Insulator metamorphic detection robot mechanism

A technology of insulators and robots, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of manual recycling, low detection efficiency, and high labor intensity, and achieve easy portability and installation, safe and reliable operation, and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

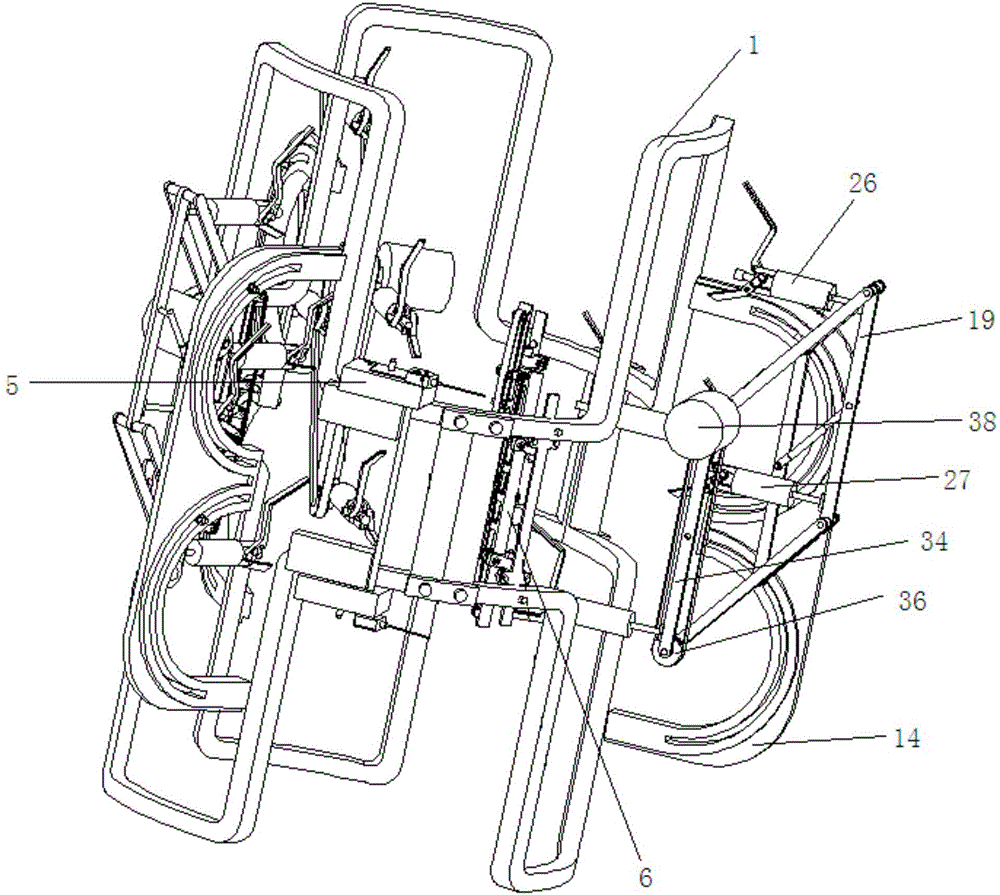

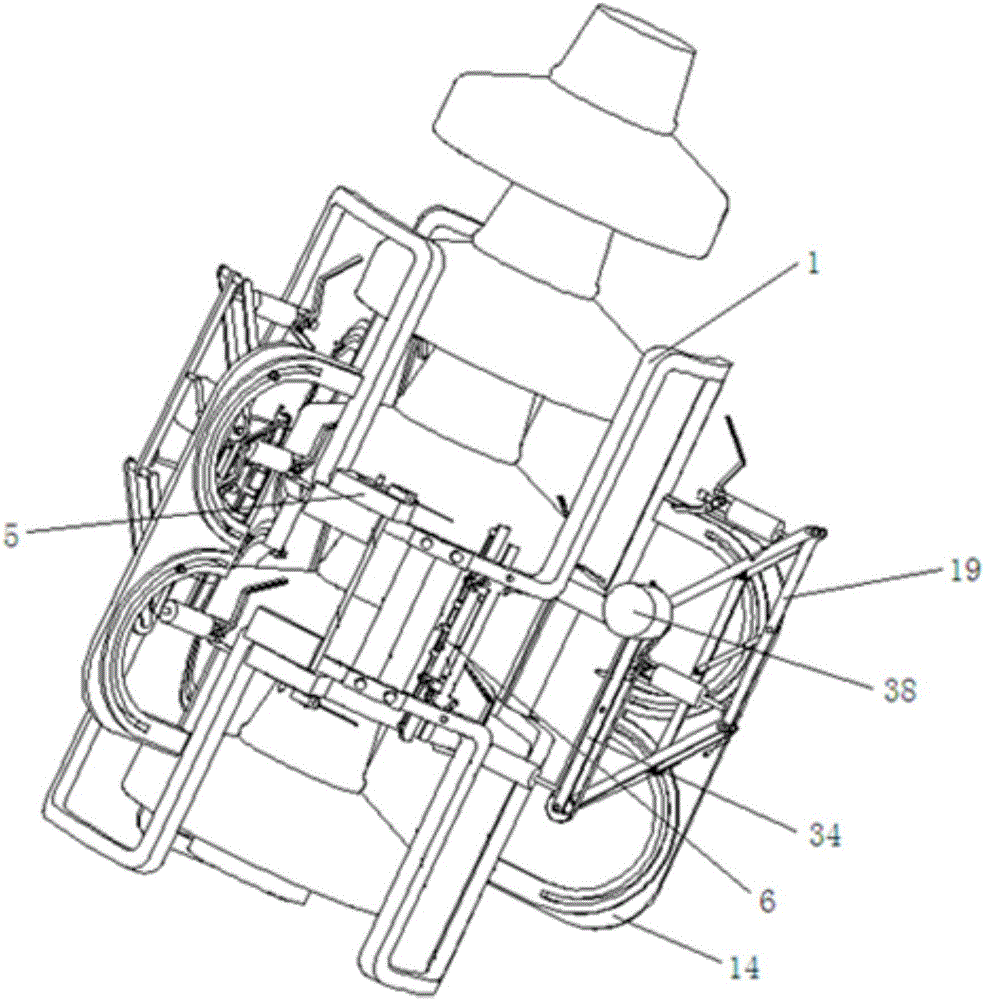

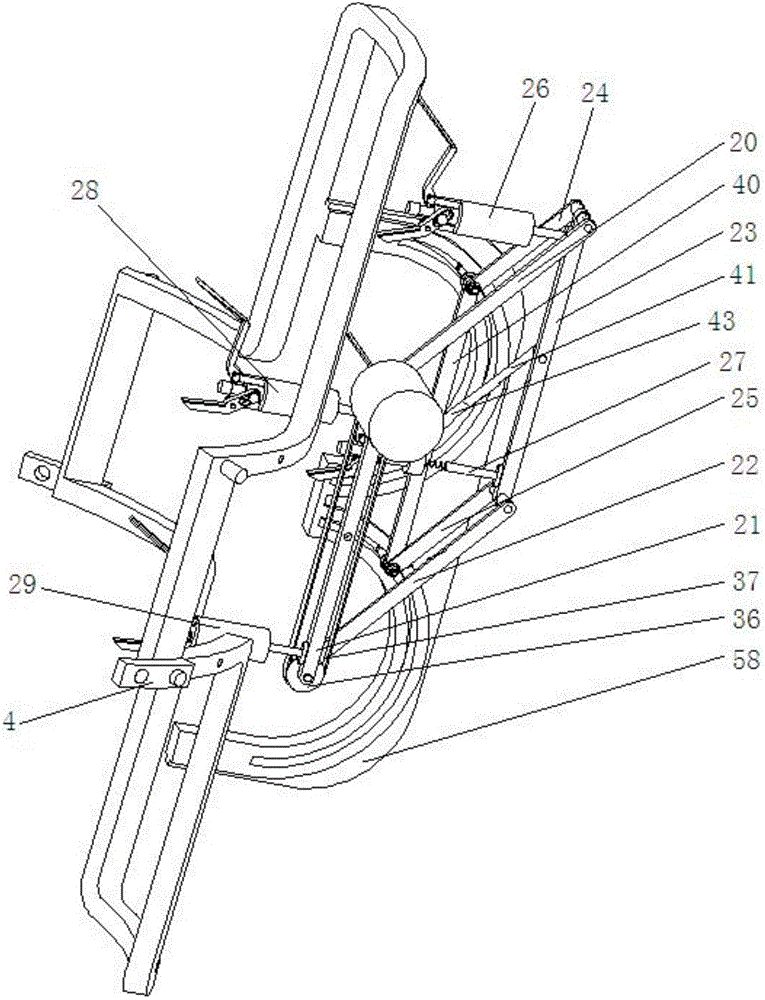

[0029] Combine below Figure 1 to Figure 15 A robot mechanism for insulator metamorphosis detection of the present invention will be further described in detail with specific embodiments.

[0030] according to Figure 1 ~ Figure 2As shown, a robot mechanism for insulator metamorphosis detection includes a mobile unit and a detection element, and at least two groups of the mobile units are connected to each other as a whole to form a mobile mechanism that surrounds the insulator string; the number of mobile units should be based on actual needs For selection, in this embodiment, three groups of mobile units are selected, and when the insulator string is inspected, the three groups of mobile units are connected in pairs by buckles 4 to form a ring structure, which surrounds the insulator string in a circumferential direction, and The insulator string is translated and moved step by step, and the insulator string is detected by the detection element 5 .

[0031] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com