Patents

Literature

57results about How to "Reduce molding cycle time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

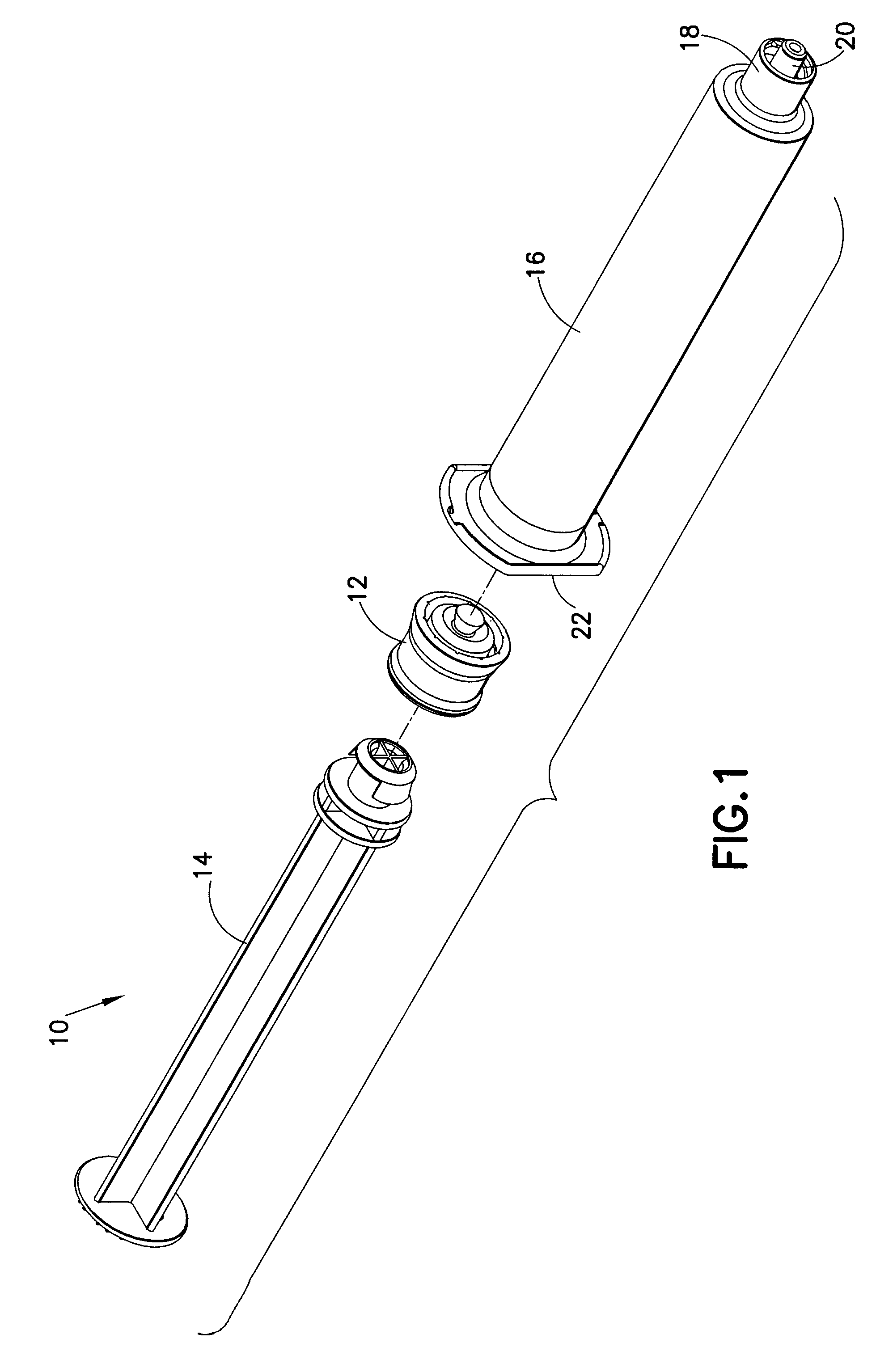

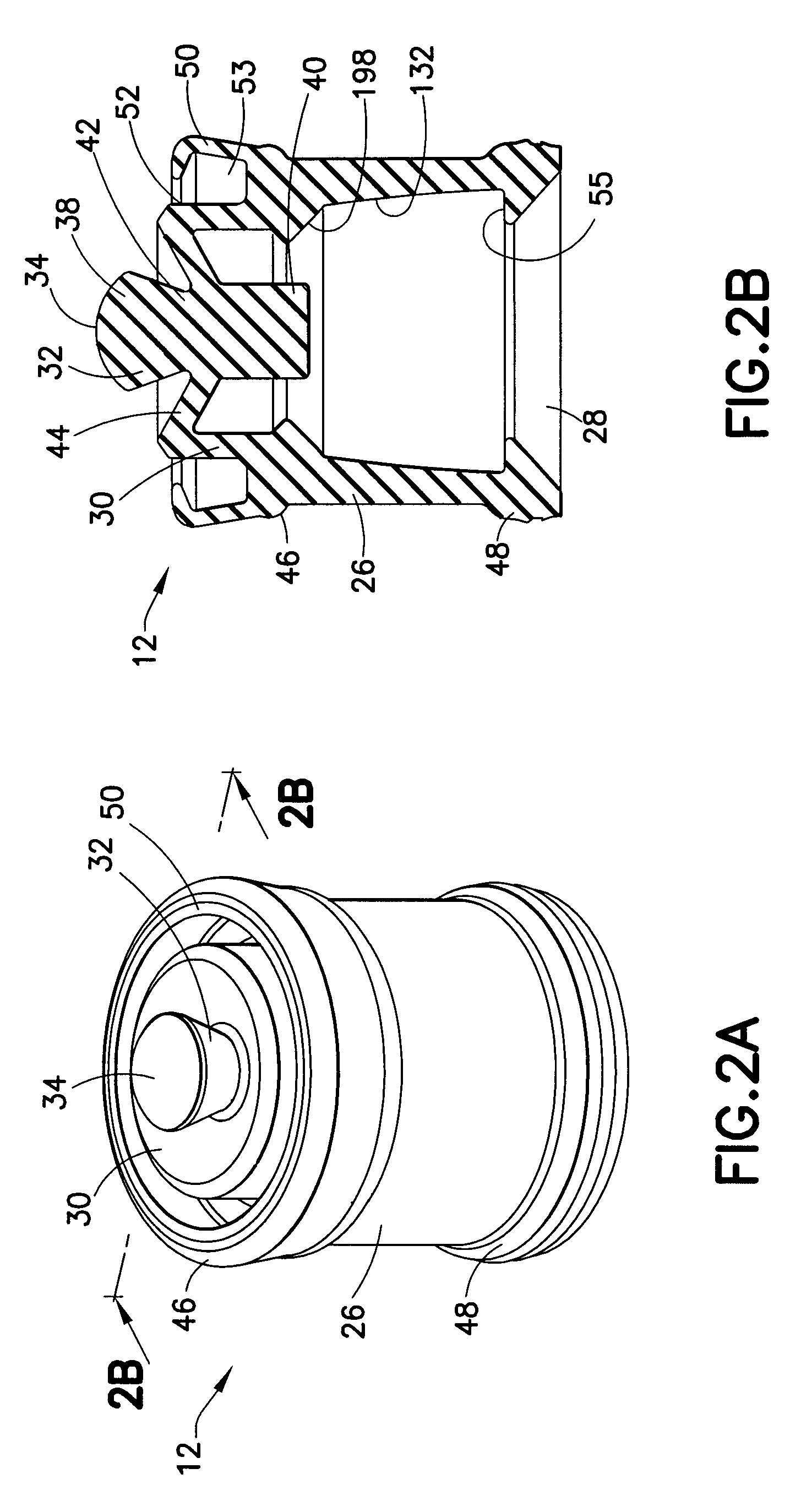

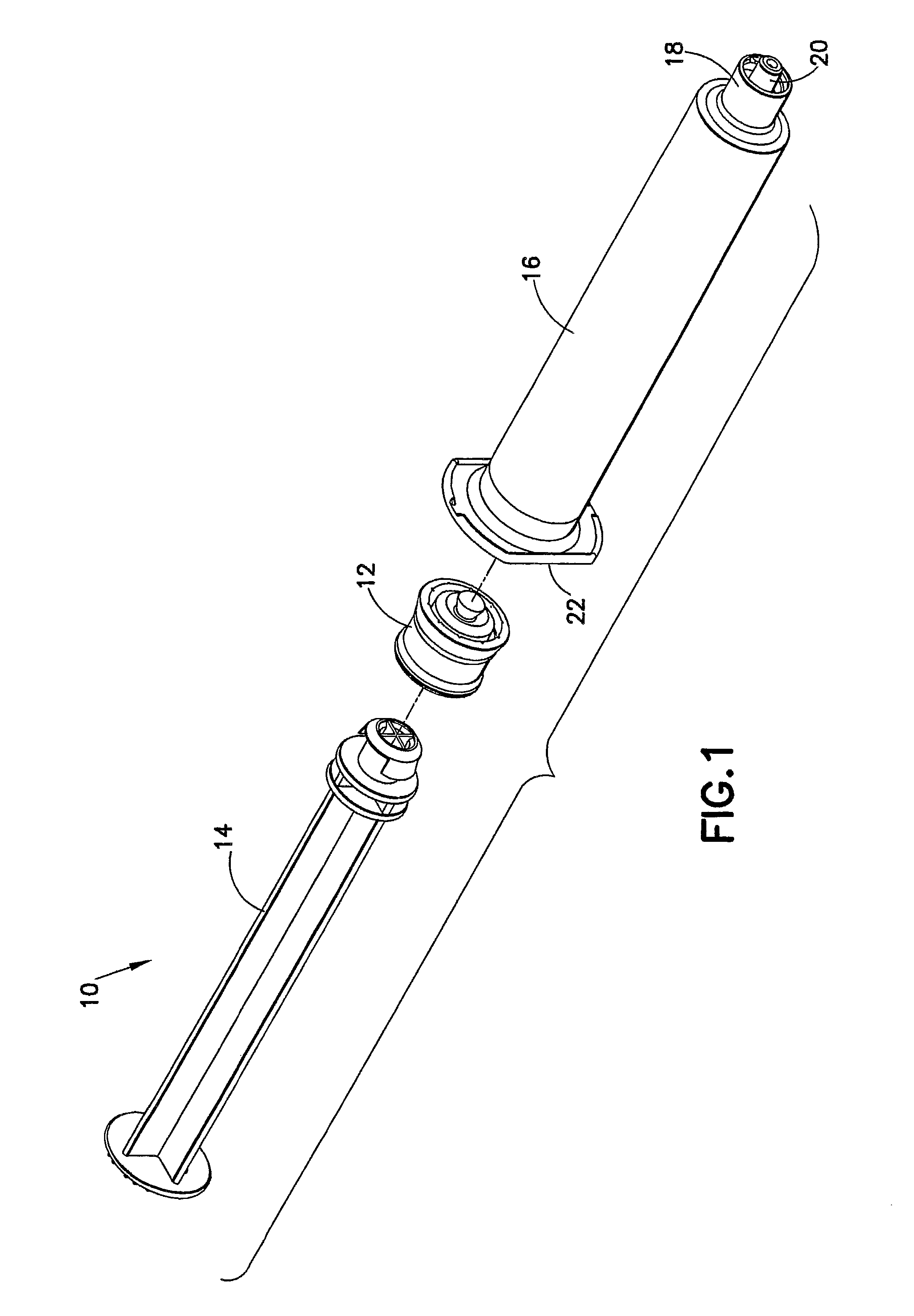

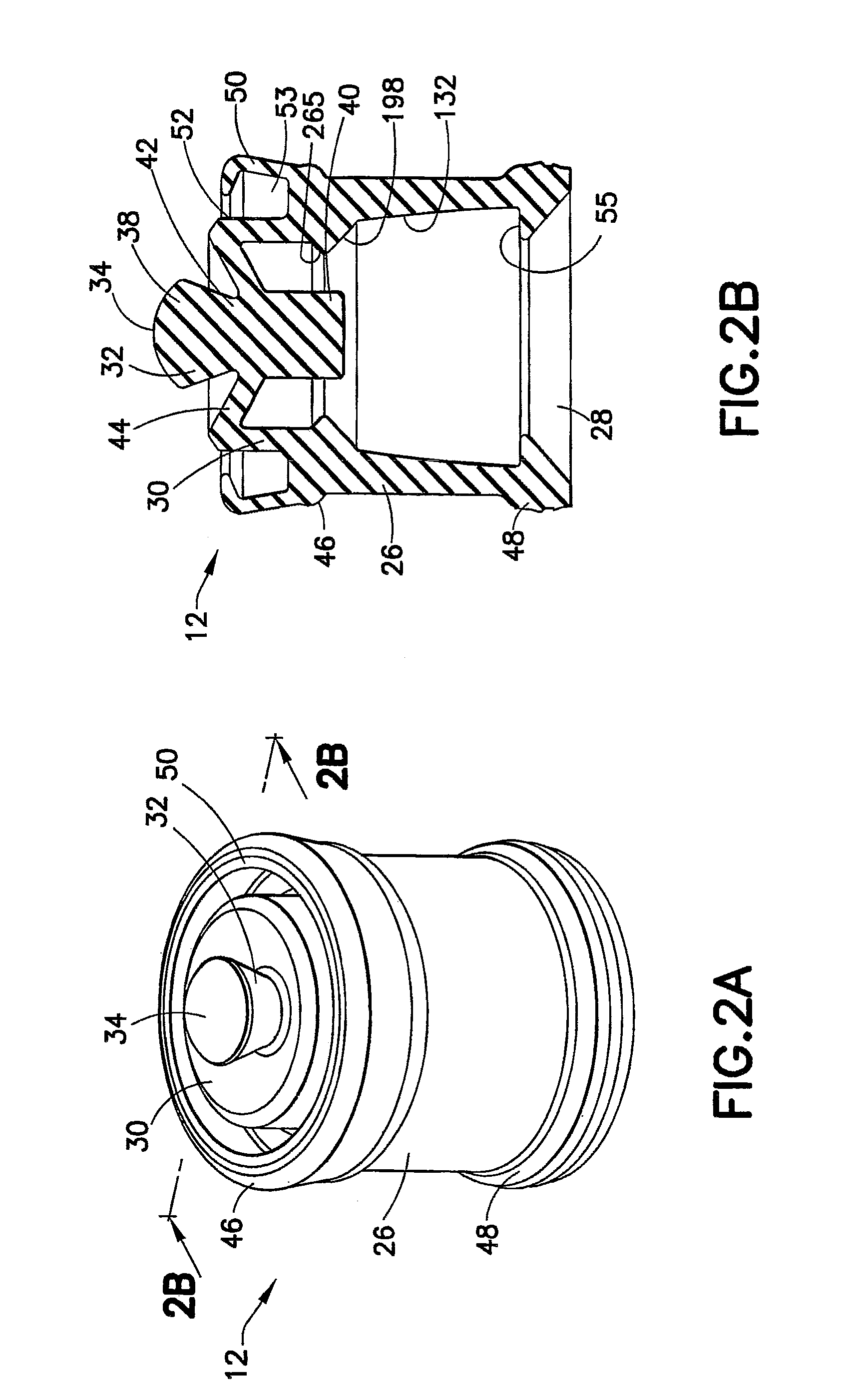

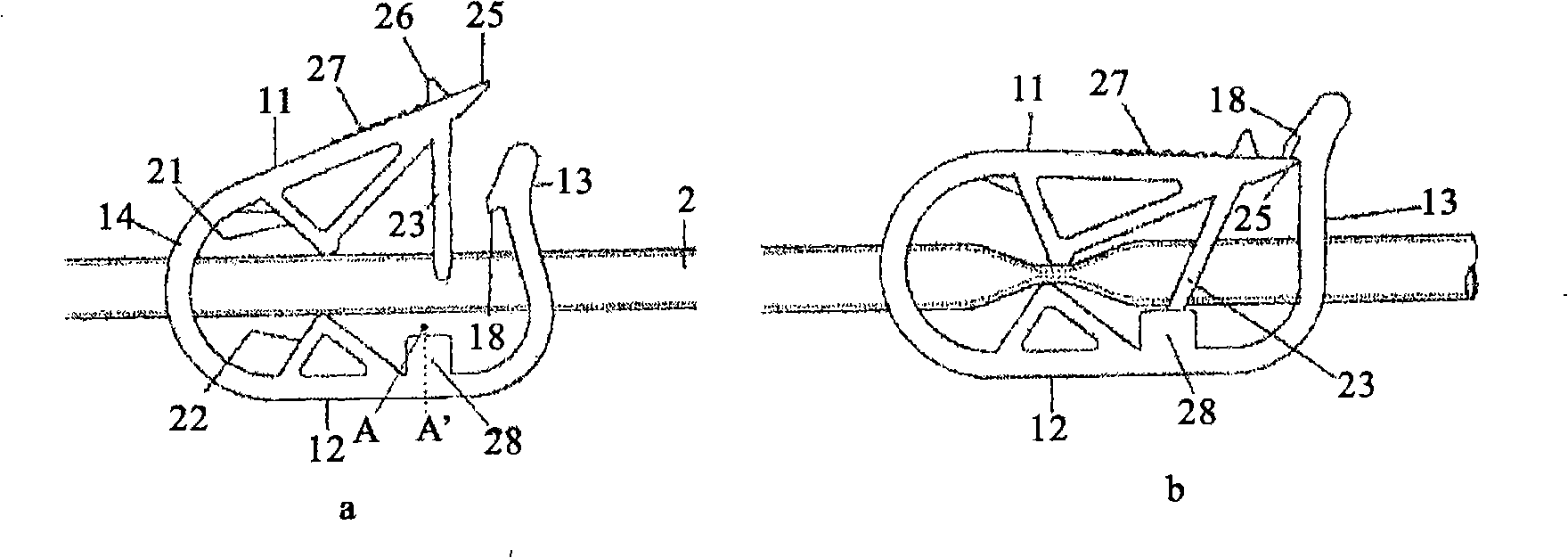

Positive displacement stopper for a pre-filled syringe

ActiveUS20080300550A1Prevent leakageEffectively and consistently reducing and eliminating refluxInfusion syringesIntravenous devicesPrefilled SyringeNose

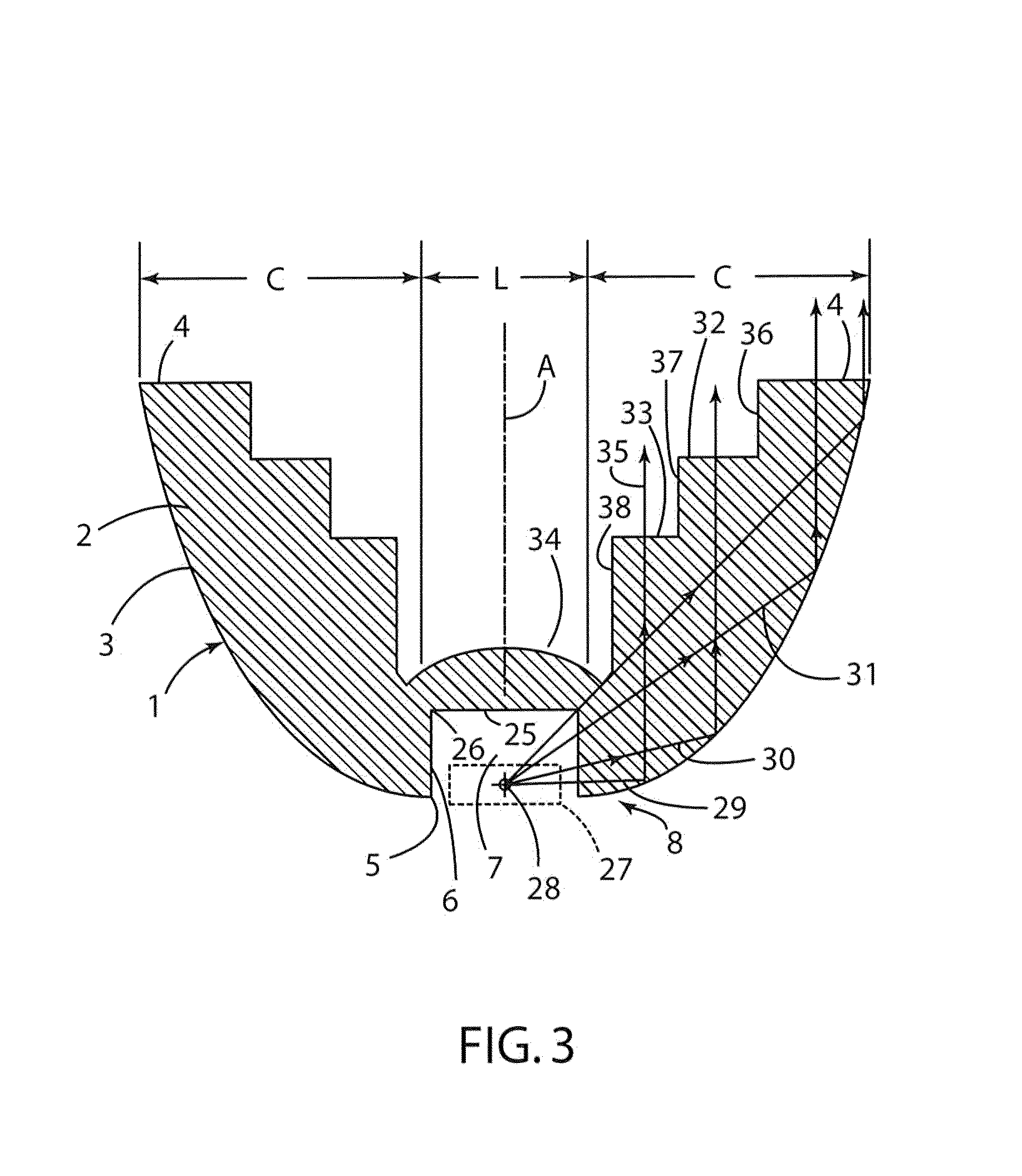

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with said main body adjacent the closed front end. The core member includes a nose portion having a profile adapted to create a positive seal with an outlet opening of such syringe barrel.

Owner:BECTON DICKINSON & CO

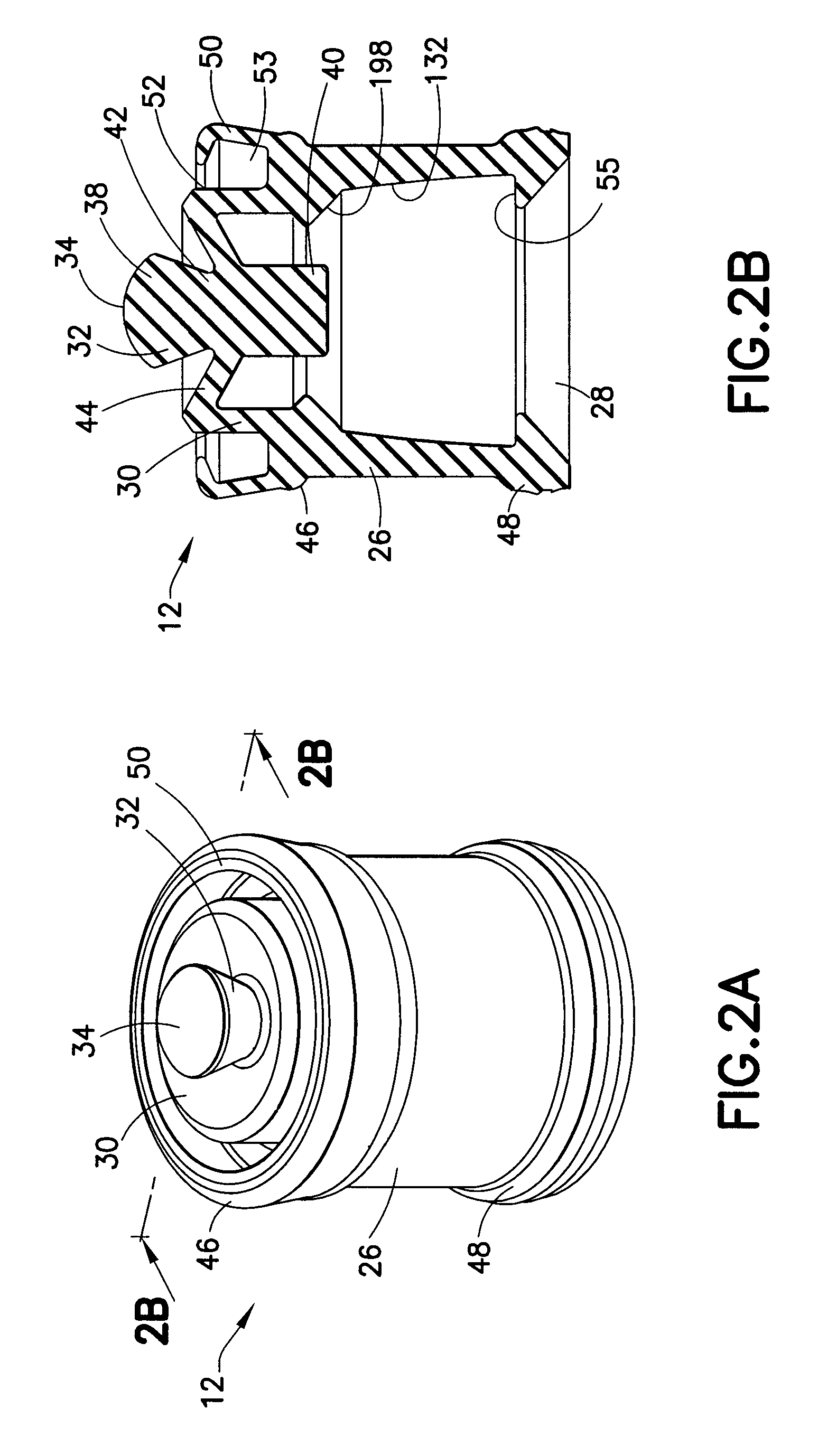

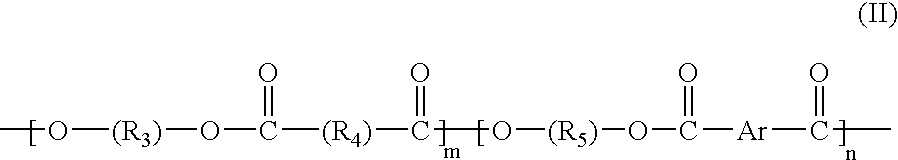

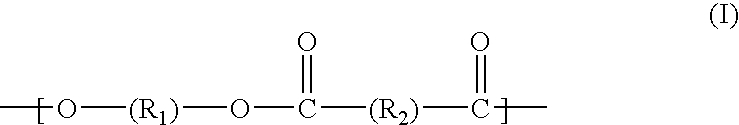

Polylactic acid composition, transparent heat resistant biodegradable molded article made of the same, and method for making the article

InactiveUS20070259195A1Reduce mold cycle timeReduce molding cycle timeSynthetic resin layered productsDomestic containersCopolyesterPolylactic acid

A polylactic acid composition includes polylactic acid, and a biodegradable nucleating polymer in an amount from 0.1 to 10 wt %, based on the total weight of the polylactic acid composition. The biodegradable nucleating polymer is used as a nucleating agent, and is selected from the group of aliphatic polyester other than polylactic acid, aliphatic-aromatic copolyester, and polyethylene glycol.

