Post structure

A pillar structure and pillar technology, applied in the direction of connecting components, detachable tables, furniture connections, etc., can solve problems such as layout changes, and achieve the effects of preventing snapping, preventing loosening, and simple loading and unloading operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

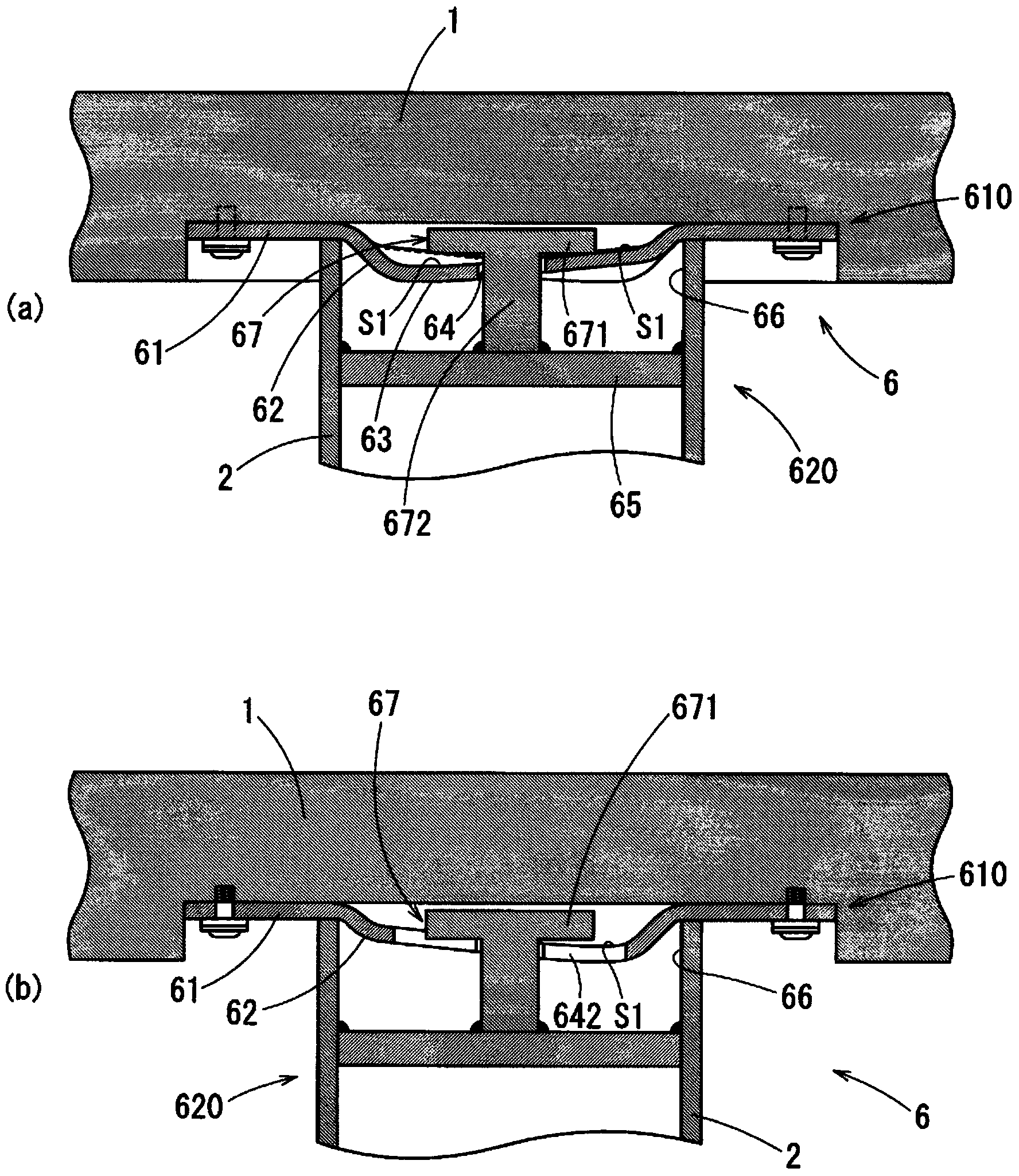

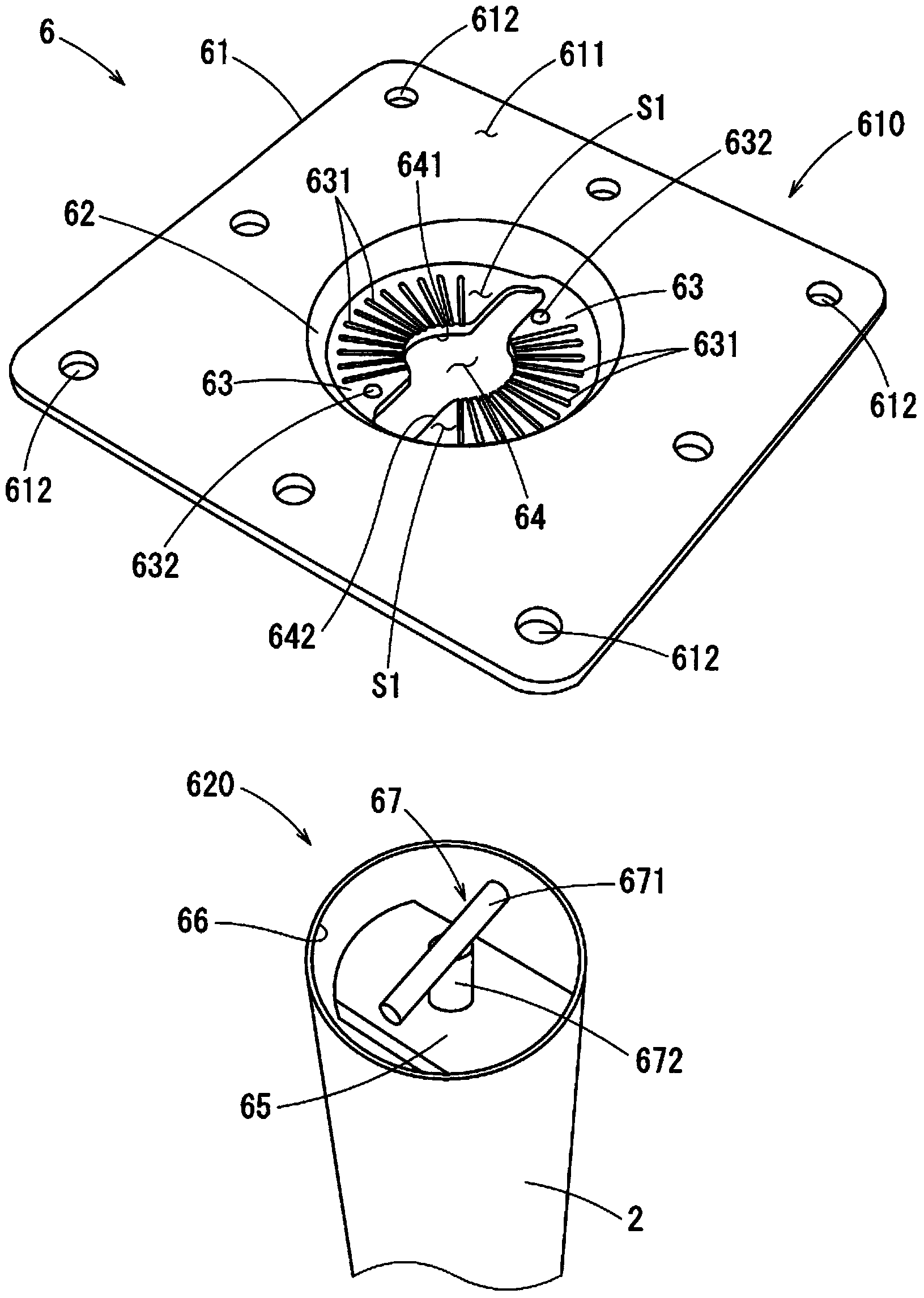

[0083] Refer below Figure 5 , 6 illustrates Embodiment 2 of the present invention. Figure 5 It is a sectional view showing the fixing metal fitting of Example 2. Image 6 It is a sectional view showing the disassembled same fixing metal fittings. The main difference between the second embodiment and the first embodiment is the structure of the fixing part 610 of the fixing metal part 6 .

[0084] Such as Figure 5 Figure (a) and Image 6 As shown, the fixing part 610 of the second embodiment fits the second base 71 concave upwards and the first base 61 concave downwards in such a way that the respective concave parts are opposite to each other, so that it can be closed like a shell cover. state composition. That is, the second base 71 above is stabilized in the recess of the top plate 1, and the first base 61 is screwed on the top plate 1 from below in a manner facing the second base 71, and a gap is formed between the facing recesses. Hollow 80. The cavity 80 accommo...

