Patents

Literature

1140results about How to "Avoid stuck phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure cooker

ActiveCN106724784ASolve technical problems with placementEasy to cleanPressure-cookersEngineeringPressure cooking

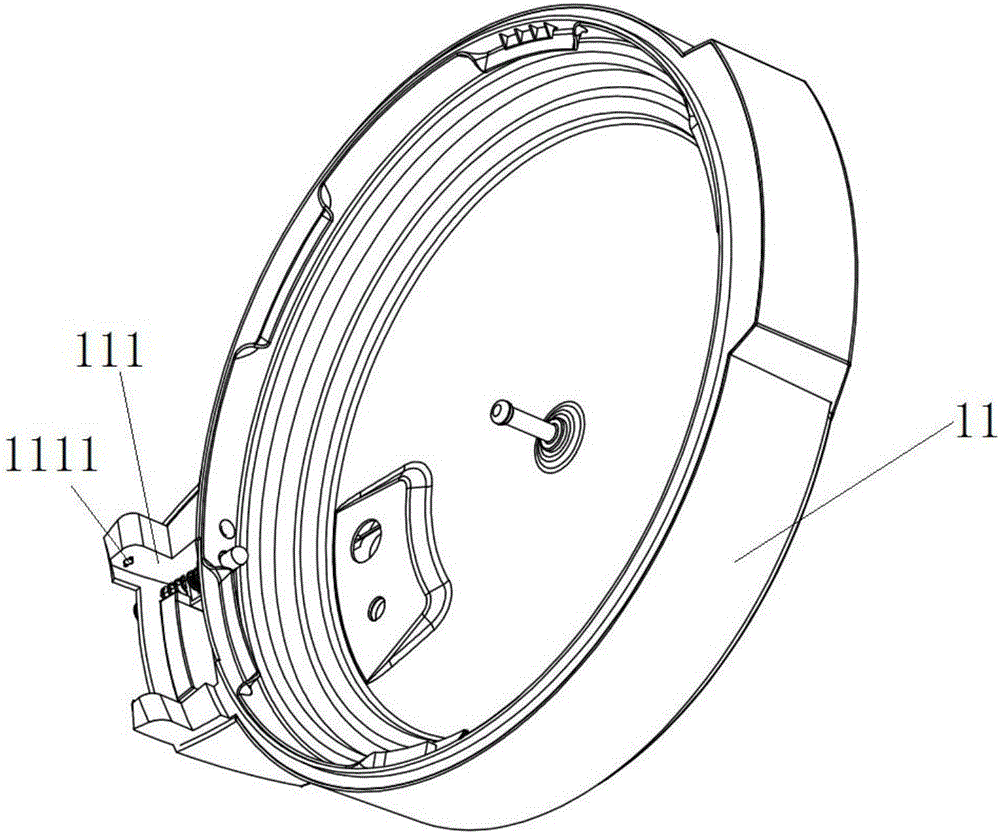

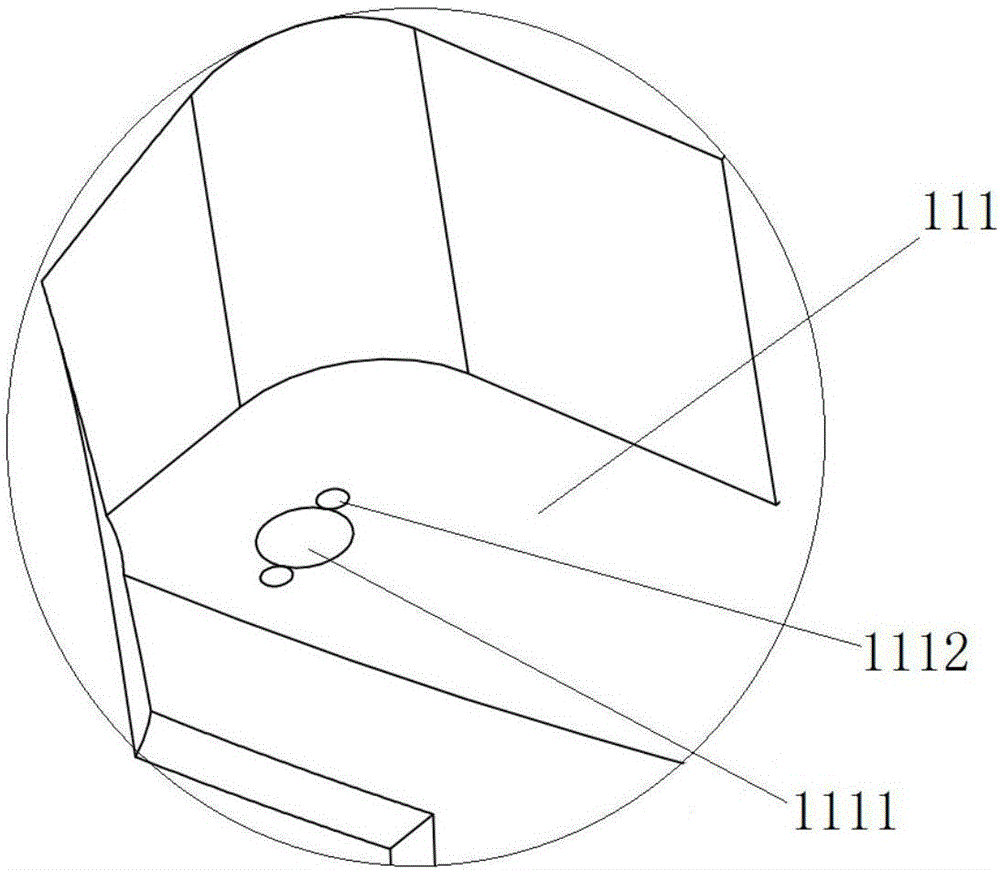

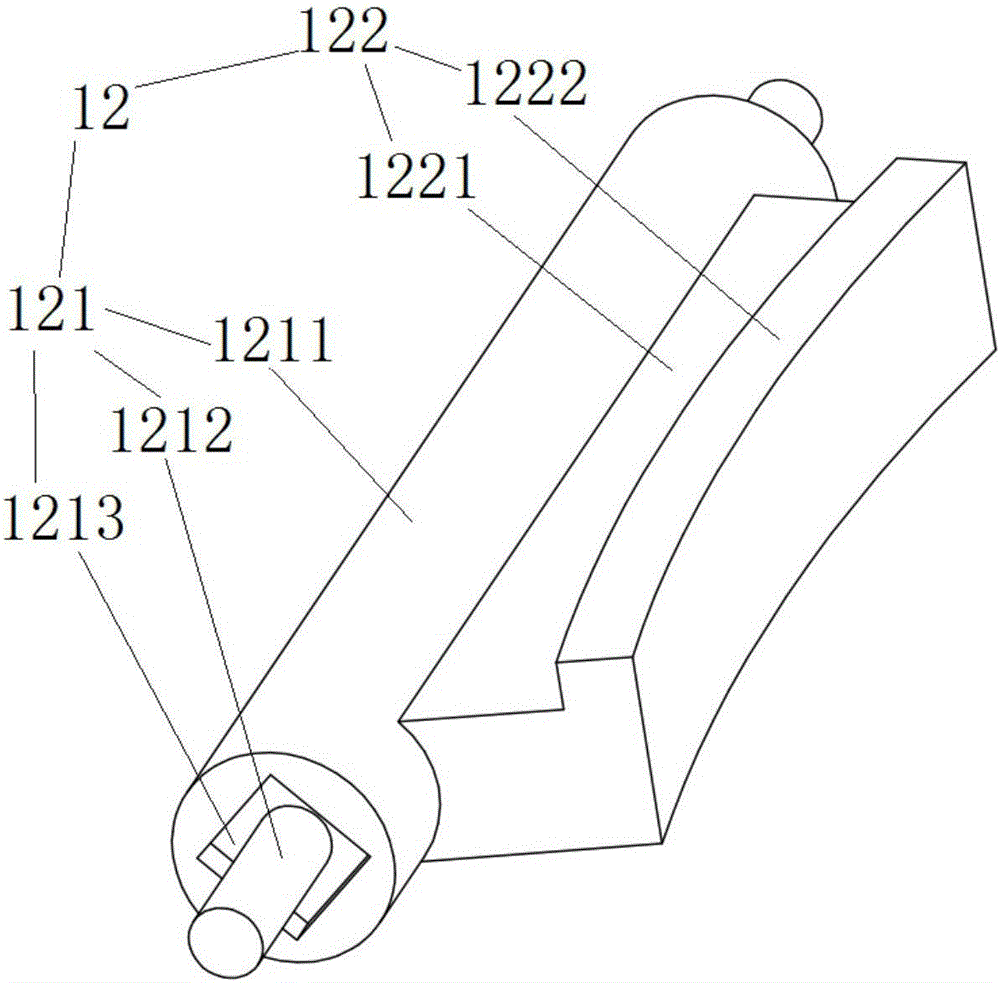

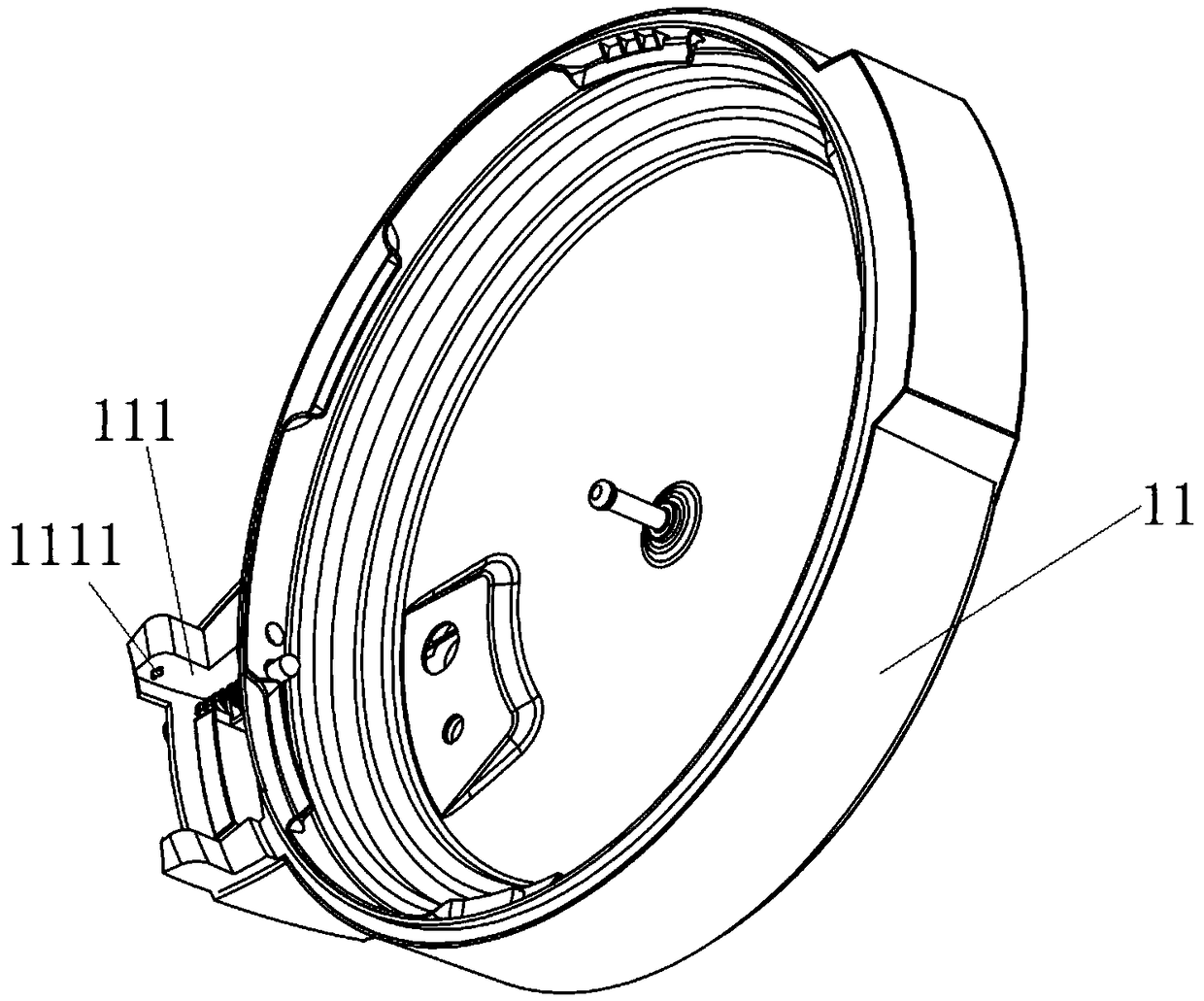

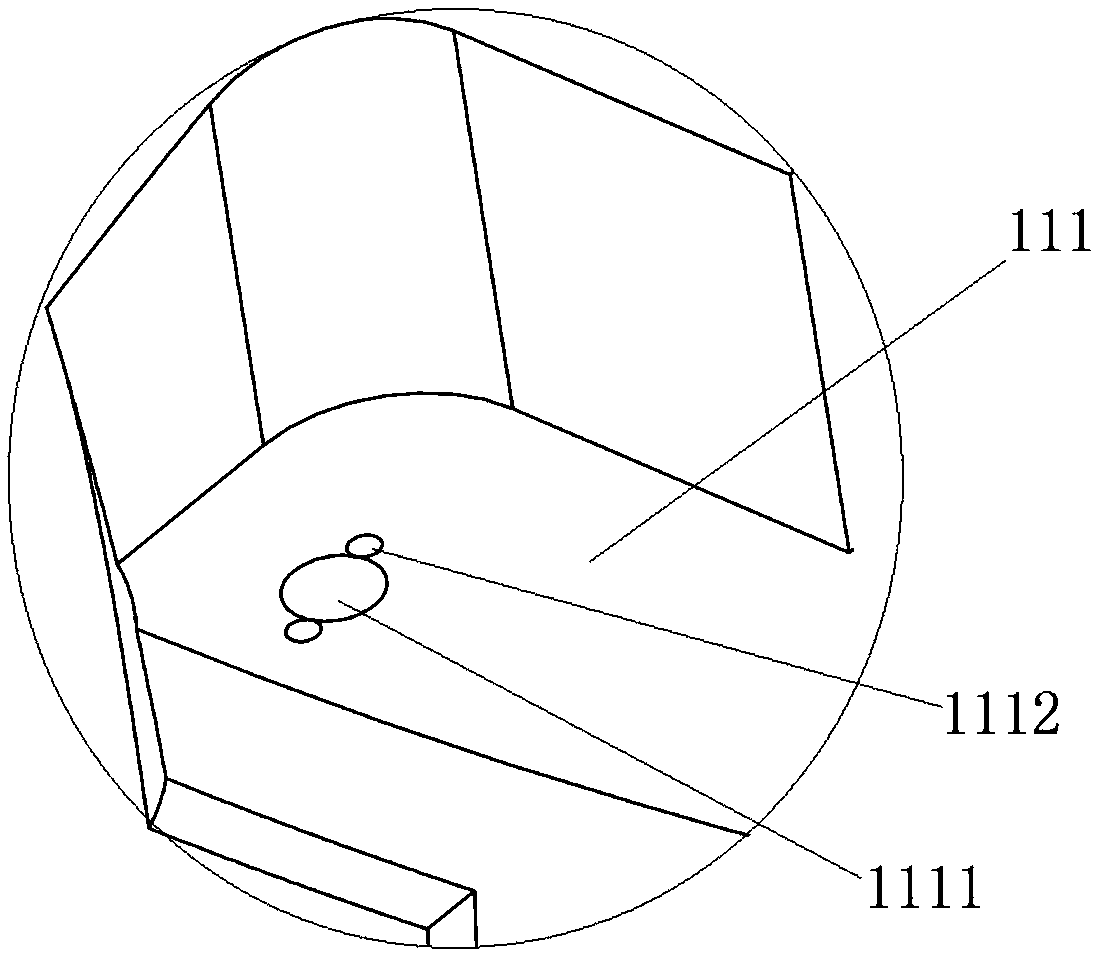

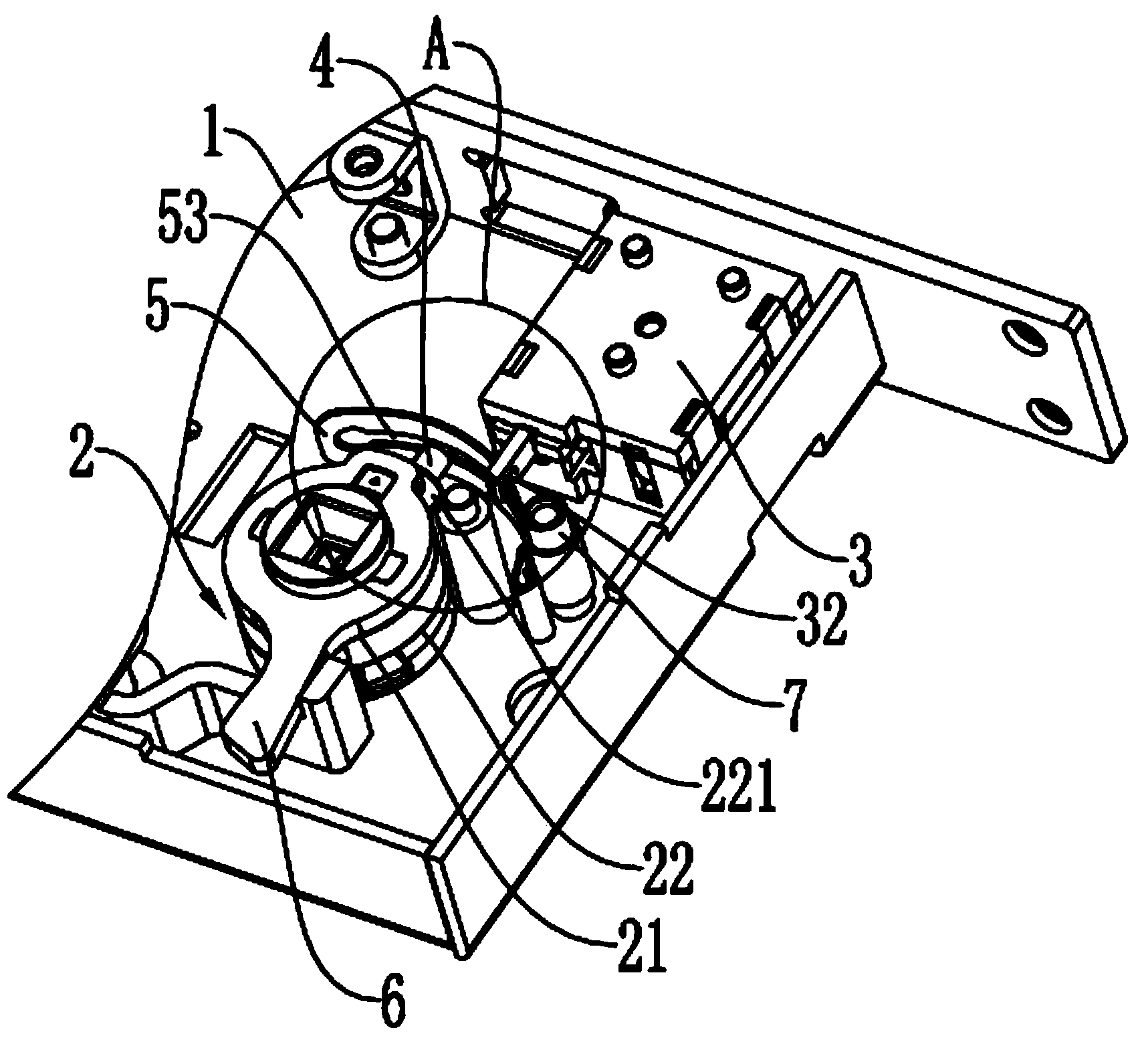

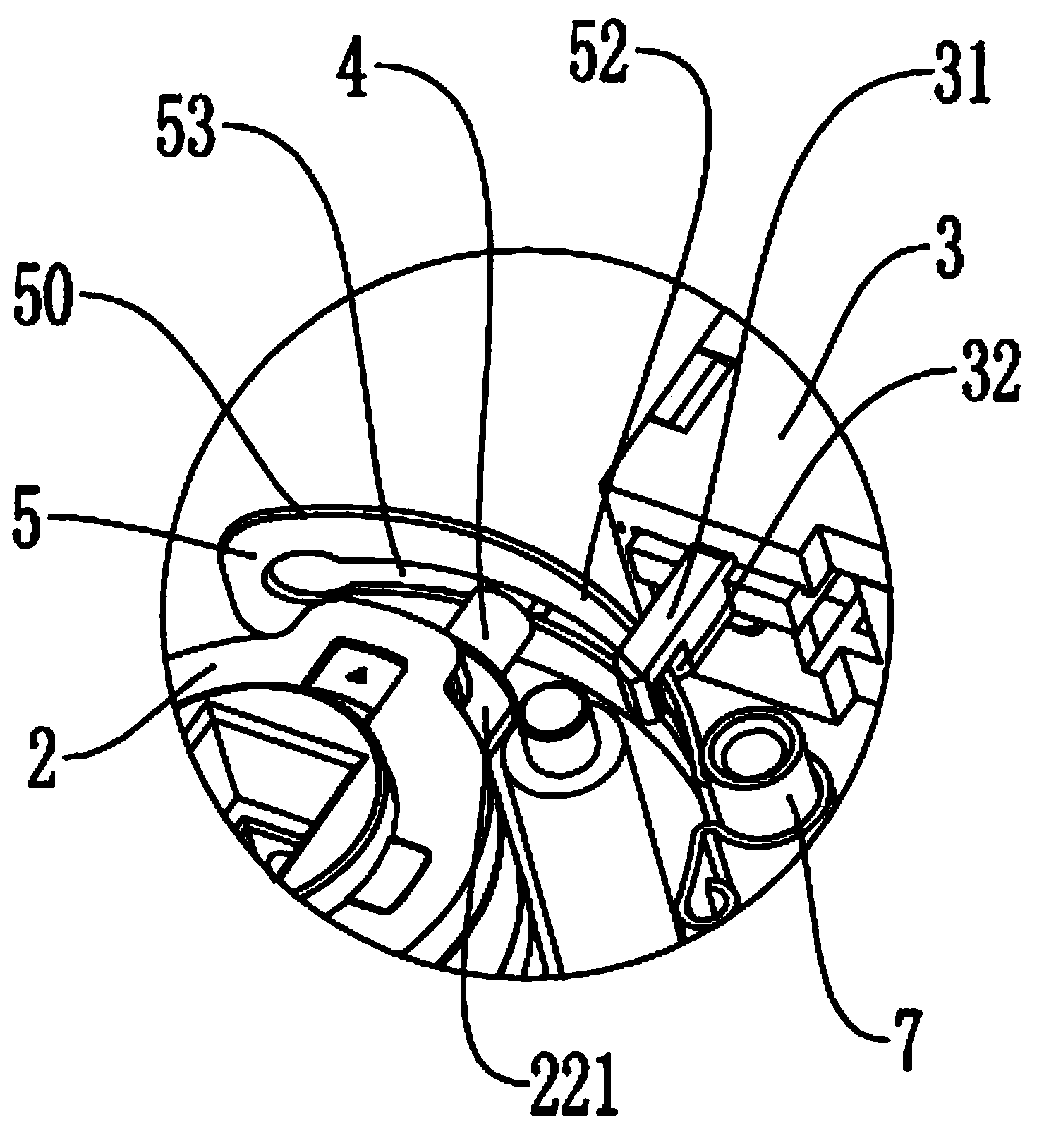

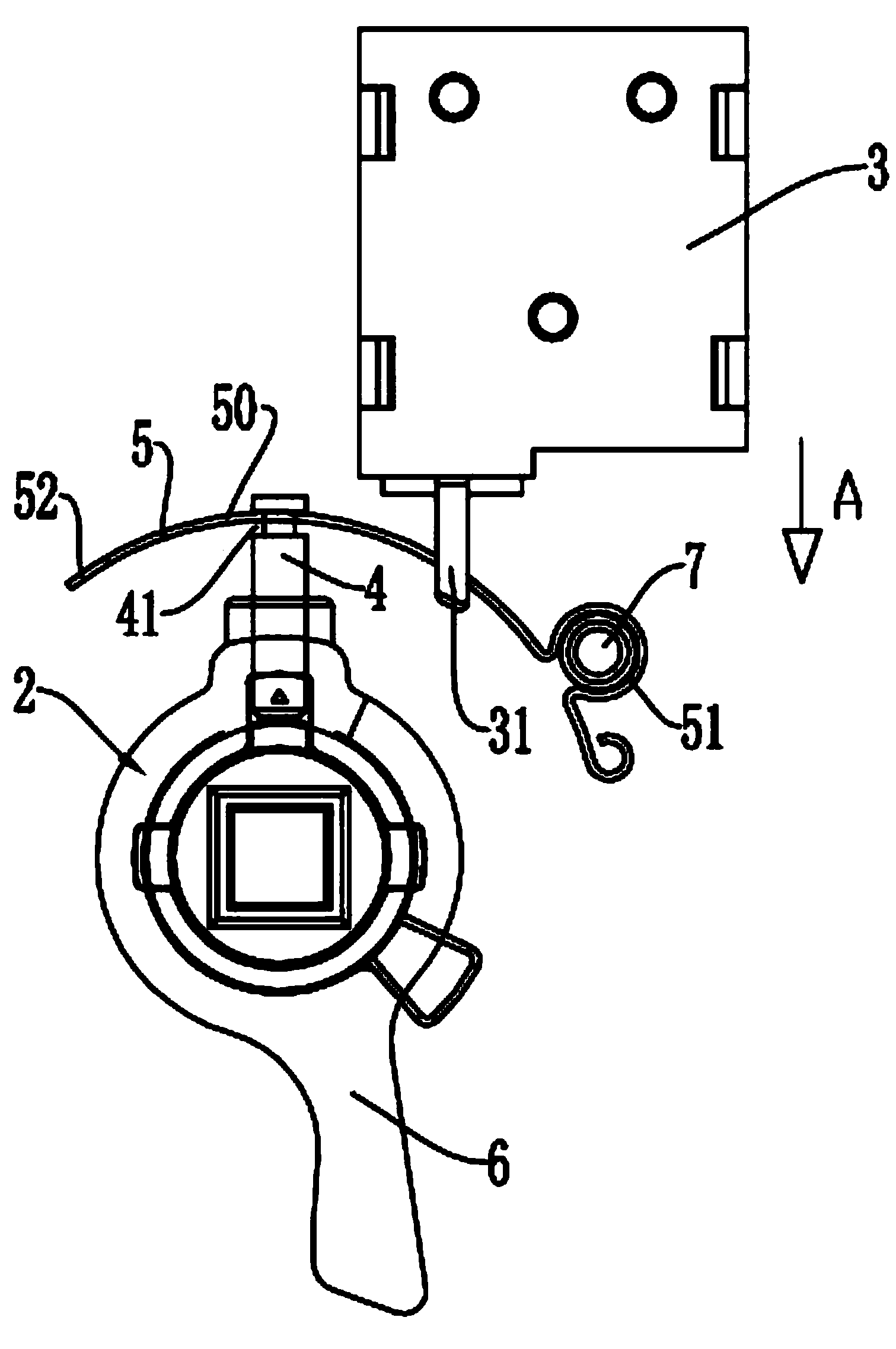

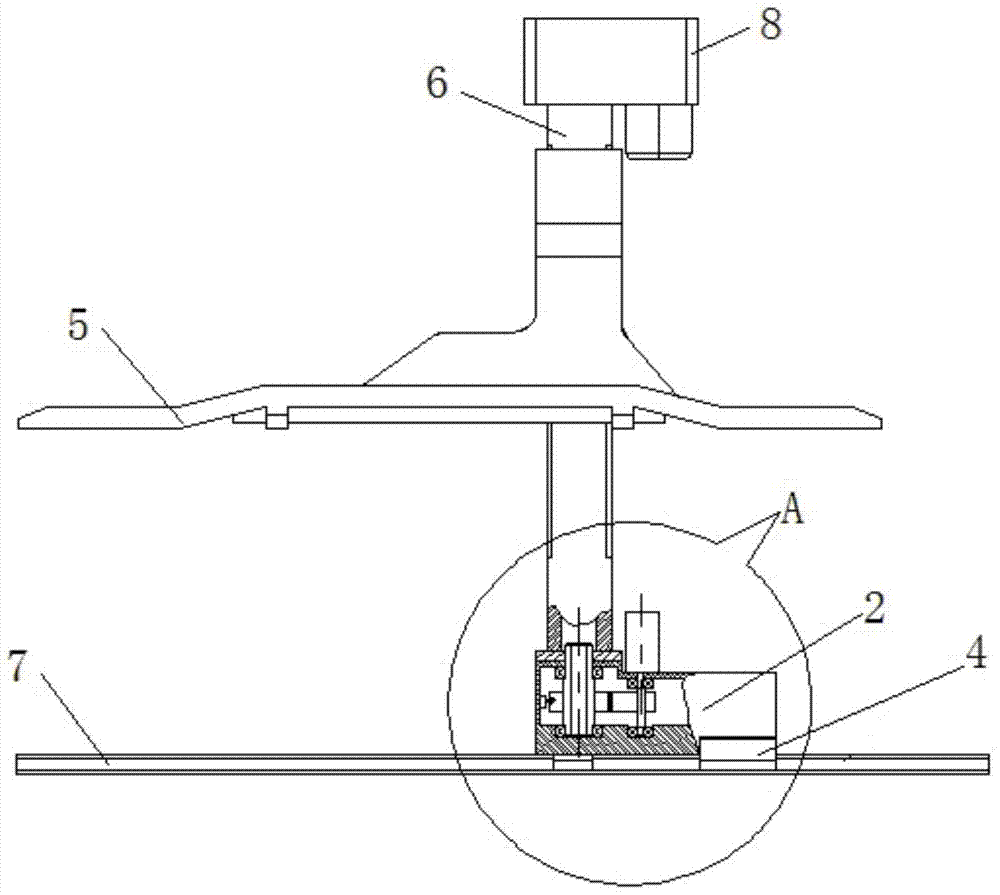

The invention provides a pressure cooker and relates to the technical field of household electrical appliances. According to the mainly-adopted technical scheme, the pressure cooker comprises a pot cover and a pot body, wherein the pot cover comprises a pot cover body and fixing parts; the pot cover body is connected with the fixing parts in a rotating mode so that the pot cover body can rotate relative to the fixing parts; the pot body is provided with a lock catch structure, wherein when the pressure cooker is in an uncovered state, the fixing parts are locked on the lock catch structure in a detachable way. The invention mainly aims at providing the pressure cooker, wherein the pot cover is detachably connected with the pot body, and the stability of the rotation of the pot cover is improved during the process when the pot cover is opened and closed; and the phenomenon of stagnation caused by too large an angle of the opened pot cover is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

a pressure cooker

ActiveCN106724784BSolve technical problems with placementEasy to cleanPressure-cookersEngineeringPressure cooking

