Flow control valve

一种流量调节阀、阀座的技术,应用在流量调节阀领域,能够解决大同轴度误差、驱动轴78绕度大、材料成本增加等问题,达到消除同轴度误差、避免松动问题、可靠性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

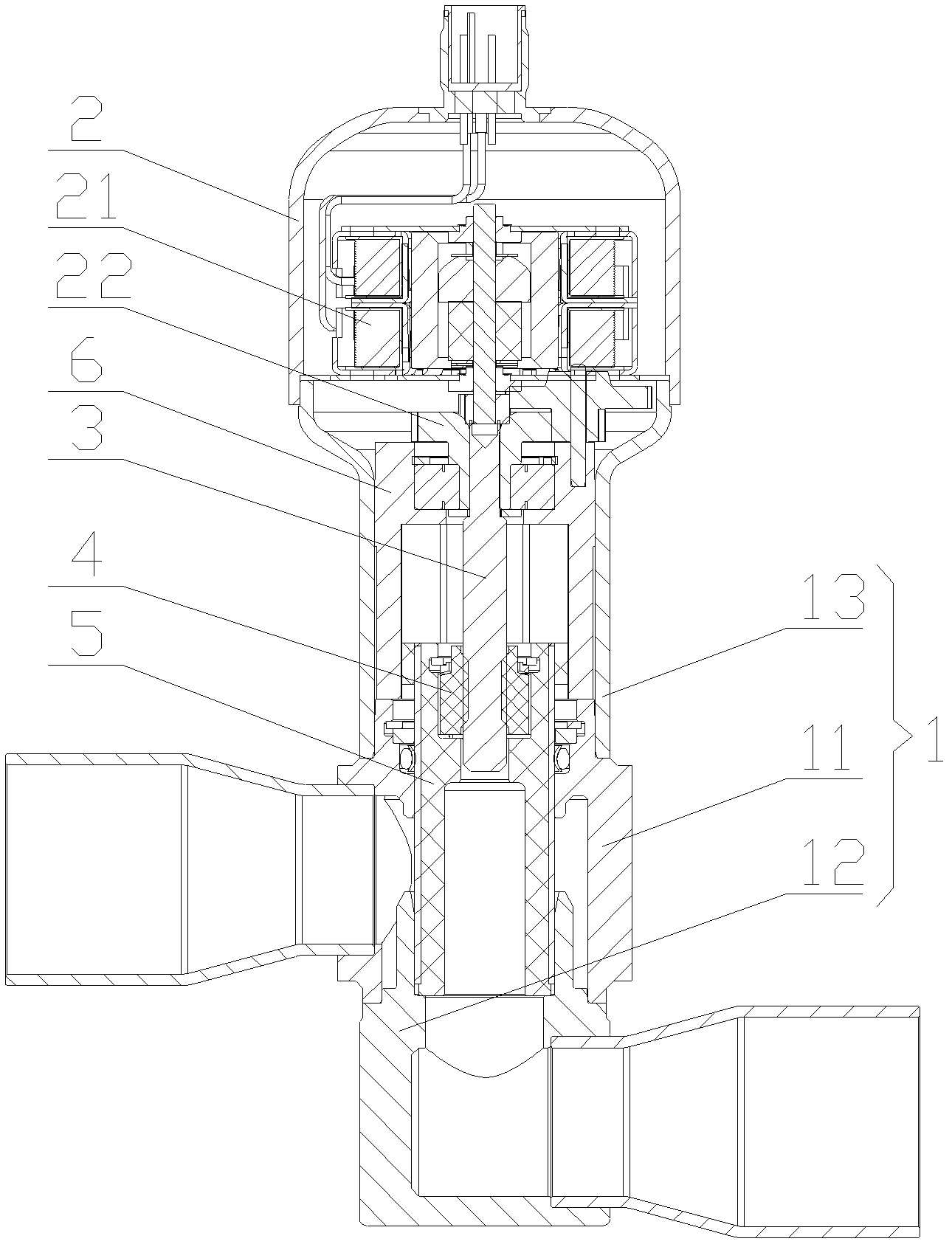

[0048] The core of the present invention is to provide a flow regulating valve. On the one hand, the structural design of the flow regulating valve can eliminate the coaxiality error between the screw rod and the nut caused by the processing and assembly of parts, and on the other hand, it can improve the nut. Reliability of axial limit.

