Patents

Literature

107results about How to "Avoid snapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

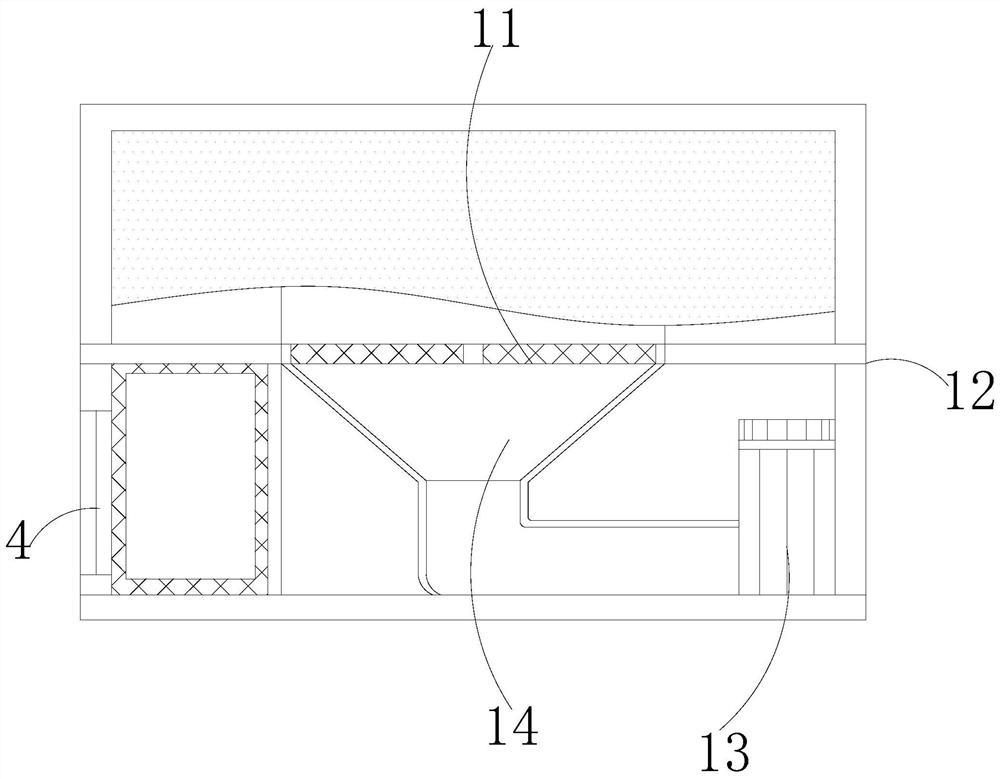

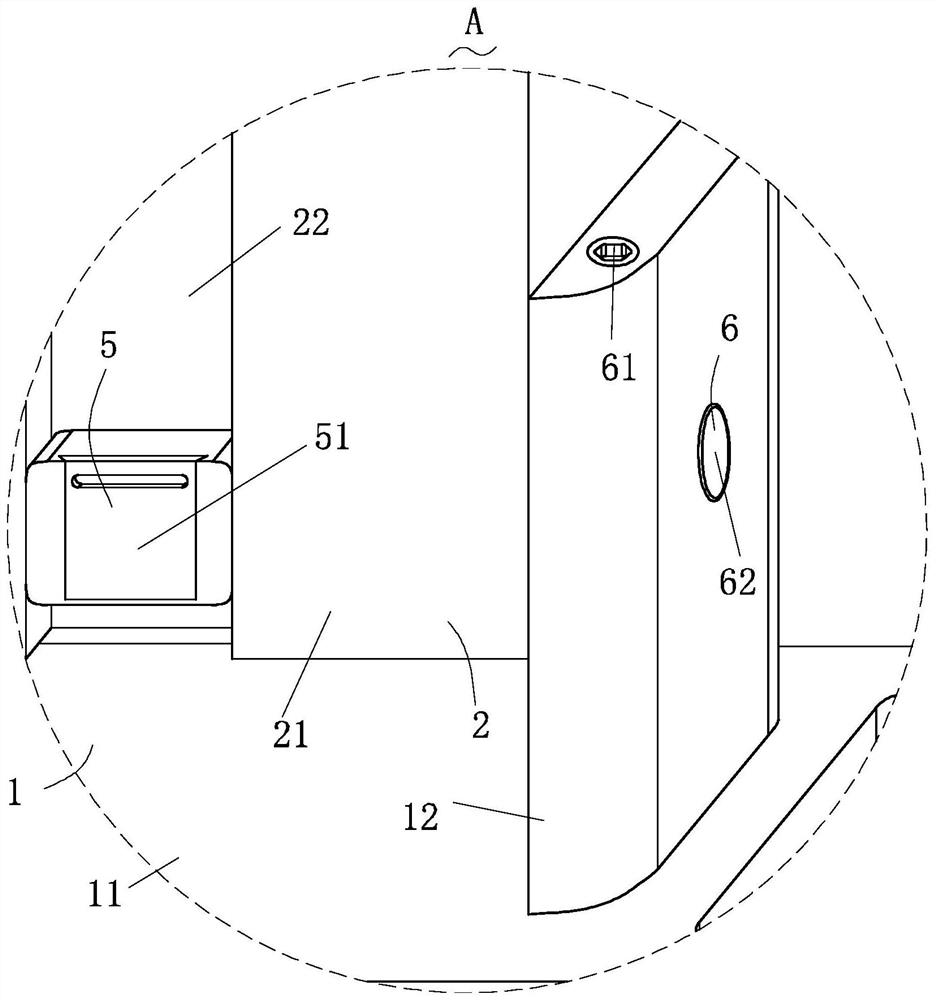

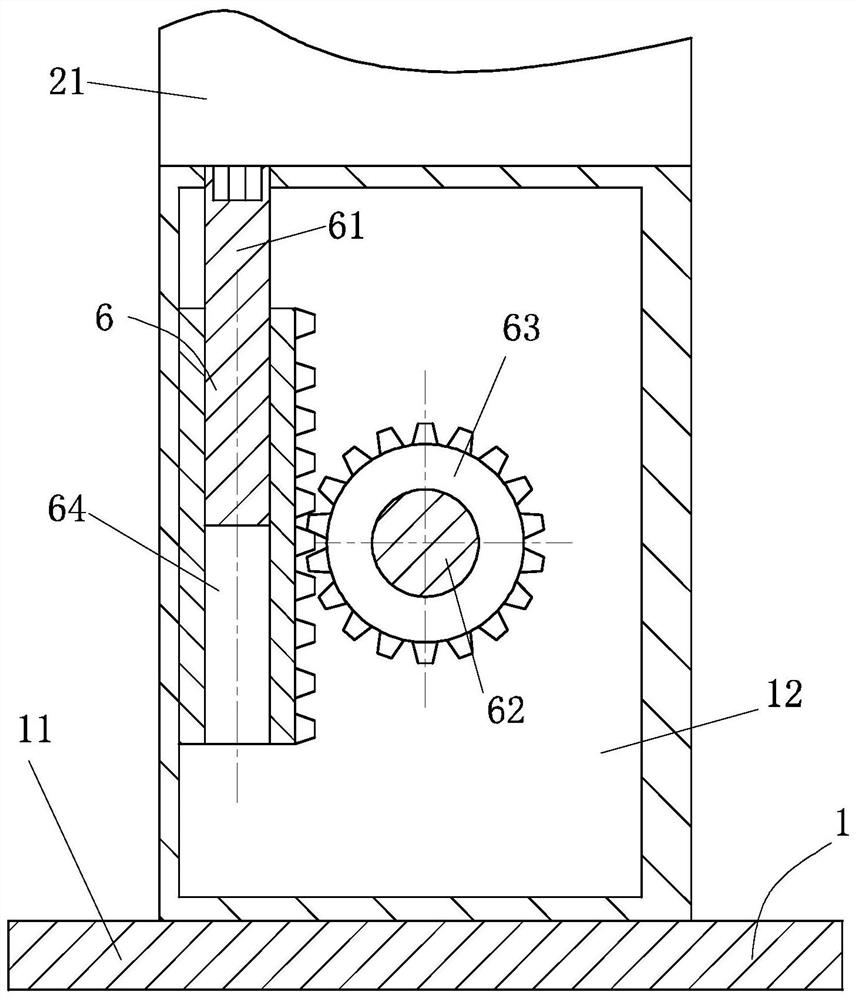

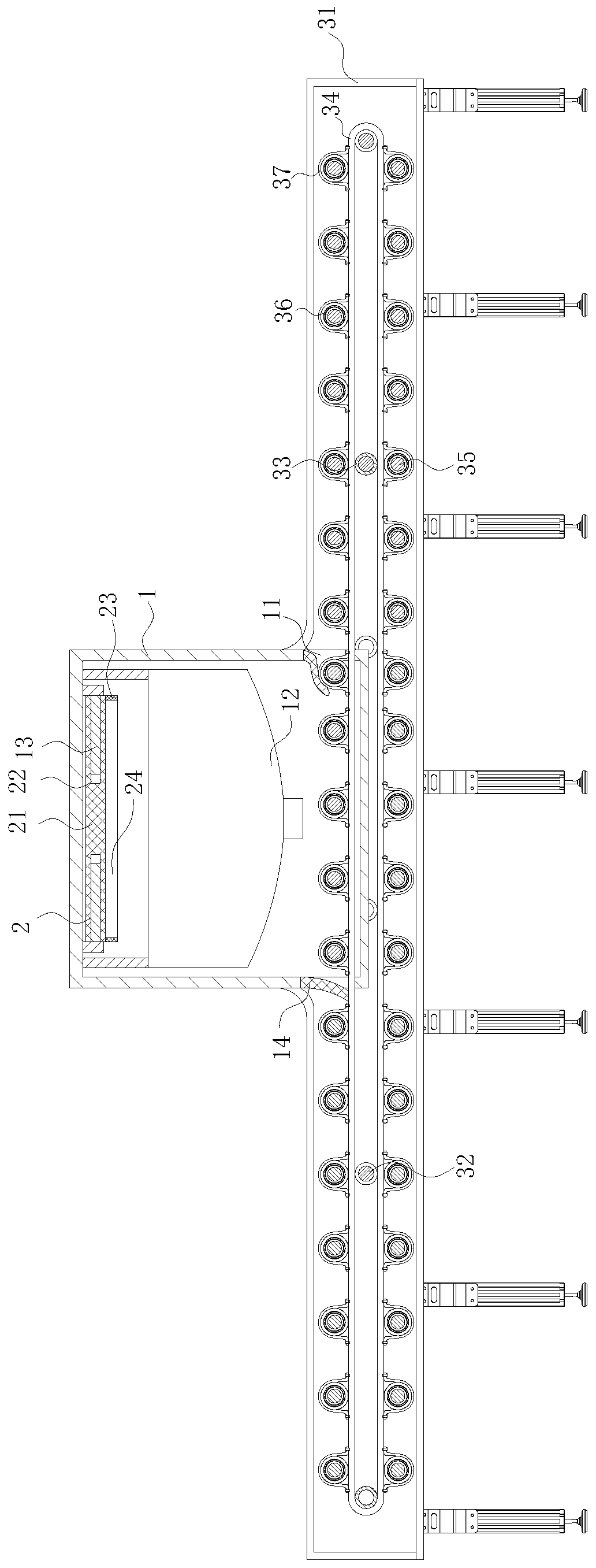

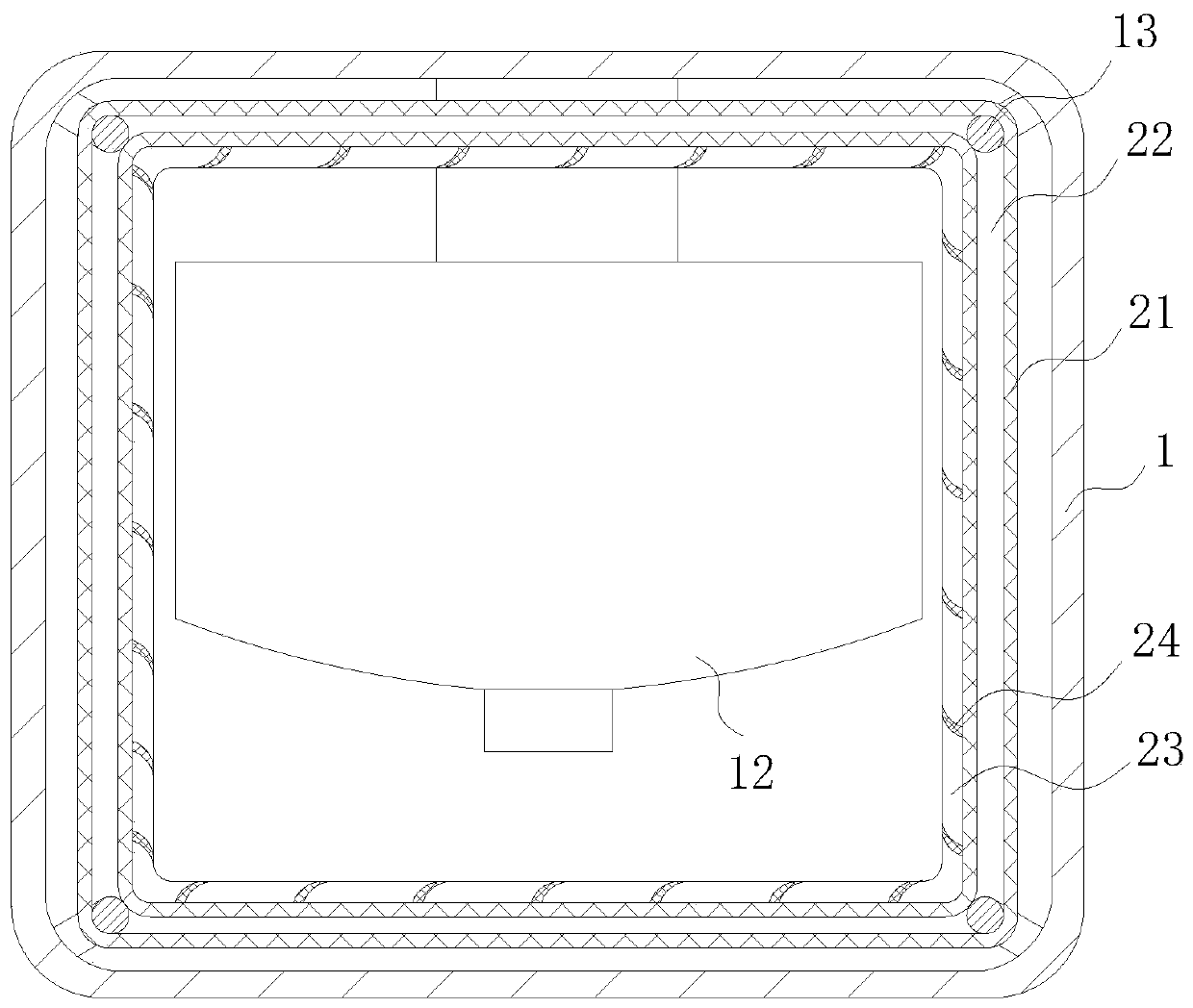

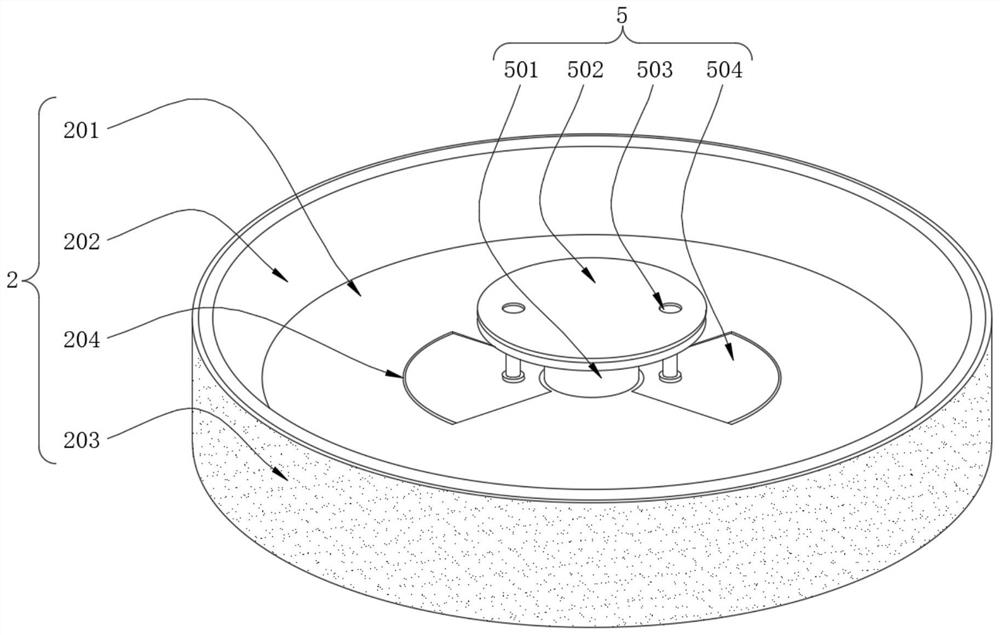

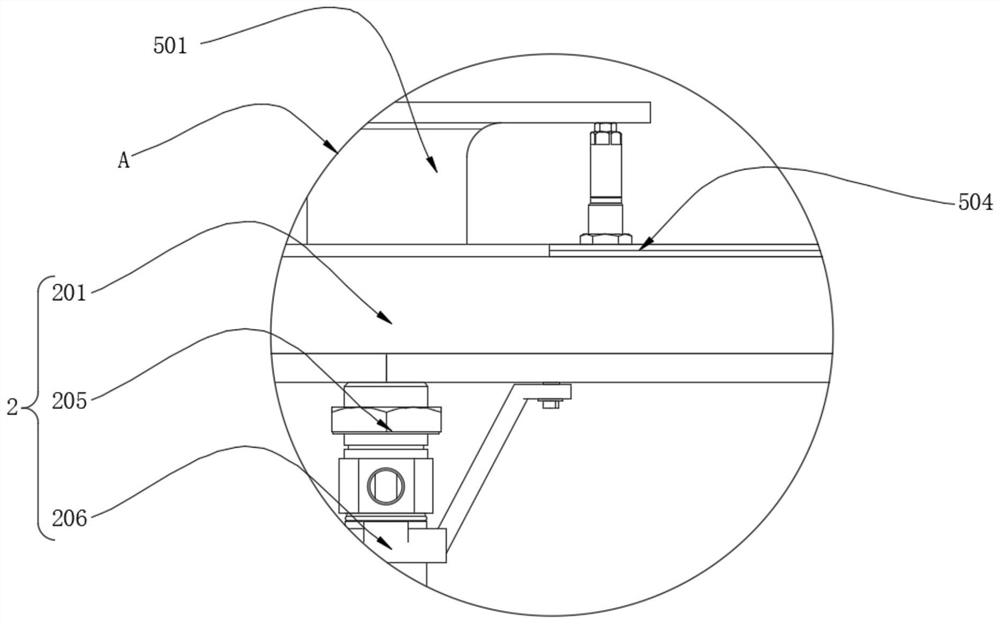

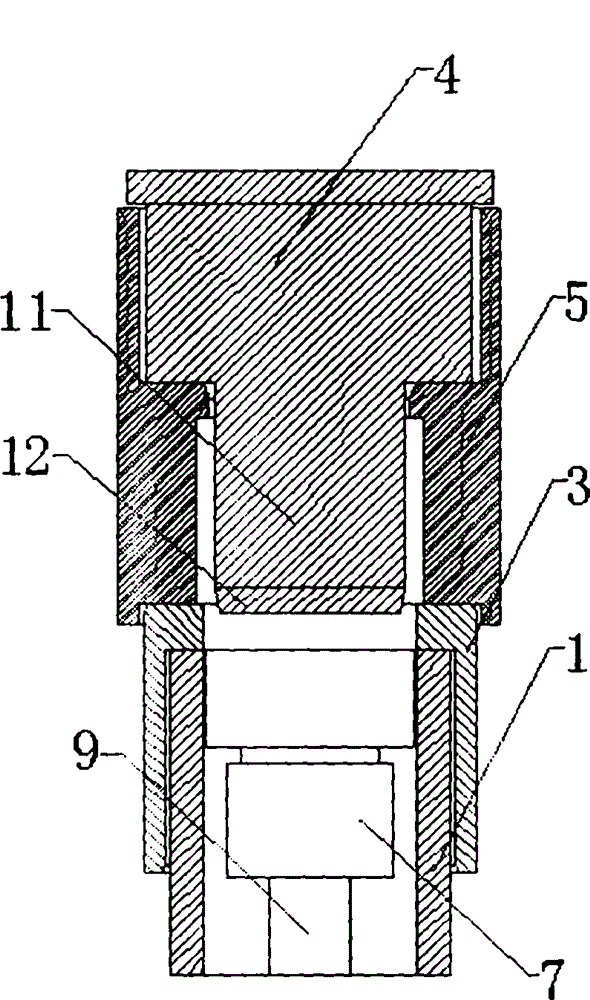

a pressure cooker

ActiveCN106724784BSolve technical problems with placementEasy to cleanPressure-cookersEngineeringPressure cooking

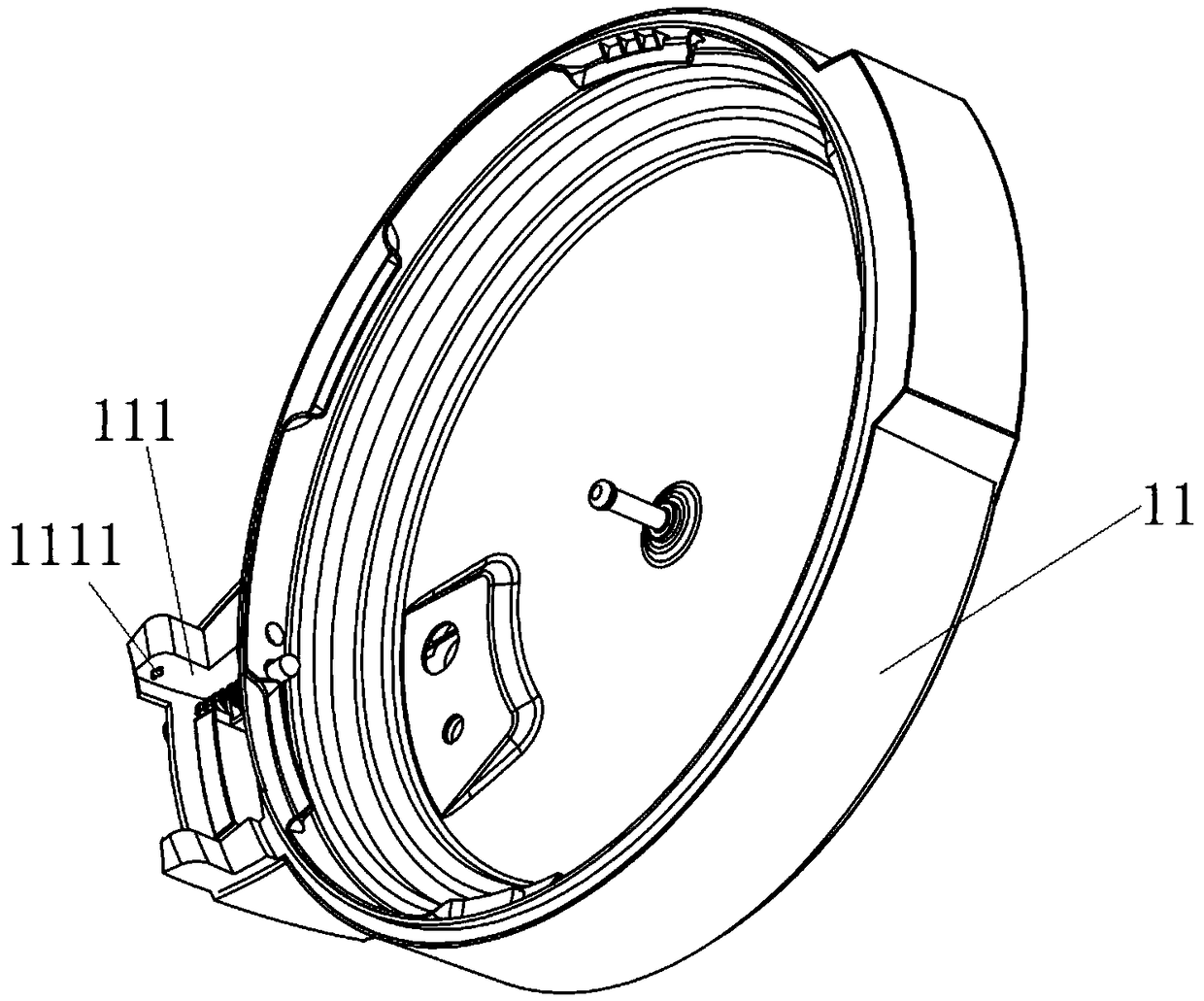

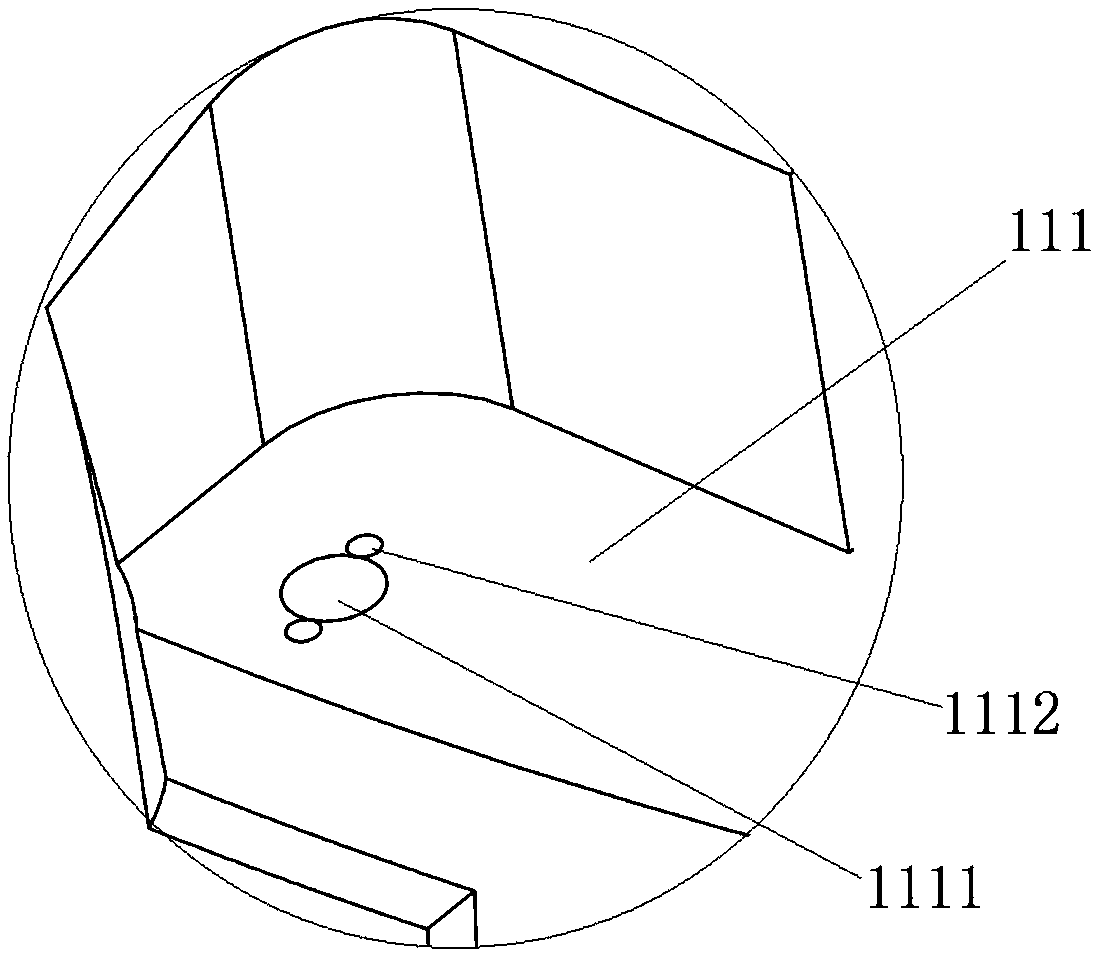

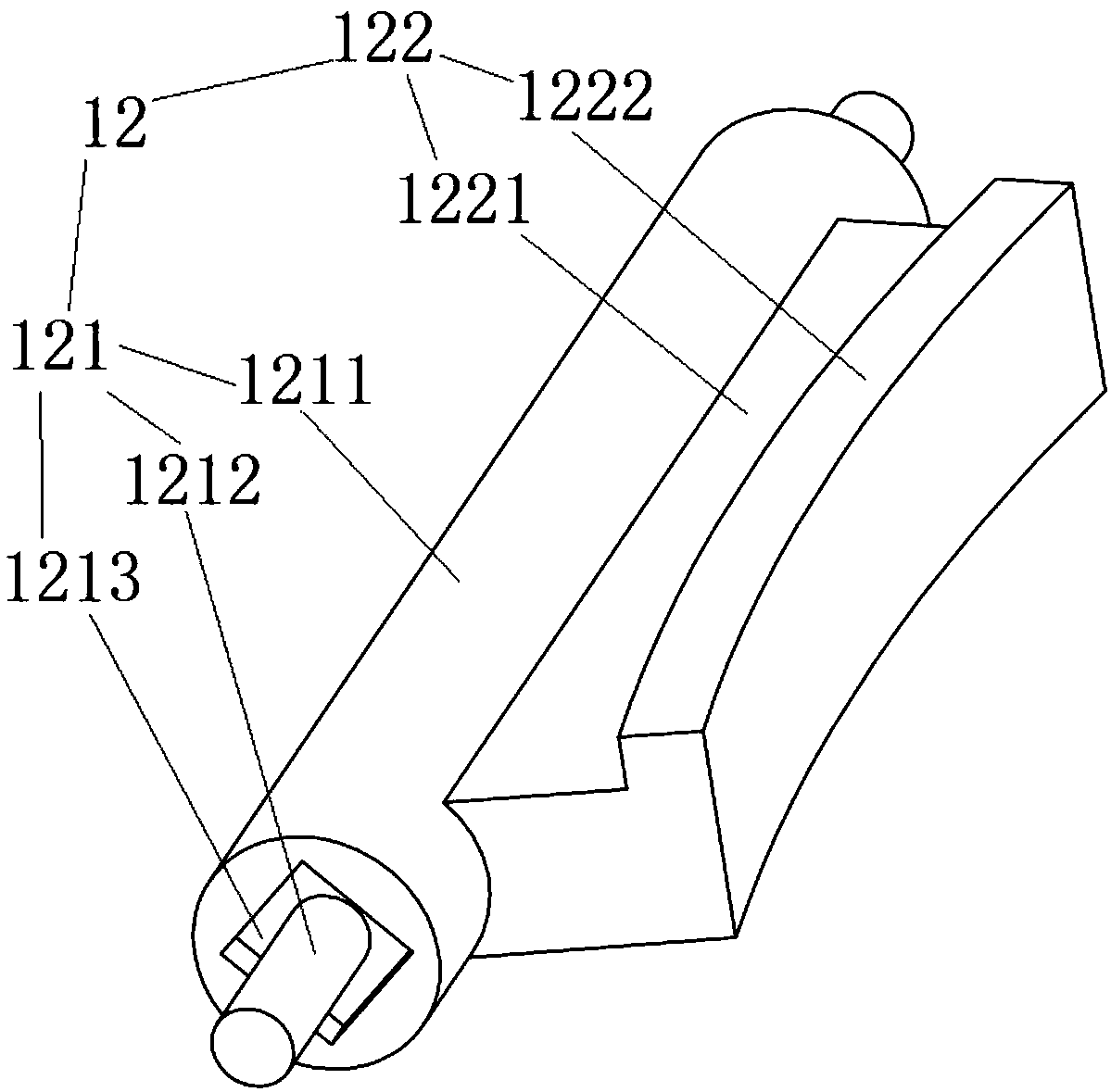

The invention provides a pressure cooker and relates to the technical field of household electrical appliances. According to the mainly-adopted technical scheme, the pressure cooker comprises a pot cover and a pot body, wherein the pot cover comprises a pot cover body and fixing parts; the pot cover body is connected with the fixing parts in a rotating mode so that the pot cover body can rotate relative to the fixing parts; the pot body is provided with a lock catch structure, wherein when the pressure cooker is in an uncovered state, the fixing parts are locked on the lock catch structure in a detachable way. The invention mainly aims at providing the pressure cooker, wherein the pot cover is detachably connected with the pot body, and the stability of the rotation of the pot cover is improved during the process when the pot cover is opened and closed; and the phenomenon of stagnation caused by too large an angle of the opened pot cover is prevented.