Owner:FAR EASTERN NEW CENTURY COPRRATION

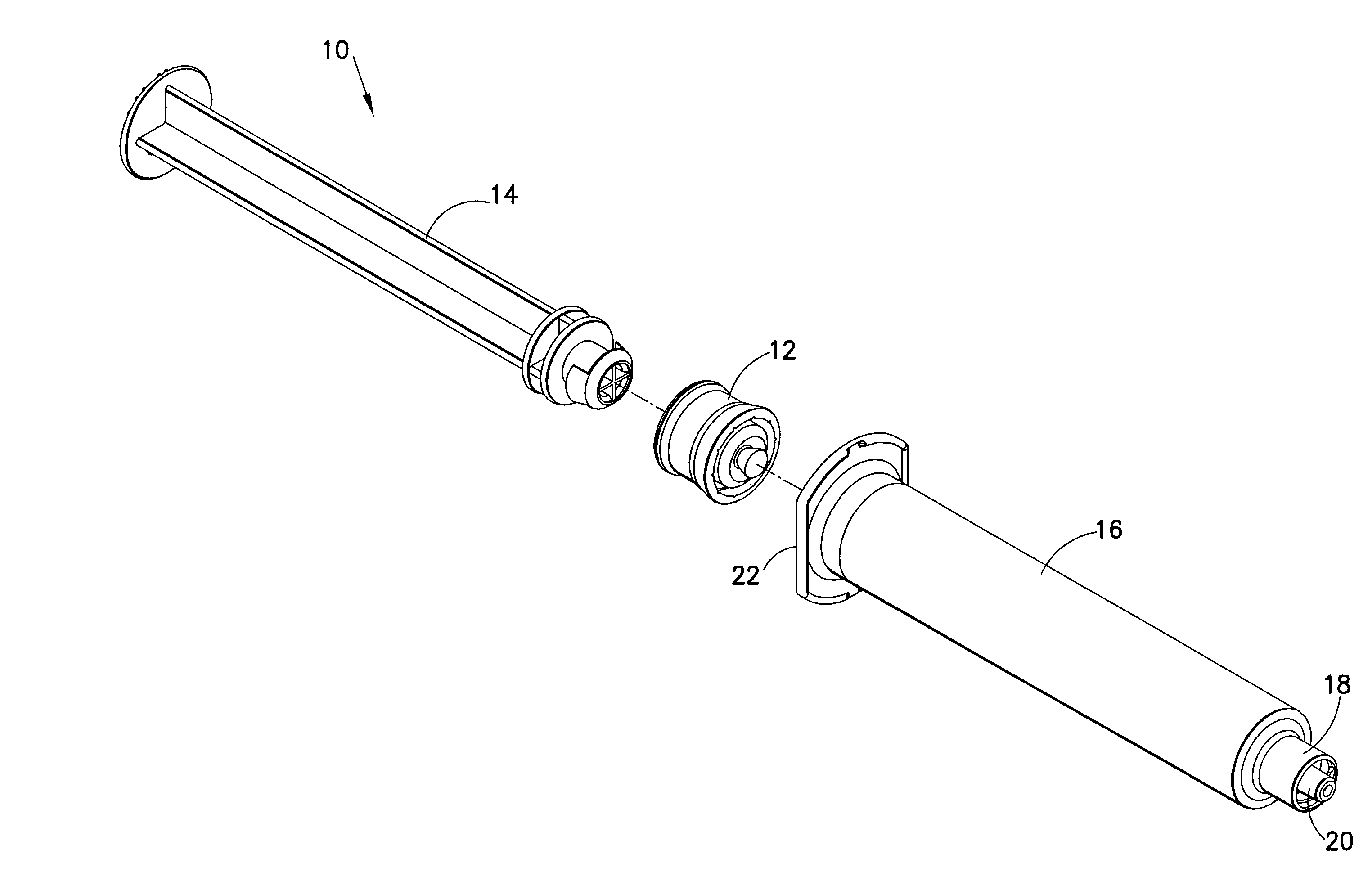

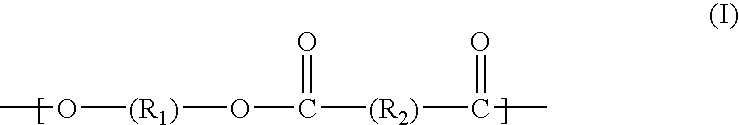

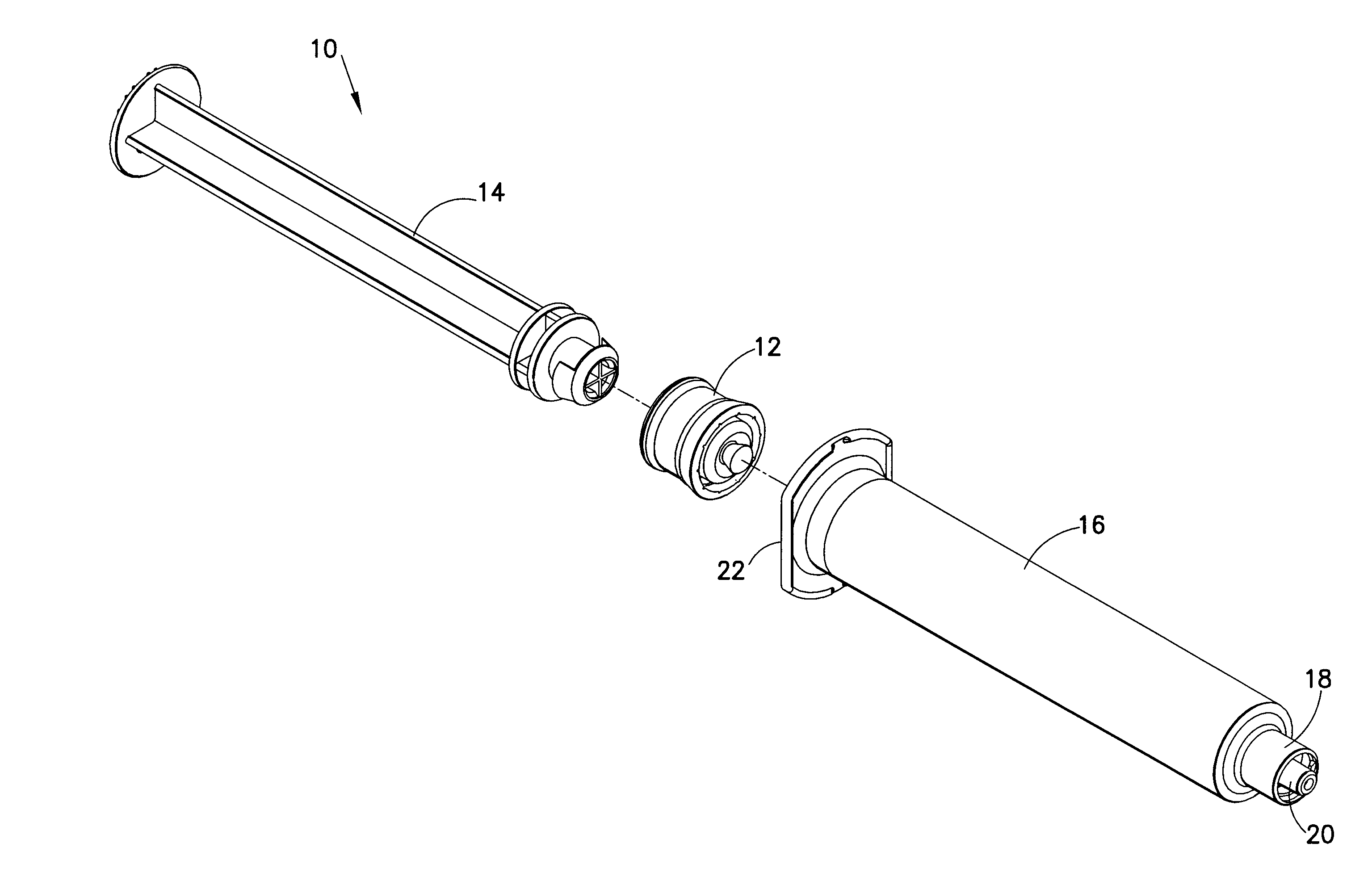

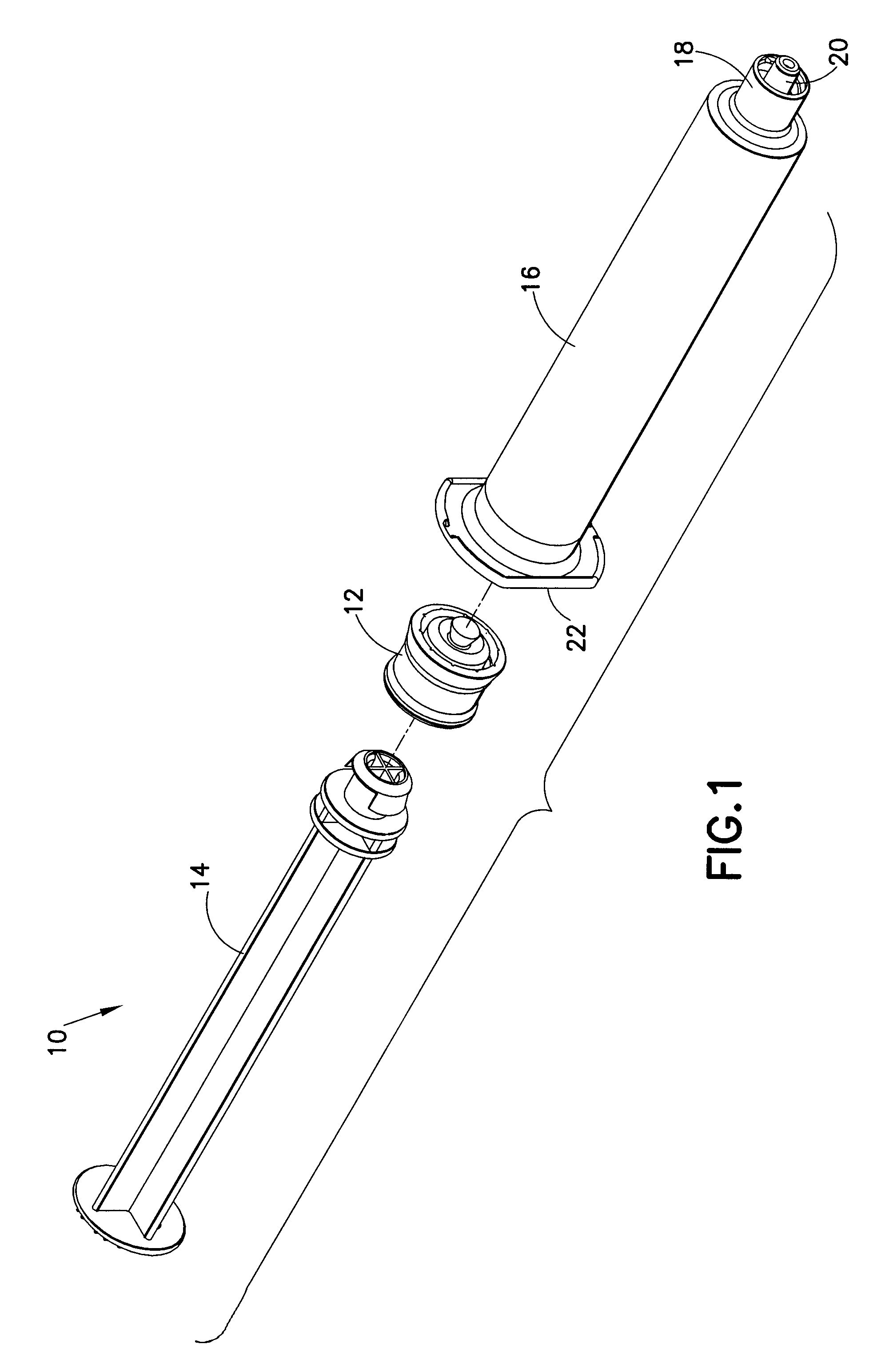

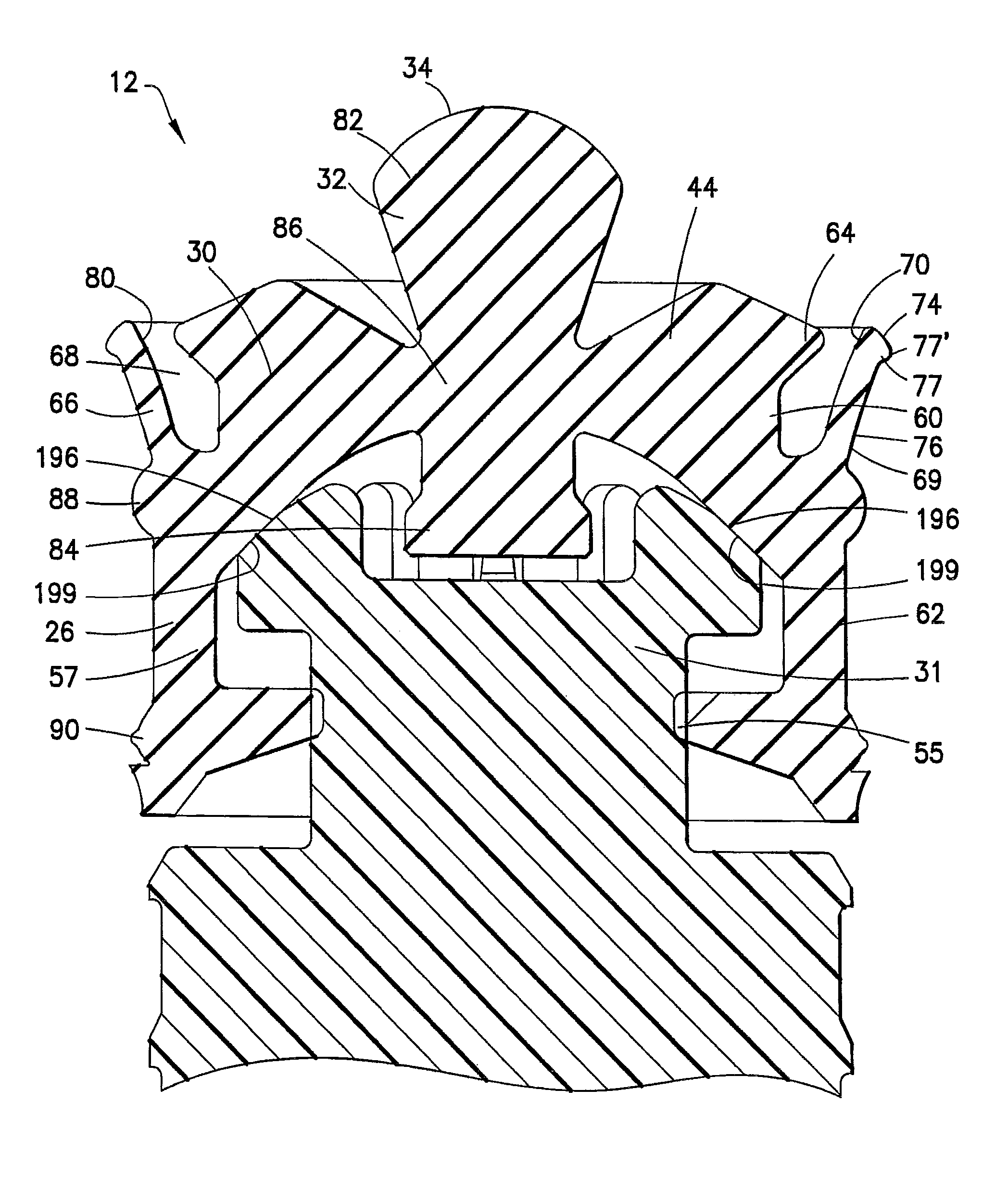

Stopper and plunger rod for a pre-filled syringe

ActiveUS20080300551A1High contact pressurePrevent leakageInfusion syringesIntravenous devicesPrefilled SyringeBiomedical engineering

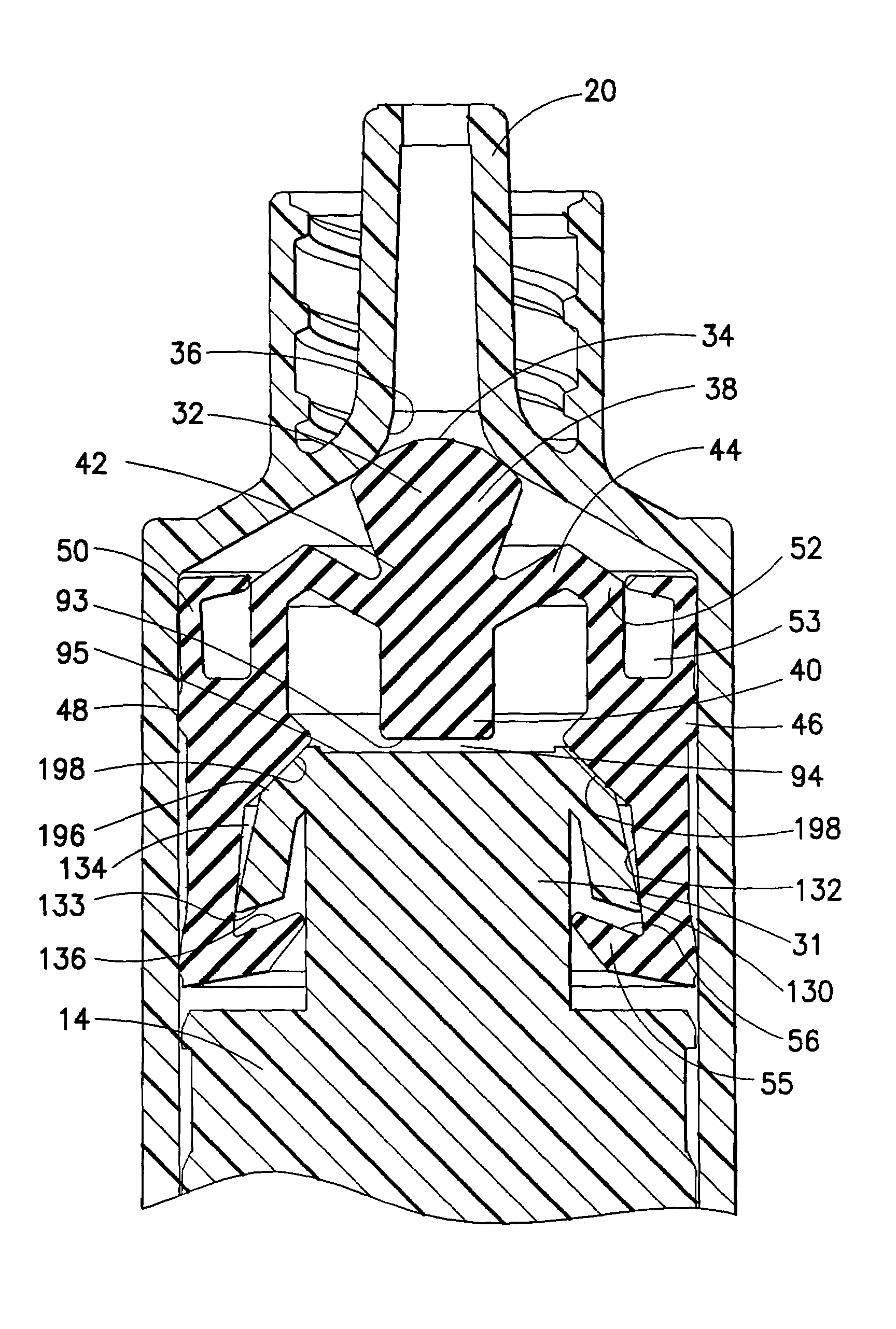

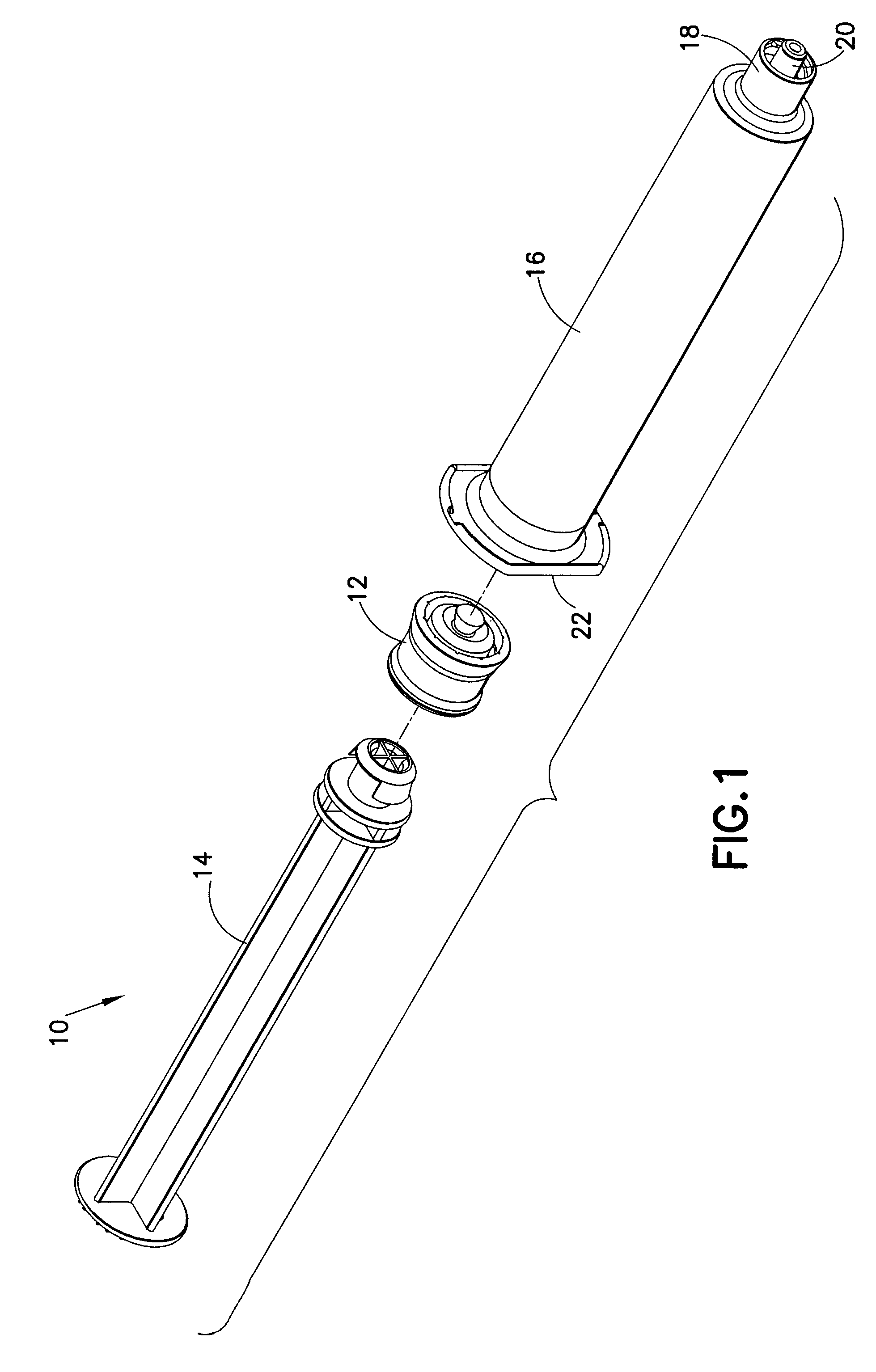

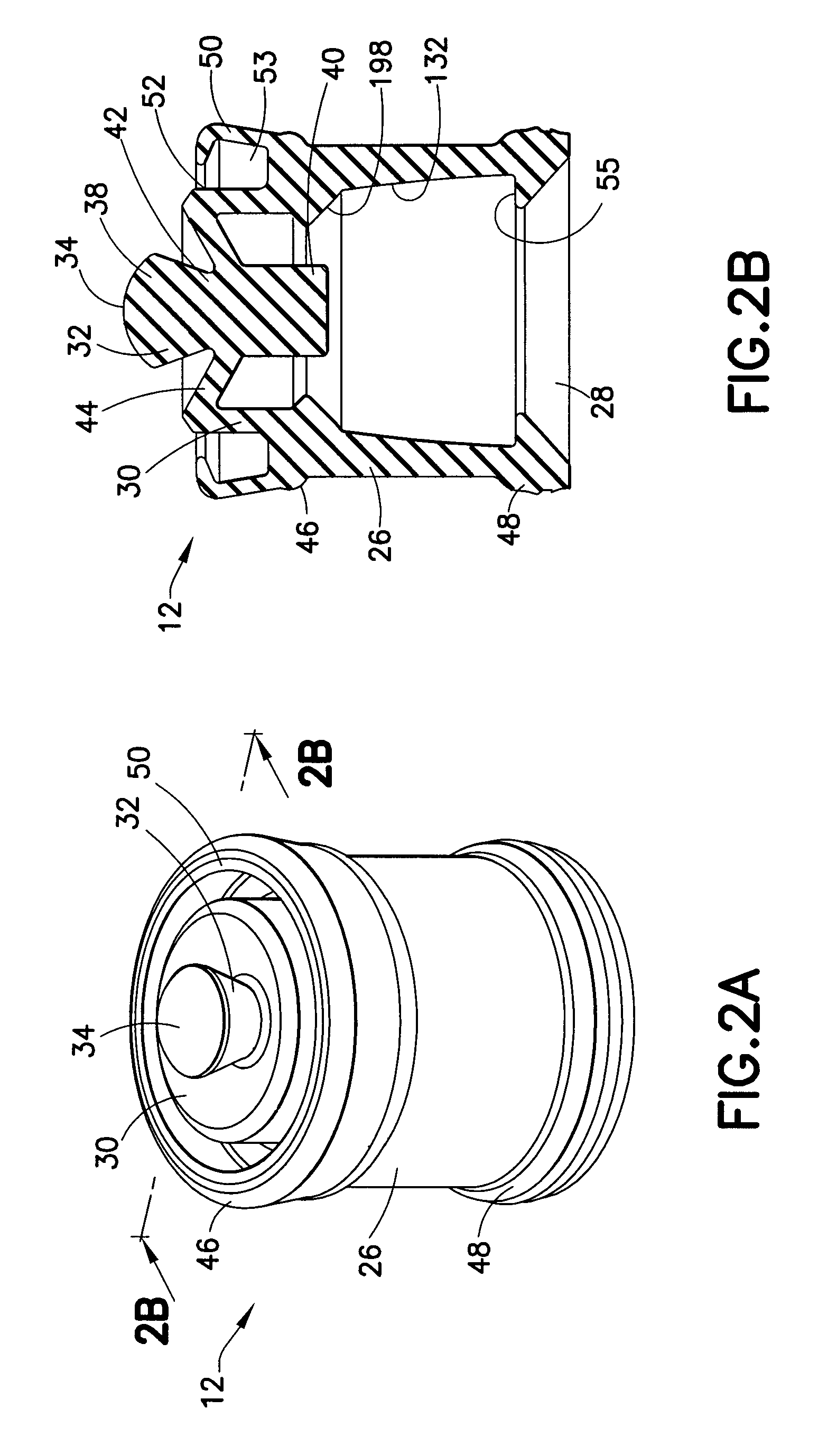

A plunger rod adapted for attachment with a stopper for use with a syringe barrel is disclosed. The plunger rod includes an elongated member having a front end and a back end, the plunger rod extending along a longitudinal axis. The plunger rod includes at least one deflecting arm associated with the front end of the elongated member. The deflecting arm is capable of deflecting radially inward during insertion of the plunger rod into a stopper, and deflecting outward into contact with an inner surface of the stopper after insertion to lock the plunger rod within the stopper.