Embodiment 3

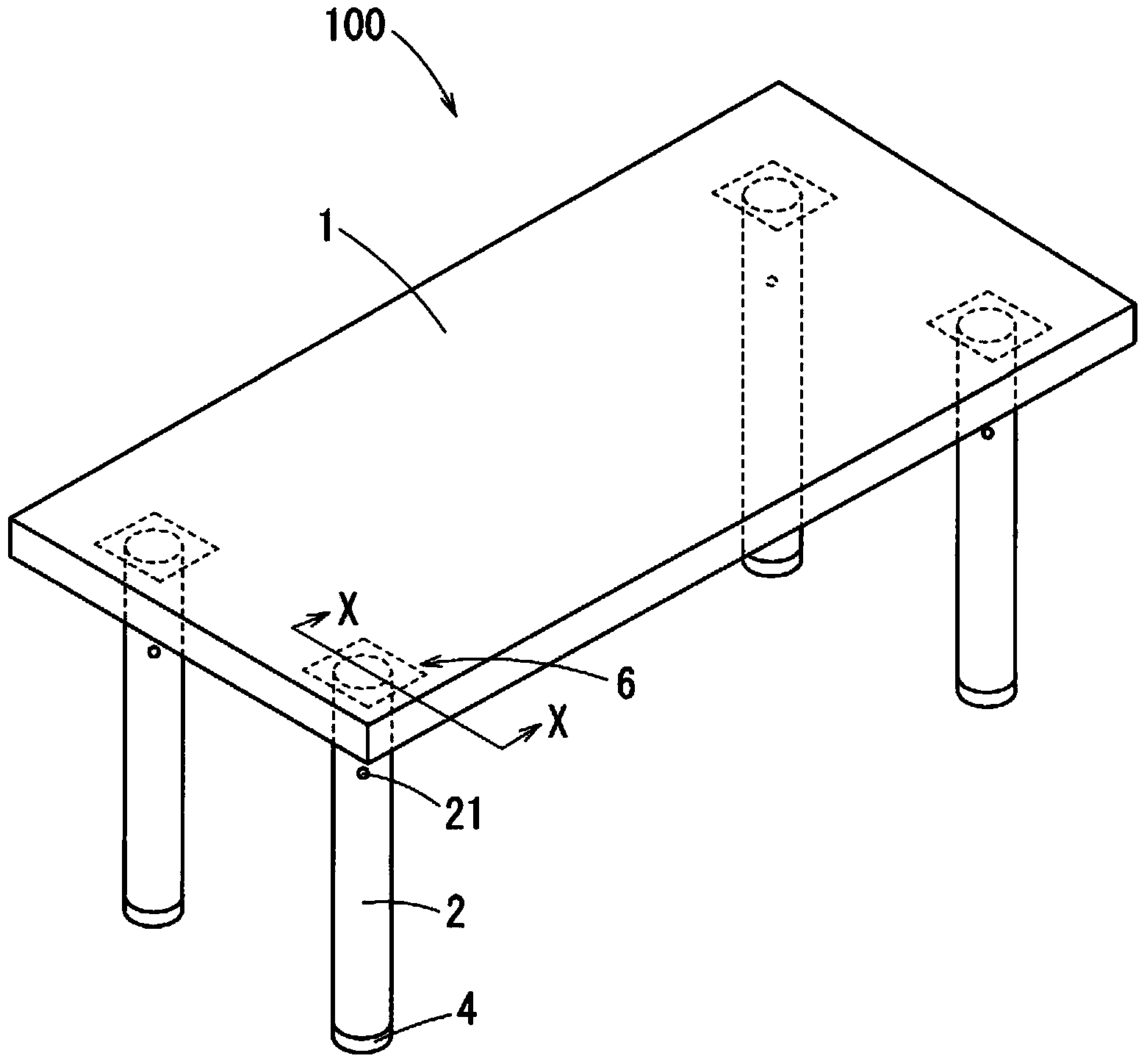

[0091] Below, refer to Figure 8 , 9 Embodiment 3 of the present invention will be described. Figure 8 It is a perspective view of the desk of Example 3, Figure 9 The (a) figure is the inner surface view of the top plate, and the (b) figure in the same figure is the top view of the bottom plate. The main difference between Embodiment 3 and Embodiments 1 and 2 is that the upper end of the pillar 2 uses the fixing metal piece 6 to fix the top plate 1 , on the other hand, the lower end of the pillar 2 uses the fixing metal piece 6 to fix the bottom plate 3 .

[0092] Such as Figure 8 As shown, the table 200 of embodiment 3 uses the same fixing metal piece 6 as in embodiment 1 or embodiment 2 to fix the top plate 1 at the upper end of the pillar 2 and fix the bottom plate 3 at the lower end. In addition, since it can be quickly disassembled and disassembled into three parts of the top plate 1, the pillar 2, and the bottom plate 3 after use, it is convenient for transportat...

Embodiment 4

[0094] Below, refer to Figure 10 Embodiment 4 of the present invention will be described. Figure 10 It is a perspective view of the display rack of Example 4. The main difference between Embodiment 4 and Embodiments 1 to 3 is that the pillar 2 is fixed on the bottom plate 3 by using the fixing metal piece 6 .

[0095] Such as Figure 10 As shown, the display rack 300 of Embodiment 4 has left and right pillars 2, 2, using the same fixing metal parts as in Embodiment 1 and Embodiment 2, the lower ends of the pillars 2, 2 are respectively fixed on the Bottom plate 3. That is, the (first) base 61 of the fixing metal part 6 is fixed on the base plate 3 by screw connection etc., and the lower end of the pillar 2 is fixed on the ( First) on the base 61. In addition, a display rack 300 is formed by erecting shelves 5 in multiple layers on the left and right pillars 2 , 2 through a plurality of cutouts 22 in the axial direction (up and down directions). In the display rack 300 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com