounting base body. The output end of the power mechanism is fixedly connected with the center of the surface of the supporting rotating shaft, an air inlet and an air outlet are formed in the two corresponding sides of the surface of the shell correspondingly, a driving device is arranged at the position, close to the air inlet, in the shell, and the output end of the servo motor is fixedly connected with one end of the driving device. And an impurity removal device is arranged at the position, close to the driving device, in the shell. The supervision device for ideological and political learning of college students achieves the effect of high adaptability, can perform multi-angle shooting, reduces limitation, dissipates heat in time, reduces dust entry, prolongs the service life of equipment, is safe and reliable, and improves the use performance.

Owner:封歆野

Preparation method of high-temperature resistant and anti-aging rubber conveyor belt

The invention discloses a preparation method of a high-temperature resistant and anti-aging rubber conveyor belt, and belongs to the technical field of chemical rubber new material manufacturing. According to the preparation method of the high-temperature resistant and anti-aging rubber conveyor belt, the antioxygenic performance of the rubber conveyor belt is improved by using tea polyphenol andcamellia in camellia oil, the content of unsaturated fatty acid is up to 80% or above, free radical attack of an oxygen molecule residue initiator in air can be restrained, and thus thermo-oxidative aging resistance of the rubber conveyor belt is improved; and on the other hand, a carbon nanotube has the special pipeline structure and the high specific surface area, and can be used as a carrier oftitanium dioxide to prepare anti-aging modified filling rubber powder, the carbon nanotube, a nano-graphite flake layer and silicon carbide have high heat resistance, the heat dissipation performanceof the rubber conveyor belt can be improved, absorption of ultraviolet light by the titanium dioxide is improved, light aging is reduced, the cross-linking density of the rubber conveyor belt is improved by light energy conversion of the photocatalysis of the titanium dioxide, the cohesion of the rubber conveyor belt is increased, the hardness and the mechanical strength of the rubber conveyor belt are improved, and broad application prospects are achieved.