The invention provides a pressure cooker and relates to the technical field of household electrical appliances. According to the mainly-adopted technical scheme, the pressure cooker comprises a pot cover and a pot body, wherein the pot cover comprises a pot cover body and fixing parts; the pot cover body is connected with the fixing parts in a rotating mode so that the pot cover body can rotate relative to the fixing parts; the pot body is provided with a lock catch structure, wherein when the pressure cooker is in an uncovered state, the fixing parts are locked on the lock catch structure in a detachable way. The invention mainly aims at providing the pressure cooker, wherein the pot cover is detachably connected with the pot body, and the stability of the rotation of the pot cover is improved during the process when the pot cover is opened and closed; and the phenomenon of stagnation caused by too large an angle of the opened pot cover is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

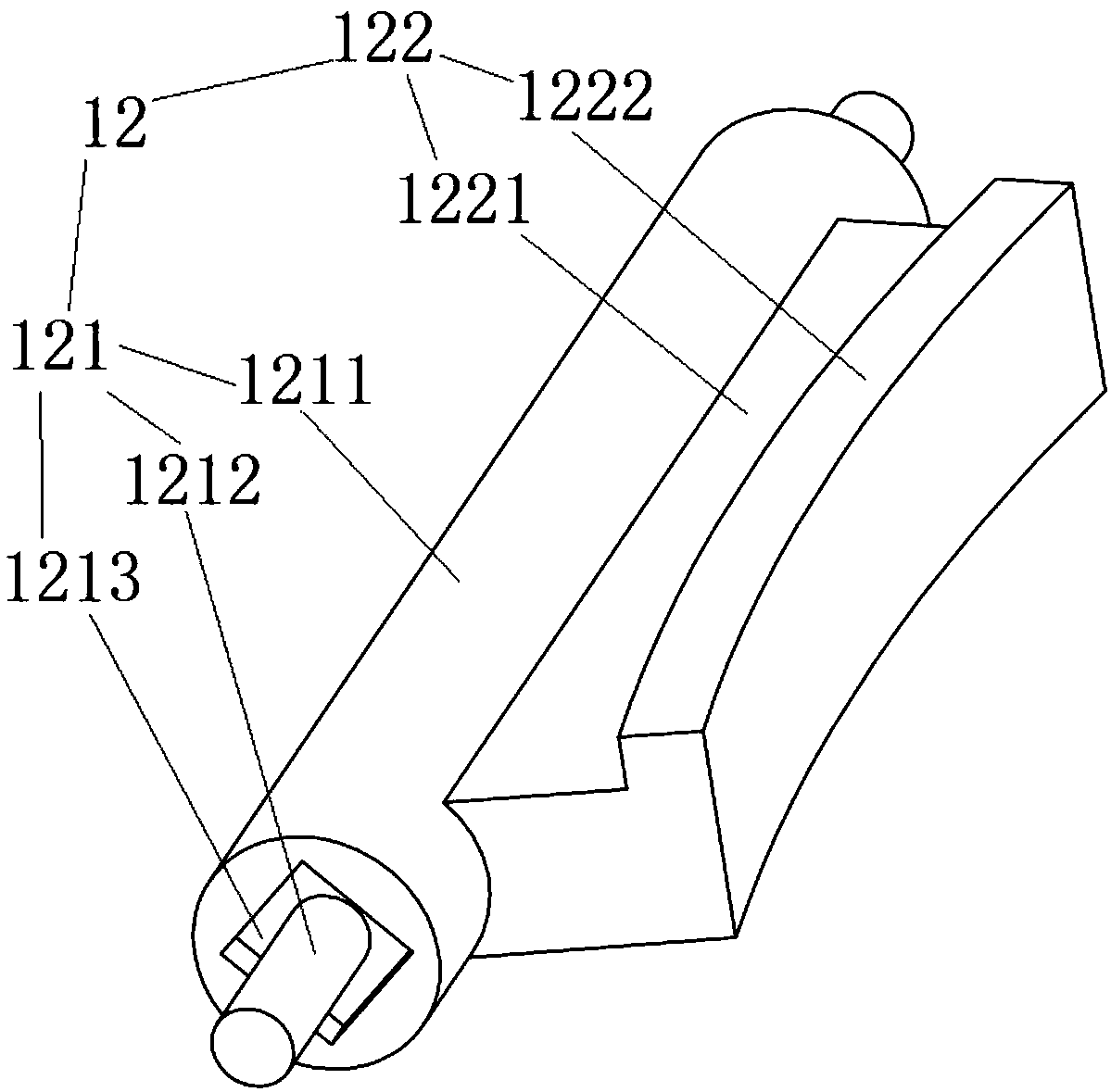

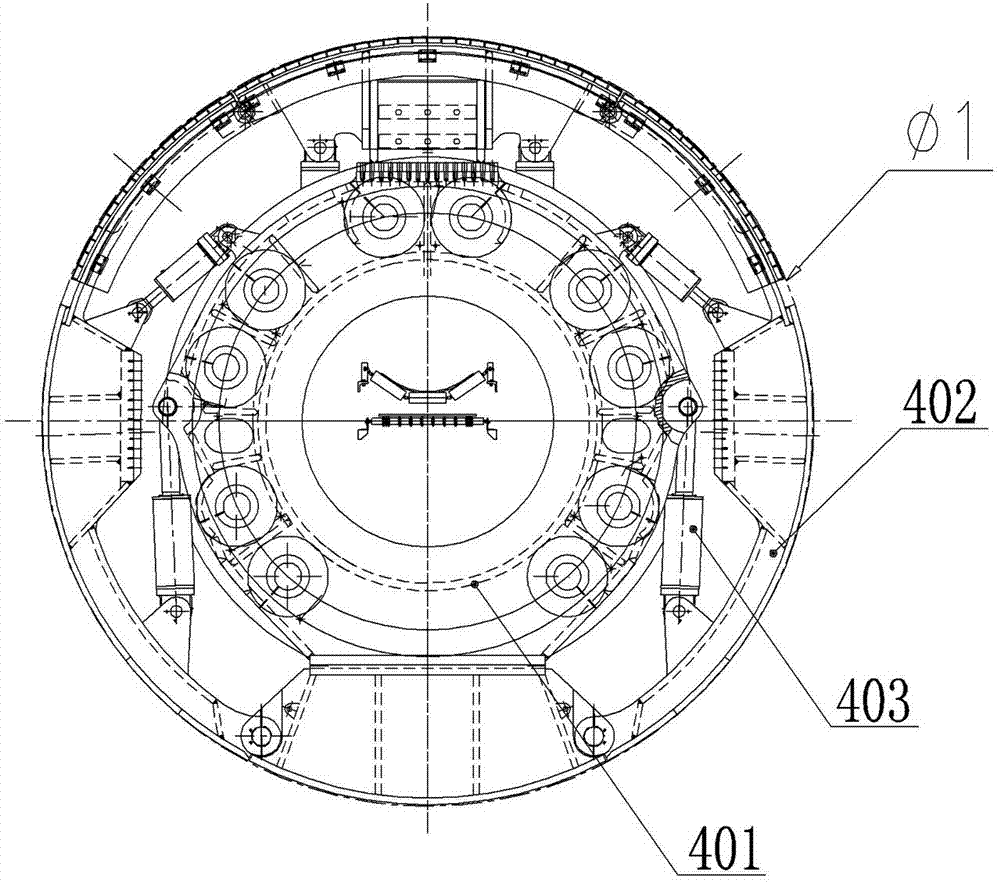

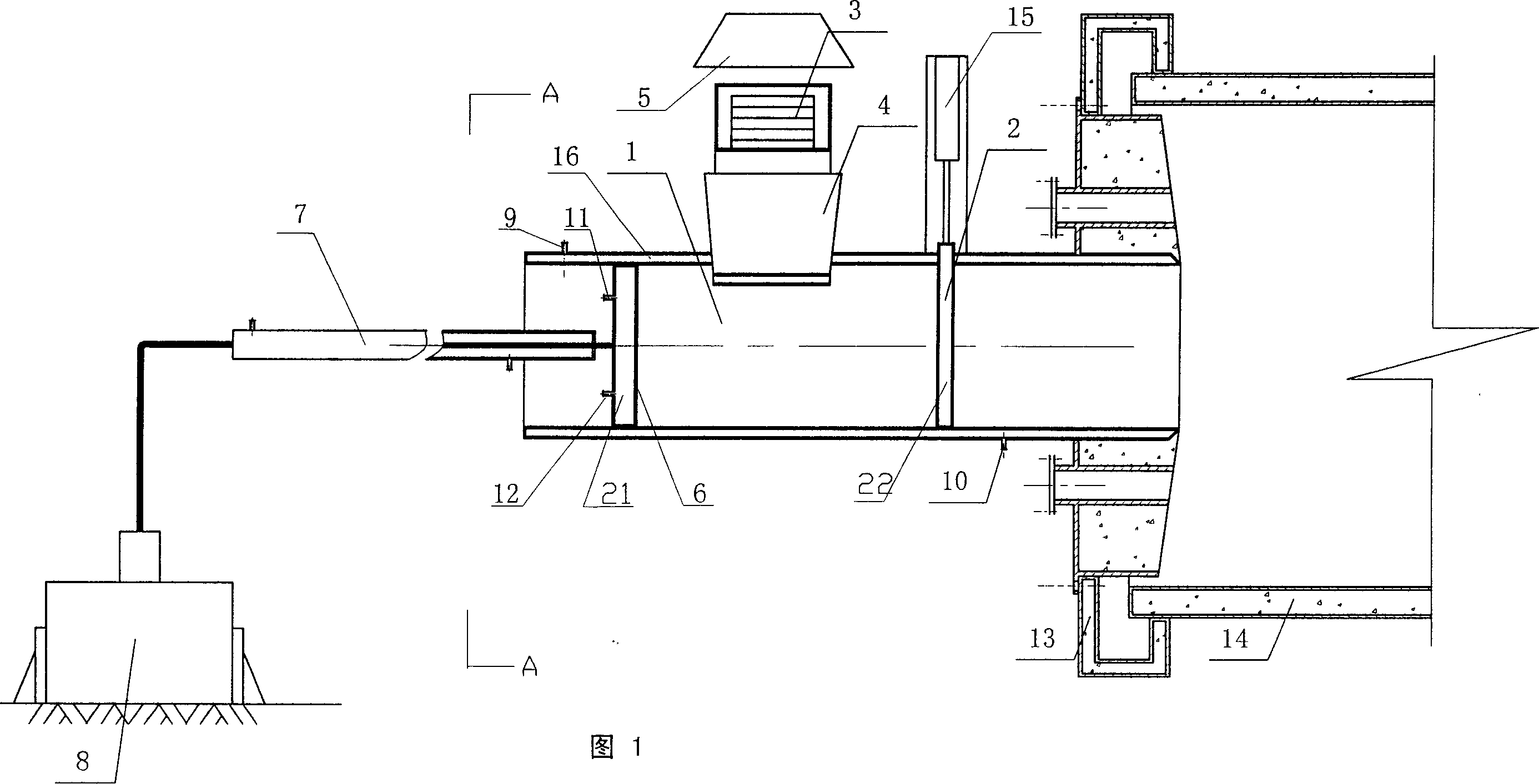

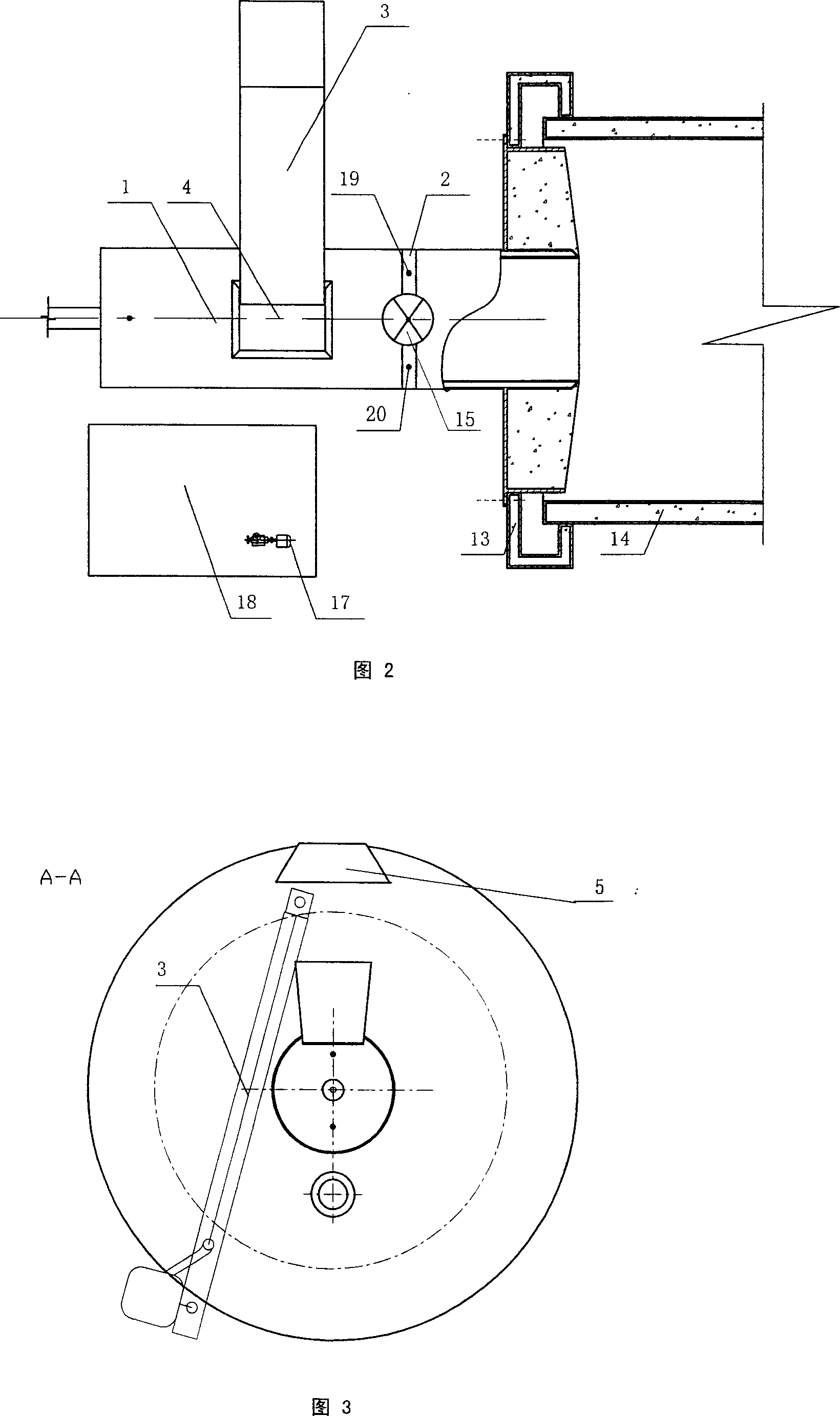

Pipe segment diameter adjustable hard rock tunneling machine adopting double-layer supporting mode and construction method thereof

ActiveCN104747200AEasy to assembleImprove stabilityUnderground chambersTunnel liningRock tunnelStructural engineering

The invention discloses a pipe segment diameter adjustable hard rock tunneling machine adopting a double-layer supporting mode and a construction method thereof. The pipe segment diameter adjustable hard rock tunneling machine comprises a cutter disc capable of performing expanded excavation, a round shield capable of extending radially, a flexible steel arch frame splicing machine, a pipe segment splicing machine and the like. The hard rock tunneling machine creatively enables shield clamping to be nipped in the bud through coordinative operation of expanded excavation, flexible supporting, pipe segment supporting, pea gravel filling, grouting and other processes in the high-stress formation tunneling process, and meanwhile lining operation of a hard rock tunnel can be completed from beginning to end without stopping in a mechanical mode. Therefore, the shield clamping problem of the hard rock tunneling machine can be avoided, further the tunneling efficiency is improved, and the lining time and the amount of used labor of the hard rock tunnel can be also decreased.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

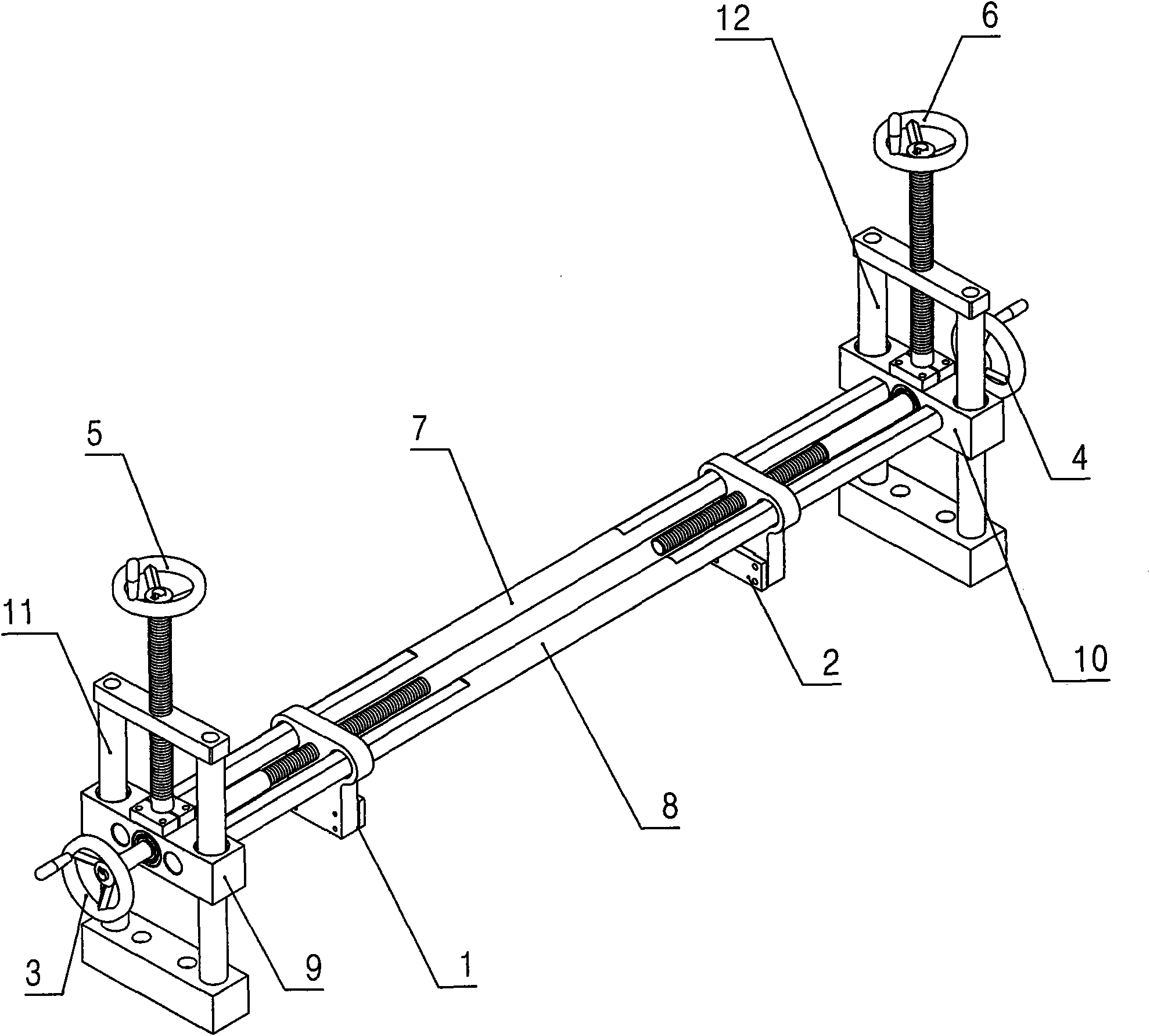

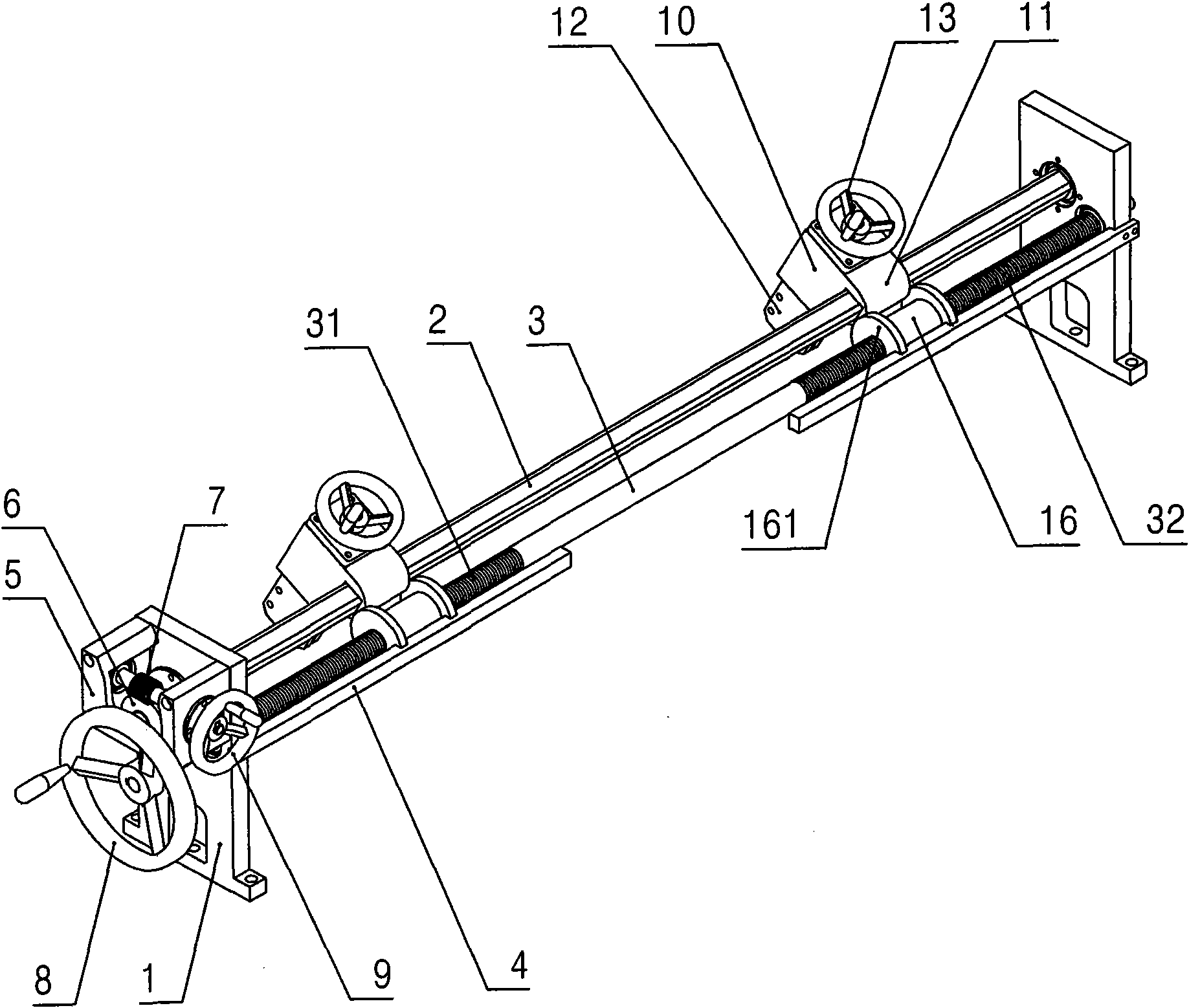

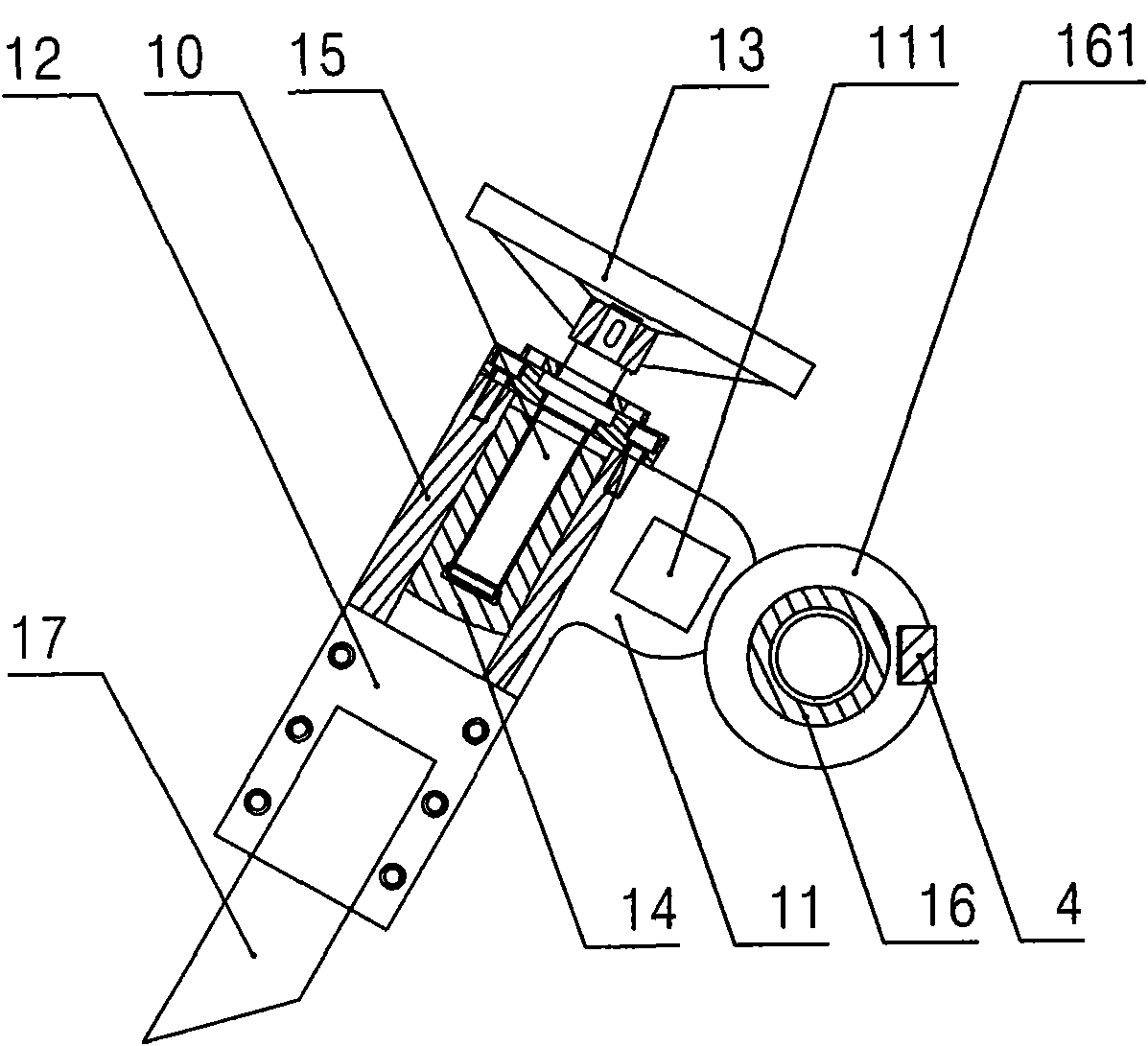

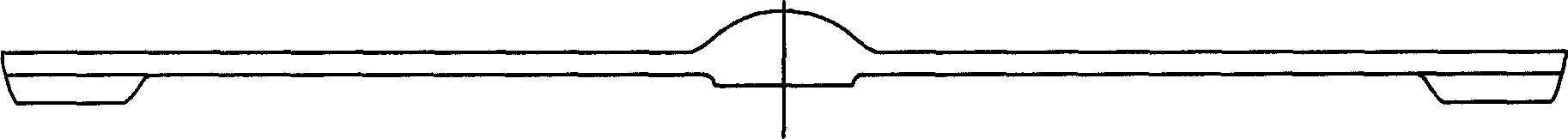

Breadth edge-cutting device

ActiveCN101941213AAvoid stuck phenomenonEasy to operateMetal working apparatusSheet materialEngineering

