Angle-free stone automatic cutting machine

An arbitrary angle cutting machine technology, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve problems such as no consideration, achieve the effect of stable cutting, accurate detection and control process, and convenient loading and unloading of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

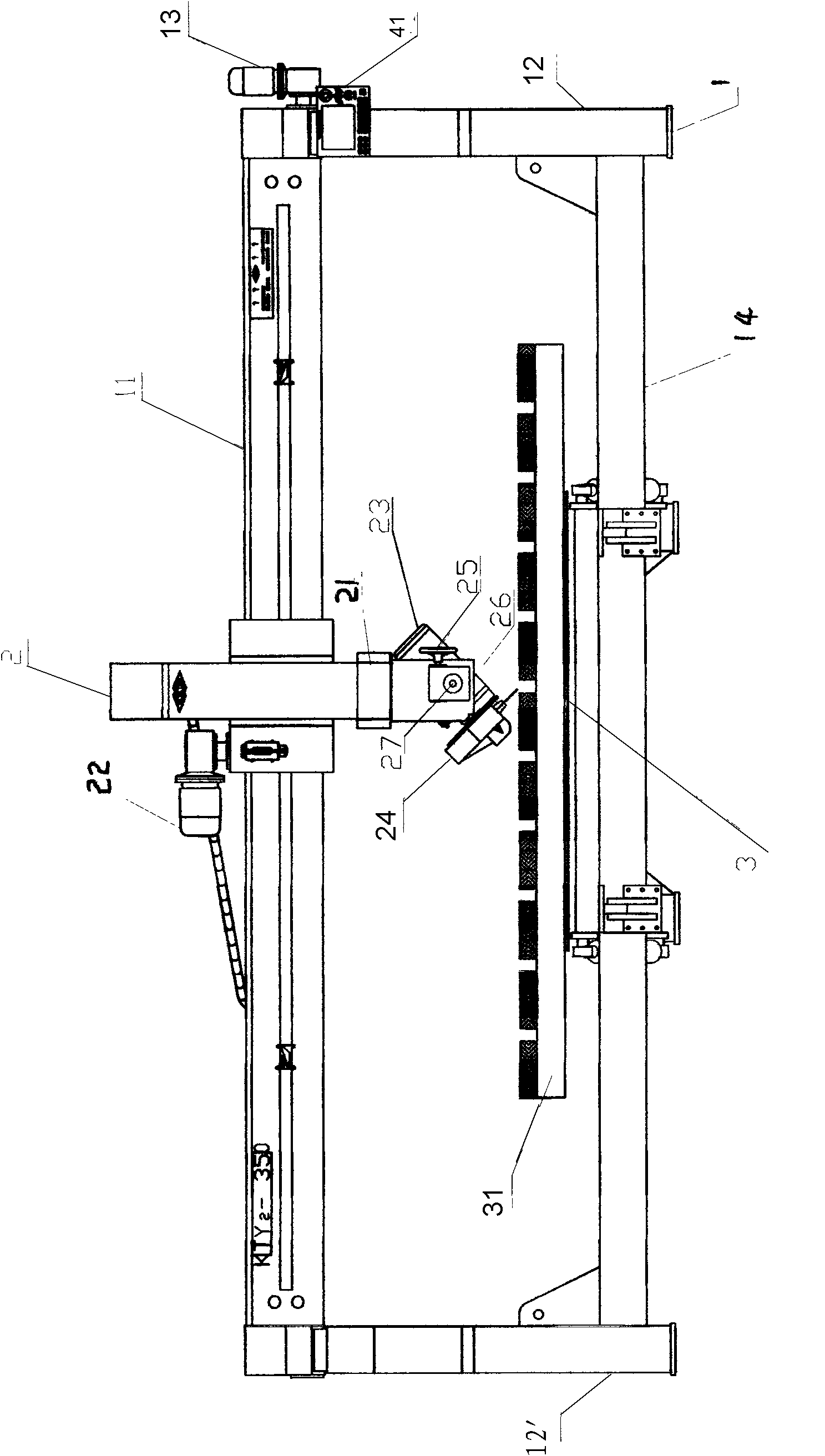

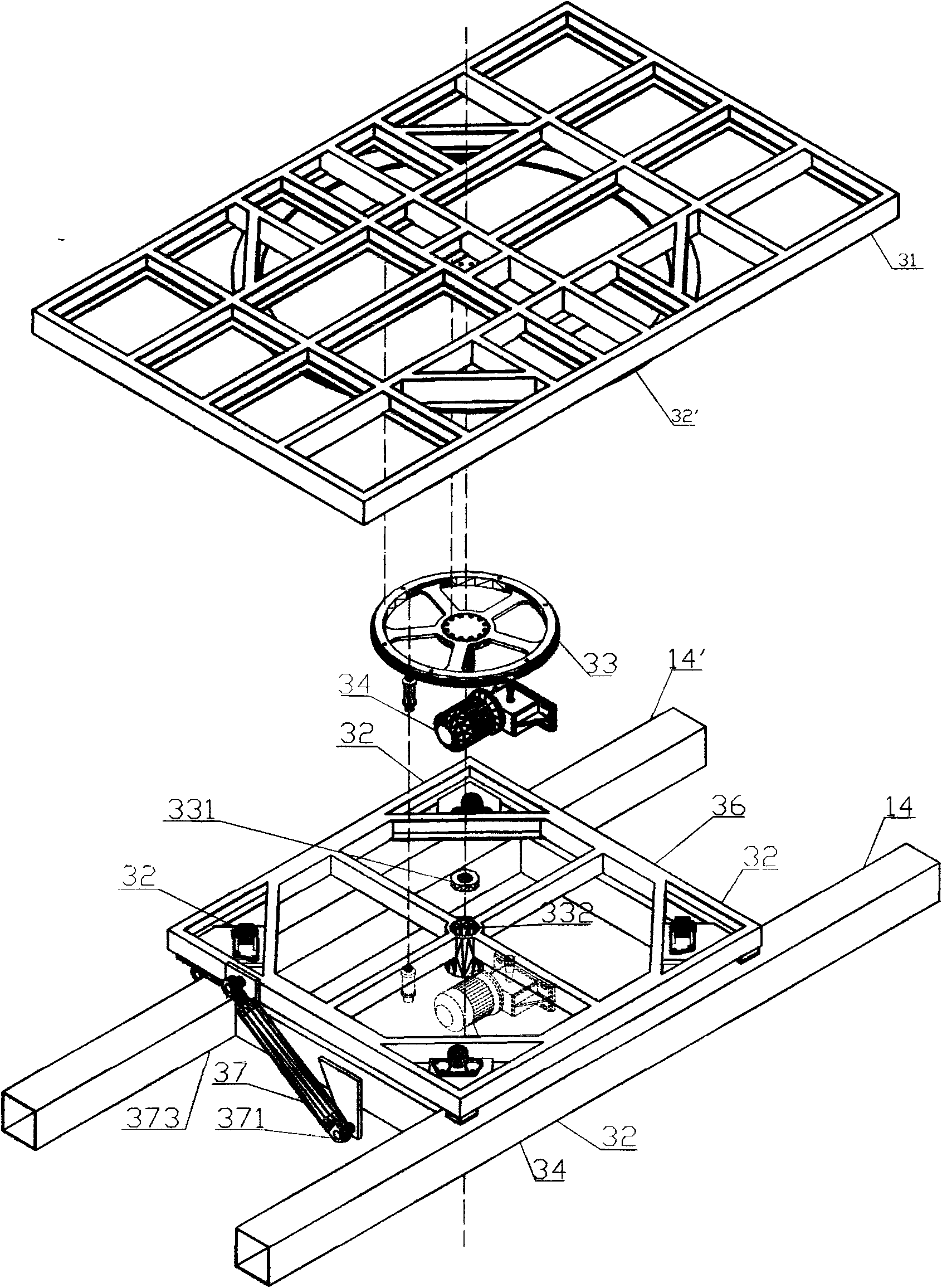

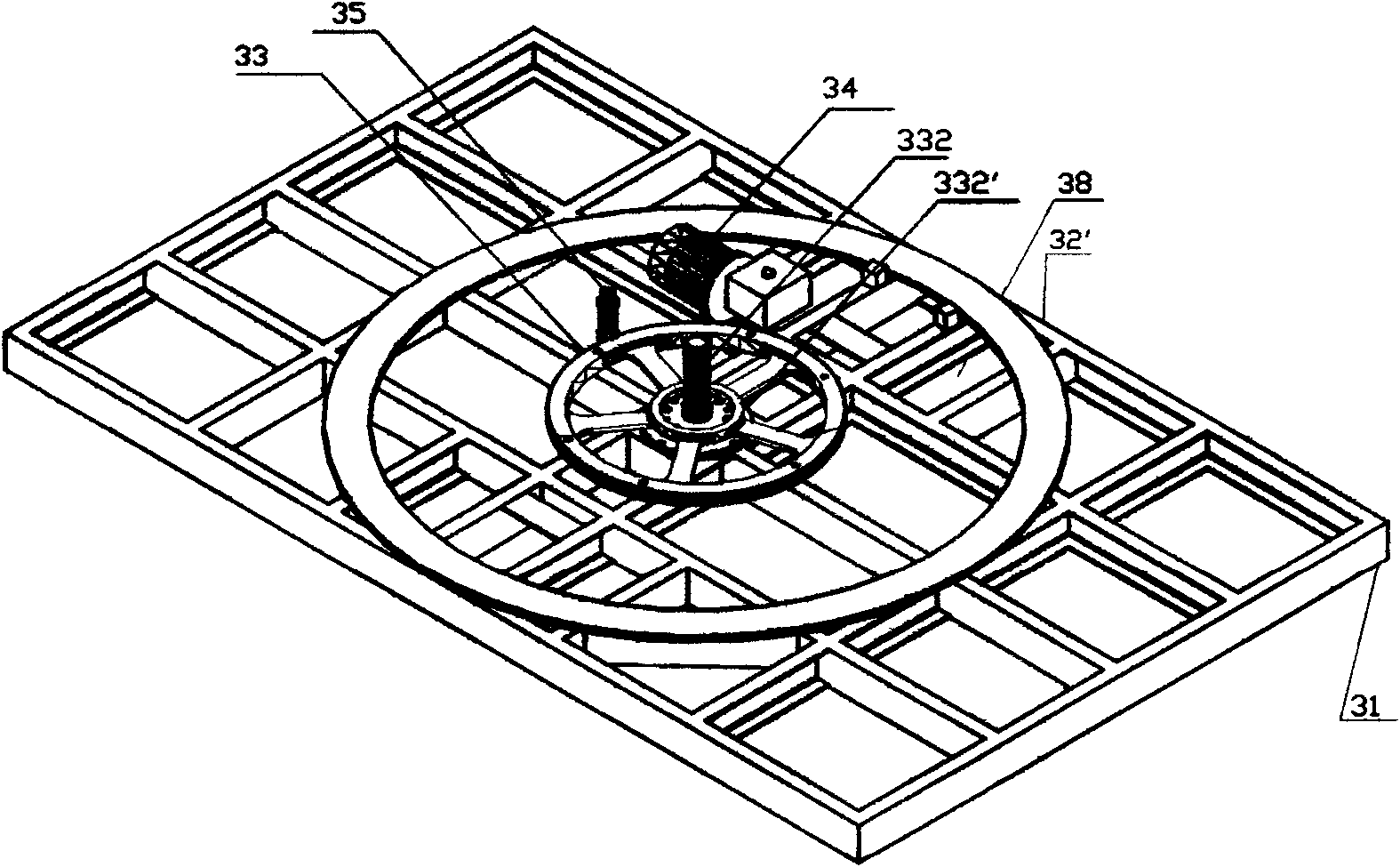

[0030]On a bridge frame 1 that is made up of crossbeam 11, two rail supports 12, 12', two bottom crossbeams 14, 14', and corresponding supporting parts, install cutting head 2 and workbench 3, and cooling water system and automatic control system. The assembled automatic stone cutting machine has dimensions of length, width and height of 5.6m×3m×2.25m. It can be used to process stones with a maximum size of 3.2m×1.95m. On the cutting machine, the two ends of the crossbeam 11 are erected on the guide rail support 12, 12', and two bottom crossbeams 14, 14' are connected under the support, and a workbench 3 is installed on the base of the crossbeam; The driving motor 13 drives the beam 11 through the transmission track, slides in the guide rail supports 12 and 12' on both sides, and moves in parallel in the longitudinal direction. The cutting head 2 installed on the beam 11 is driven by a horizontal drive motor Driven by 22, it moves horizontally in the left and right direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com