Owner:李承忠

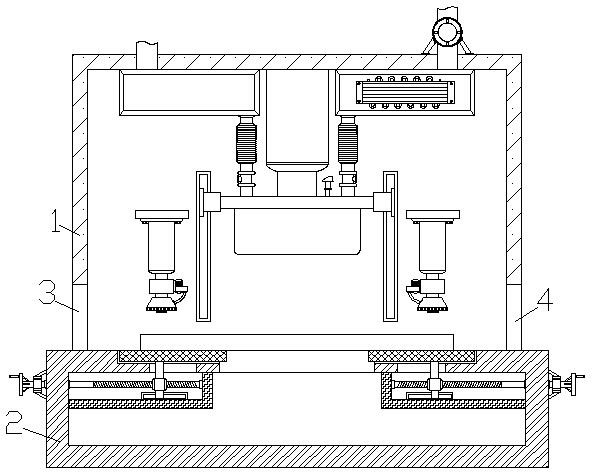

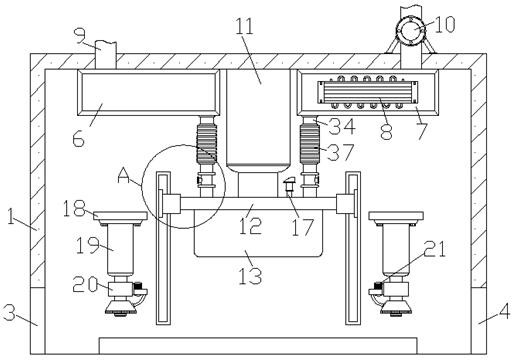

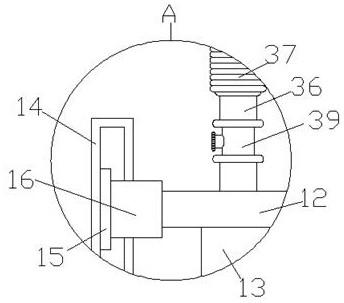