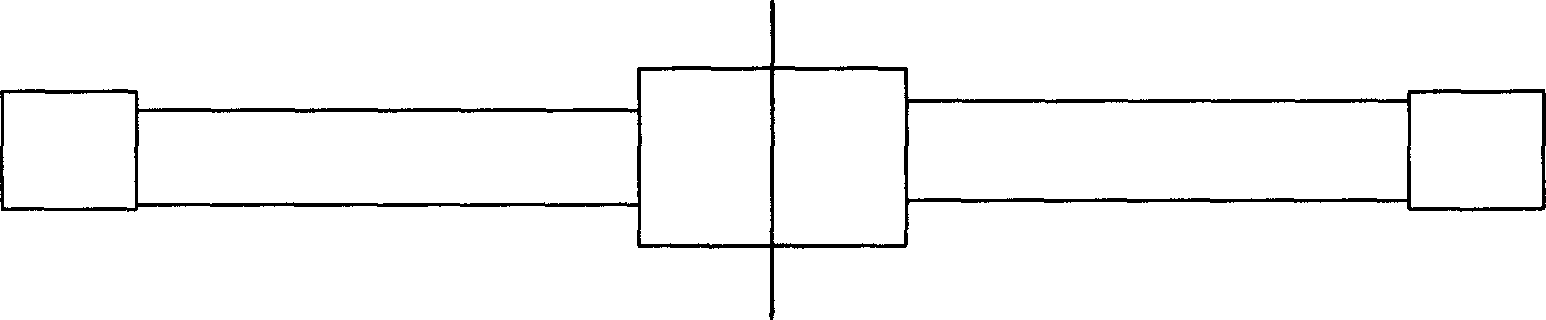

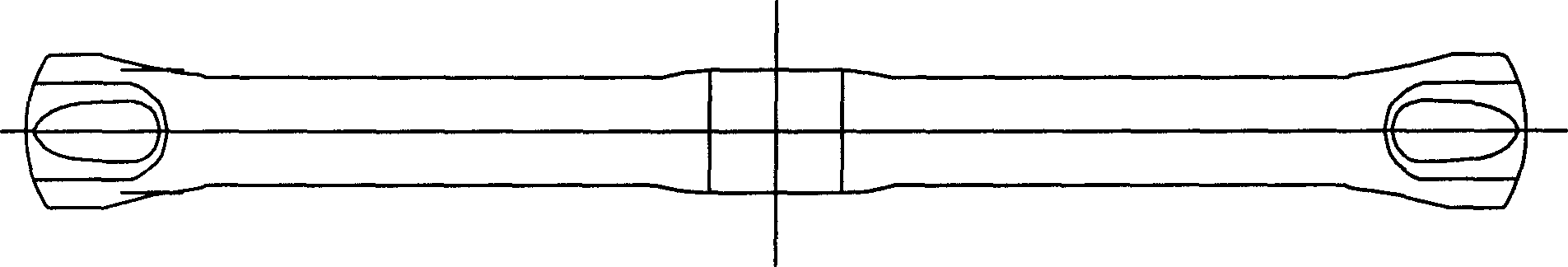

The invention discloses a breadth edge-cutting device with quite convenient operation and quite easy regulation, which comprises a pair of parallel fixed seats and a pair of knife seats with cutting knives, wherein a square supporting shaft and a distance-regulating lead screw shaft which are mutually parallel are movably penetrated between the pair of fixed seats, reverse threads are arranged at both ends of the distance-regulating lead screw shaft, a guide rod parallel to the distance-regulating lead screw shaft is also arranged on each fixed seat, a supporting hole matched with the cross section of the supporting shaft is arranged on the supporting ear of each knife seat, each knife seat is movably penetrated on the supporting shaft through the supporting hole, a distance-regulating thread sleeve is respectively sleeved on the distance-regulating threads at both ends of the distance-regulating lead screw shaft, and the supporting ear of each knife seat is clamped between a pair of limiting edges of the corresponding distance-regulating thread sleeve; and a worm wheel-worm case is arranged on one fixed seat, a worm wheel and a worm which are mutually matched are arranged in the worm wheel-worm case, the worm wheel is connected with the end part at one corresponding side of the supporting shaft, and a cutting-knife fine-adjusting mechanism is arranged between each knife seat and each cutting knife. The invention is mainly used on flow lines for producing sheet materials, coiled materials and the like.

Owner:JIANGSU VICTORY MACHINERY

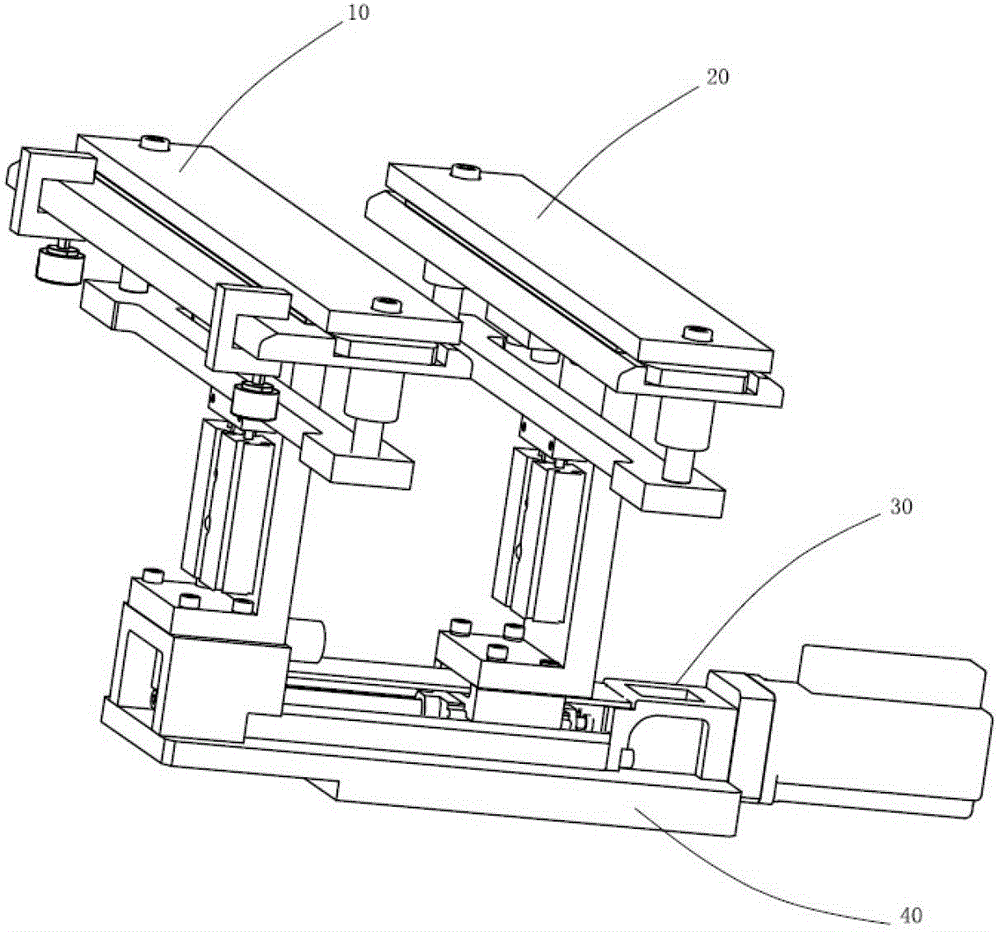

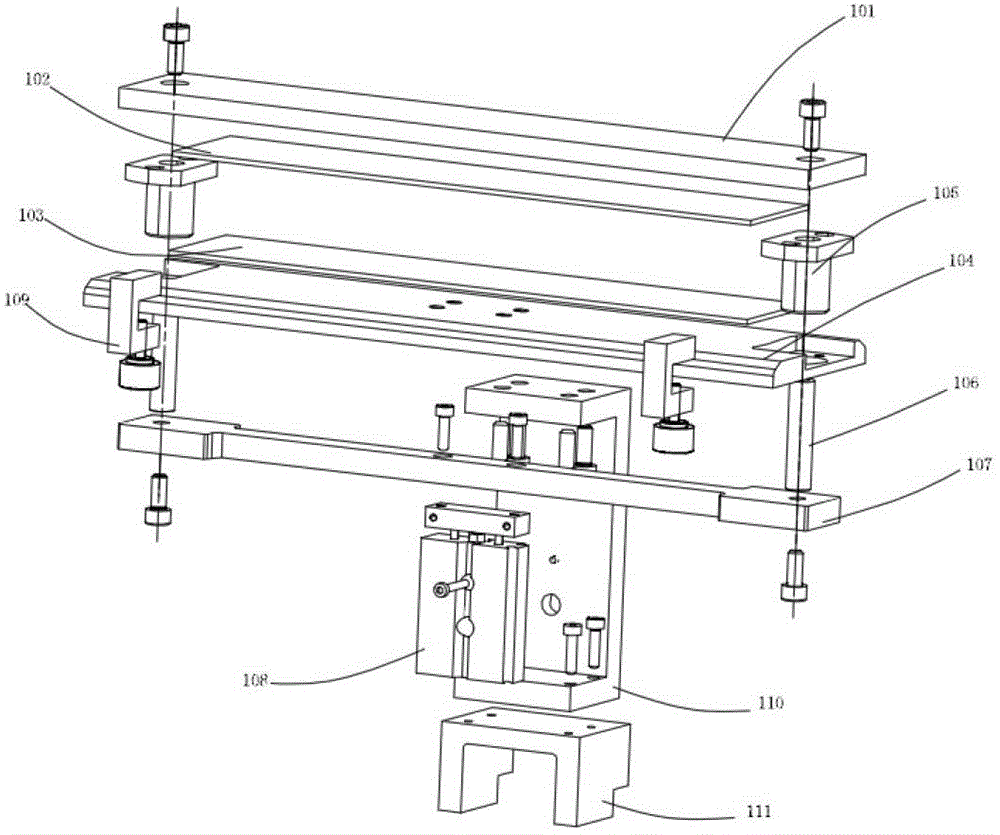

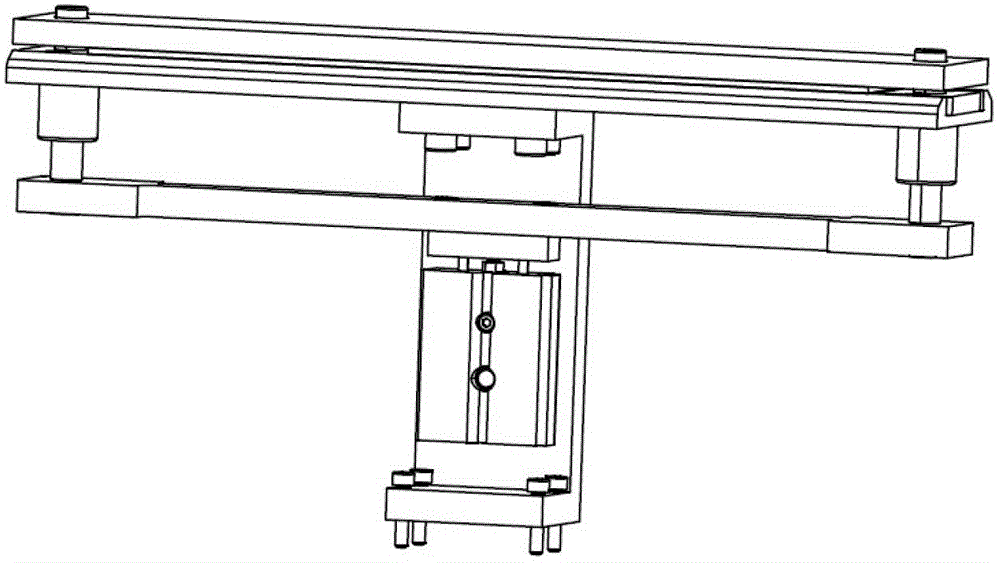

Clamping device for intermittently feeding films

The invention discloses a clamping device for intermittently feeding films. The clamping device comprises a supporting base, a driving component, a fixed clamping piece and a movable clamping piece; the fixed clamping piece is fixedly arranged on the driving component; the movable clamping piece is movably arranged on the driving component; the structure of the fixed clamping piece is similar to that of the movable clamping piece; and each of the fixed clamping piece and the movable clamping piece comprises a base, a single driving cylinder, a horizontal supporting plate, an upper clamping plate, a lower clamping plate and a pair of linear bearings, the single driving cylinder is arranged along a vertical direction, the horizontal supporting plate is fixedly connected with a piston of the driving cylinder, the upper clamping plate is connected with the supporting plate through a pair of vertical guide shafts, the upper clamping plate and the supporting plate jointly form a frame structure, the lower clamping plate is positioned between the upper clamping plate and the supporting plate, and the linear bearings are respectively used for accommodating and installing the vertical guide shafts and are fixed at two ends of the lower clamping plate. By the clamping device for intermittently feeding films, the phenomenon of jamming or uneven pressure caused by double-cylinder drive can be avoided, damage of elements such as the cylinders is avoided by the linear bearings and corresponding structures, feeding accuracy and clamping stability are improved, and accordingly the films can be ensured to be accurately clamped and conveyed.

Owner:HUAZHONG UNIV OF SCI & TECH

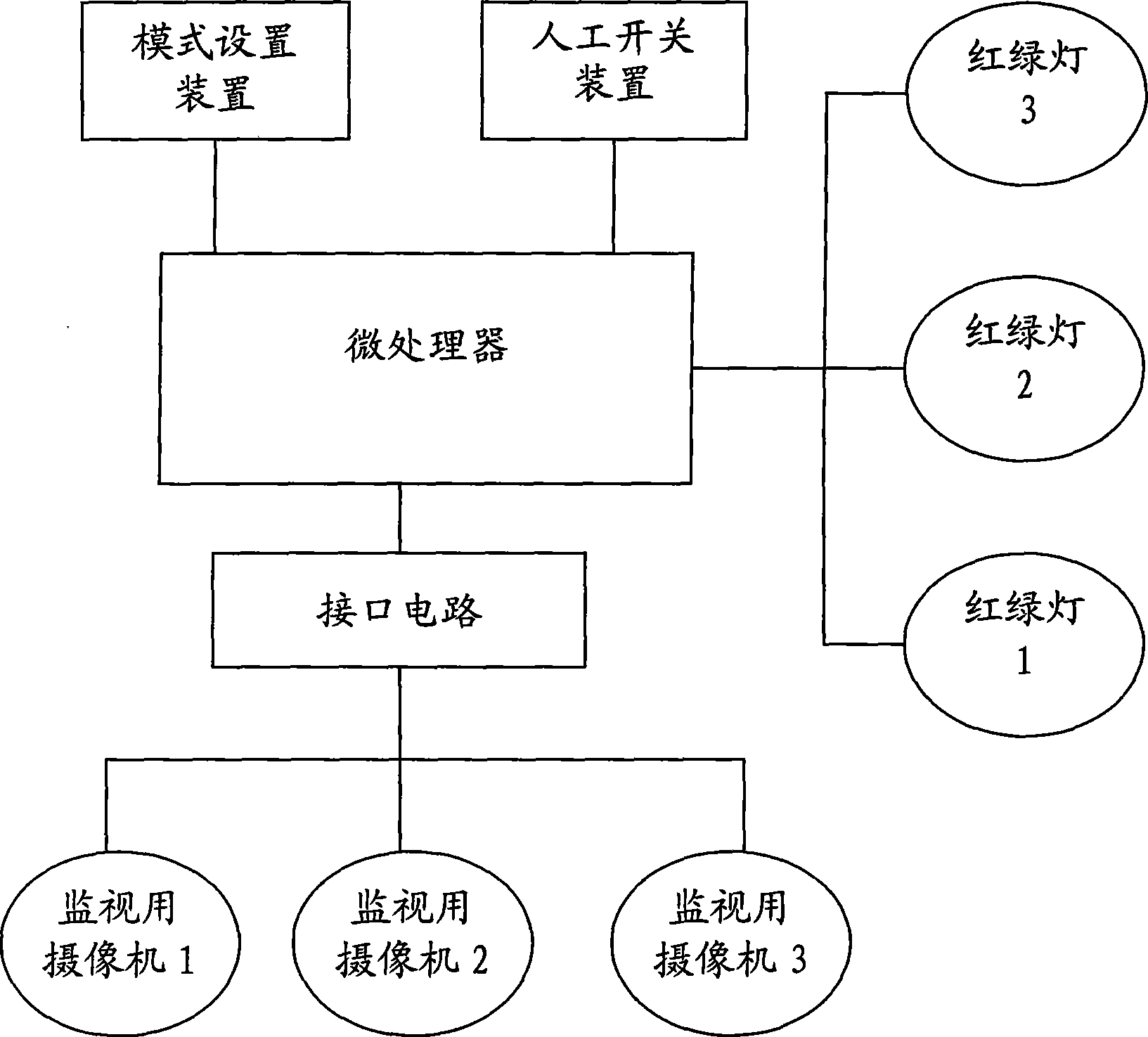

Traffic light control system suitable for intersection control

InactiveCN101472366AGuarantee unimpededSolve the problem of subjective judgment whether you can drive through the intersectionControlling traffic signalsPavement lightsTraffic signalEngineering

Owner:AOCHENGTONGLI S&T DEV BEIJING

Lock with striking-opening-resistant clutch

InactiveCN103835575AAvoid stagnation and instabilityPrevent unlockingNon-mechanical controlsEngineeringClutch

The invention relates to a lock with a striking-opening-resistant clutch. The lock comprises a lock shell, the clutch accommodated in the lock shell and a drive device. The drive device is located on the side of the clutch. The clutch comprises an inner clutching block and an outer clutching block, wherein the inner clutching block and the outer clutching block can rotate relative to each other. The clutch is further provided with a clutching pin capable of controlling the inner clutching block and the outer clutching block to be connected or disconnected. The lock is characterized in that the lock further comprises an intermediate transmission piece arranged between the clutching pin and an output shaft of the drive device and provided with an arc-shaped part. The intermediate transmission piece is connected with the output shaft of the drive device as well as the clutching pin. The output shaft of the drive device or the clutching pin is slidably connected to the intermediate transmission piece along the arc-shaped part of the intermediate transmission part.

Owner:GUANGDONG ARCHIE HARDWARE

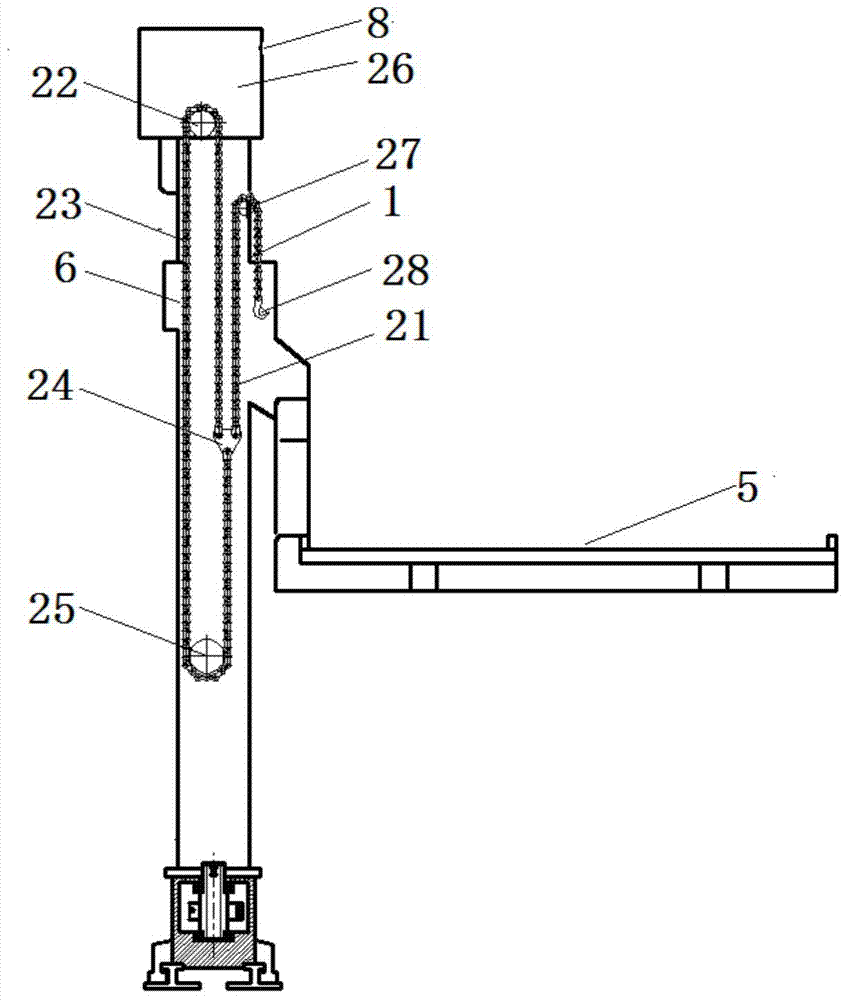

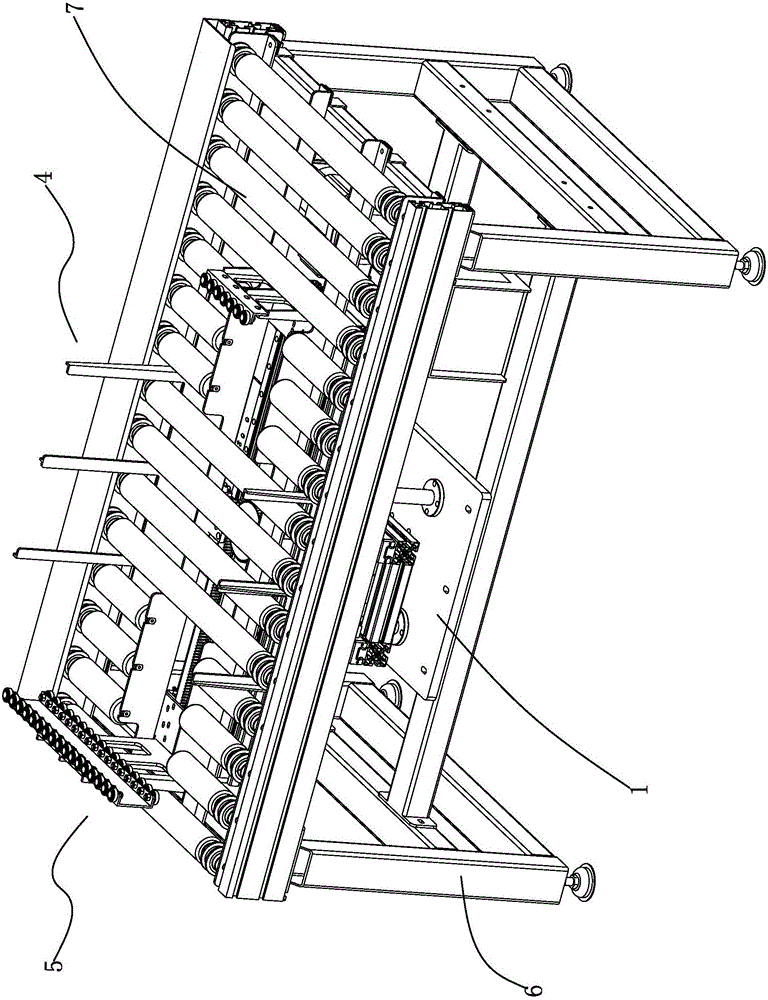

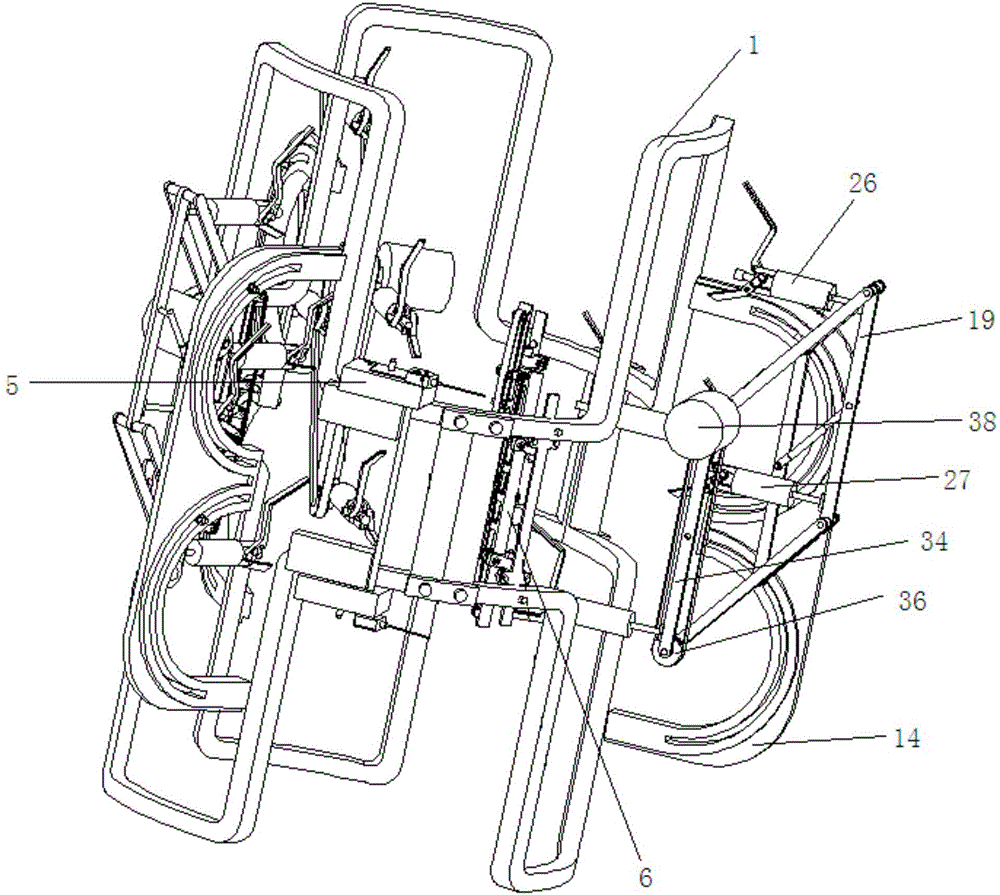

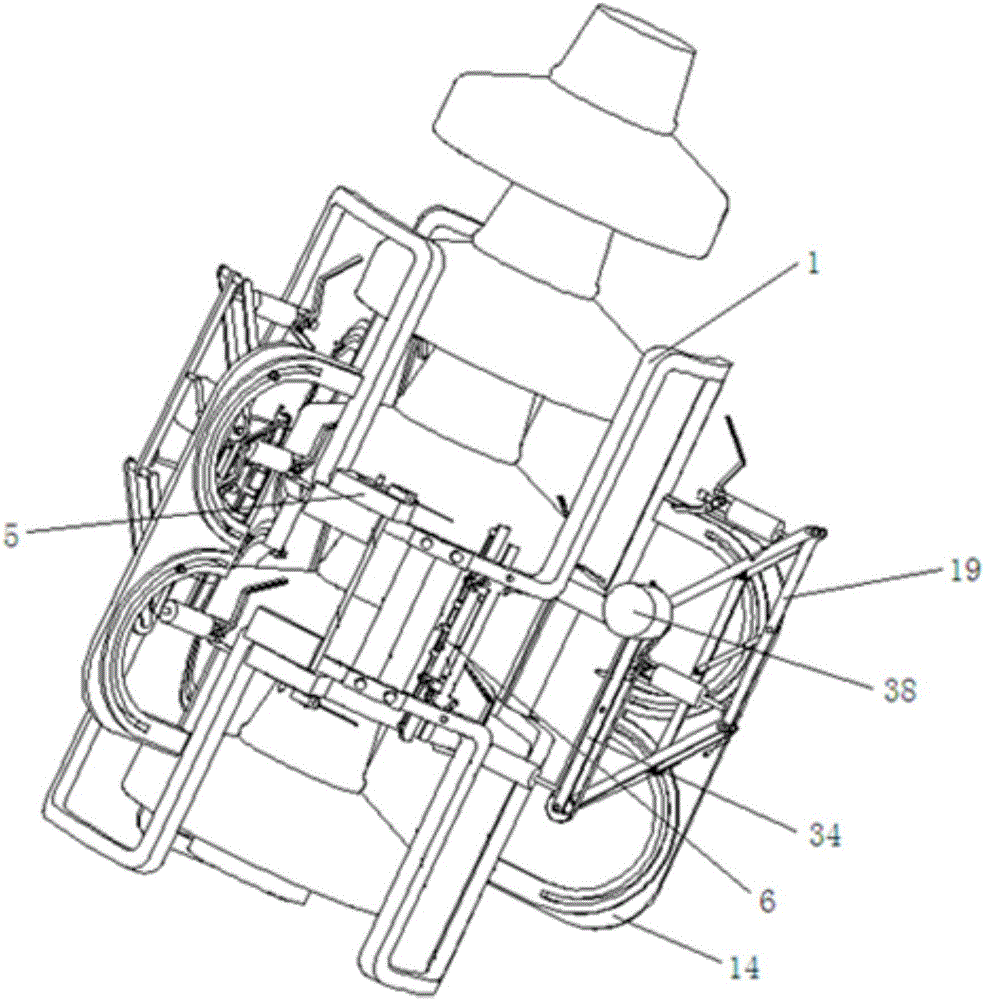

Avoidance needless type stereoscopic garage

InactiveCN103572996ASimple controlSimple transmission structureParkingsElectric machineryControl mode

The invention discloses an avoidance needless type stereoscopic garage. The avoidance needless type stereoscopic garage comprises an upright post, a vehicle carrying board, a track, a lifting device, a rotating device, a moving device and an anti-falling device, wherein the vehicle carrying board is mounted on the upright post and can be controlled by the lifting device to move up and down along the upright post; the upright post is mounted on the rotating device which can drive the upright post to rotate, and the rotating device is mounted on the moving device, a driving wheel and a guide wheel of the moving device are mounted on the track and drive the rotating device to move along the track horizontally; the anti-falling device is further arranged on the upright post; the lifting device adopts chain transmission for transmission, so that the transmission is stable; the rotating device adopts an incomplete gear mechanism for transmission, so that the installation space of the avoidance needless type stereoscopic garage is saved; and the anti-falling device adopts an anti-falling baffle which is arranged in a transverse sliding chute of the upright post, and the anti-falling safety performance is good. The avoidance needless type stereoscopic garage adopts three motors for independent control, the control mode is simple, further, the structure is simple, and maintenance and repairing are facilitated.