Owner:BECTON DICKINSON & CO

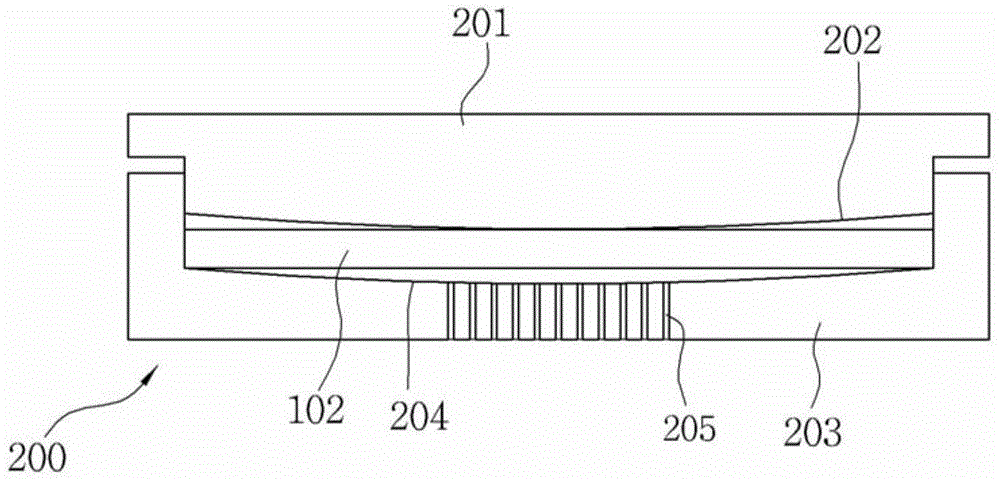

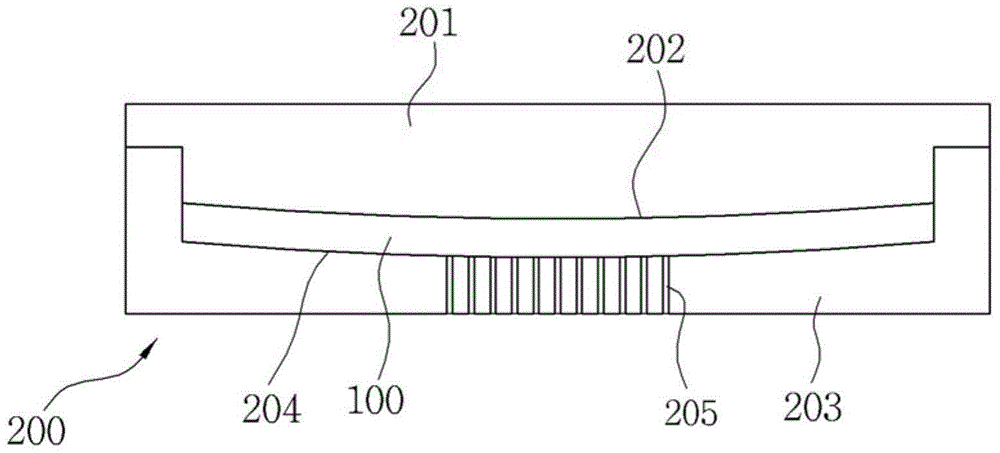

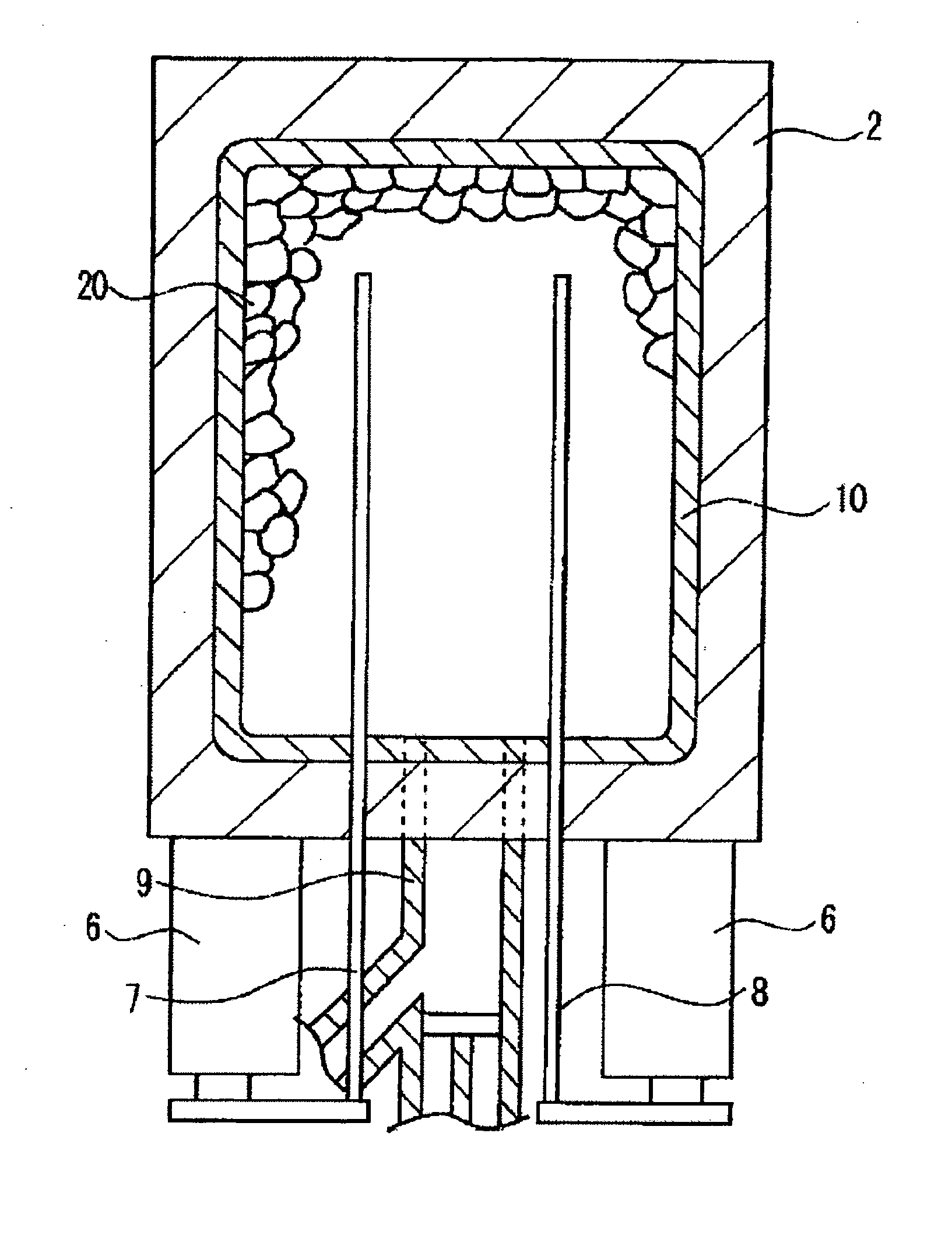

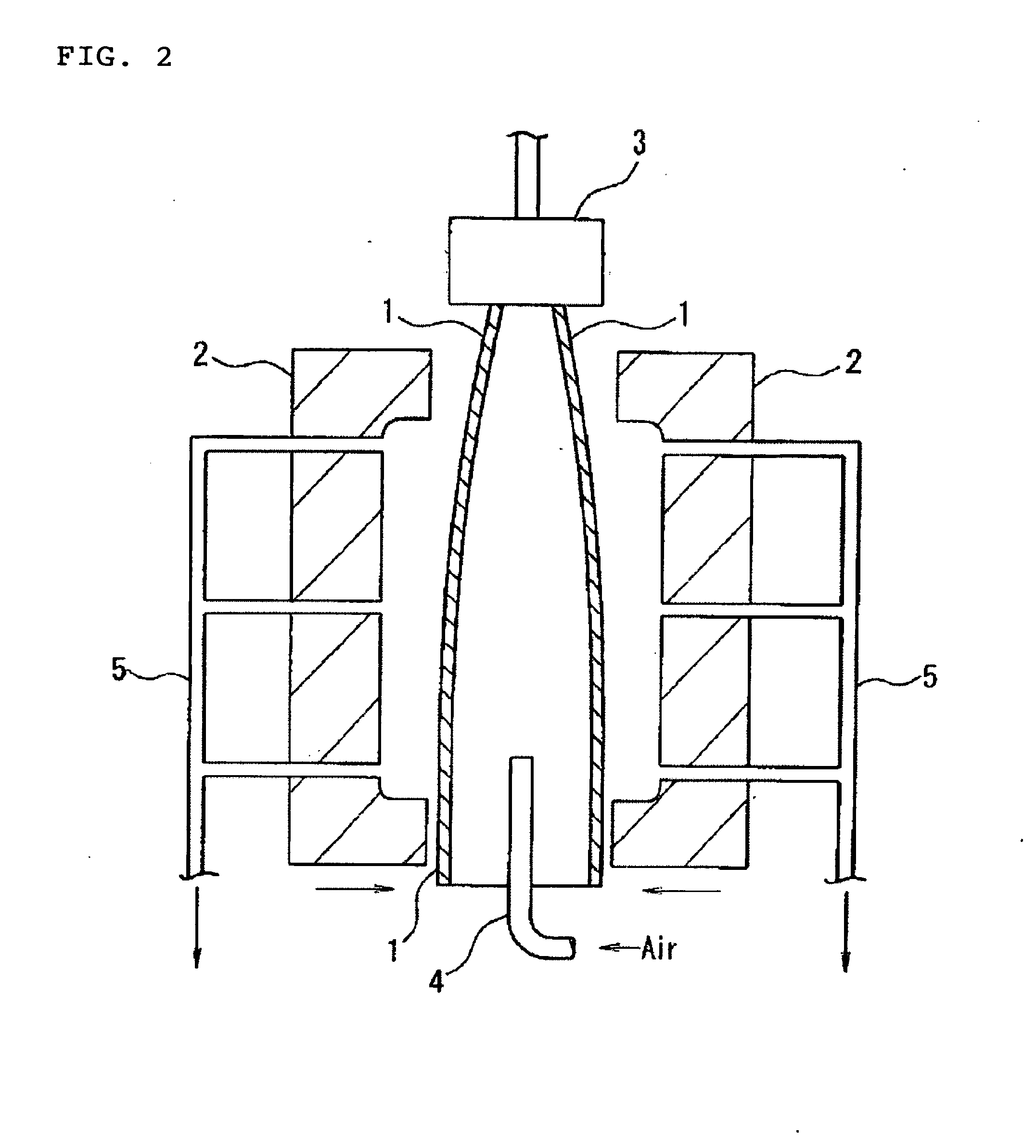

Molding device of glass molding articles

ActiveCN104556644AReduce CooldownReduce molding cycle timeGlass reforming apparatusVacuum pressureMaterials science

The invention relates to a molding device of glass molding articles. More specifically, the molding device of the glass molding articles comprises a pre-heating mechanism contacted with a mold body in a non-load state for pre-heating, a discharge cooling line provided with a cooling water line is formed at an outlet side of a molding chamber, the cooling time in the molding chamber is shortened, the whole molding period time of glass with a curved surface portion is further shortened, a plurality of suction holes into which vacuum pressure flows are formed at the bottom of a lower mold of the mold body, vacuum pressure absorption materials flowing into the suction holes are employed during molding motions, the glass with the excellent curved surface portion is molded, an inlet side of the molding chamber is provided with a vacuum mechanism for vacuum treatment of the mold body, and the molding device can be applied to the molding of infrared glass optical lenses.

Owner:DAEHO TECH CO LTD

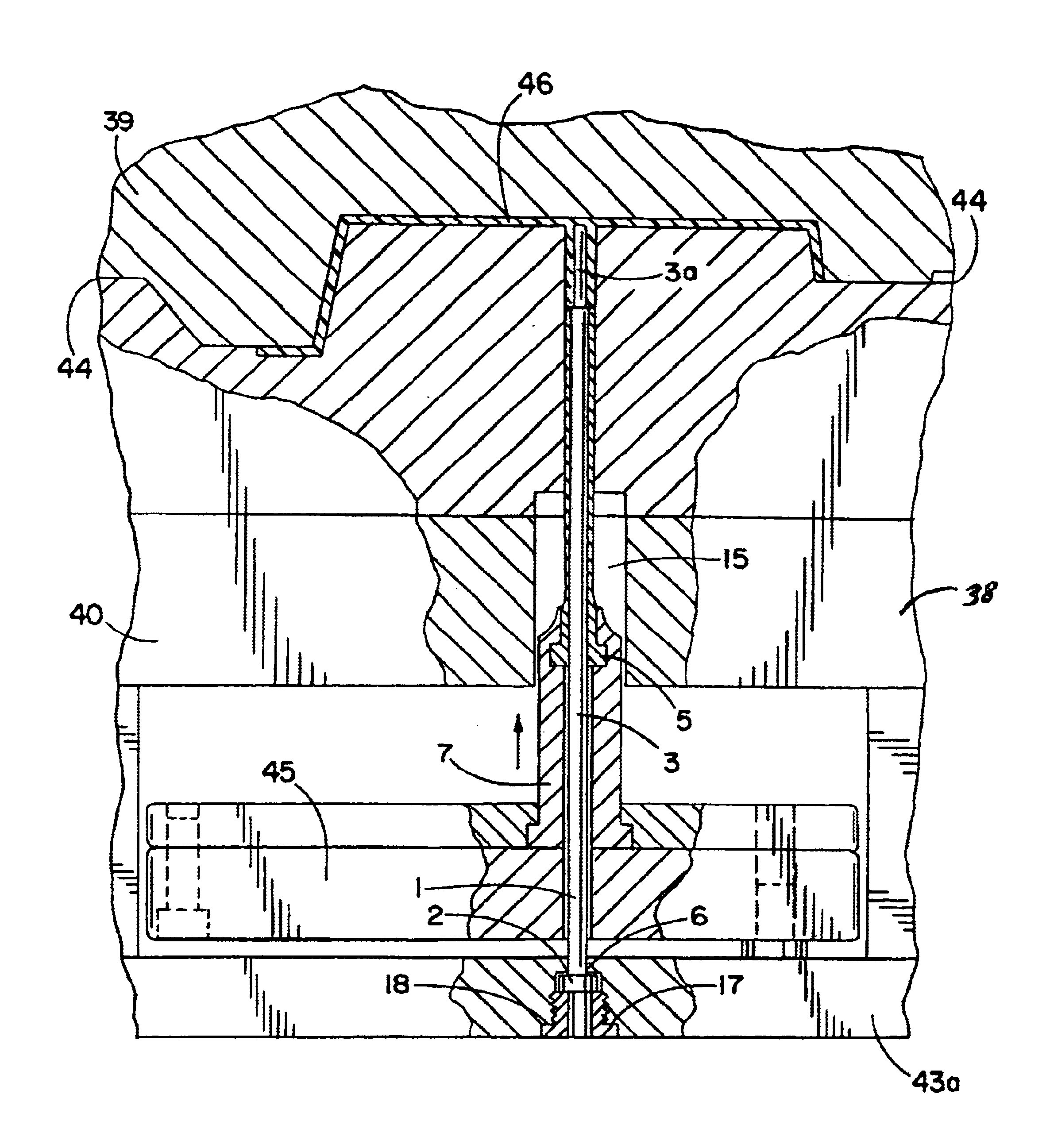

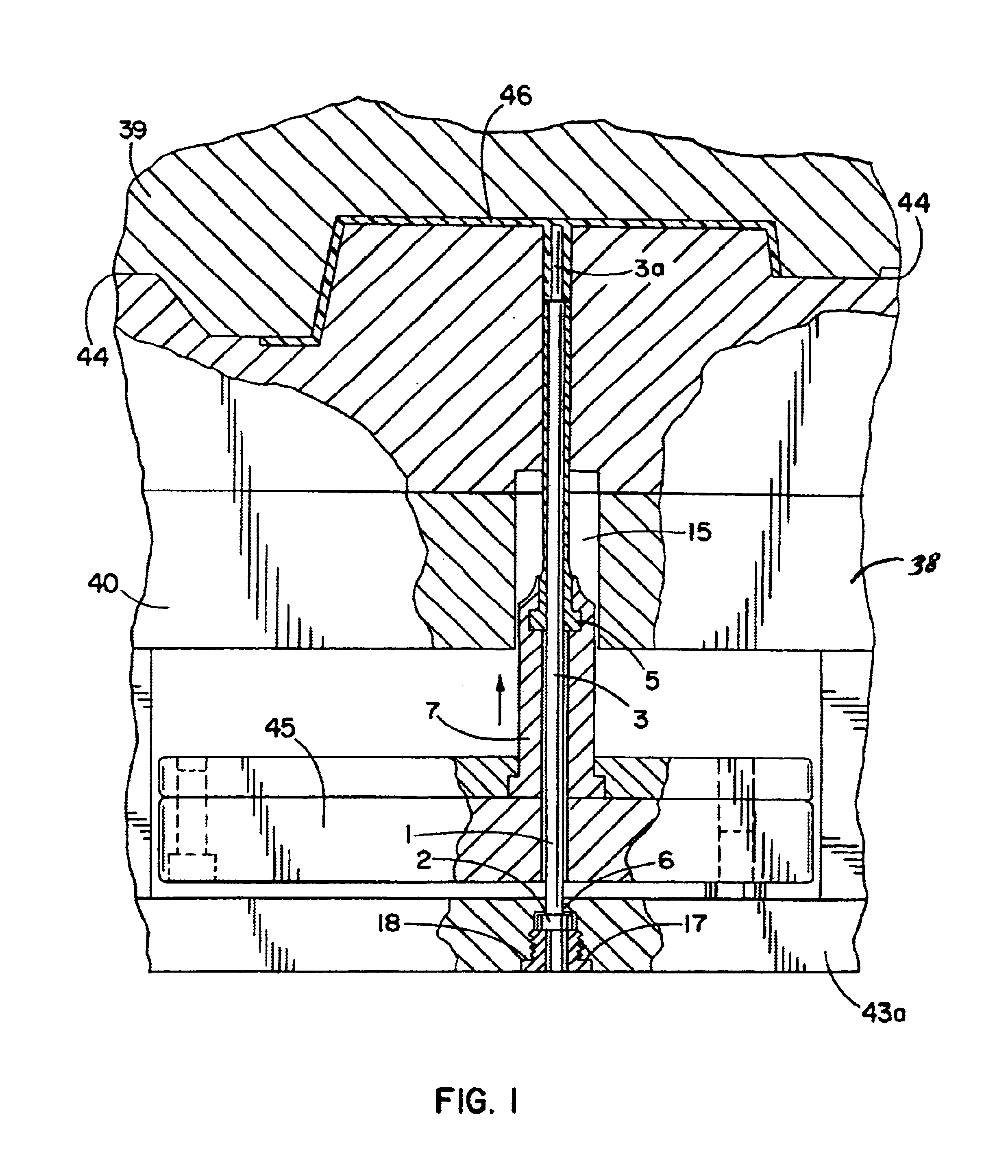

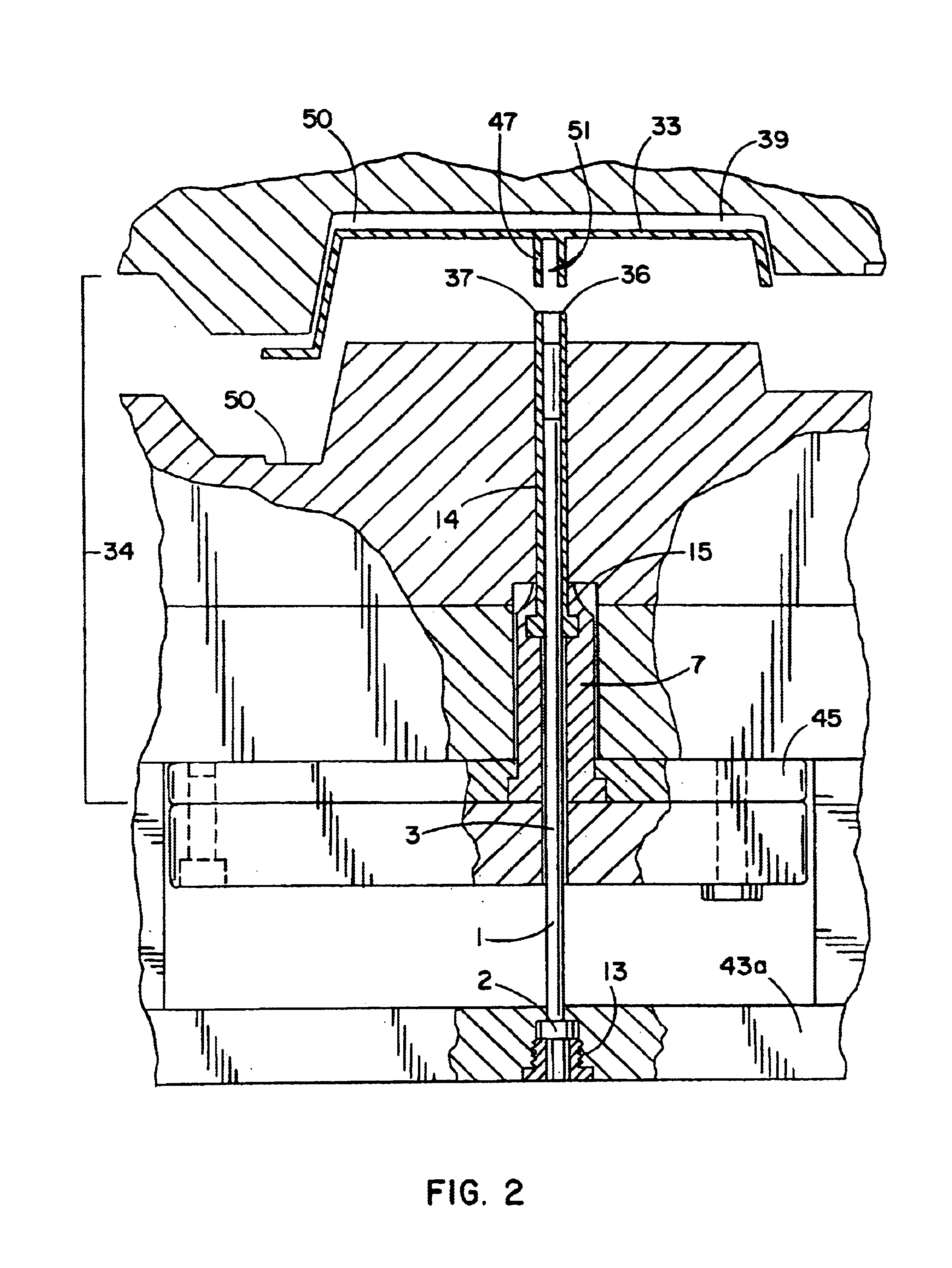

Ejector sleeve for molding a raised aperture in a molded article

The present invention includes an improved ejector sleeve (5) having thinner side-walls than prior sleeves. The sleeves generally include a ring (31) for mounting the sleeve, a central bore (42) for receiving a core pin (1), a tube portion extending from the ring to a tube end portion. The side-walls defining the tube end portion have a thickness of less than forty thousandths, and preferably thirty thousandths of an inch. Preferably, the coated ejector sleeve is provided in which a thin, lubricous coating of nickel, chromium or alloys of chromium or nickel is applied to at least a portion of the sleeve. The coating is applied in thickness of less than 0.0001 inch which improves the wear characteristics of the pins and sleeves as well as allowing the coated pins and sleeves to be stocked and used as nominal thickness parts.

Owner:PROGRESSIVE COMPONENTS INT CORP

Skin-covered propylene resin foamed molded article

ActiveUS20080275148A1Improve relationshipSmall thicknessThin material handlingApparent densityBlow molding

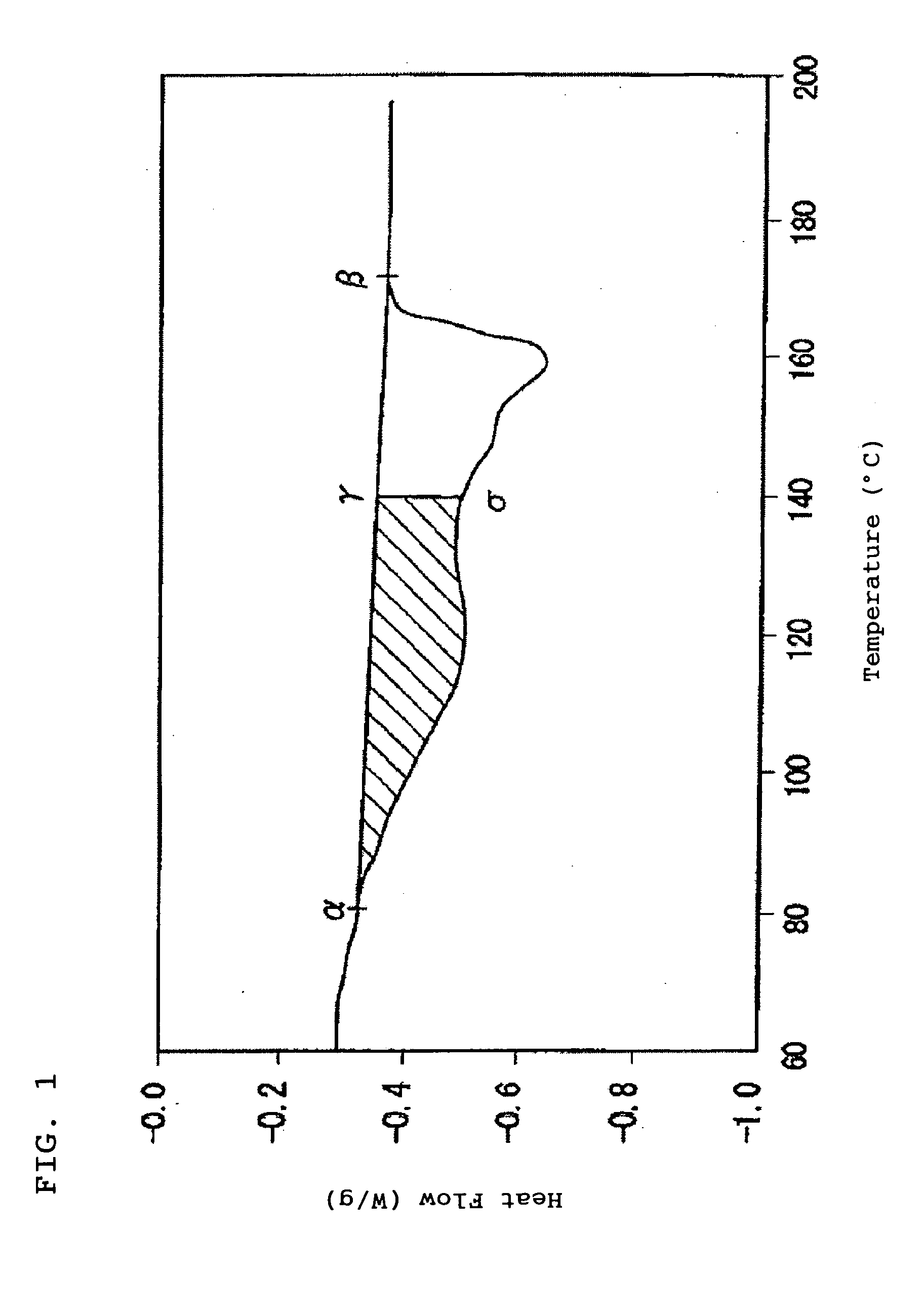

The present invention pertains to a skin-covered foamed molded article of expanded propylene resin beads having excellent lightness in weight, mechanical properties and appearance.The present invention provides a skin-covered foamed molded article of propylene resin expanded beads, with the skin covering substantially the entire surface of the molded article of the expanded beads. The skin, within which the molded article of expanded propylene resin beads is placed, is a propylene resin hollow molded body obtained by blow molding. A base resin of which the skin is formed comprises a propylene resin having a partial heat of fusion in a temperature range between 80 and 140° C. of at least 15 J / g and a ratio of the partial heat of fusion to a total heat of fusion (partial heat of fusion / total heat of fusion) of at least 0.2 as measured by heat flux differential scanning calorimetry. The skin has a thickness in the range of 0.3 to 3.5 mm, and the molded article of expanded propylene resin beads has an apparent density in the range of 0.015 to 0.15 g / cm3. The skin is fuse-bonded to the molded article of expanded beads, and the expanded beads from which the molded article is formed are fuse-bonded to each other.