Owner:GREE ELECTRIC APPLIANCES INC

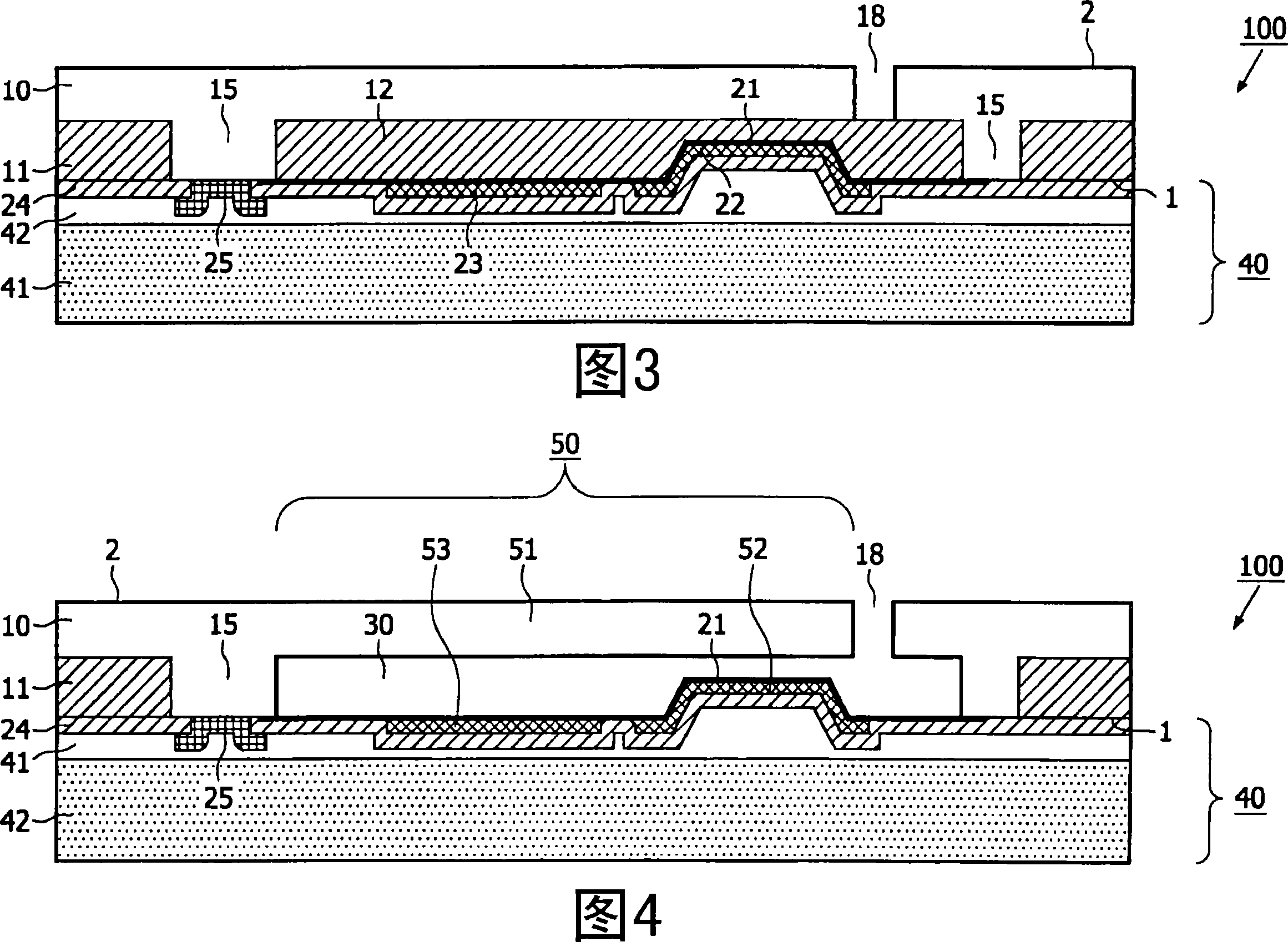

A method of manufacturing a mems element

InactiveCN101213142AAdjustable mechanical propertiesHigh resolutionDecorative surface effectsChemical vapor deposition coatingSemiconductor materialsBiomedical engineering

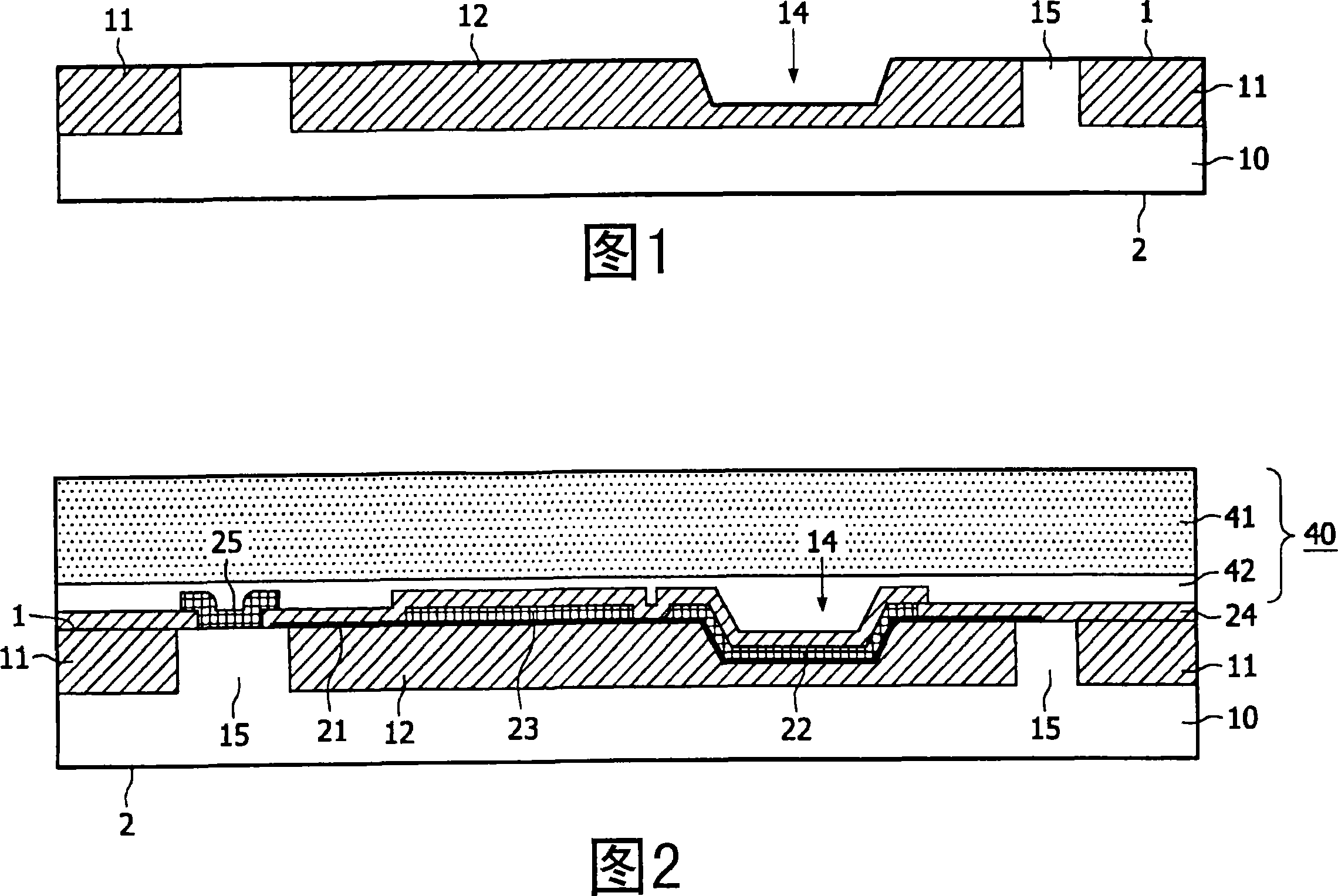

The device (100) comprises a semiconductor material substrate (10) having a first surface and an opposite second surface (1, 2), and a microelectromechanical (MEMS) element (50) provided with fixed electrodes and movable Movable electrodes (52, 51) are located in the cavity (30). One of the electrodes (51, 52) is defined in the substrate (10). The movable electrode (51) is movable toward and from the fixed electrode (52) between a first gap position and a second position. The cavity (30) is opened by a hole (18) in the substrate (10), said hole (18) being exposed on the second surface (2) of the substrate (10). The cavity (30) has a height defined by at least one post (15) in the base plate (10), which substantially surrounds the cavity (15) laterally.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

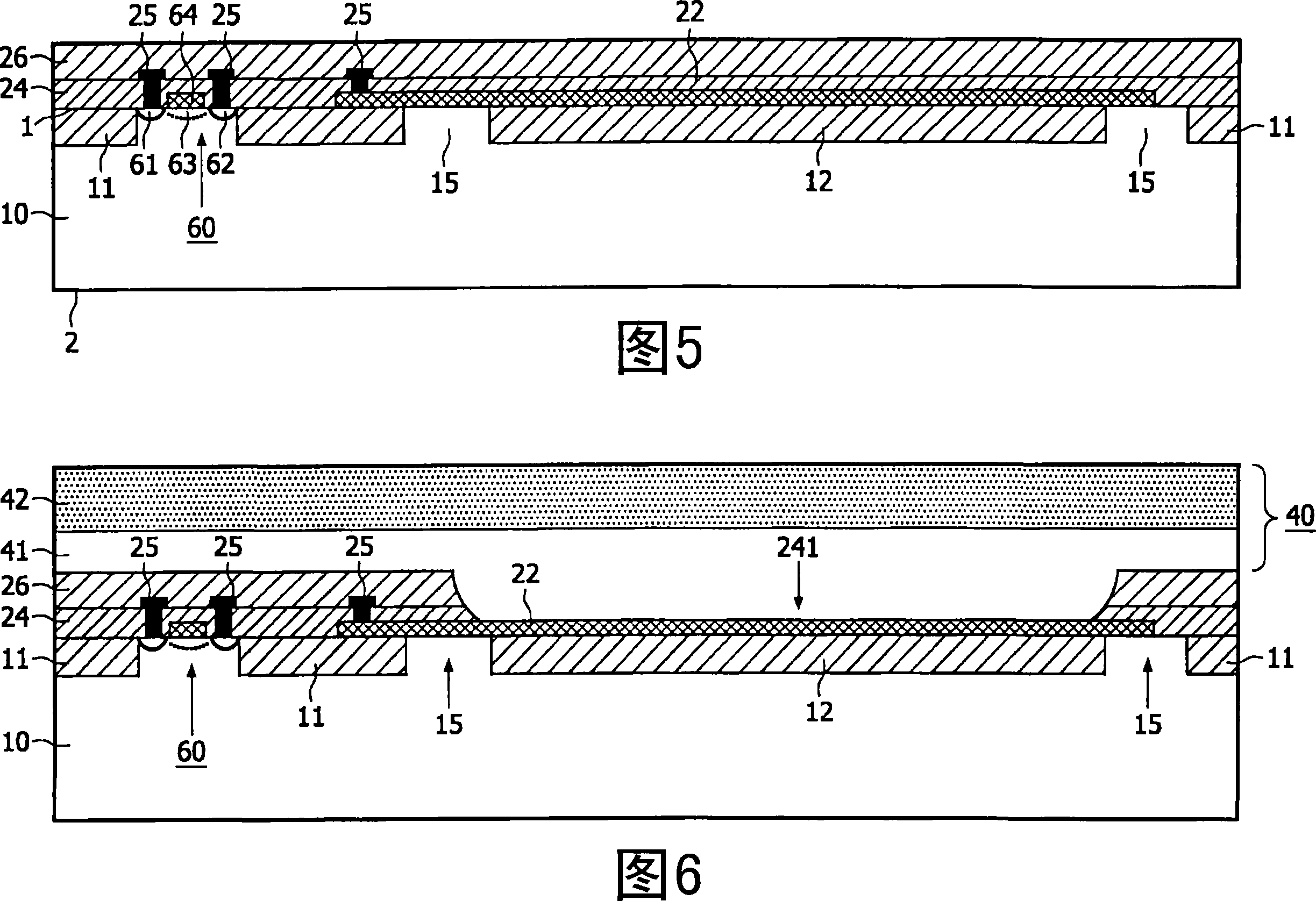

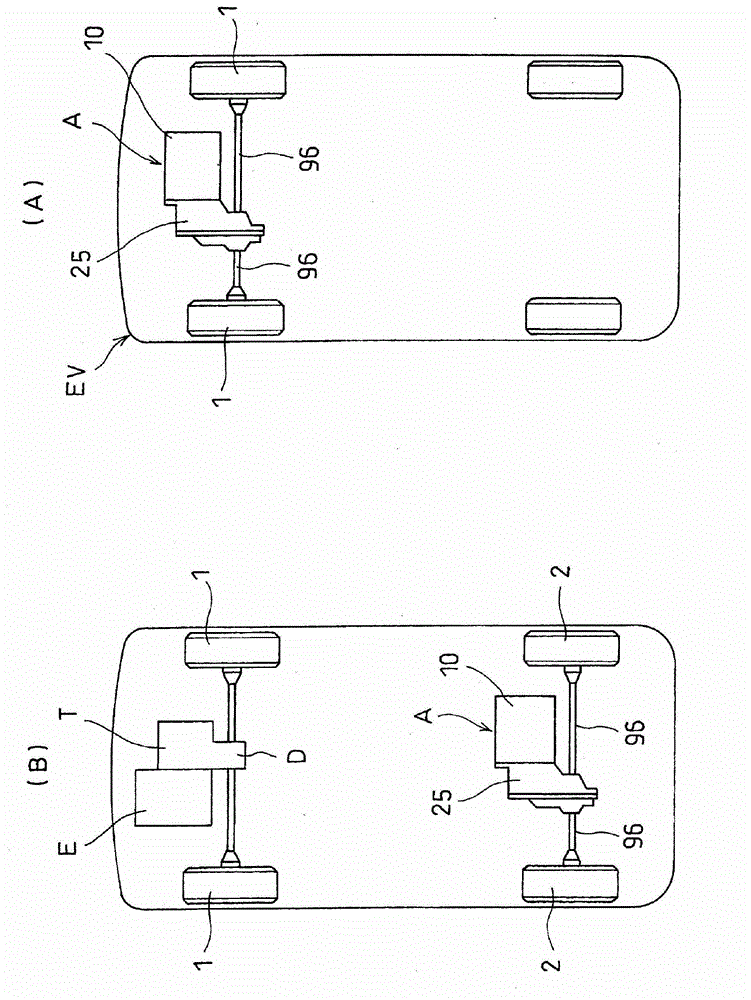

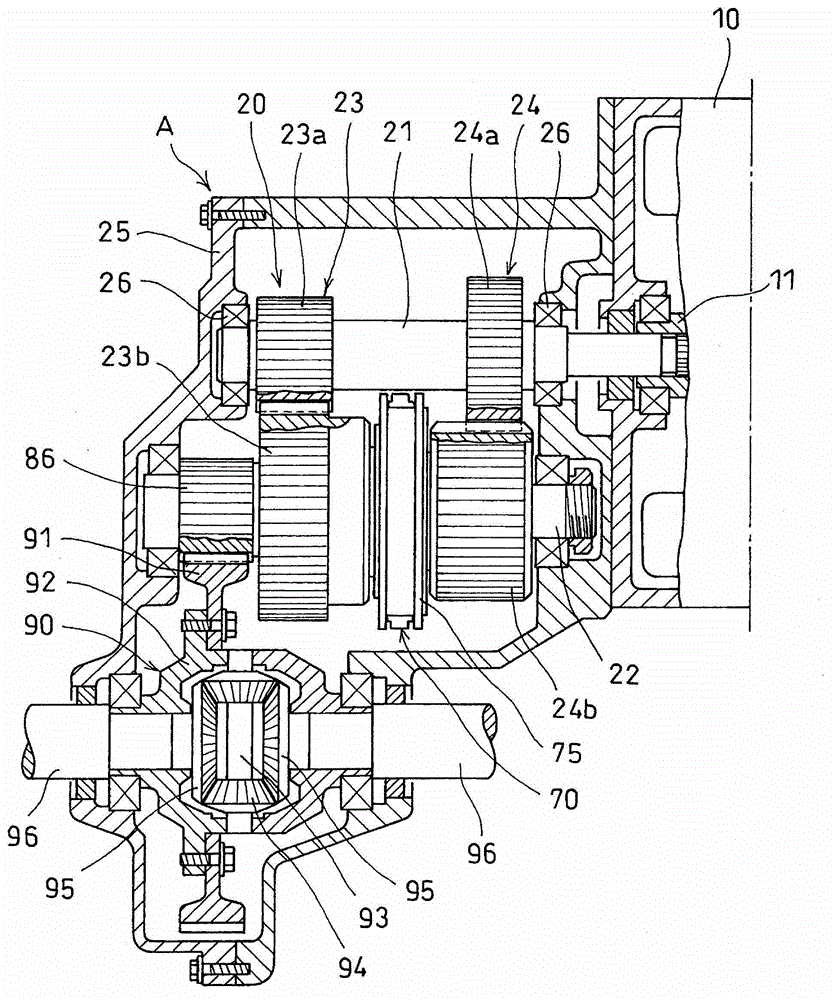

Vehicle drive device

ActiveCN103171430AIncrease profitReduce power consumptionHybrid vehiclesVehicle sub-unit featuresWheel driveSpur gear

The present invention provides a vehicle drive device which can generate a desired yawing moment when left and right reverse torque control is carried out and control first and second motors to be at any target rotating speed simultaneously. A back-wheel drive device is equipped with a left-wheel drive unit possessing a first motor and a first planetary gear reducer arranged on the transmission paths of the first motor and a left back-wheel; a right-wheel drive unit possessing a second motor and a second planetary gear reducer arranged on the transmission paths of the second motor and a right back-wheel; and a control unit. The first motor is connected with a sun gear of the first planetary gear reducer, and the second motor is connected with a sun gear of the second planetary gear reducer; the left back-wheel is connected on a planetary gear carrier of the first planetary gear reducer, the right back-wheel is connected on a planetary gear carrier of the second planetary gear reducer, and inner gears are connected with each other.