Owner:GUANGXI UNIV

Special feed for loach and preparation method of same

The invention discloses a special feed for a loach. The special feed for loach is a dragon beard-shaped or granular soft feed and is prepared from the following raw materials in mass percentage: 20-30% of flour, 10-25% of soybean meal, 15-25% of rapeseed meal, 3-7% of fishmeal, 10-15% of cottonseed meal, 5-8% of soybean protein powder, 1-2% of soybean oil, 1-3% of calcium dihydrogen phosphate, 1-3% of premix, 5-8% of corn protein powder and 5-8% of corn protein feed. The invention further discloses a preparation method of the special feed for loach. The special feed for loach is reasonable in compatibility; the feed form adapts to body features and life habits of loach; the special feed for loach is lower in nutrient loss rate than expanded granular feed and softer than hard granular feed; the special feed for loach can effectively avoid a phenomenon of throat blockage caused by swallowing the hard granular feed; the loss rate of high nutrition is low and the utilization ratio of the special feed for loach is improved; the special feed for loach can effectively promote the growth rate of loach; the preparation method is more reasonable in process design and simple in process; and the obtained special feed for loach has the advantages of long service life, low nutrition loss rate and the like.

Owner:陈忆凤

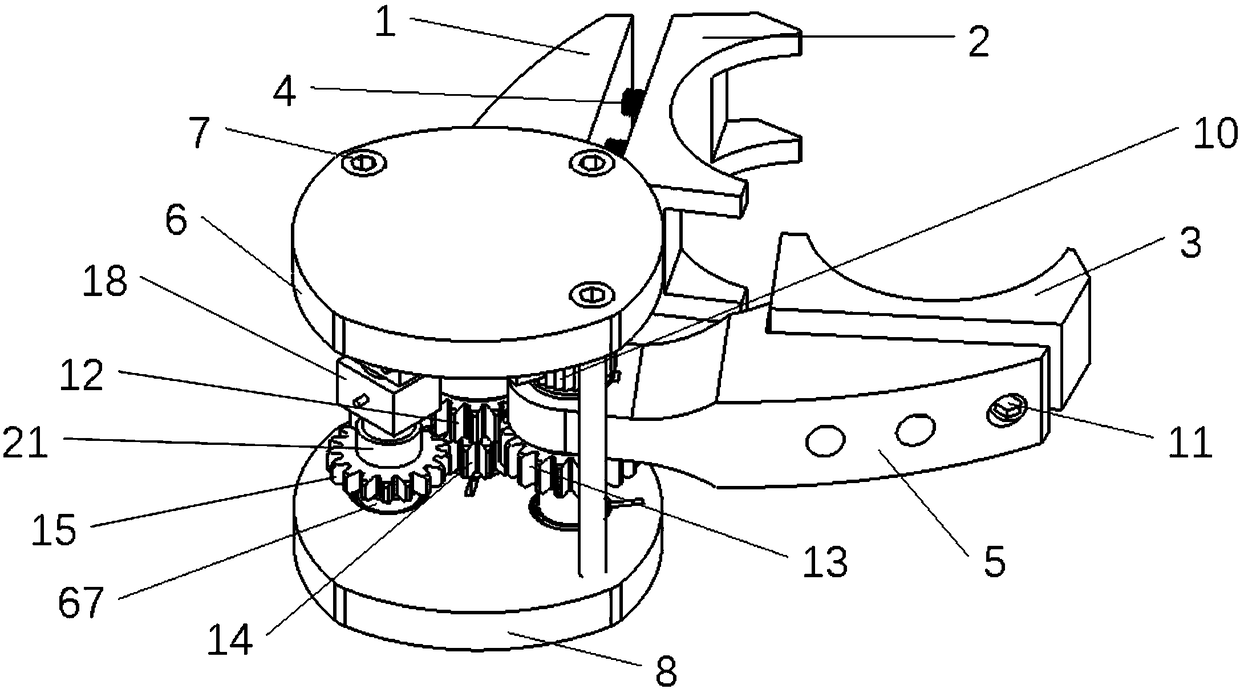

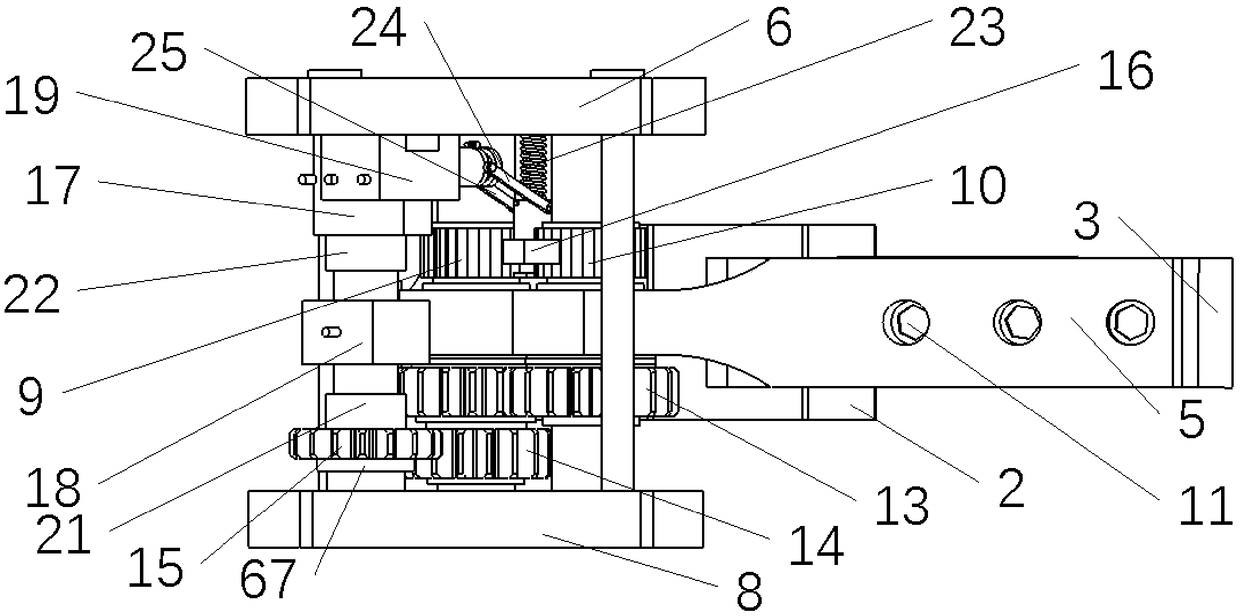

Redundancy self-locking type manipulator gripper with precisely controlled clamping force

ActiveCN108621188AImprove utilization efficiencyImprove safety and usabilityGripping headsTorque sensorManipulator

The invention relates to a redundancy self-locking type manipulator gripper with a precisely controlled clamping force. The redundancy self-locking type manipulator gripper comprises a hand claw, a transmission mechanism, a locking mechanism, a power mechanism and a power loop, wherein the transmission mechanism and the shaft of the hand claw are coaxially arranged; the locking mechanism and the shaft of the hand claw are coaxially arranged; the power mechanism is combined with the transmission mechanism and provides a driving force to the hand claw; the power loop is used for conducting the driving force; when the hand claw needs to stop action, the locking mechanism and a power lock in the power loop cooperate with each other to complete dual locking of the position and the clamping force of the manipulator gripper. The manipulator gripper is applicable to situations that the clamping force needs to be precisely controlled, in addition, after the driving force is released, a ratchetwheel lock is matched with a hand claw clamping force locking spring, so that the energy is saved, and a self-locking effect is improved. With the combination of a swinging motor, a proportional overflow valve and a torque sensor, precise control on an output clamping force is completed, and the energy utilization efficiency is remarkably improved.

Owner:YANSHAN UNIV

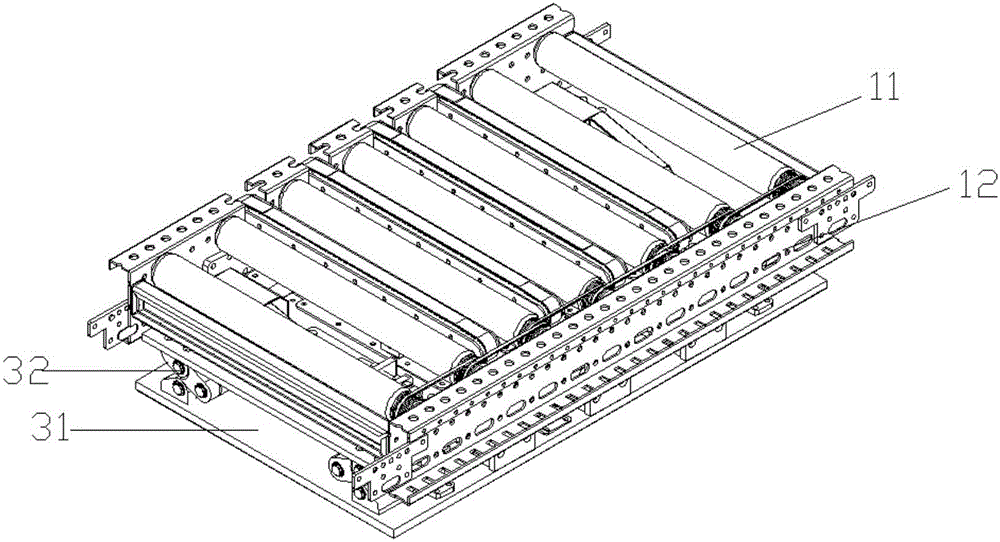

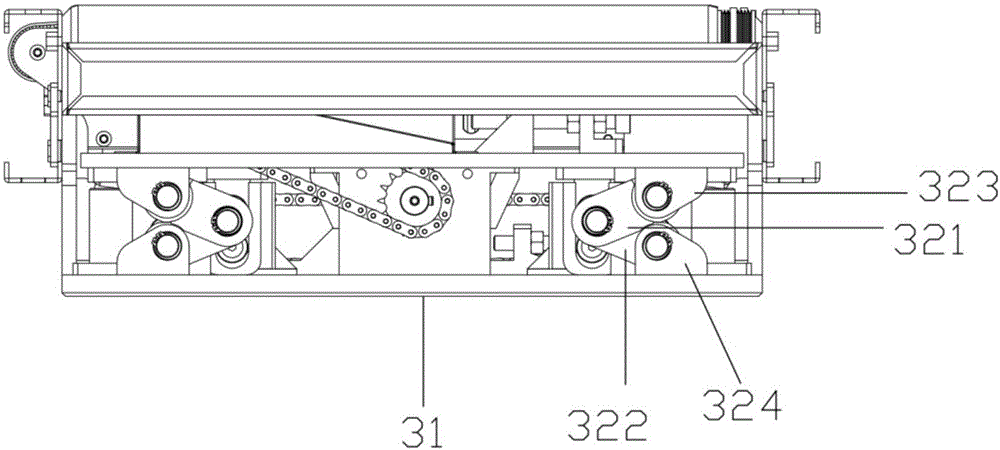

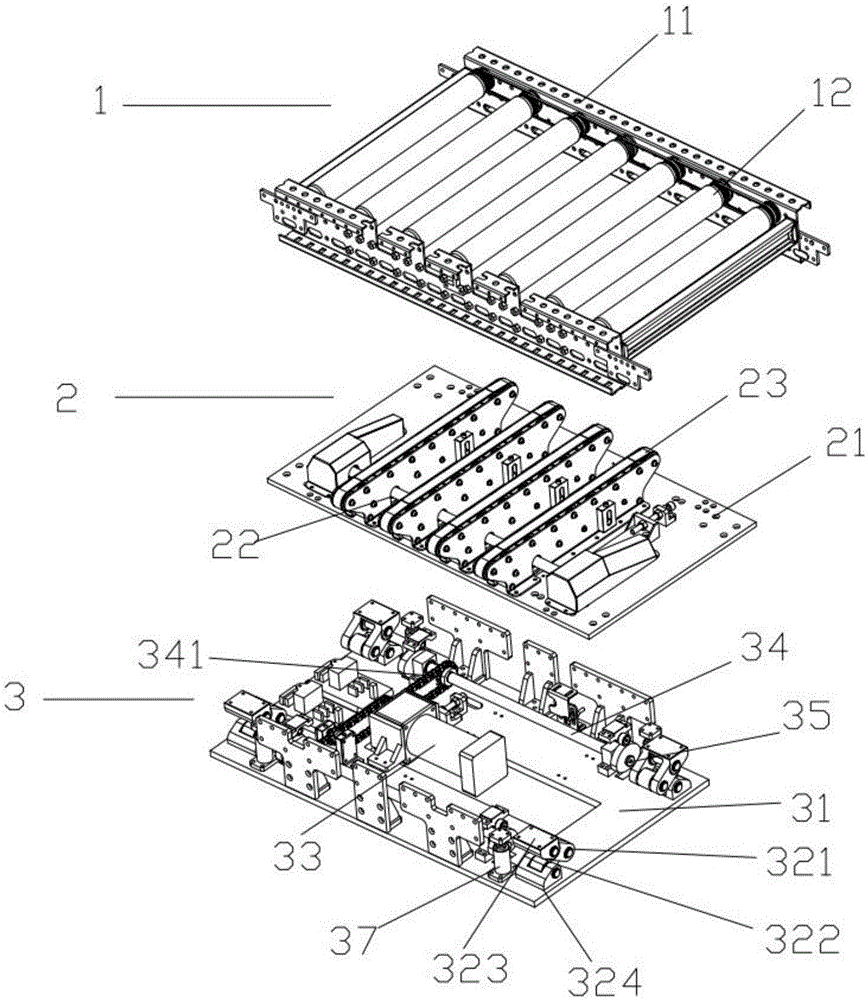

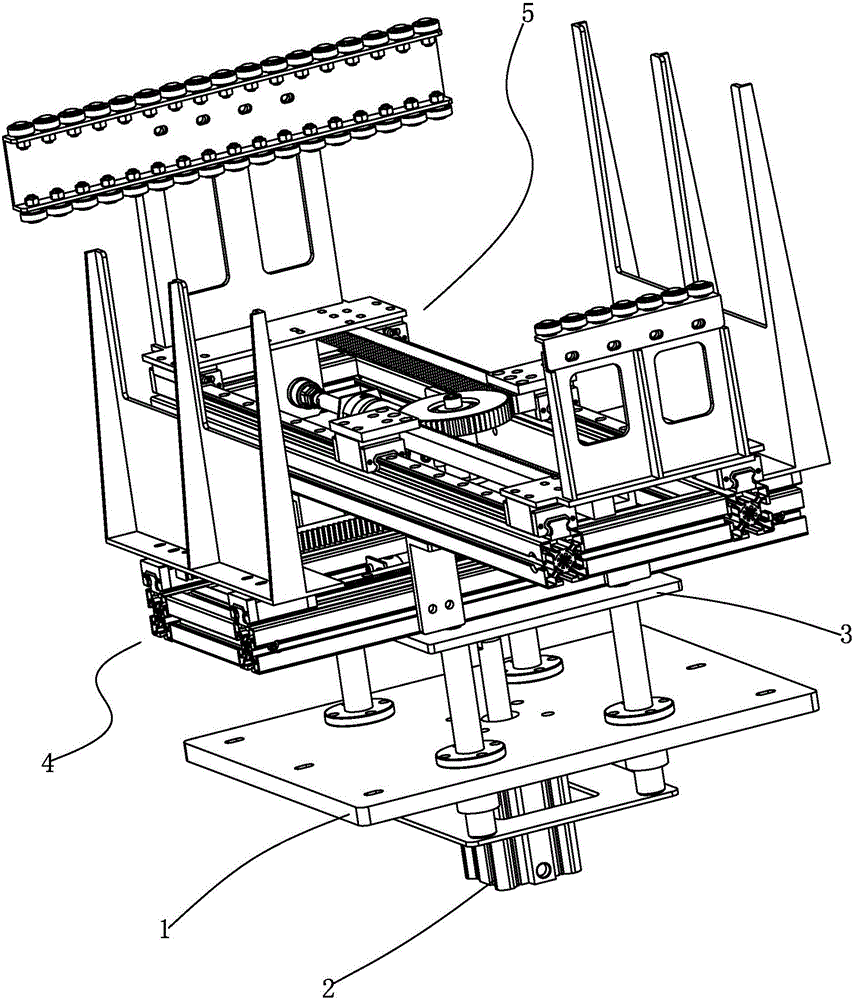

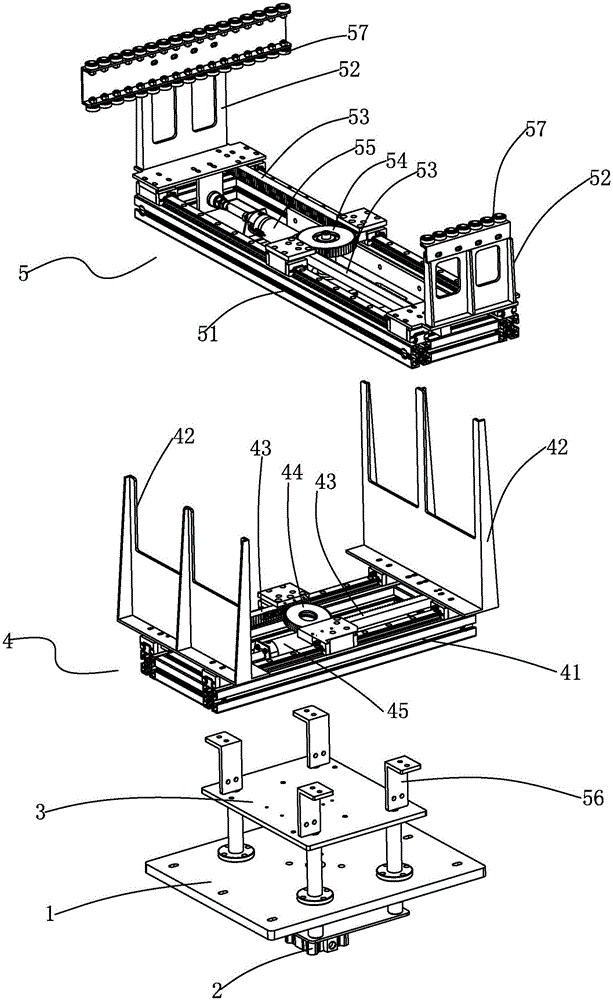

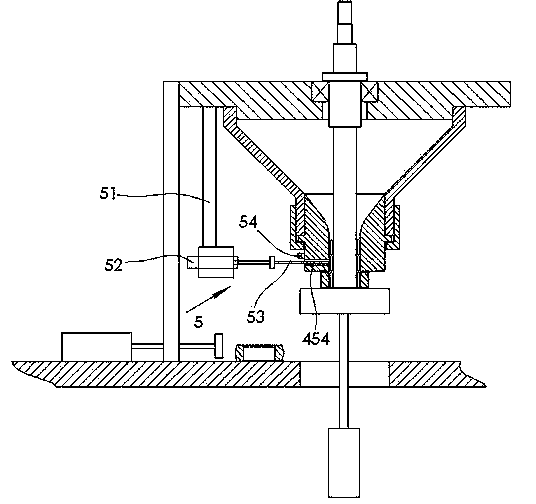

Jacking transplanting machine

The invention discloses a jacking transplanting machine. The jacking transplanting machine comprises a first conveying part, a second conveying part and a jacking part. The first conveying part is consistent with the direction of the main conveying line. The second conveying part intersects with the main conveying line. The jacking part comprises a base plate, four joint assemblies, a drive mechanism and a cam mechanism. The joint assemblies, the drive mechanism and the cam mechanism are all fixed to the base plate. The drive mechanism drives the cam mechanism to move so as to drive the second conveying part to rise and fall, and the relative height of cooperation of the first conveying part and the second conveying part is changed. The other ends of the joint assemblies are fixed to the second conveying part. The second conveying part rises and falls to drive the joint assemblies to be stretched out / drawn back. By means of the joint assemblies, supporting and limiting of a stop plate are achieved, the rolling and movable joint design is adopted, no stuck points exist, the horizontal consistency of the top plate in the rising and falling process is ensured, and the stuck phenomenon is avoided. The number of electronic components is small, the fault rate is low, and maintenance and installation are convenient.

Owner:JIANGSU HUAZHANG LOGISTICS TECH CO LTD

Intelligent lock and lock/unlock method thereof

ActiveCN1920230AAvoid failureAvoid deadlockNon-mechanical controlsElectric permutation locksEngineeringElectromagnet

The invention relates to an intelligent door lock used in outdoor box, and relative locking and unlocking method, wherein said door lock comprises a rotational handle, a read head, a lock pin element and a locking plate; said lock pin element comprises bottom plate, circuit board, driving device, locking pin, lever, button, and pin; said pin is matched to the pin hole of locking plate; the read head is connected to the key to power; the driving device drives the locking pin to lock and release the lever; the button will rotate the lever when the locking pin releases the lever, and the lever will drive the pin to leave the pin hole of locking plate; the motion of lock pin element is powered by key, to avoid failure of power resource or dead lock of circuit board; the driving device is electromagnetic magnet and the locking pin is the movable iron core of electromagnetic magnet, to avoid limiting the movable iron core, when moving; and the lever pin will not be clamped. The invention has simple structure and high reliability.

Owner:SUS TELECOMM +1

Hexagonal flange type nut conveyor

InactiveCN102152944AAvoid stuck phenomenonAvoid stickingJigging conveyorsConveyor partsEngineeringDistributor

The invention discloses a hexagonal flange type nut conveyor which belongs to the technical field of automobiles and is used for improving the projection welding efficiency. The technical scheme is as follows: the hexagonal flange type nut conveyor comprises a base and a hopper, a vibration plate, a profiling pipe and a distributor which are mounted on the base, wherein a discharge port of the hopper is positioned above the vibration plate; the distributor is positioned below the lateral part of the vibration plate, and a feed inlet of the distributor is connected with a discharge port of thevibration plate through the profiling pipe; the discharge port is connected with a nut conveying gun through a nut conveying pipe; the sectional shape of the pipe cavity of the profiling pipe is matched with the axial section of the hexagonal flange type nut; and the profiling pipe and the hexagonal flange type nut are in clearance fit. According to the invention, the hexagonal flange type nut isconveyed to the distributor from the vibration plate by the profiling pipe; and as the sectional shape of the pipe cavity of the profiling pipe is matched with the axial section of the hexagonal flange type nut, nuts can not be overlapped in the profiling pipe, thereby effectively avoiding the clamping stagnation, and greatly improving the working efficiency of projection welding of nuts.

Owner:GREAT WALL MOTOR CO LTD

Tech. for forging forming of hook fastener flame of wagon and maould thereof

InactiveCN1792544AShorten the lengthSave materialForging/hammering/pressing machinesOther manufacturing equipments/toolsTruckRailway freight car

A technology for manufacturing the coupler tail frame of cargo train by forging includes such steps as blanking, heating, making raw coupler tail frame, die forging step by step, that is, forging one end and then another end, removing excessive edge, bending an welding. Its die set is composed of upper die with internal cavity whose length is equal to that of finished blank, and lower die with internal cavity having a central locating pit.