Owner:JSP CORP

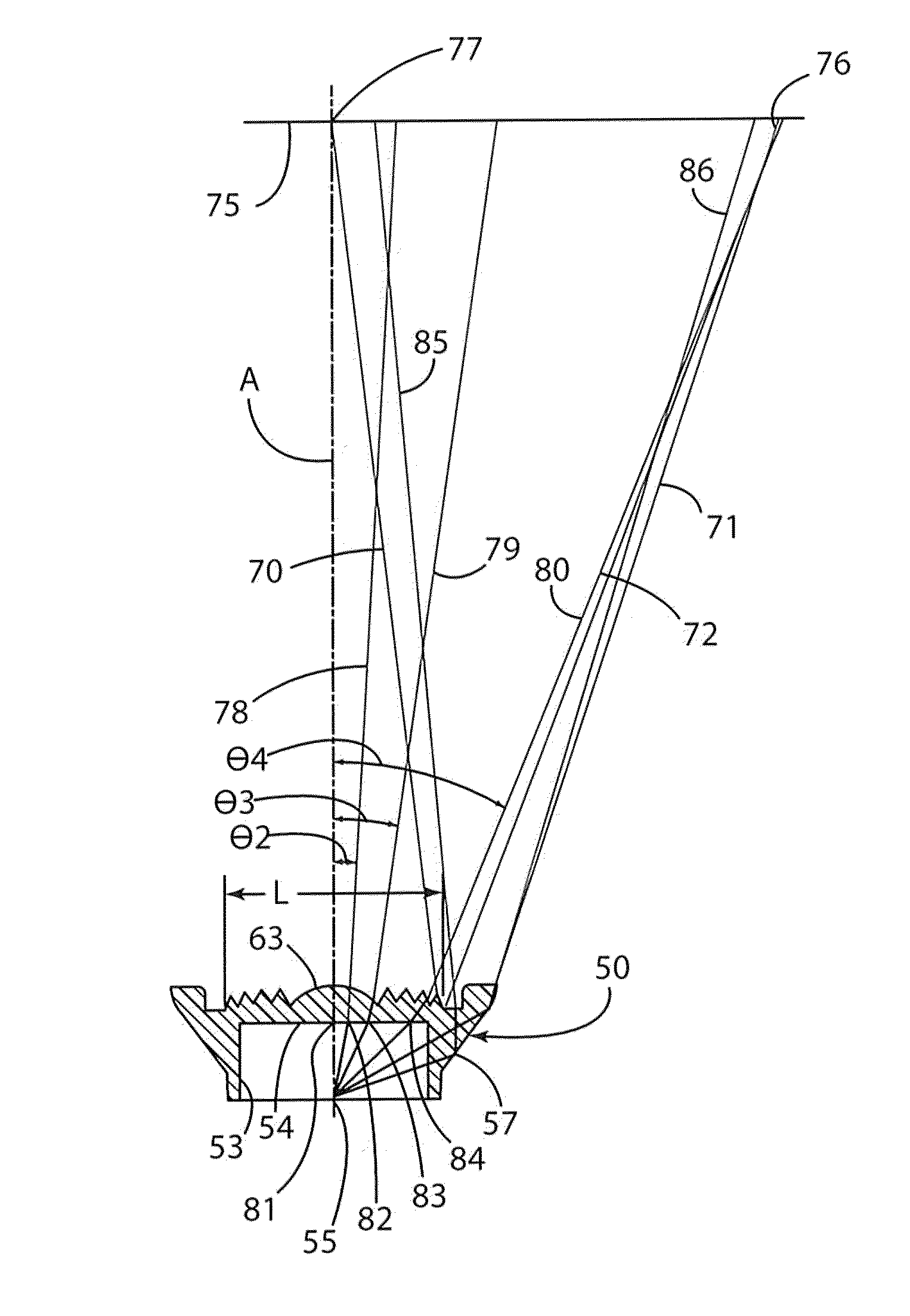

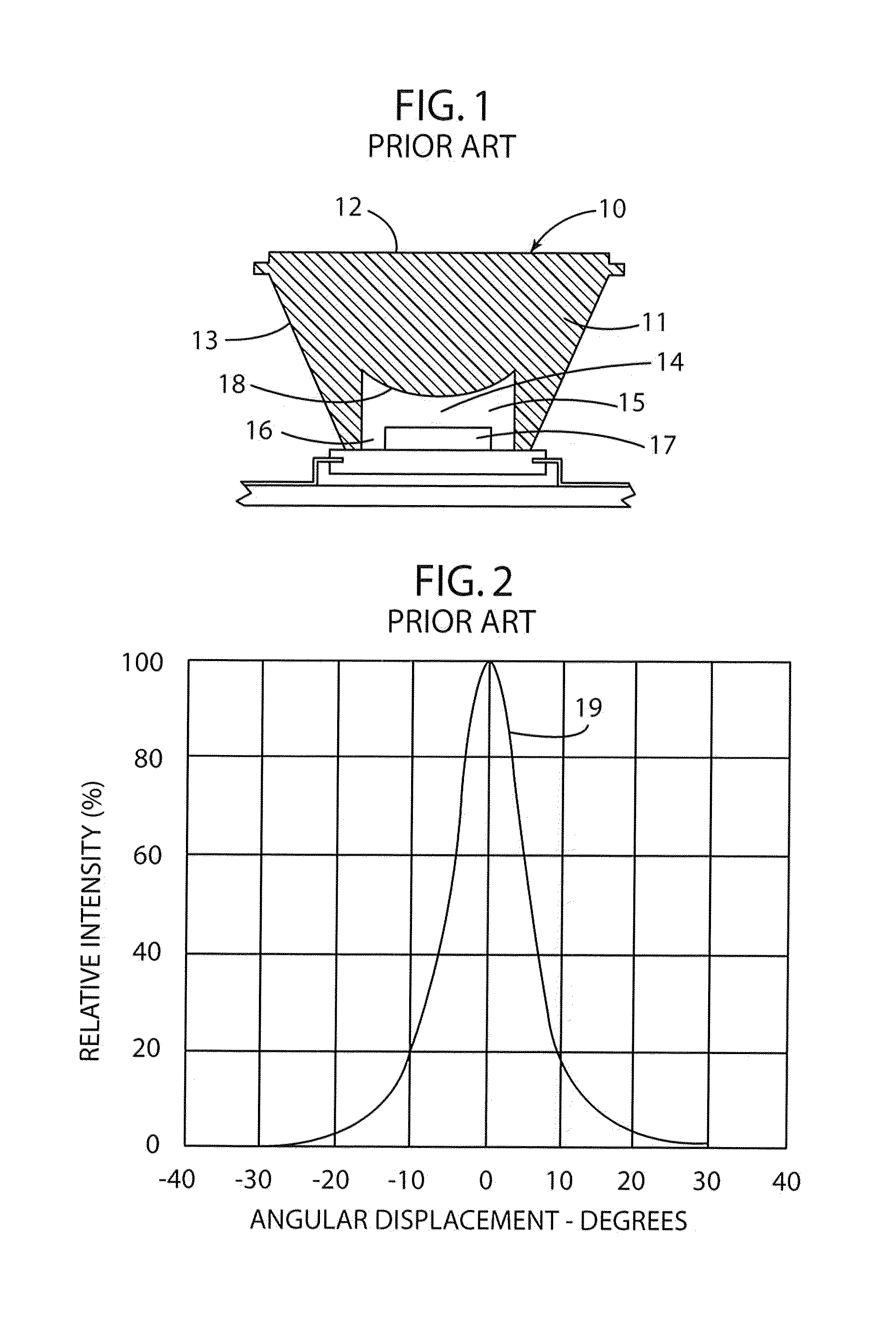

Lens system for LED lights

ActiveUS7837359B2Low costReduce inconveniencePoint-like light sourceSemiconductor devices for light sourcesCamera lensCycle time

An optical device for distributing light produced by a white LED or other light-producing device includes a lens portion that refracts the light to provide a desired light intensity distribution, and a collimating portion that internally reflects light from the white LED. The optical device may be molded from an acrylic polymer material or the like. The reduced thickness of the device facilitates low cycle times and reduces warpage or other distortion that would otherwise be generated during the molding process.

Owner:INNOTEC CORP

Positive displacement stopper for a pre-filled syringe

ActiveUS8475415B2Prevent leakageEffectively and consistently reducing and eliminating refluxInfusion syringesIntravenous devicesNosePrefilled Syringe

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with said main body adjacent the closed front end. The core member includes a nose portion having a profile adapted to create a positive seal with an outlet opening of such syringe barrel.

Owner:BECTON DICKINSON & CO

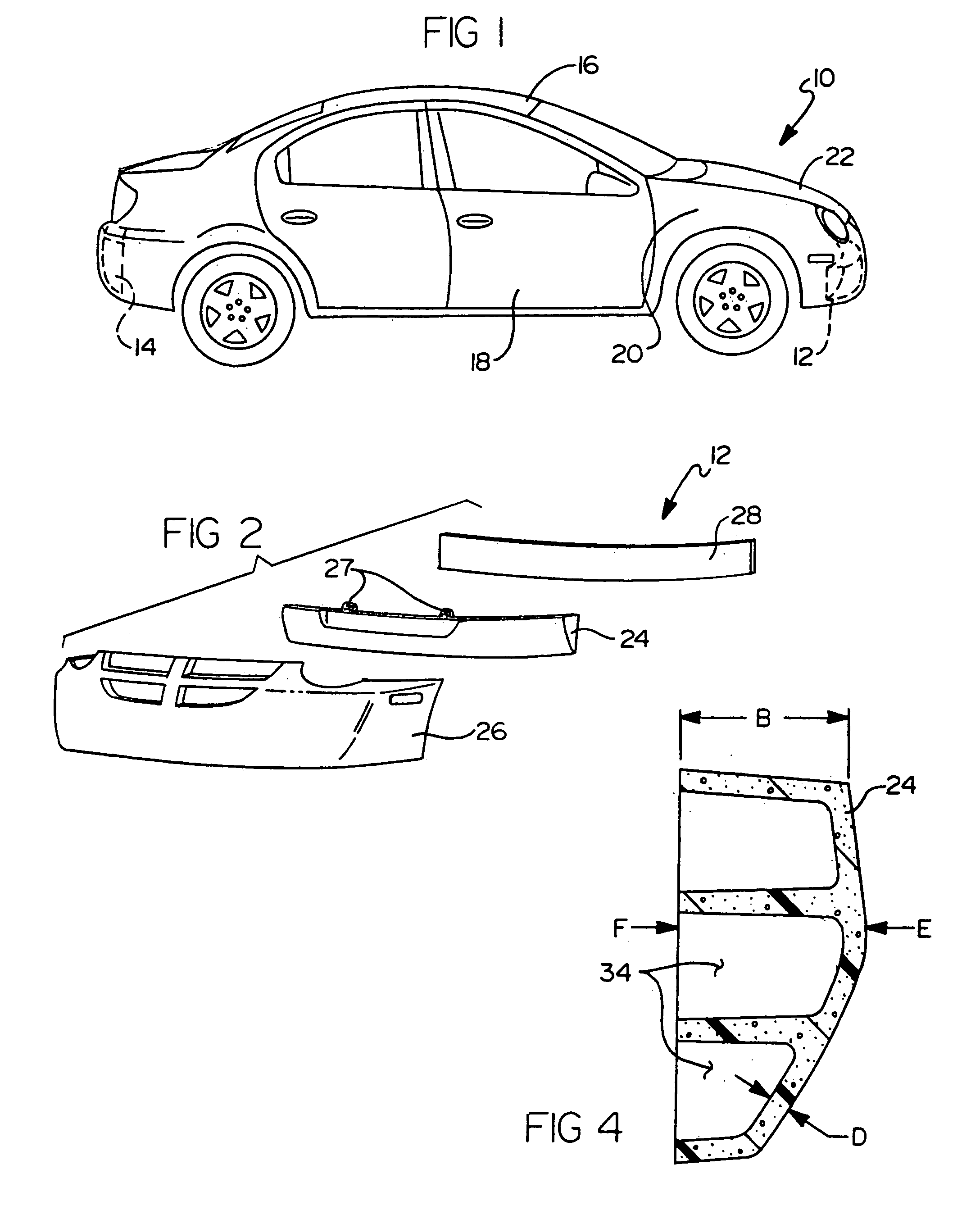

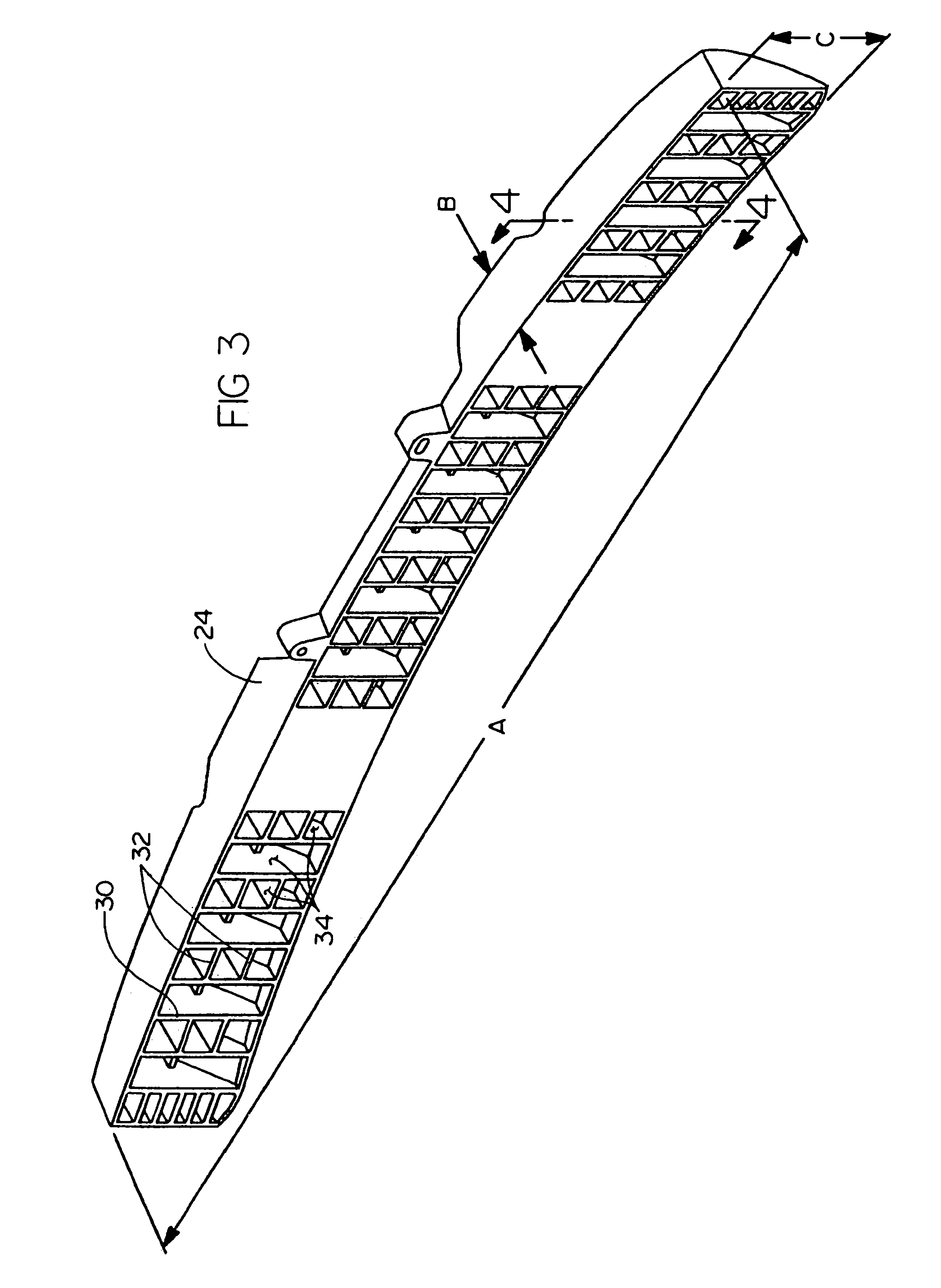

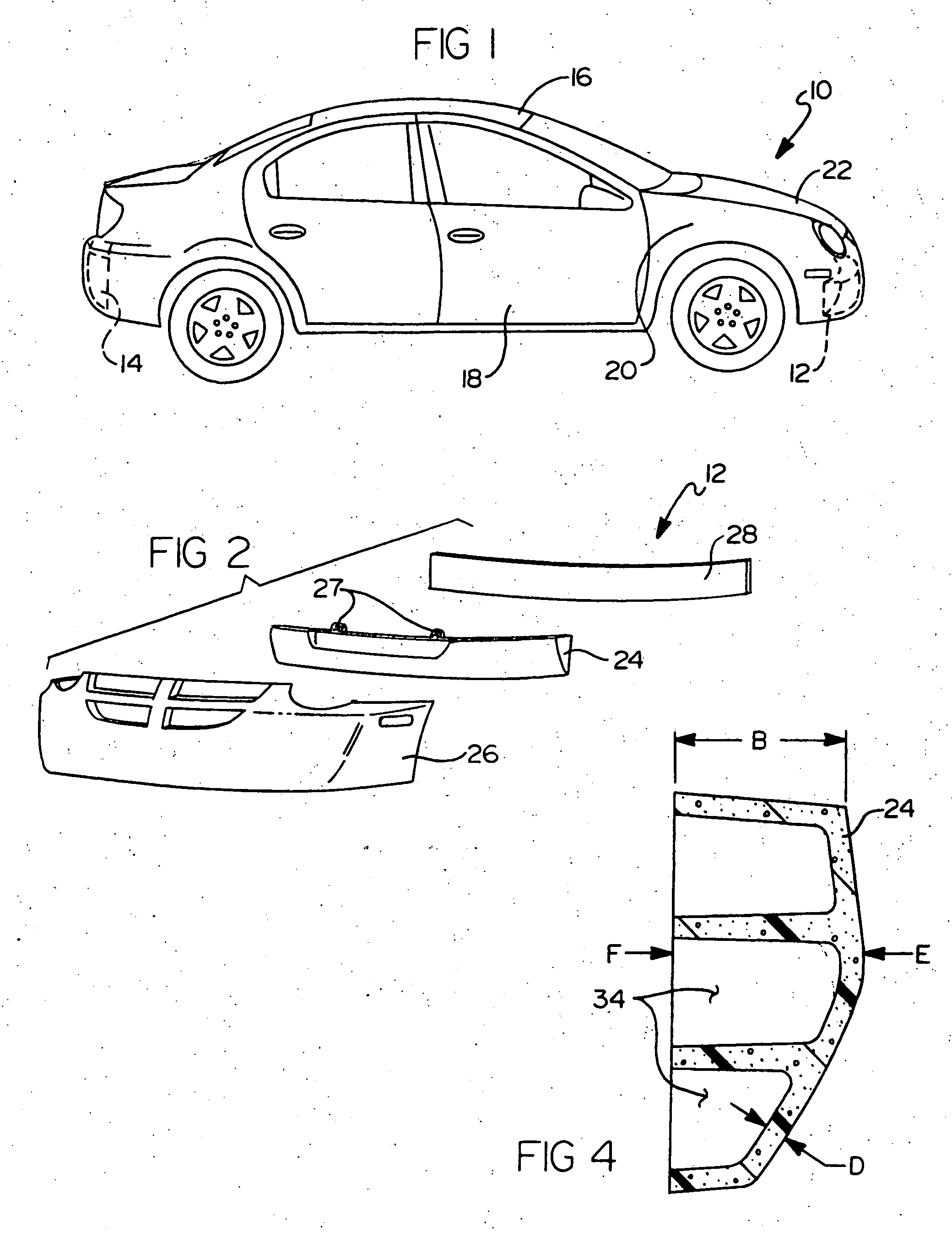

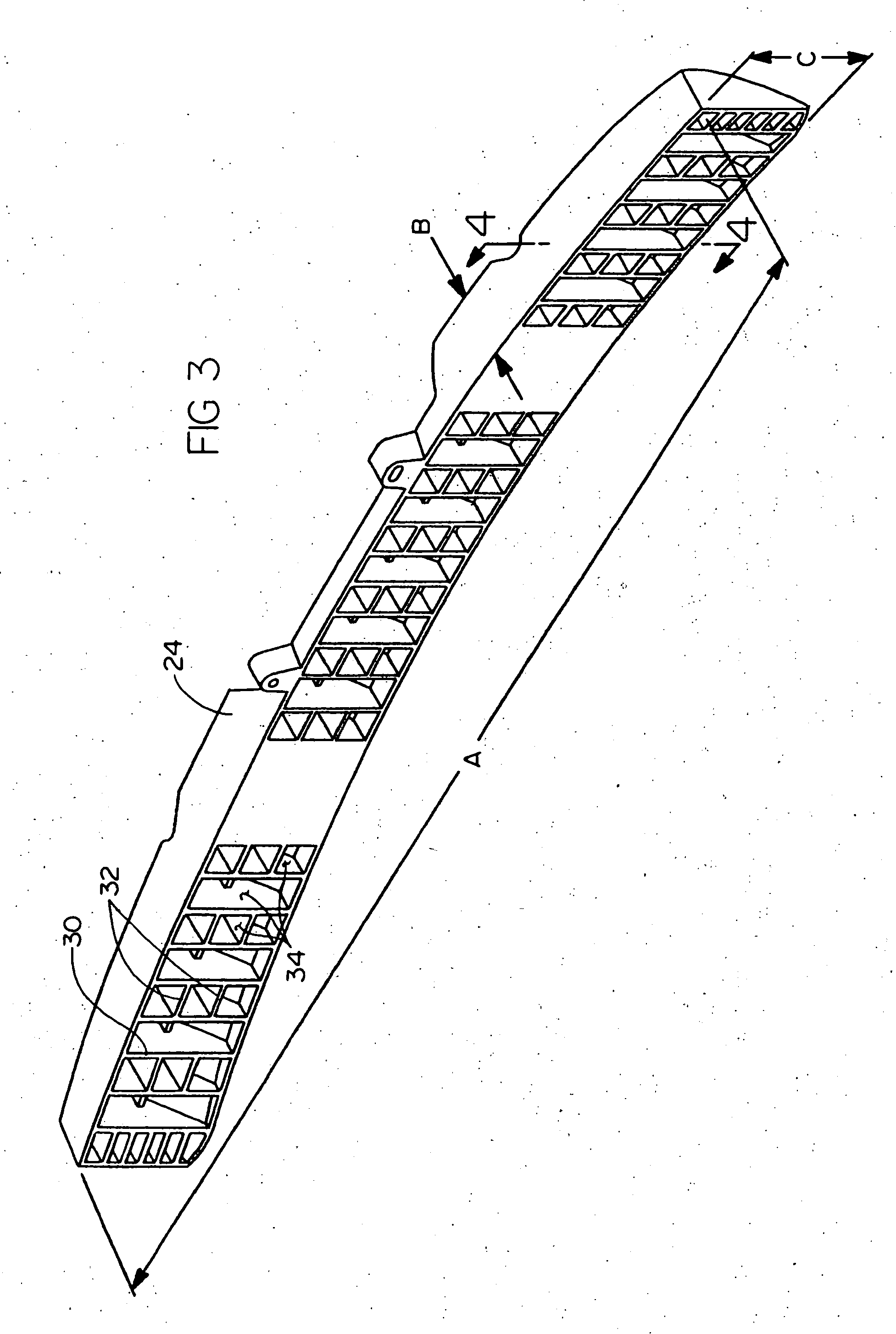

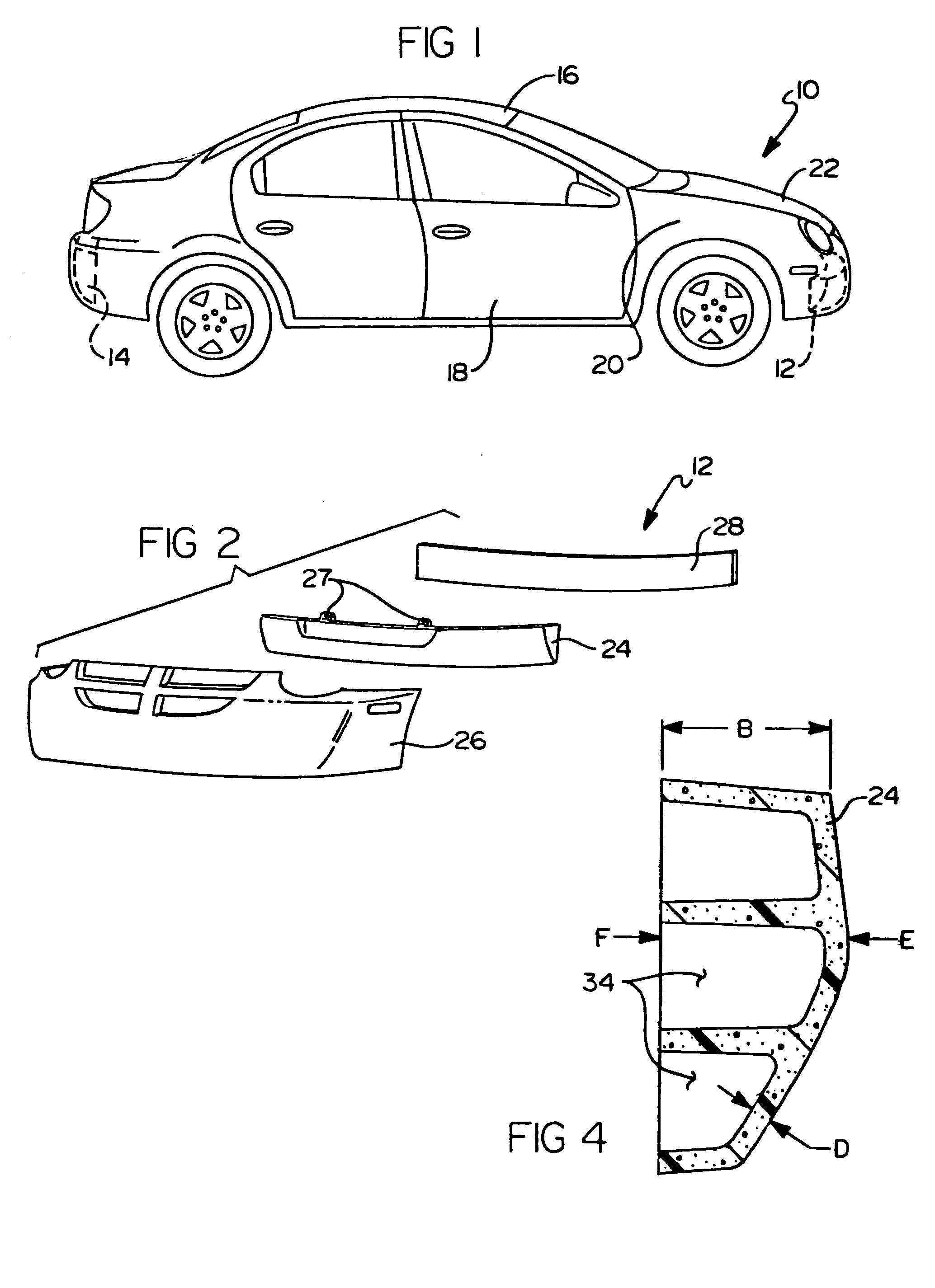

Molded foam vehicle energy absorbing device and method of manufacture

Owner:CADILLAC PRODS AUTOMOTIVE

Stoppers used in pre-filled syringes

ActiveUS8740856B2Simple moldingPrevent leakageInfusion syringesIntravenous devicesPrefilled SyringeBung