Owner:HONDA MOTOR CO LTD

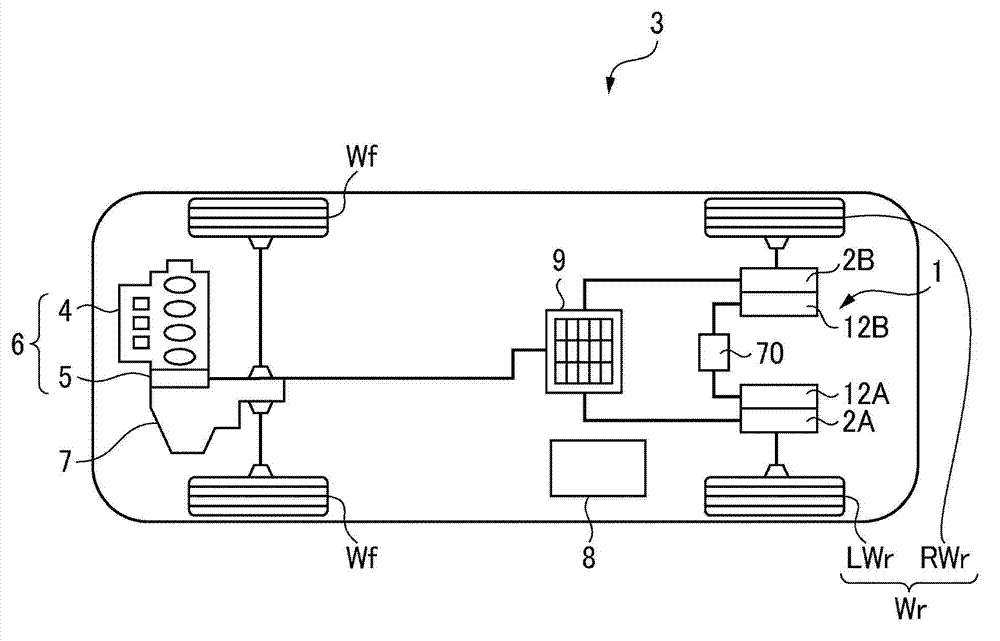

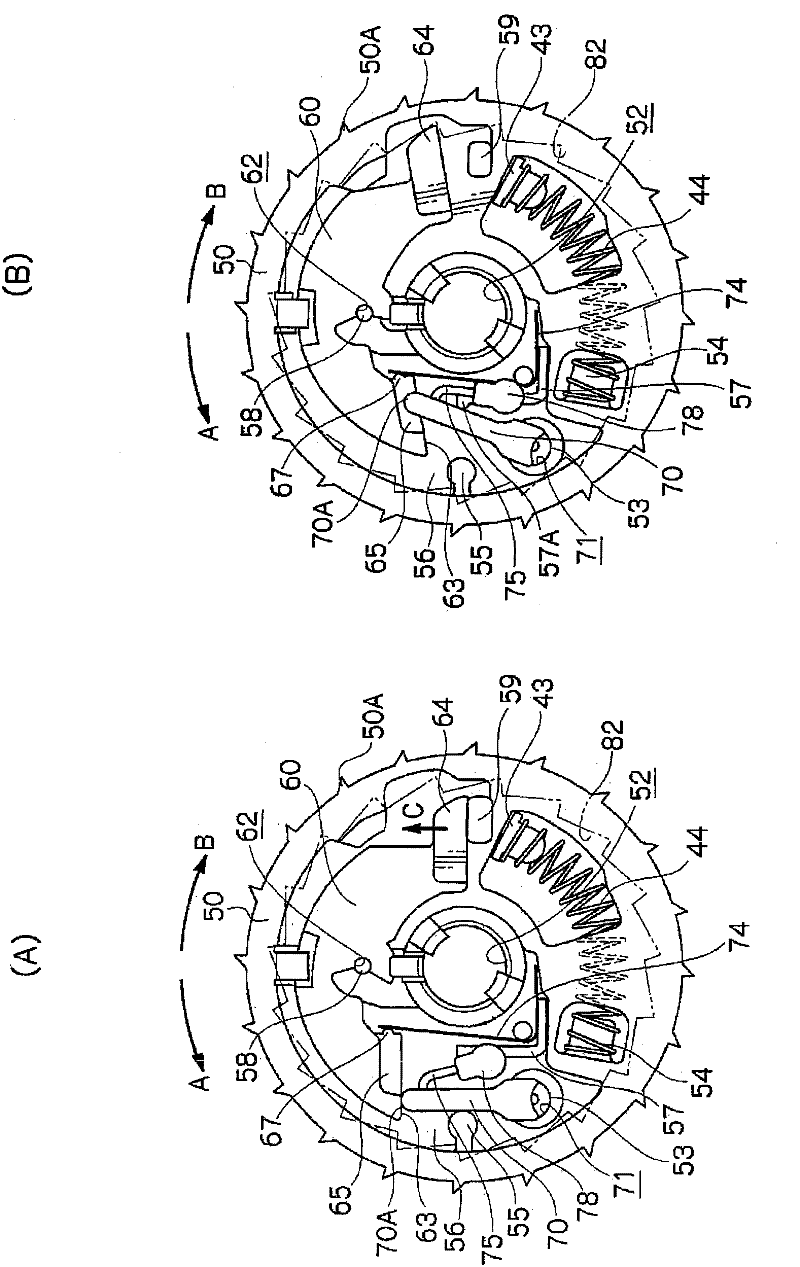

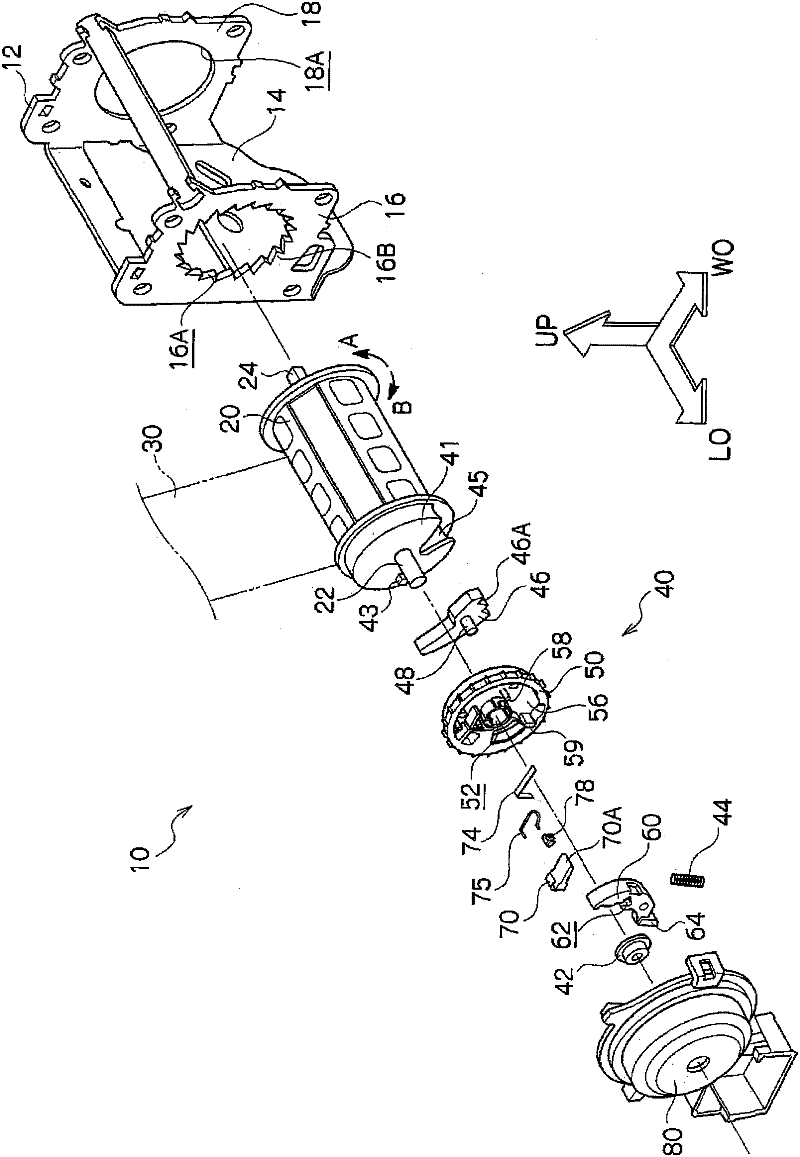

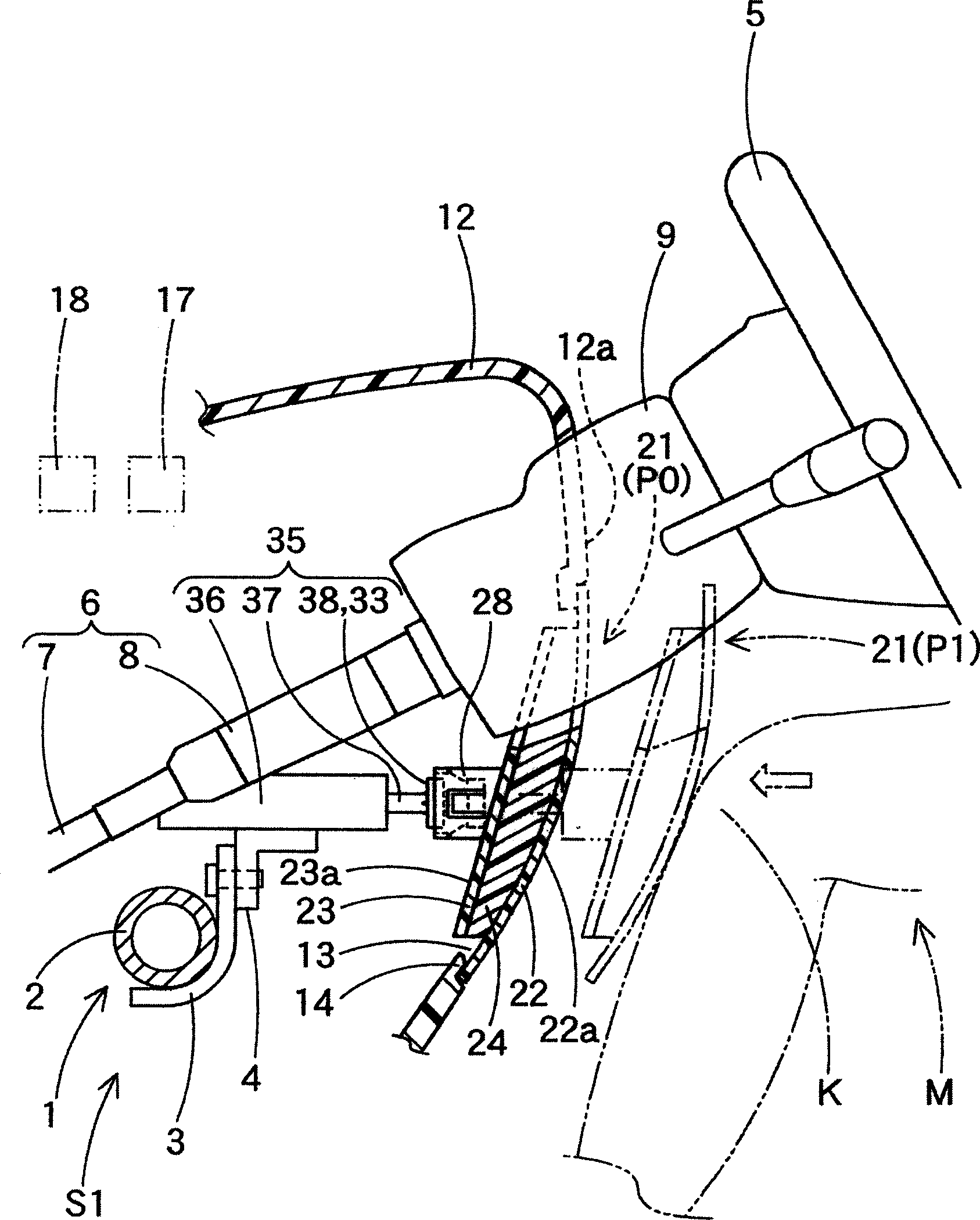

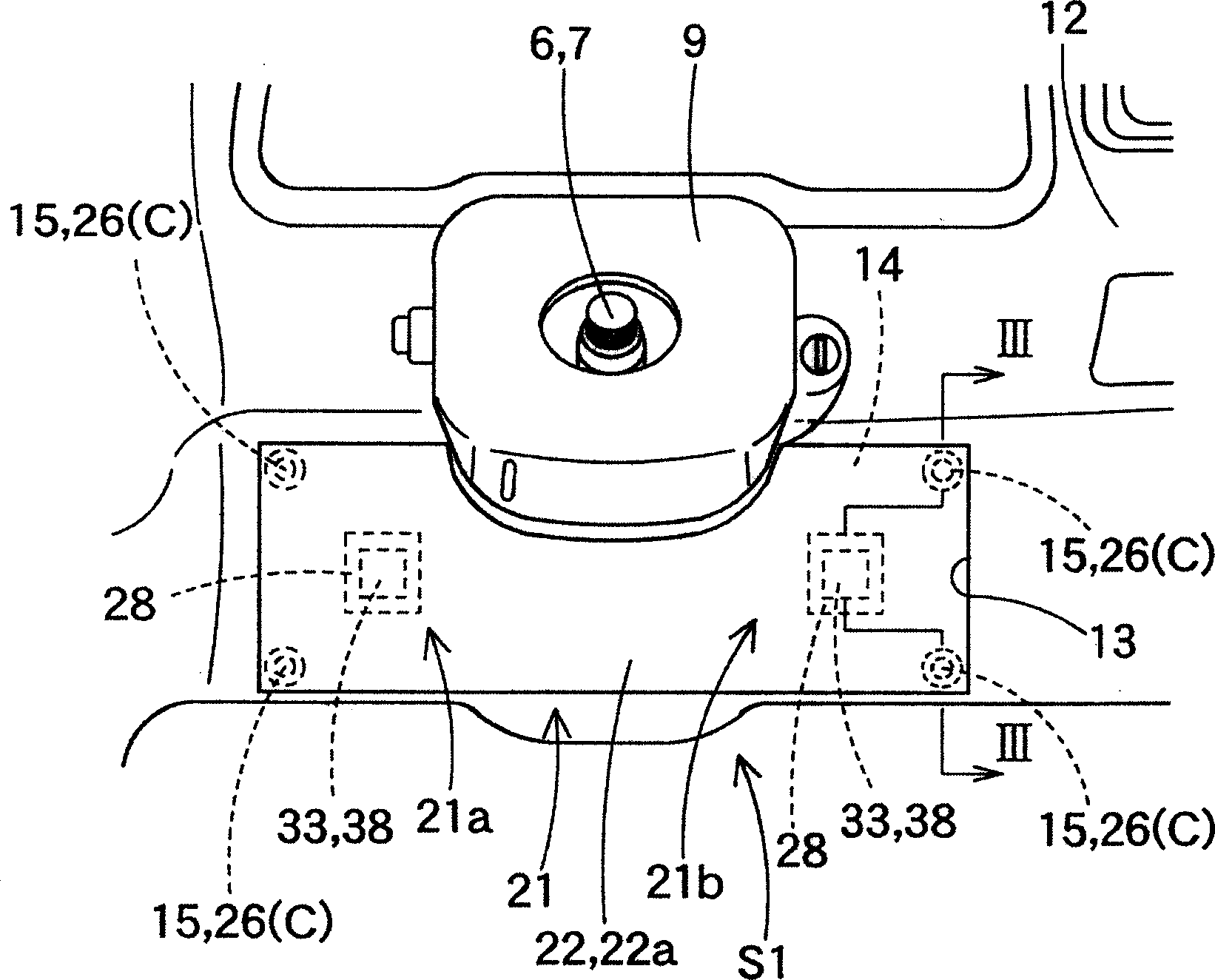

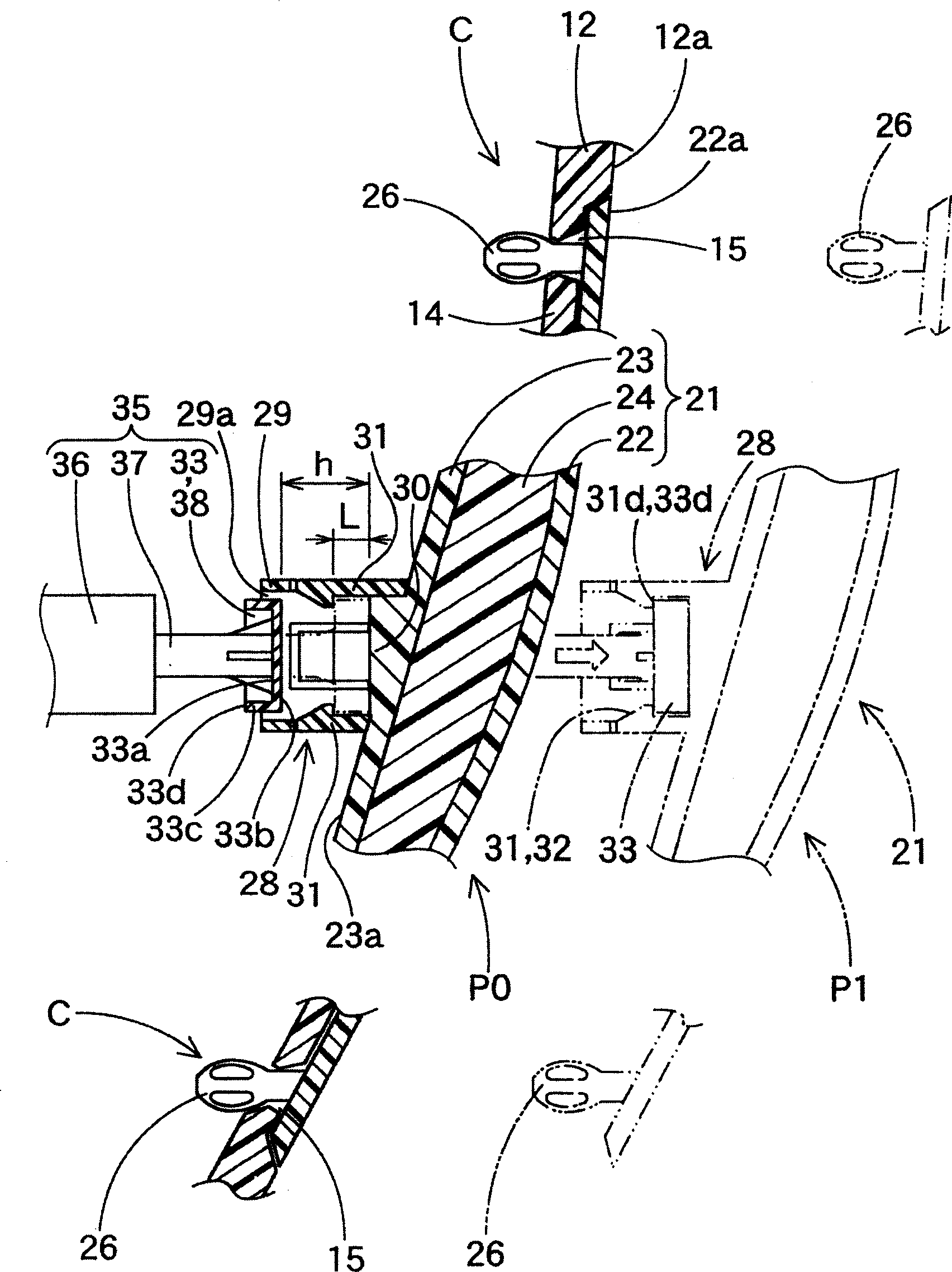

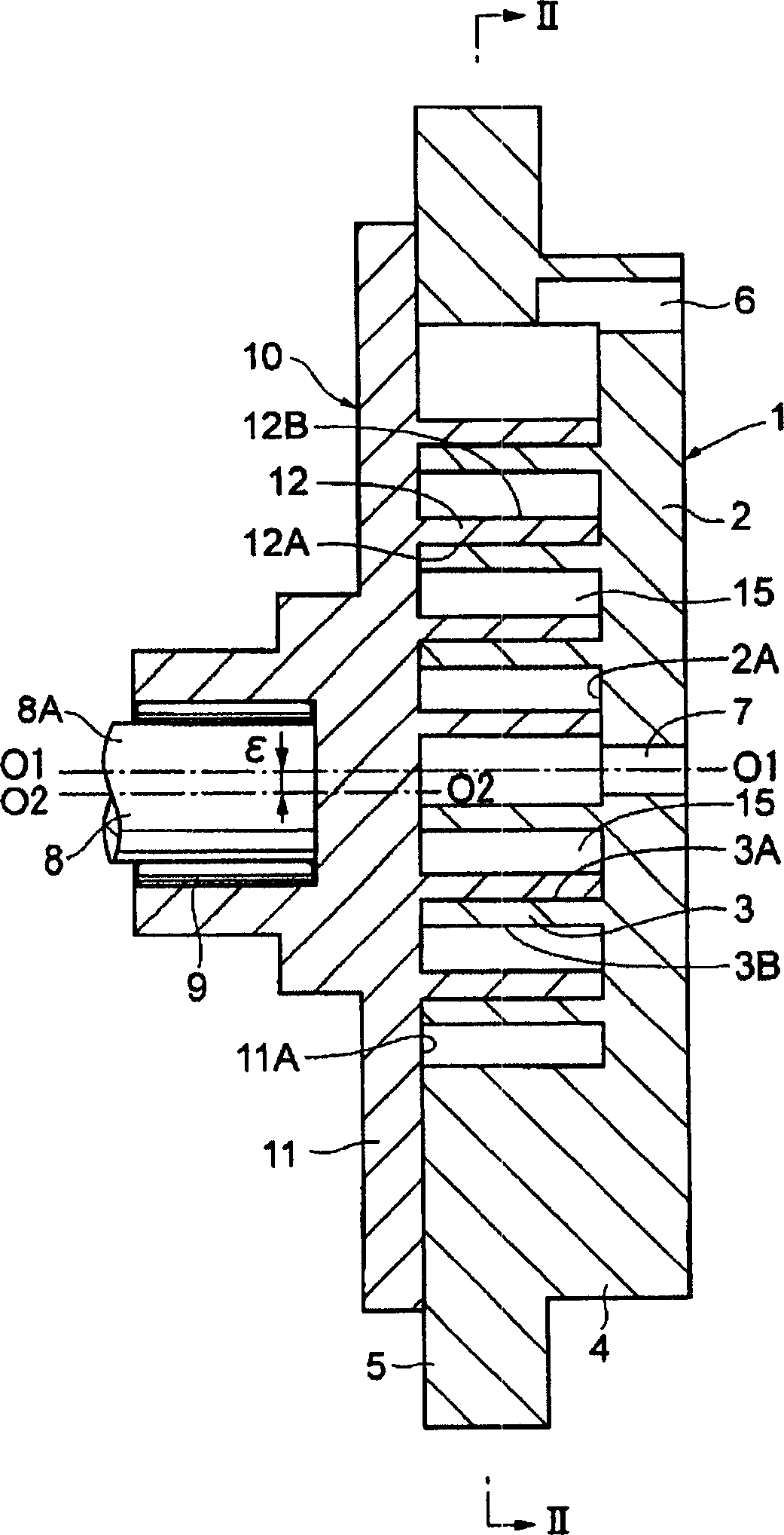

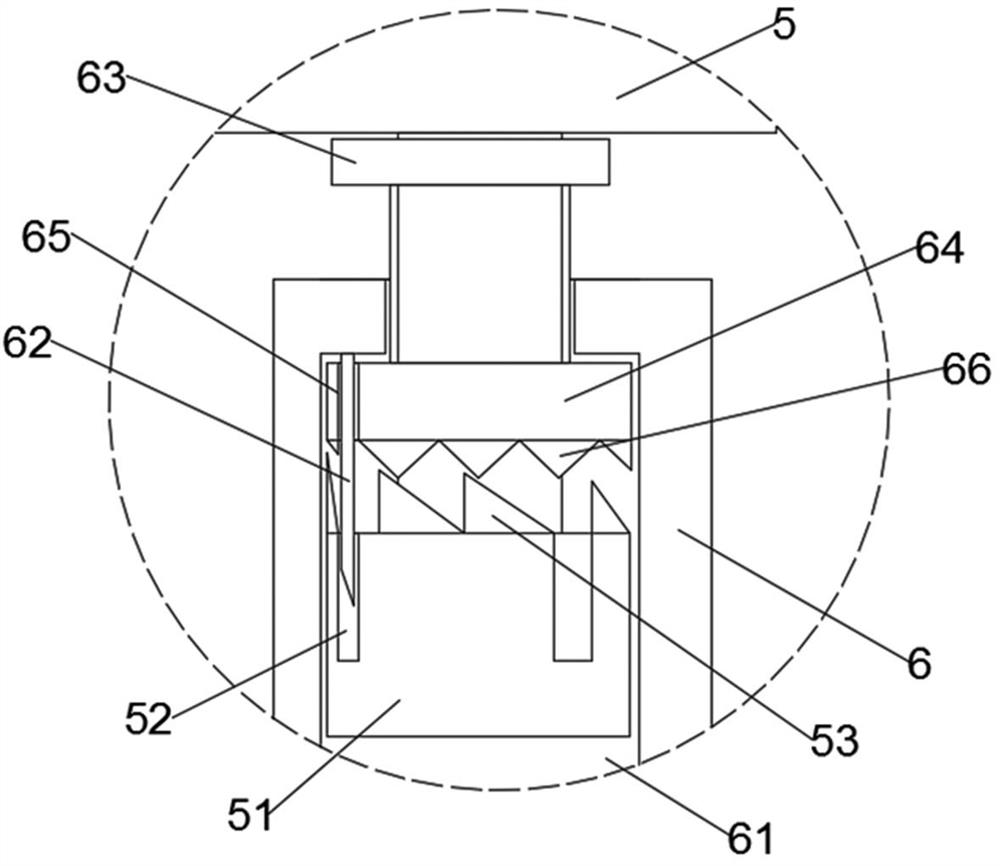

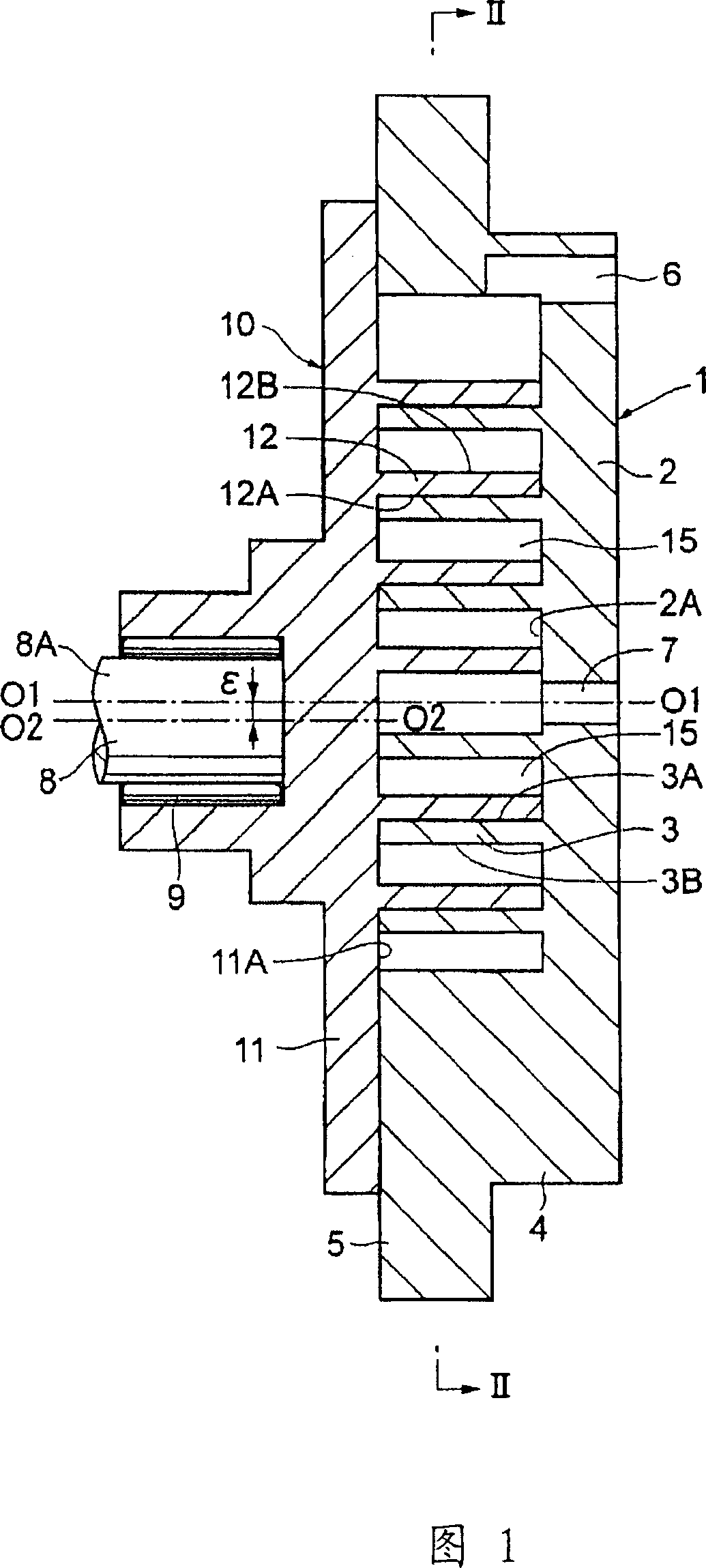

Motor drive apparatus for vehicle, and automobile

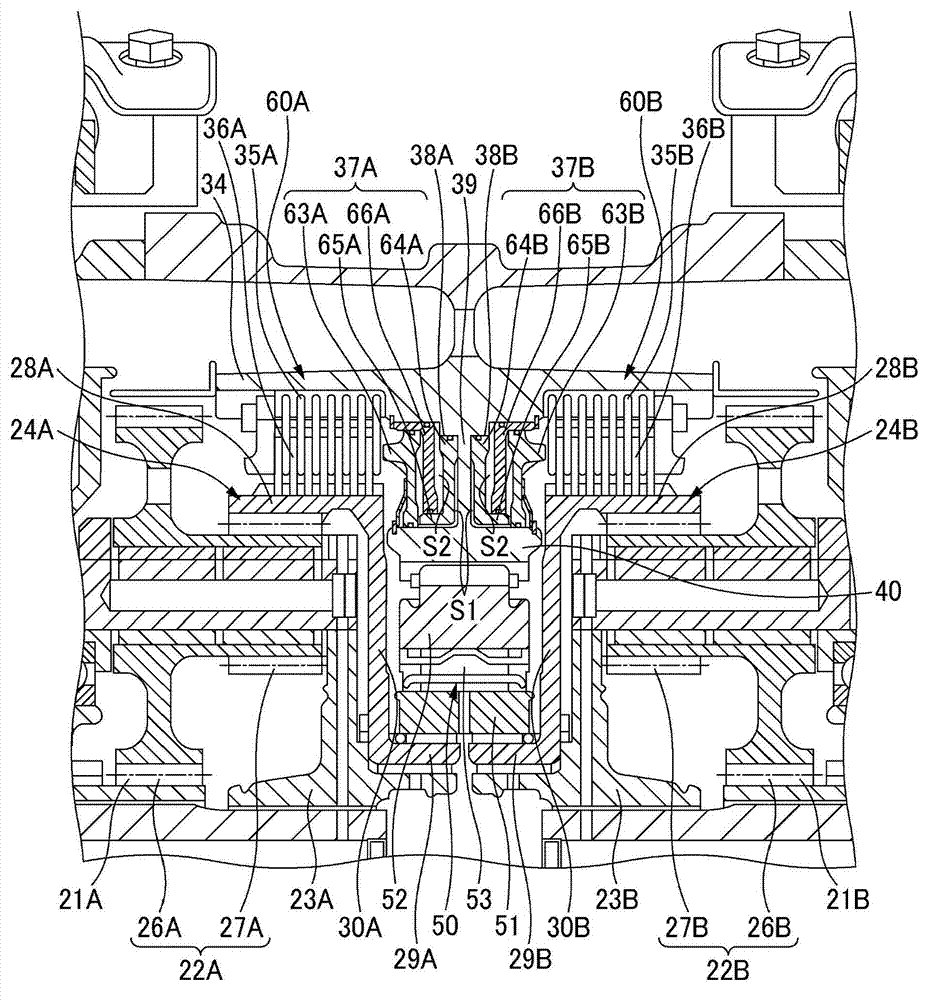

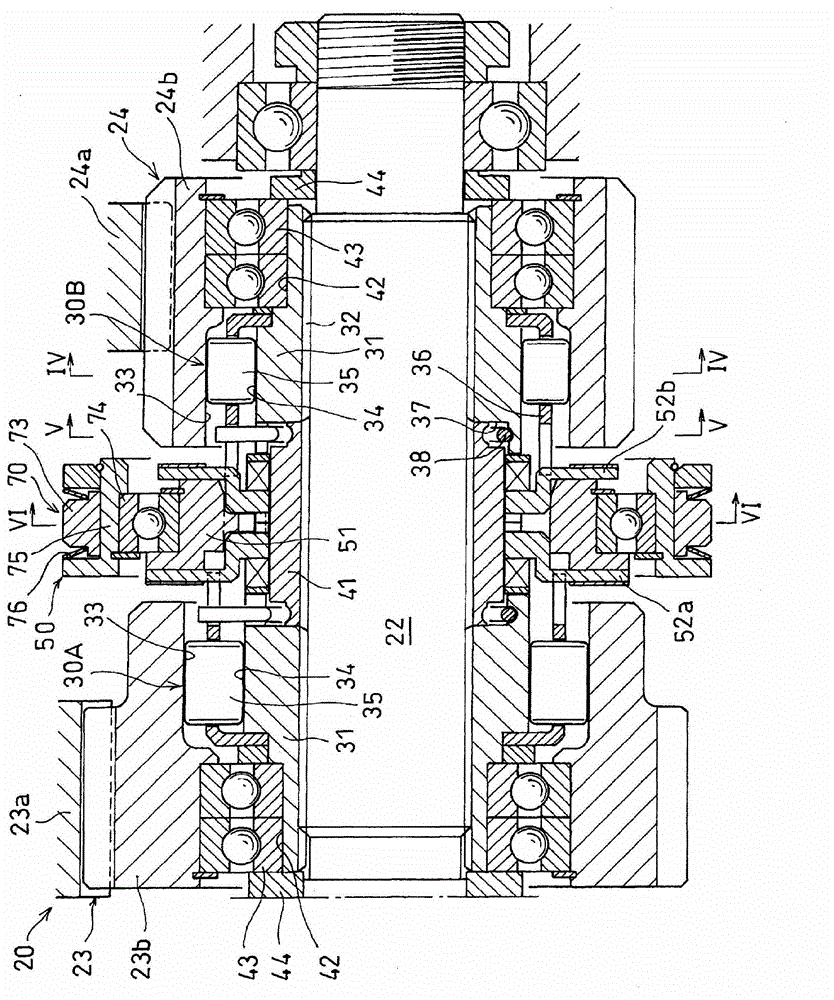

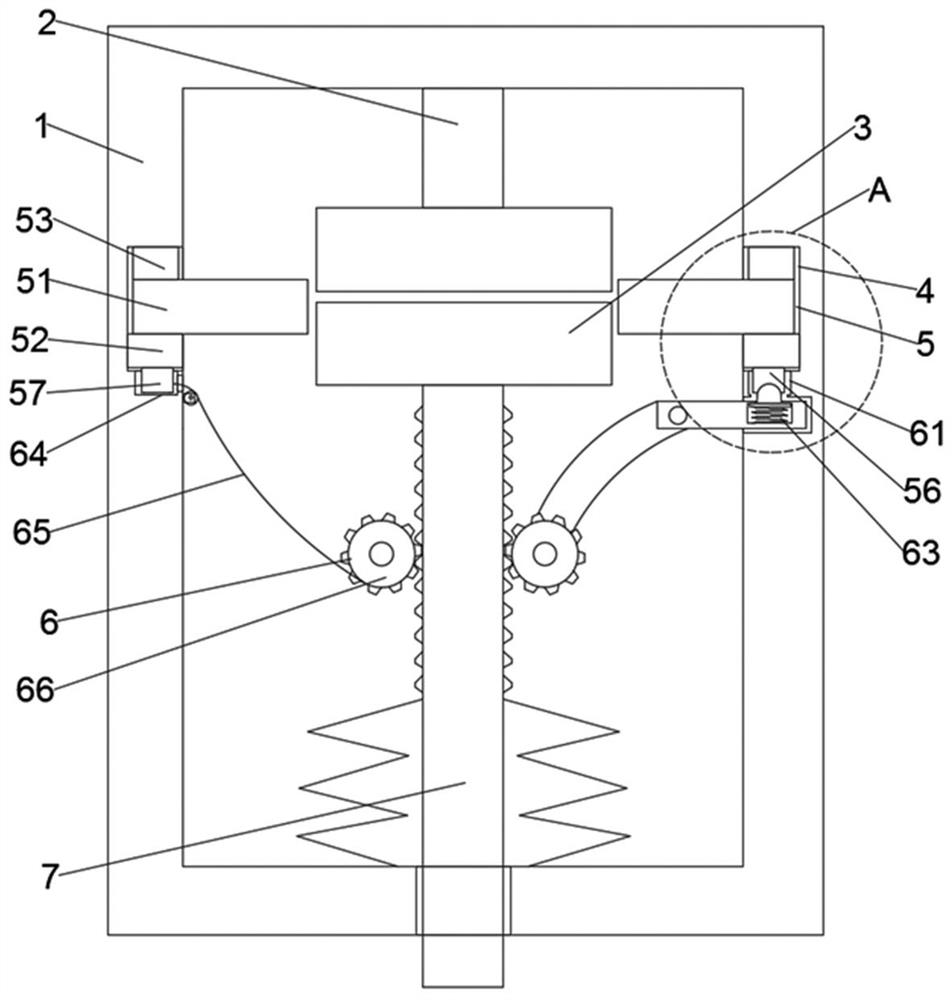

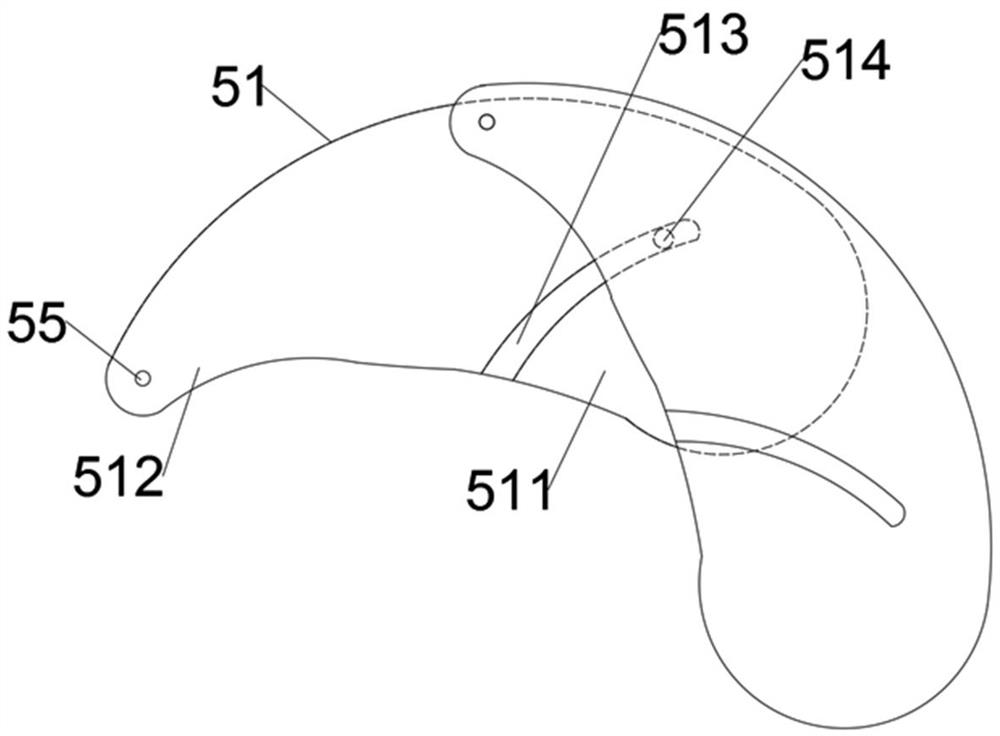

InactiveCN102947627AAvoid snappingPower cycle does not occurToothed gearingsPropulsion using engine-driven generatorsAxial displacementMotor drive

Provided is a motor drive apparatus for a vehicle, wherein a plurality of two-way clutches incorporated in a gearbox can be reliably prevented from engaging at the same time. A first reduction gear train (23) and a second reduction gear train (24) are provided between an input shaft (21) and an output shaft (22) to be rotary-driven by an electric motor (10). First and second two-way clutches (30A, 30B) are incorporated in a space between a first output gear (23b) of the first reduction gear train (23) and the output shaft (22) and a space between a second output gear (24b) of the second reduction gear train (24) and the output shaft (22), respectively. A first friction plate (52a) and a second friction plate (52b) are retained by retainers (36) of the two-way clutches (30A, 30B), and a control ring (51) is incorporated in a space between the friction plates (52a, 52b). The control ring (51) is shifted in the axial direction by a shift mechanism (70), so that the first friction plate (52a) moves in the axial direction, to engage the first two-way clutch (30A), and the second friction plate (52b) moves in the axial direction, to engage the second two-way clutch (30B). The first friction plate (52a) and the second friction plate (52b) are retained at their neutral positions, by a first anti-rotation means (57) and a second anti-rotation means (61), so that the first and second two-way clutches (30A, 30B) cannot engage at the same time.

Owner:NTN CORP

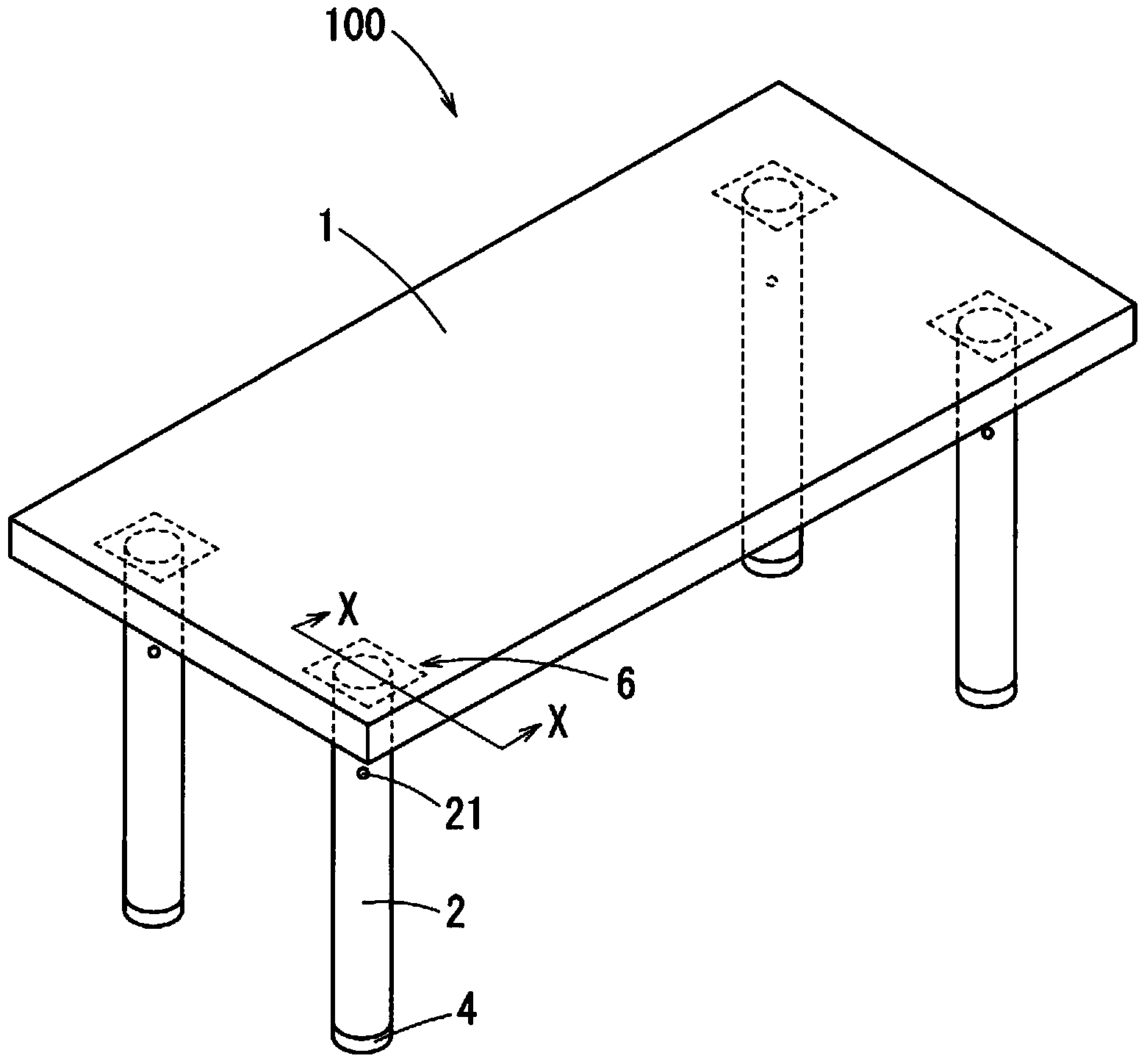

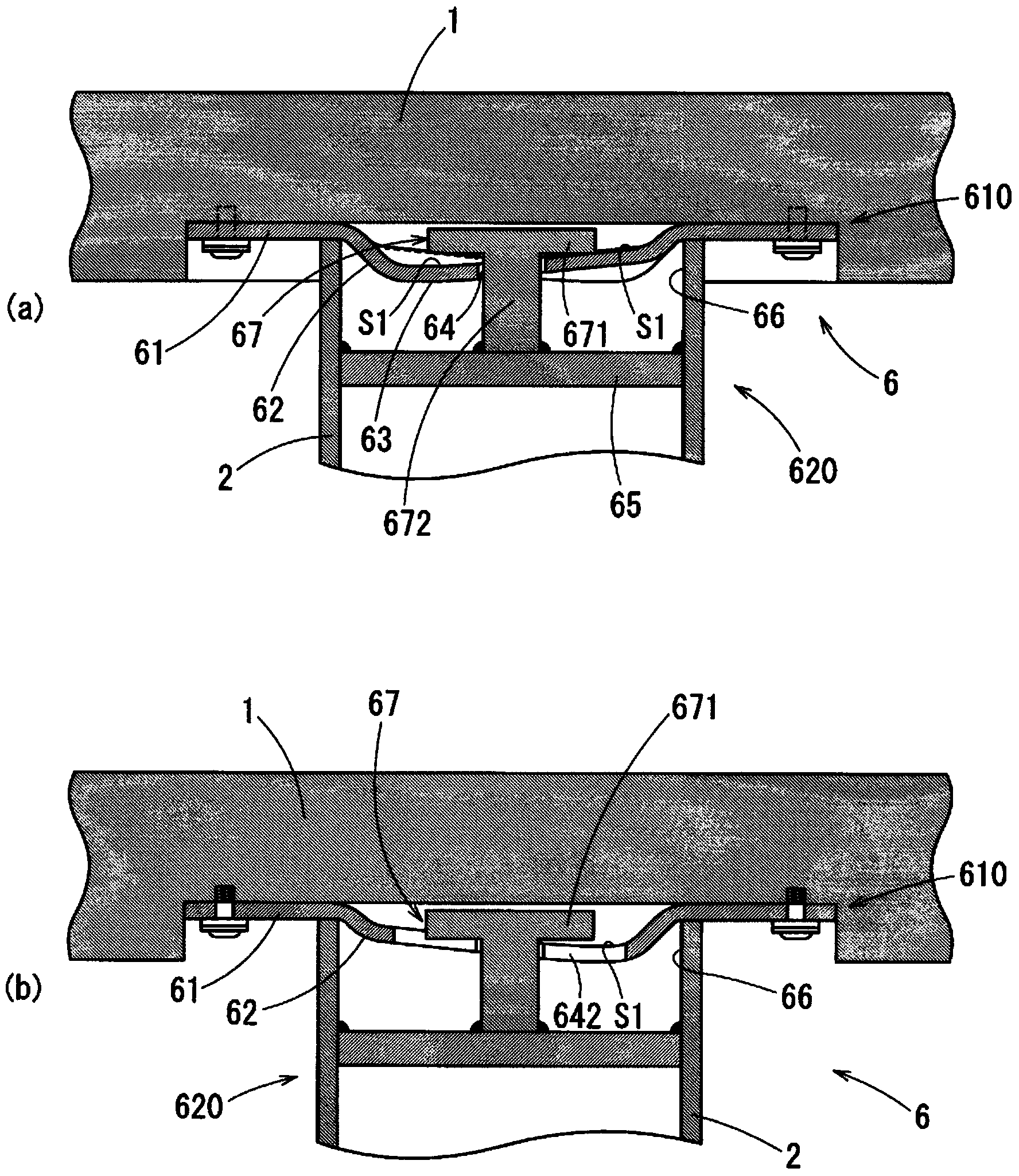

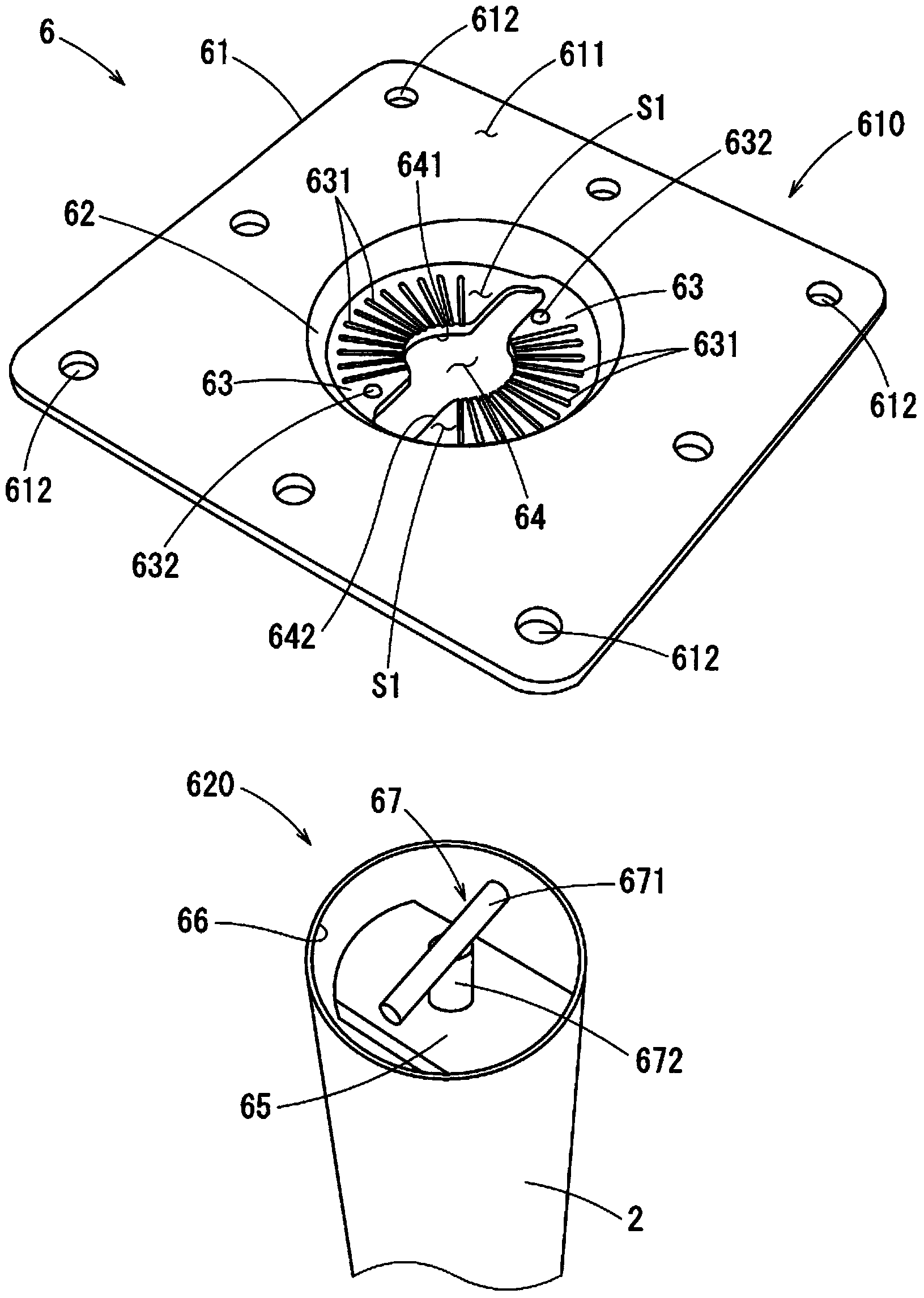

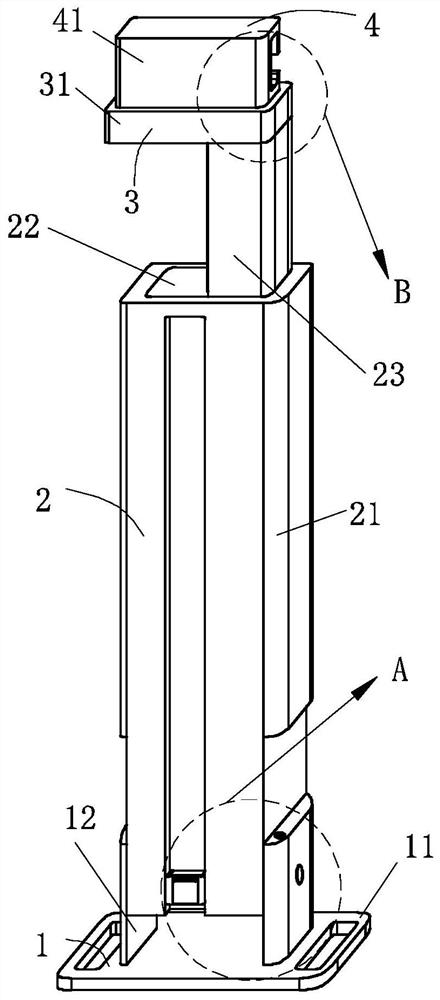

Post structure

InactiveCN104364537AEasy loading and unloadingPrevent looseningFoldable tablesStowable tablesEngineeringMoving parts

[Problem] To design for convenient storage / transport of a table, display case, etc. when not in use by quick removal of posts from the tabletop and / or base plate thereof. [Solution] A post structure in which a rotationally moving part is fitted into a stationary part wherein: a base configuring the stationary part is fastened to the table top and / or base plate, a short cylindrical interlocking projection juts out from the base, an insertion hole is drilled in the bottom face of the interlocking projection and helical surfaces that each slope gently are formed on both sides of the insertion hole; meanwhile, the moving part is fixed on the end of the post, a cross plate is made to bridge the post in the diameter direction almost at the end thereof, and a T-shaped locking rod is provided to stand substantially at the center of the cross plate; and by inserting the interlocking projection of the stationary part into the inner circumference of the post of the rotationally moving part while inserting the fastening rod of the T-shaped locking rod in the insertion hole of the bottom face and turning the post around the axis, the fastening rod is tightened onto the helical surface while the rotationally moving part is fastened to the stationary part. Grooves are provided on the helical surface at equal angular intervals in a radiating pattern.