Owner:CHONGQING UNIV OF TECH

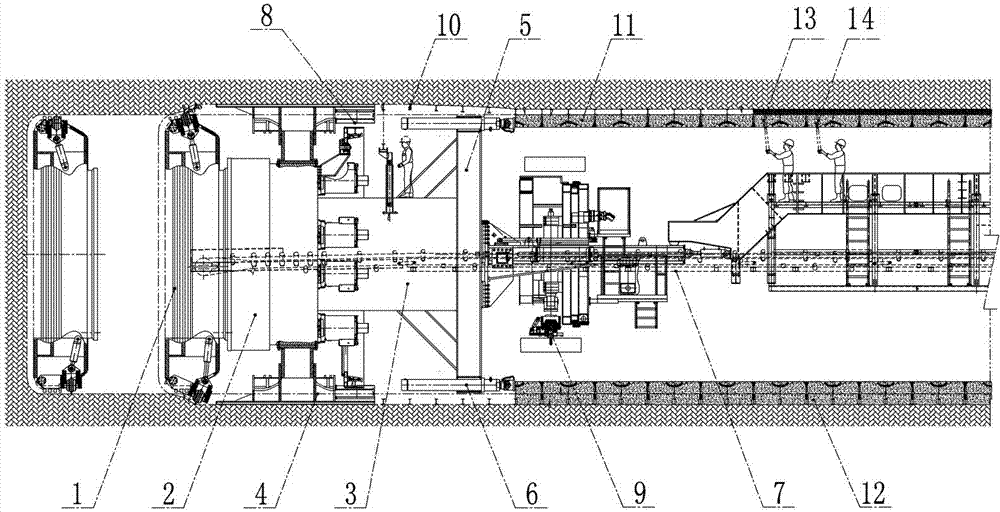

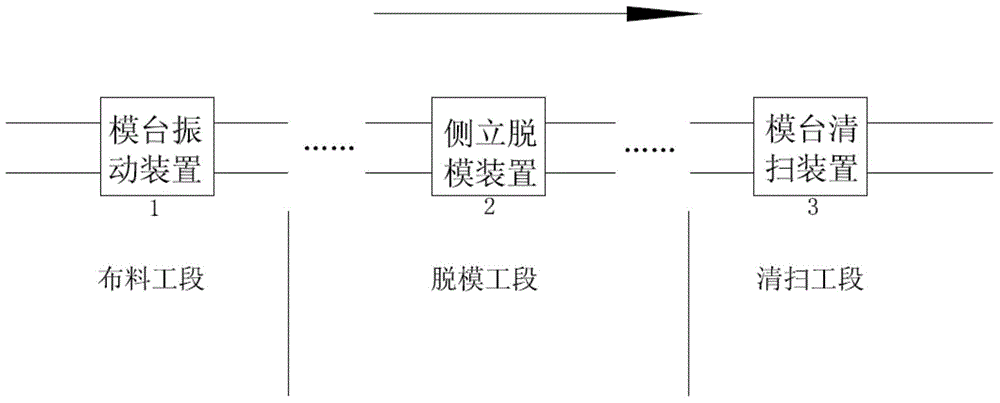

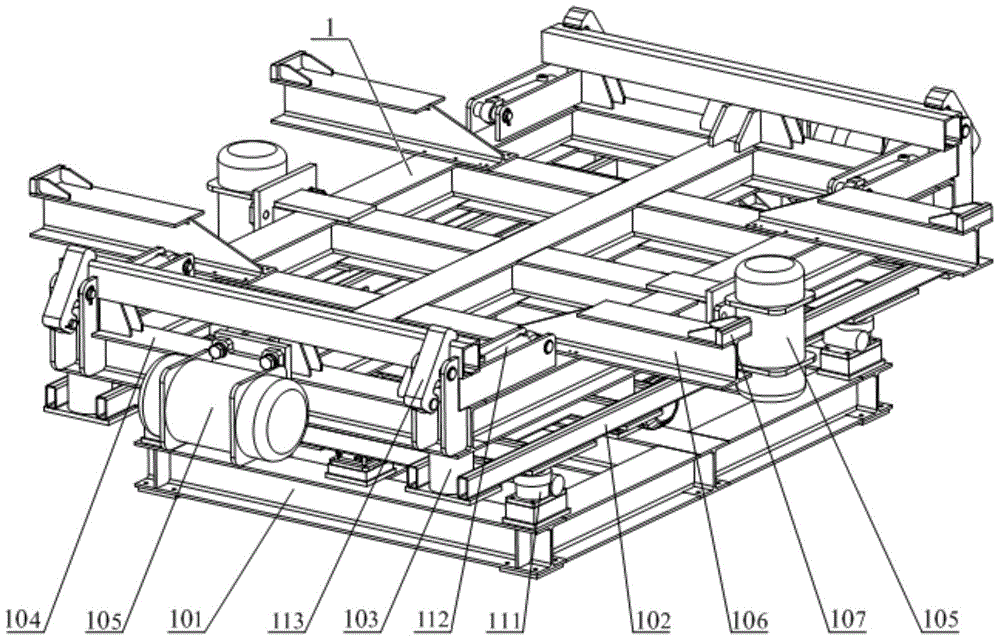

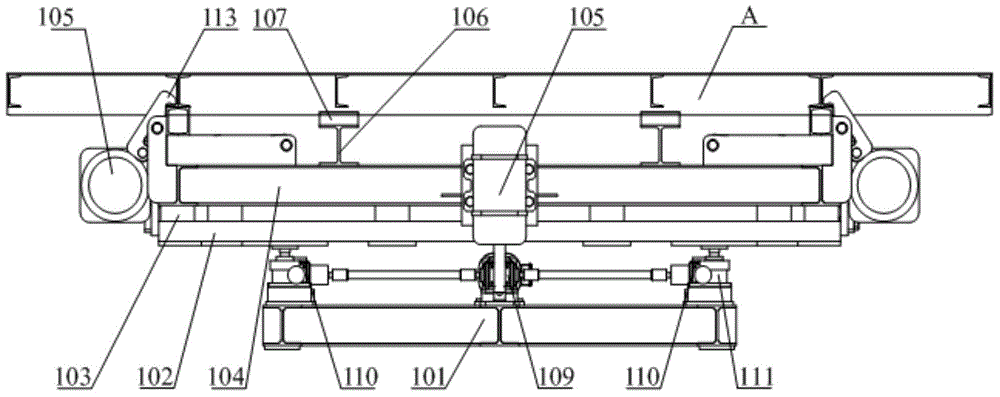

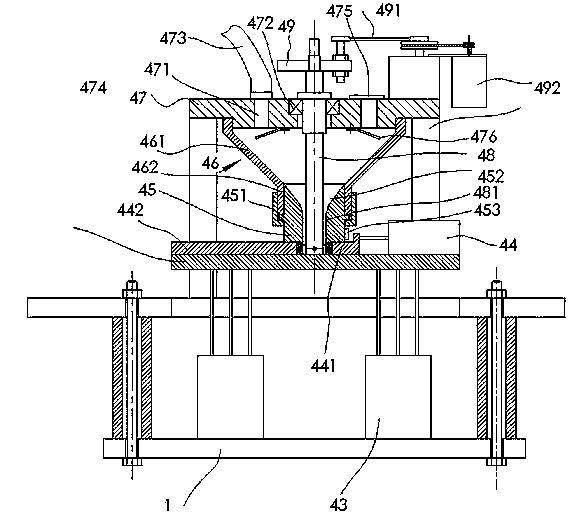

Novel production line of concrete precast plate

ActiveCN104476666AAvoids situations where the rollers of the travel system cannot be accurately dropped backSimple structureDischarging arrangementCeramic shaping plantsProduction lineIndustrial engineering

The invention discloses a novel production line of a concrete precast plate. The novel production line of the concrete precast plate comprises a material distributing section, a demoulding section, and a cleaning section, the material distributing section is provided with a platform vibration device, the demoulding section is provided with an edge-on demoulding device, the cleaning section is provided with a platform cleaning device, a lifting device of the platform vibration device is synchronously lifted by a lead screw elevator, the technology is mature and the reliability is high. In addition, a support lifting part is arranged at the lower part, a vibration holding positioning part is arranged at the upper part, and the middle part is connected by an elastic device, the parts are not intervened mutually, and the graduation is clear. The cleaning efficiency of the platform cleaning device is high, the platform vibration device and the platform cleaning device are provided with position detecting devices suitable for various layouts of the production line, and the practicability is strong. The edge-on demoulding device is provided with an assistant demoulding device, the positioning precision is high, and the demoulding efficiency is higher.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

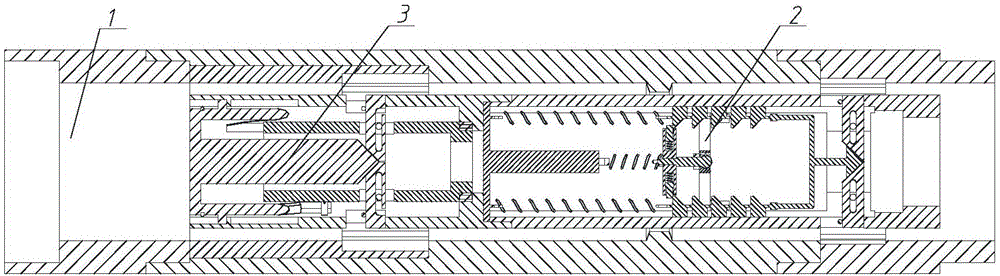

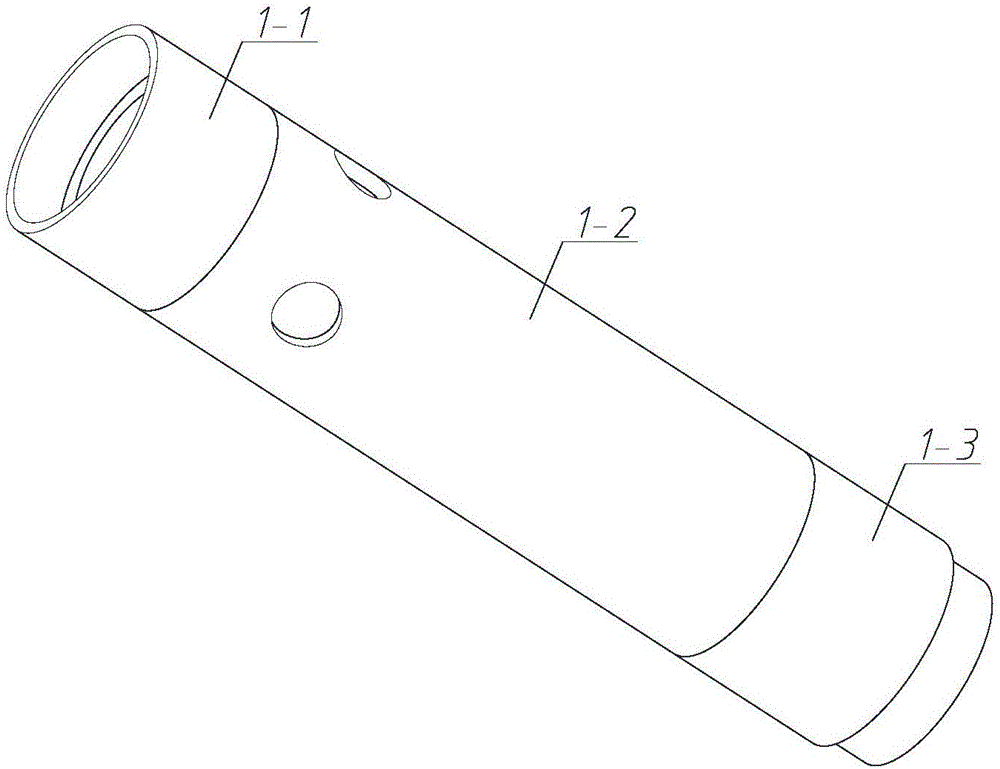

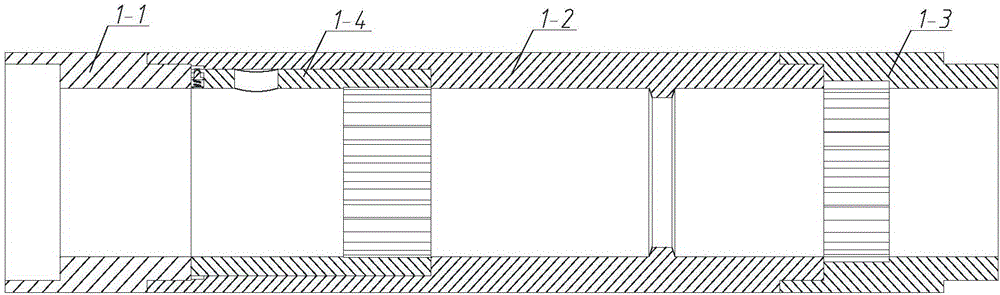

Downhole full-bore infinite sliding-pin slide bushing switch

ActiveCN106761640AAvoid wear and tearEasy to replaceFluid removalWell/borehole valve arrangementsMechanical engineeringEngineering

The invention discloses a downhole full-bore infinite sliding-pin slide bushing switch and solves the problems of inconvenience in maintenance and the like due to the fact that the conventional fracturing slide bushing needs to be wholly lowered into downhole. The downhole full-bore infinite sliding-pin slide bushing switch specifically comprises a main slide bushing body and a tenon block mechanism, wherein the tenon block mechanism comprises a tenon block recognition mechanism and a tenon block switch mechanism, during use, the main slide bushing body is lowered into the downhole, and the tenon block mechanism is lowered for recognizing a fracture layer when a fracture channel needs to be opened or closed. The slide bushing switch has high recognition degree for different fracture layers, parts are convenient and simple to replace and maintain, and the working stability and accuracy are enhanced greatly.

Owner:黑龙江赛恩思科技信息咨询服务有限公司

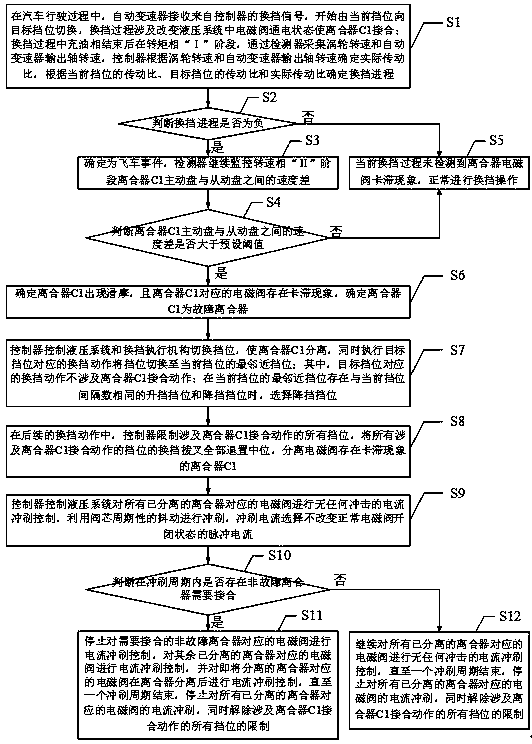

Clutch solenoid valve clamping stagnation monitoring and protecting method and device in gear shifting process

The invention discloses a clutch solenoid valve clamping stagnation monitoring and protecting method and device in the gear shifting process. According to the clutch solenoid valve clamping stagnationmonitoring and protecting method and device in the gear shifting process, through galloping detection in the gear shifting process, a clutch which possibly break down can be positioned in advance, whether a solenoid valve corresponding to the clutch is clamped and stagnated or not can be accurately judged in combination with clutch sliding friction detection, and meanwhile, gear limiting drivingis carried out according to a fault gear, driving safety can be guaranteed, clutch abrasion aggravation is prevented, impact-current-free scouring control is carried out on the clamped and stagnated solenoid valve, and the clamping stagnation phenomenon can be effectively avoided. Compared with an existing monitoring and protecting method, the strategy for positioning the fault clutch and judgingsolenoid valve clamping stagnation more accurately and the method for solving solenoid valve clamping stagnation more quickly are provided, the fault clutch in the gear shifting process can be detected and positioned, and meanwhile, the clamped and stagnated solenoid valve is effectively prevented and treated.

Owner:SHENGRUI TRANSMISSION

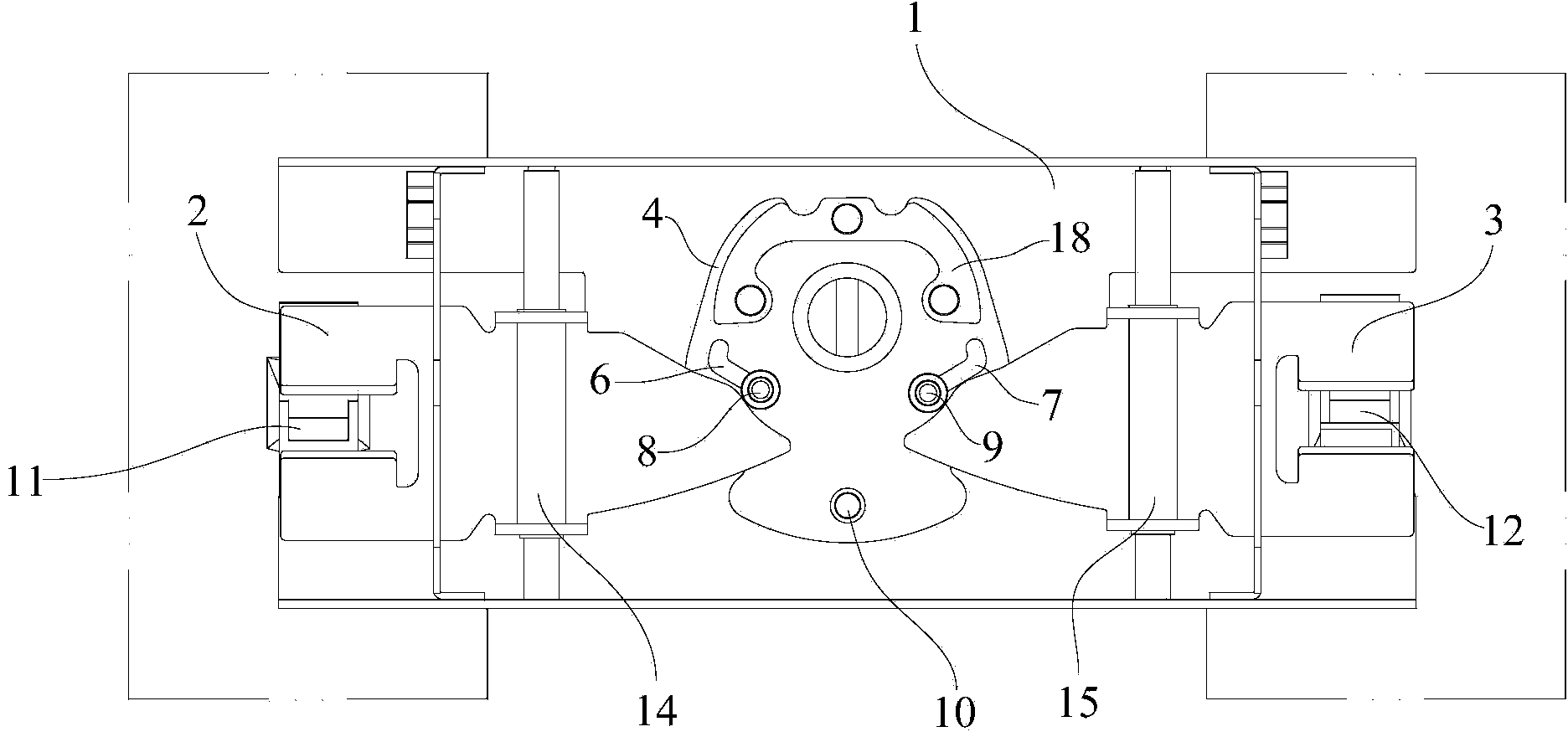

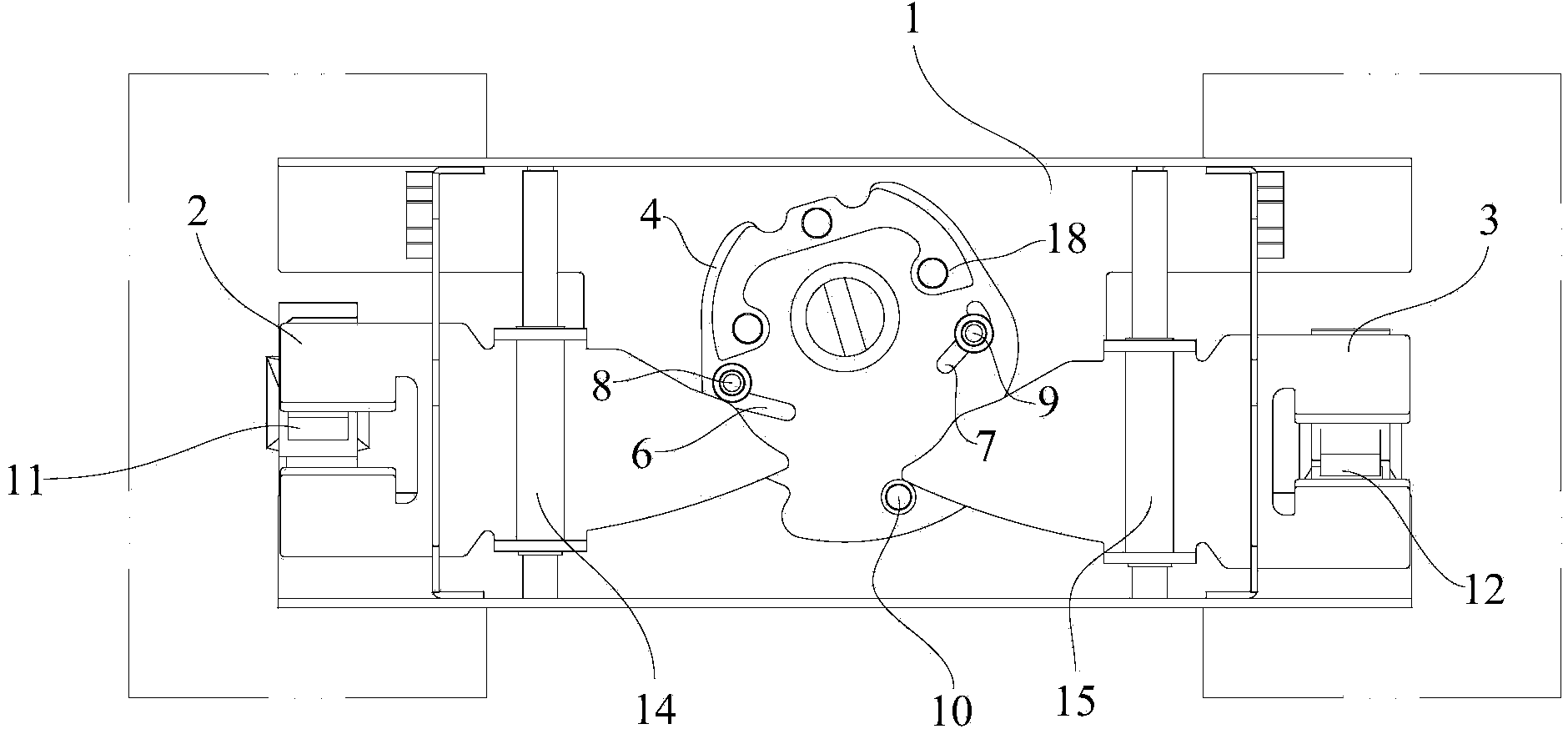

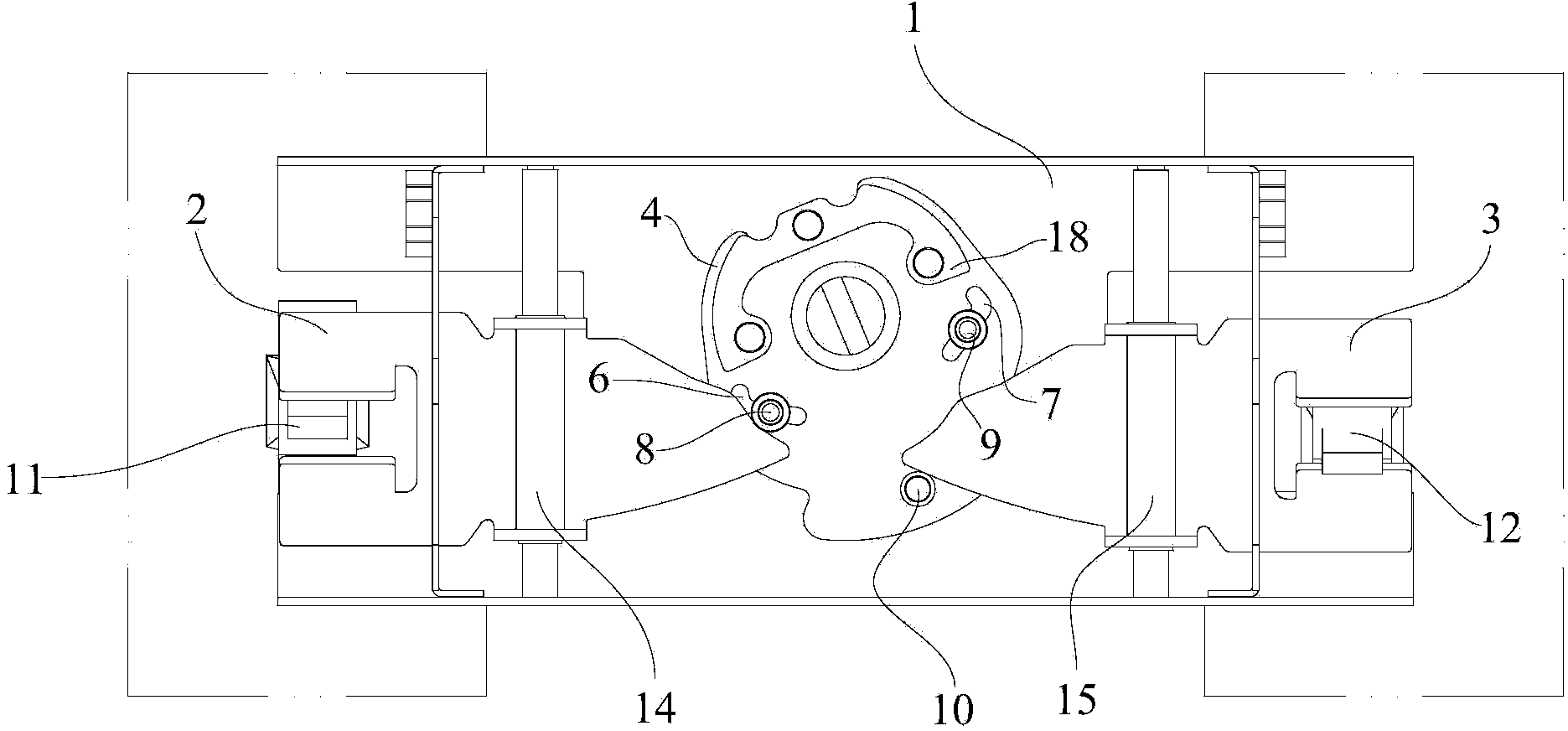

Transmission mechanism of dual power automatic transfer switch

ActiveCN104036986AAvoid stuck phenomenonSimple structureContact driving mechanismsEmergency power supply arrangementsPower switchingTransfer switch

Disclosed is a transmission mechanism of a dual power automatic transfer switch. The transmission mechanism of the dual power automatic transfer switch comprises a motor, a mounting seat, a first power switching slide block, a second power switching slide block, a rotation disc, a first toggle pillar, a second toggle pillar and a provoking pillar 10. The transmission mechanism is rotated by using power provided by the motor, and then drives the rotation disc to rotate. The first toggle pillar, the second toggle pillar and the provoking pillar 10, which are located in the rotation disc, are respectively matched with arc surfaces of the first power switching slide block and the second power switching slide block, enable the first power switching slide block and the second power switching slide block to move up and down, and drive handles of circuit interrupters to close or open upwards and downwards, and finally automatic switchover between a normal power source and an emergency power source is achieved. The transmission mechanism of the dual power automatic transfer switch is simple in structure, and smooth and steady in switching, can guarantee that only one of the two circuit interrupters is located in a close position by firstly cutting off one of the two power sources and secondly switching on the other power source, and provides reliability of the dual power switchover.