Owner:BECTON DICKINSON & CO

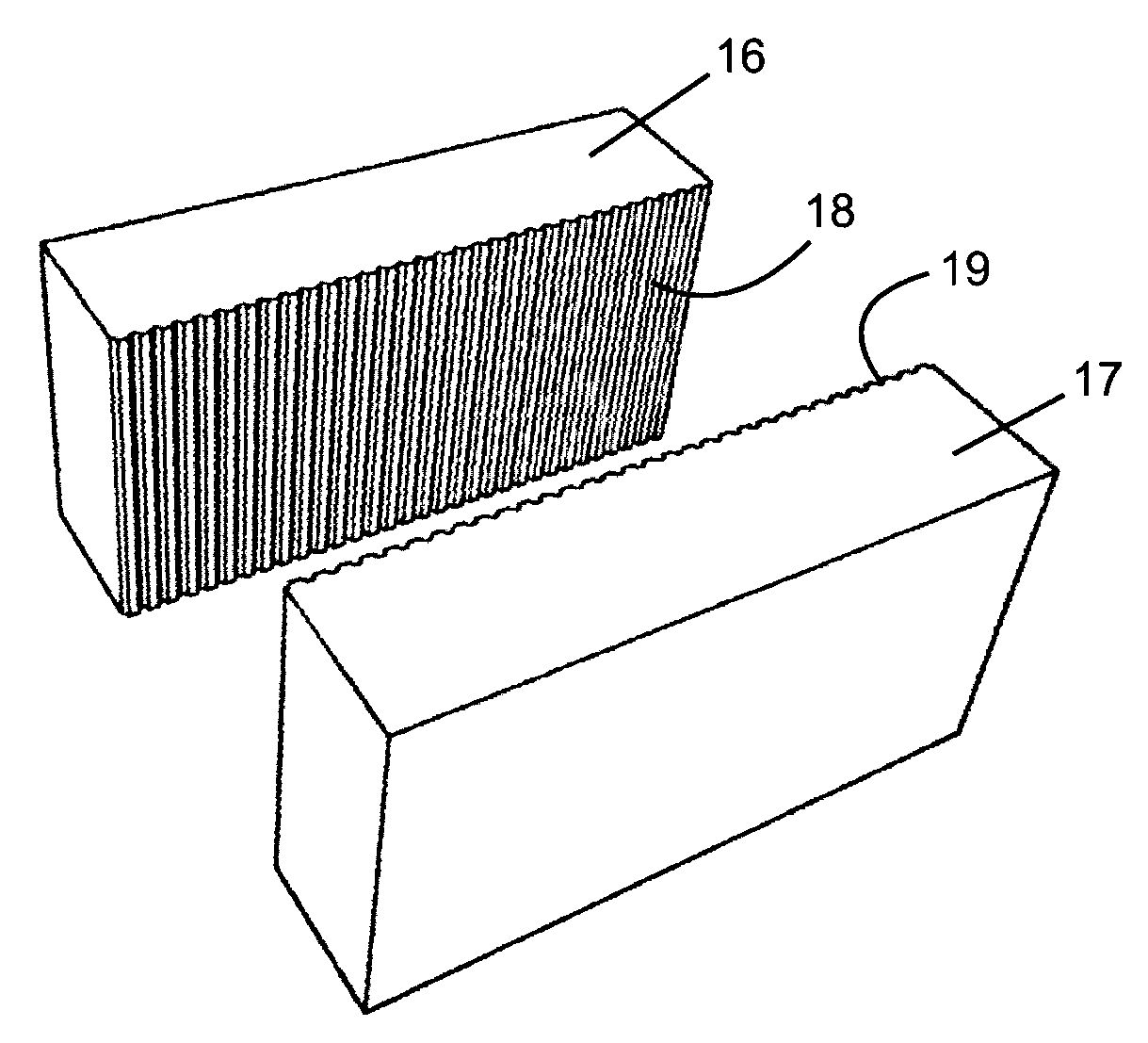

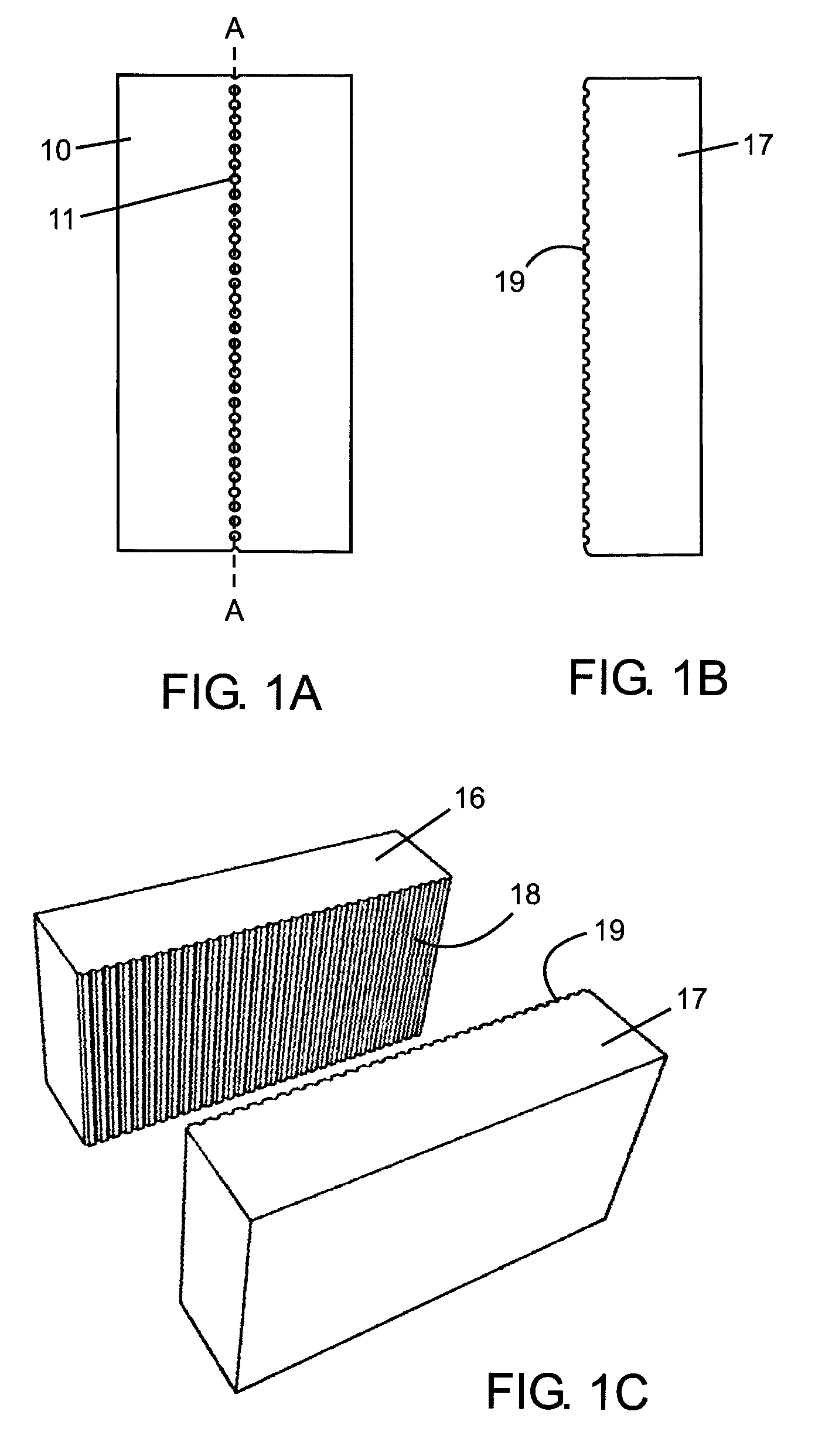

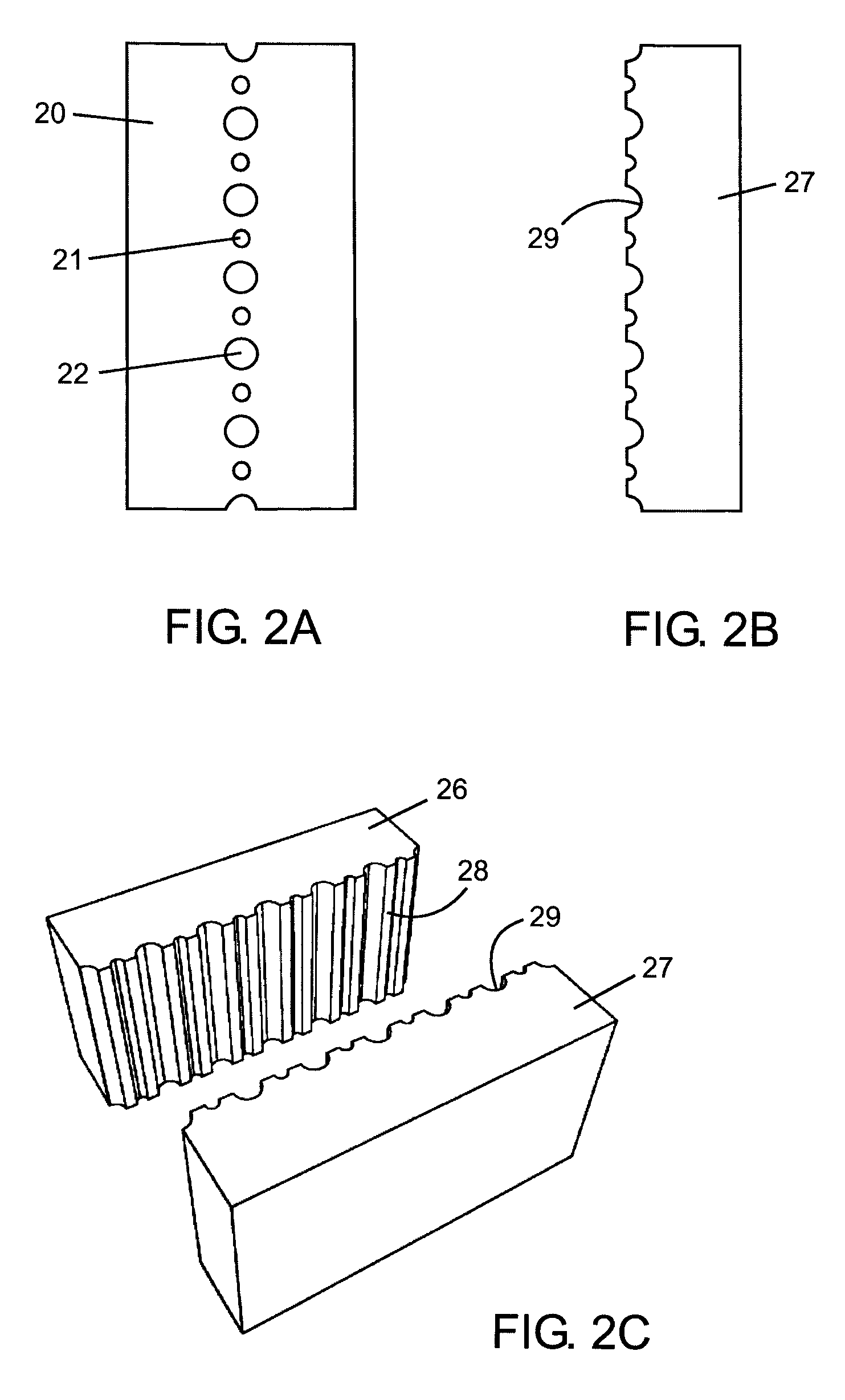

Brick/block/paver unit and method of production therefor

InactiveUS20070277471A1Reduce molding cycle timeEfficient manufacturing operationConstruction materialWallsEngineeringMethods of production

In a method of splitting a base block to form brick, block or paver units, a cementitious or stone base block having a first side, an opposed second side and a plurality of perforations is provided. Each perforation extends through the base block from the first side to the opposed second side, the plurality of perforations creating a splitting path in the base block. The splitting path has a cross-section consisting of from 70-50% by area of perforated regions and from 30-50% by area of unperforated regions. The base block may be split along the splitting path by a light shock to produce the brick, block or paver units. A wide variety of consistent and reproducible facing surfaces on brick, block and paver units may be produced that integrate texture, pattern, configuration and shape.

Owner:SIDNEY GIBSON LTD

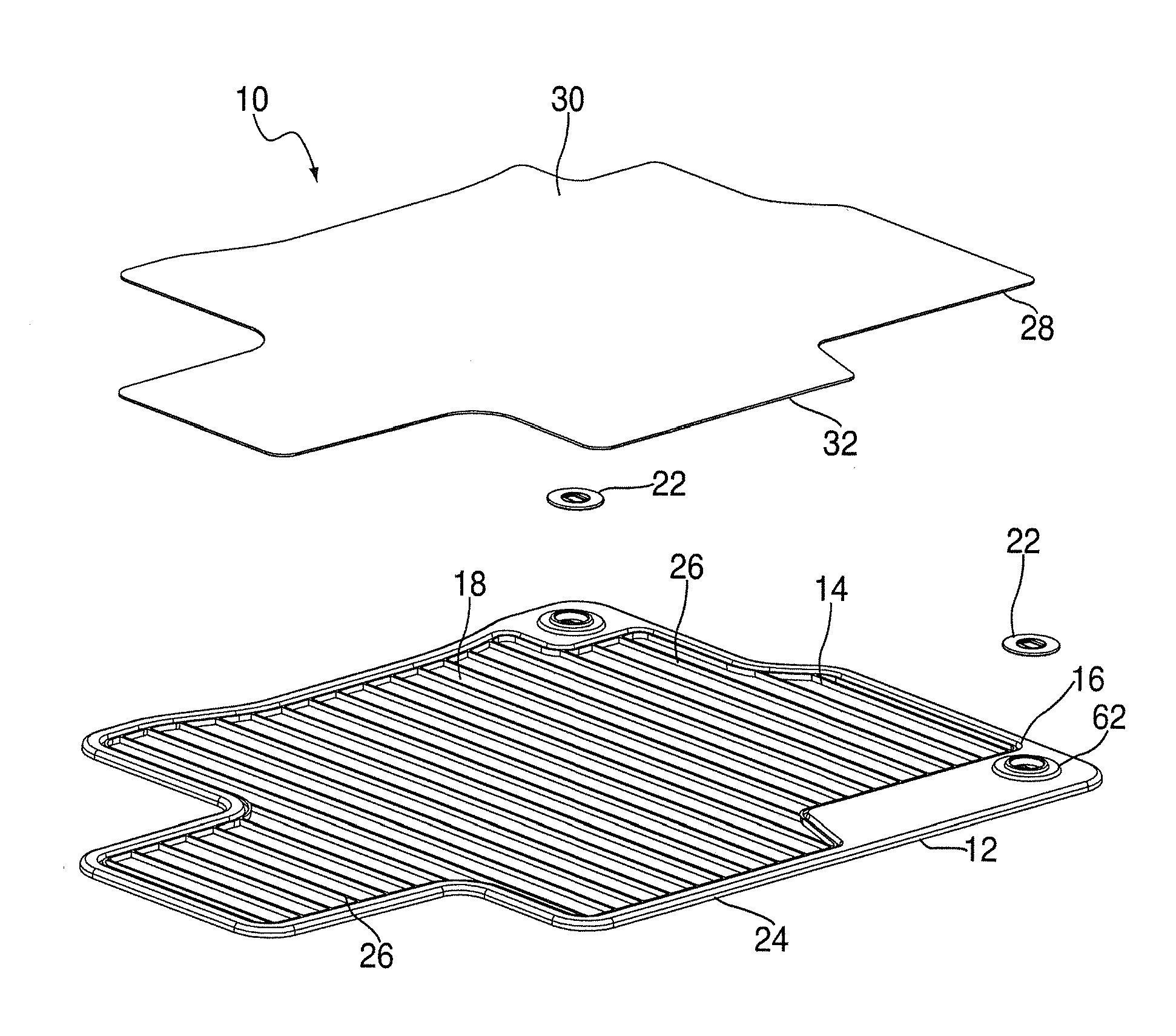

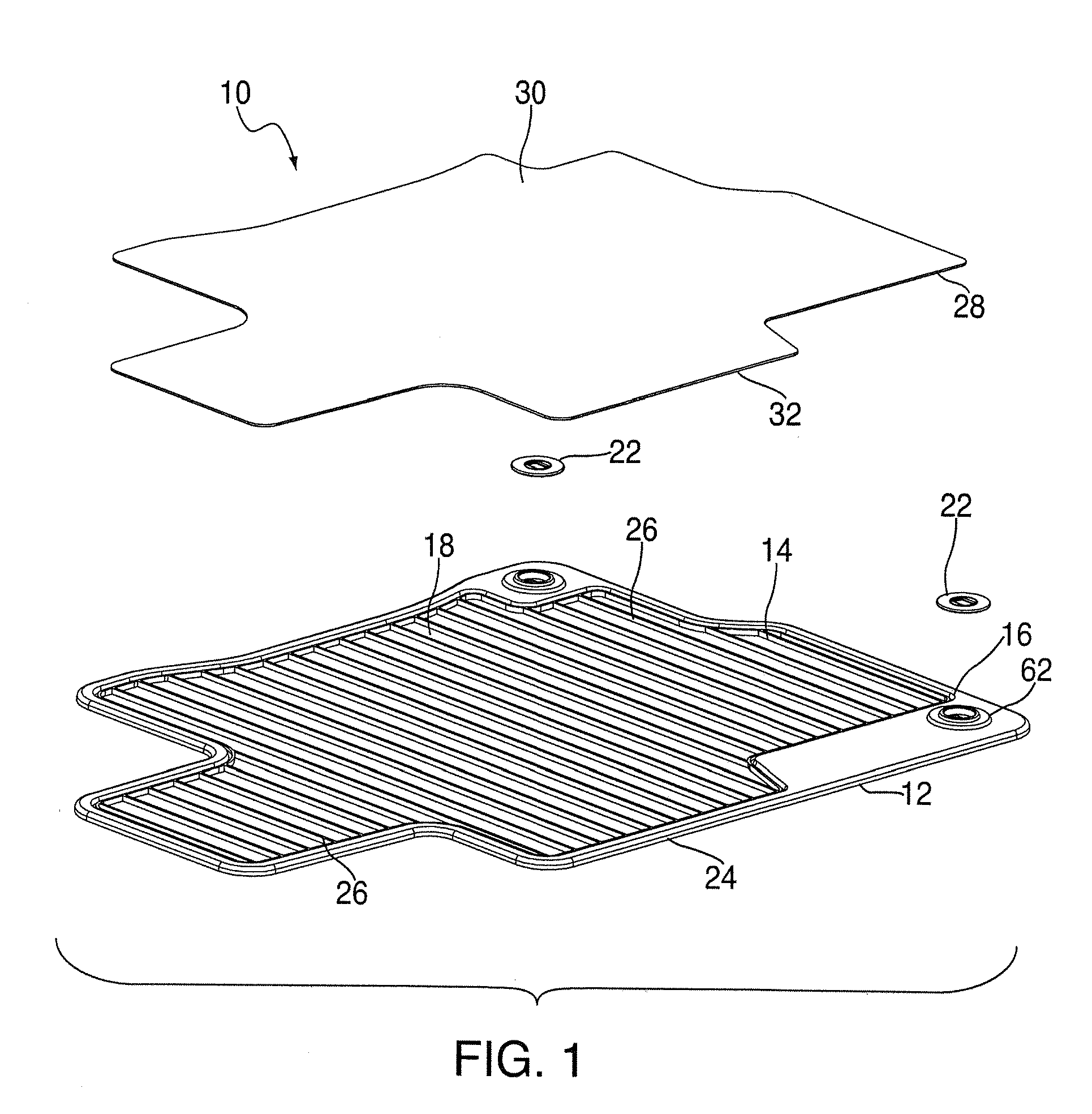

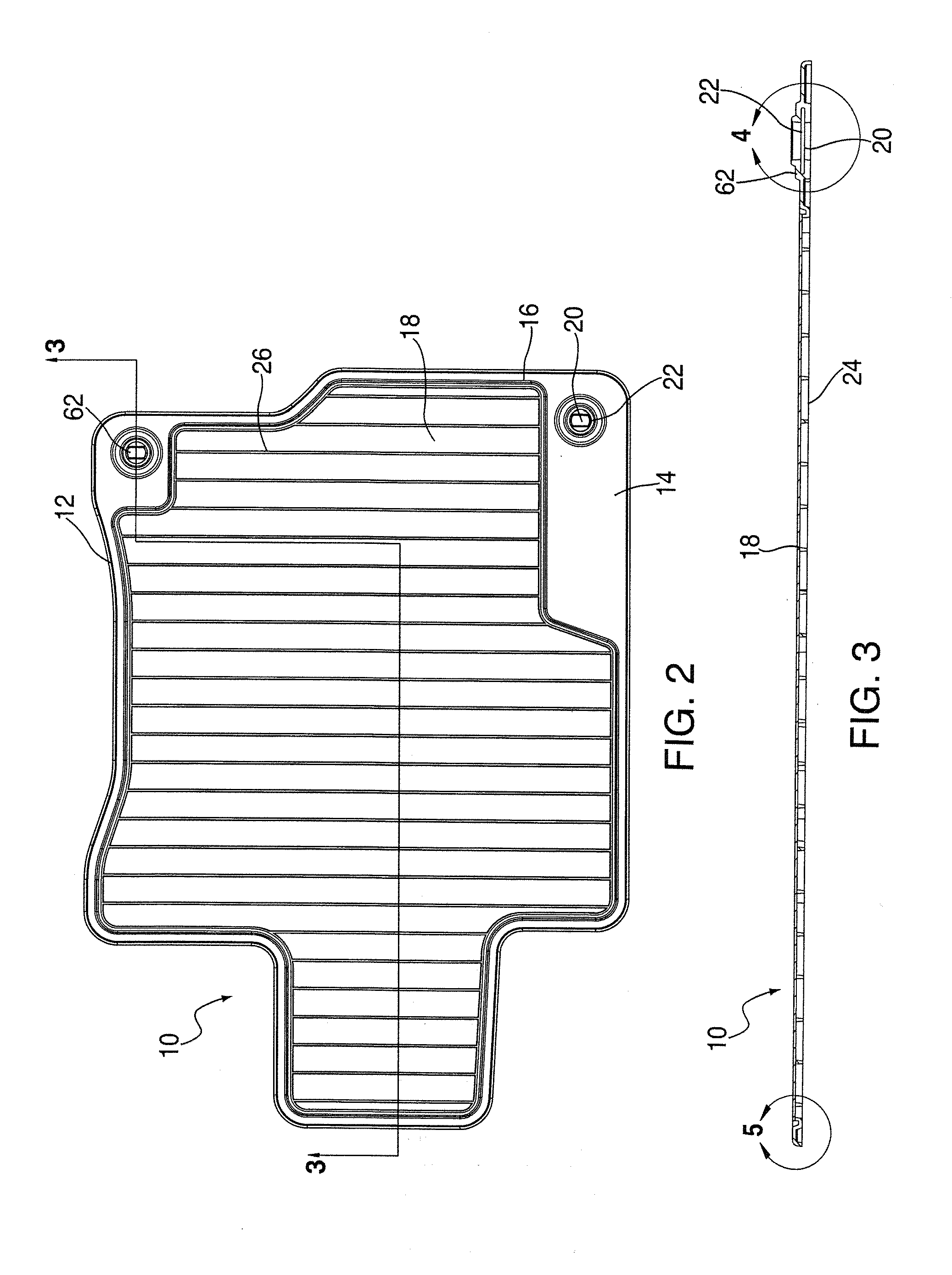

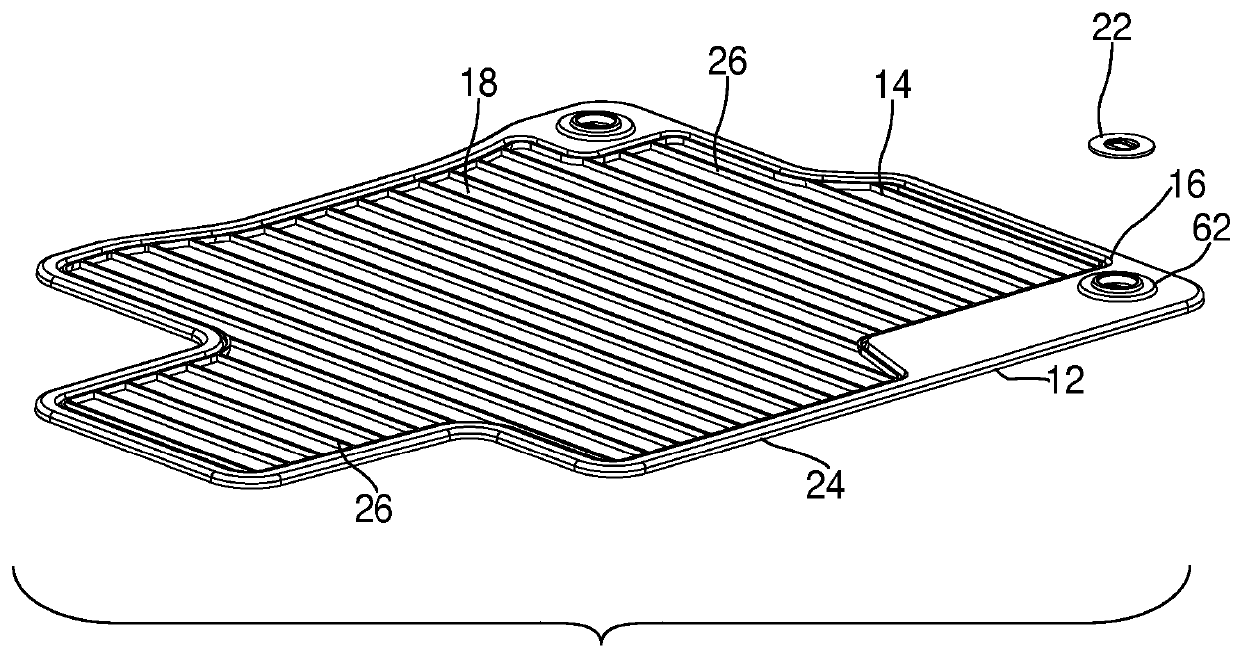

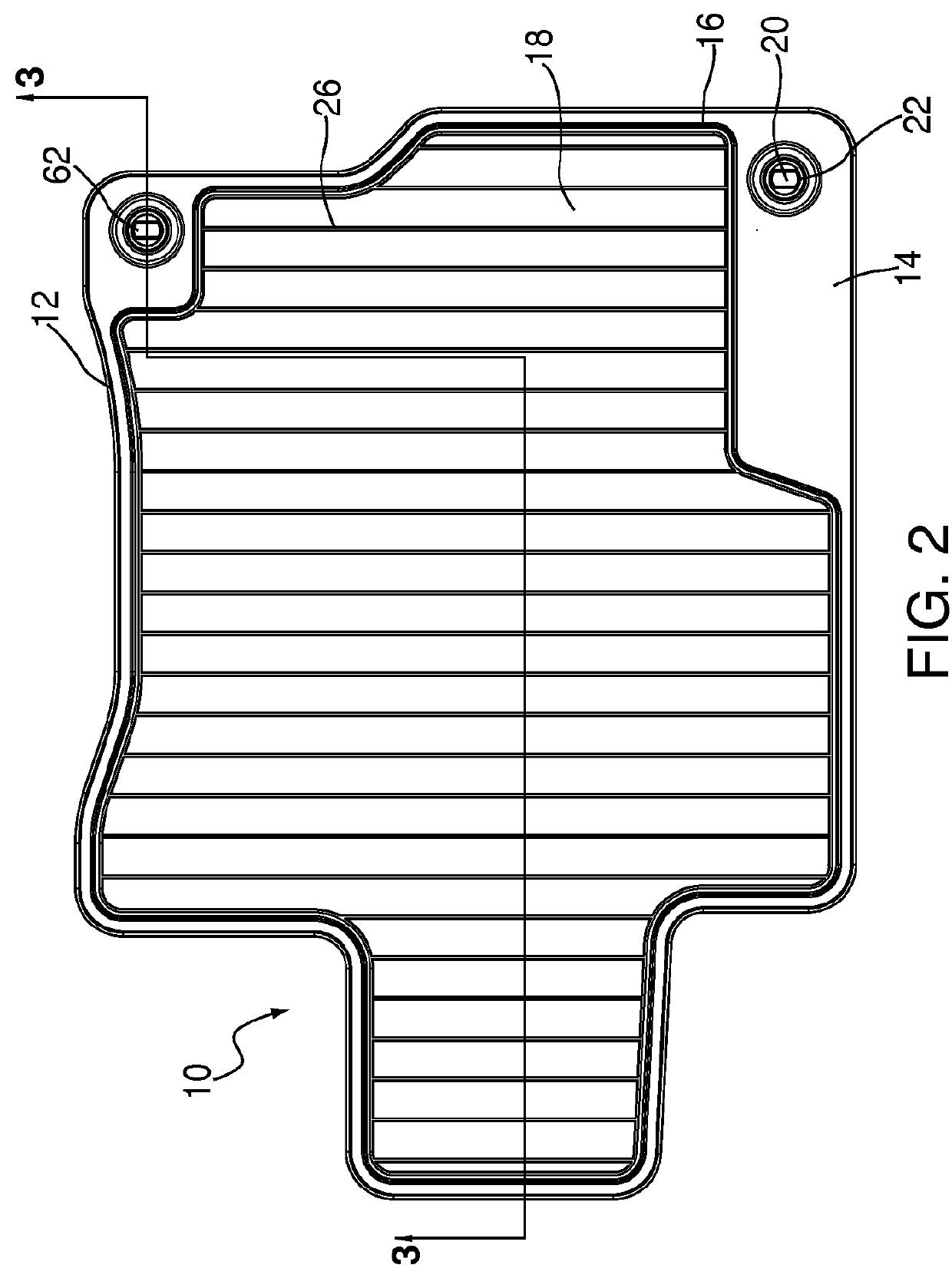

Carpet floor mat having plastic migrating prevention formation, and associated injection mold

ActiveUS20130260083A1Mass production be facilitateReduce mold cycle timeVehicle arrangementsLayered productsEngineeringInjection moulding

An injection molded carpet mat includes a flexible base having an upper surface defining a carpet recess, and an opposite lower surface. A carpet sheet is secured in the carpet recess by being integrally formed with the base, and having a napped top surface, a bottom surface and a peripheral edge. The lower base surface having a plurality of spaced ribs supporting the carpet bottom surface adjacent the peripheral edge and defining a track on the lower base surface corresponding to the peripheral edge of the carpet sheet.