Owner:KYOSHIN SANGYO

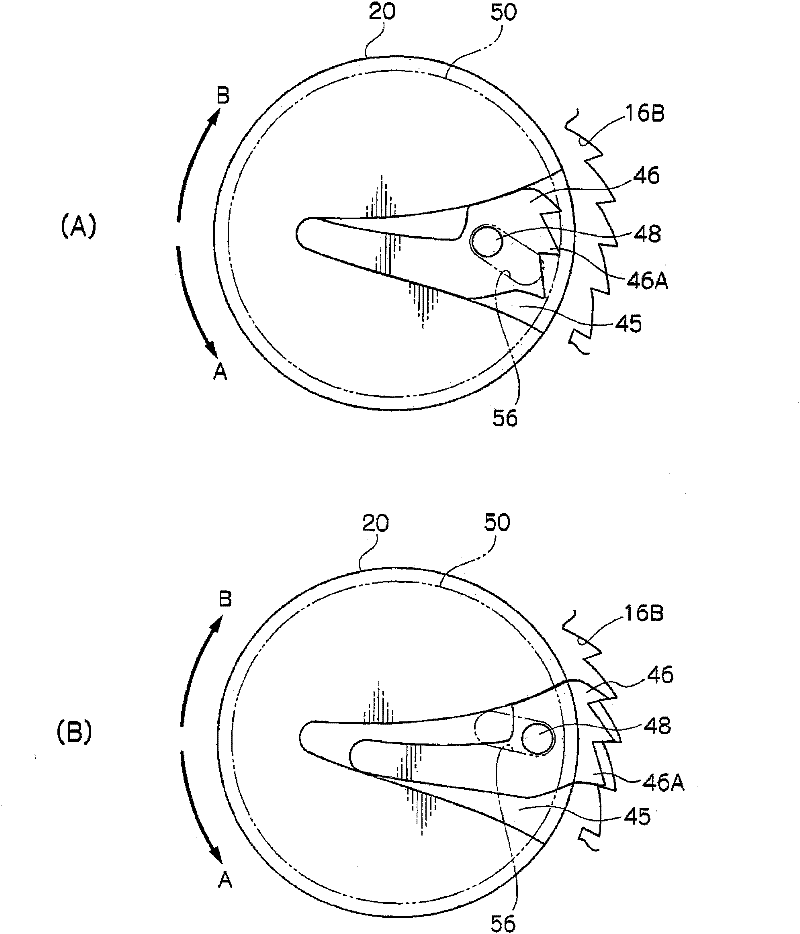

seat belt retractor

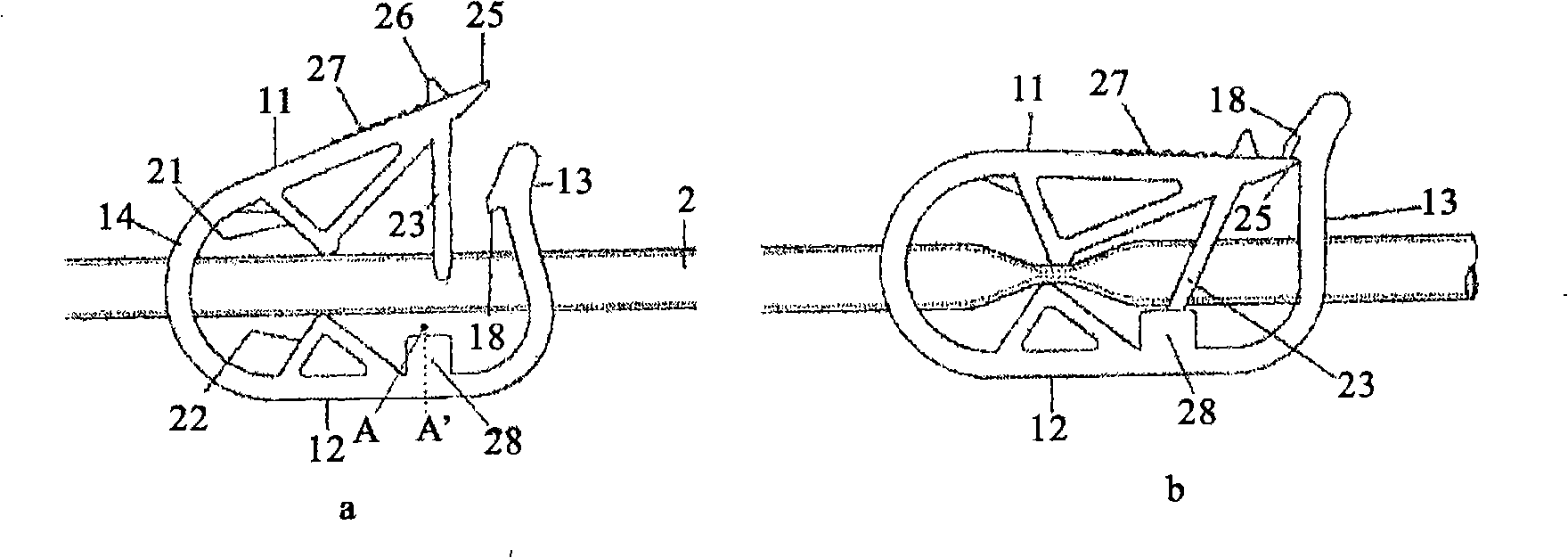

The invention aims at providing a webbing retractor capable of realizing miniaturization of a rotation body. Wherein, a V-shaped gear is connected at a spool in a mode of capability of rotation with the spool, pawls ELF are disposed at the V-shaped gear. When the V-shaped gear rotates in the pulled-out direction and a W paw is relatively displaced with respect to the V-shaped gear, a lock piece limits rotation of the spool in the pulled-out direction. Additionally, via rotation of the V-shaped gear in a retraction direction, an engaging portion of ratchet teeth is engaged with the W pawl, and the pawls limit displacing of the W pawl with respective to the V-shaped gear caused by resulting from rebound of the stopping of the retraction of the webbing. Herein, due to rotation of the V-shaped gear in the pulled-out direction, the engagement of the engaging portion with the W pawl is released as the engaging portion is displaced toward a radial direction inside of the V-shaped gear. Therefore, miniaturization of the V-shaped gear can be realized without disposing of a space for displacement of the engagement portion at the engagement position of the W pawl and the engagement portion toward the radial external side of the V-shaped gear.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

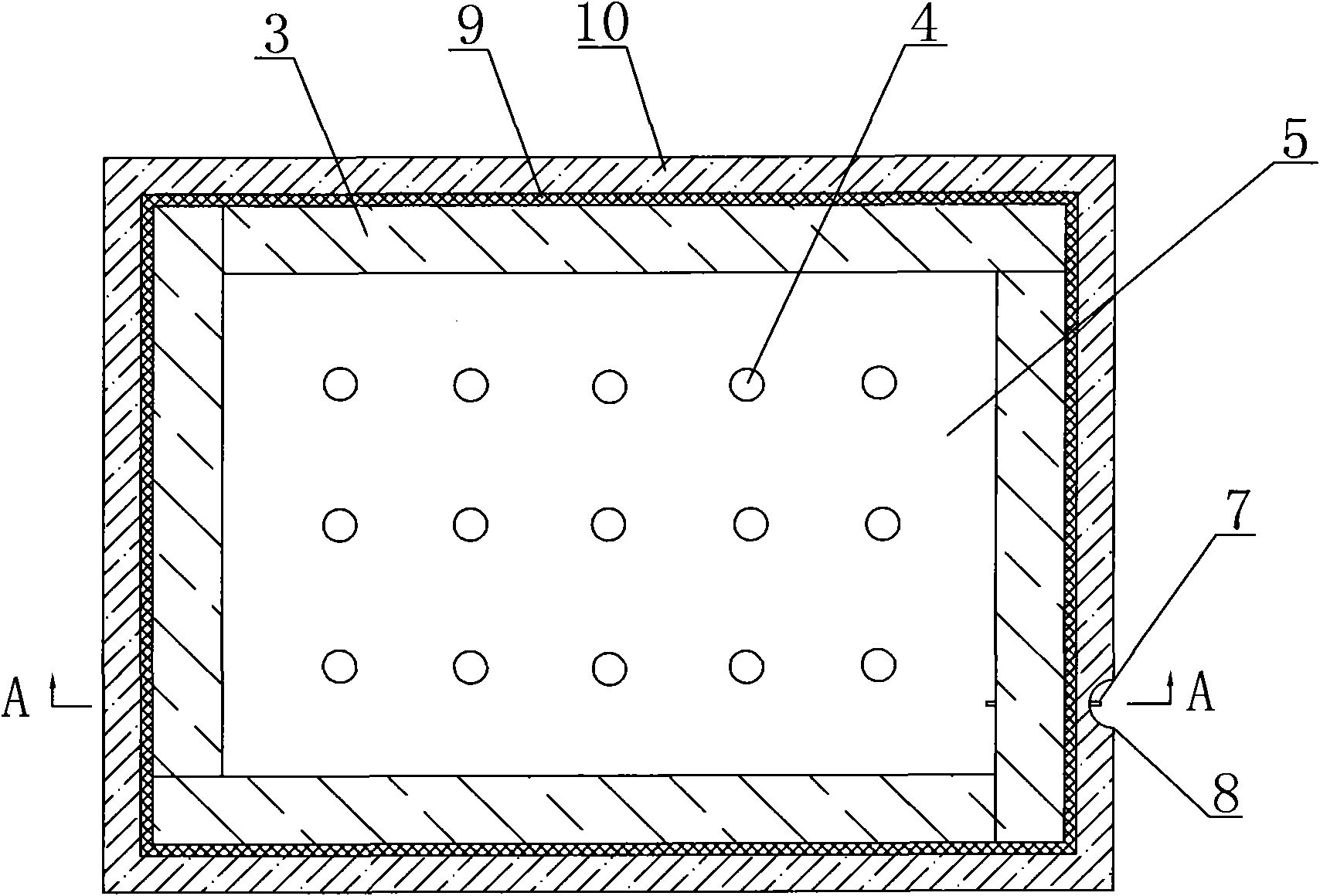

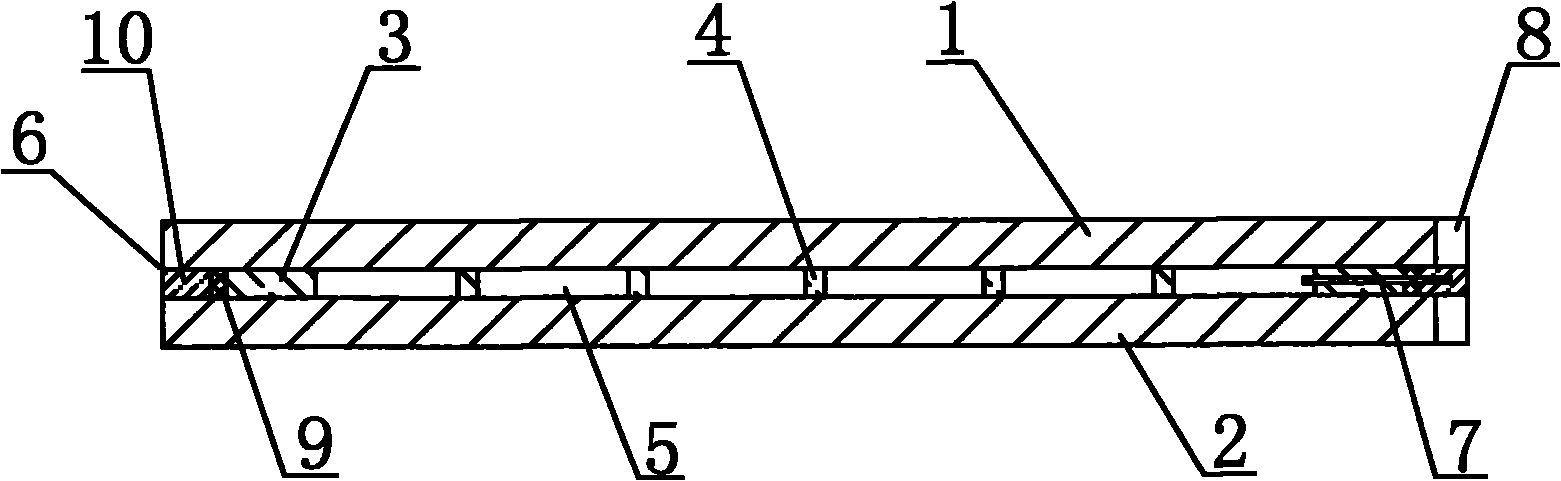

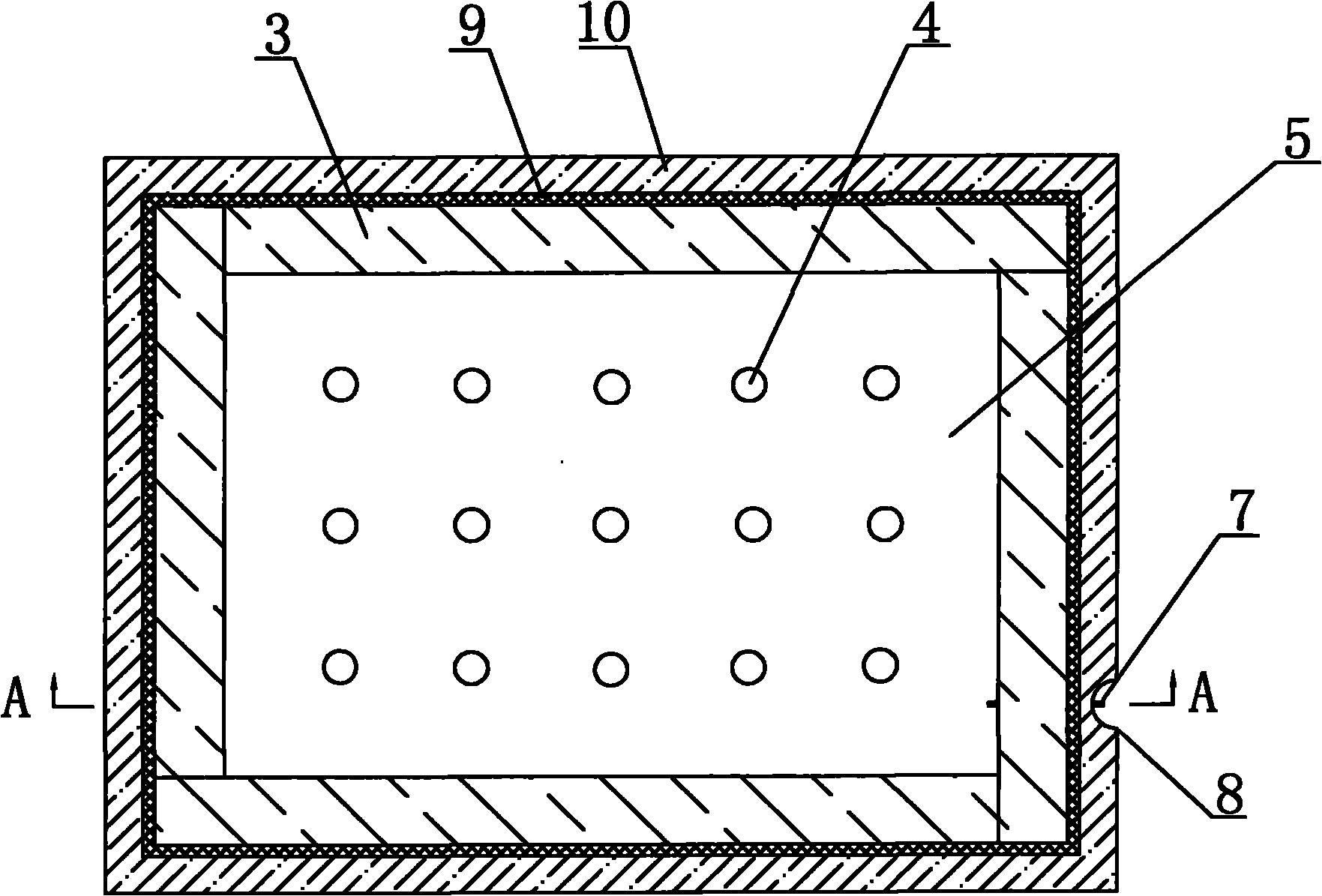

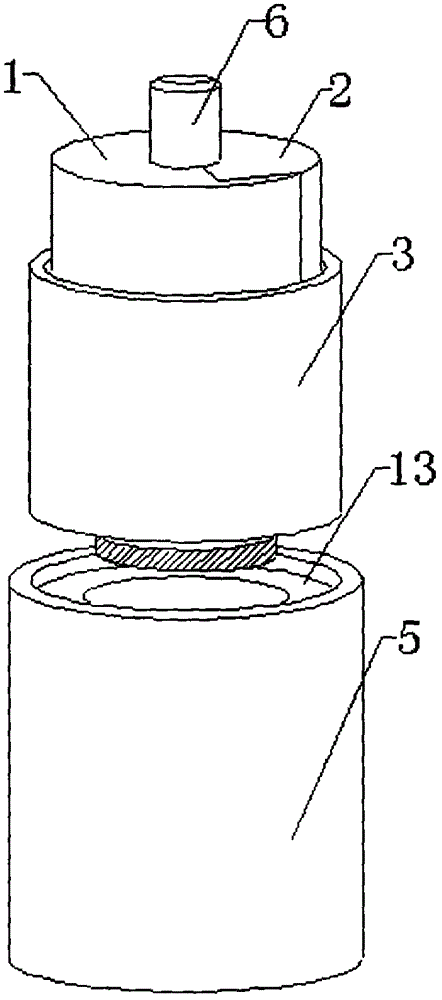

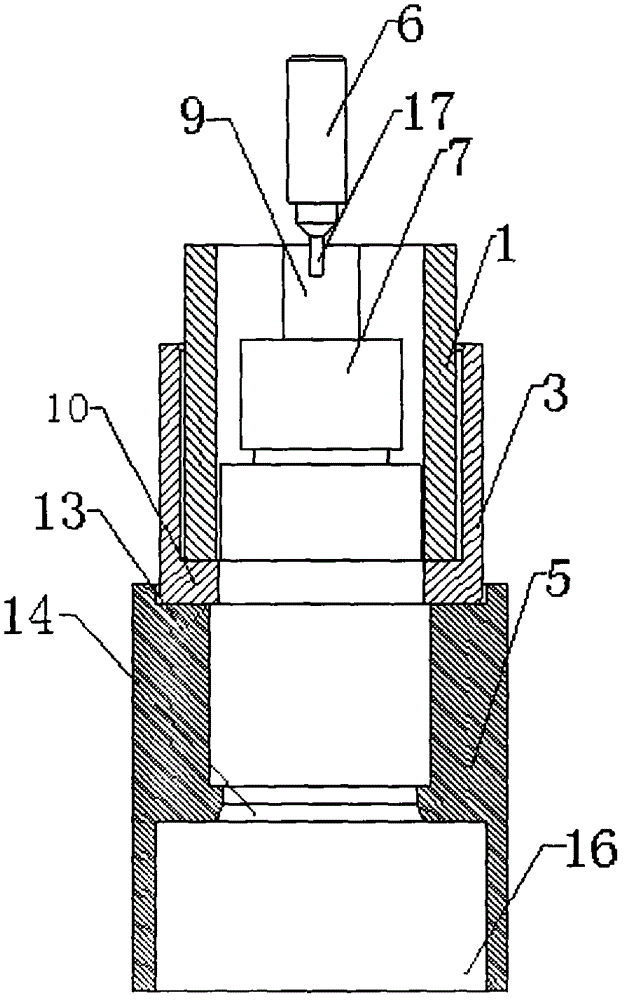

Vacuum glass and preparation method thereof

InactiveCN102092964AEasy to useAvoid the problem of being too thick and easy to leakAdhesiveEngineering

The invention discloses a method for preparing a vacuum glass, which comprises the following steps of: taking two glasses with semicircular gaps processed on the edges, sticking a supporting point on the middle part of one glass, sticking glass strips on the edges of four sides, arranging air extraction needles at the reserved openings of the glass strips by using adhesive, overlaying and sticking the two set glasses, filling the adhesive into a groove formed by the edges of the two glasses for two times, vacuumizing the cavity between the two glasses by using a vacuum pump through the air extraction needles, and finally, melting the heads of the air extraction needles at the temperature of between 1,800 and 2,000 DEG C to seal so as to obtain a product. The vacuum glass prepared by adopting the technical scheme can effectively prevent vacuum recession, and the service life of the vacuum glass is prolonged. Four sides of the glasses of two layers are supported and sealed by using the glass strips, and the sealing layer formed by the filled adhesive and the glass strips improve the strength for supporting, so the distance between the two glasses can be enlarged, the suction of the two glasses after vacuumizing is prevented, and the heat insulation and sound insulation properties of the vacuum glass are improved.

Owner:石应选

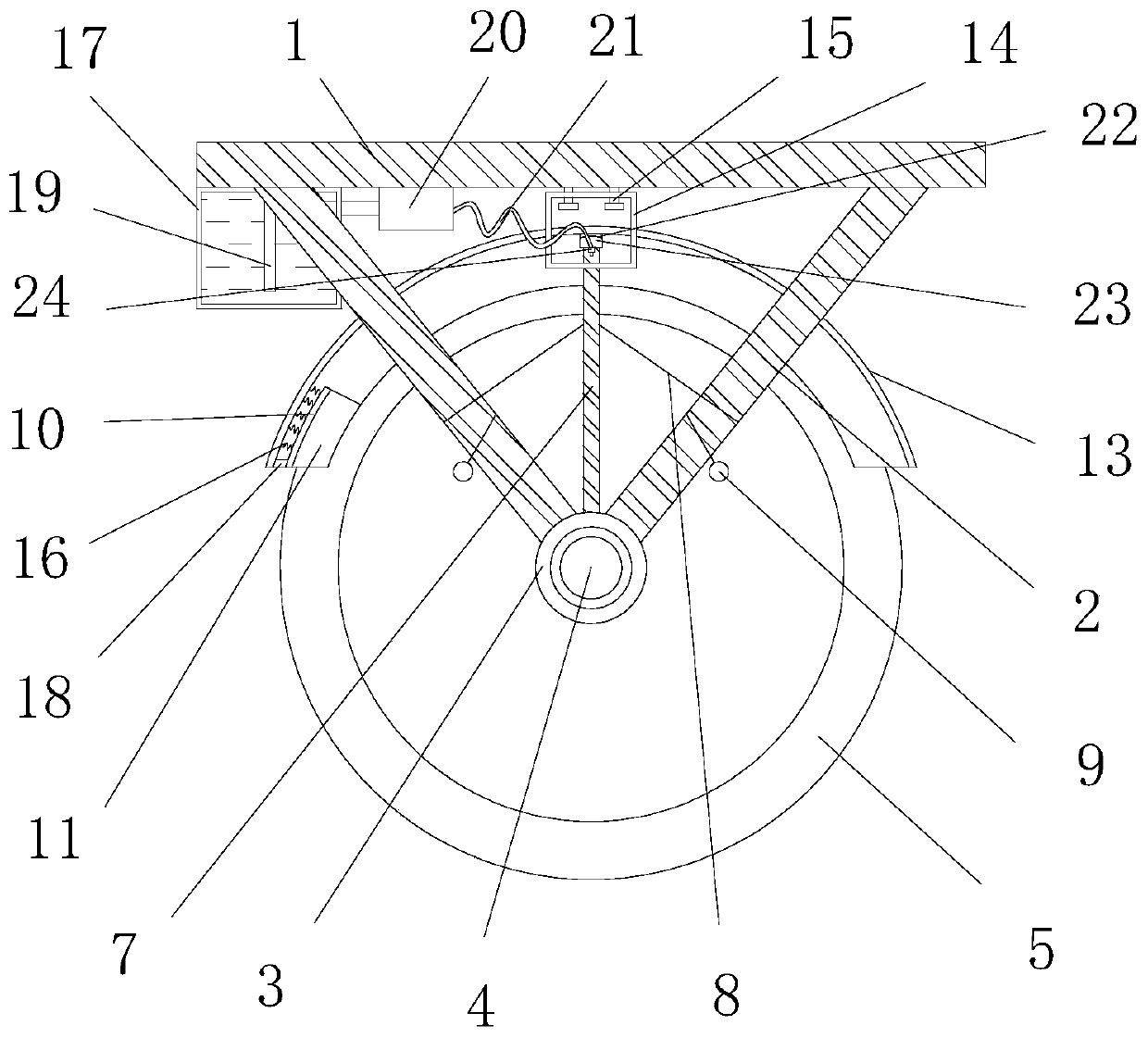

Mud blocking device arranged at back wheel of electric bicycle

InactiveCN109955830ASimple structureInnovative designVehicle cleaningMud-guardsWater storageFixed frame

The invention discloses a mud blocking device arranged at a back wheel of an electric bicycle. The mud blocking device comprises a fixing seat, a fixing rod, a sleeve ring, a rotating shaft, a back rolling wheel, a rotating ring, a connecting rod, a steel wire rope, a regulating block, a hair brush seat, a hair brush, a spray head, a mud blocking plate, a fixing frame, a fixing screw bolt, a spring, a water storage case, a blockage prevention plate, a blockage prevention hole, a water extraction pipe, a water extraction pump, a telescopic pipe, a scraping plate and a connecting seat. The mud blocking device arranged at the back wheel of the electric bicycle has the advantages that the structure is simple; the design is novel; the mud water thrown out by the back wheel can be blocked; the mud water is prevented from being thrown to the back side of a bicycle rider; the rider can conveniently realize the stable riding; meanwhile, through the arrangement of the blockage prevention plate,big mud blocks can be conveniently cleaned; the mud blocks are prevented from the clamped between the mud blocking plate and the back wheel; the rider can conveniently realize the easy riding; throughthe arrangement of the cleaning mechanism, mud and dust adsorbed onto the surface of the inner wall of the mud blocking plate can be conveniently cleaned; the friction between the mud blocking plateand the back wheel can be reduced; the physical strength of the rider can be saved.

Owner:NANJING CHUQING ELECTRONICS TECH CO LTD

Knee protection system

InactiveCN1676376AAvoid snappingPedestrian/occupant safety arrangementDashboardsIn vehicleKnee protector

Owner:TOYOTA JIDOSHA KK +1

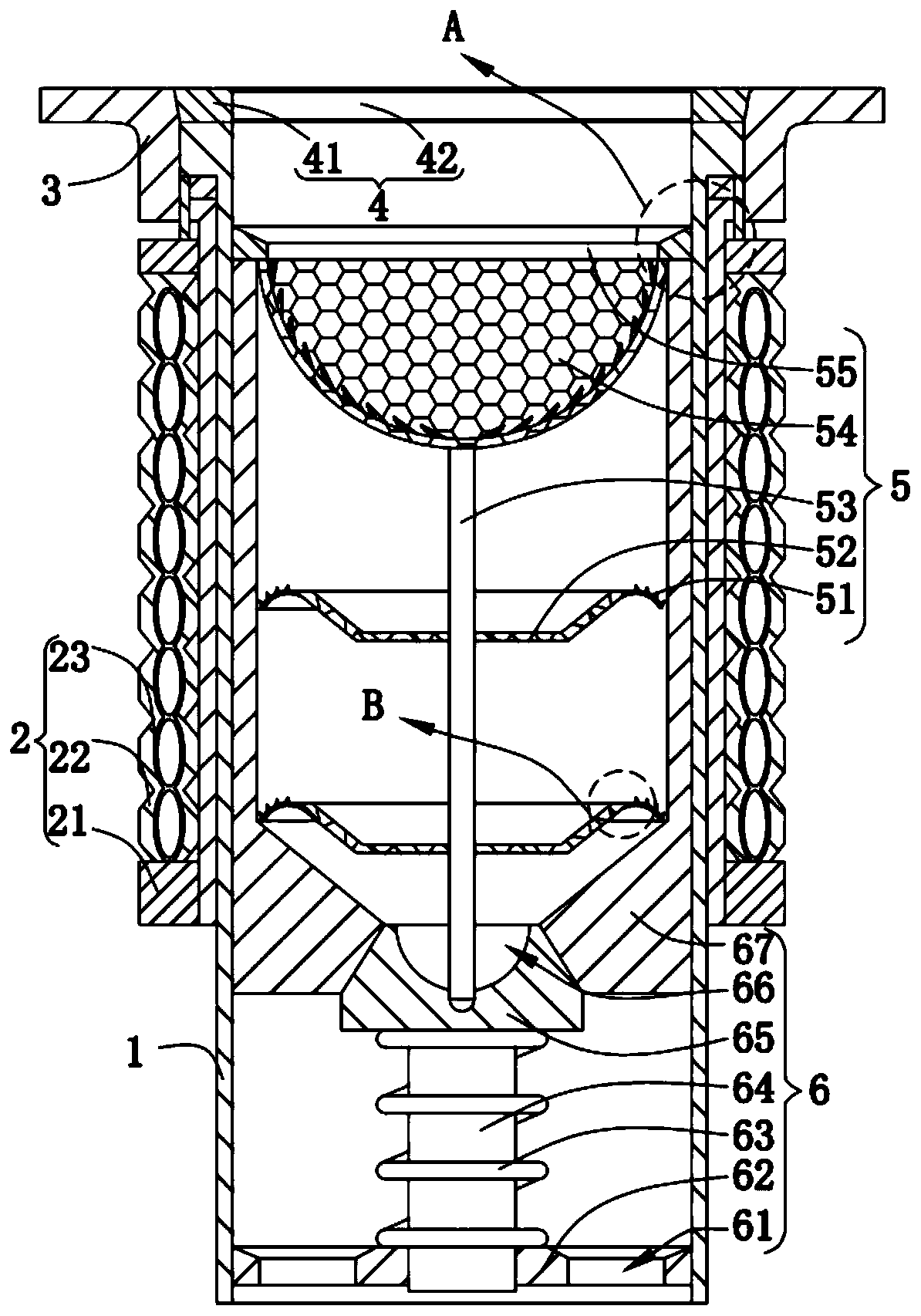

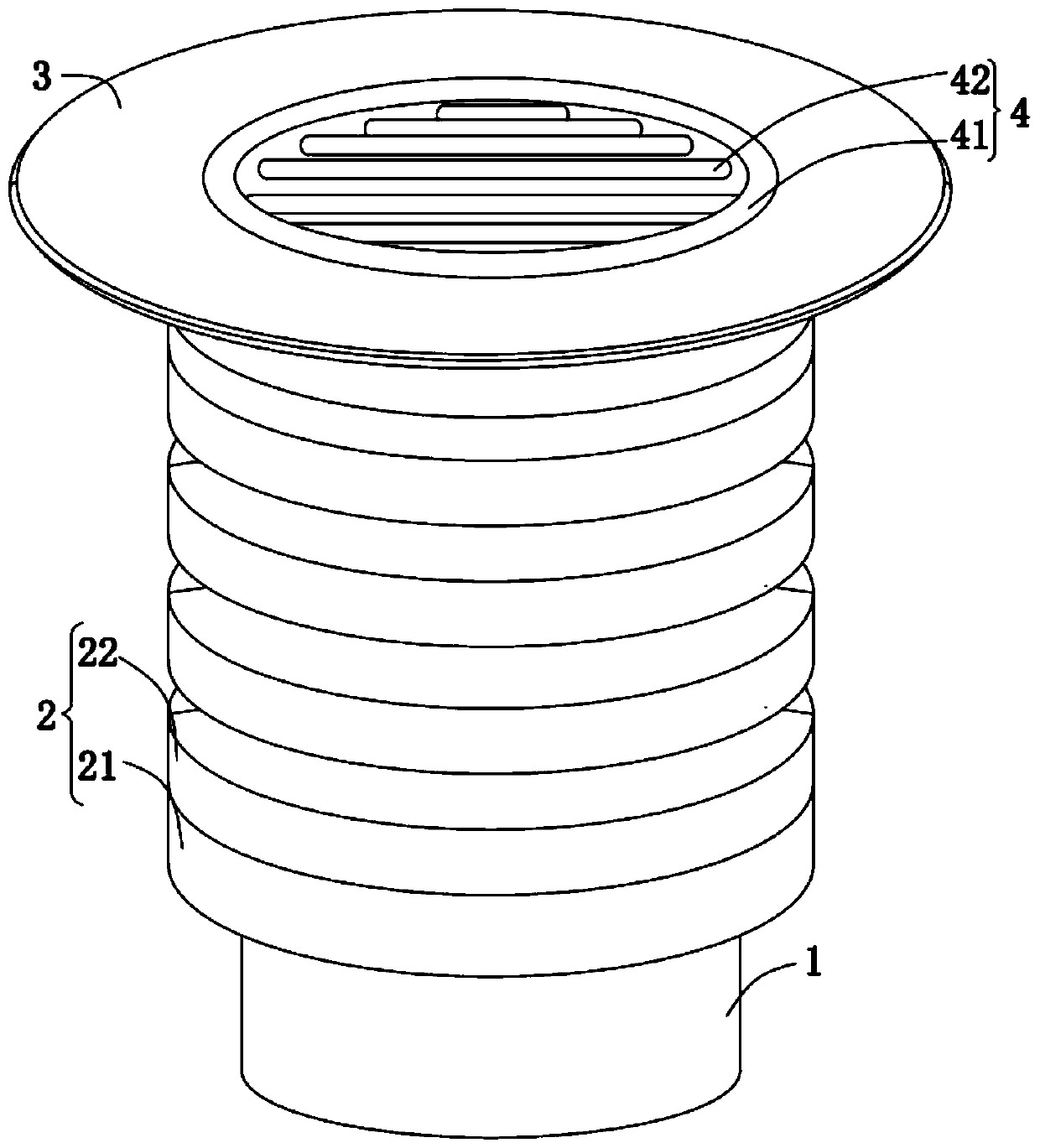

Water storage device located at floor drain of house

The invention provides a water storage device located at a floor drain of a house. The water storage device at the floor drain of the house comprises a limiting sleeve, a connecting pipe, a sealing structure, a first filter structure, a second filter structure and a drainage structure, wherein the second filter structure comprises two water storage sleeves, a positioning rod, a filter sleeve, a second limiting ring, a plurality of first anti-blocking blocks, a plurality of anti-blocking teeth and a plurality of drainage holes, the second limiting ring is clamped with the connecting pipe, the filter sleeve for filtering hair is fixed to the second limiting ring, the multiple first anti-blocking blocks are arranged on the inner surface of the latticed filter sleeve of a hemispherical structure in a staggered mode, and the multiple anti-blocking teeth are linearly distributed on the first anti-blocking blocks; and the drainage structure comprises a plurality of through holes, a third limiting ring, a reset spring, a sliding rod, a sealing plug and a check block. The water storage device at the floor drain of the house has the advantages that a pipeline in a bathroom is automatically sealed conveniently, anti-blocking performance is good, and the hair is convenient to clear.