Owner:南京朗熙环保科技有限公司

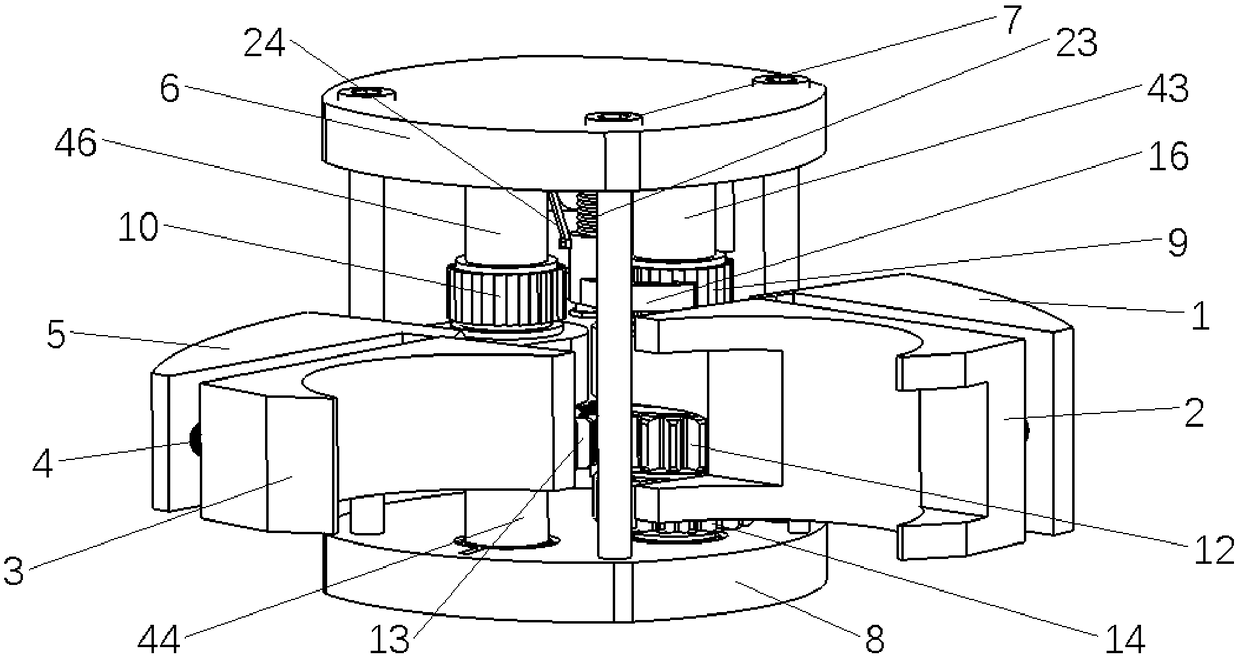

Center positioning device

ActiveCN106112427AHigh positioning accuracy and stabilityGuaranteed smooth assemblyMetal working apparatusEngineering

Owner:GUANGDONG HANDSOME INTELLIGENT EQUIP CO LTD

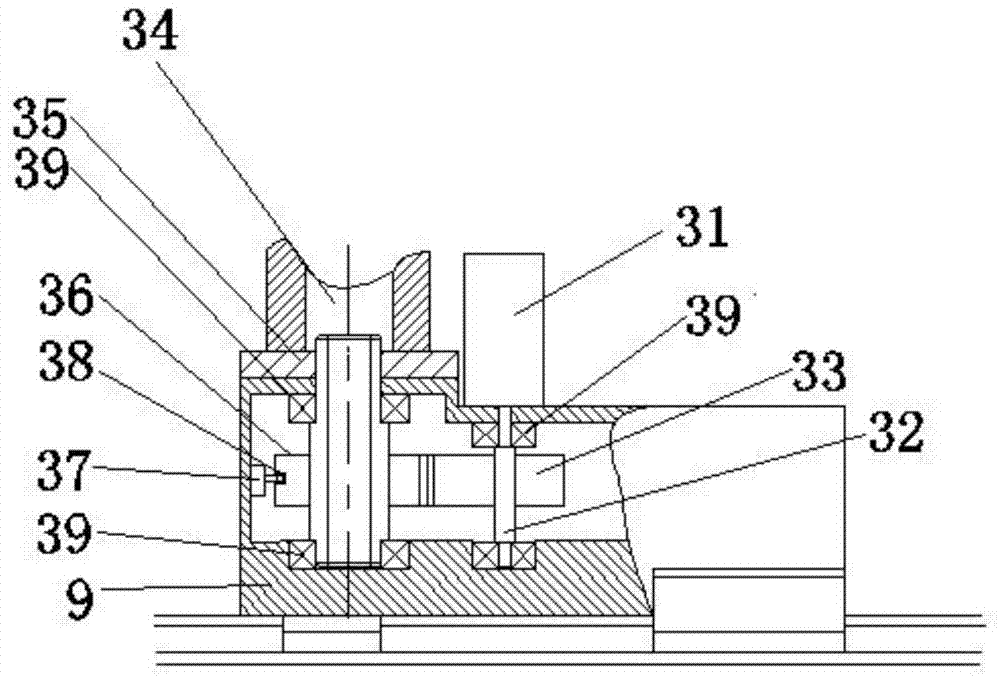

Anti-falling device of stereo garage

InactiveCN103573000APrevent damage to partsImprove securityParkingsEngineeringMechanical engineering

The invention discloses an anti-falling device of a stereo garage. The anti-falling device comprises a transverse chute in an upright post as well as an anti-falling baffle capable of sliding in the chute, wherein a limit groove is formed in the anti-falling baffle; a limit pin matched with the limit groove is arranged in the chute; a free end of the anti-falling baffle extends out of the upright post, a connecting end is hinged to one end of an ejector rod, and the other end of the ejector rod penetrates into a sleeve and is connected with a compression spring mounted in the sleeve; and the tail end of the sleeve is fixedly connected with an electromagnet. According to the anti-falling device, the anti-falling baffle is arranged in the chute of the upright post, so that when a car loading board falls accidentally, stressed pressure or impact of parts which are directly connected or contacted with the anti-falling baffle is reduced, the parts which are directly connected or contacted with the anti-falling baffle are effectively prevented from damage, and the security during accidental falling of the car loading board is improved; and when the car loading board is lifted or dropped, the ejector rod only receives small radial force action and is not prone to bending deformation, and a deadlocking phenomenon due to bending deformation of the ejector rod is avoided.

Owner:GUANGXI UNIV

Pin-forming mold for integrated circuits

The invention belongs to the field of press-forming integrated circuits and particularly relates to a pin-forming mold for DIP (Dual Inline Package) / IDF (Intermediate Distributing Frame) package integrated circuits. The mold comprises a fixing device which is used for holding down a product to be formed and pins of the product; conjugate roller wheel devices which are used for enabling pins to be formed are respectively arranged at two sides of the fixing device; and a taper wedge device which is used for guiding the conjugate roller wheel device to work is arranged at one side of each of the conjugate roller wheel devices far away from the fixing device. The mold is made from a pair of conjugate roller wheels, i.e. main roller wheels and auxiliary roller wheels, which can swing; when the pins are formed, the main roller wheels and the auxiliary roller wheels generate conjugate movement, i.e. the main roller wheels and the auxiliary roller wheels mutually rotate in opposite directions so as to ensure that the pins of the product are formed by means of pure rolling, thus the quality of the product can be greatly improved; and meanwhile, the phenomenon of clamping stagnation generated between a mandrel and roller wheels in a single-roller wheel forming manner can be avoided.

Owner:TONGLING SANJIA YAMADA TECH

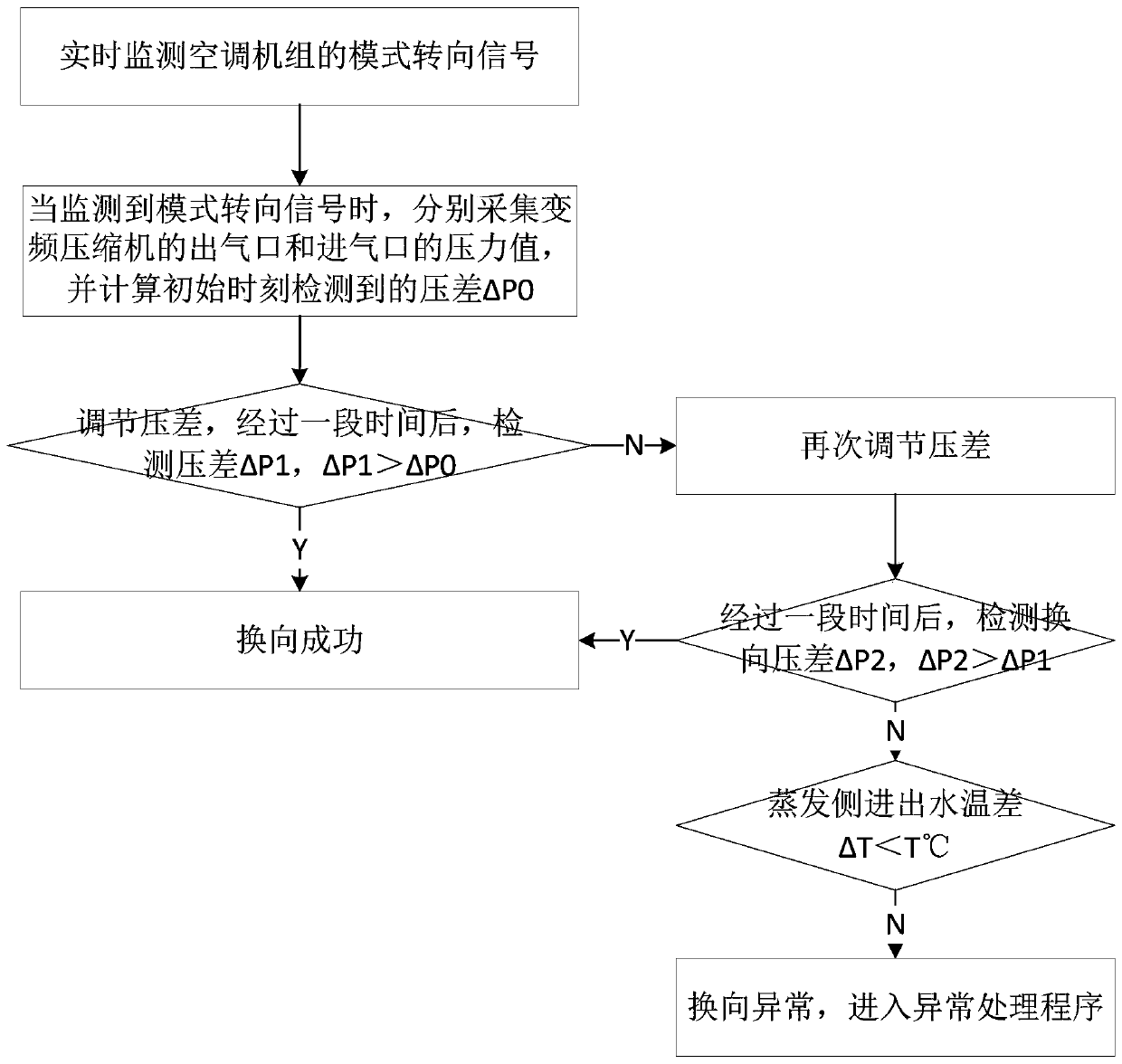

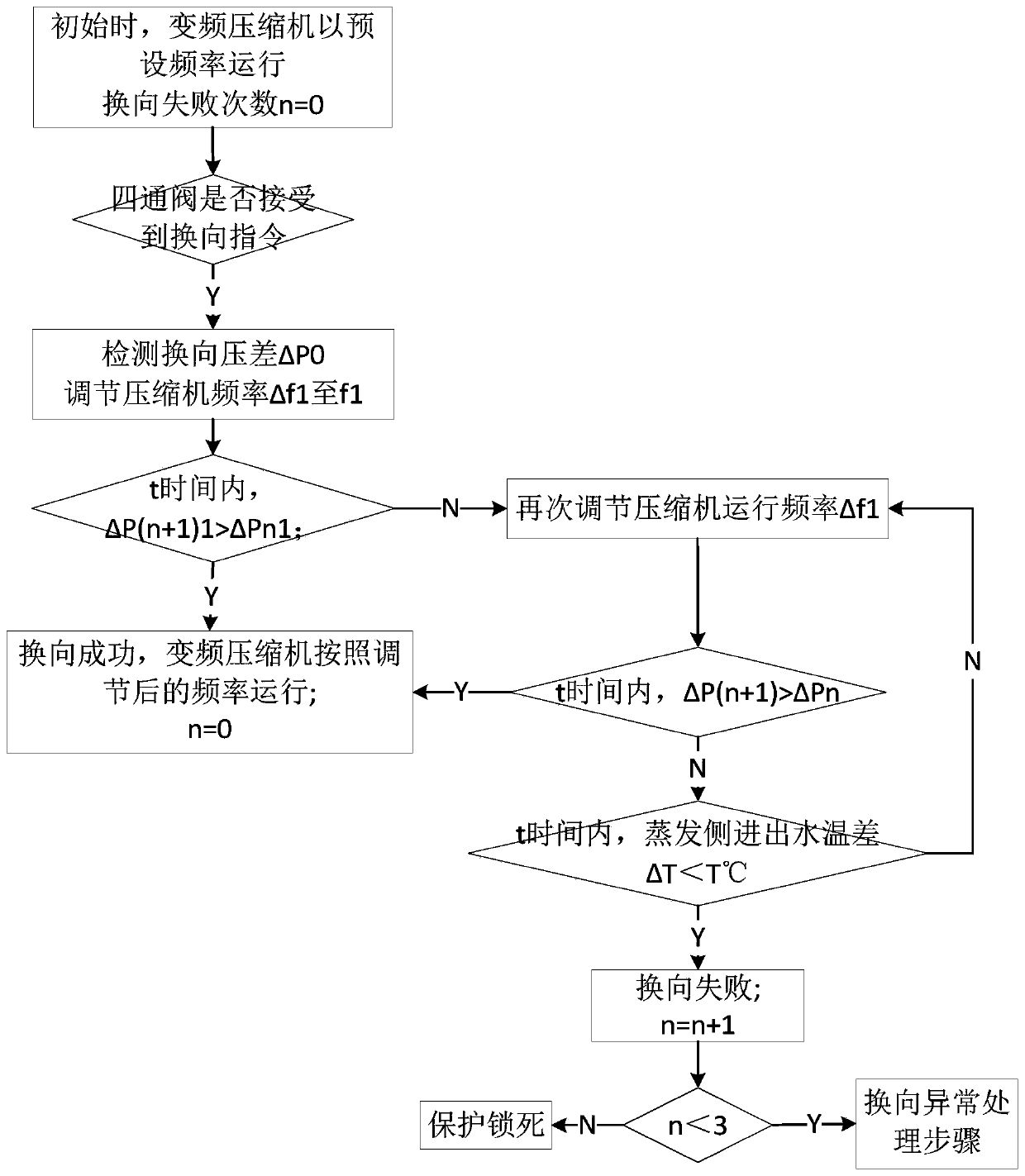

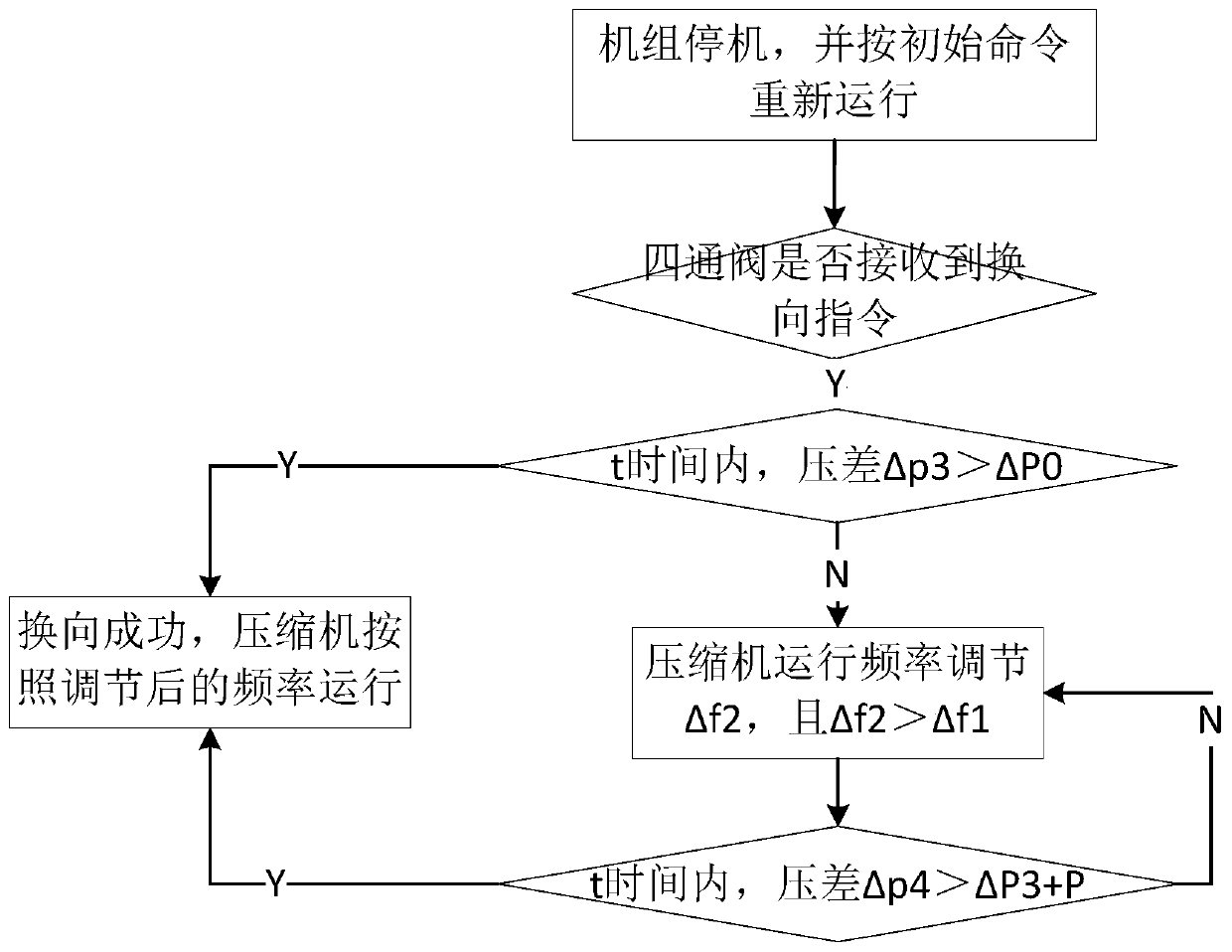

Four-way valve reversing monitoring method and device, and air conditioning system

ActiveCN110411057AAvoid stuck phenomenonGuaranteed reliabilityMechanical apparatusSpace heating and ventilation safety systemsFour-way valveFrequency conversion

The invention discloses a four-way valve reversing monitoring method and device, and an air conditioning system. The monitoring method comprises the steps of controlling the reversing of a four-way valve and monitoring mode conversion signals of an air conditioning unit in real time when the refrigeration mode or heating mode of an air conditioning unit is switched; acquiring the pressure difference between an air outlet and an air inlet of a frequency conversion compressor when the mode conversion signals are detected; and changing the frequency of the frequency conversion compressor and regulating the pressure difference, and judging whether the reversing of the four-way valve succeeds or not through comparison between the pressure difference detected in this time and the pressure difference detected in the last time. According to the monitoring method, through real-time control in the reversing process of the four-way valve, real-time regulation of the operating frequency of the compressor is achieved through a unit according to the reversing time and the reversing pressure difference of the four-way valve, so that the pressure difference change of the air conditioning unit is controlled effectively, and the reversing reliability of the four-way reversing valve is ensured effectively.