Owner:THERMOFLEX

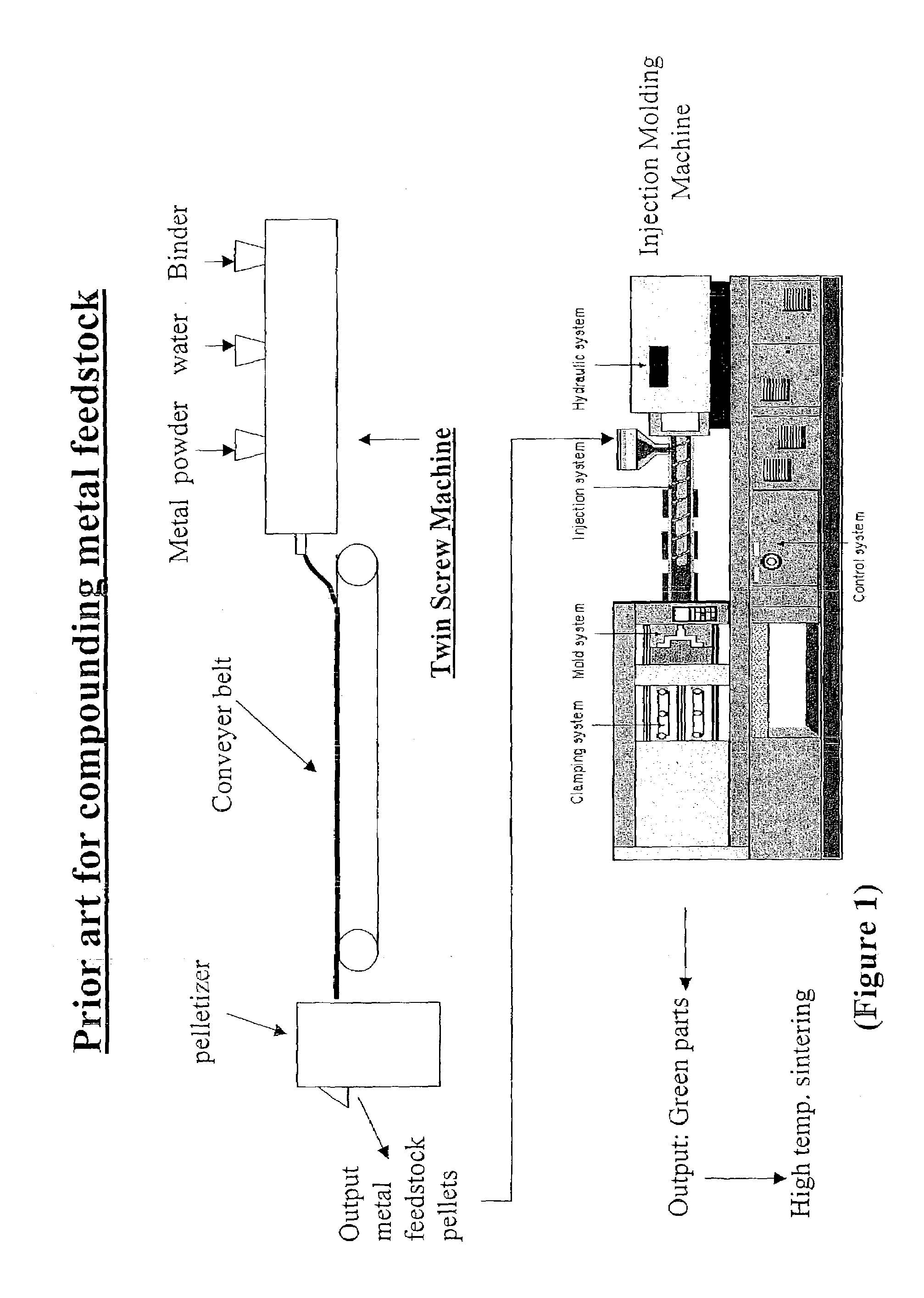

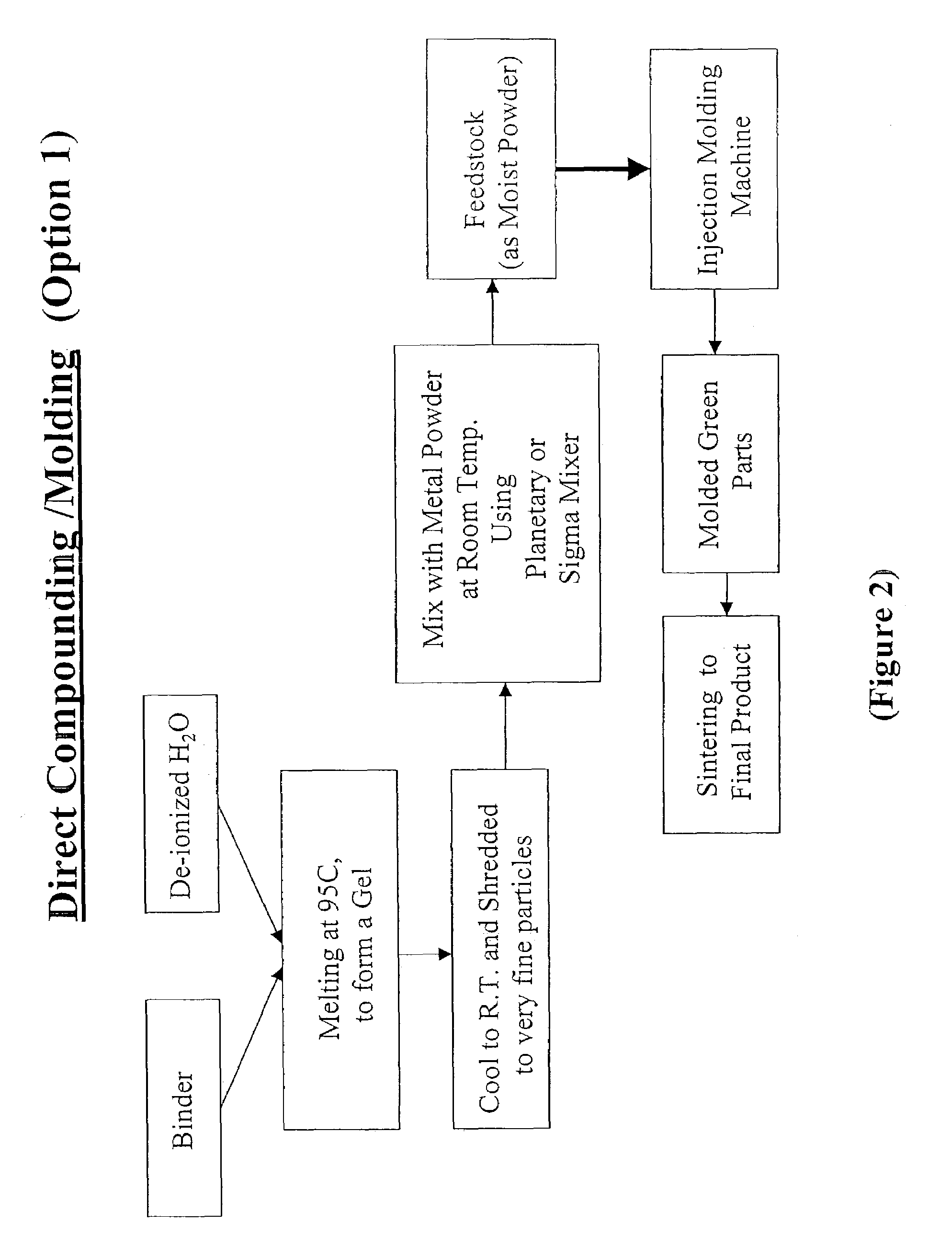

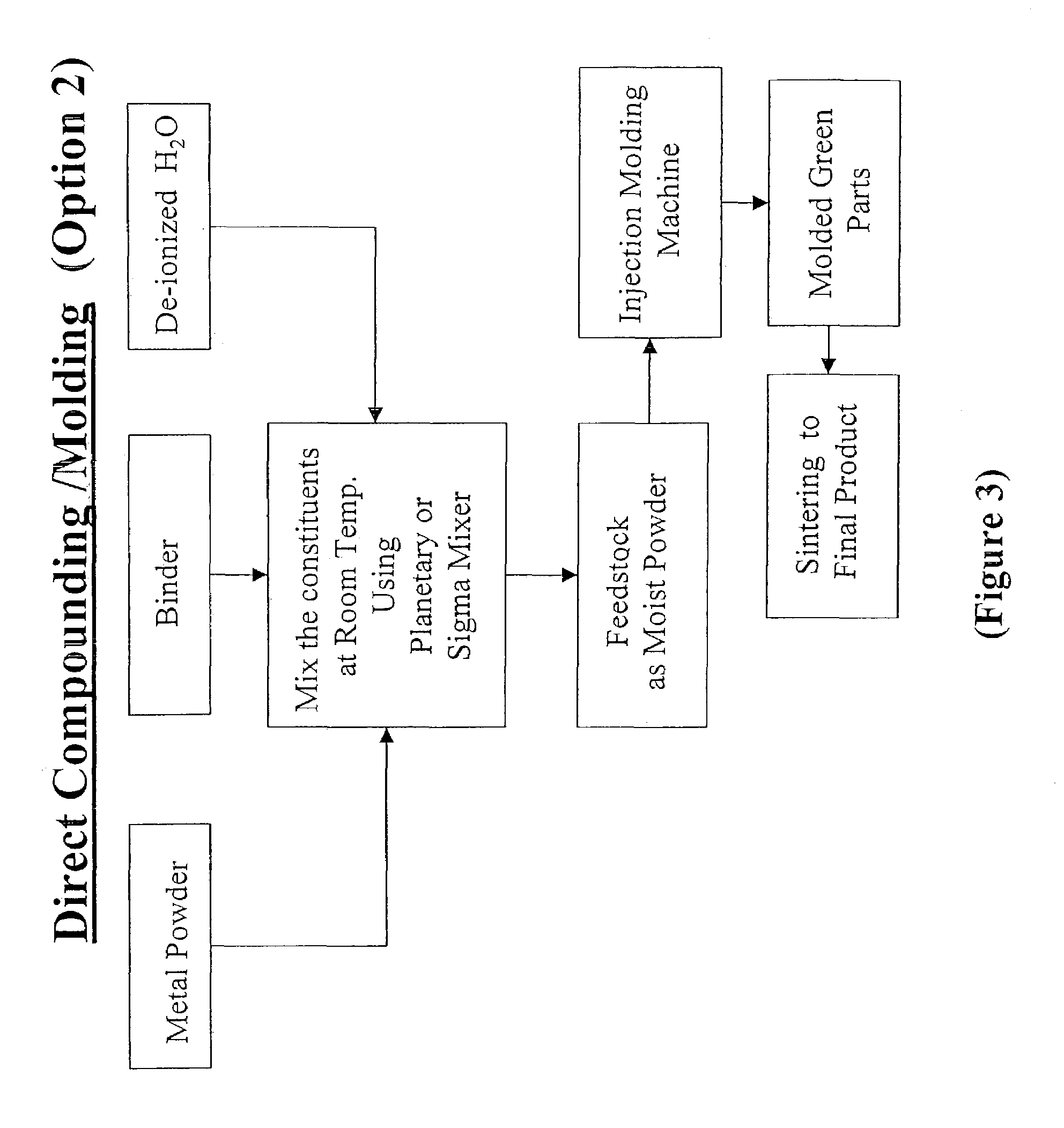

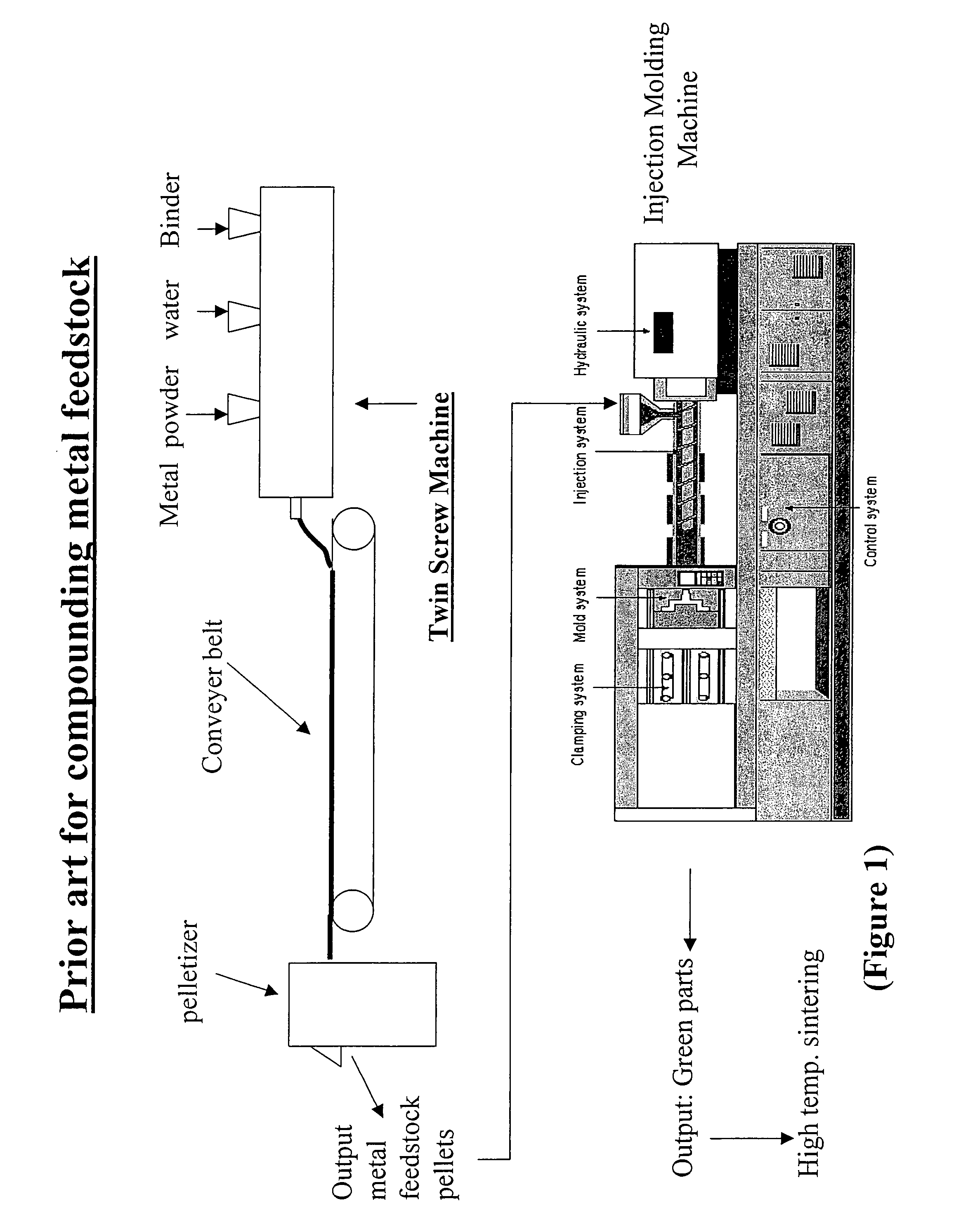

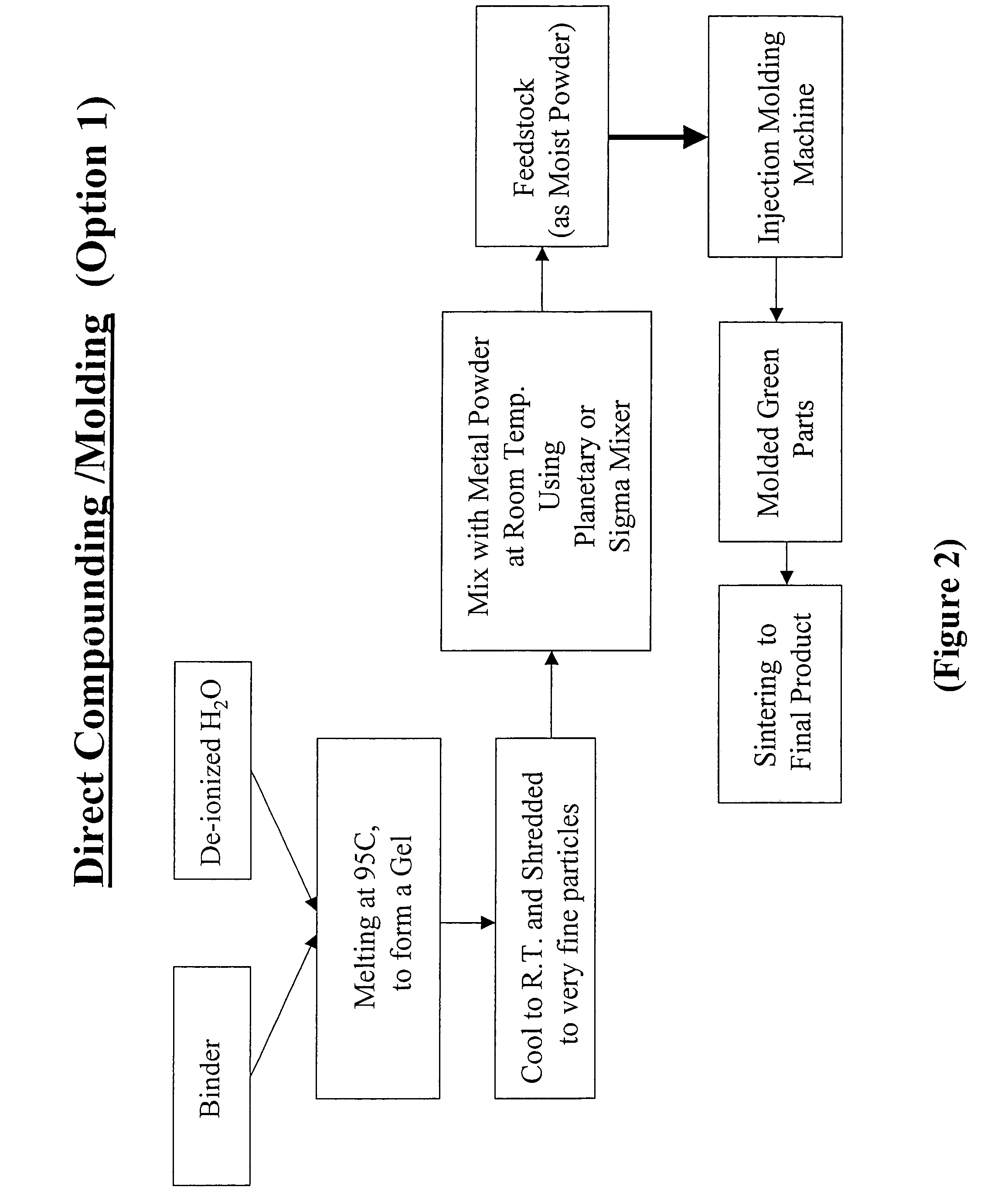

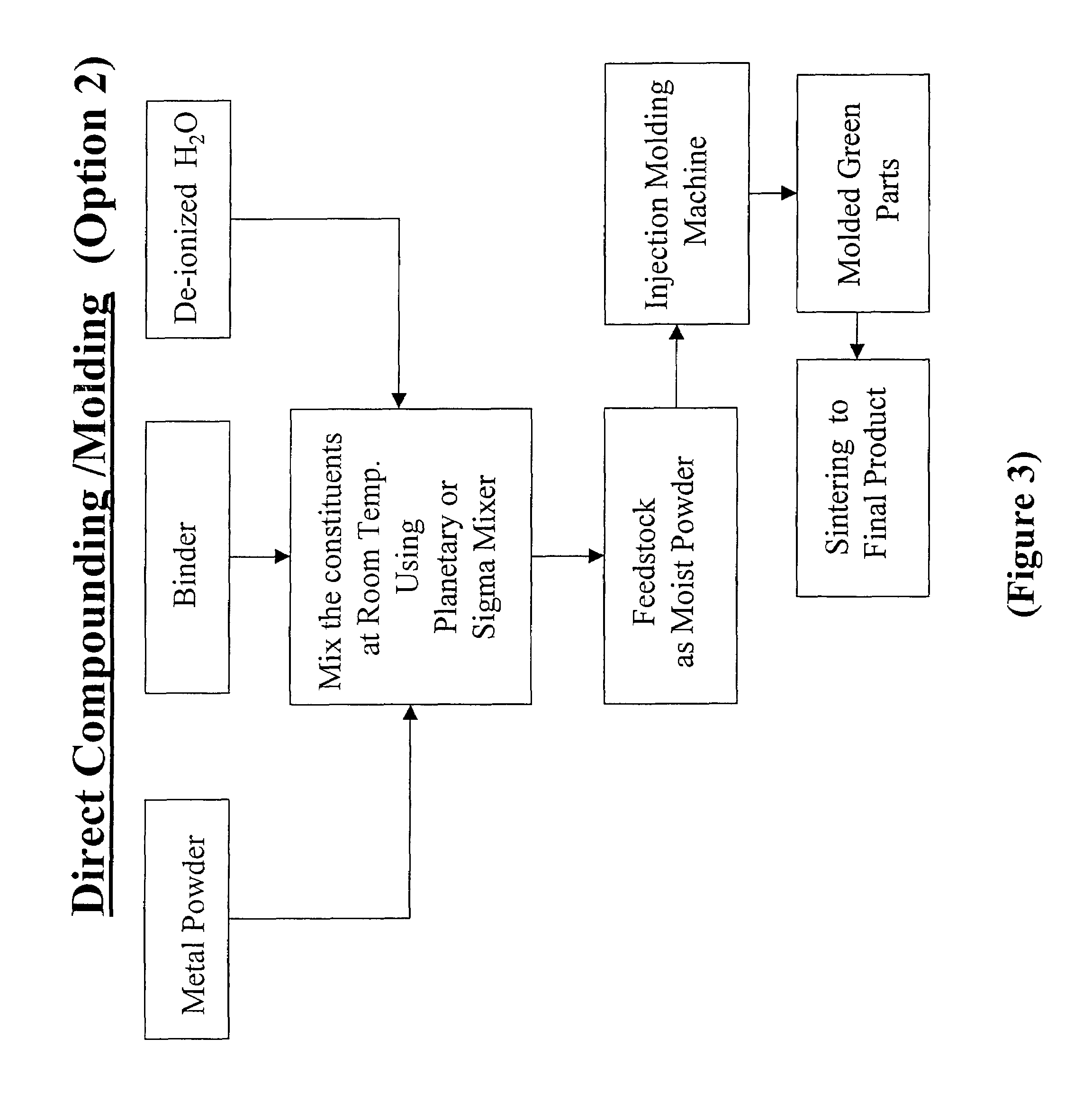

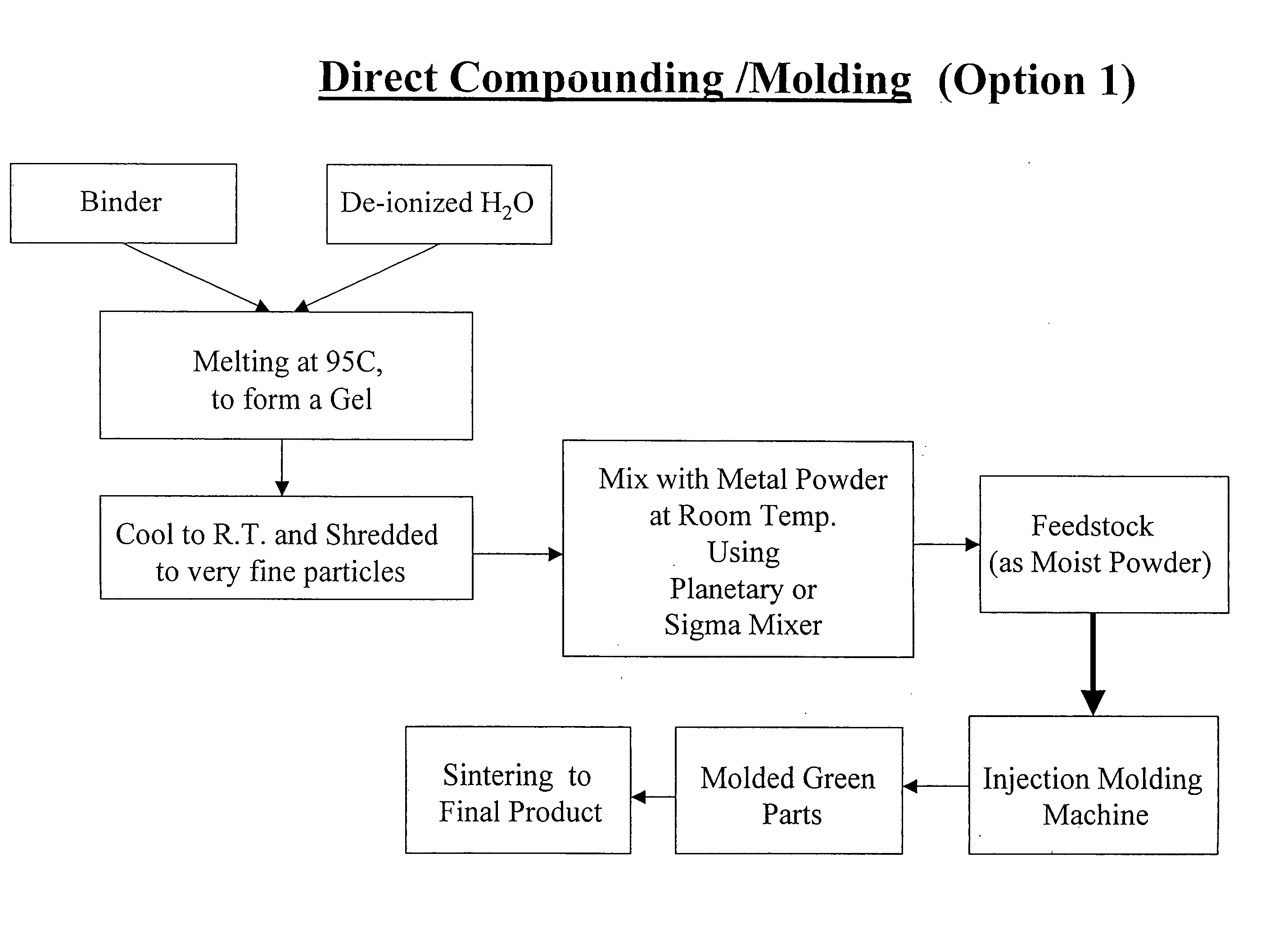

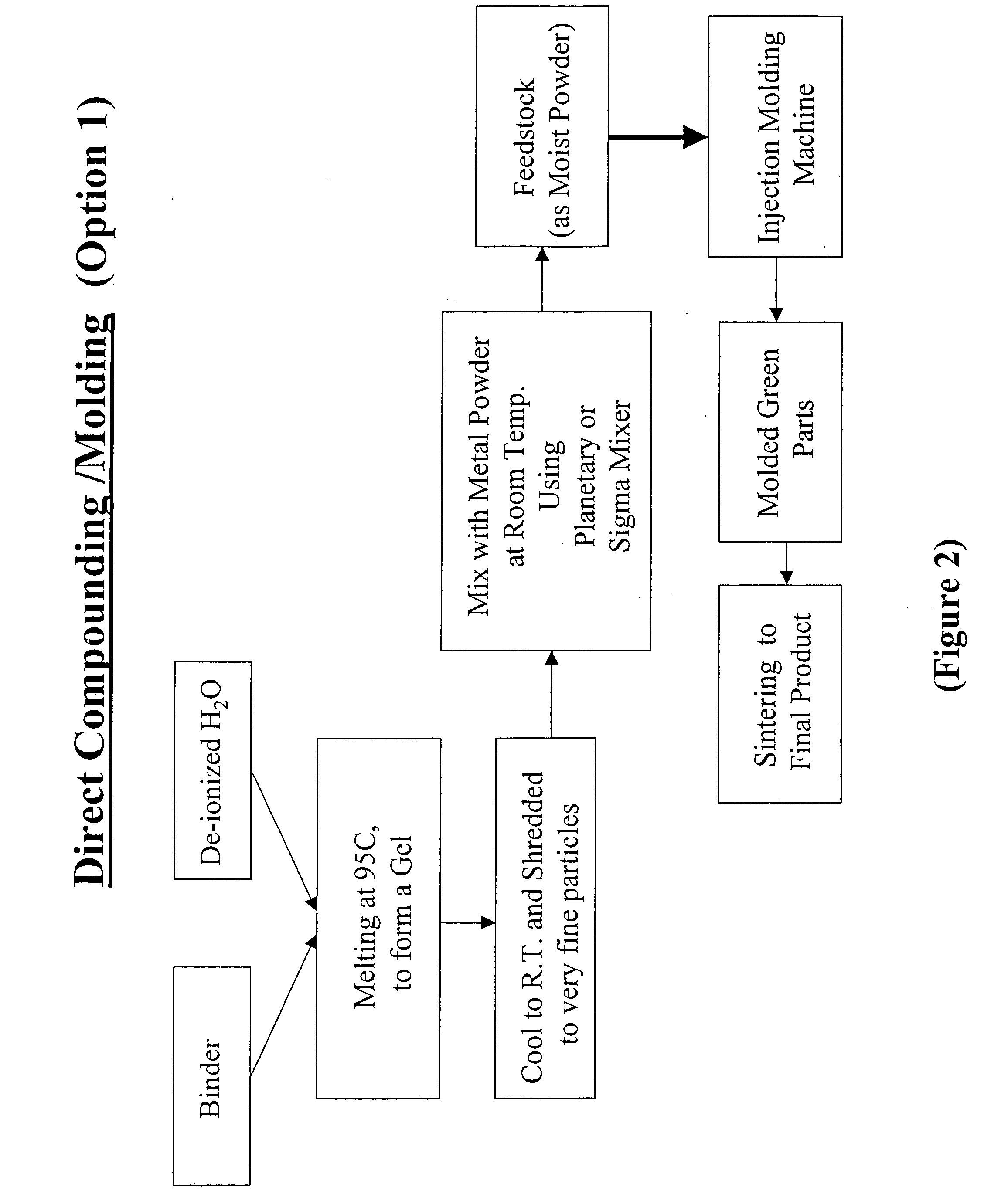

Aqueous binder formulation for metal and ceramic feedstock for injection molding and aqueous coating composition