[0049] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

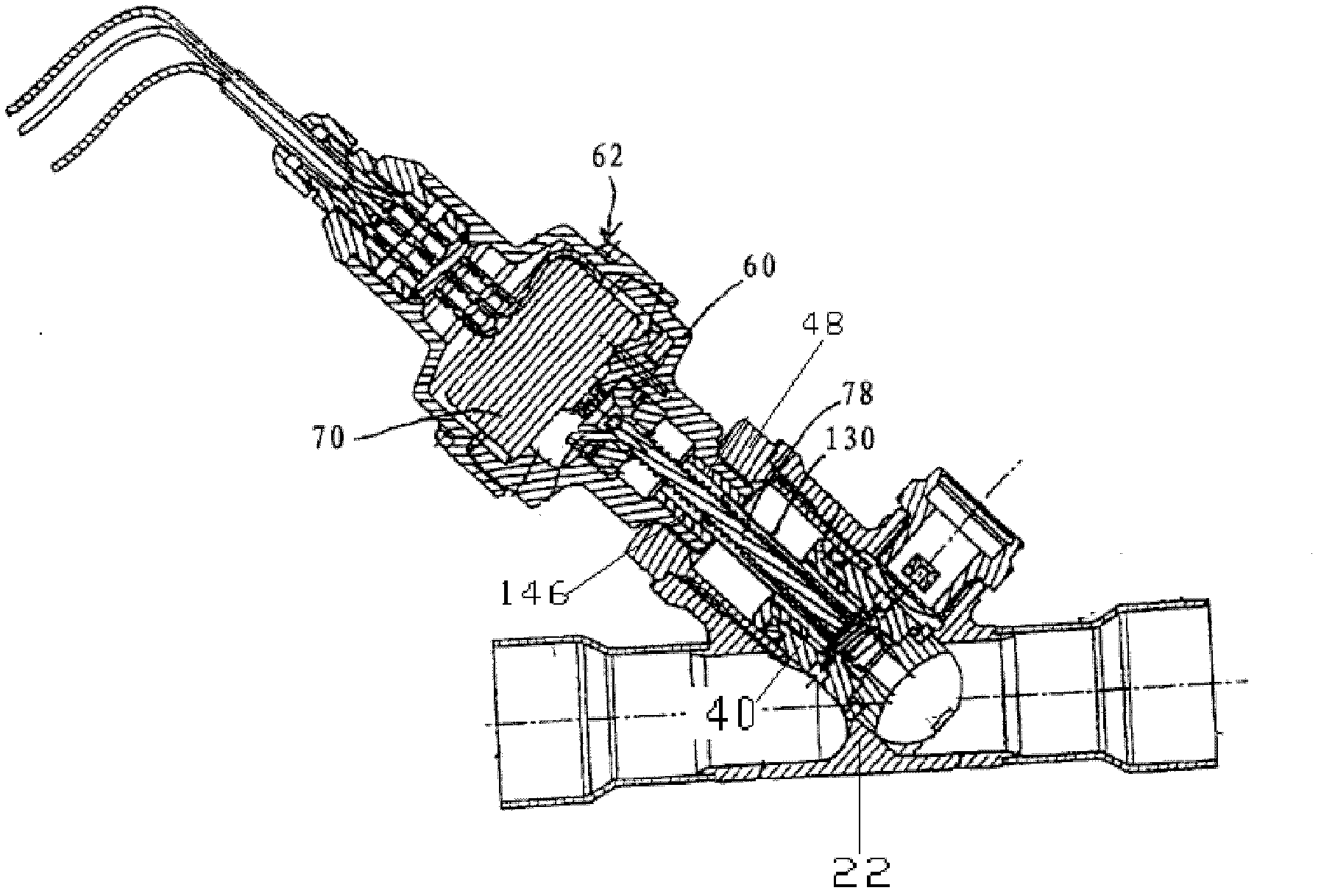

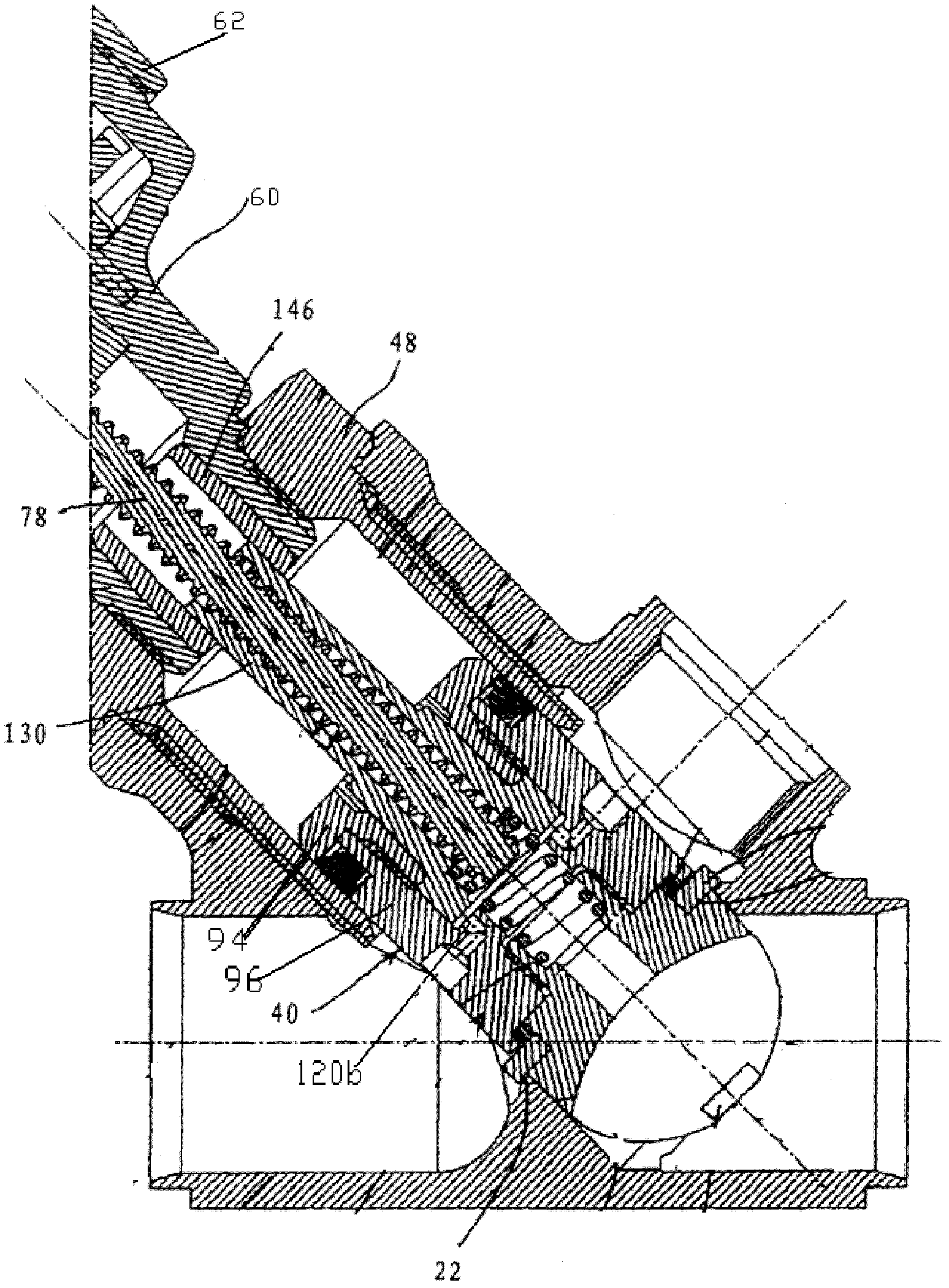

[0050] Please also refer to Figure 3 to Figure 4-4 , image 3 It is a structural schematic diagram of the flow regulating valve in the first embodiment of the present invention; Figure 4 for image 3 Schematic diagram of the structure of the valve stem of the medium flow regulating valve; Pic 4-1 for Figure 4 Sectional view of the valve stem; Figure 4-2 for Pic 4-1 Exploded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com