Owner:GREE ELECTRIC APPLIANCES INC

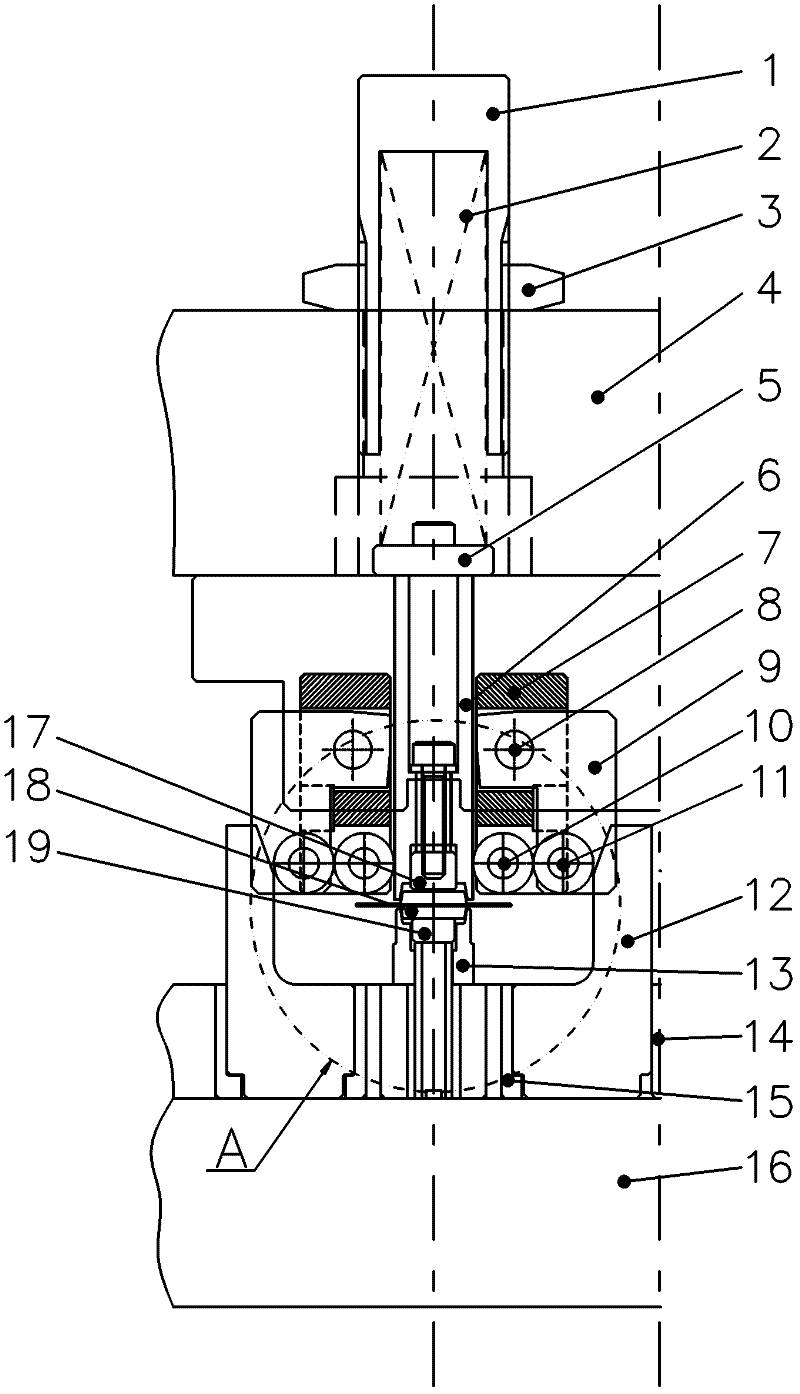

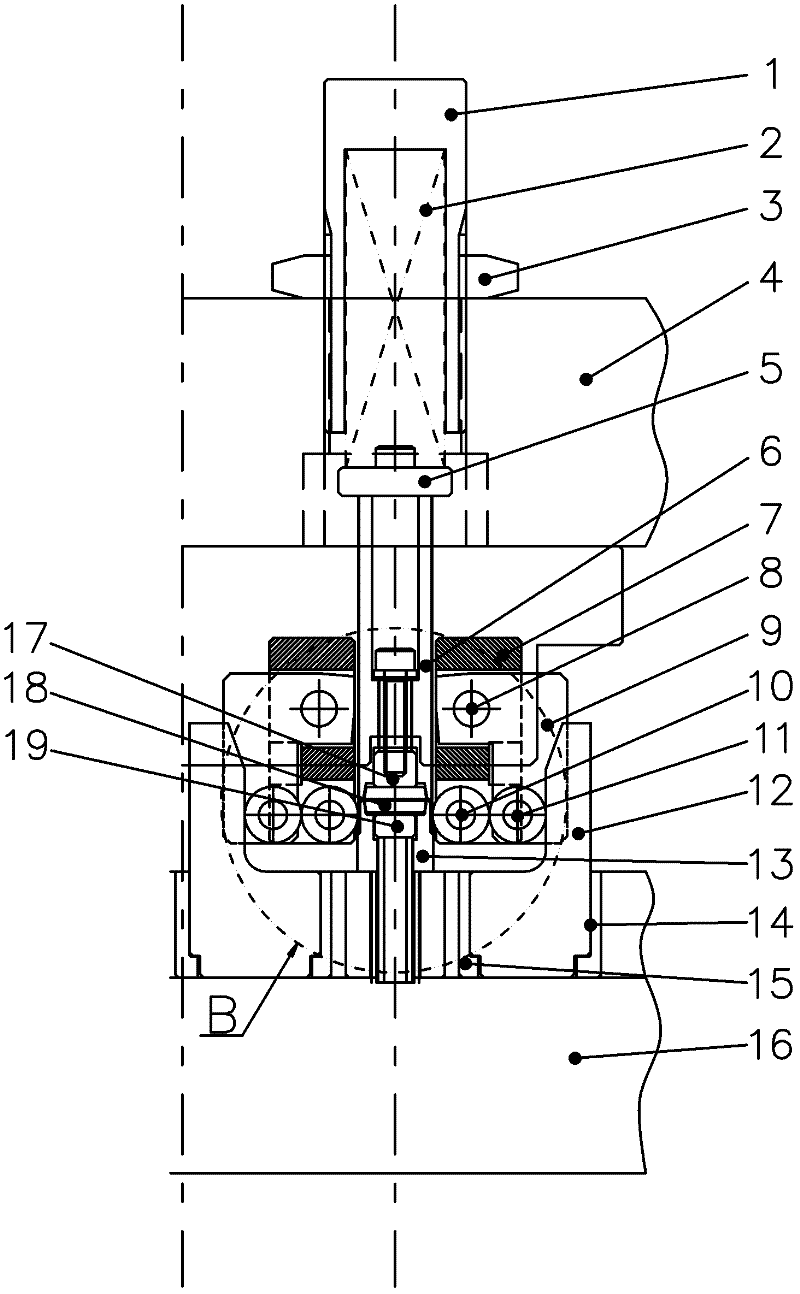

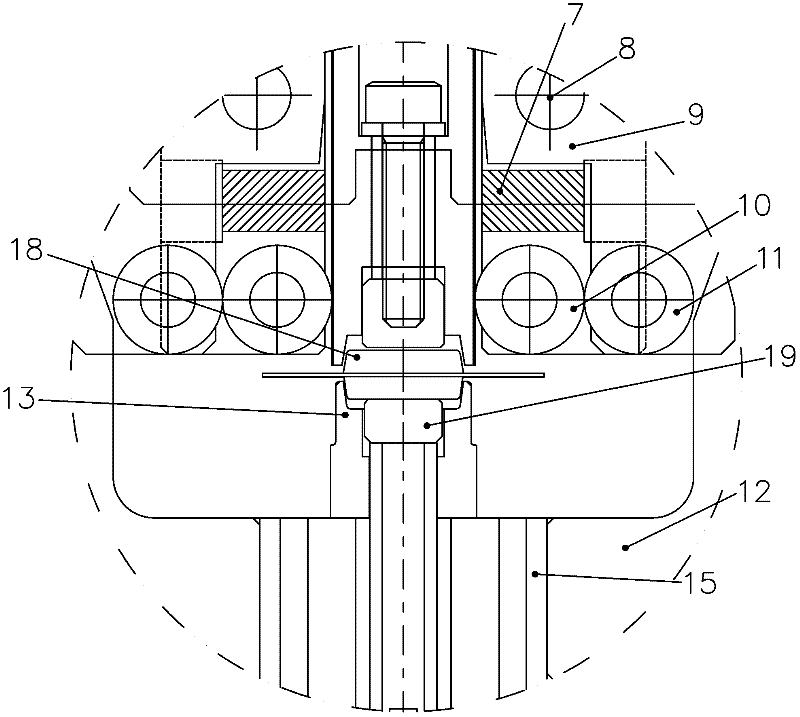

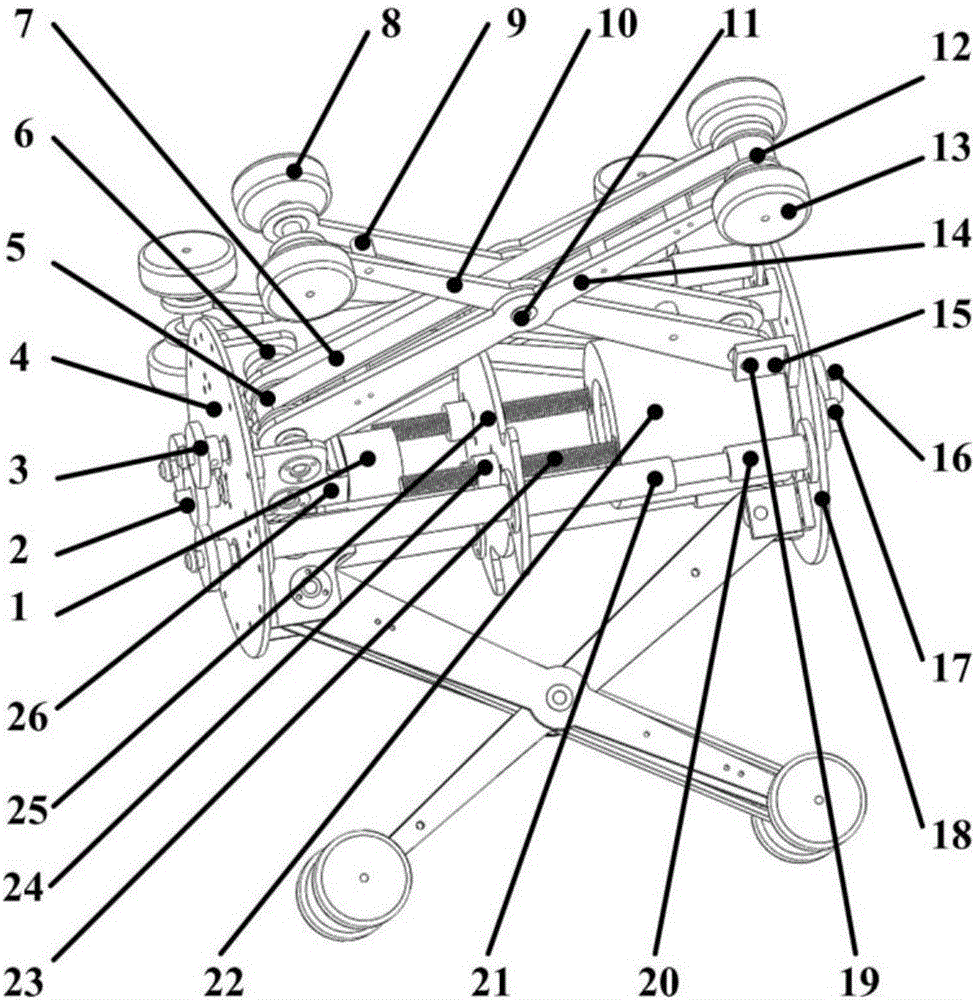

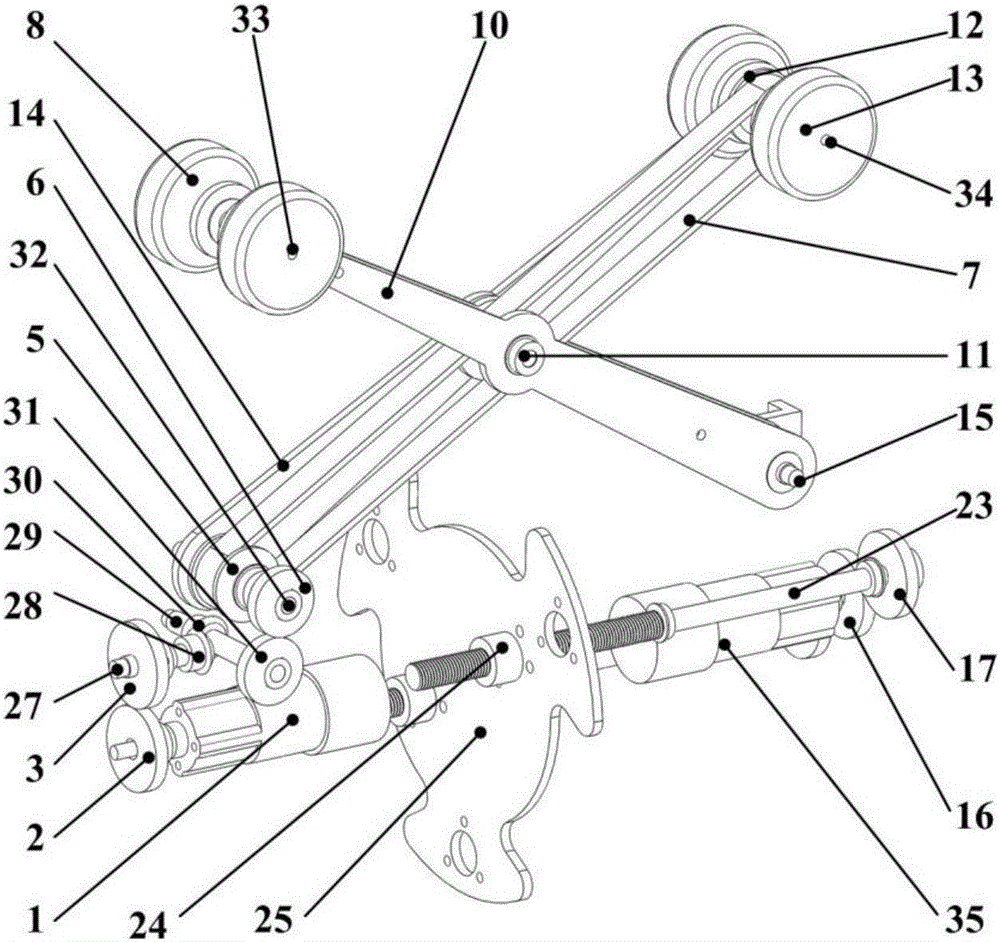

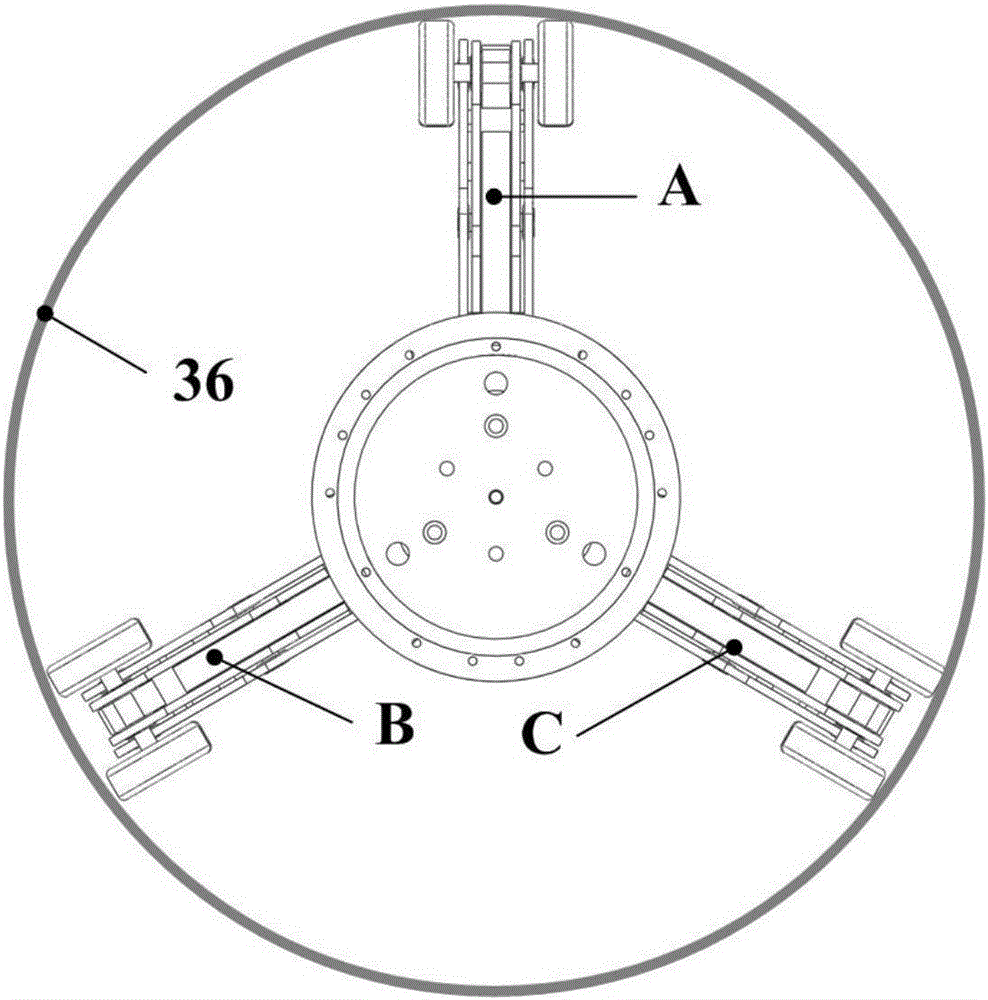

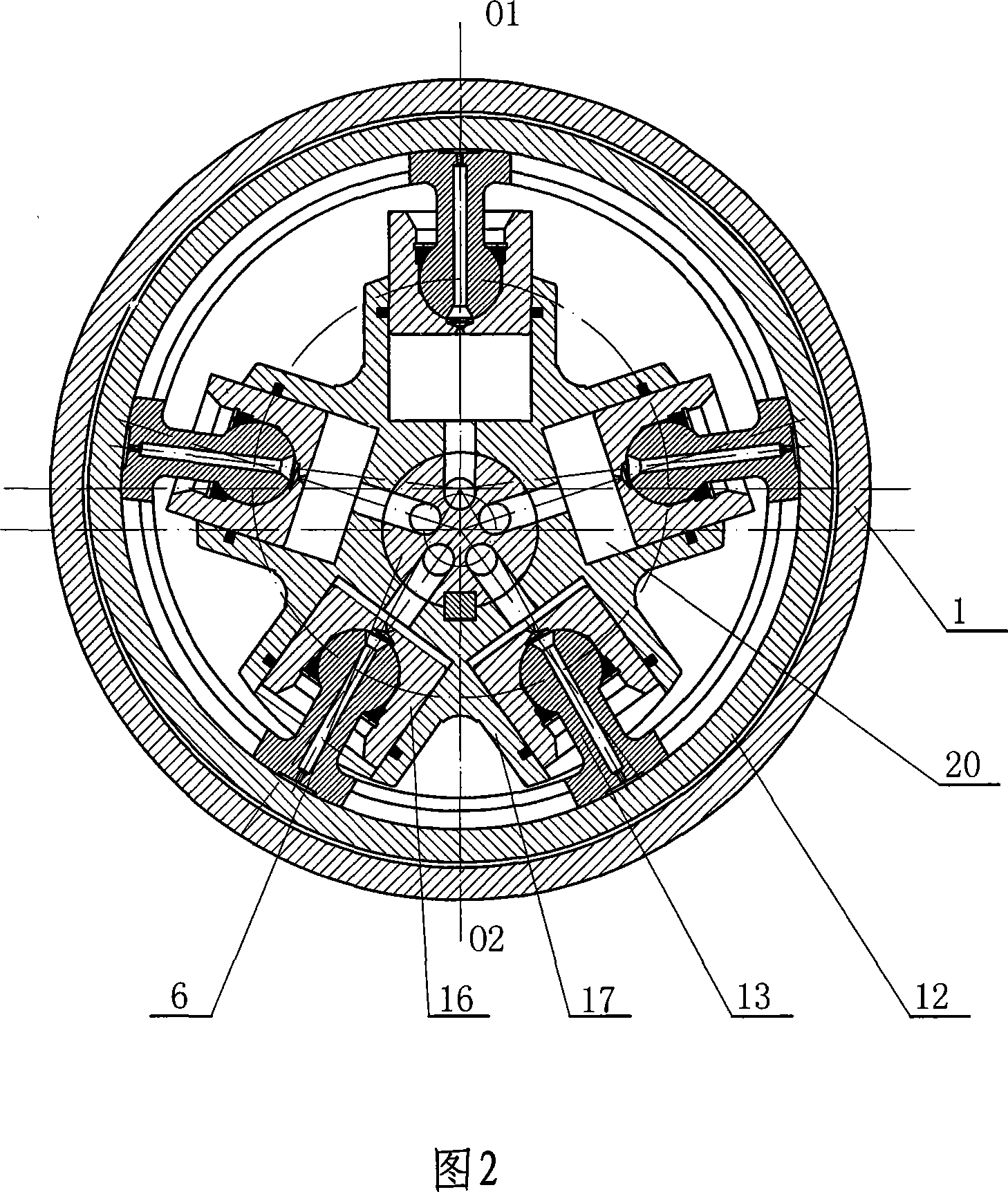

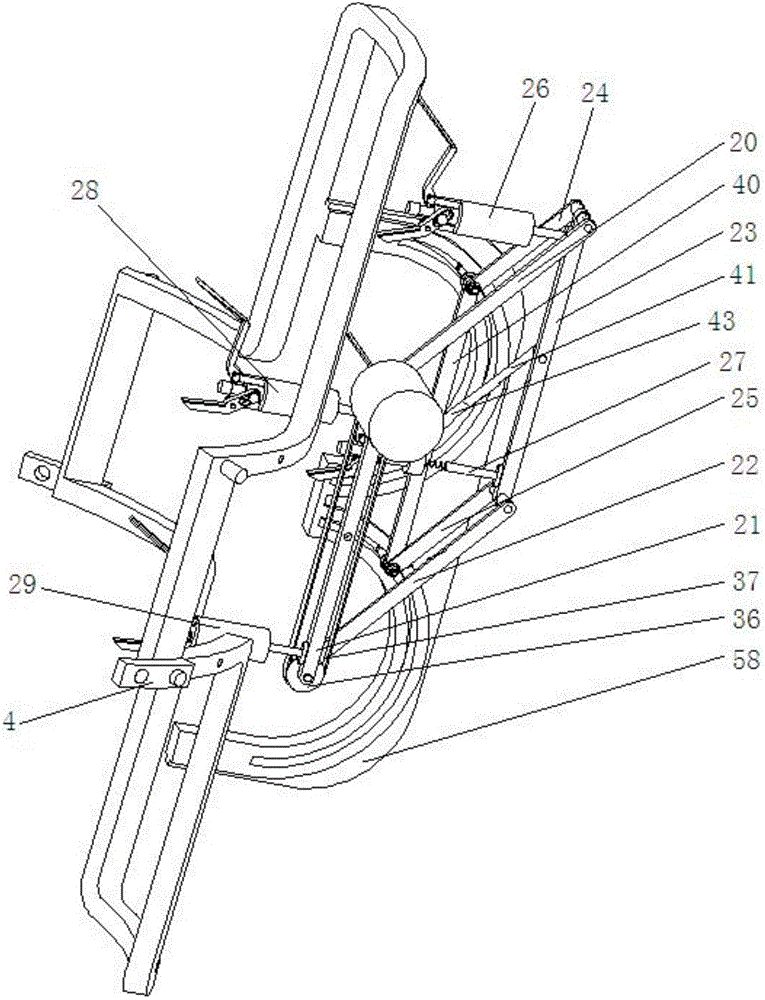

Portable type large-variable-diameter all-wheel-drive type pipeline robot

The invention provides a portable type large-variable-diameter all-wheel-drive type pipeline robot which comprises a front end plate, a rear end plate, a front rocker arm, a rear rocker arm, a scissor-type reducing mechanism and a positioning all-wheel-drive mechanism, wherein the positioning all-wheel-drive mechanism is arranged on the front end plate; the scissor-type reducing mechanism is arranged on the rear end plate; one end of the front rocker arm is hinged with the front end plate; the rear rocker arm is hinged with the rear end plate; the front rocker arm is hinged with the rear rocker arm to form a shears-fork structure; the scissor-type reducing mechanism is connected with the positioning all-wheel-drive mechanism; and the scissor-type reducing mechanism can slide relative to the positioning all-wheel-drive mechanism to drive the front rocker arm and the rear rocker arm to form shears-fork motion. According to the portable type large-variable-diameter all-wheel-drive type pipeline robot provided by the invention, when the reducing motor rotates, a nut pulls the front end plate to get close to a guide post or get away from the guide post, and scissor-type rocker arms which are synchronously fixedly arranged on the front end plate and the rear end plate open and close, so that a supporting radius of the robot is changed.

Owner:SHANGHAI SUJIE ROBOT TECH

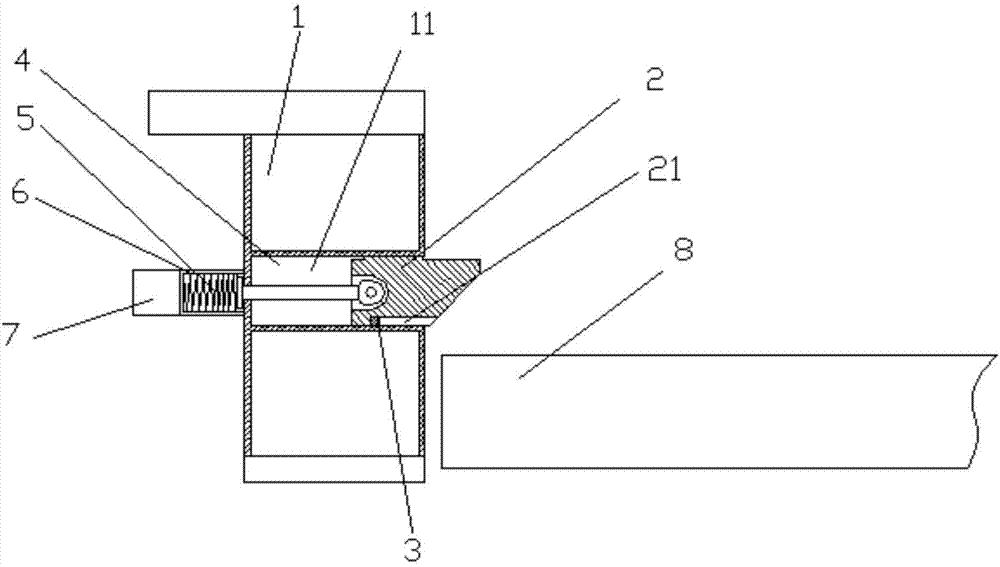

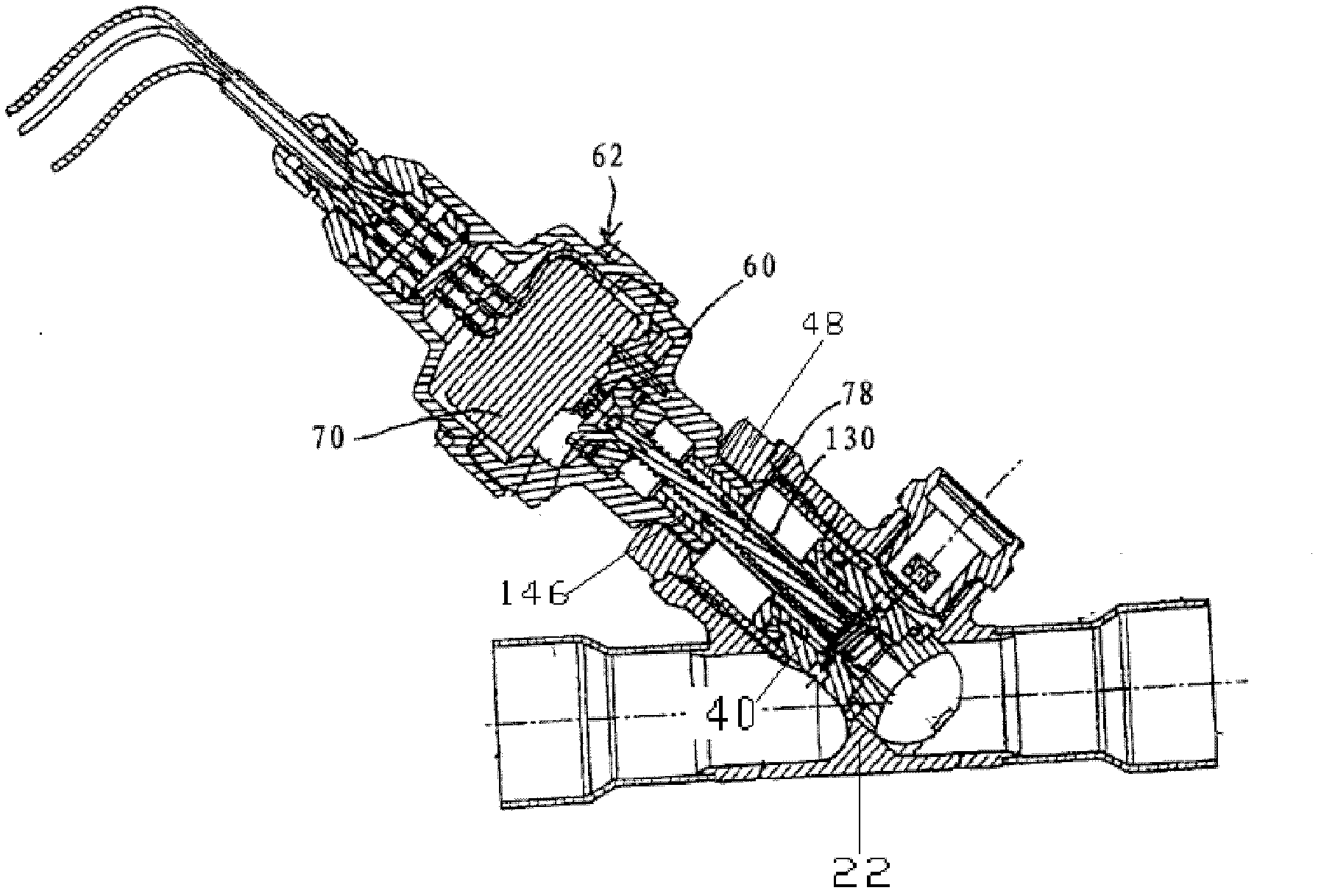

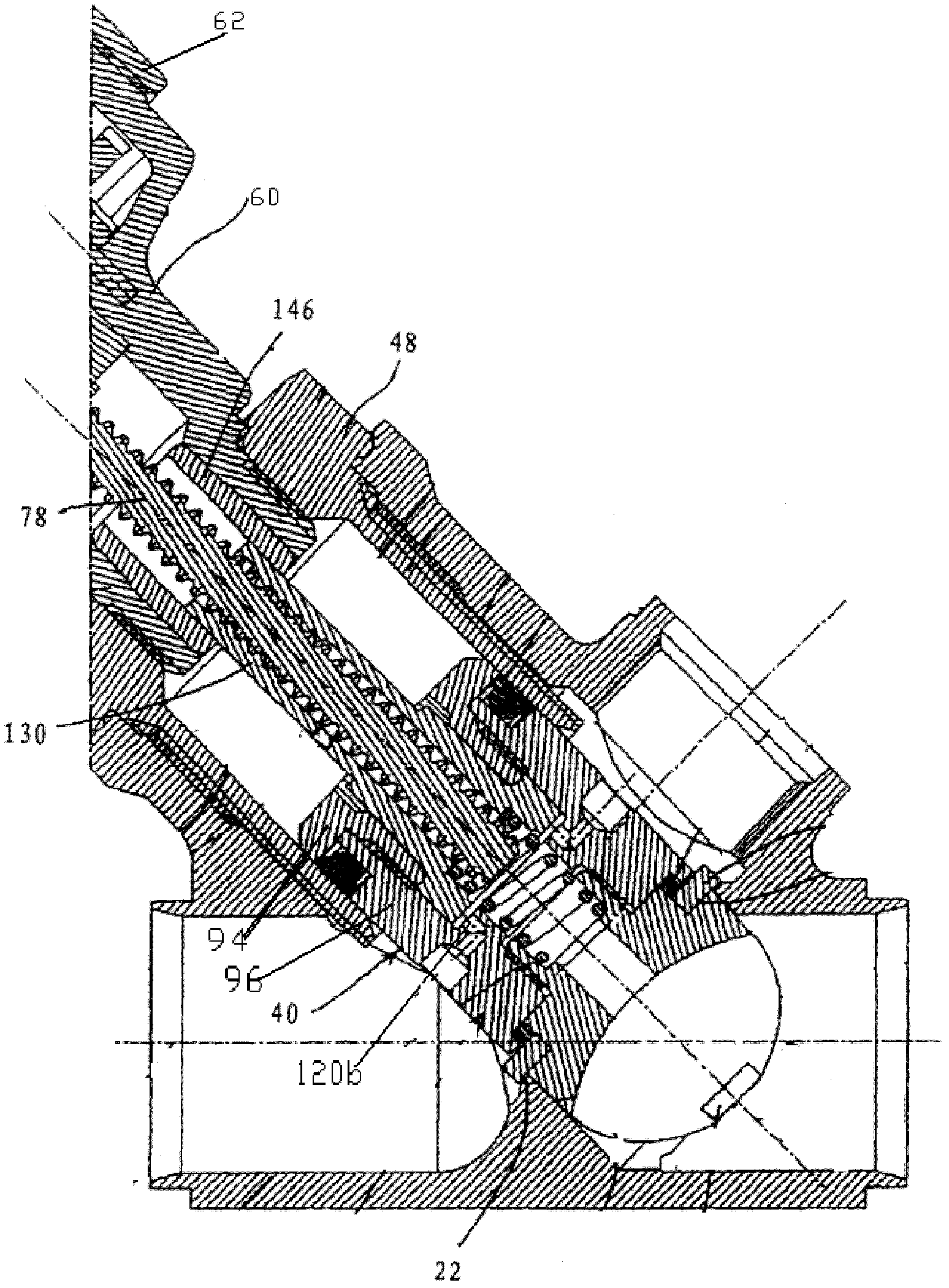

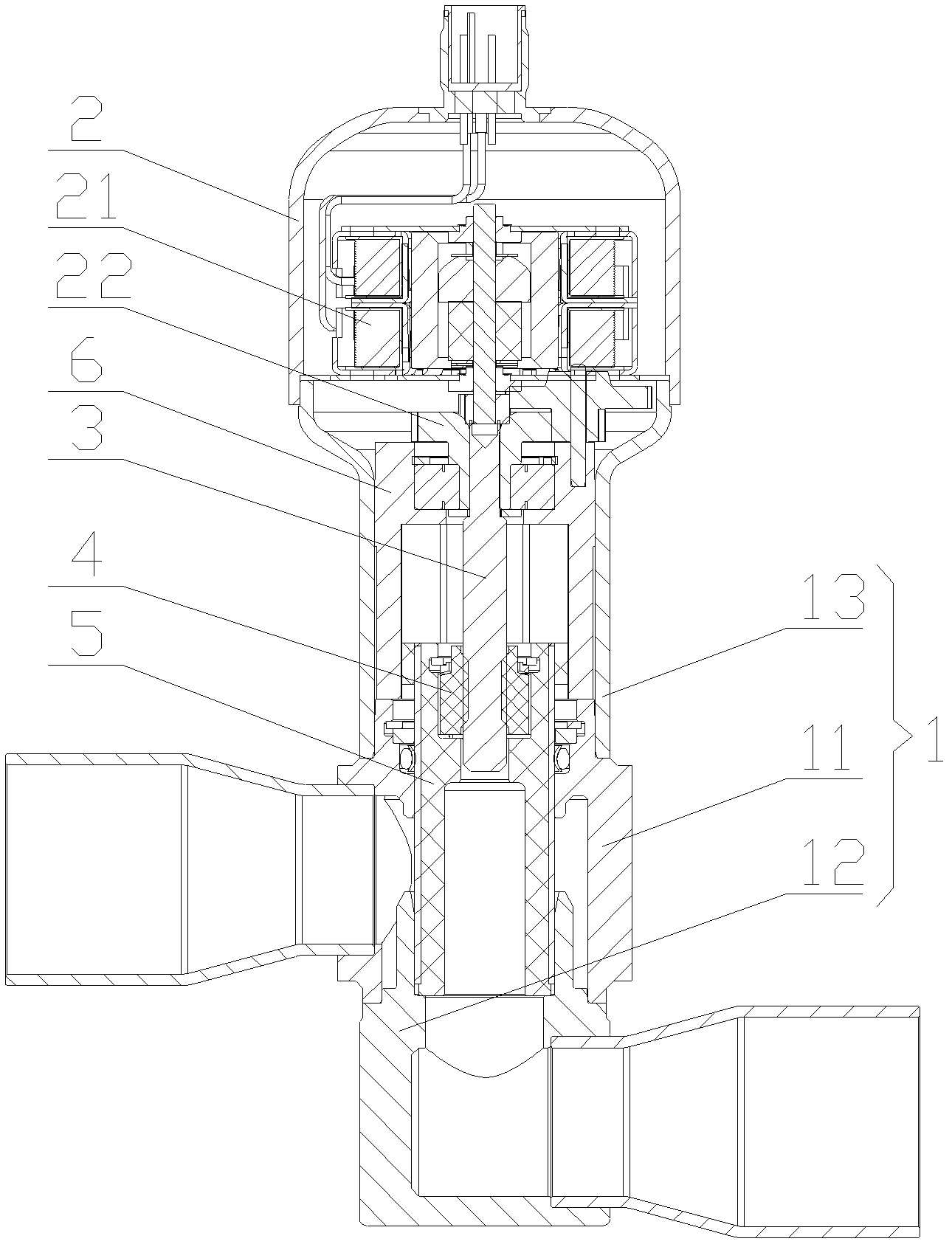

Flow control valve

ActiveCN102853100AAvoid stuck phenomenonEliminate concentricity errorsOperating means/releasing devices for valvesEfficient regulation technologiesEngineeringValve seat

The invention discloses a flow control valve. The flow control valve comprises a valve seat (1) and a shell (2), wherein a motor (21) is arranged inside the shell (2) and is connected with a screw rod (3) by the output shaft of the motor; the screw rod (3) is connected with a nut (4); the nut (4) is connected with a valve rod (5); an installation groove (51) is arranged inside the valve rod (5); the nut (4) is in radial clearance fit in the installation groove (51); a ring-shaped limiting groove (52) is arranged on the inner wall of the installation groove (51); and a limiting part (53) which axially limits the nut (4) and is in clearance fit outside the nut (4) is arranged in the ring-shaped limiting groove (52). The flow control valve has the following beneficial effects that through the structural design, on the one hand, the coaxiality errors between the screw rod and the nut, which are caused by part processing and assembling, can be eliminated, and on the other hand, the axial limiting reliability of the nut can be improved.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CONTROLS CO LTD SHAOXING CITY

Feeding device for garbage burning rotary kiln end

InactiveCN1963301ABurn out preventionReduce the impact of high temperatureIncinerator apparatusWater flowIncineration

The invention relates to the modification to the feeding device of the rotary kiln for the burning of wastes, particularly hazardous wastes. Inside of the feeding line connects with the interior of the kiln with dog-house on the line and piston propelling plate and fire block door of the garbage propelling device inside the pipe. A manifold sandwich is made by he feeding line, propelling plate and the fire block door, and the pipe cooling water running channel is composed of water inlet, manifold sandwich space, and water outlet. The circulating cooling water can bring away the heat from the line, maintaining a relative low temperature of the outside wall, avoiding the melting, gluing, and locking of wastes due to the waste touching the high temperature line. Utilizing hydraulic propelling method, it can avoid the damage to the motor due to mechanical blocking. Meanwhile, big hydraulic thrusting force can make quick retraction of the piston propelling plate after the feeding of wastes into the kiln, lowering harsh requirement for the fire resistant feature of the piston propelling plate, improving the running reliability and extending its durability.