ActiveUS6986810B1Easy and low costEasy and low and techniqueFireproof paintsAntifouling/underwater paintsGelatinMetal

Owner:UNITED MATERIALS TECH

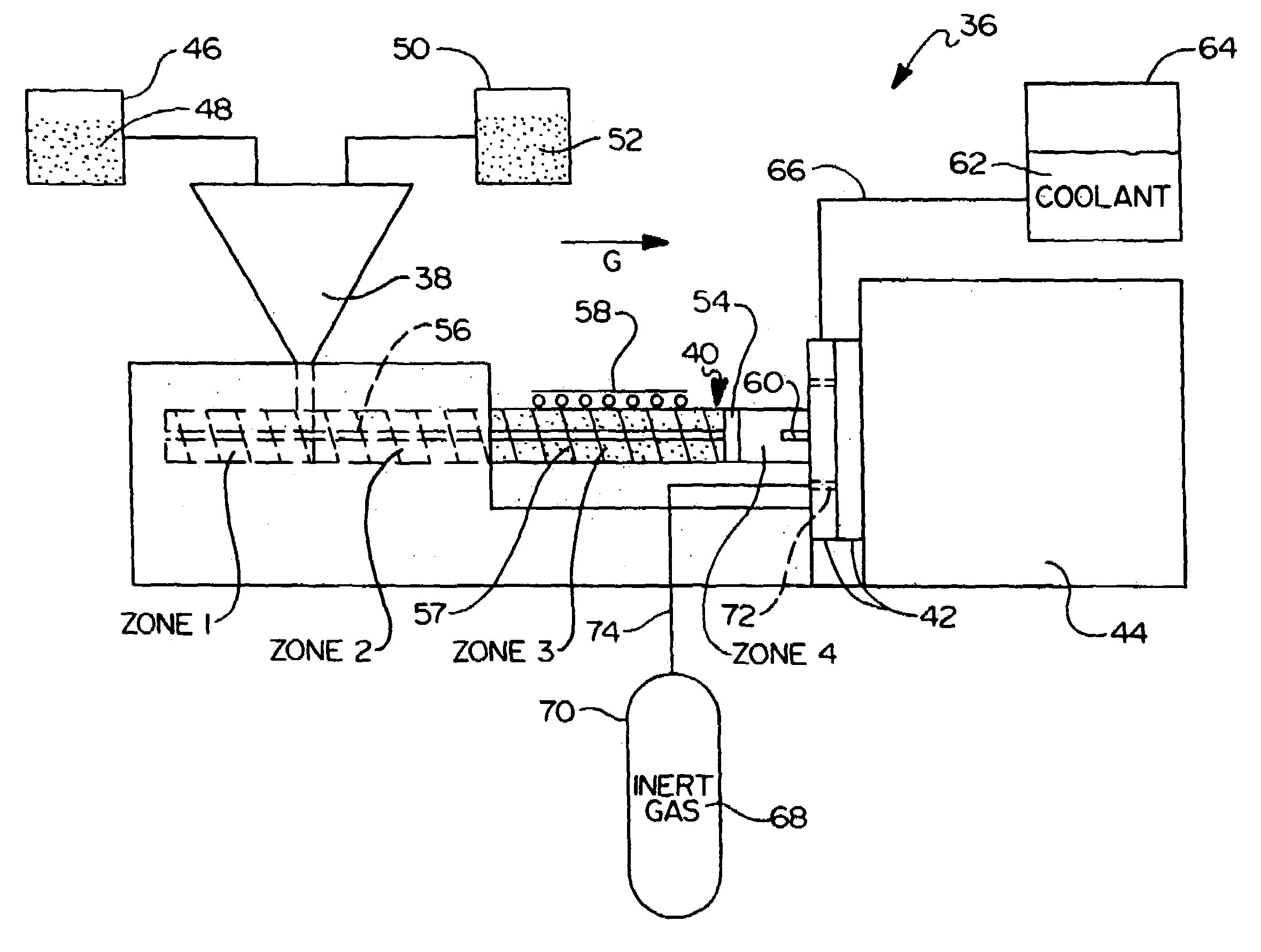

Molded foam vehicle energy absorbing device and method of manufacture

A method for forming energy absorbing components for motor vehicles includes mixing a polymeric resin and blowing agent combination. The combination is heated, liquefied, and pressurized. A mold for receiving the liquefied combination is pre-cooled. The liquefied combination is injection molded in the mold to form the energy absorbing component.

Owner:CADILLAC PRODS AUTOMOTIVE

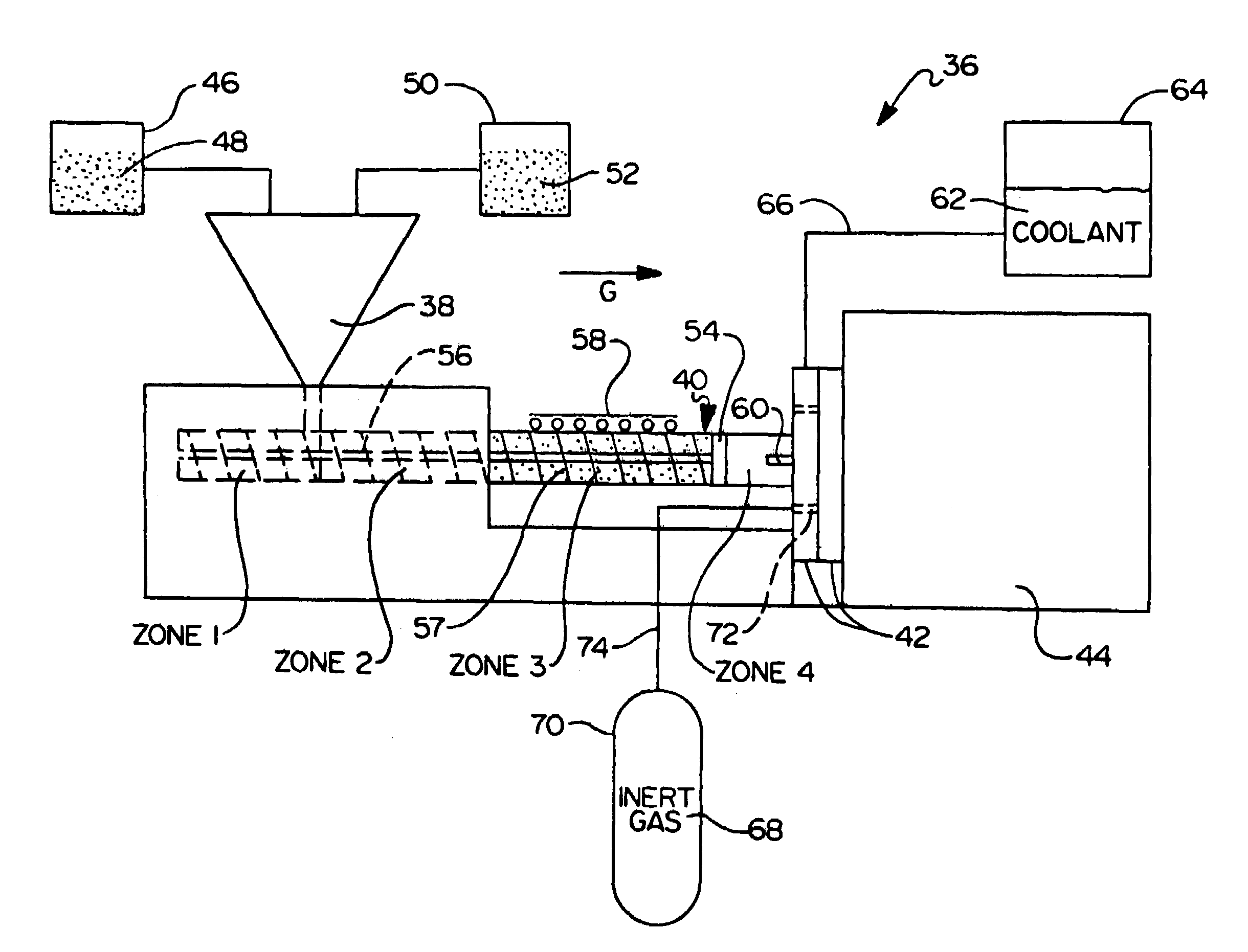

Molded foam vehicle energy absorbing device and method of manufacture

InactiveUS7220374B2Less costlyLess-costly base materialLayered productsMetal rolling stand detailsShell moldingEnergy absorption

A method for forming energy absorbing components for motor vehicles includes mixing a polymeric resin and blowing agent combination. The combination is heated to liquefy it. A mold for receiving the liquefied combination is cooled. The liquefied combination is injected into the mold in less than 1.5 seconds and preferably in 0.5 seconds or less.

Owner:CADILLAC PRODS AUTOMOTIVE

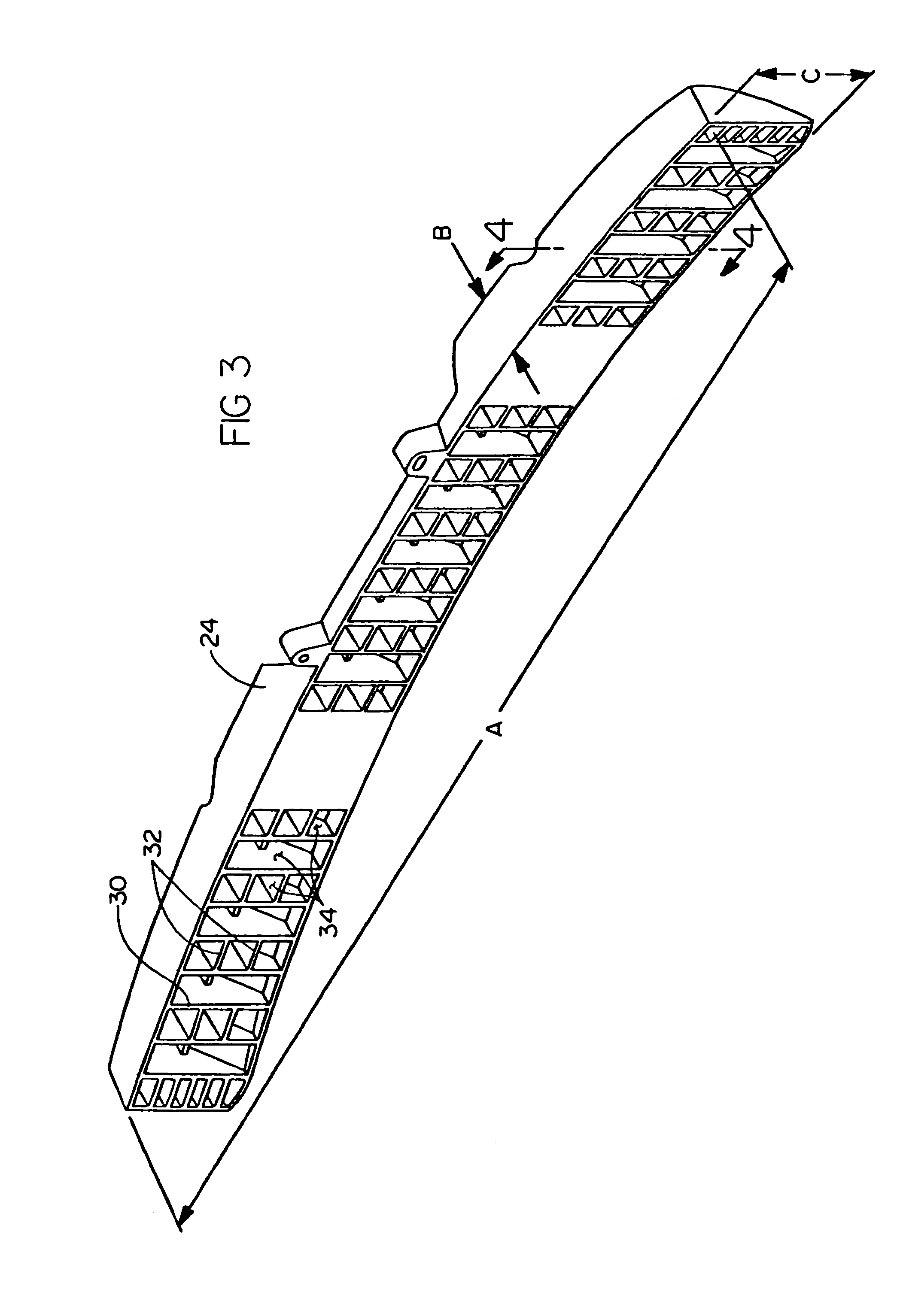

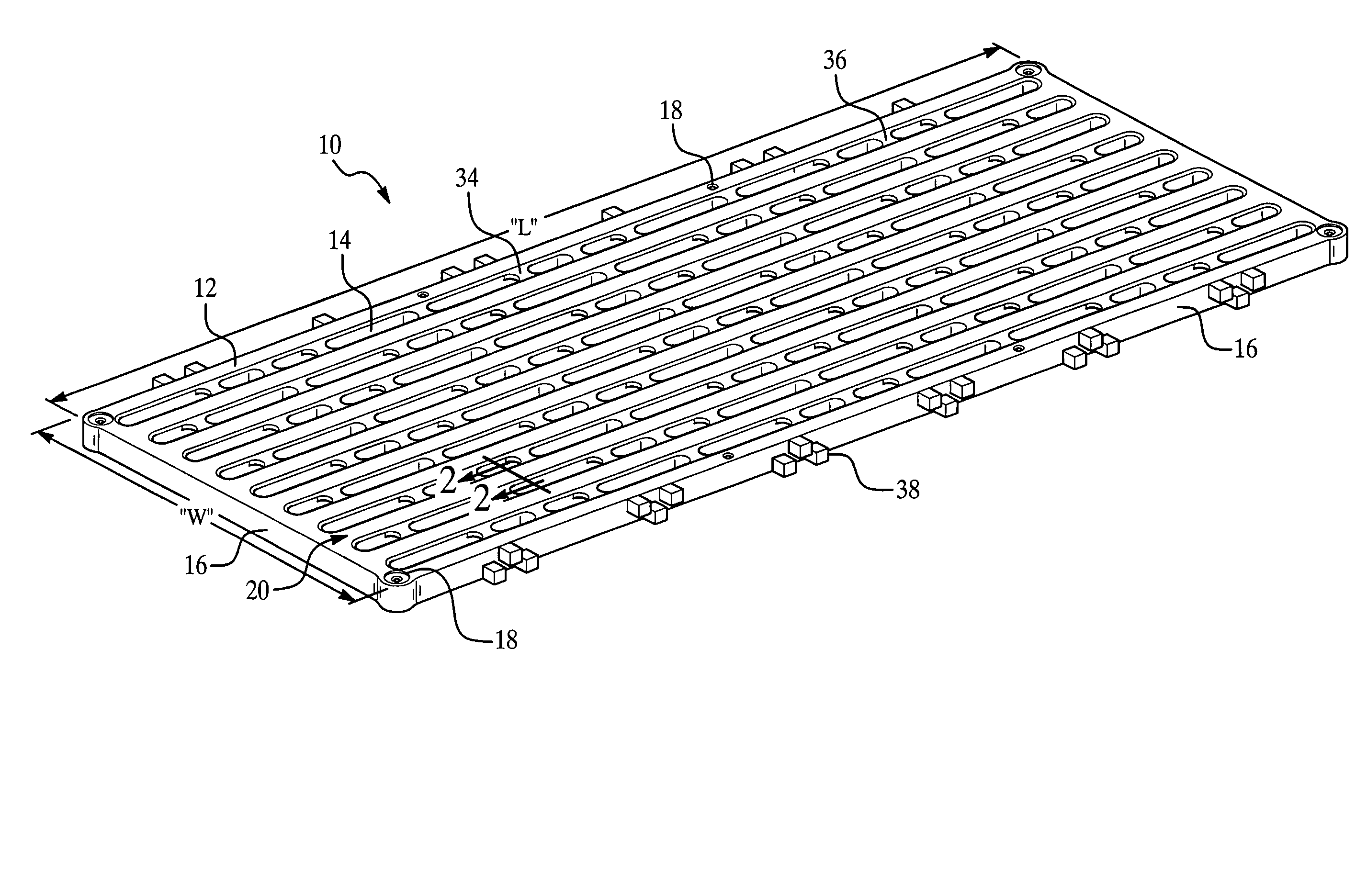

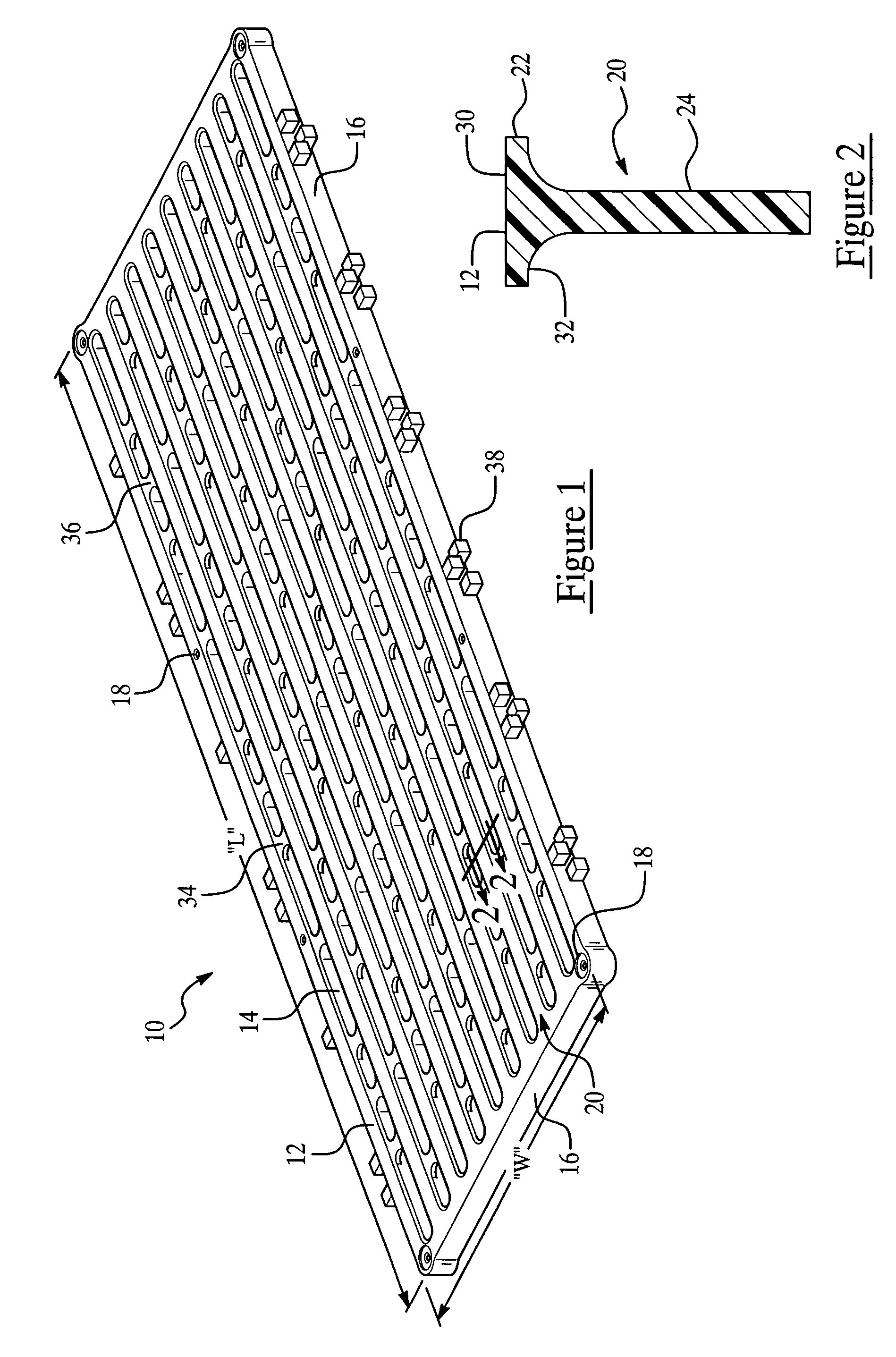

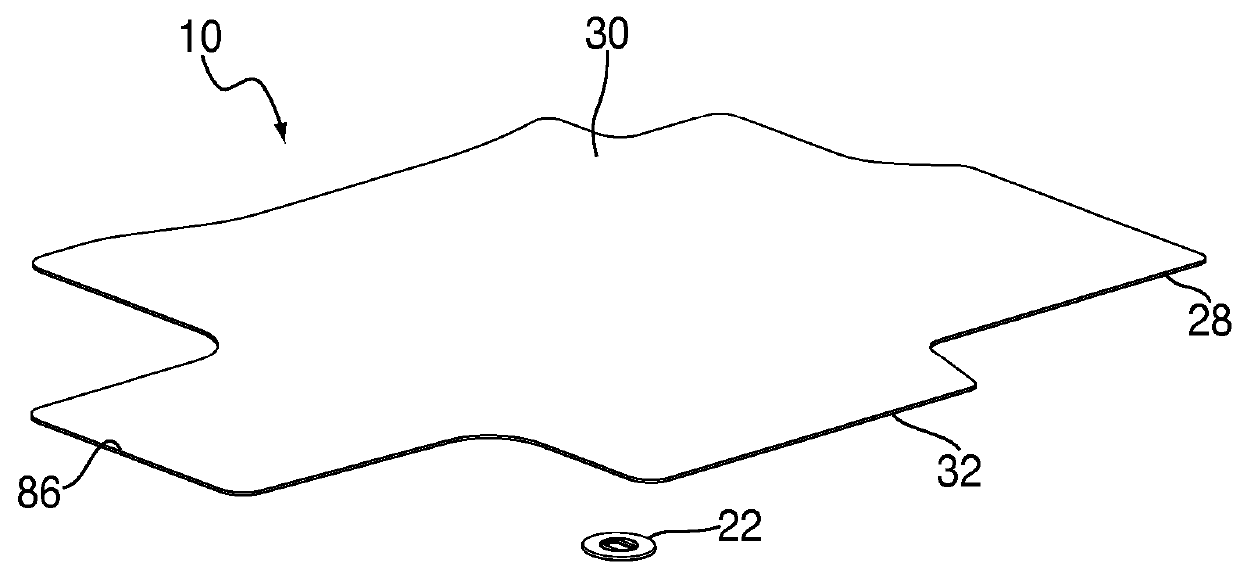

Molded panel

A deck panel is adapted to be secured on a supporting frame structure to create a deck surface. The deck panel comprises a thermoplastic material impregnated with a fibrous stranded material. The panel includes a top surface and four lateral sides extending downward from the top surface. The top surface is formed as a grid having a plurality of openings. A plurality of supporting ribs extend parallel to each other from one of the four lateral sides to an opposite one of the four lateral sides. The upper surface of each supporting rib is adapted to form longitudinal portions of the grid pattern of the top surface. A plurality of tabs extend outward from the lateral sides that are adapted to interlock with a corresponding plurality of tabs extending from a like deck panel so that a plurality of deck panels may be juxtaposed in abutting relationship.