Owner:ZHONGXIN CONSTR GROUP

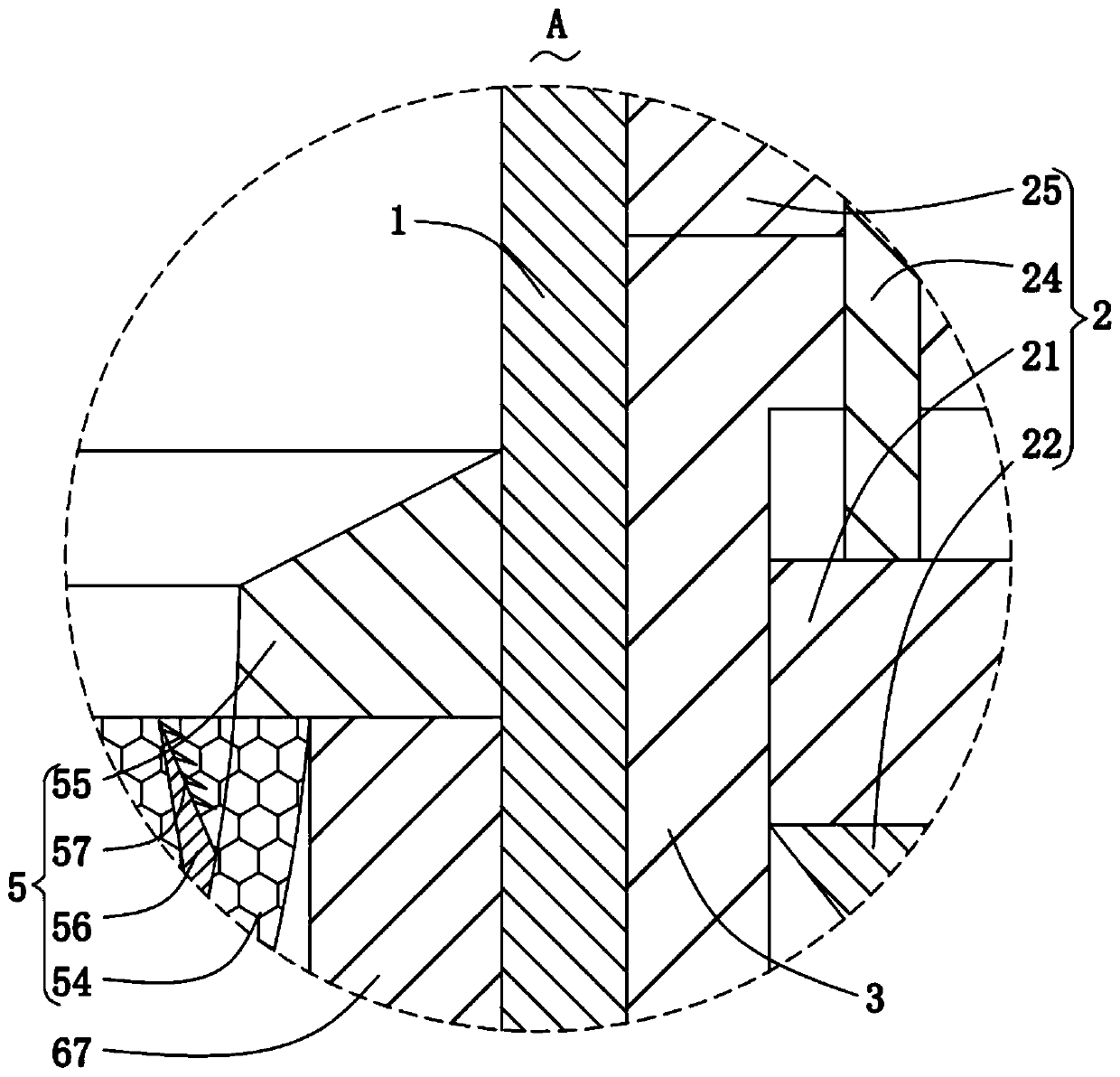

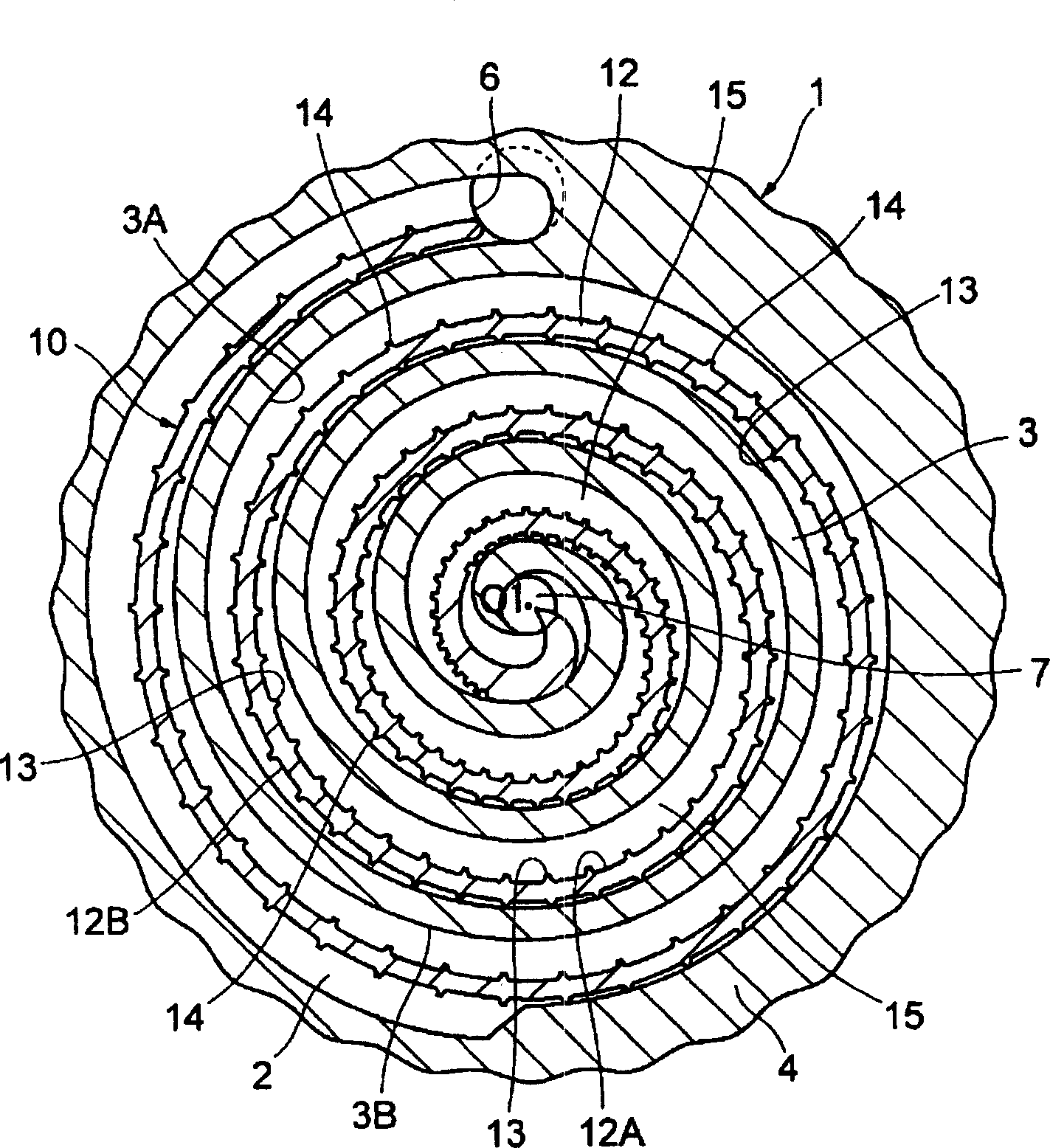

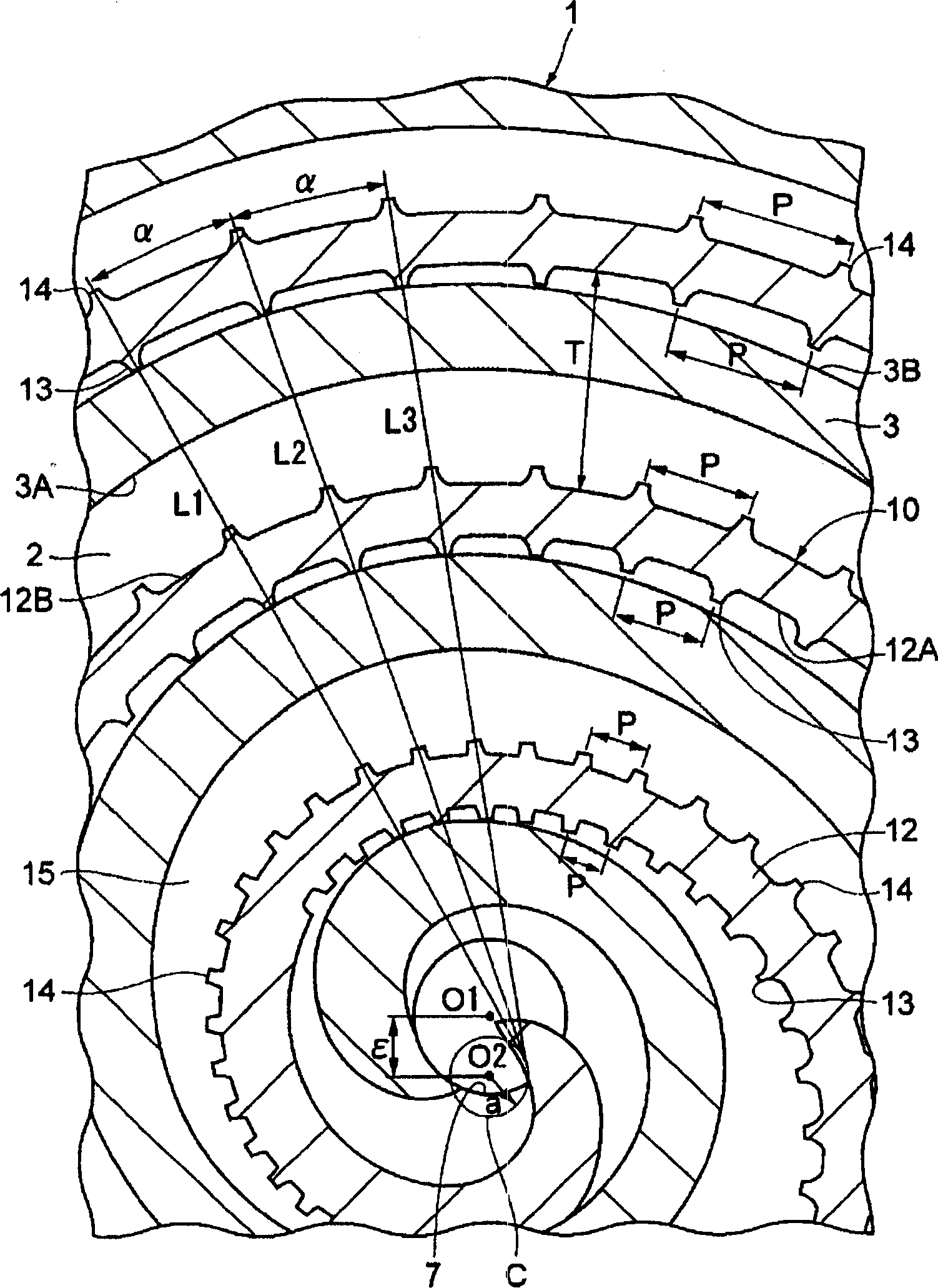

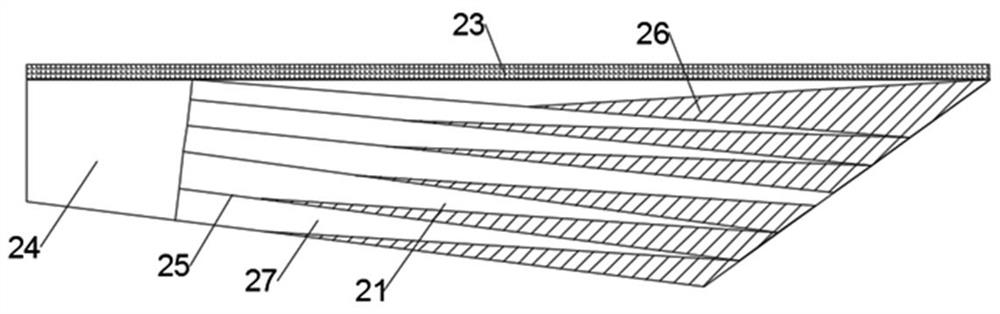

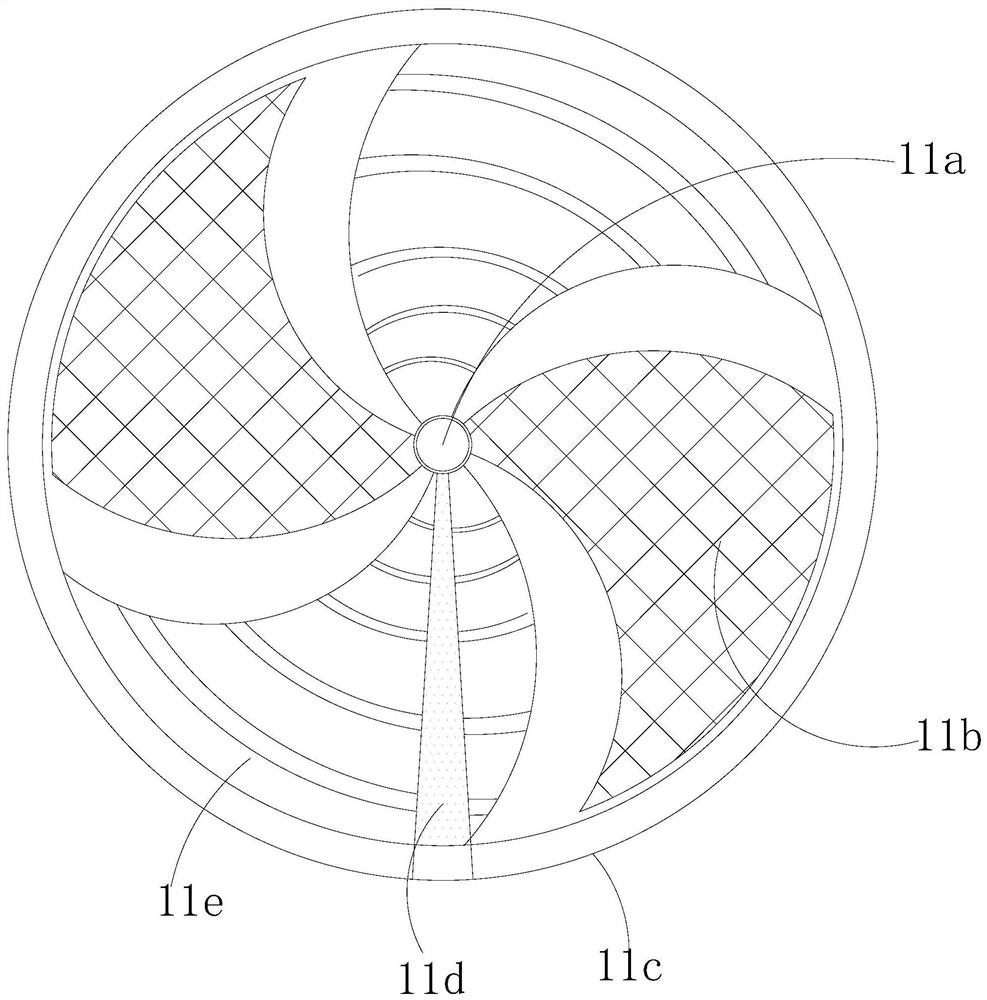

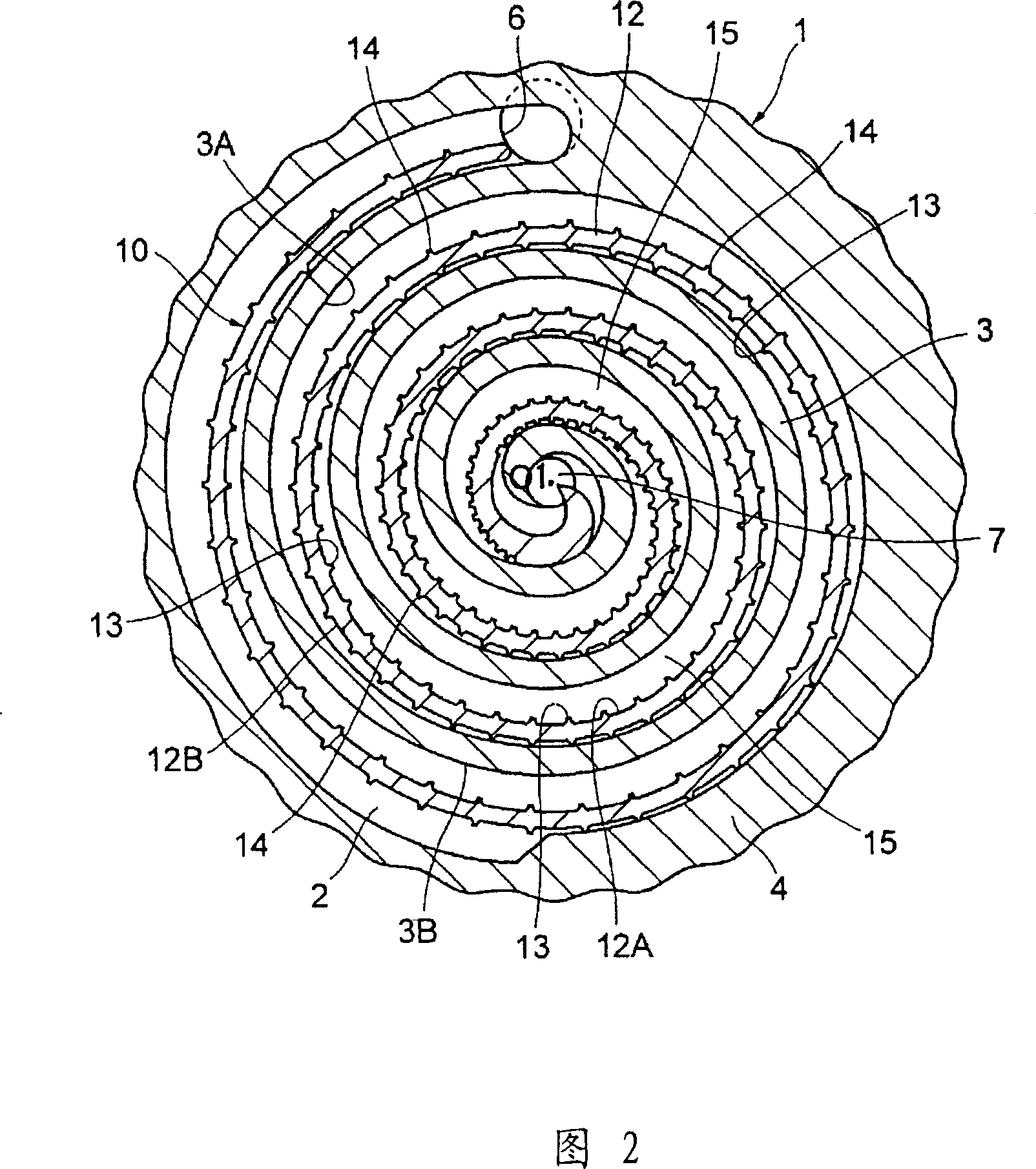

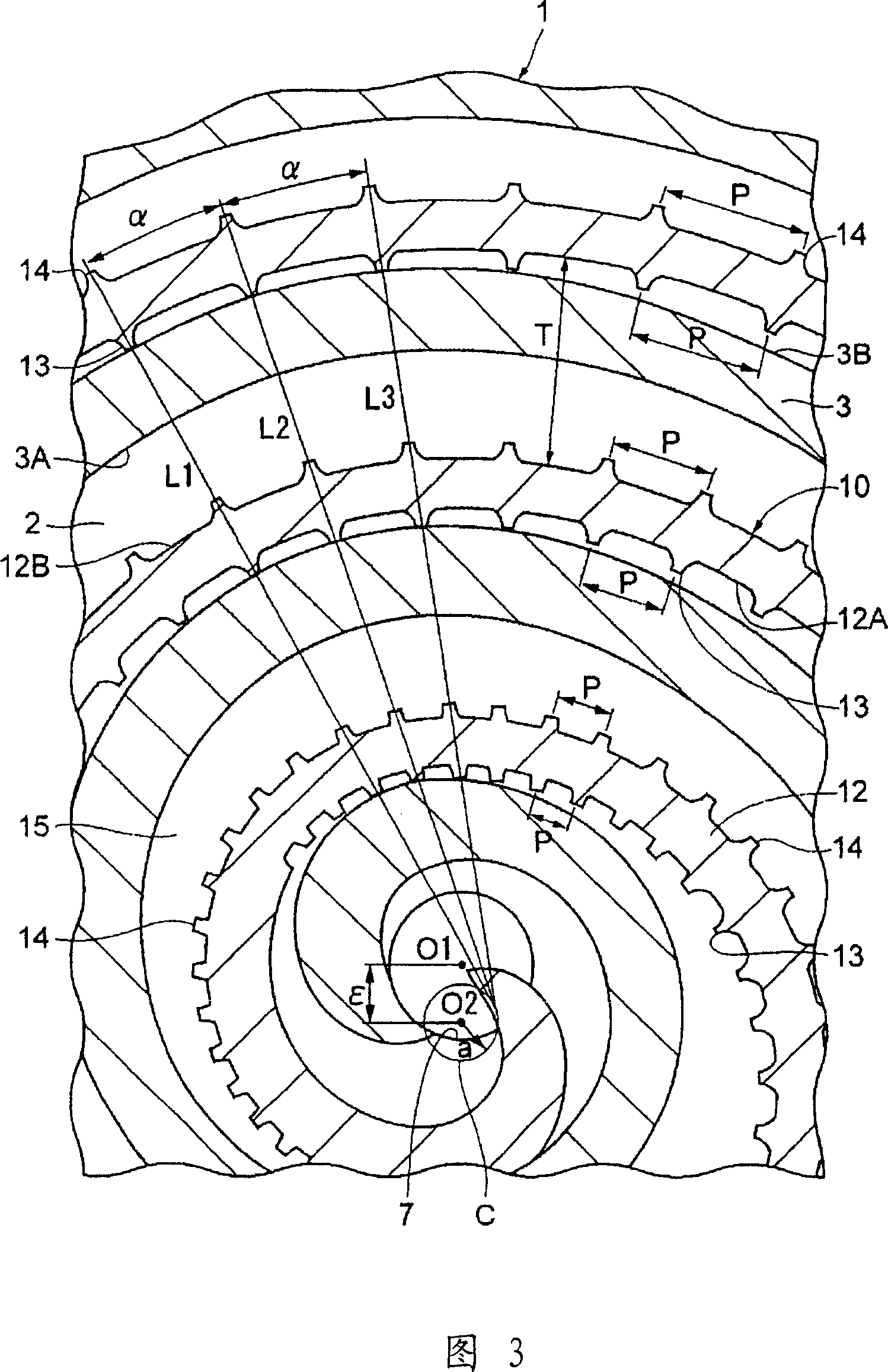

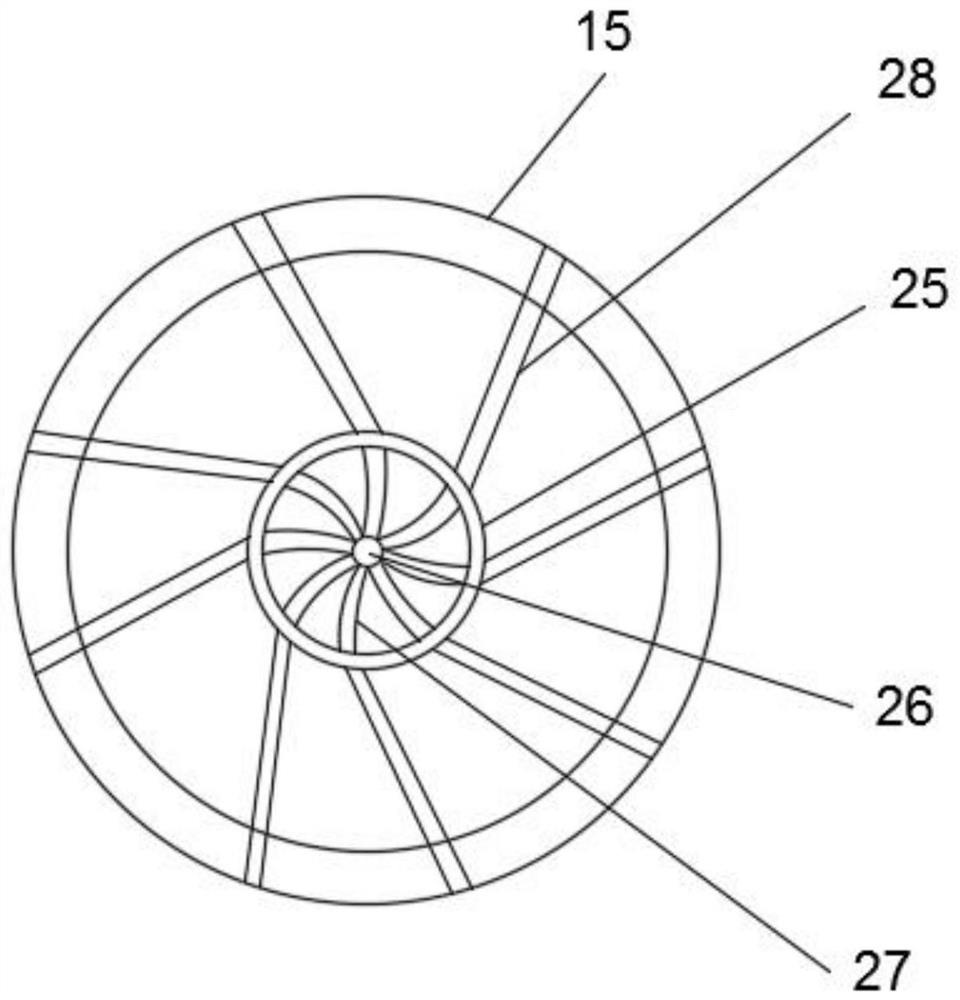

Swirl fluid machinery

ActiveCN1601090AIncrease widthHigh strengthRotary piston pumpsRotary piston liquid enginesStress concentrationEngineering

The purpose of this invention is to prevent a motive power loss and noise in operation, while enhancing sealability of a compression space, by properly setting its angle, while enhancing strength of projections arranged in a lap part. The inner diameter side projection 13 and the outer diameter side projection 14 are respectively arranged on an inner peripheral surface 12A and an outer peripheral surface 12B of the lap part 12 of a revolving scroll 10, and these cross sections are formed in a substantially triangular shape. Thus, the projections 13 and 14 can enhance the strength by preventing stress concentration by concave circular arc surfaces 13B and 14B, and top parts 13A and 14A can easily become familiar by contacting with the lap part 3. An angle [alpha] formed by the adjacent projections 13 and 14 is set in a predetermined range. Thus, the sealability of the compression space 15 is enhanced, and workability of the lap part 12 and the projections 13 and 14 can be enhanced.