Owner:龚德明

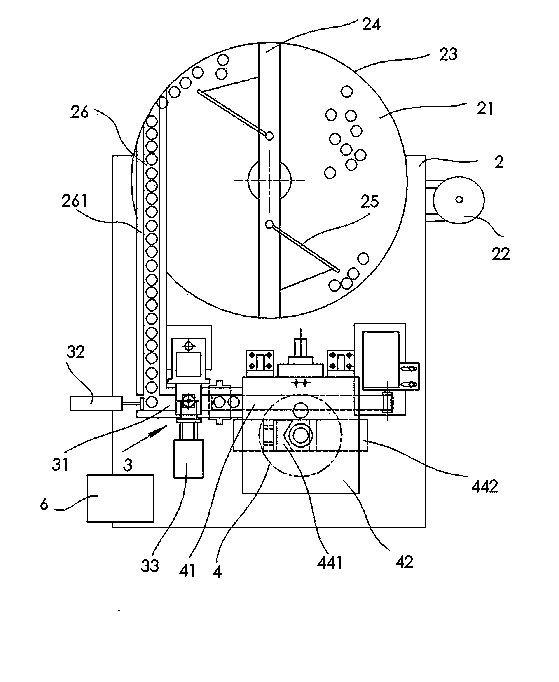

Automatic assembling device for needle roller bearing

ActiveCN103388630AHigh degree of automationMake up needles in timeBearing componentsNeedle roller bearingEngineering

The invention discloses an automatic assembling device for a needle roller bearing; the automatic assembling device comprises an automatic material loading mechanism, an automatic grease injection mechanism, an automatic needle loading mechanism and an automatic needle roller detecting mechanism, wherein a turntable I connected with a motor I is arranged on a bracket of a stand, a guardrail and a material outlet passage are arranged on the periphery of the stand, the guardrail is provided with a cross rod, the lower part of the cross rod is provided with guide plates; the automatic grease injection mechanism comprises a material conveying passage, a material pushing cylinder I, a locating cylinder I and a grease injection passage, and a clamping and locating seat is arranged in front of the locating cylinder I; the automatic needle loading mechanism is provided with a conveying belt device, a material pushing cylinder II is connected below a locating bottom plate; a locating cylinder II connected with a locating block is arranged above the locating bottom plate, a fixing block is mounted on the locating cylinder II, a needle roller guide block, a needle loading plate and an upper end cover are arranged above the locating block in sequence, a needle hole is formed in the upper end cover, a central shaft is arranged at the central part of the upper end cover, and the upper end of the central shaft is connected with a turntable II connected with a motor II; the automatic needle roller detecting mechanism comprises a detecting cylinder provided with a probe at the head part of the detecting cylinder and arranged on a small bracket outside the needle locating plate, a detecting hole is formed in the needle roller guide block, and a displacement sensor is arranged on the cylinder side. As materials are automatically loaded, greases are automatically injected and needles are automatically loaded, the automatic assembling device for the needle roller bearing, disclosed by the invention, has the advantages of high automation and stable quality.

Owner:WANXIANGQIANCHAO CO LTD +1

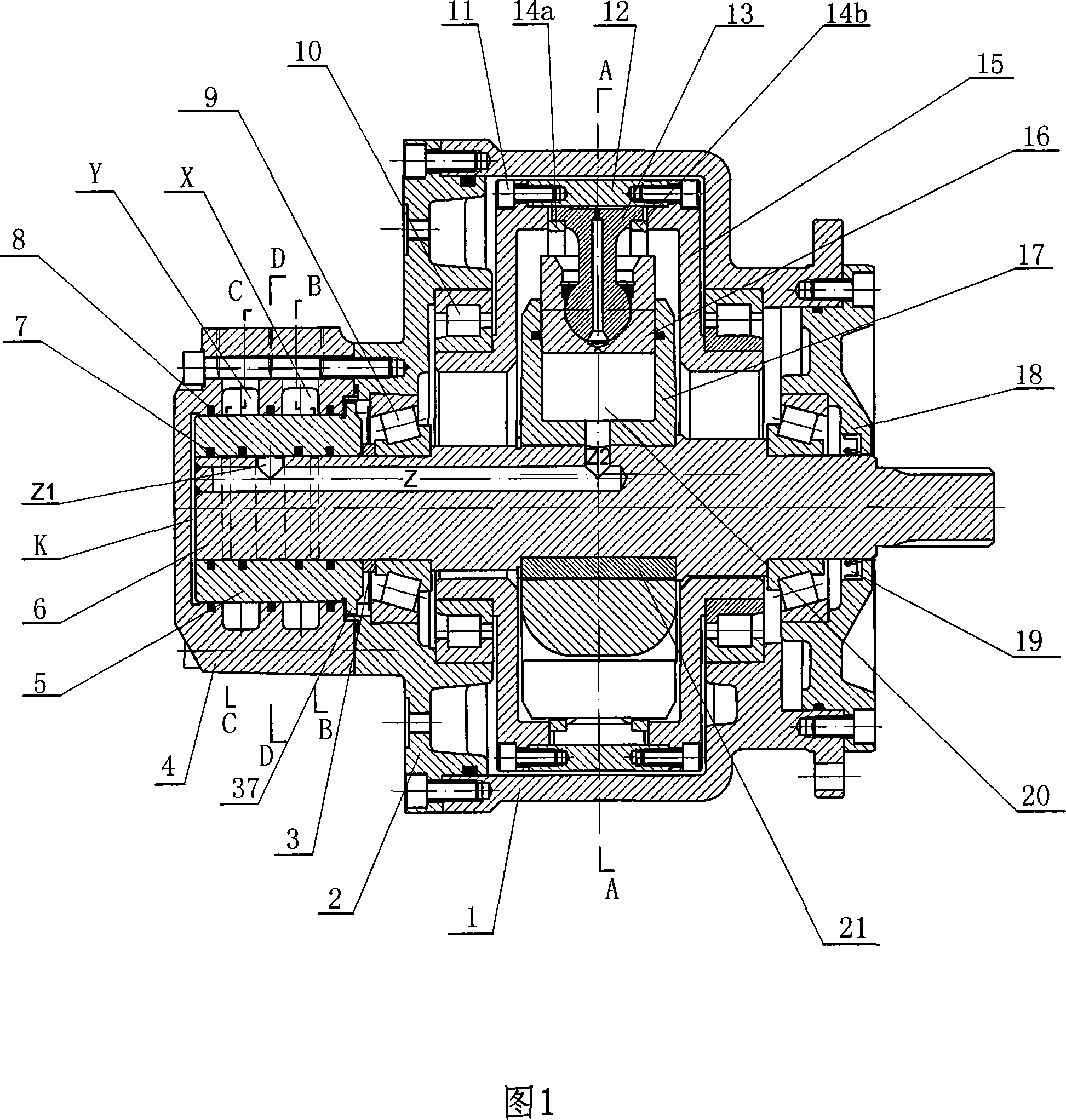

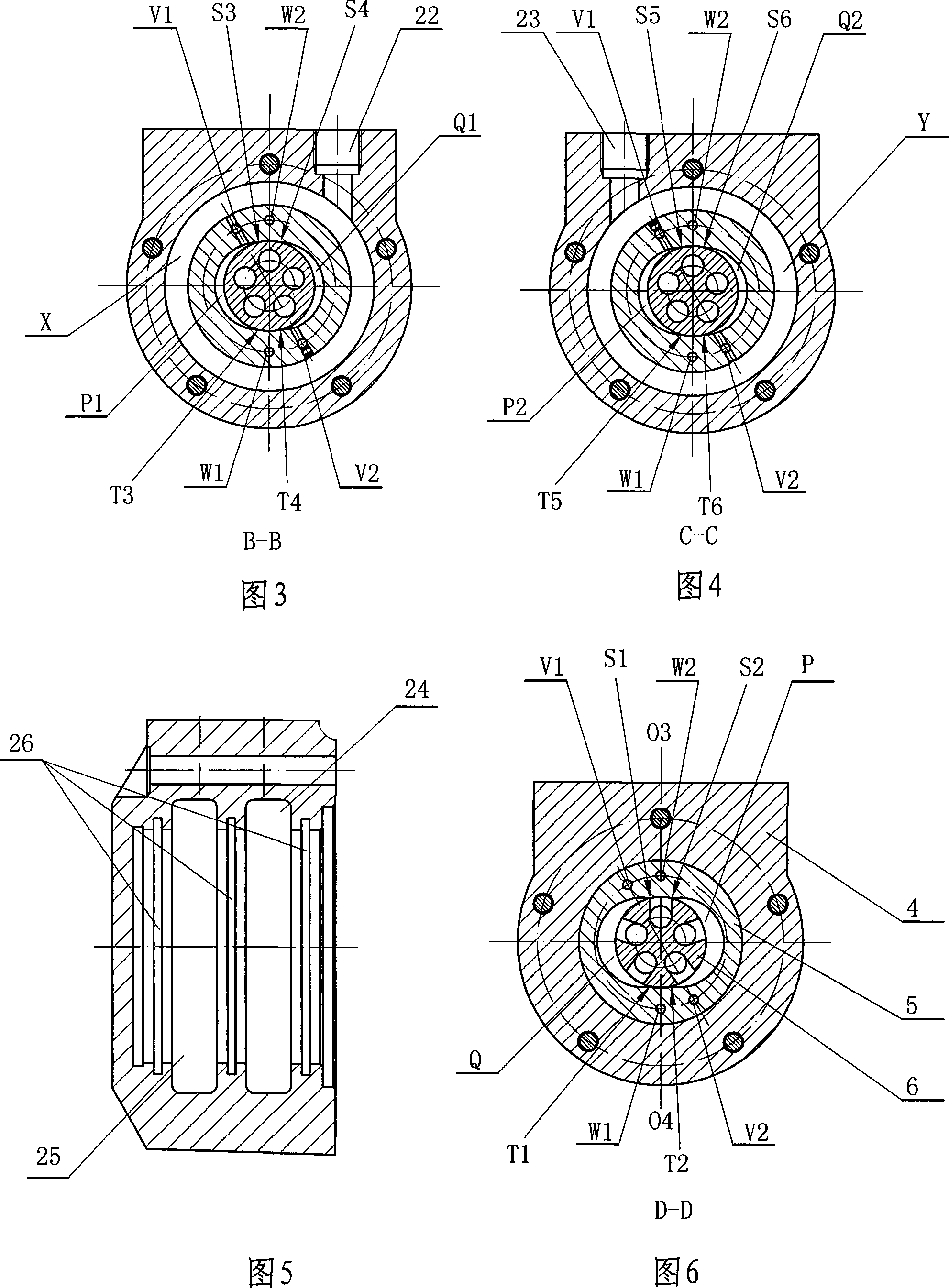

Oil distribution axle linkage rod type hydraulic motor

InactiveCN101117938AReduce axial sizeShaft oil distribution is compactReciprocating piston enginesPistonLinkage concept

A shaft-distribution-oil link-type oil hydraulic motor is improved on the basis of the original shell, the shaft-distribution-oil configuration, the rotating shaft, and the plunger piston-link assembly, etc., namely that the shaft-distribution-oil configuration consists of an oil-through disk and an oil distribution jacket. No.1 and No.2 hydraulic fluid ports are opened on the oil-through disk, and No.1 and No.2 ring grooves are opened on one of the interfaces of the oil-through disk and the oil distribution jacket to airproof and form No.1 and No.2 oil reservoirs; at the same time, No.1 and No.2 under cut slots which are separated by the contact crown faces are symmetrically opened on the same ring face of the inner wall of the oil-through jacket. The No.1 and No.2 under cut slots are arranged between the No.1 and No.2 oil reservoirs to airproof and form the No.1 and No.2 main oil reservoirs. A plurality of flow passages corresponding to the main oil reservoirs and connected with the plunger piston are arranged on the rotating shaft. The adopted structure forms the oil-through configuration and the oil distribution configuration into adjacency configurations, approximately distributing in the same orientation to greatly decrease the axial size of the oil distributor, and make the structure of the oil hydraulic motor closer and more reasonable.

Owner:宁波欧易液压有限公司

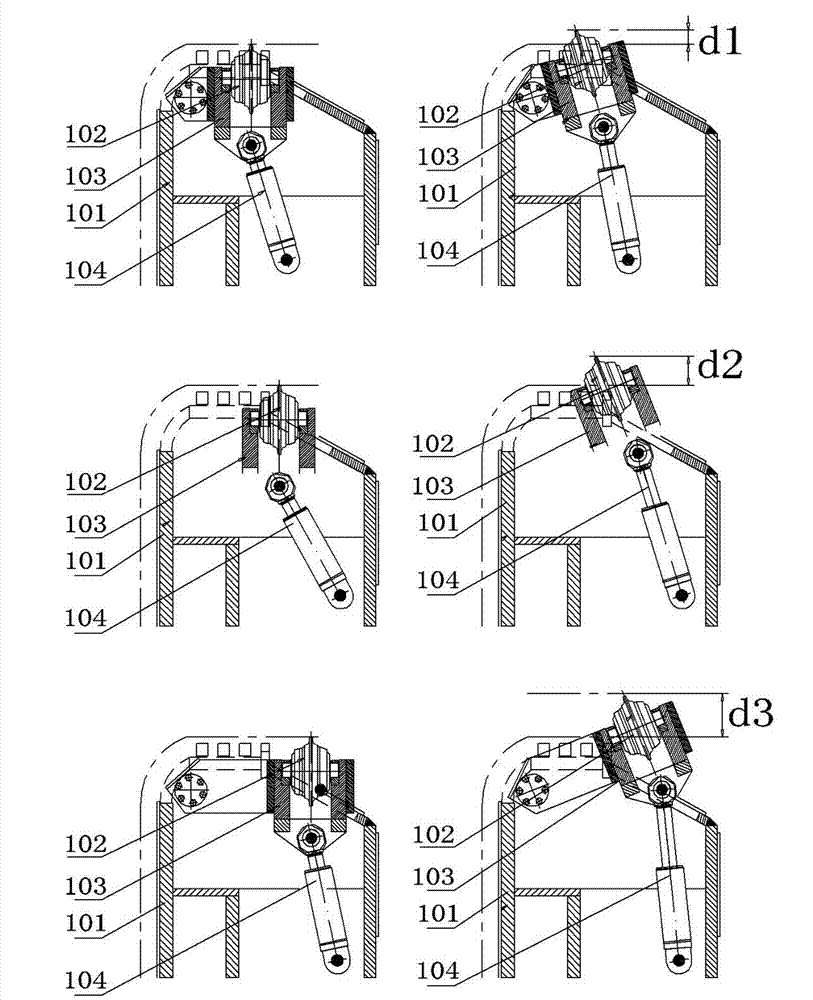

Insulator metamorphic detection robot mechanism

ActiveCN106002912AEasy to carry and installSafe and reliable operationProgramme-controlled manipulatorCamEngineering

The invention discloses an insulator metamorphic detection robot mechanism. The mechanism comprises mobile units and a detection element, and least two mobile units are adopted and mutually connected into a whole to form a mobile mechanism surrounding an insulator chain. Each mobile unit comprises a hook surface frame with the hollowed-out middle, a cam mechanism is arranged on one side of the hook surface frame, a parallelogram mechanism is arranged on the cam mechanism, a driving device is mounted on the parallelogram mechanism, clamping jaws are arranged on the parallelogram mechanism, and a crawler belt type guide mechanism is arranged on the hook surface frame in the radial direction of insulators. Disassembling and assembling can be conducted, operators can carry and mount the mechanism conveniently, operation is relatively safe and reliable, and the crawler belt type guide mechanisms achieving the guiding function make flexible contact with the insulator chain, so that abrasion of the surfaces of the insulators in the guiding process is avoided; and the mechanism can well adopt to errors of the insulators, the mechanism is reasonable in structure design, stable in operation, capable of detecting horizontal, overhung and oblique insulator chains and wide in application range.

Owner:NORTHEASTERN UNIV

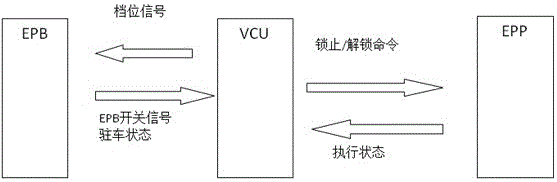

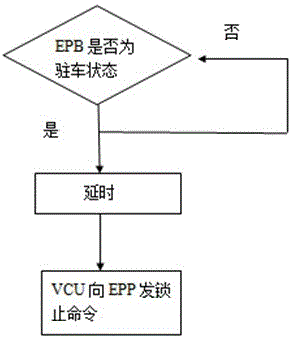

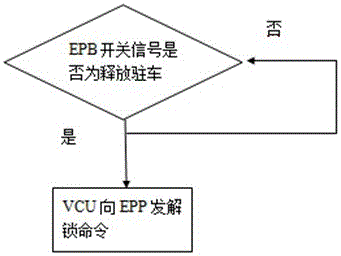

Electric parking brake (EPB) control method for electric car

InactiveCN106335487AImprove reliabilityAvoid stuck phenomenonBraking action transmissionElectric parking brakeAutomatic control

The invention relates to the field of vehicle automatic control and in particular relates to a parking brake control method. An electric parking brake (EPB) control method for an electric car is characterized by carrying out following control after setting the delay time: from a driving state to a parking brake lock state, firstly carrying out lock operation on a vehicle by using an EPB system, waiting for the delay time and then sending a parking brake signal to an electric parking pawl (EPP) system by a vehicle control unit to carry out lock operation on the vehicle; and from the parking brake lock state to the driving state, firstly controlling the EPP system to be unlocked by the vehicle control unit after a brake pedal is depressed, waiting for the delay time and then unlocking the EPB system. The method has the beneficial effects that the reliability of the EPP system is improved by starting the EPB and EPP systems in sequence, thus avoiding seizure of the EPP system under the full load condition or the long ramp condition and eliminating abnormal sounds produced by parking on the short ramp and unlocking under the full load condition; and meanwhile, parking and unlocking can be smoothly carried out under the long ramp condition, thus improving the reliability of vehicle control.

Owner:SAIC MOTOR

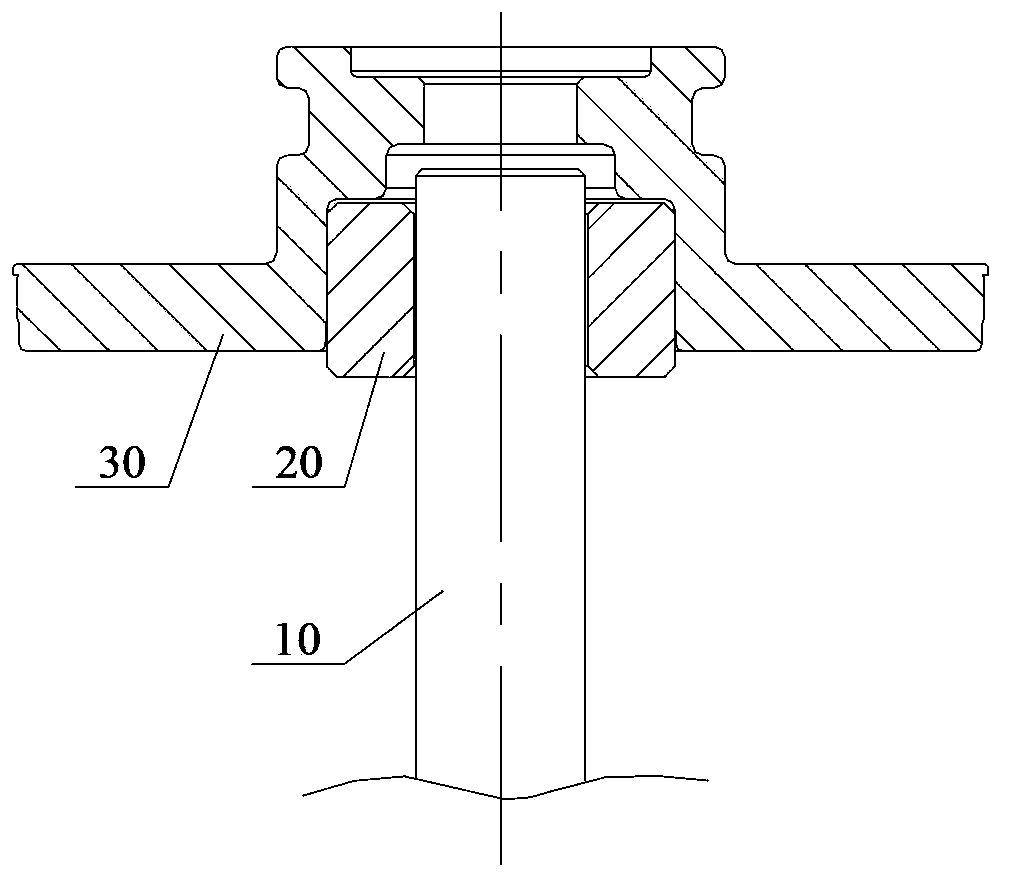

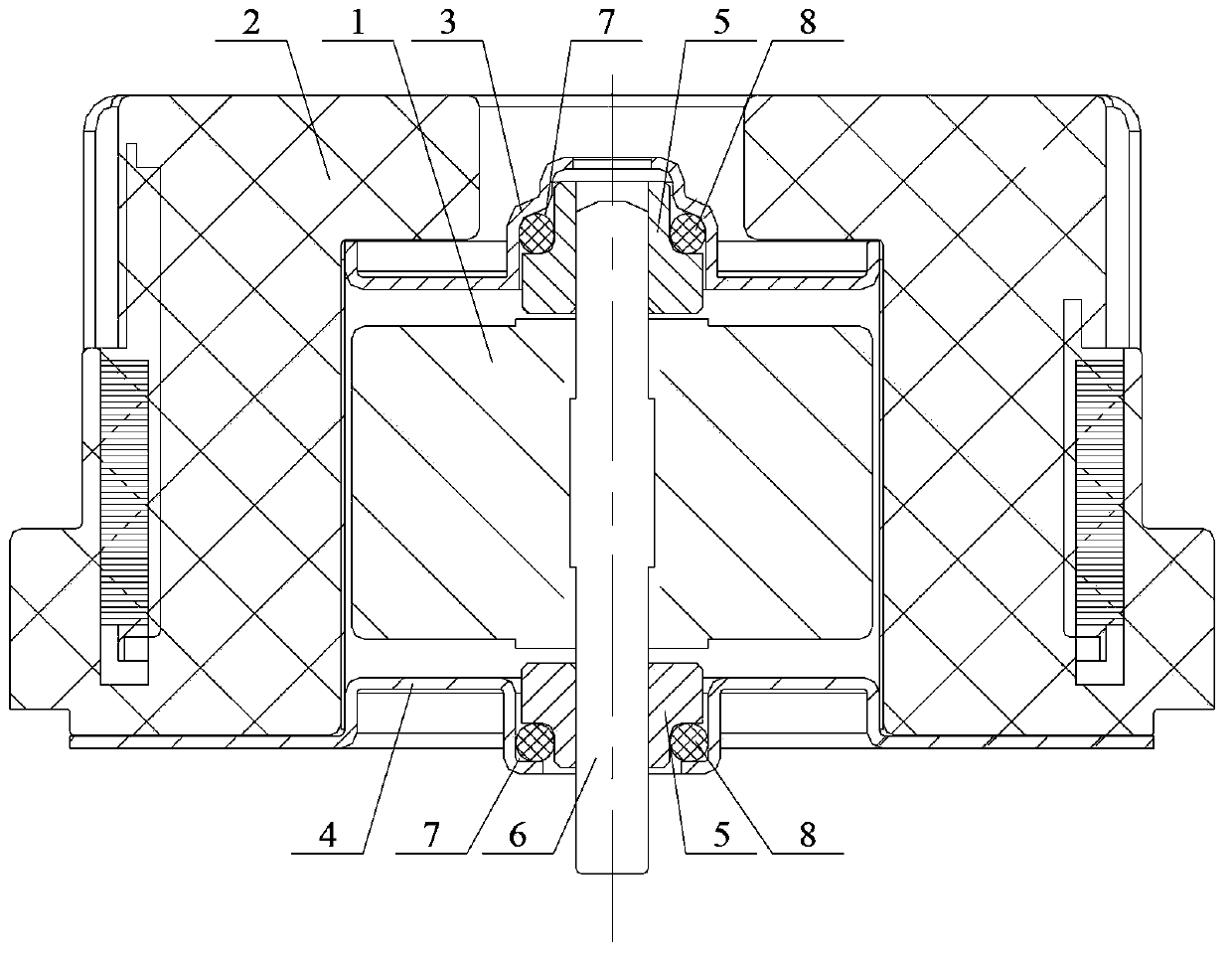

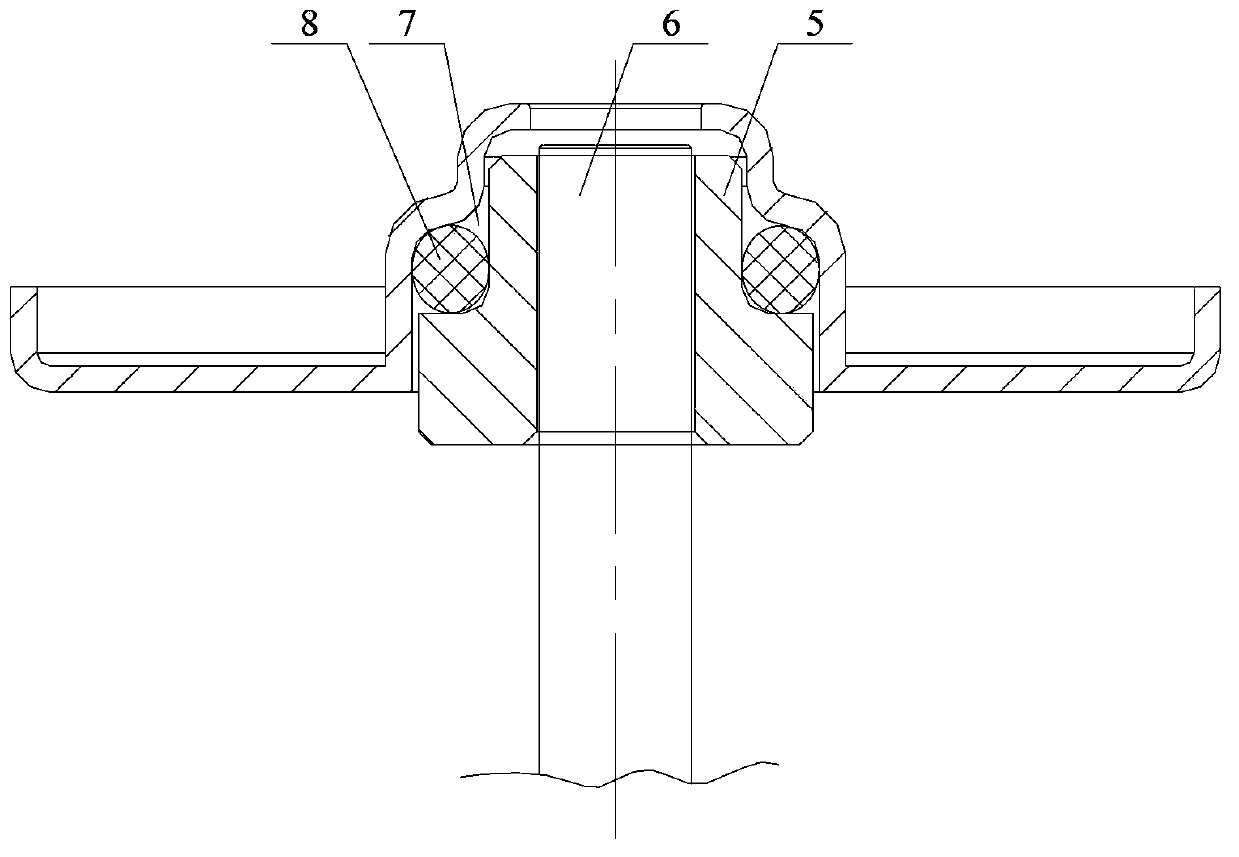

Motor and connection structure of end covers and bearings thereof

ActiveCN104184248AAvoid stuck phenomenonReduce working noiseSupports/enclosures/casingsEngineeringMechanical engineering

The invention discloses a connection structure of end covers and bearings. Each end cover is provided with a bearing cavity for accommodating a corresponding bearing. Annular accommodating parts are formed between the inner walls of the bearing cavities and the outer surfaces of the bearings. Precompression elastic support parts are arranged in the annular accommodating parts, and radial gaps are arranged between the bearing cavities and the bearings. Through an optimization design, deformation of bearing bores after assembly completion is not generated so that cooperation of the bearings with a rotating shaft is not affected and thus happening of a jamming phenomenon in an operation process of a motor is prevented completely. At the same time, the elastic connectors between the end covers and the bearings are capable of using deformable characteristics to realize automatic self-aligning so that coaxiality of the members is ensured and a reliable guarantee is provided to reduction of work noises and vibration of the motor. On the basis, the invention provides the motor which applies the connection structure.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com