Automatic assembling device for needle roller bearing

A technology for automatic assembly and needle roller bearings, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low efficiency, heavy manual labor, unstable quality, etc., and achieve high efficiency, high degree of automation, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

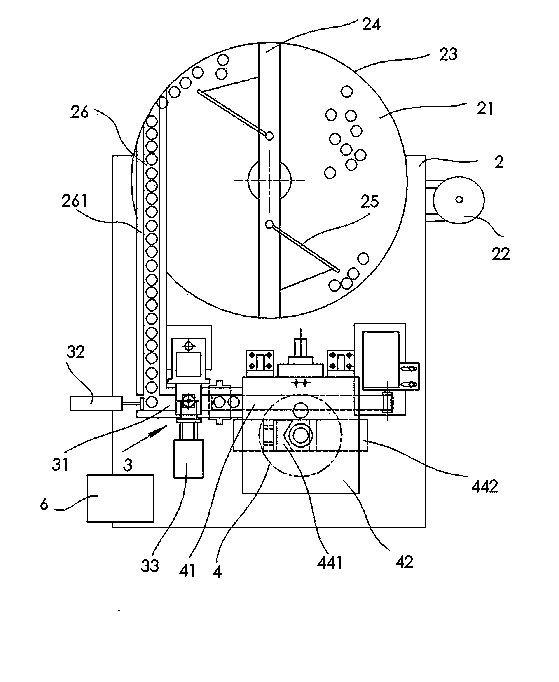

[0034] Embodiment 1: as figure 1As shown, an automatic assembly equipment for needle roller bearings, including a machine base, is equipped with:

[0035] 1), the automatic feeding mechanism, including the support 2 fixed on the machine base 1, the support 2 is provided with a turntable 21, the turntable 21 is connected with the motor 22 fixed on the support 2 through a reduction device, and the periphery of the turntable 21 Guardrail 23 is fixedly arranged, is connected with crossbar 24 on the guardrail 23, and below crossbar 24 is connected with some guide plates 25 that form a certain angle with the radial direction of turntable one 21. There are two guide plates 25, and the guide plates 25 pass through screws Connected to different positions below the cross bar 24, the angle of the guide plate 25 relative to the cross bar 24 can be adjusted; The guard plates 261 on both sides are formed, and the relative distance between the guard plates 261 on both sides can be adjusted....

Embodiment 2

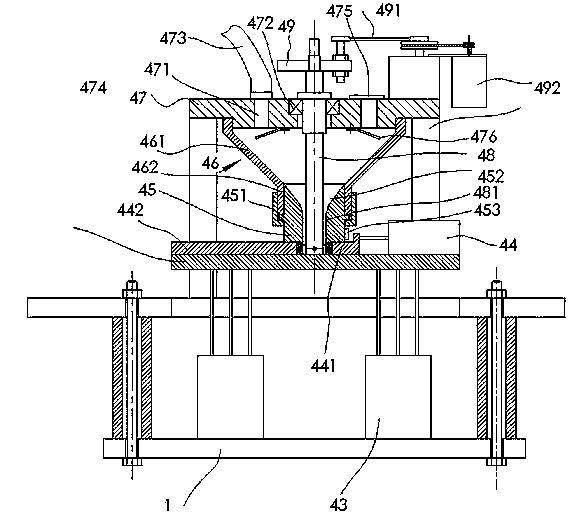

[0046] Embodiment 2: The middle part of the central shaft 48 is covered with a push needle sleeve 71, the push needle sleeve 71 is slidingly fitted with the central shaft, the upper end of the push needle sleeve 71 is connected with two symmetrically arranged push rods 72, the middle section of the push rod 72 is connected to the upper end The two through holes of the cover 47 are clearance fit, and the upper sections of the two push rods 72 are connected with the electromagnet 74 through an annular plate 73, and the electromagnet 74 is installed on the upper bracket 75 fixed on the upper end cover 47; The outer diameter is 1-3 mm smaller than the inner diameter of the lower end of the needle guide block 45;

[0047] The lower end of the needle roller guide block 45 is provided with a rubber sleeve 76, the upper end of the rubber sleeve 76 has a rib 761 inside, the outer surface of the needle roller guide block has a groove, the rib 761 is stuck in the groove, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com