Owner:HITACHI LTD

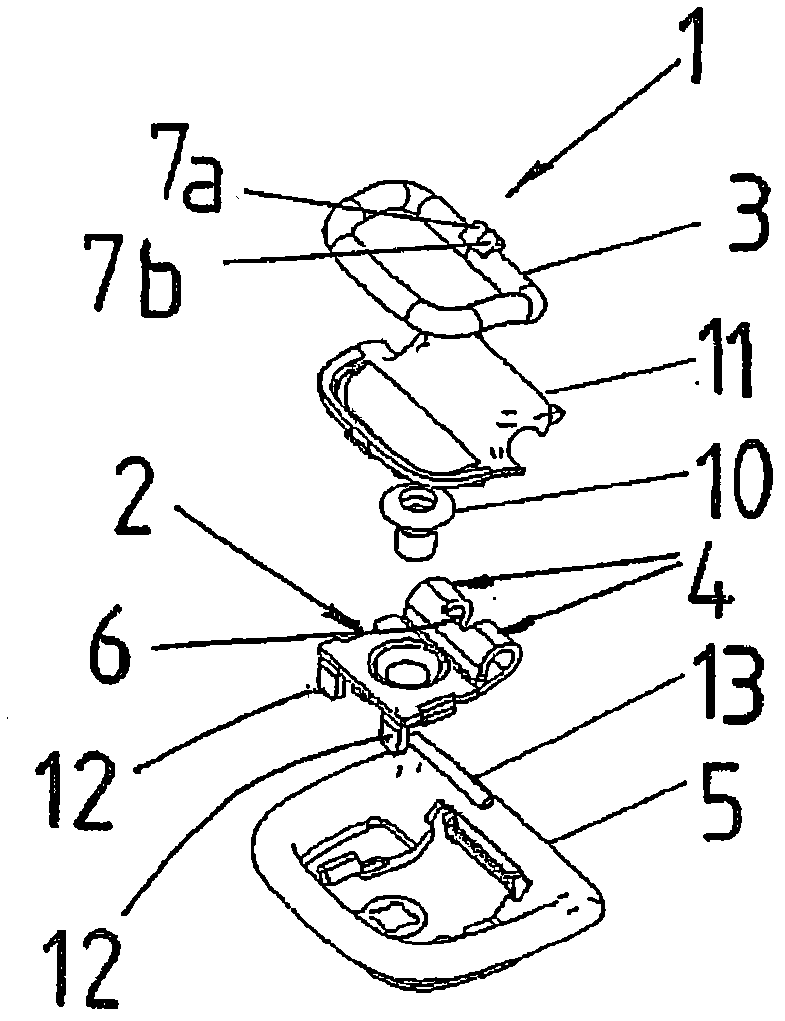

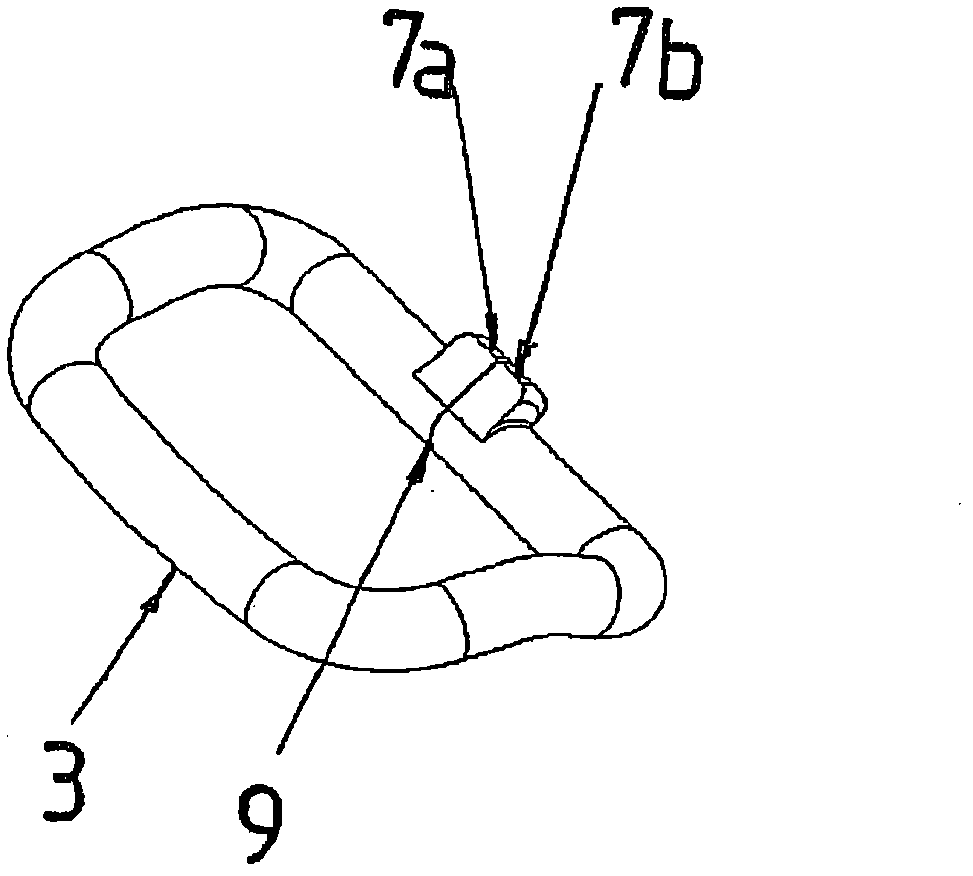

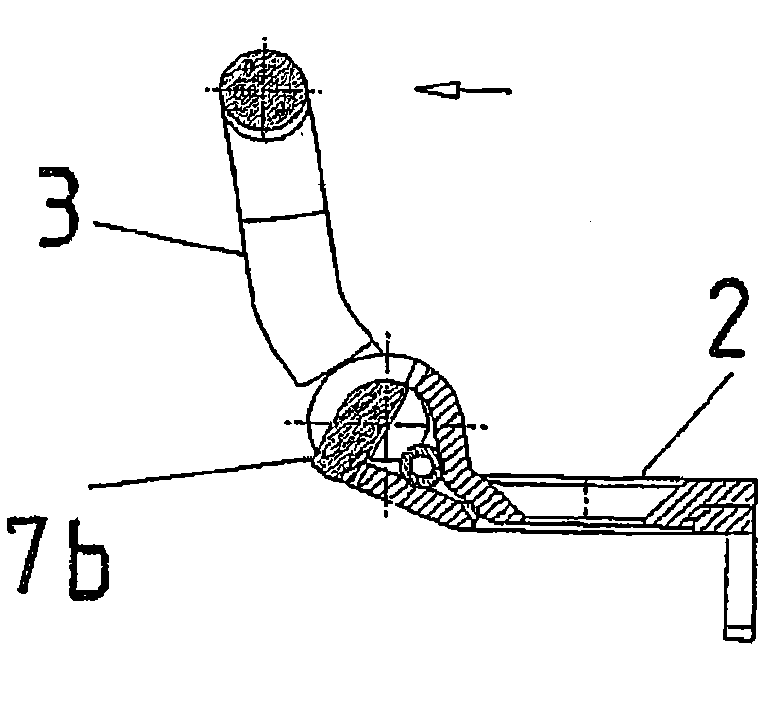

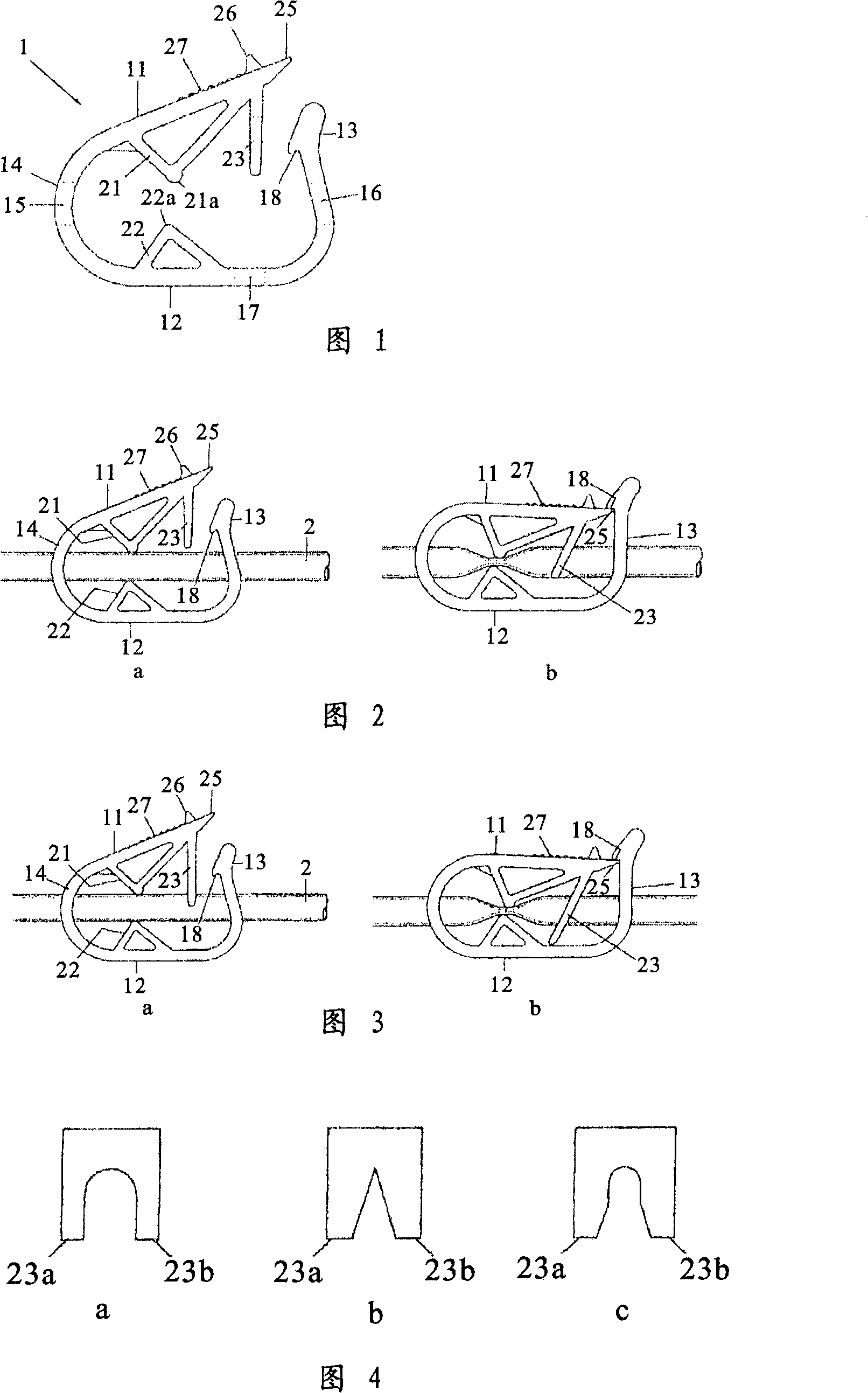

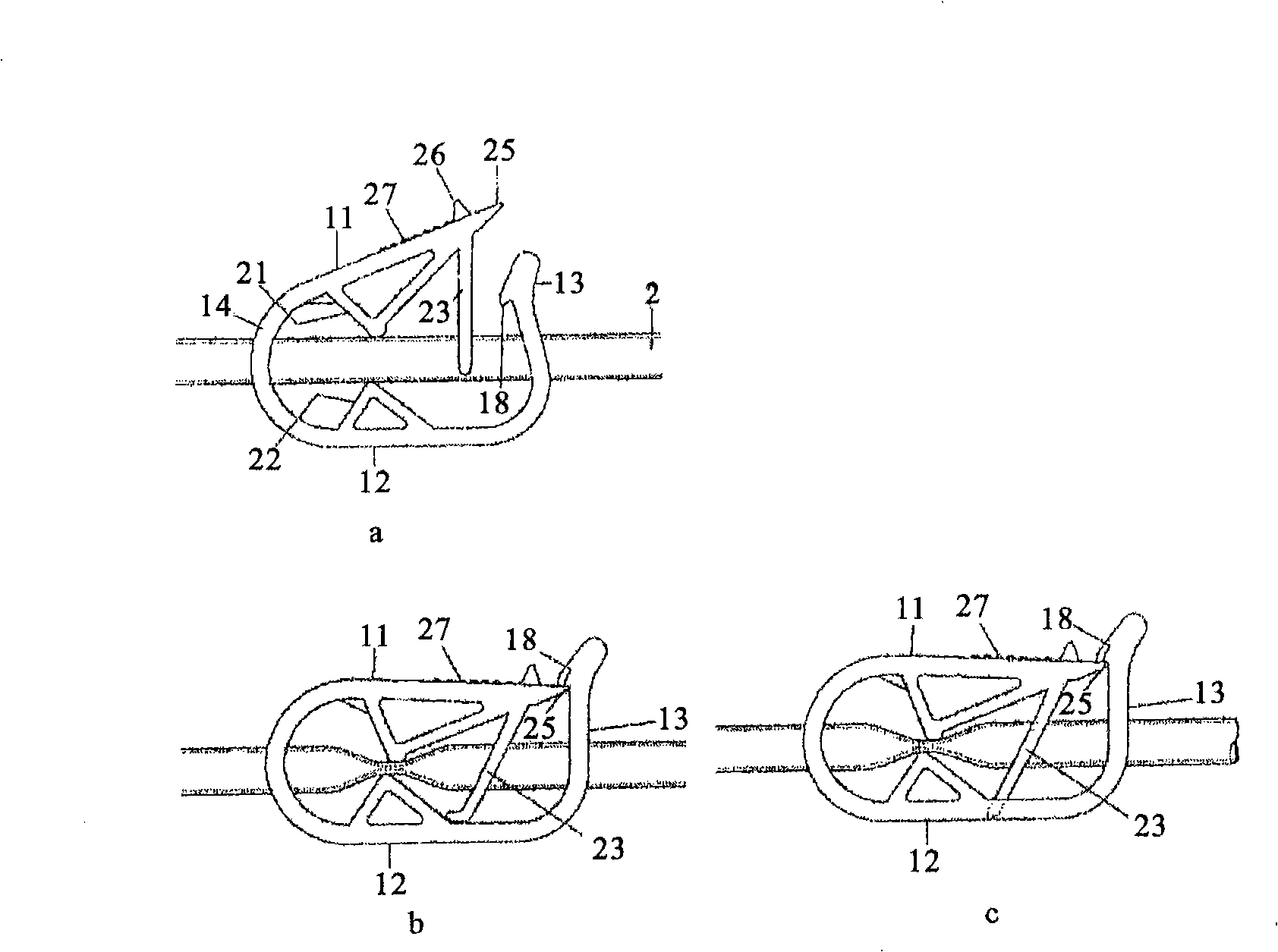

Tie-down eye

ActiveCN102700455AReduce noiseAvoid snappingLoad securingHaberdasheryEngineeringMechanical engineering

A tie-down eye (1) for a cargo space of a motor vehicle has an annular loop (3) pivoted on a mount (2) that is formed with a journal part wrapped around a portion of the loop, and the mount and the loop are secured in a frame element (5) fixed in a floor of the cargo space. The loop, which serves for attachment of securing straps, retaining ropes, retaining nets, or similar load-securing elements on or against the cargo surface can pivot between a nonuse position recessed in the frame element and use position projecting upward therefrom. The mount is formed with a cutout (6) in its journal part (4) wrapped around the loop, and a projection (7a, 7b) extending radially from the loop extends through this cutout and bears against an inner peripheral edge (8) of the cutout when in the use position.

Owner:SODECIA AUTOMOTIVE EURO GMBH

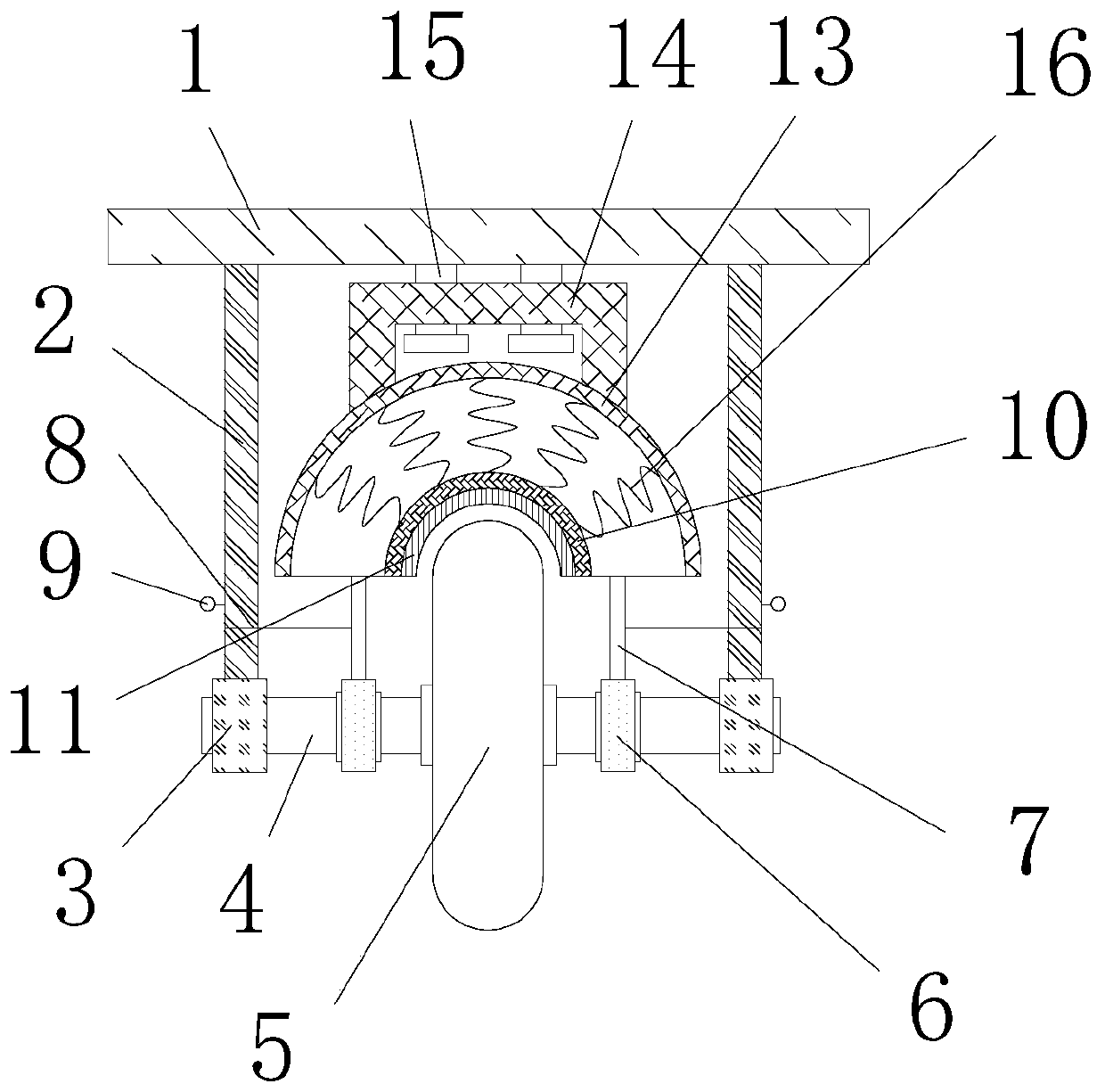

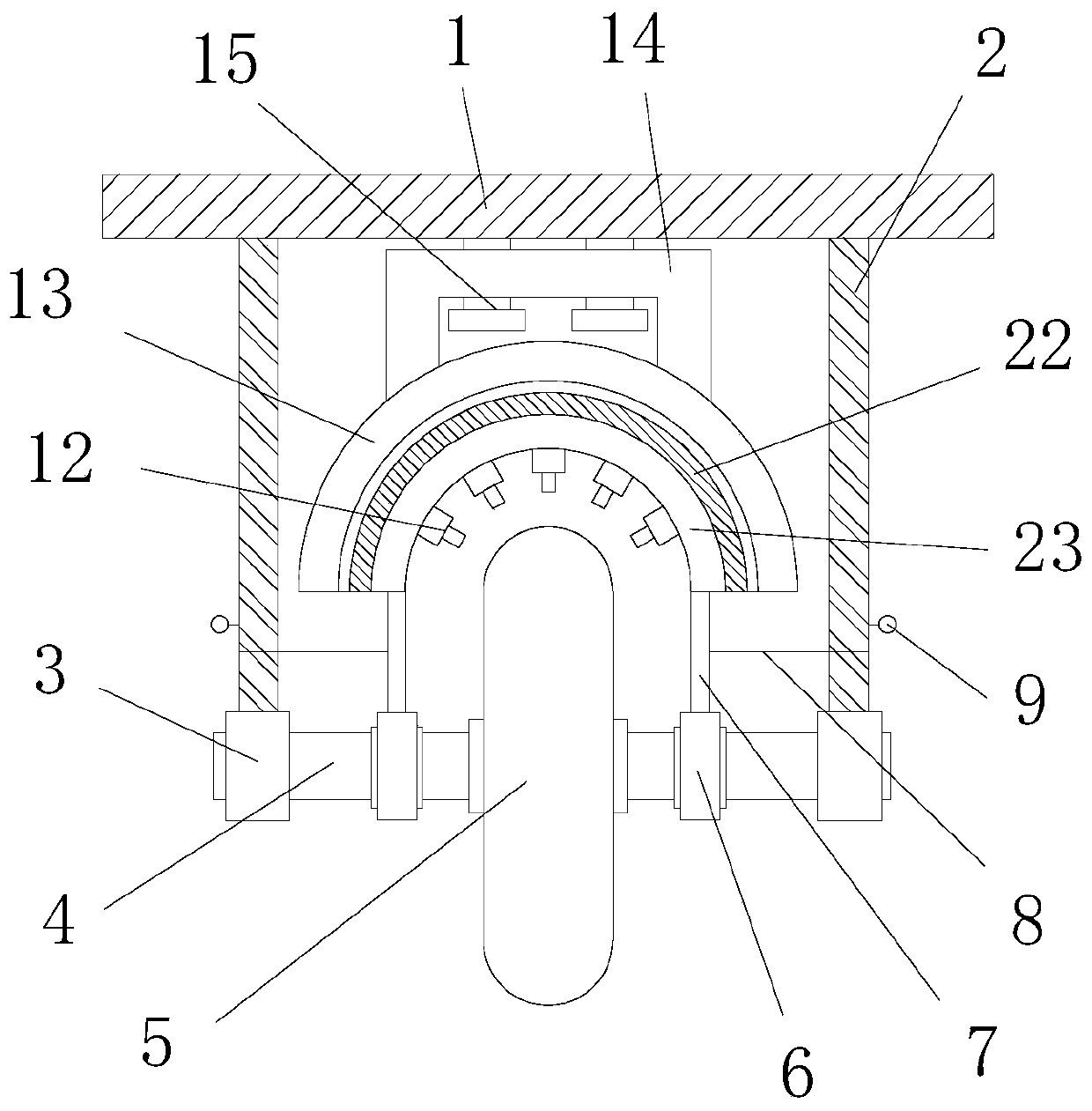

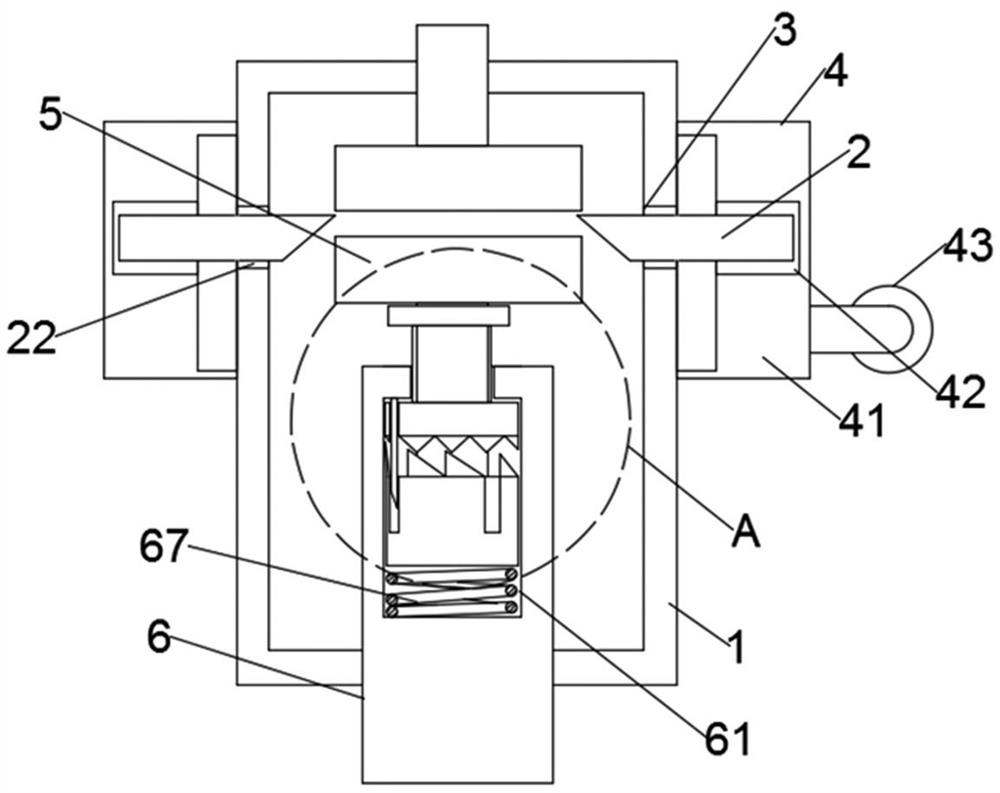

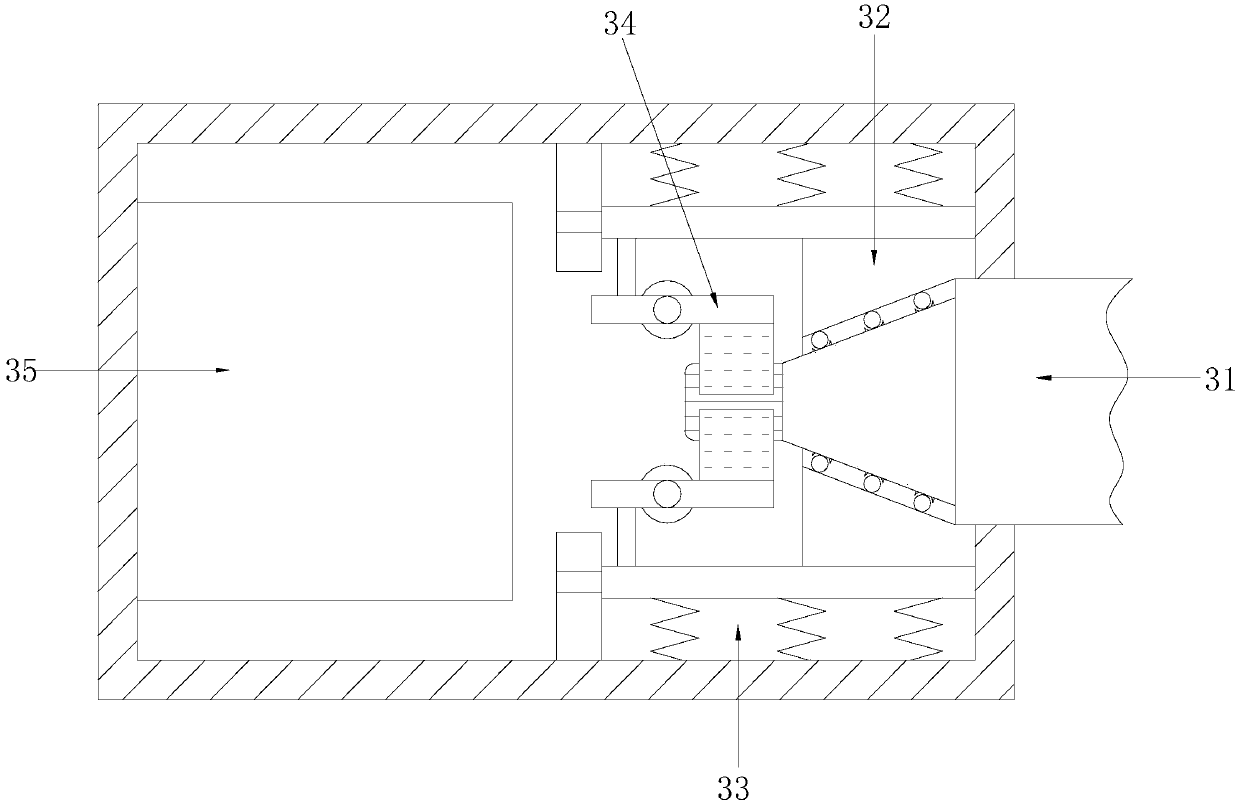

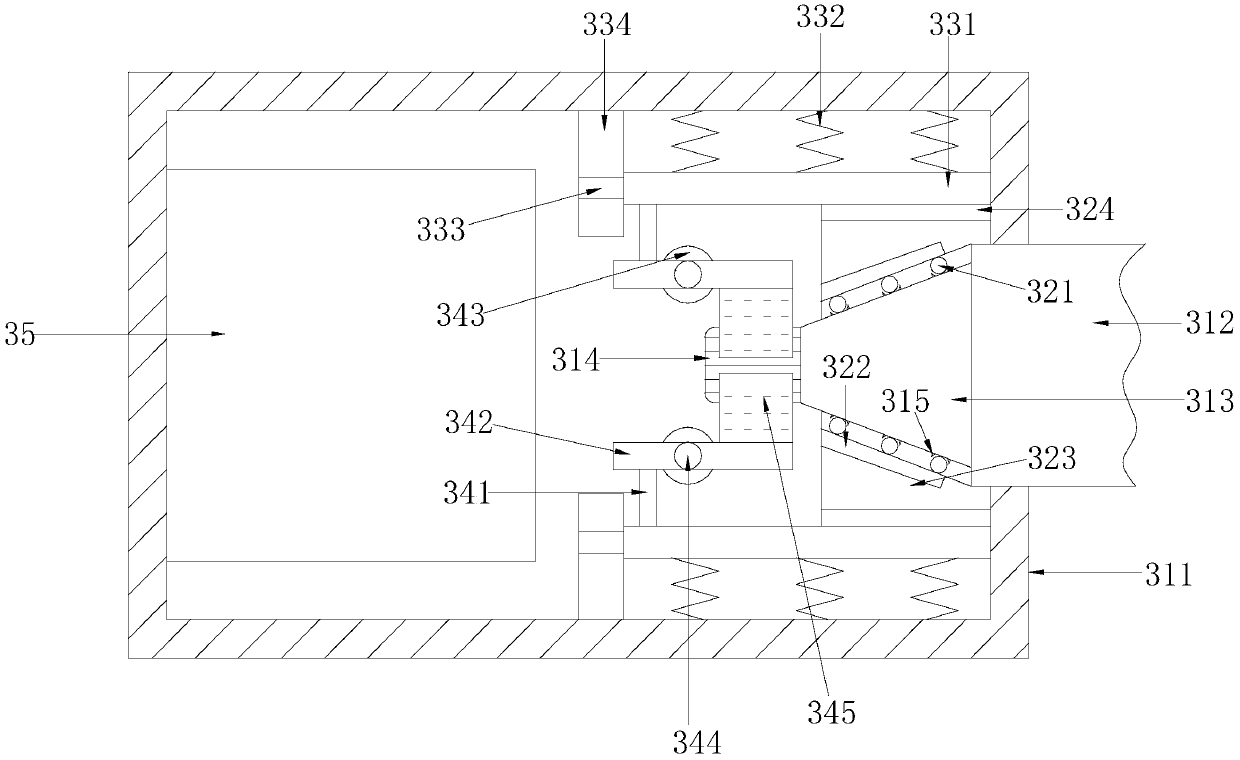

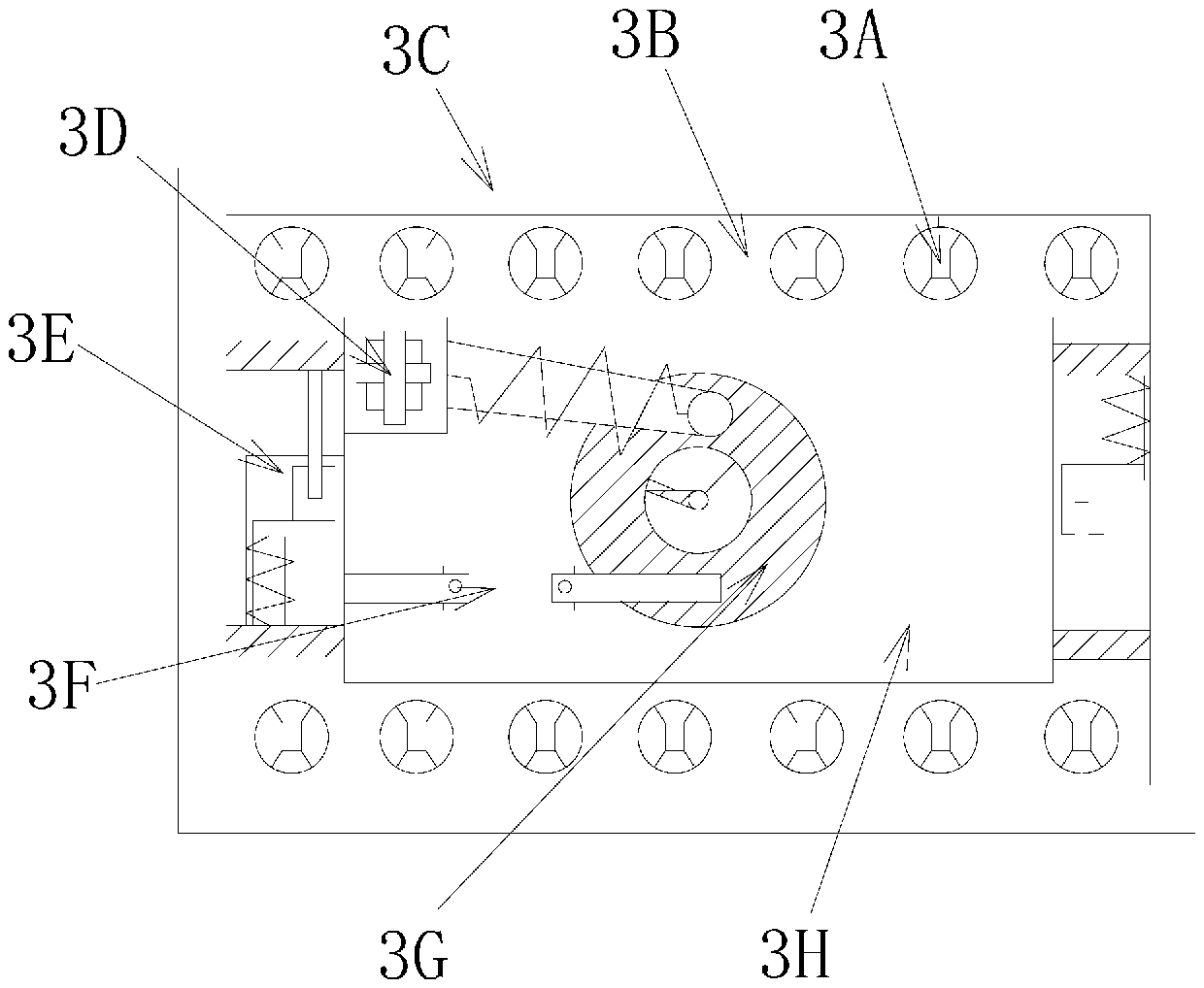

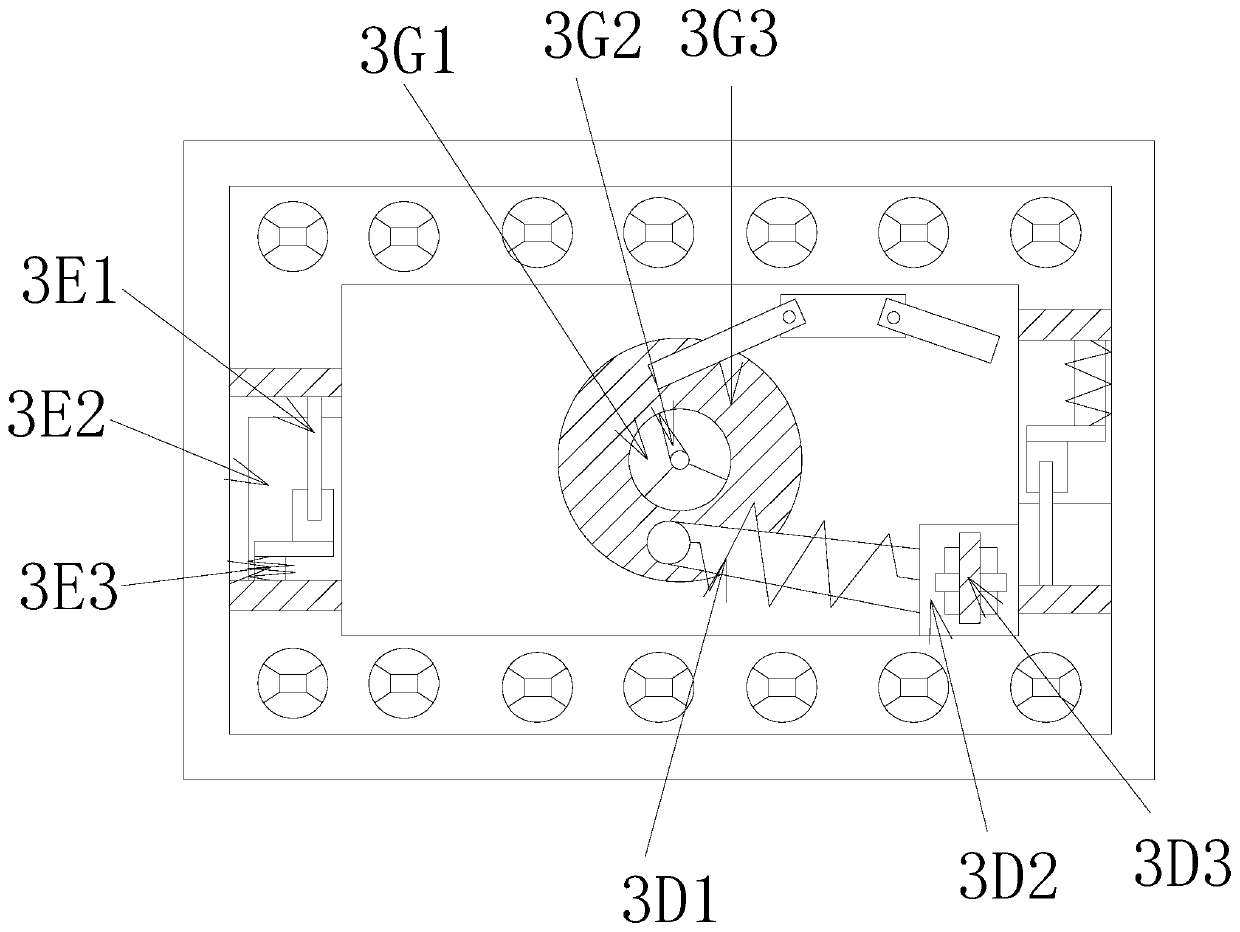

Operating mechanism of vacuum circuit breaker

ActiveCN111816502APlay the role of openingImprove arc extinguishing performanceHigh-tension/heavy-dress switchesAir-break switchesStructural engineeringVacuum circuit breakers

