Multilayer anisotropic puncture type conductive fabric adhesive and FPC reinforcing shielding structure using same

A technology of conductive cloth and conductive particles, applied in conductors, circuits, electrical components, etc., can solve the problems of explosion, serious electromagnetic interference, poor metal flexibility, etc. The effect of lack of generality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

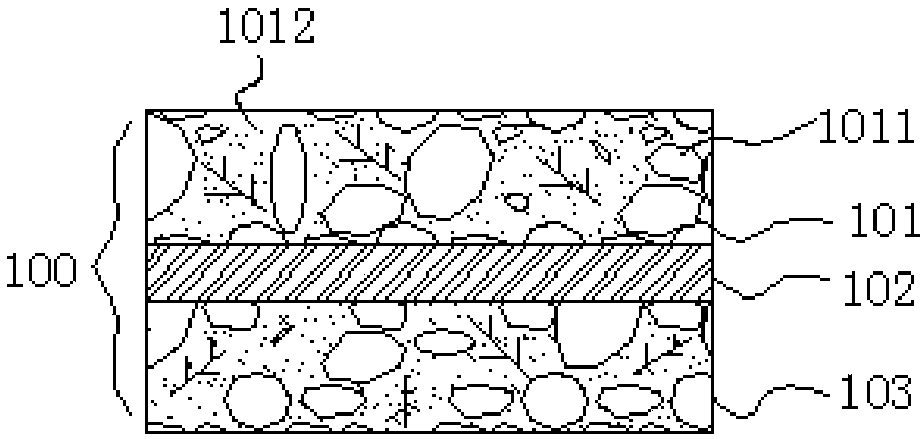

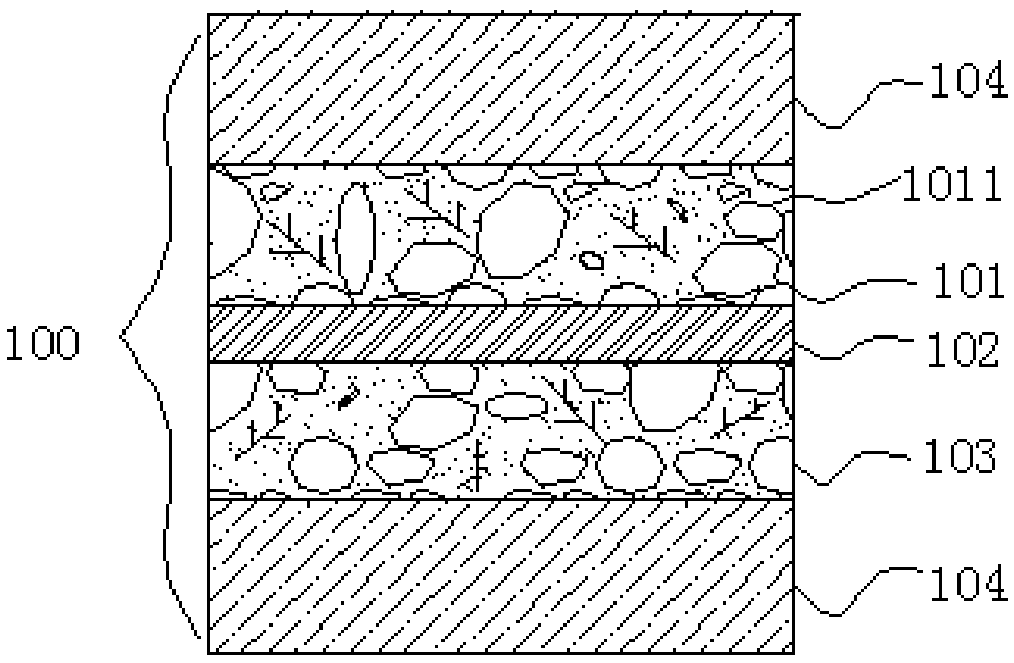

[0063] Embodiment 1: A kind of multi-layer anisotropic puncture type conductive cloth glue 100, such as figure 2 with image 3 As shown, it includes an upper conductive adhesive layer 101, an ultra-thin conductive cloth layer 102 and a lower conductive adhesive layer 103, and the ultra-thin conductive cloth layer 102 is formed on the upper conductive adhesive layer and the lower conductive adhesive layer. between;