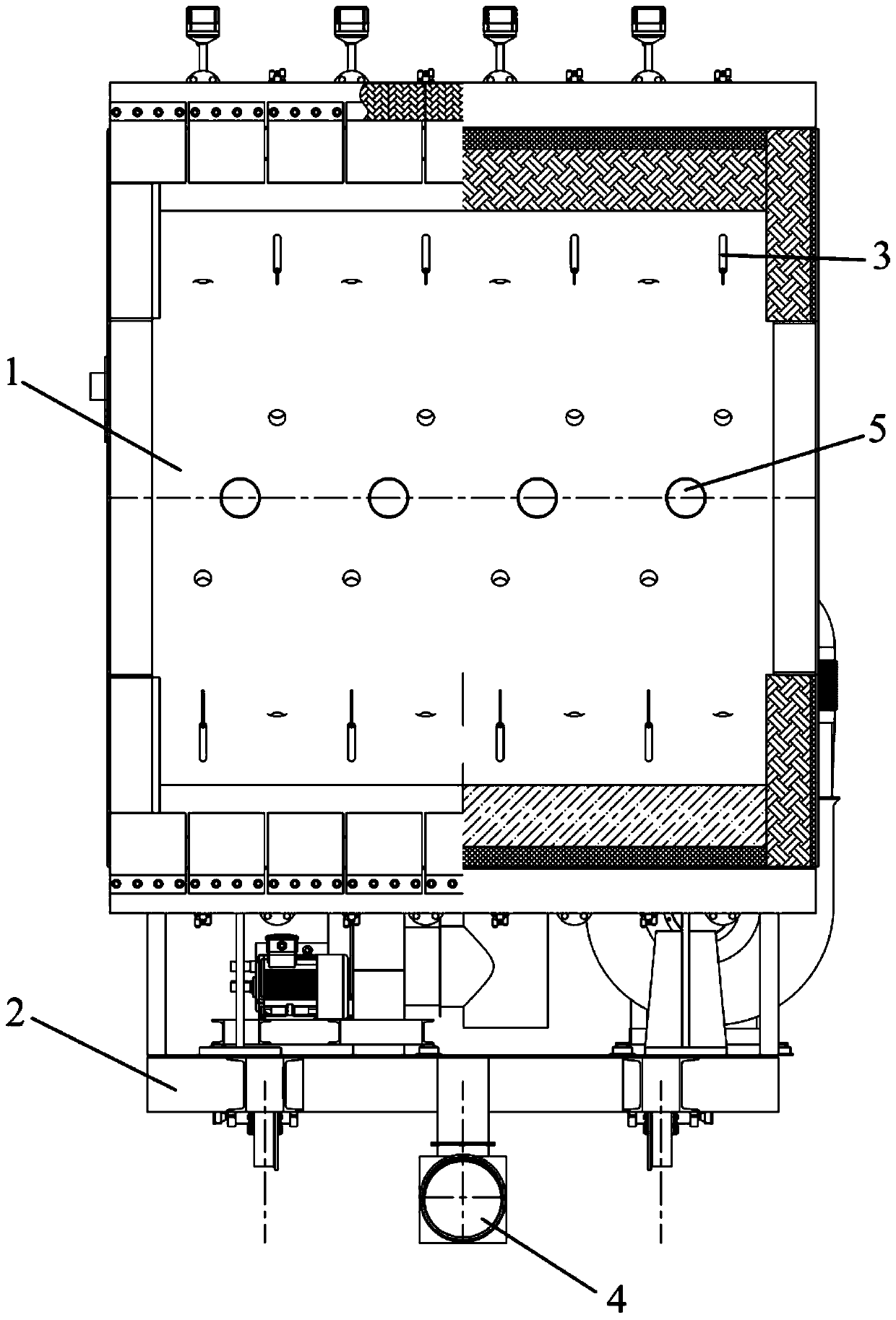

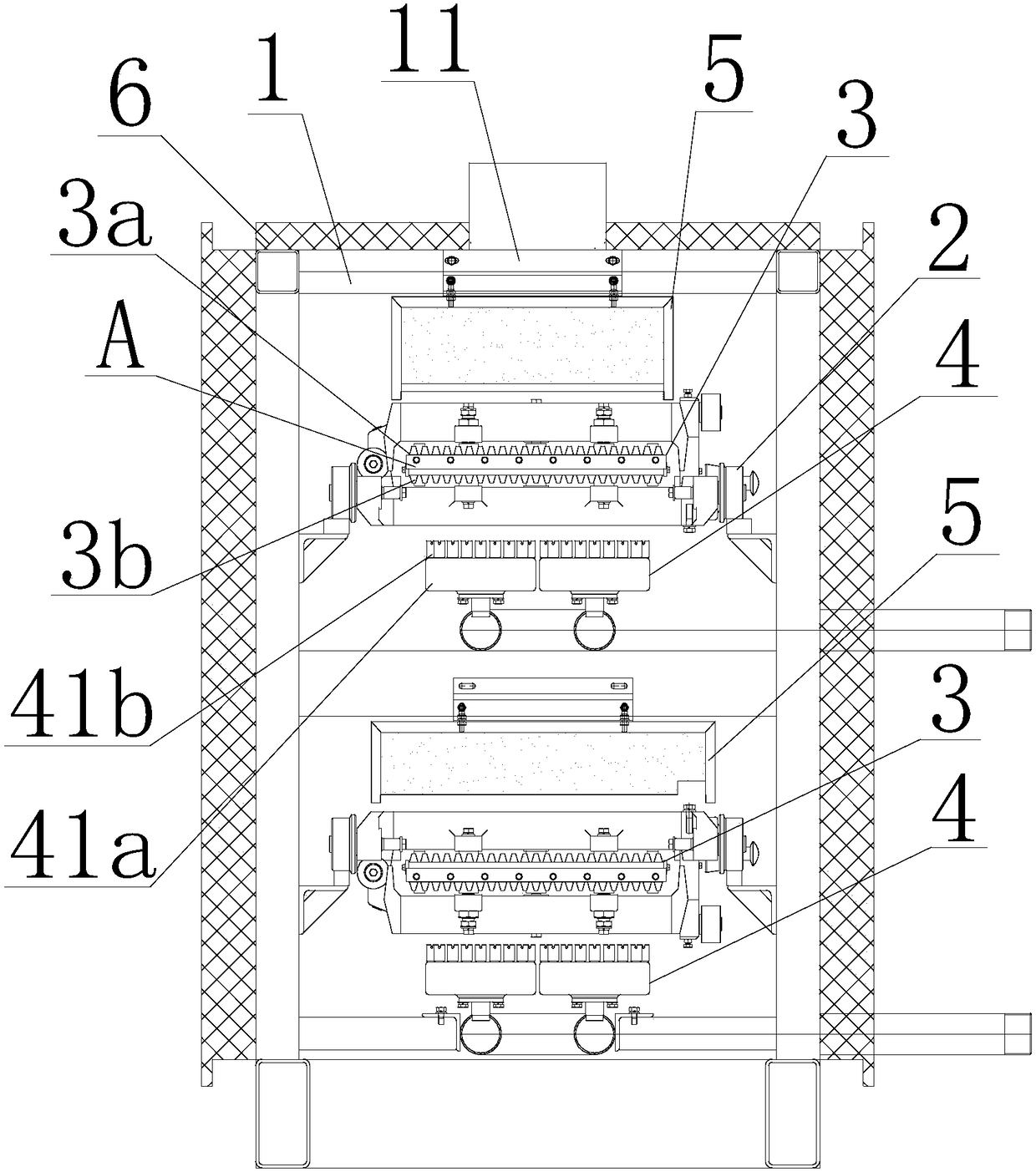

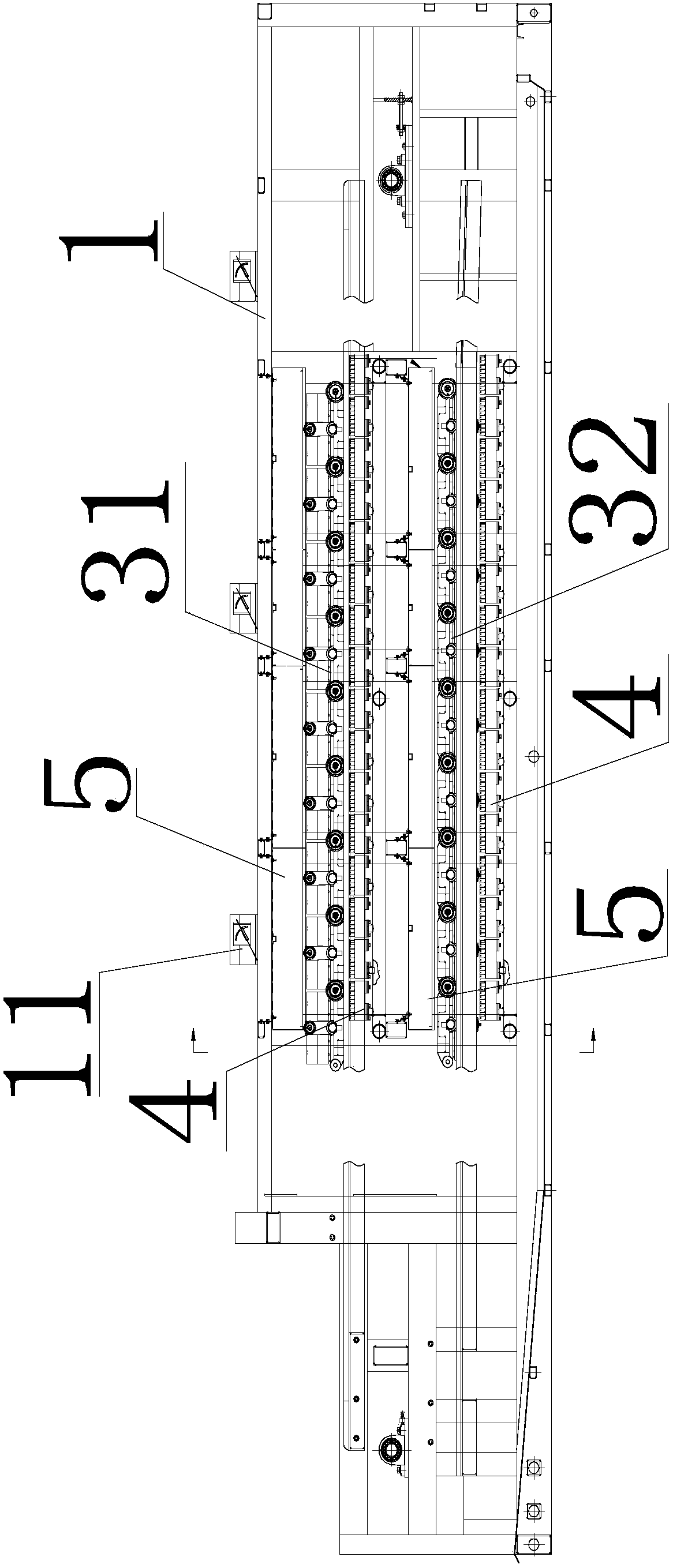

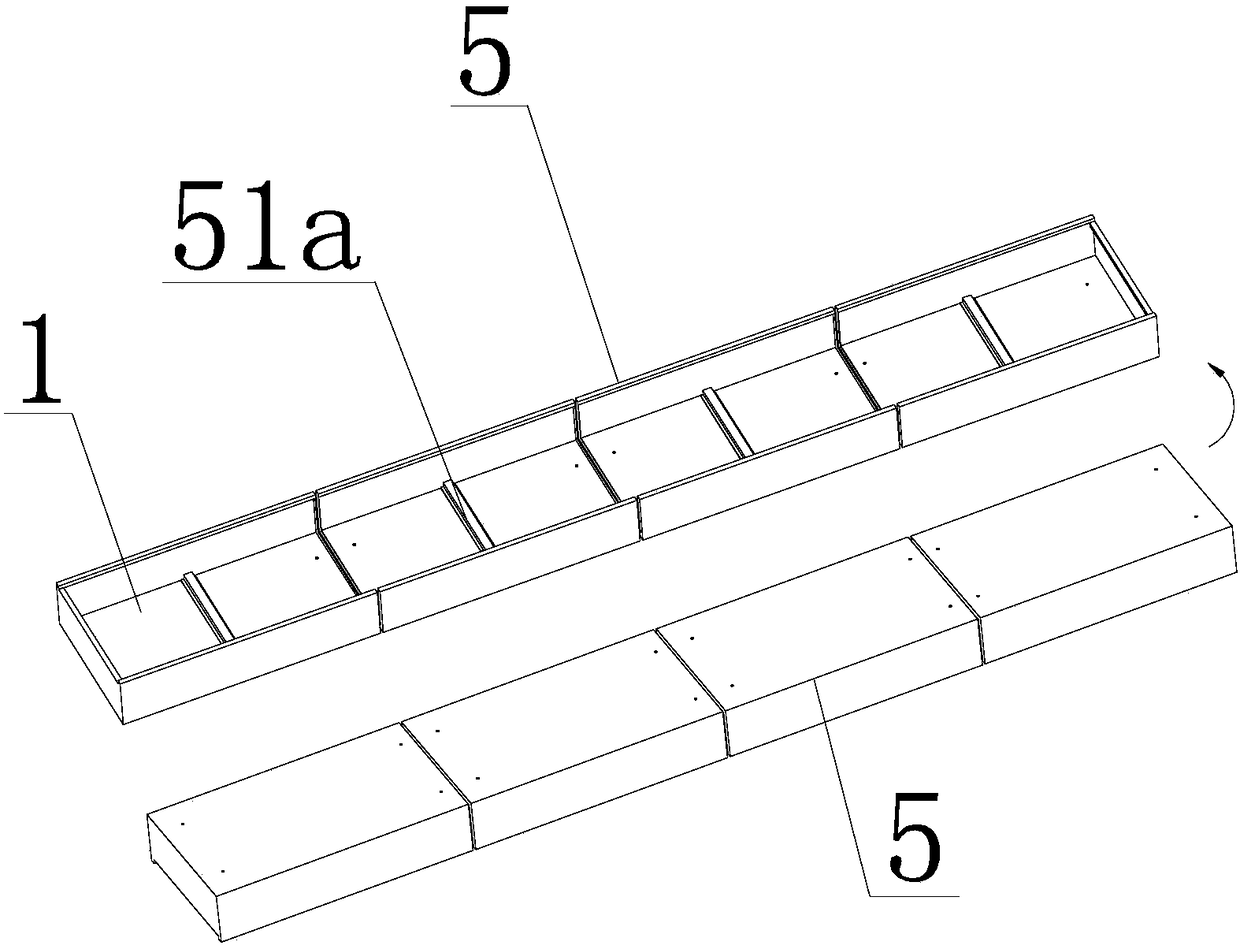

