Oil distribution axle linkage rod type hydraulic motor

A hydraulic motor and connecting rod type technology, applied in the field of hydraulic motors, can solve the problems such as the radial size of the rolling bearing unit cannot be increased at will, the bearing capacity of the rolling bearing unit cannot be increased, and the high pressure work requirements cannot be met, so as to prevent the oil stuffing phenomenon and reduce the Machining accuracy, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

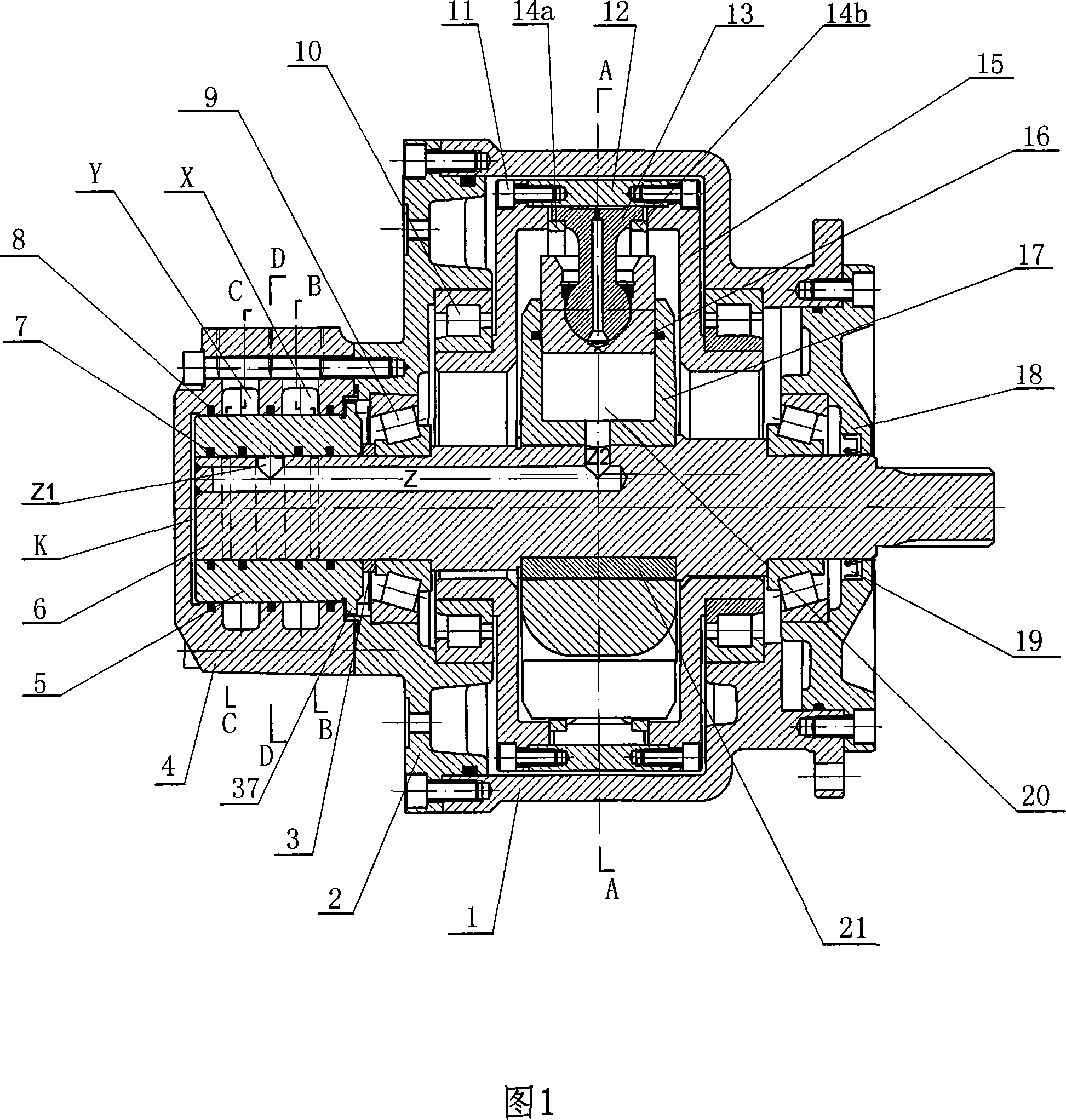

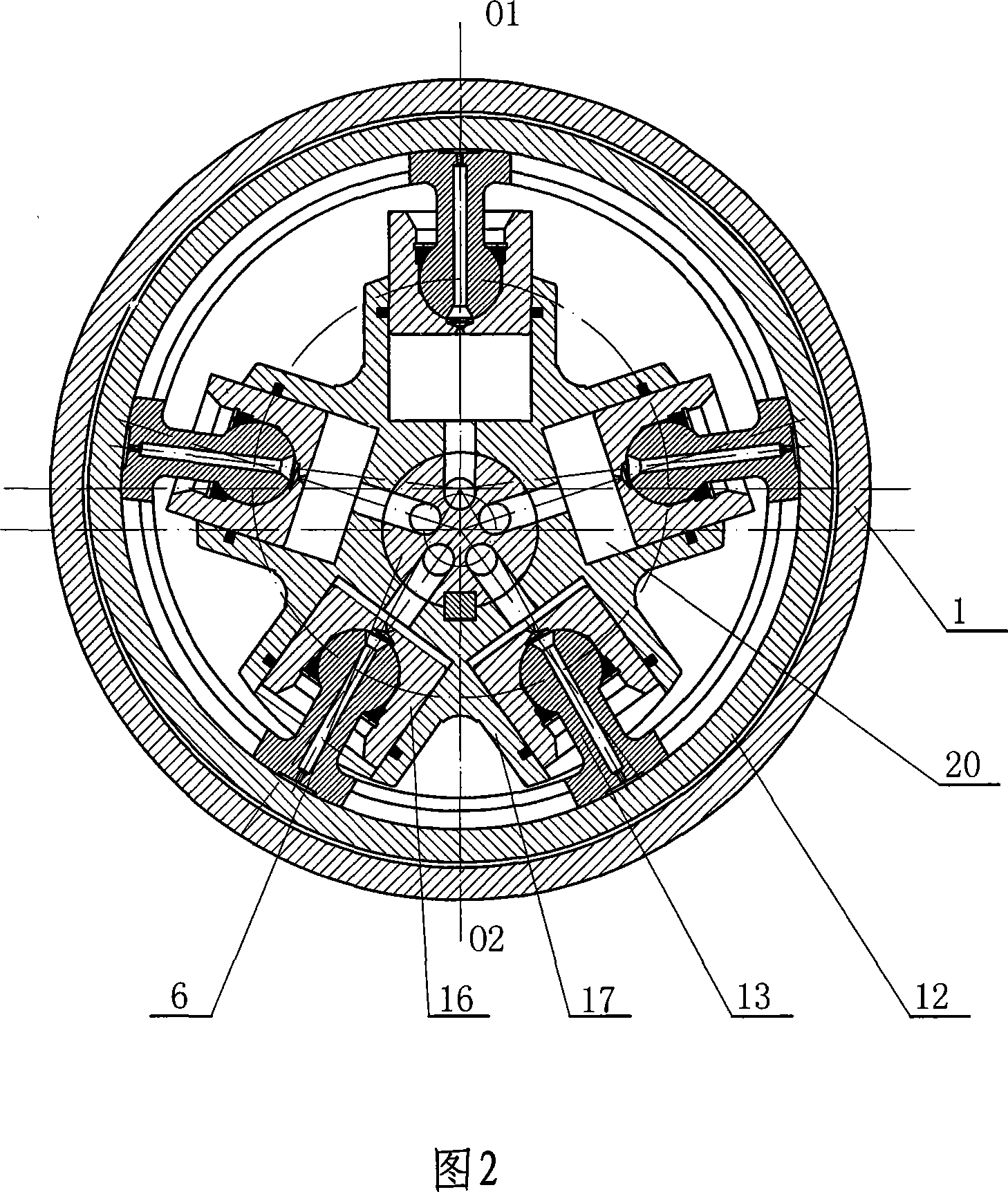

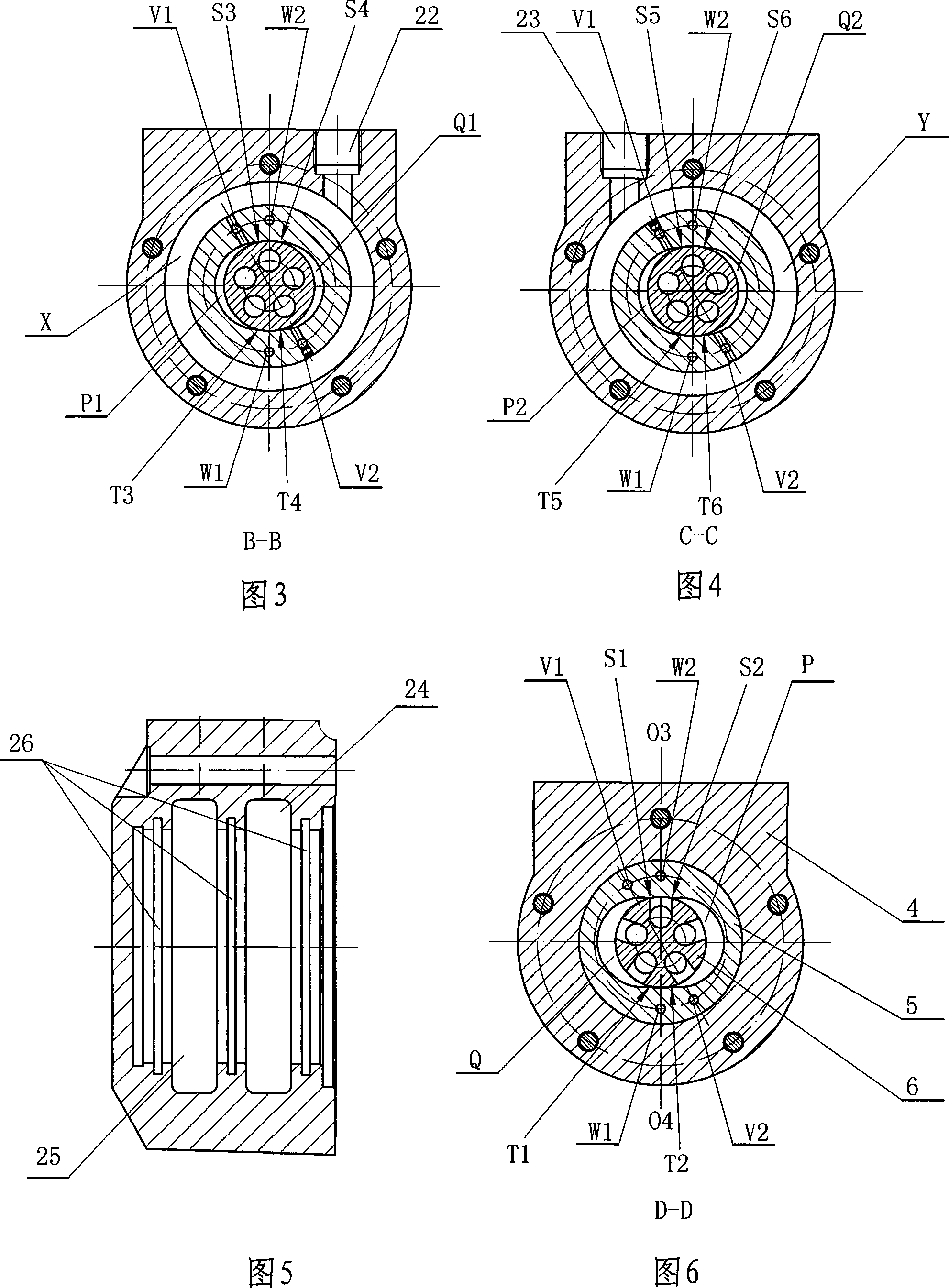

[0031]As shown in Figures 1 and 2, the connecting rod hydraulic motor includes a housing, a shaft oil distribution structure, a rotating shaft 6, five plunger-connecting rod assemblies and a rotating sleeve 12, wherein the housing is composed of the housing 1 and the bolts The front cover 18 and the rear cover 2 fixed to the housing are composed; the shaft oil distribution structure is composed of the oil pan 4 fixed on the rear cover 2 by bolts and the oil distribution sleeve 5 located in the oil pan; The rotating shaft 6 is placed eccentrically in the inner cavity of the casing, and is supported on the front cover 18 and the rear cover 2 through the first group of roller bearings 9. One end of the rotating shaft is fitted with the above-mentioned oil distribution sleeve 5, and is fixed with a positioning ring. 3. Limit the axial position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com