[0064] The thickness of the upper conductive adhesive layer 101 is 15-25 μm, the thickness of the lower conductive adhesive layer 103 is 35-45 μm, and both the upper conductive adhesive layer and the lower conductive adhesive layer include metal conductive particles , the metal conductive particles are at least two of dendritic metal powder, chain metal powder, acicular metal powder, flake metal powder and spherical metal powder, and the particle size of the metal conductive particle is 40-100 μm;

[0065] The thickness of the ultra-thin conductive cloth layer 1...

Embodiment 2

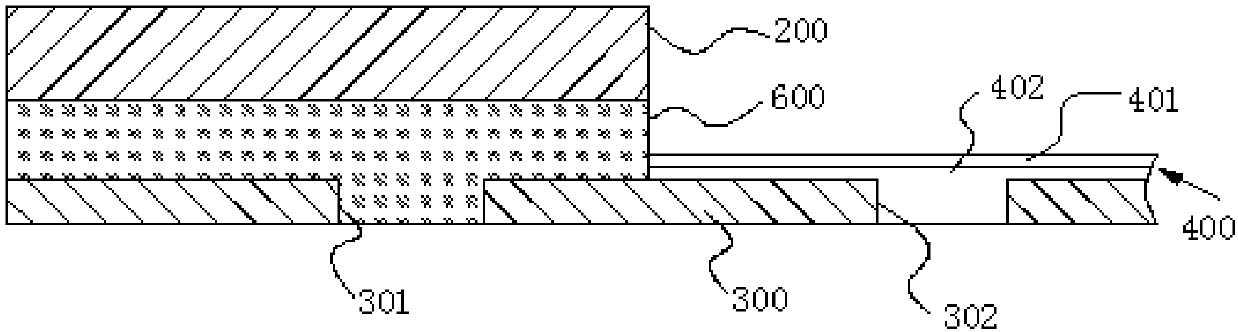

[0091] Embodiment 2: as Pic 4-1 As shown, a FPC reinforced shielding structure using the multi-layer anisotropic puncture type conductive cloth glue includes steel sheet 200, EMI film 400 and FPC 300, and the conductive cloth glue is attached to the steel sheet The lower surface, the EMI film is attached to the lower surface of the conductive cloth glue, and the FPC is attached to the lower surface of the EMI film;

[0092] The thickness of the steel sheet is 0.05-0.2mm;

[0093] Described EMI film 400 comprises ink layer 401 and conductive adhesive layer 402, and described ink layer is positioned at the top of described conductive adhesive layer, and the total thickness of described EMI film is 10-20 μ m, and the thickness of described ink layer is 5- 10 μm, the thickness of the conductive adhesive layer is 5-10 μm.

[0094] The steel sheet is a nickel-plated steel sheet, and the total thickness of the nickel-plated steel sheet is 0.05-0.2mm.

[0095] Preferably, the tota...

Embodiment 3

[0098] Embodiment 3: as Figure 4-2 As shown, the FPC reinforced shielding structure includes a steel sheet 200, an FPC 300, a first ground hole 301, an EMI film 400 and a conductive cloth glue 100, the FPC has a first ground hole 301 and a second ground hole 302, and the steel sheet There is conductive cloth glue between 200 and FPC. That is, the top of the first ground hole 301 and part of the FPC is covered with conductive cloth, and the top of the conductive cloth is pressed with a steel sheet.

[0099] After thermal pressing, the upper and lower conductive adhesive layers of the conductive adhesive tape melt and flow into the first ground hole 301 to conduct with the FPC for ground shielding. Compared with the background technology, it solves the glue overflow flow of the ordinary conductive adhesive film itself In this case, the conduction effect is also better than that of the ordinary conductive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com