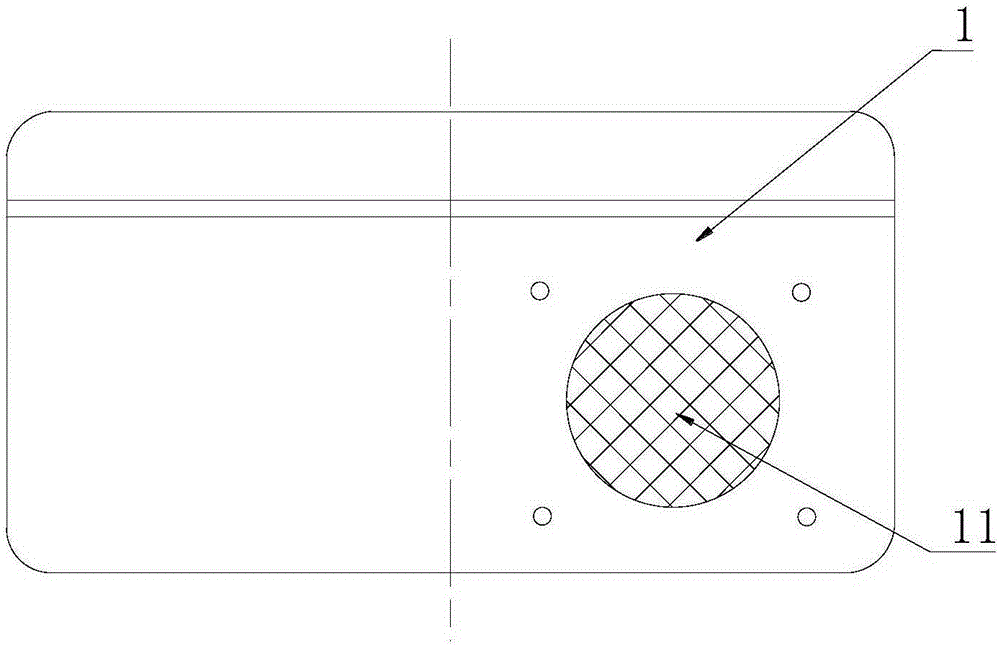

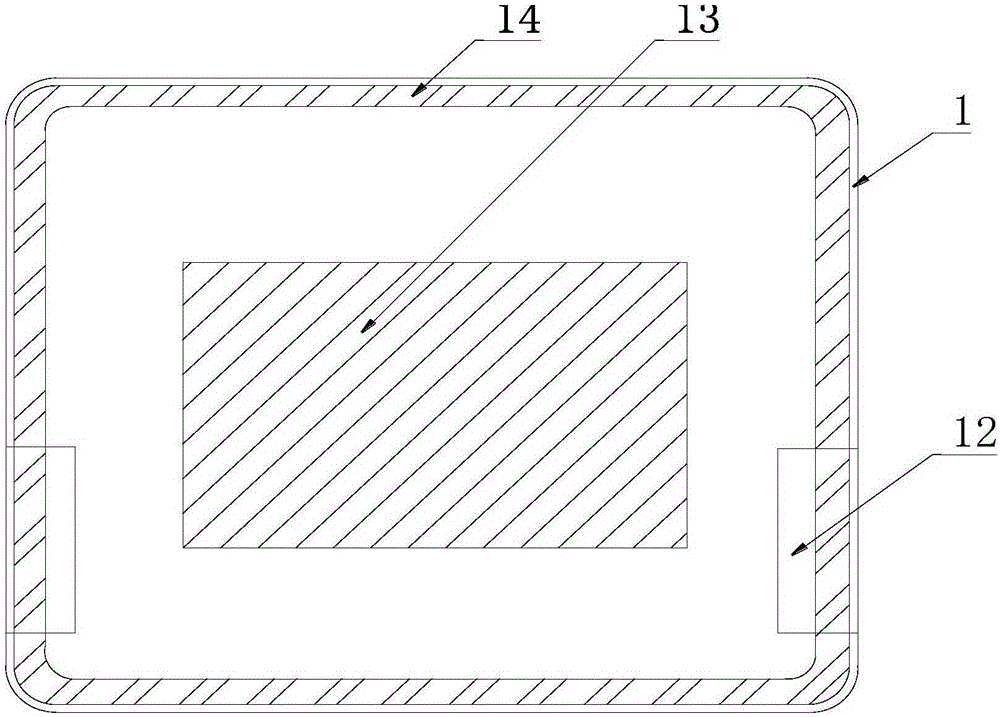

A double-furnace sealed and heat-insulating structure for a spherical wafer automatic production line

ActiveCN105941516BReduce the temperatureReduce the impact of high temperatureFood processingBaking ovenProduction lineProcess engineering

