Feeding device for garbage burning rotary kiln end

A technology of waste incineration and feeding device, applied in incinerators, combustion methods, combustion types, etc., can solve the problems affecting the working stability and service life of the components and connecting structures of the feeding device, high waste disposal costs, and short maintenance cycles, etc. problems, to reduce the effect of high temperature, prolong service life, and reduce harsh requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

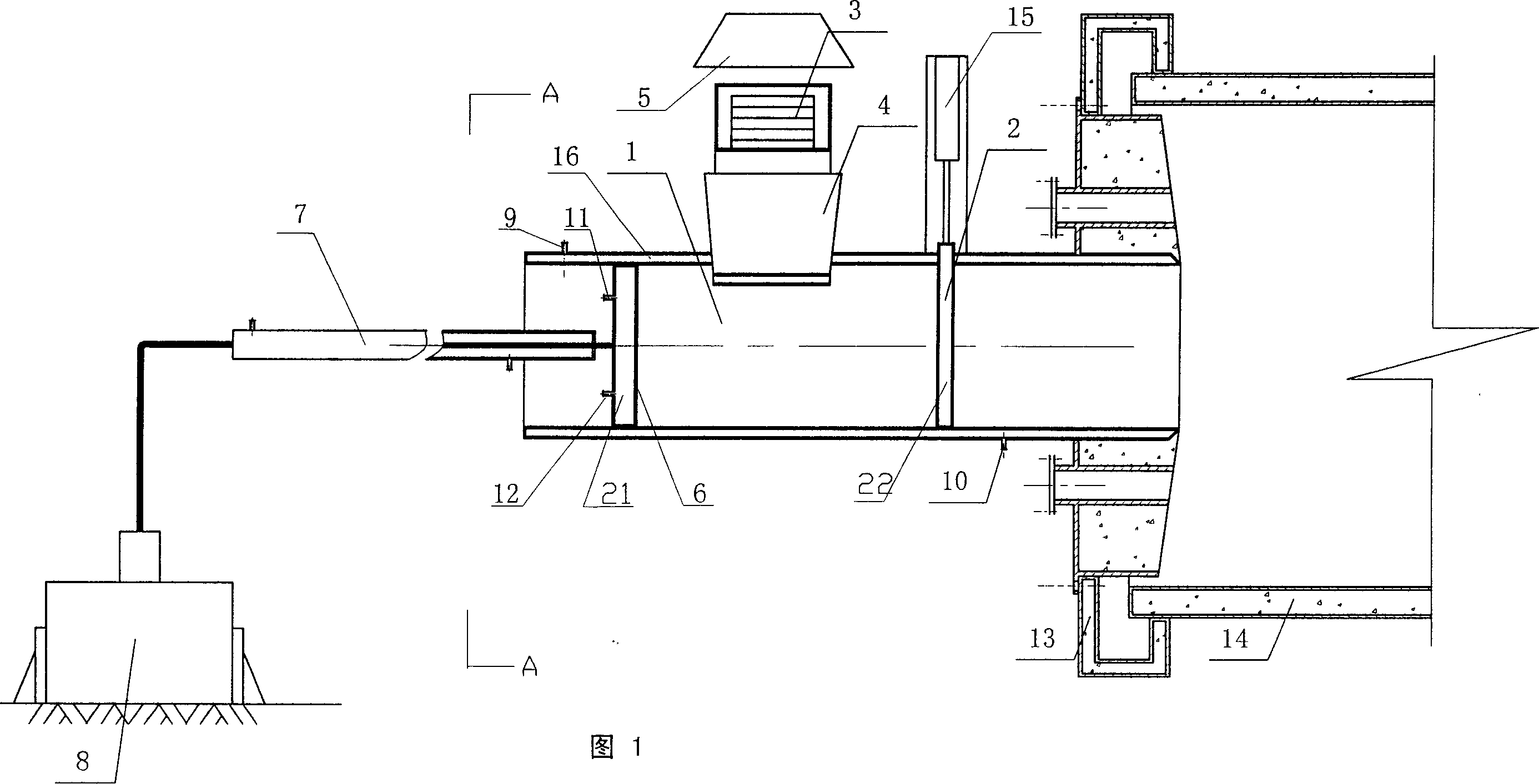

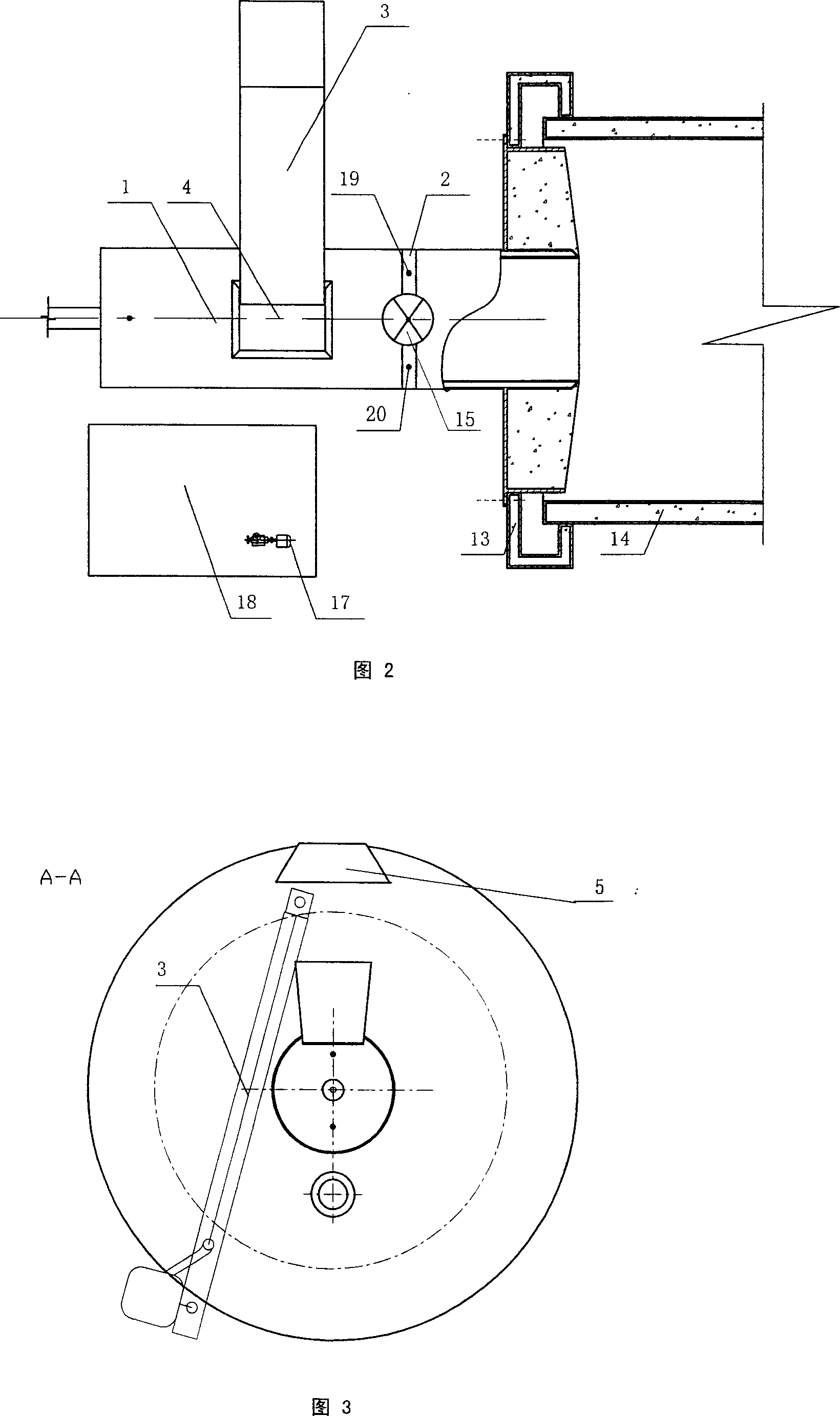

[0013] Referring to the accompanying drawings, the feeding device of the kiln head of the rotary kiln for waste incineration, the metal feed pipe 1 is made into a sandwich 16 structure, and its inner end extends into the kiln head 13 and communicates with the inside of the rotary kiln 14, and a water inlet 9 is installed on the upper part of the pipe 1 , A water outlet 10 is installed at the bottom, so that the space in the water inlet 9, the interlayer 16, and the water outlet 10 form a cooling water flow channel. A radial feeding port 4 is installed on the pipeline near the kiln head 13, and the garbage pushing mechanism is composed of a piston-type pushing plate 6 that reciprocates in the pipeline 1 driven by a hydraulic cylinder 7. Garbage is sent into the kiln. Piston pusher plate 6 is made into interlayer structure, and the water inlet 11 of the pusher plate, the space in the interlayer 21, and the water outlet 12 form the cooling water flow channel of the pusher plate. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com