The invention discloses an operating mechanism of a vacuum circuit breaker. The operating mechanism comprises an arc extinguishing chamber, one side of the arc extinguishing chamber is provided with astatic contact, a moving contact is arranged on the other side of the arc extinguishing chamber, an arc extinguishing partition plate is arranged at the position, close to the joint of the moving contact and the static contact, of the arc extinguishing chamber, an annular groove used for installing the arc extinguishing partition plate is formed in the arc extinguishing chamber around the perimeter of the arc extinguishing partition plate, and the arc extinguishing partition plate penetrates through the arc extinguishing chamber along the annular groove to be connected with a push plate assembly; the moving contact comprises a contraction part which is arranged at one end close to the static contact, and a wrapping part used for wrapping the contraction part; and the push plate assembly pushes the arc extinguishing partition plate to move towards the joint of the static contact, and the arc extinguishing partition plate pushes the contraction part to contract and move towards the interior of the wrapping part. The push plate assembly drives the arc extinguishing partition plate to move towards the joint of the moving contact and the static contact, thereby separating the moving contact from the static contact through the acting force of the arc extinguishing assembly, and achieving the switching-off effect of the moving contact and the static contact.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

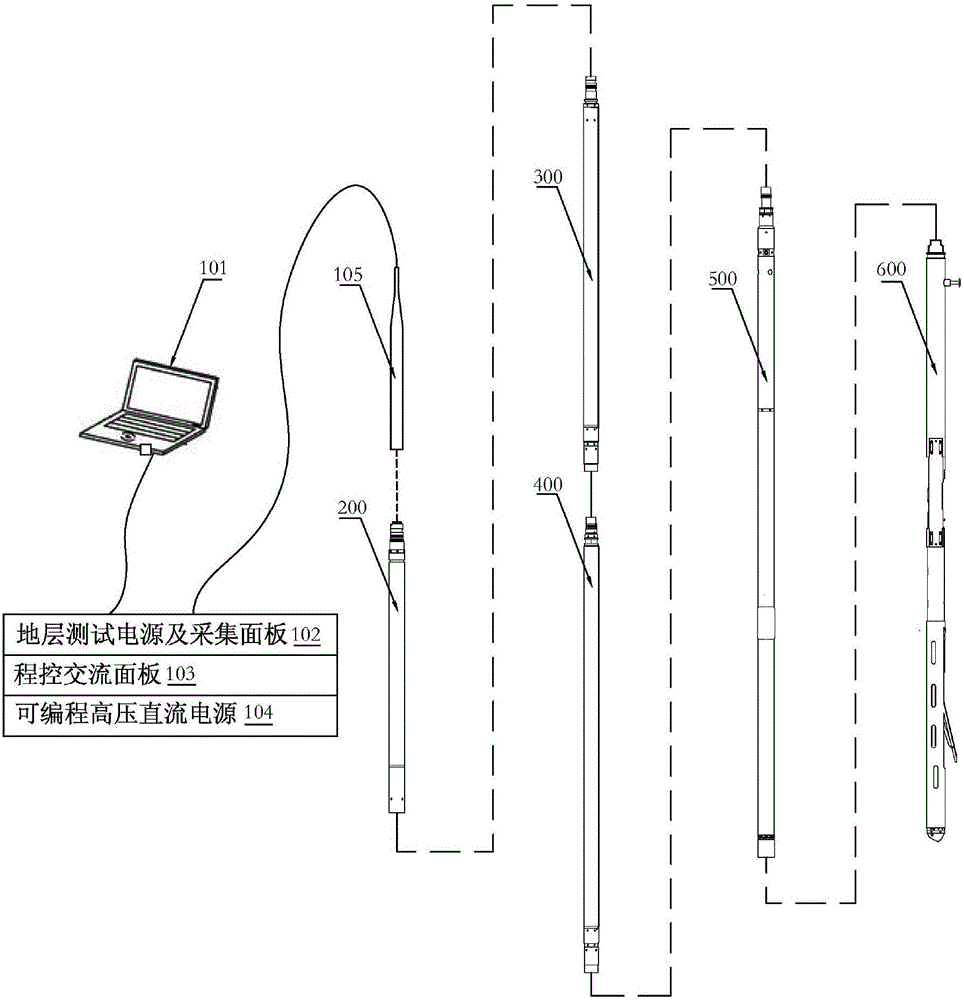

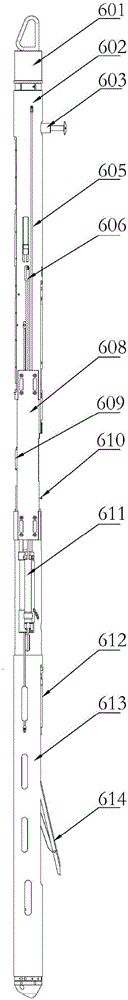

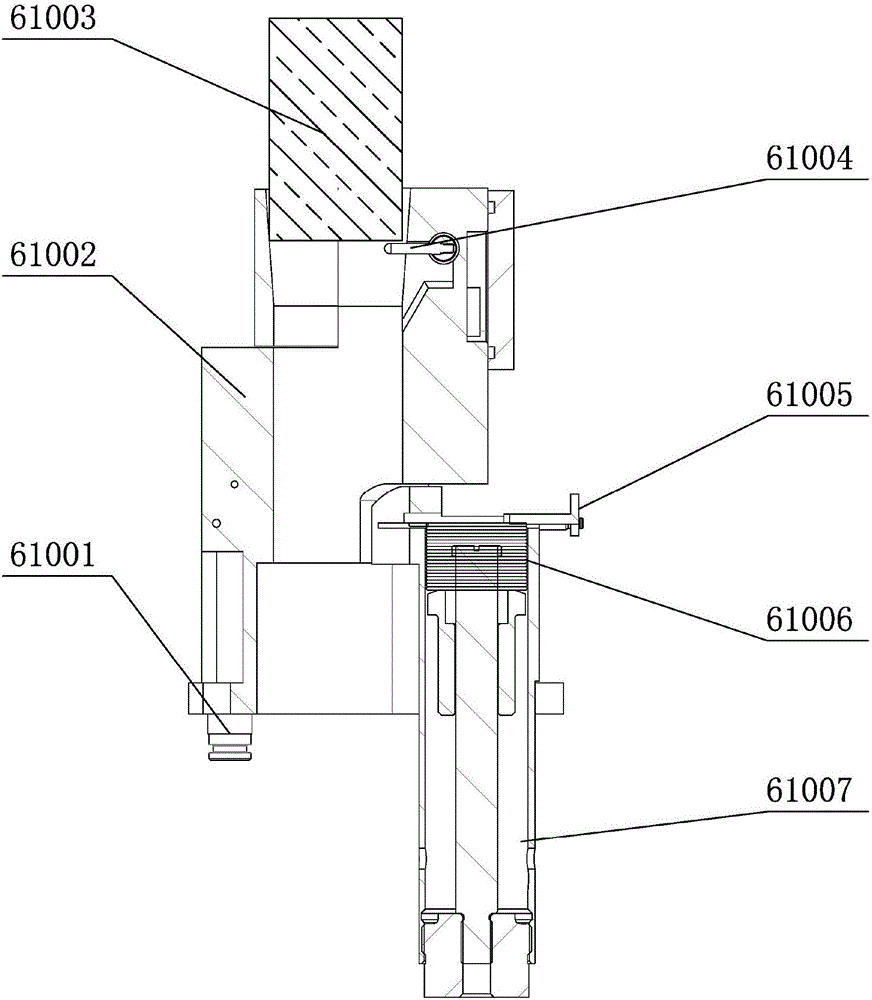

Slim hole large-grain mechanical type side-wall coring device

The invention relates to a slim hole large-grain mechanical type side-wall coring device and a method for acquiring a cylinder rock core sample with the diameter of 1.5 inches (38.1mm) and length of 2.5 inches (63.5mm) from an oil well by adopting a mechanical type side-wall coring device (MSC-127) with an outer diameter of 5 inches. The device mainly comprises a ground control system, phi mechanical type side-wall coring software (software copyright register number: 2015SR265183), a communication nipple, a power supply section, an electronic section, a hydraulic section and a mechanical section. The device is used for drilling to sample the rock core sample from the side wall (30 / 60 grains) and safely bringing the sample to the ground. The device has the main functions of: 1) drilling the rock core at a preset depth and displaying the specific orientation; 2) collecting the arrayed rock cores according to the drilling sequence and separating the adjacent rock cores by a spacer; 3) safely and completely bringing the rock cores to the ground.

Owner:BEIJING JIEWEISITE TECH CO LTD

Clamping device for an operation

InactiveCN101352589ACheap manufacturingReduce molding cycle timeIntravenous devicesFlow controlMechanical engineering

Owner:HANACO MEDICAL CO LTD

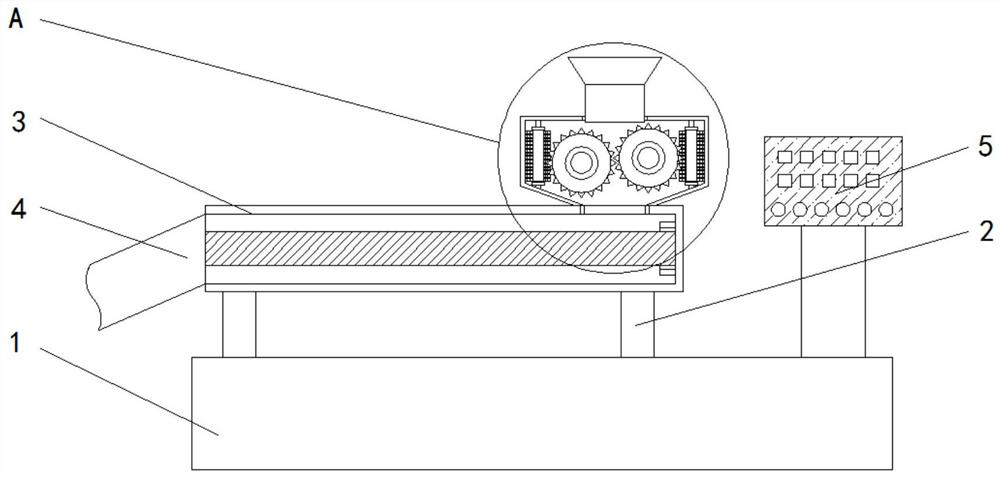

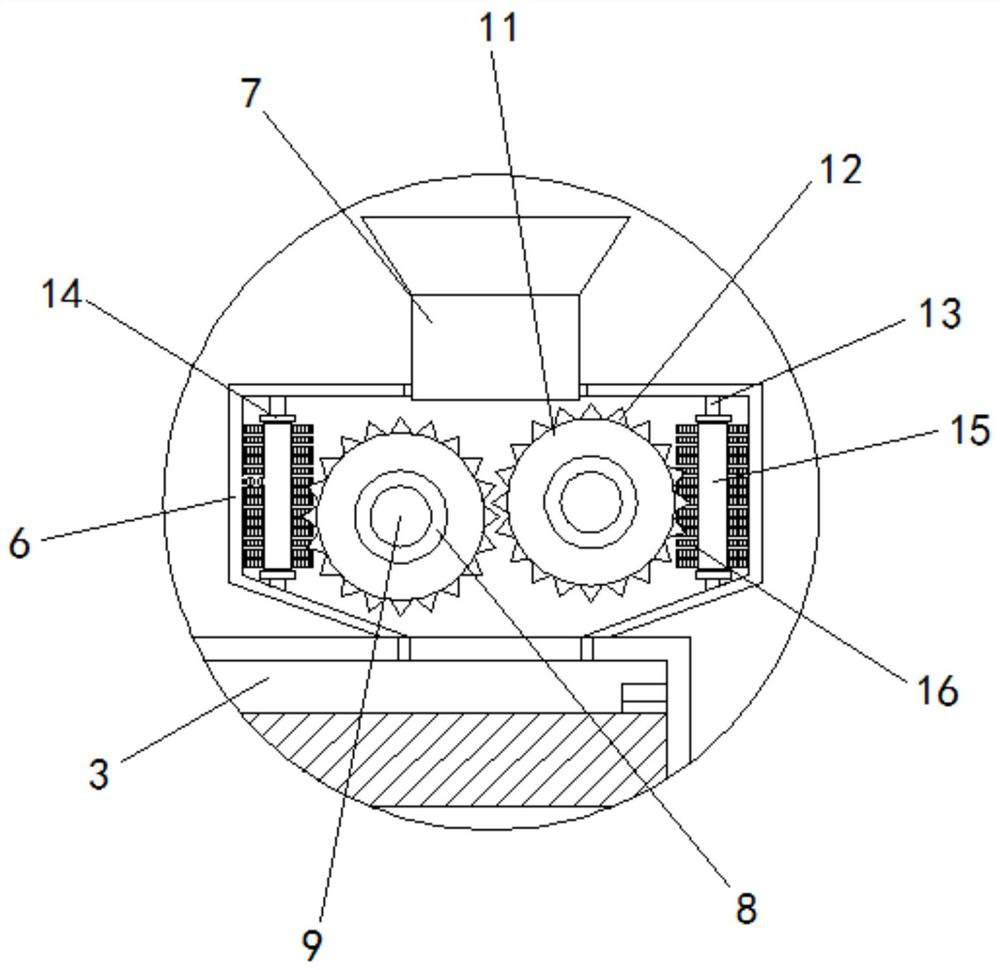

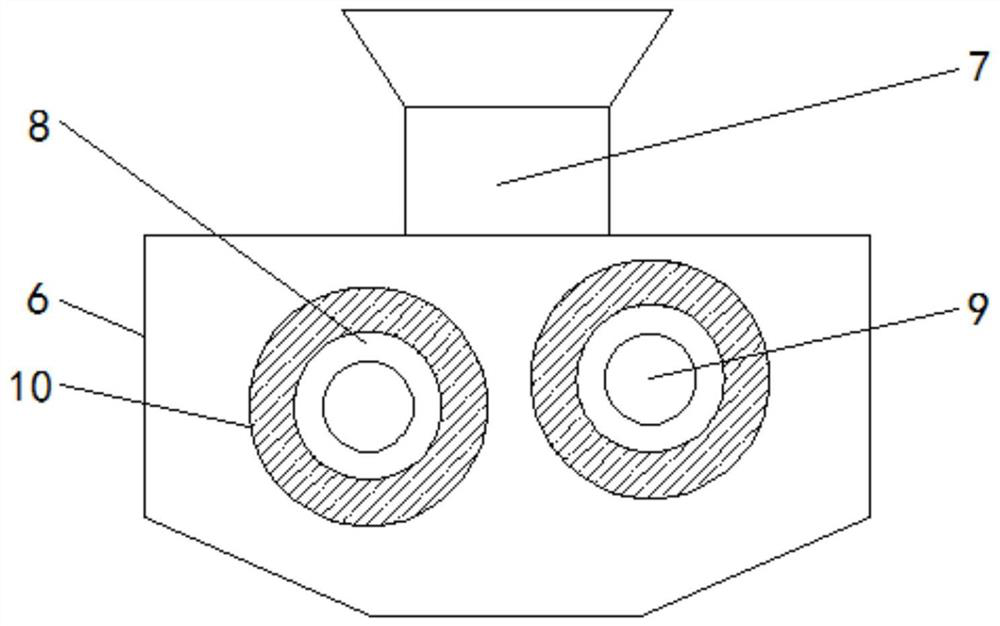

Double-screw extruder for cable material production

PendingCN113799359AImprove cleanlinessPrevent snappingCleaning using toolsGrain treatmentsEngineeringMechanical engineering

The invention relates to the technical field of double-screw extruders, and discloses a double-screw extruder for cable material production, which comprises a workbench. According to the double-screw extruder for cable material production, through the arrangement of a crushing box, when the double-screw extruder is used, two servo motors are started to rotate in opposite directions, output shafts of the servo motors rotate to drive a movable shaft, a roller and a cutter device to rotate along with the servo motors, at the moment, feeding is conducted through a feeding pipe, plastic particles fall into the crushing box through the feeding pipe, and then the plastic particles are crushed; and through rotary clamping of the cutter device, a cutter cuts up all plastic particles, the cut-up plastic particles naturally fall into a double-screw extruder body below and are shaped through the double-screw extruder body, a cleaning brush cleans the plastic particles adhering to the cutter device on the side face, and at the moment, a limiting ring plays a limiting role, so that the plastic particles are completely cut up through the cutter device, cleanness of the cutter device is guaranteed, the cutter device is prevented from being clamped, use is easy, and operation is more convenient.

Owner:扬州实嘉电缆材料有限公司

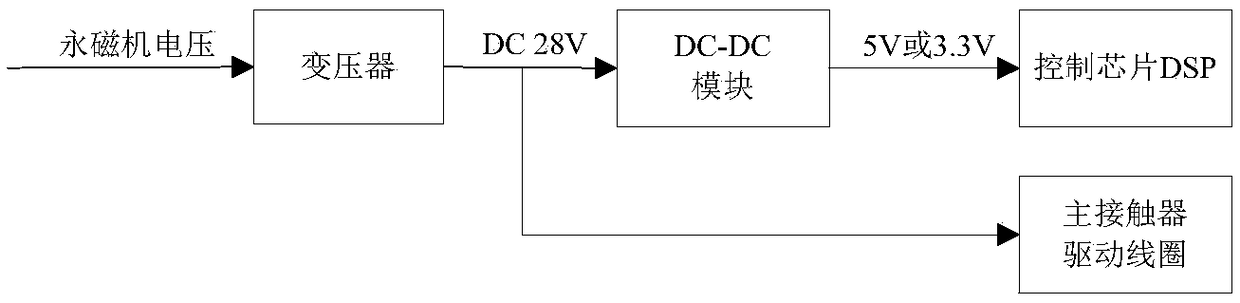

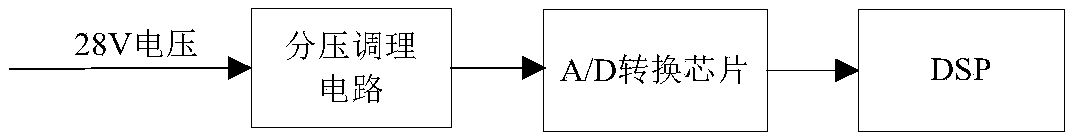

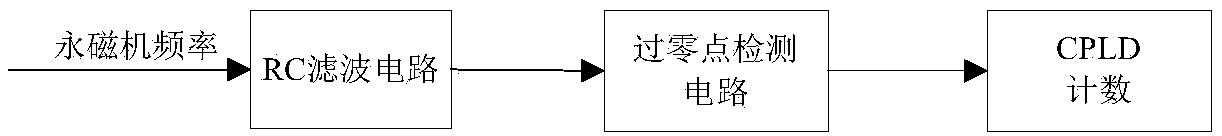

Anti-beating method based on generator controller of aircraft power supply system

ActiveCN109450309AImprove securityImprove reliabilityElectric generator controlElectricityInstability

The invention provides an anti-beating method based on a generator controller of an aircraft power supply system. A working voltage 28V of the generator controller and a generator rotating speed valueare collected by hardware, whether the controller is normally powered off is judged in software, if the controller is not normally powered off, a fault symbol and a fault code are set, and the powersupply system is prohibited from generating power and importing the power into a grid during the next power-on, thereby effectively solving the problem of beating of a main contactor caused by the power supply instability in the prior art and improving the safety and reliability of the power supply system.

Owner:SHAANXI AVIATION ELECTRICAL

Hardware polishing dust recycling machine

InactiveCN112809536APrevent crushing and bondingPrevent echoPolishing machinesDispersed particle separationControl switchIndustrial engineering

The invention discloses a hardware polishing dust recycling machine. The hardware polishing dust recycling machine structurally comprises recycling equipment, a control switch, a closing door and an exhaust hole, wherein the control switch is fixedly embedded in the side face of the recycling equipment, the closing door is clamped to the side face of the lower end of the recycling equipment, and the exhaust hole is formed in the side face of the lower end of the recycling equipment; a semicircular hole in a scraping mechanism is in clearance fit with a strip-shaped structure on the surface of a barrier plate, so that magnetic dust is prevented from being crushed and adhered to the surface of the barrier plate under an acting force of a plastic plate, the effect of cleaning the magnetic dust is achieved, and the magnetic dust is prevented from being attached to the surface of a barrier mechanism; a fixed fixing mechanism is used for scraping and cleaning a rotating plate in a cleaning structure, so that a movable mechanism is compressed through a spring rod, solidified dust is prevented from sliding through fixing effect of a stress plate on the right side of a rubber sleeve on dust, and the solidified dust is prevented from being clamped in the stress plate under blocking of the rubber sleeve; therefore, the dust is cleaned under the acting force of movement, and the solidified dust is prevented from blocking subsequent dust collection.

Owner:广州万邦运输服务有限公司

Swirl fluid machinery

ActiveCN100359176CIncrease widthHigh strengthRotary piston pumpsRotary piston liquid enginesStress concentrationGreek letter alpha

The purpose of this invention is to prevent a motive power loss and noise in operation, while enhancing sealability of a compression space, by properly setting its angle, while enhancing strength of projections arranged in a lap part. The inner diameter side projection 13 and the outer diameter side projection 14 are respectively arranged on an inner peripheral surface 12A and an outer peripheral surface 12B of the lap part 12 of a revolving scroll 10, and these cross sections are formed in a substantially triangular shape. Thus, the projections 13 and 14 can enhance the strength by preventing stress concentration by concave circular arc surfaces 13B and 14B, and top parts 13A and 14A can easily become familiar by contacting with the lap part 3. An angle [alpha] formed by the adjacent projections 13 and 14 is set in a predetermined range. Thus, the sealability of the compression space 15 is enhanced, and workability of the lap part 12 and the projections 13 and 14 can be enhanced.

Owner:HITACHI LTD

Buckle base structure in plastic mold tensioning mechanism

The invention discloses a buckle base structure in a plastic mold tensioning mechanism. The structure comprises a device locking block, two threaded connecting blocks, a plug extrusion alignment forceremoving device, an upper mold plate tensioning block and a lower mold plate tensioning block, wherein the two threaded connecting blocks penetrate through and are integrated with the inside the device locking block; and the right side surface of the device locking block is connected with the left side surface of the plug extrusion alignment force removing device. According to the structure, an alignment rod can be installed and inserted into the buckle base to be installed, and an internal bonding rubber ring is matched with an insertion rubber block to stabilize so as to ensure that the installed buckle base is on the same horizontal plane and the buckling of the buckle base is not broken due to unbalance stress; and when the buckle base exceeds the stroke, internal high-pressure air can be squeezed by squeezing and impacting the rubber block to push the force removing plate to remove the pulling force exceeding the stroke, so that deformation or breakage of the buckle base is avoided.

Owner:佛山市天驭塑料制品有限公司

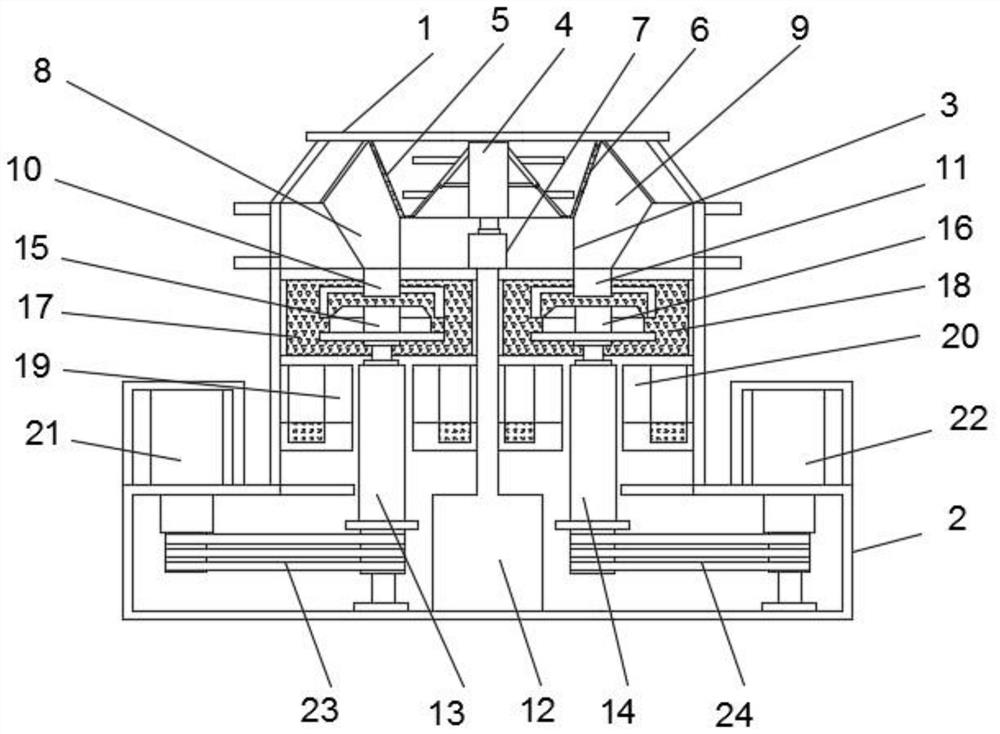

Vertical shaft impact crusher

ActiveCN112756063AImprove crushing effectAvoid snappingPlastic recyclingGrain treatmentsImpellerStructural engineering

The invention discloses a vertical shaft impact crusher. The vertical shaft impact crusher comprises a crusher body, a base, a stirring mechanism, a first crushing mechanism and a second crushing mechanism, the base is fixedly installed at the lower end of the crusher body, a partition plate is fixedly installed at the position, close to the middle, in the base, a supporting seat is installed at the upper end of the partition plate, the stirring mechanism is installed at the position, close to the middle, of the upper end of the supporting seat, first supporting plates are slidably connected to the two sides of the stirring mechanism, third supporting plates are connected to the positions, close to the lower portions, of the interiors of the first supporting plates, and second supporting plates are fixedly installed on the sides, close to the stirring mechanism, of the first supporting plates. According to all aspects disclosed by the invention, the problem that the crushing effect is poor due to the influence of centrifugal force when the materials are thrown out of an impeller can be solved, and the problem that the crushing effect of the materials is poor due to the fact that the materials of different specifications are subjected to the same impact force because the materials of different specifications are not screened can be solved.

Owner:唐山东道实业有限公司

Big data optical fiber wire installation limiting device

InactiveCN111812790AExpand the range of supportLow installation position requirementsFibre mechanical structuresEngineeringMaterials science

The invention relates to the field of optical fiber installation limiting devices, in particular to a big data optical fiber wire installation limiting device which comprises a fixing structure, a telescopic structure, a first angle adjusting structure, a guiding structure, a driving structure and a second angle adjusting structure. The arrangement of the telescopic structure facilitates the adjustment of the supporting height of an optical fiber wire, enables the supporting range of the optical fiber wire to be larger, and reduces the requirements for the installation position of a telegraphpole; through the arrangement of the driving structure, limiting of the telescopic structure can be done conveniently, and the telescopic structure is more stable after height adjustment; and one endof the telescopic structure used for adjusting the supporting distance is fixed to the second angle adjusting structure, the angle between the telescopic structure and the fixing structure can be conveniently adjusted through the second angle adjusting structure, the supporting angle of the optical fiber wire in the vertical direction can be conveniently adjusted to be changed, and the supportingrange of the optical fiber wire is larger; and meanwhile, the optical fiber wire with different angles can be conveniently supported and guided, and the operation flexibility of optical fiber wire fixing is improved.

Owner:永旗农业科技发展(杭州)有限公司

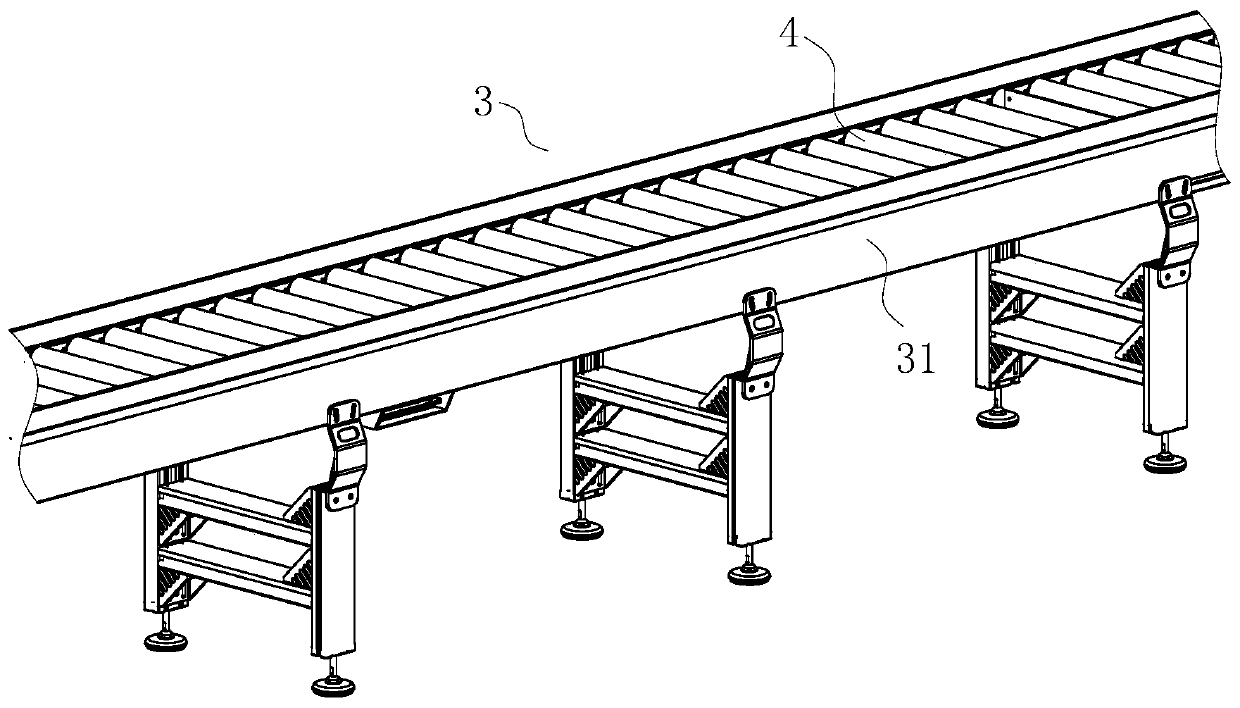

Recyclable shot blasting device

ActiveCN110712136AAchieve recyclingReduce the amount requiredConveyorsAbrasive machine appurtenancesStructural engineeringMachine

The invention belongs to the technical field of industrial production, and particularly discloses a recyclable shot blasting device. An installing frame is installed on the two sides of an opening ofa machine body in a penetrating mode. A rotating frame is formed in the inner side of the installing frame. A plurality of first rotating shafts are installed in the installing frame through a rotating sleeve in the horizontal direction of the installing frame. The first rotating shafts are sleeved with rotating rollers. Rotating bearings are arranged at the two ends of each second rotating shaftcorrespondingly. The rotating bearings are installed on a conveying belt through fixing sleeves. Rotating belt wheels are installed at the two ends of each second rotating shaft. The rotating belt wheels are located outside the rotating bearings. The rotating belt wheels are rotationally connected through a belt. A rotating cylinder is installed on each second rotating shaft. A converting mechanism is arranged outside the installing frame and used for exerting the transmission effect on the conveying belt and the rotating cylinders. It is effectively avoided that the fracture or breakage phenomenon is generated when the rotating cylinders work for a long time in the machine body and the safety operation of the rotating cylinders is affected.