Owner:肇庆市珊瑚食品机械有限公司

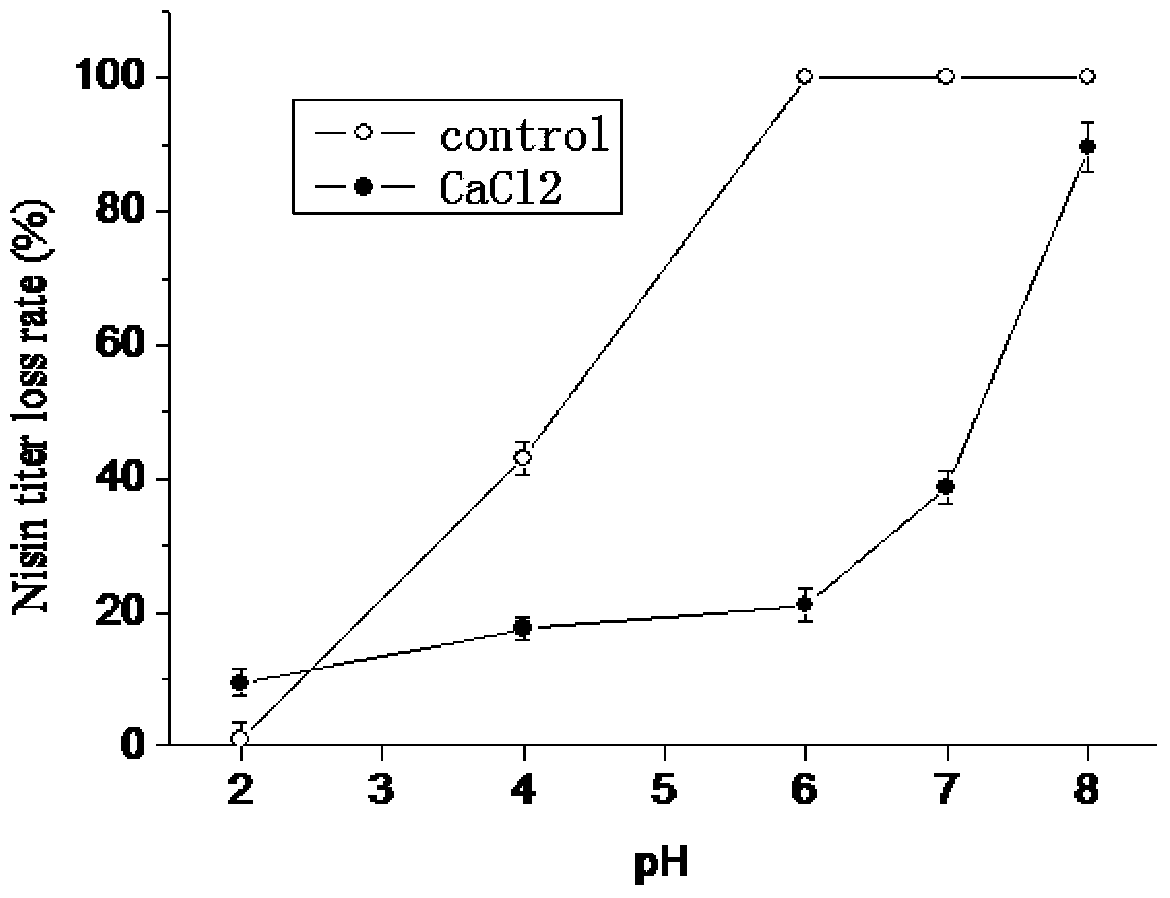

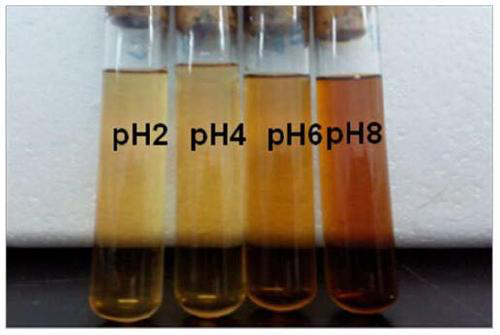

A method to effectively improve the thermal stability of nisin

InactiveCN105265994BImprove thermal stabilityOvercome the unfavorable factors of limited application rangeFood preservationFermentationEmulsionPolyethylene glycol

The invention relates to a method effectively improving heat stability of Nisin. 0.05-4.0% (g / 100ml) of calcium salt, 0.02-0.1% (g / 100ml) hydroxypropyl-beta cyclodextrin, 0.25-0.8% (g / 100ml) bean oil and 0.01-0.1% (g / 100ml) of polyethylene glycol as protective substance are added at the beginning, during and at the end of fermentation; Nisin emulsion is finally obtained after homogeneous emulsification; or further drying is performed to form dry powder of the Nisin emulsion; and the heat stability of Nisin is improved in a non-low acid environment. The Nisin emulsion and the dry powder of the Nisin emulsion is prepared by the method, so that the heat stability of Nisin is effectively improved; an application scope of Nisin can be extended; Nisin can be applied in non-low acid food; and the heat stability during high-temperature sterilization is improved.

