Non-elastic suspension frame structure of automatic guiding vehicle

A self-guiding, inelastic technology, applied to rigid suspensions, suspensions, motor vehicles, etc., can solve problems such as increasing the hidden danger of collisions, and achieve the effect of preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

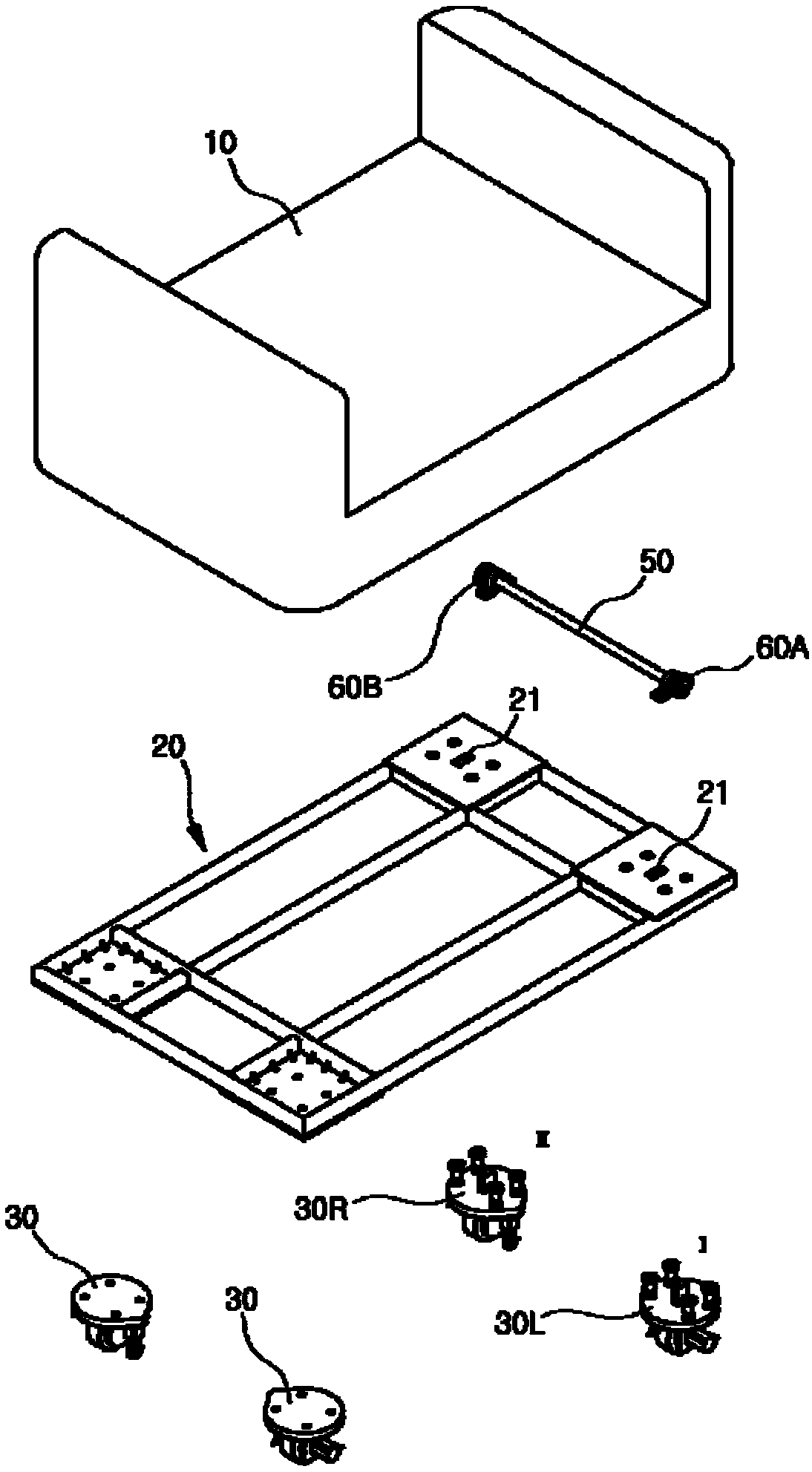

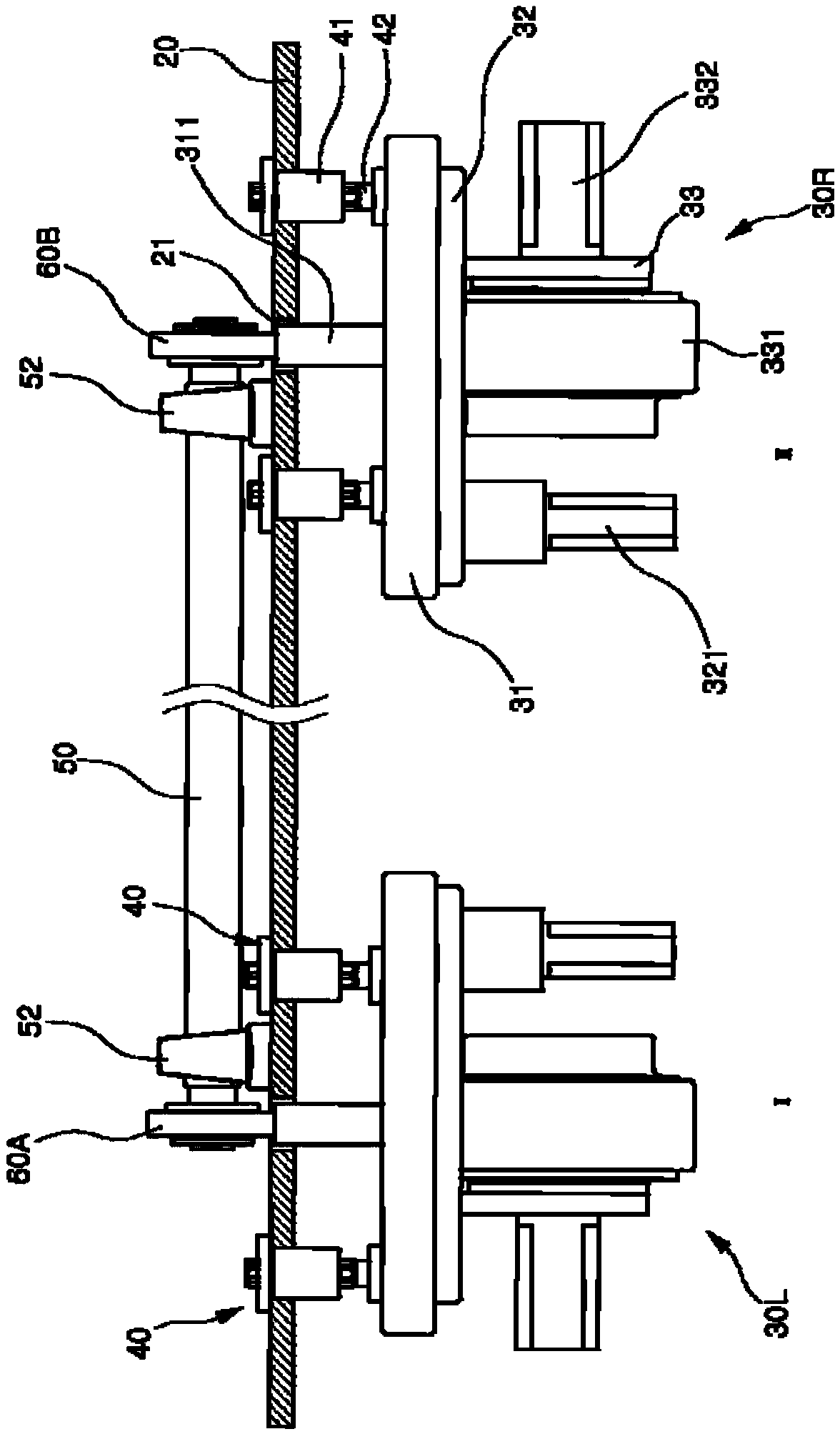

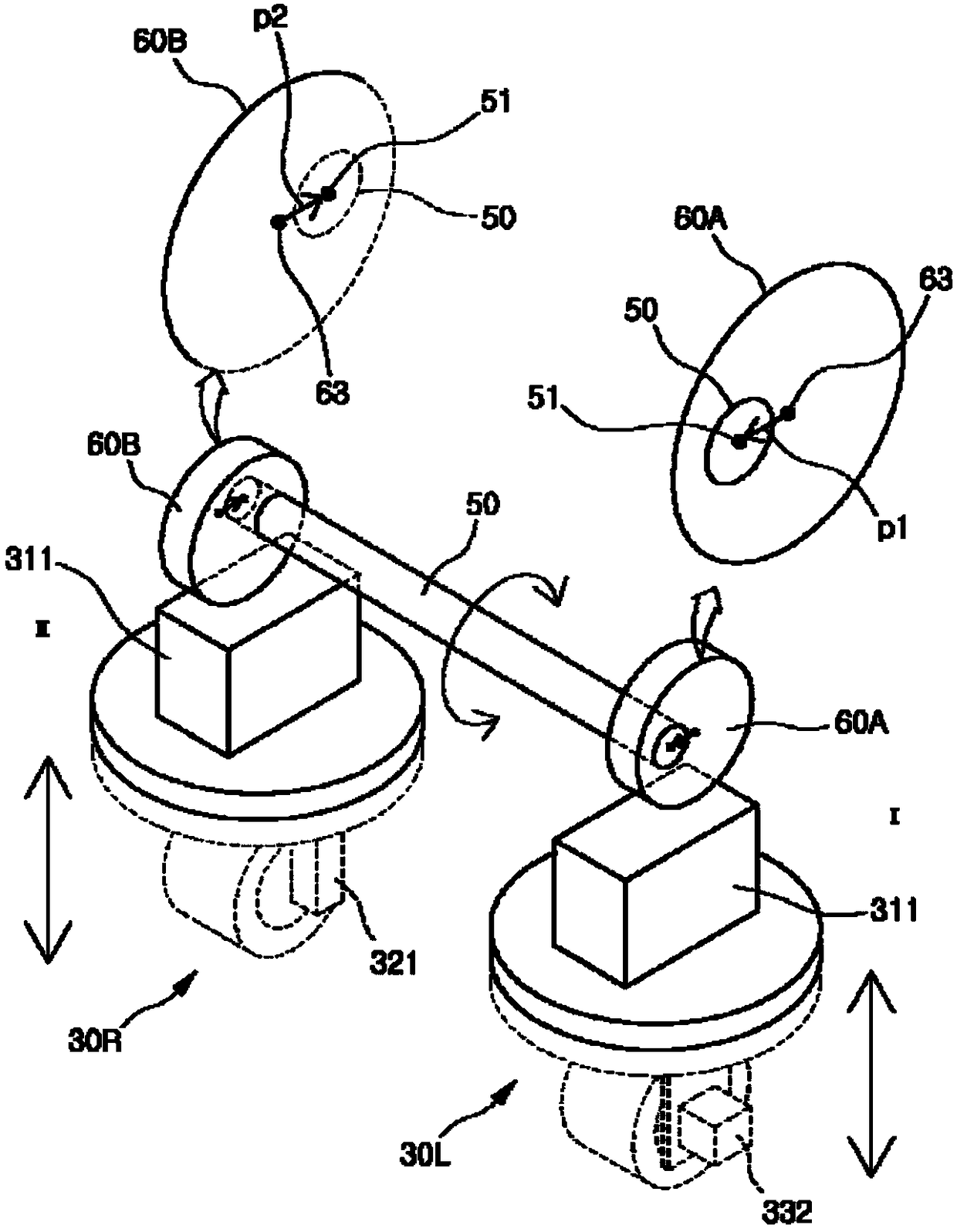

[0047] The configuration, function and effect of the inelastic suspension structure of an automatic guided vehicle according to the present invention will be described with reference to the following drawings. However, in the drawings and examples, the reference numerals for the same or similar constituent elements will be used uniformly.

[0048] In addition, in the following description, terms such as "first" and "second" are used for the purpose of easily distinguishing constituent elements having the same technical meaning. That is, any one of the constitutions may be named "first constitution" or "second constitution".

[0049] The accompanying drawings are used to illustrate the applicable embodiments of the present invention, therefore, the technical idea of the present invention should not be limited and explained by the accompanying drawings. From the perspective of experts in the technical field, if a part or all of the drawings shown in the drawings are interpret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com