Owner:南京六合高新建设发展有限公司

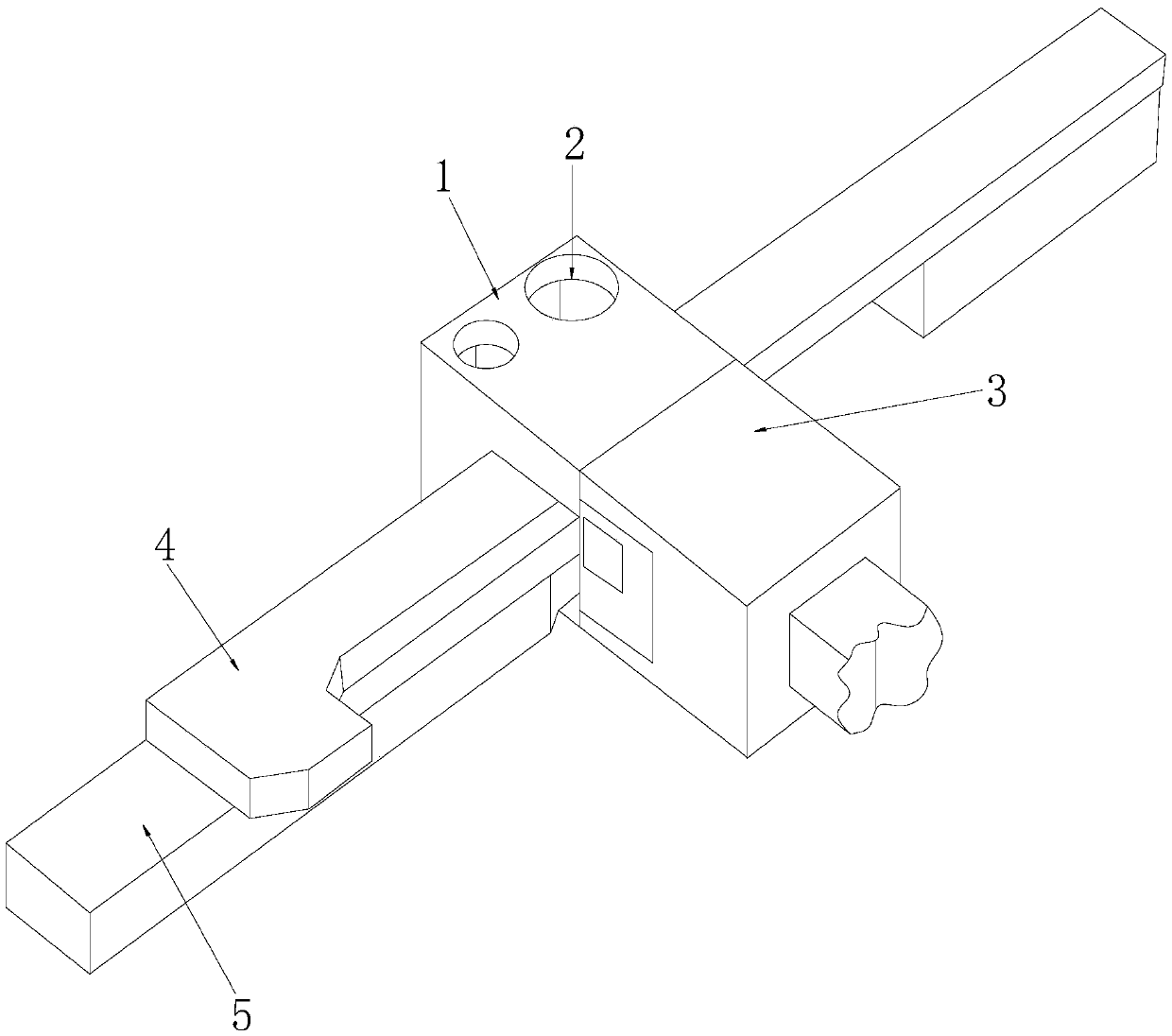

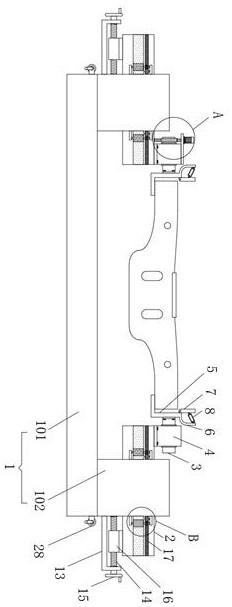

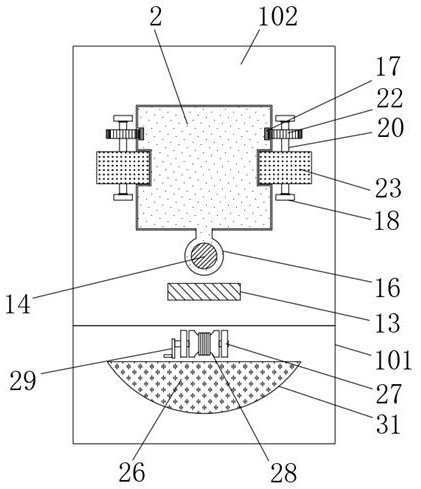

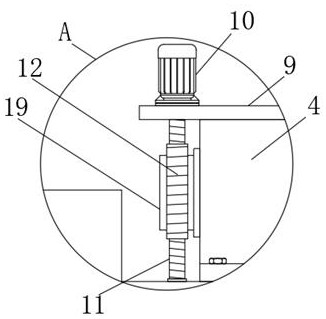

Train swing bolster clamping device facilitating positioning

ActiveCN112475957AEasy to useStrong applicabilityWork clamping meansRailway transportElectric machineryClip device

The invention relates to the technical field of train swing bolster machining, and discloses a train swing bolster clamping device facilitating positioning. A base is included and comprises a cross beam and two end seats, the two end seats are fixedly welded to the two ends of the top of the cross beam correspondingly, guide holes are formed in the two end seats correspondingly, and movable seatsare arranged in the guide holes. A sliding block is arranged on the inner wall of each guide hole, a sliding groove matched with each sliding block is formed in the side face of the corresponding movable seat, and a position adjusting device is arranged at the bottom of one end of each movable seat. According to the train swing bolster clamping device easy to position, the two ends of a swing bolster are placed on two L-shaped pressing plates, then air cylinders are started to drive movable pressing plates to rotate so that the swing bolster can be pressed and positioned, a motor is started todrive a worm to rotate, then a worm wheel and a rotating shaft are driven to rotate, and the swing bolster can be driven to rotate to a proper angle; and compared with the prior art, using is more convenient, applicability is higher, the machining efficiency is improved, and manpower is saved.

Owner:CRRC YANGTZE TONGLING CO LTD

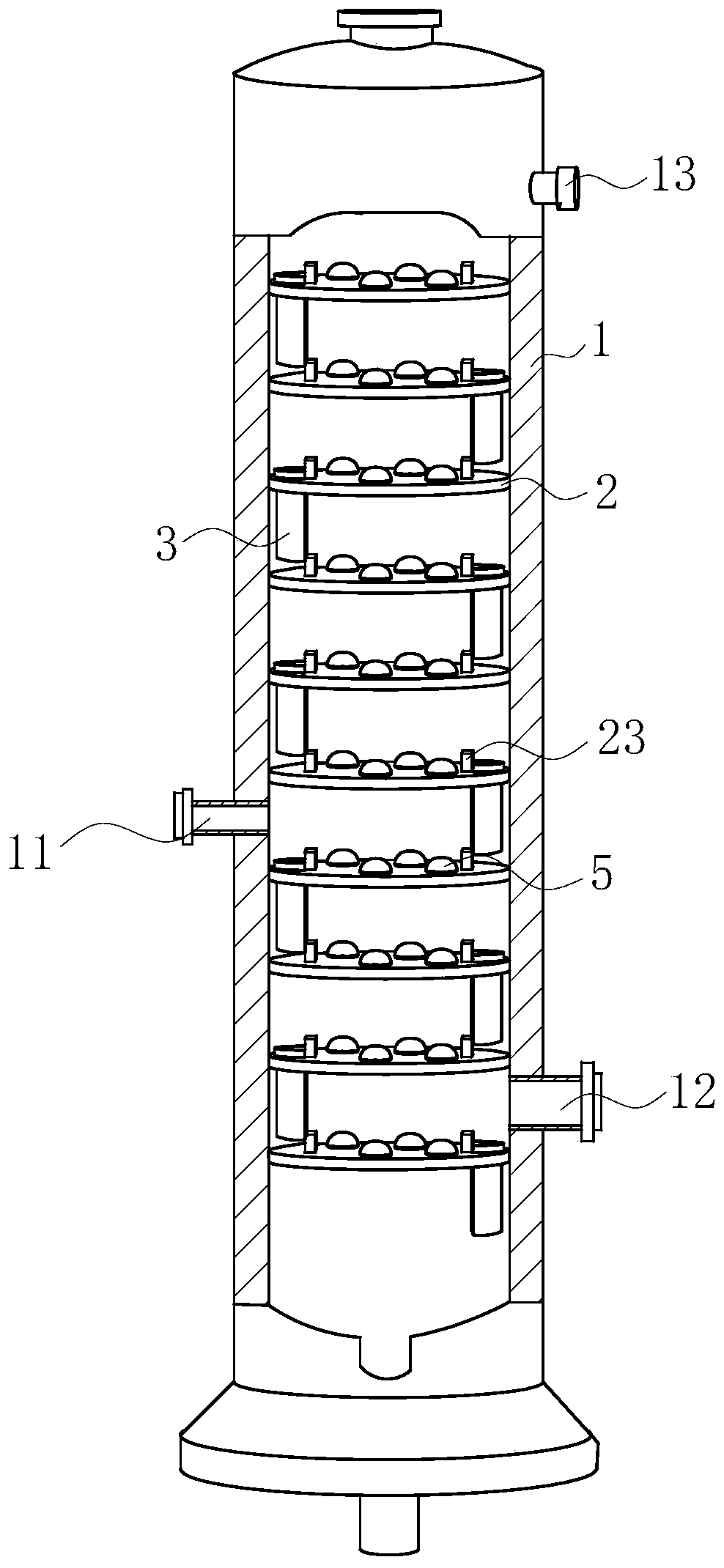

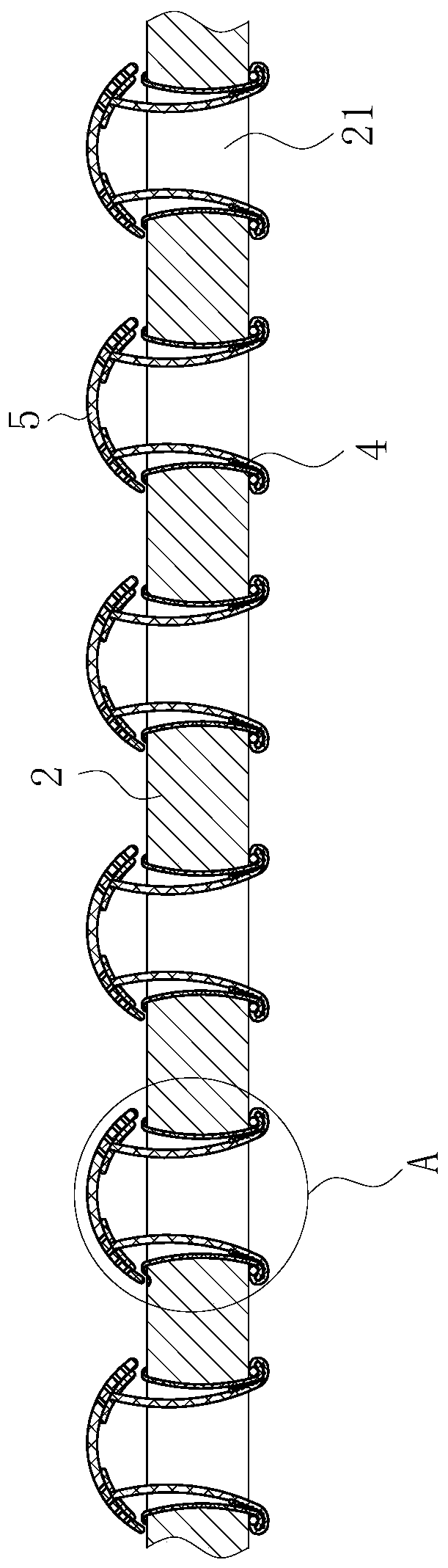

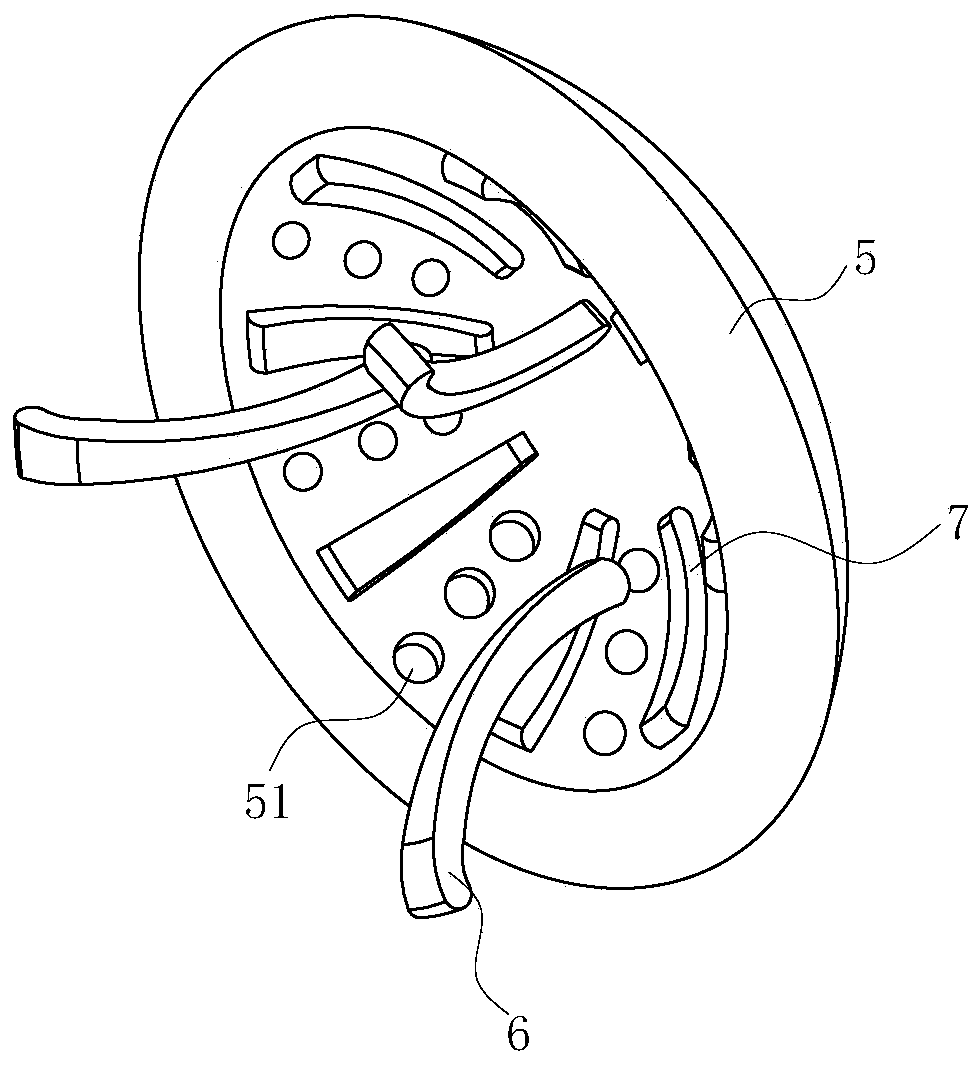

Plate type fractionation tower

The invention belongs to the technical field of fractionation towers, in particular to a plate type fractionation tower. The plate type fractionation tower comprises a tower body and tower plates, wherein the tower plates are evenly installed inside the tower body; an overflow weir is installed on the upper surface of each tower plate, and the side surface of the overflow weir is provided with a downflow spout; downflow spouts between two adjacent tower plates are arranged in a staggered way; elastic hat-like rings are inserted and arranged in the overflow holes, and the bottom ends of the elastic hat-like rings are provided with annular roll rims; the elastic hat-like rings are made of a fiberglass material; hat-like valve blocks are arranged above the overflow holes, made of the fiberglass material, and arranged on and connected with the elastic hat-like rings through elastic fiber ribbons; and the bottom ends of the elastic fiber ribbons are provided with roll rim clamping balls which are clamped in the annular roll rims. The plate type fractionation tower of the invention effectively prevents the phenomenon of wearing or rusting obstruction of the hat-like valve blocks caused by wearing or rusting of the hat-like valve blocks during long-term usage.

Owner:姚传亮

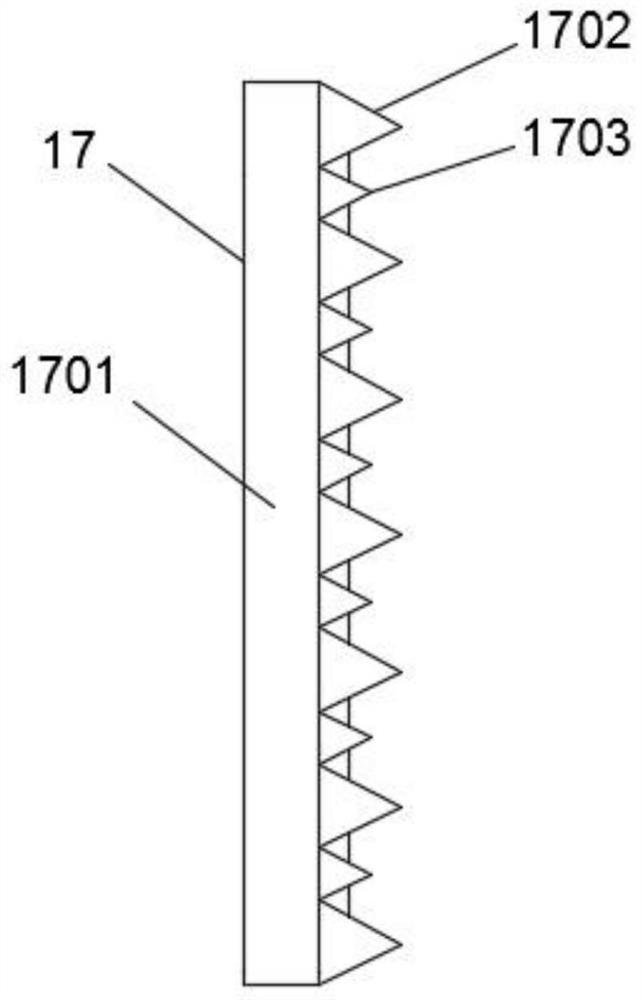

Gravel screening equipment for building construction

InactiveCN114472158AAvoid snappingEnsure stabilitySievingScreeningArchitectural engineeringSupport plane

The gravel screening equipment for building construction comprises a screening box, a screening assembly, a cleaning assembly and a screened residue treatment mechanism, the cleaning assembly is arranged at the top of the upper end of the screening box, a motor set is arranged at the bottom end of the interior of the screening box, and the screening assembly is arranged at the top of the upper end of the motor set; and a screened residue treatment mechanism is arranged at the top of the upper end of the screening assembly, and the screening assembly comprises a main screening plate, a side screening plate, a plastic layer, a discharging groove, a hydraulic rod and an auxiliary supporting frame. According to the gravel screening equipment for building construction, the filter plate serves as a main body structure for gravel screening, gravel at the upper end of the filter plate is in a movable state under the two external force modes of lifting transmission and rotating operation, gravel screening operation can be conveniently completed by penetrating through the filter plate, the gravel is washed in the screening process, and the gravel screening efficiency is improved. Therefore, the cement can be mixed with cement in the subsequent building construction, so that the adhesiveness of the cement in the building process is improved.

Owner:谢东海

Main oil pressure electromagnetic valve maintenance tool and using method thereof

ActiveCN104942750AEasy to fixEasy to disassembleMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a main oil pressure electromagnetic valve maintenance tool and a using method thereof. The main oil pressure electromagnetic valve maintenance tool comprises a valve fixing base A, a valve fixing base B, a quick release sleeve, an expansion shaft, a necking sleeve and a core rod, wherein the valve fixing base A and the valve fixing base B are used for fixing a main oil pressure electromagnetic valve, the quick release sleeve is used for fixing the valve fixing base A and the valve fixing base B, the expansion shaft is used for expanding an opening of a shell of the main oil pressure electromagnetic valve, the necking sleeve is used for tightening the opening of the shell of the main oil pressure electromagnetic valve, and the core rod is used for ejecting out an internal component of the main oil pressure electromagnetic valve. A valve fixing groove A is formed inside the valve fixing base A. A valve fixing groove B is formed inside the valve fixing base. A guiding hole is formed in the center of the upper portion of the buckled structure of the valve fixing base A and the valve fixing base B. An annular clamping boss is arranged at the bottom of the inner side face of the quick release sleeve. An extending shaft is arranged at the lower portion of the expansion shaft. An annular heightening table is arranged at the upper position of the inner side of the necking sleeve. A compressing die opening is formed inside the necking sleeve. A flaring groove is formed in the lower portion of the necking sleeve. An ejector shaft is arranged on the lower end face of the core rod. The main oil pressure electromagnetic valve maintenance tool has the advantages of being simple in structure and convenient to use.

Owner:陕西中油丝路能源有限公司

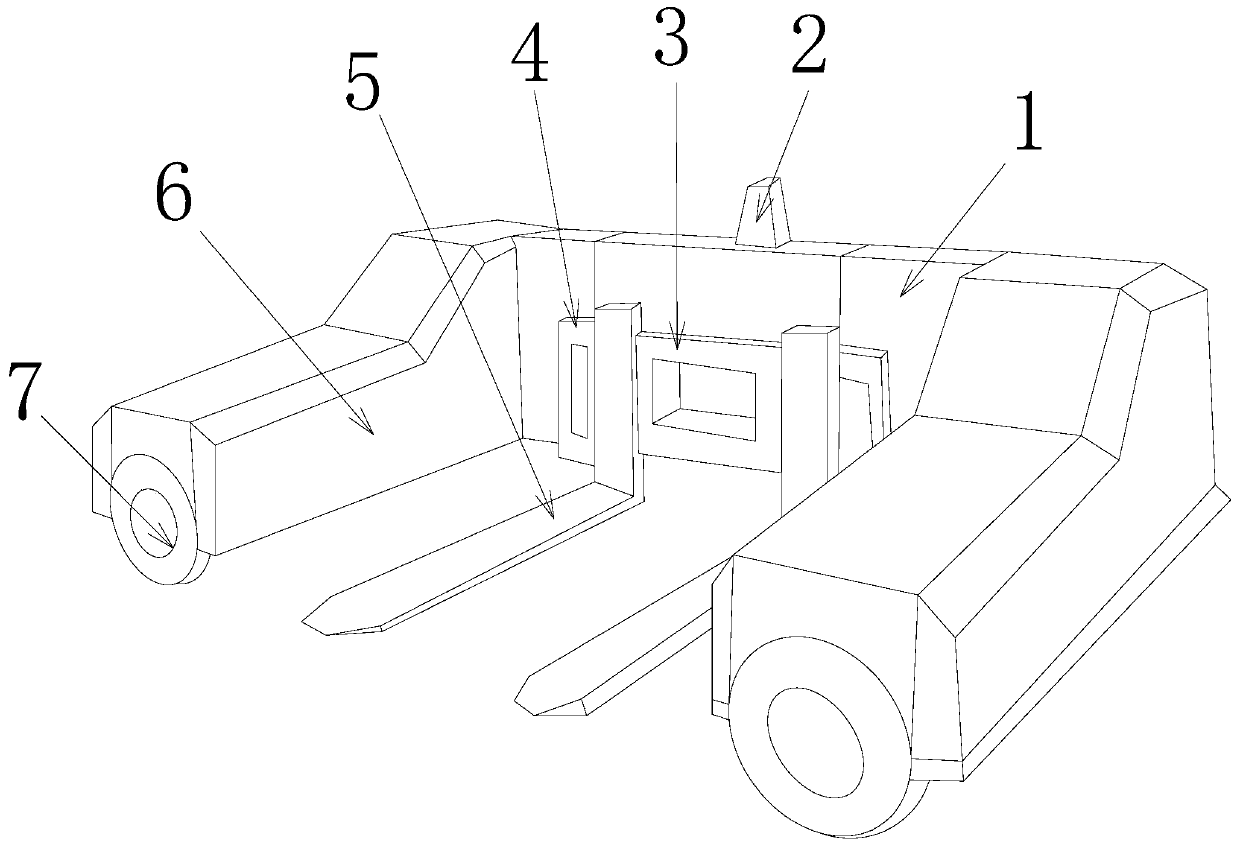

Intelligent logistics conveyor for flexible dynamic centralized reorganization and storage of warehouse

ActiveCN110654758AIncrease lift protectionGuaranteed stabilityStorage devicesLogistics managementControl engineering

The invention discloses an intelligent logistics conveyor for flexible dynamic centralized reorganization and storage of a warehouse. The conveyor comprises a stand plate column block, a lifting hooklug base, a sucker slide measuring frame groove, an auxiliary bonding frame, a fork frame support plate, a clamping buckle power arm and a moving wheel; through cooperation of the sucker slide measuring frame groove and the fork frame support plate, forklift robots with the same sizes form consistent size wrapping degrees of hoisting goods to place and unload in cell shelves; a cross scanning armis matched for slide scanning to achieve the effect of checking the package sizes in a lens ratio; an integrated plate manually programs motion programs beforehand to prevent the work collision and tofill the loophole of insufficient system size collection; and then, the hoisting of the whole frame forms clamping of a lifting extension degree through staggered stretching of the auxiliary bondingframe in a backup plate groove, so that the base damping force stability is guaranteed, the goods hoisting protectiveness is improved, the shaking is prevented, and a flexible dynamic centralized reorganization and storage system for intelligent logistics conveying is optimized.

Owner:ANHUI YUANDONG HEAVY MACHINERY

Arc extinguishing device of vacuum circuit breaker

ActiveCN111816500AAvoid snappingEnsure safetyHigh-tension/heavy-dress switchesAir-break switchesArc extinctionVacuum arc

The invention discloses an arc extinguishing device of a vacuum circuit breaker. The arc extinguishing device comprises an arc extinguishing chamber, one side of the arc extinguishing chamber is provided with a static contact through a static conducting rod, the other side of the arc extinguishing chamber is provided with a moving contact through a moving conducting rod, and a corrugated sleeve issleeved on the moving conducting rod in the arc extinguishing chamber; and an arc extinguishing assembly is arranged in the arc extinguishing chamber and close to the joint of the moving contact andthe static contact. The arc extinguishing assembly comprises a guide ring groove formed in the arc extinguishing chamber; the guide ring groove is arranged around the perimeter of the arc extinguishing chamber; a partition plate is mounted in the guide ring groove; a pushing assembly is arranged in the guide ring groove; and the pushing assembly is in transmission connection with the moving conducting rod. The arc extinguishing assembly arranged between the moving contact and the static contact provides an arc extinguishing effect for opening of the moving contact and the static contact so asto solve the technical problems that in the prior art, since a vacuum circuit breaker mainly depends on a vacuum arc extinguishing chamber for arc extinguishing, the arc extinguishing speed is low, and the contacts are prone to damage.

Owner:GUANGDONG POWER GRID CO LTD DONGGUAN POWER SUPPLY BUREAU +1

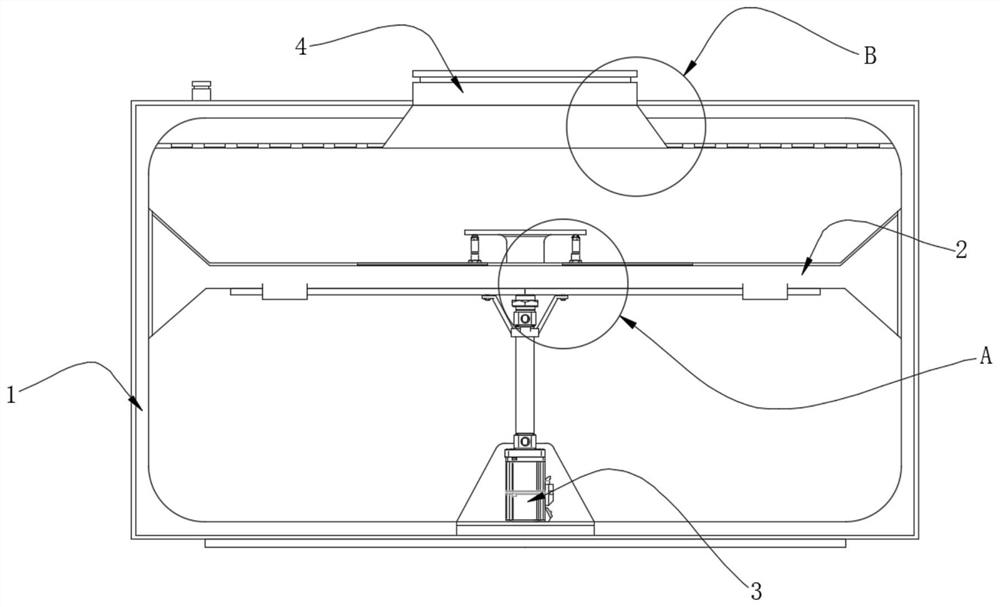

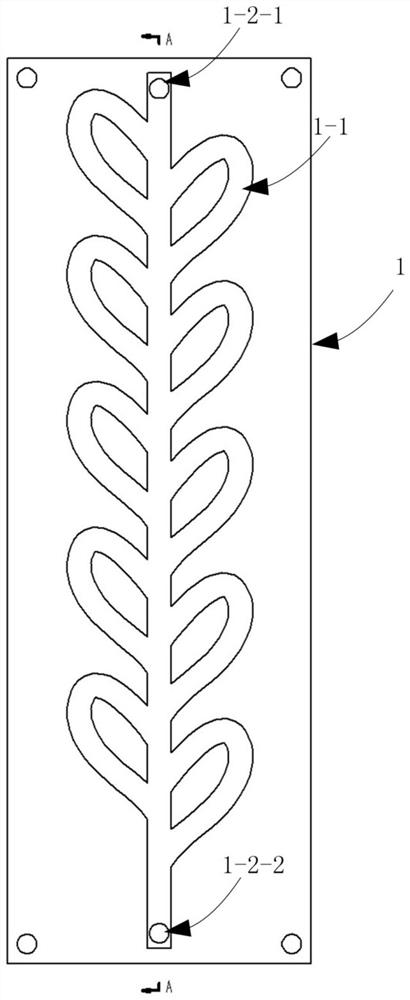

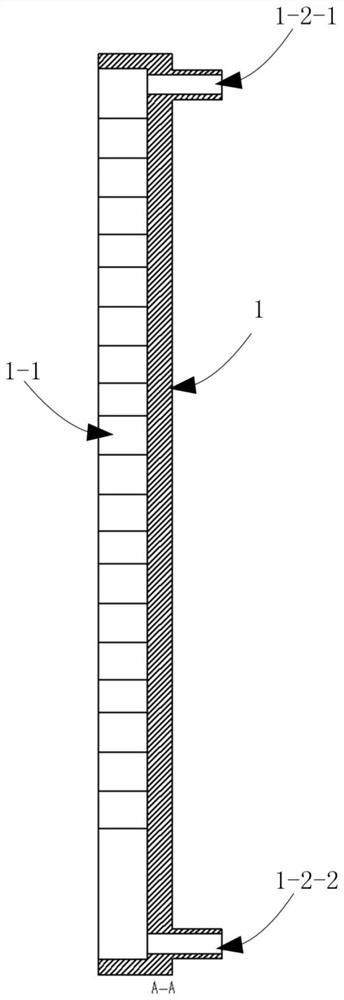

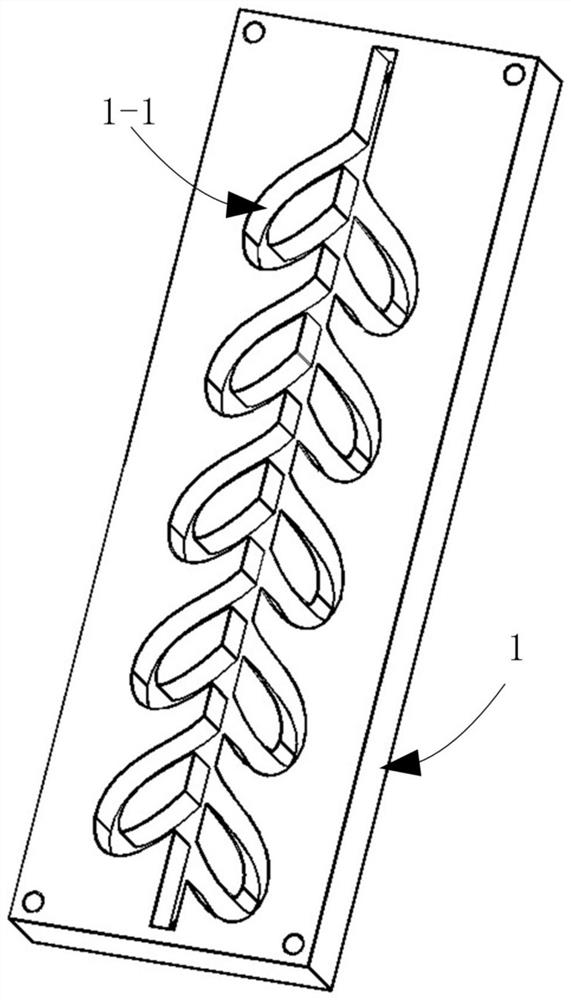

Tesla valve convenient to clean, fluid control system and chemical device

InactiveCN112303295AEasy to operateShorten maintenance timeCheck valvesCleaning using toolsFluid controlControl system

The invention belongs to the field of fluid valves. A Tesla valve convenient to clean comprises a main body (1), a scraper blade (2), a cover plate (3) and a handle (4), wherein the scraper blade (2)is mounted in a first groove (1-1); the side wall of the scraper blade (2) is completely matched with the side wall of a groove cavity of the first groove (1-1) to form movable seal; the scraper blade(2) can move up and down in the first groove (1-1); a connecting column (2-1) of the scraper blade (2) penetrates through a connecting hole (3-1) of the cover plate (3); and the tail end of the connecting column (2-1) of the scraper blade (2) is fixedly connected with the handle (4). A fluid control system adopts the Tesla valve convenient to clean as a one-way valve. A chemical device adopts theTesla valve convenient to clean as a one-way valve for controlling the flow direction of fluid in the device. The Tesla valve convenient to clean is convenient to operate, reduces the maintenance time, reduces the damage probability, saves the manpower, and provides a new technical thought.

Owner:杭州王之新创信息技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com