Owner:TIANJIN UNIV OF SCI & TECH

Cooling device and cooling method for tilting shaft

PendingCN112695146AReduce internal temperatureReduce the impact of high temperatureBell-and-hopper arrangementCooling devicesThermodynamicsEngineering

The invention discloses a cooling device and a cooling method for a tilting shaft, and belongs to the technical field of blast furnace bell-less top equipment. The problems that the tilting shaft is made of alloy steel, is influenced by heavy load and high temperature and possibly cannot work normally or the tilting shaft deforms are solved. The cooling device comprises a box body, the tilting shaft, a water-cooled pipe support, a water inlet pipe and a water outlet pipe; the tilting shaft is installed in the box body, the tilting shaft is provided with an installation hole, the water-cooled pipe support is installed at a hole opening of the installation hole, and the water-cooled pipe support and the tilting shaft rotate relative to the box body at the same time; the water inlet pipe penetrates through the water-cooled pipe support from the outside of the tilting shaft and extends into the bottom end of the installation hole; the caliber of the water inlet pipe is smaller than that of the installation hole, and a gap is reserved between the water inlet pipe and the water-cooled pipe support; and the water outlet pipe sleeves the water inlet pipe, one end of the water outlet pipe is connected with the water-cooled pipe support, and the other end of the water outlet pipe is bent downwards along the position, close to the end part, of the water inlet pipe and is intersected and fixed with the water inlet pipe. According to the cooling device, the problems of deformation of the tilting shaft and jamming with a supporting copper sleeve are solved.

