Environmental protection type coating material and preparaton method

A kind of waterproof coating and environment-friendly technology, applied in the direction of antifouling/underwater coating, polyurea/polyurethane coating, coating, etc., can solve the problems of environmental pollution and insufficient strength of waterproof materials, achieve low price and reduce the impact of high temperature , excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

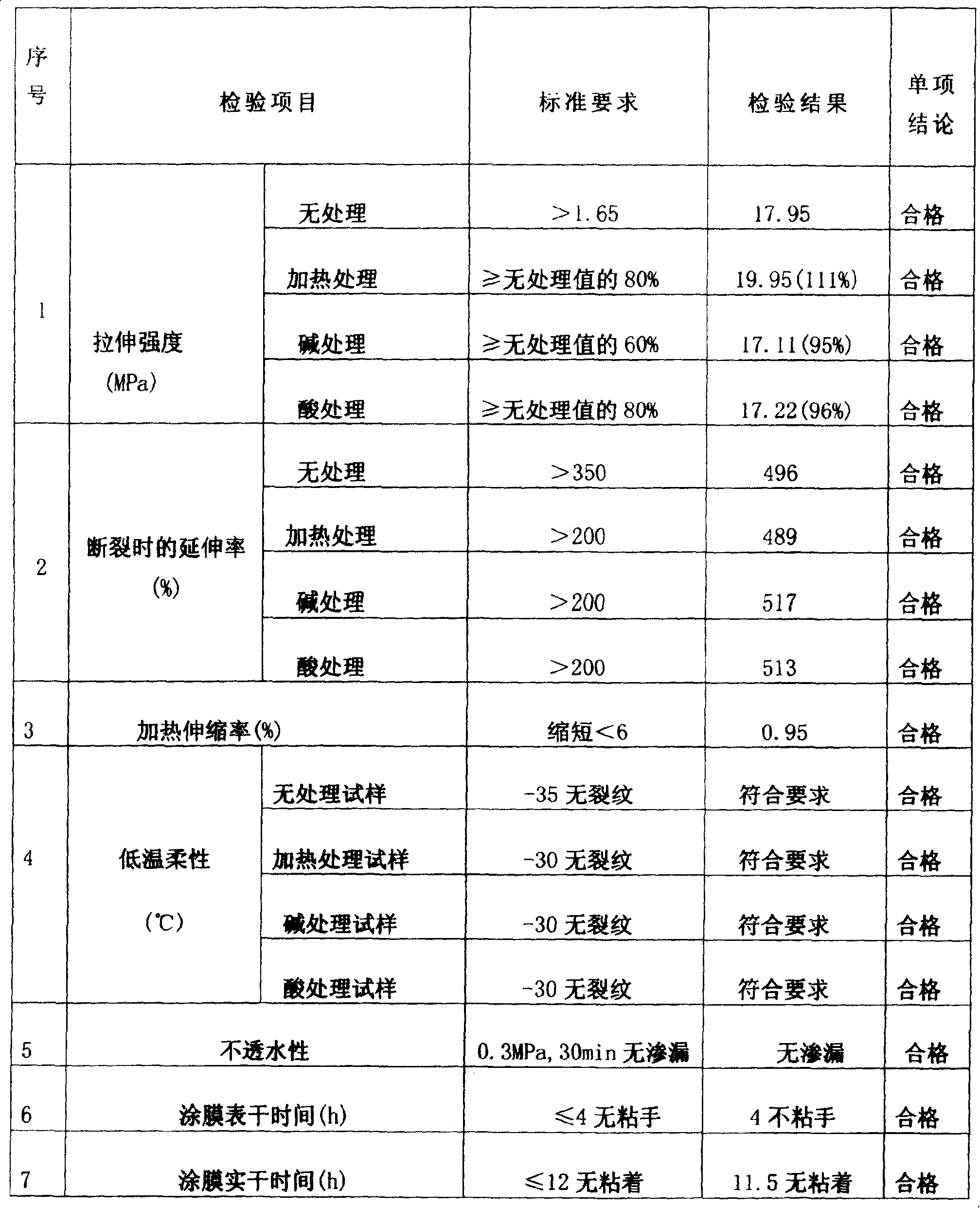

Examples

Embodiment 1

[0025] Embodiment 1: Add 7.8Kg polyether N-220 of castor oil 34.2Kg through the qualified castor oil in the reactor, stir and heat up to 40-50 ℃, add 42Kg polymethyl polyphenyl polyisocyanate (PAPi), more Methylene polyphenyl polyisocyanate (PAPi): the molar ratio of castor oil is 1: 1 ~ 2, then slowly rise to 75-80 ℃, constant temperature reaction 2.5-3 hours, sampling analysis prepolymer -NCO group content and Viscosity, depending on the viscosity, adjusted with solvent butyl acetate, cooled to 50°C, filtered and packaged. -NCO% content is 4-5; viscosity (coating -4 cups) is 35 seconds; test results: tensile strength: 19.4MPa, elongation: 600%, and other excellent properties.

Embodiment 2

[0026] Example 2: Put a total of 100Kg of treated polyether N-220 and polyether 330N in a reaction kettle, raise the temperature to 40°C, add 30Kg of toluene diisocyanate (TDi) and 30Kg of butyl acetate mixture, and slowly warm to 75-80°C ℃, keep the temperature for 3 hours, take a sample to analyze the prepolymer-NCO group content and viscosity, adjust with the solvent butyl acetate according to the viscosity, cool down to 50 ℃, filter and pack. -NCO% content is 4.2; tensile strength: 8.6MPa, elongation: 1100%, and other excellent properties.

Embodiment 3

[0027] Embodiment 3: 10kg of the prepolymer produced in embodiment 2, add treated bentonite 4kg and acetylene carbon black 5kg and mix uniformly, its tensile strength is 6.1MPa, and elongation is 870%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact resistance | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com