Owner:SINOSTEEL XIAN MACHINERY

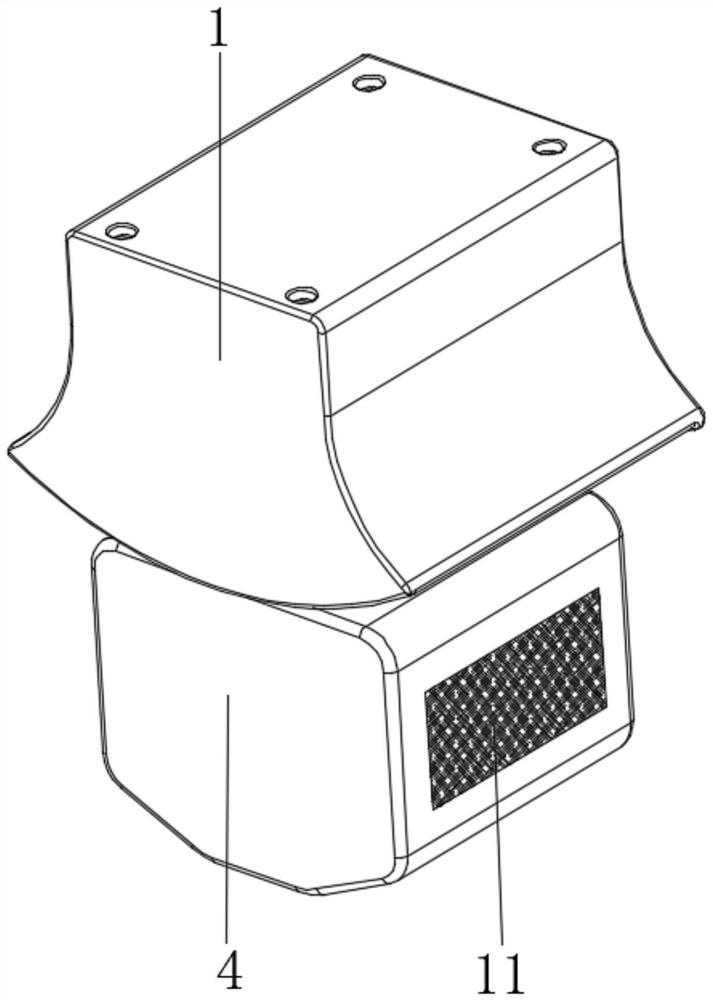

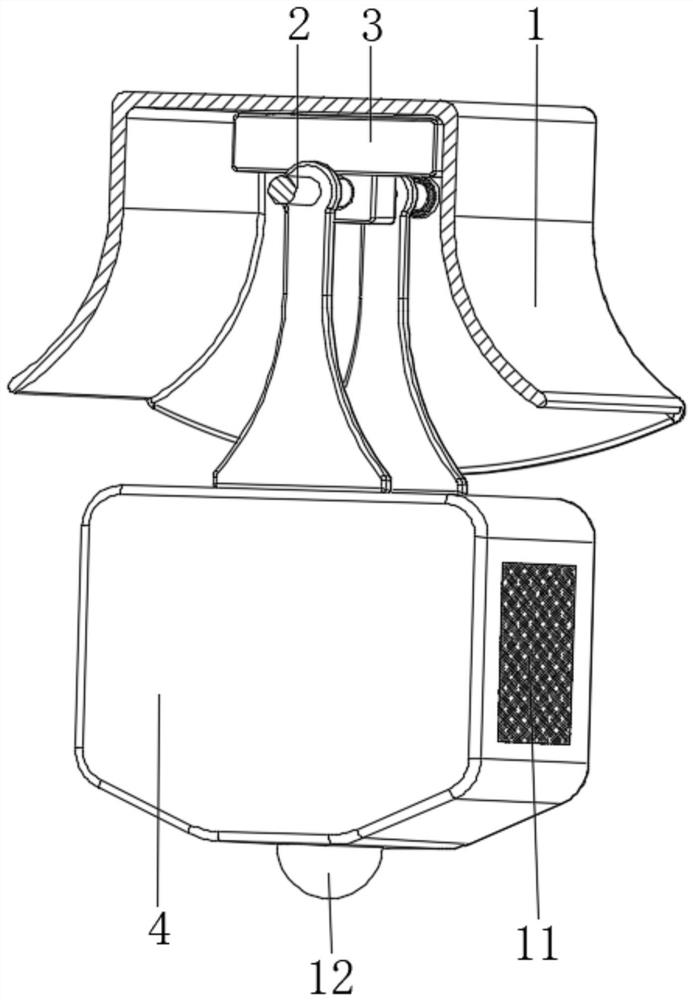

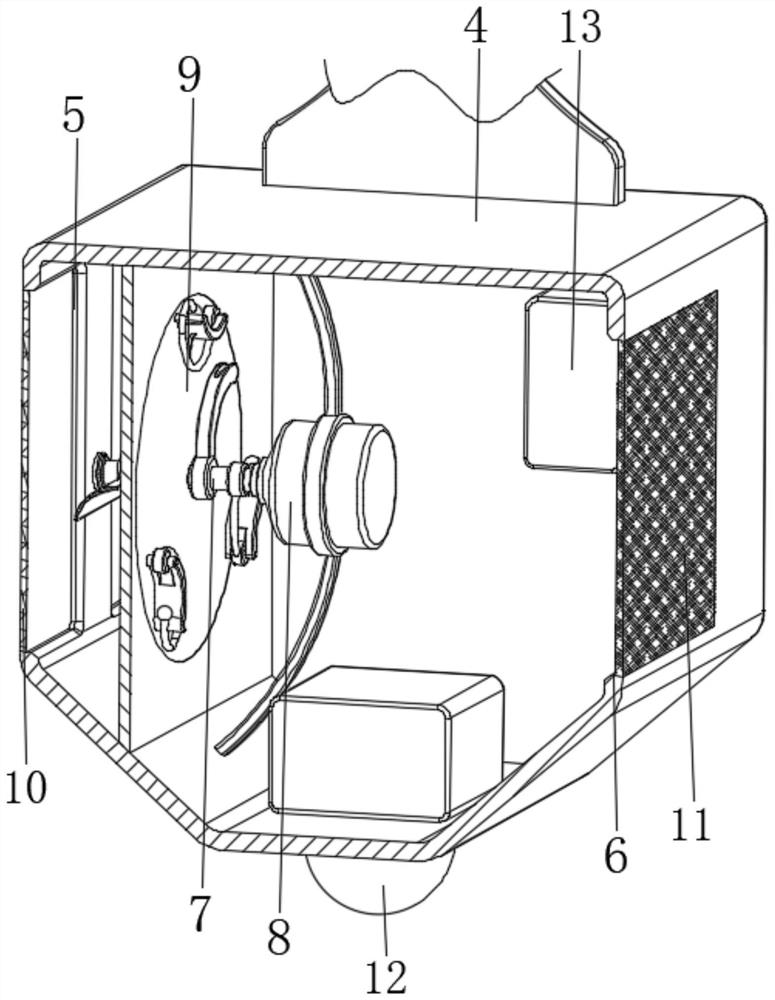

Transient receiver heat-radiation device

InactiveCN105246285ADispersed in timeReduce the impact of high temperatureCircuit arrangements on support structuresCooling/ventilation/heating modificationsEngineeringHot Temperature

The invention discloses a transient receiver heat-radiation device. The transient receiver heat-radiation device comprises a box body disposed at the external, a side wall of the box body is provided with at least one air vent, and the air vent is disposed in the side wall where a circuit board is installed. The transient receiver heat-radiation device provided in the invention comprises the box body located at the external, the side wall of the box body is provided with the air vent, and the air vent is located in the side wall, where the circuit board is installed, in the box body; and, when the circuit board works, a lot of heat is generated, and because the air vent is close to the circuit board, the generated heat can timely radiate out via the air vent, and heat radiated by the circuit board is reduced. The air vent communicate the internal of the box boy with the outside, so the internal of the box body keeps at relative low temperature, and the fact that an instrument is influenced by high temperature when the instrument is used is reduced.

Owner:CHONGQING GEOLOGICAL INSTR FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com