Owner:THRUFLOW

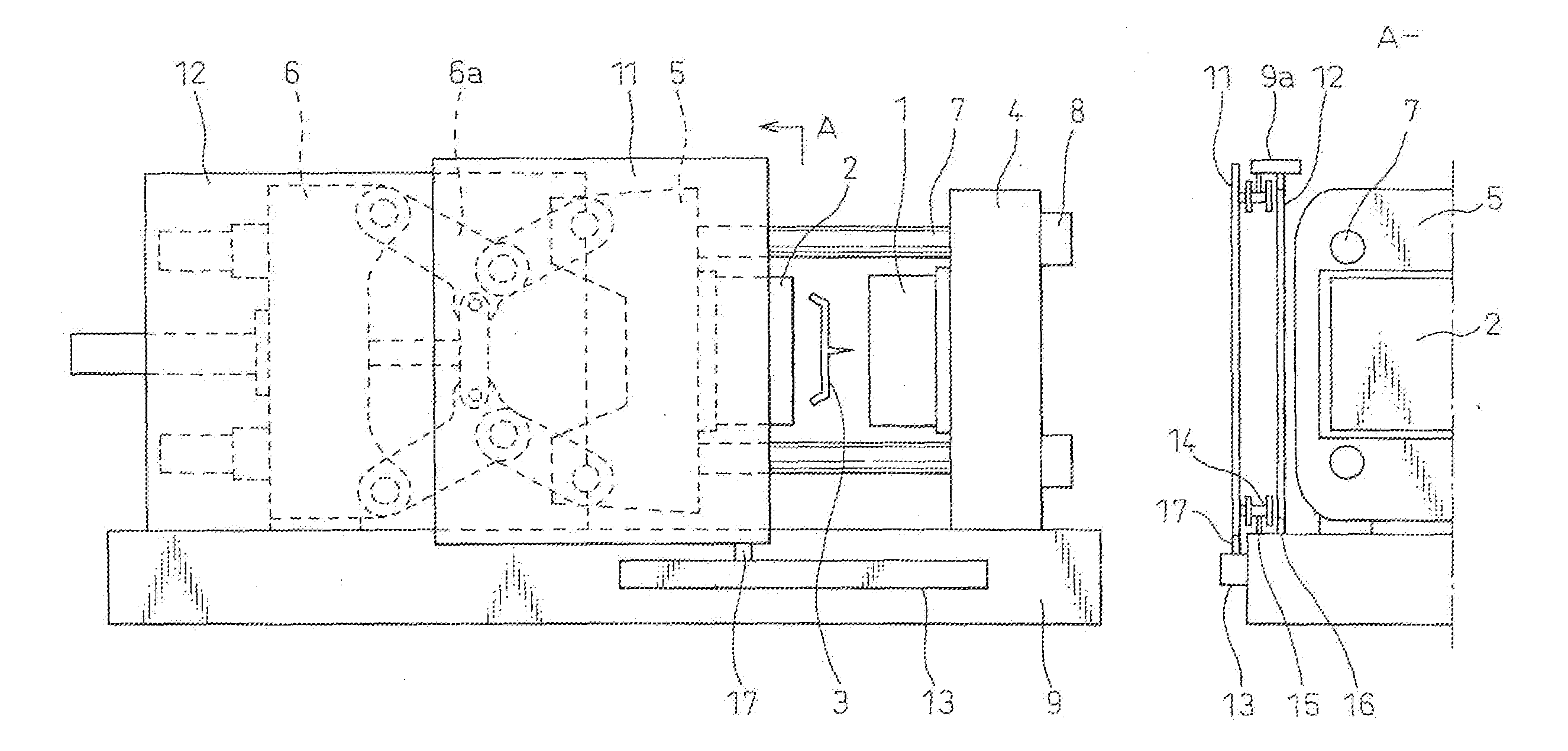

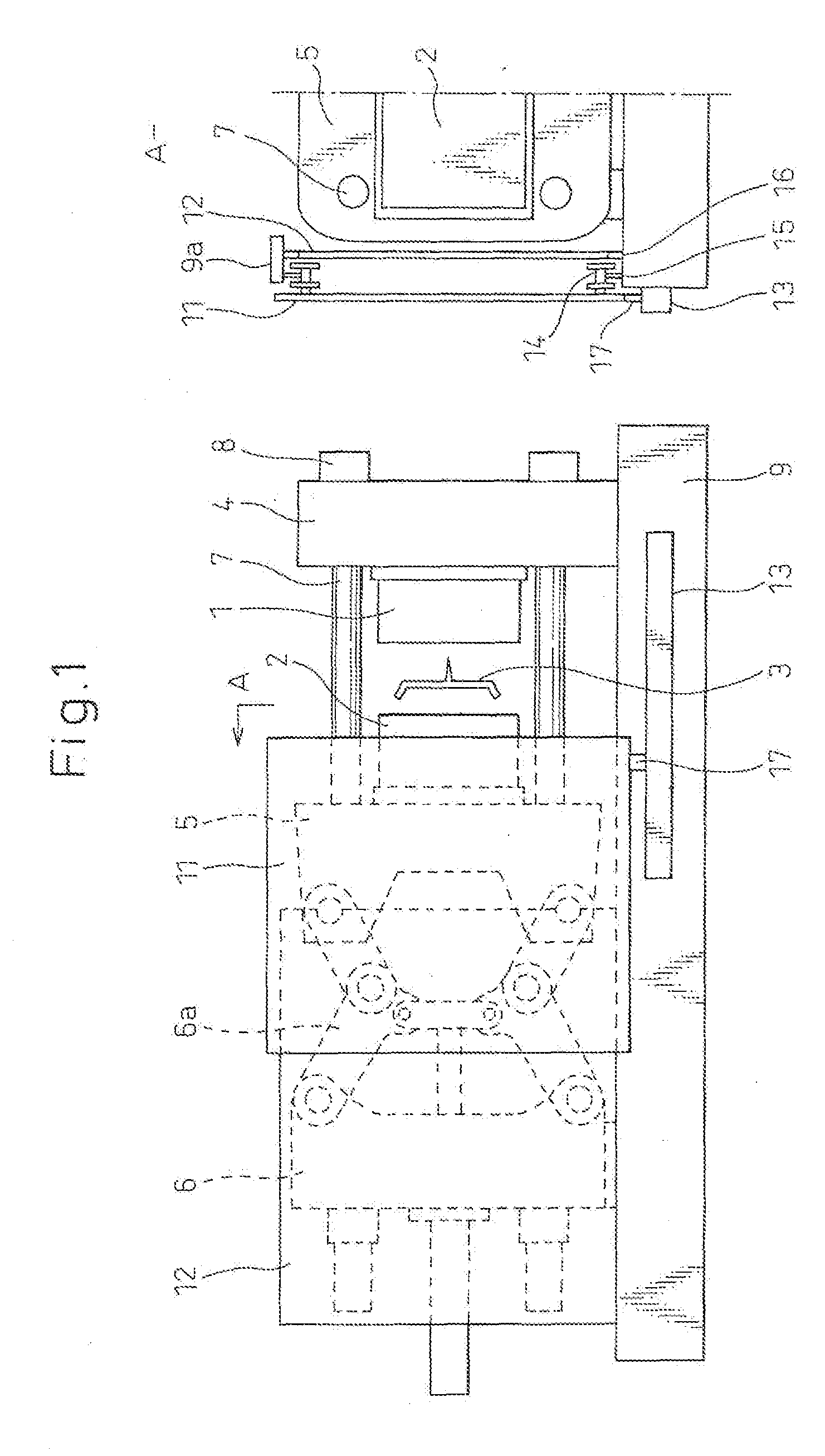

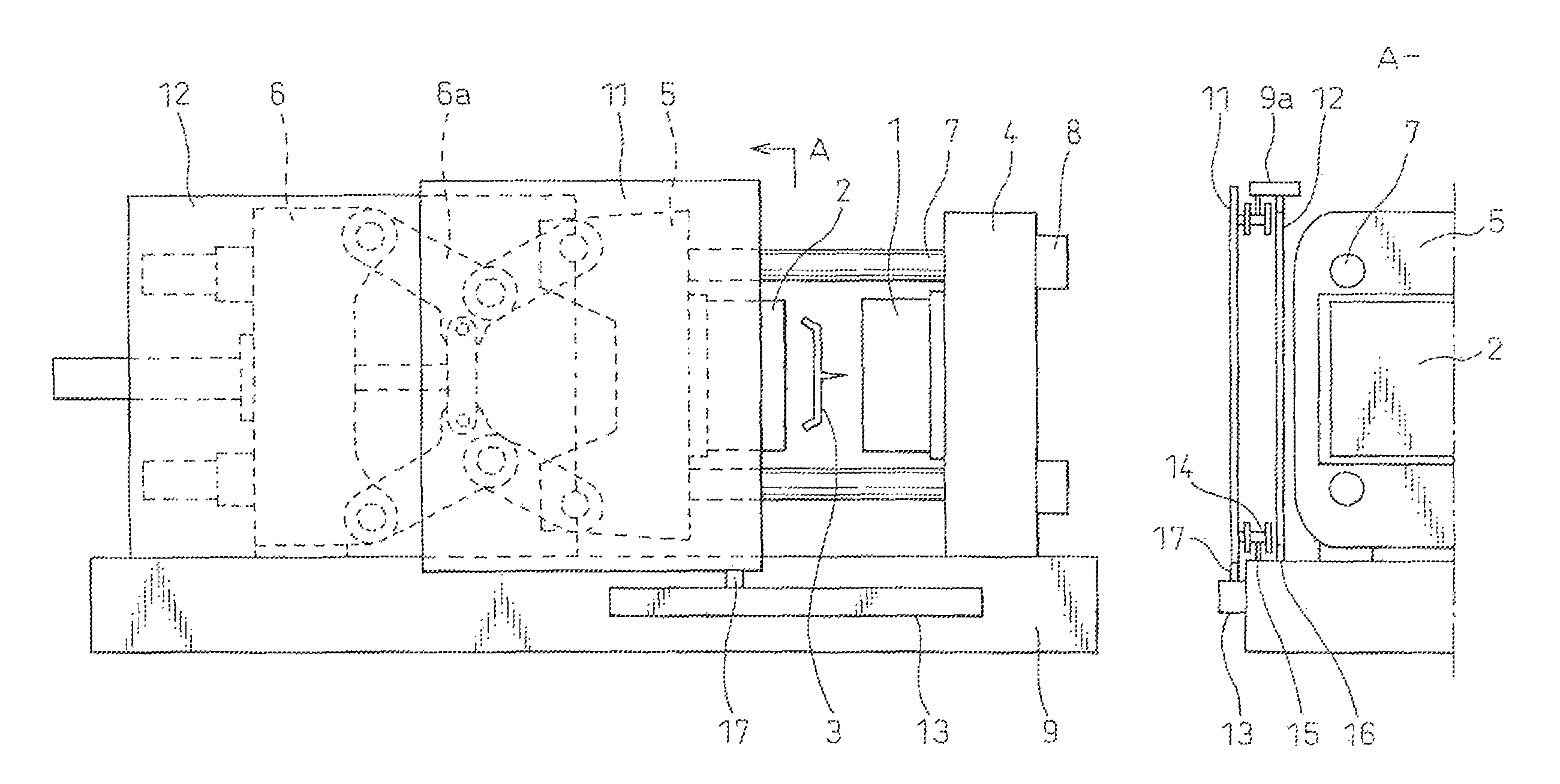

Safety door automatic opening/closing device in injection molding machine and the like and method of controlling the same

InactiveUS20100287841A1Reduce the burden onLow costMoulding plantsCasting safety devicesEngineeringInjection molding machine

A safety door automatic opening / closing device is capable of freely (arbitrarily) setting and controlling the opening / closing speed and the open position to shorten a waiting time required to open / close a safety door and capable of eliminating a touch switch; and a method of controlling the same.

Owner:UBE MASCH CORP LTD

Carpet floor mat having plastic migrating prevention formation, and associated injection mold

ActiveUS9248769B2Ease of mass productionInhibit migrationVehicle arrangementsLayered productsInjection mouldingMechanical engineering

An injection molded carpet mat includes a flexible base having an upper surface defining a carpet recess, and an opposite lower surface. A carpet sheet is secured in the carpet recess by being integrally formed with the base, and having a napped top surface, a bottom surface and a peripheral edge. The lower base surface having a plurality of spaced ribs supporting the carpet bottom surface adjacent the peripheral edge and defining a track on the lower base surface corresponding to the peripheral edge of the carpet sheet.

Owner:THERMOFLEX

Aqueous binder formulation for metal and ceramic feedstock for injection molding and aqueous coating composition

Low cost water based binder system was developed for shaping ferrous, nonferrous metals and / or ceramics parts by injection molding processes. The process comprises the steps of preparing a mixture containing a gel-forming powder comprising carrageenan, metal and / or ceramic powders, de-ionized water and a gel-strengthening additive. The mixture is injection molded to produce self-supporting articles. The present invention provides a direct compounding and molding of metal and / or ceramic feedstock. Additionally, a coating composition comprising gelatine, water and a metal and / or ceramic powder is used to form coating layers on selected materials.

Owner:UNITED MATERIALS TECH

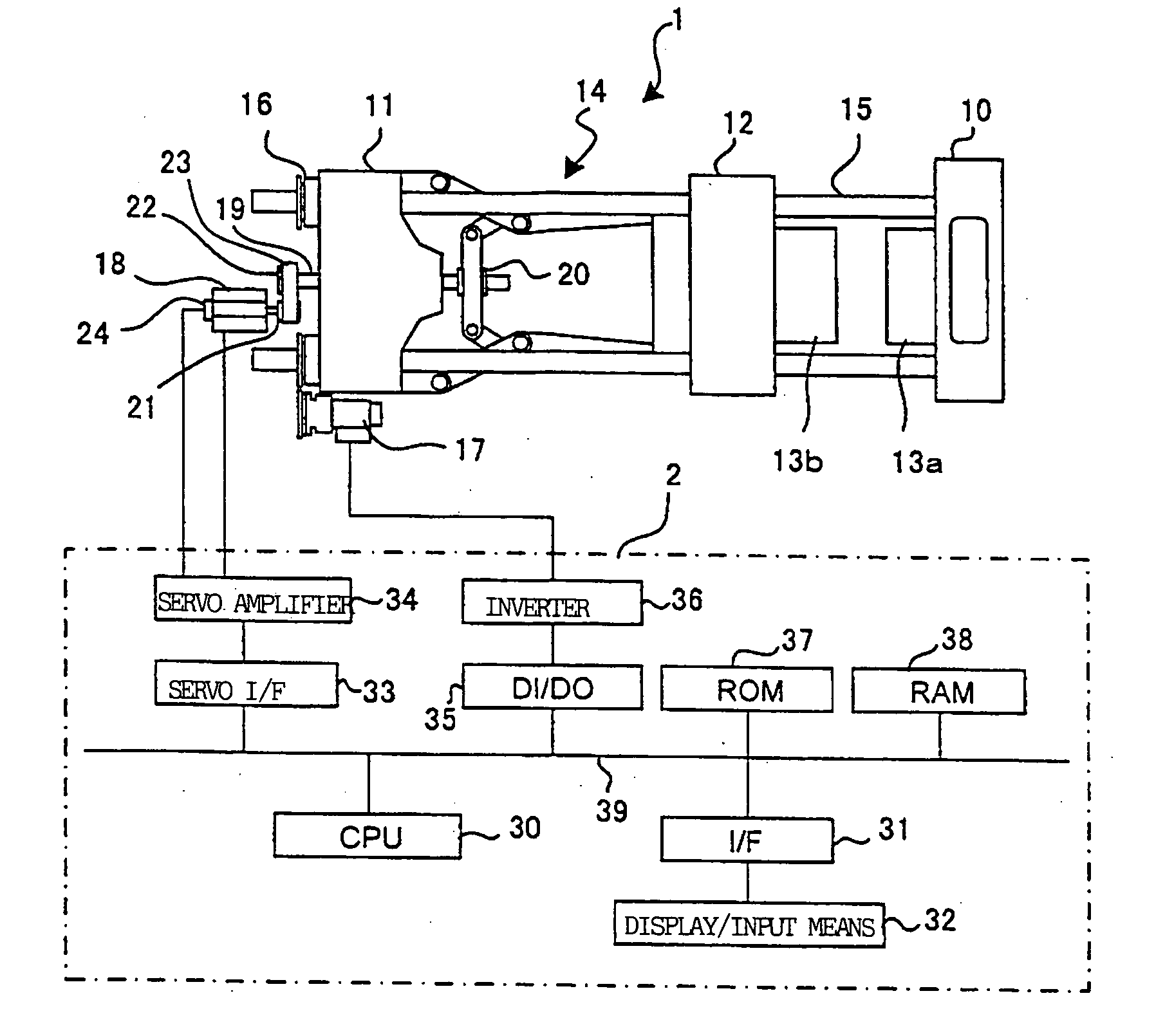

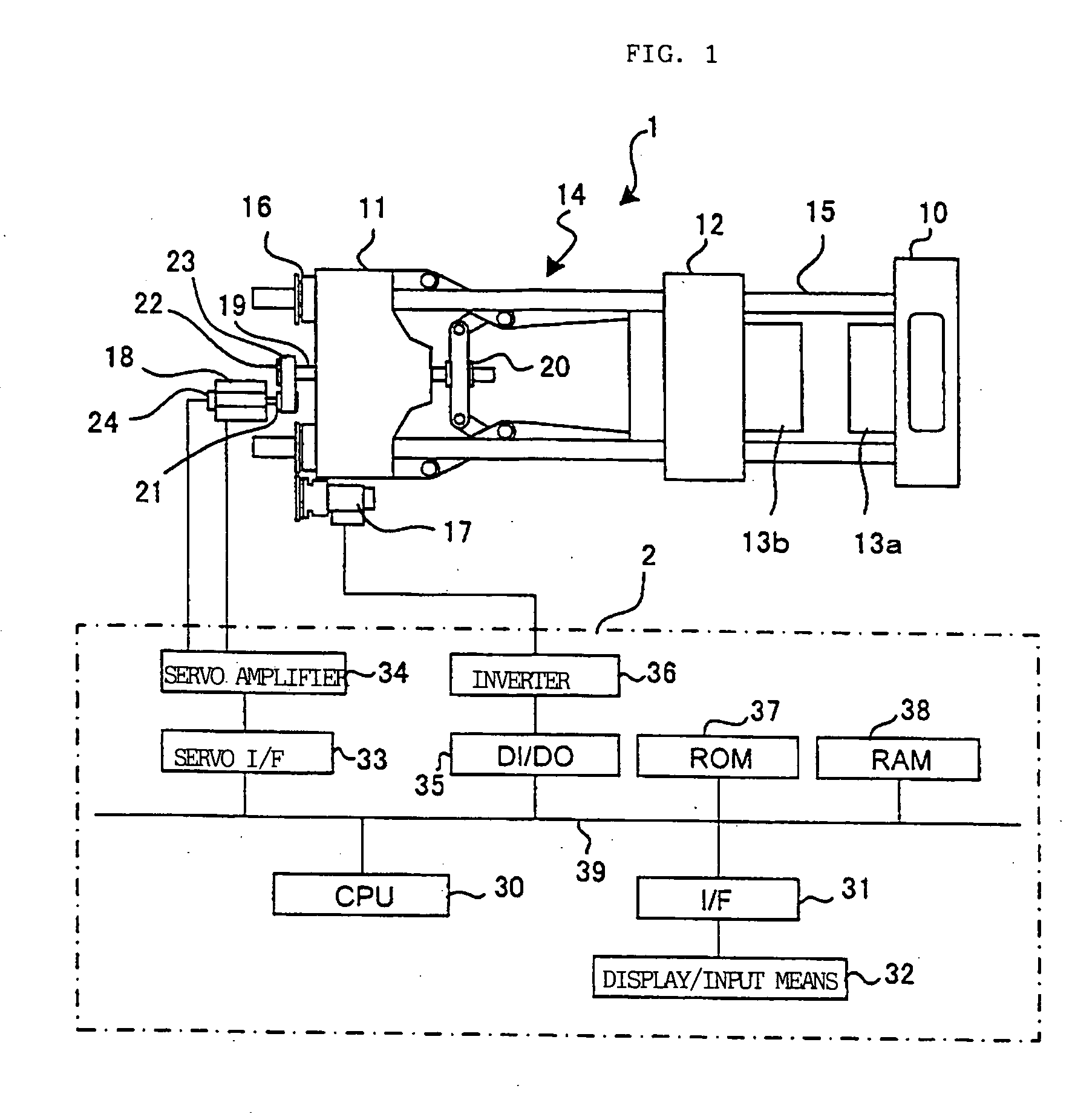

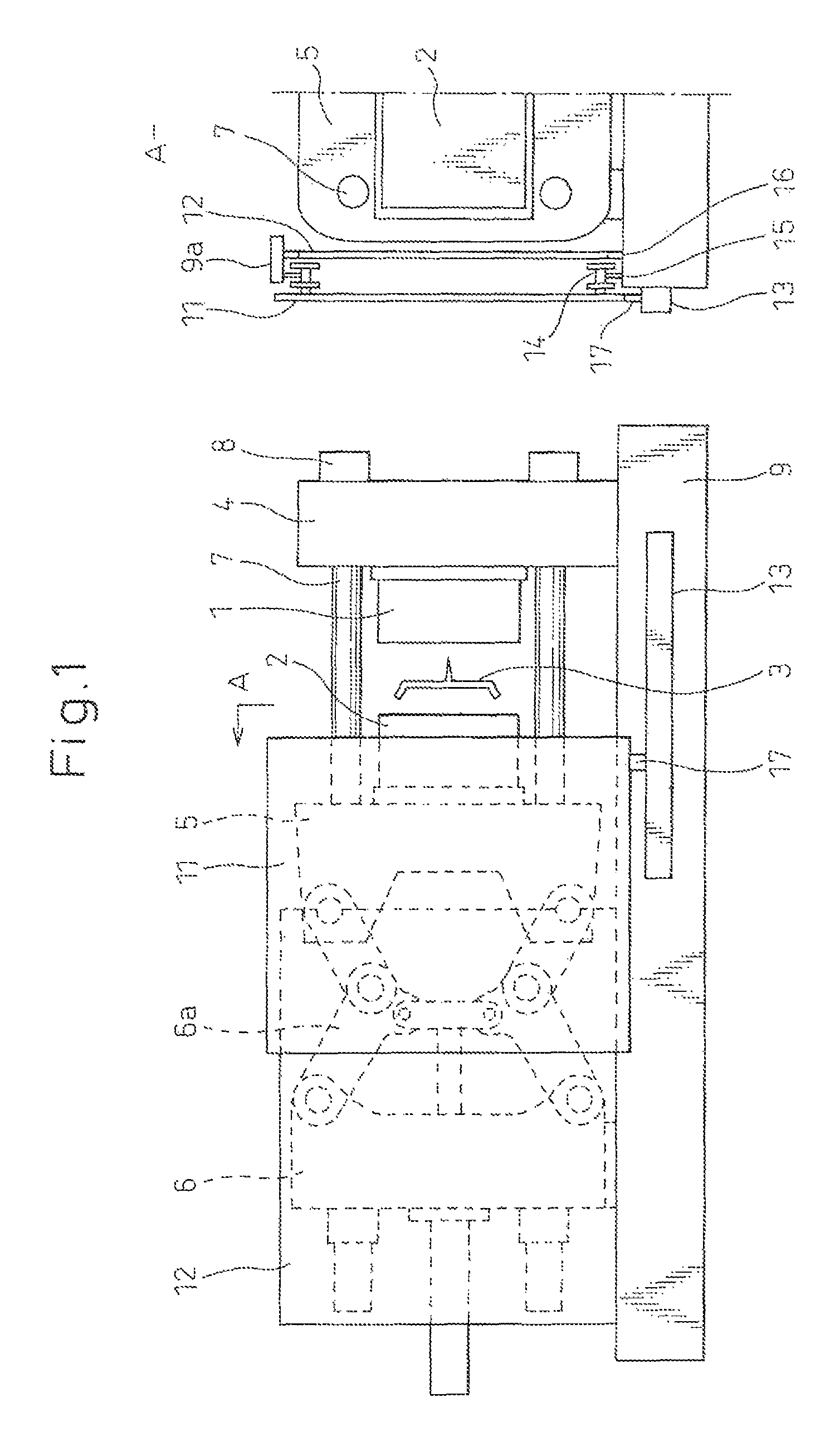

Controller of injection molding machine

InactiveUS20050244537A1Reduce molding cycle timeShorten the timeAuxillary shaping apparatusFood shapingContact positionCrosshead

A crosshead position Cf for obtaining a set mold clamping force is obtained based on a mold touch position Ct obtained in mold clamping process in immediately preceding molding cycle, and a crosshead is allowed to move to the position Cf. During that time, it is determined whether a load La of a servomotor for mold clamping operation which drives a toggle mechanism exceeds a judgment load Ls, and a crosshead position Ca when the load La exceeds the judgment load Ls is stored as a mold touch position. In the next molding cycle, a crosshead position Cf where the set mold clamping force is obtained is obtained based on this stored mold touch position.

Owner:FANUC LTD

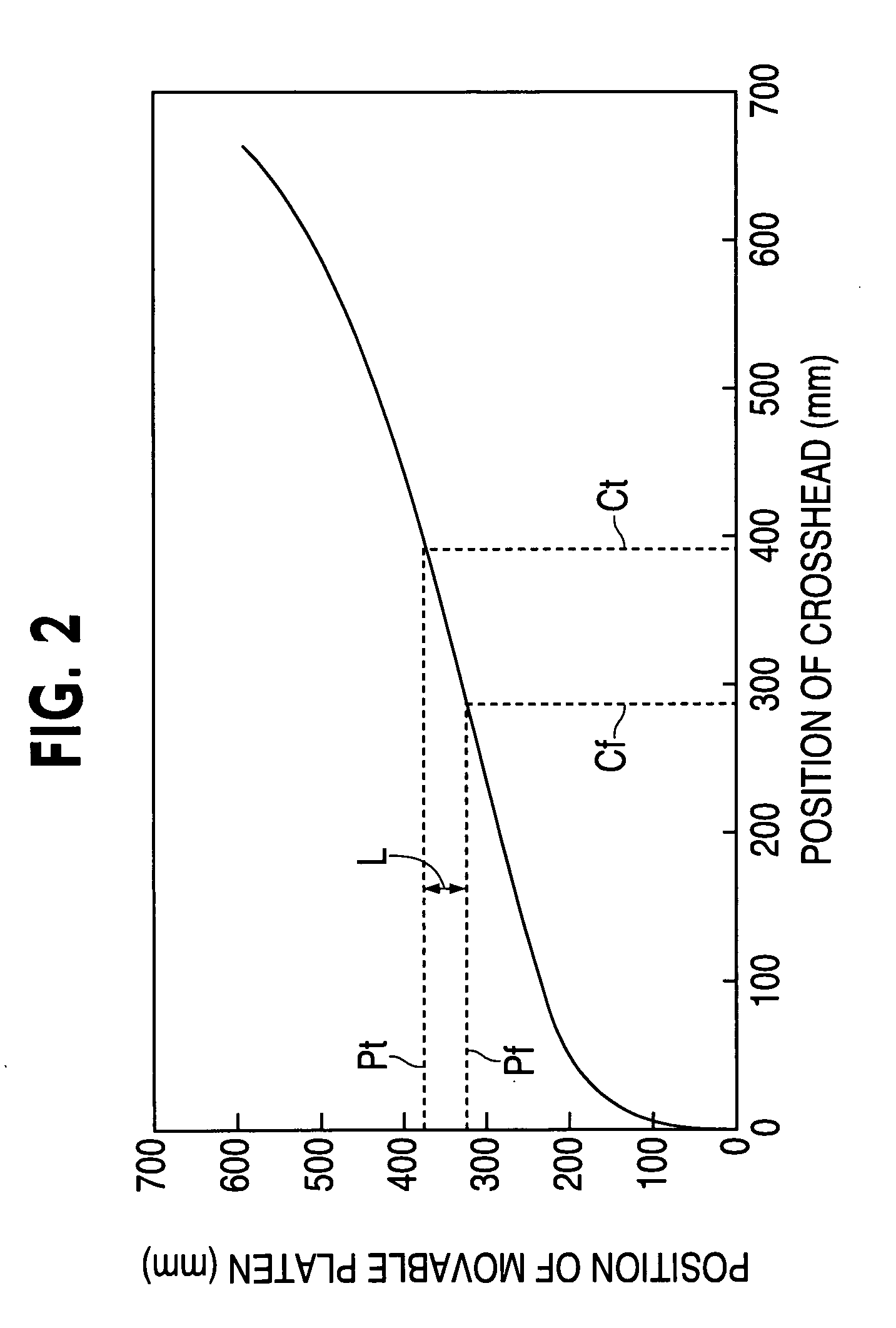

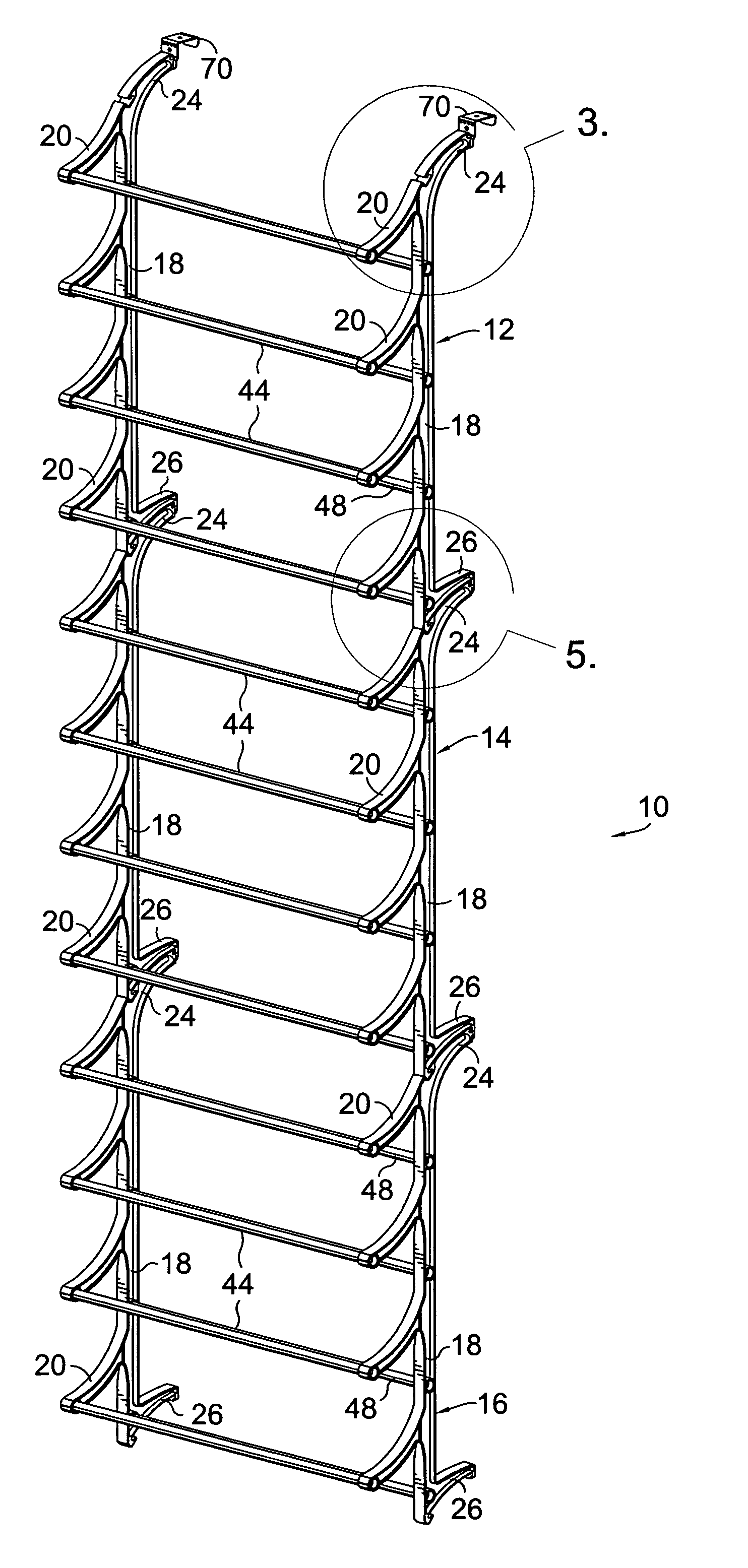

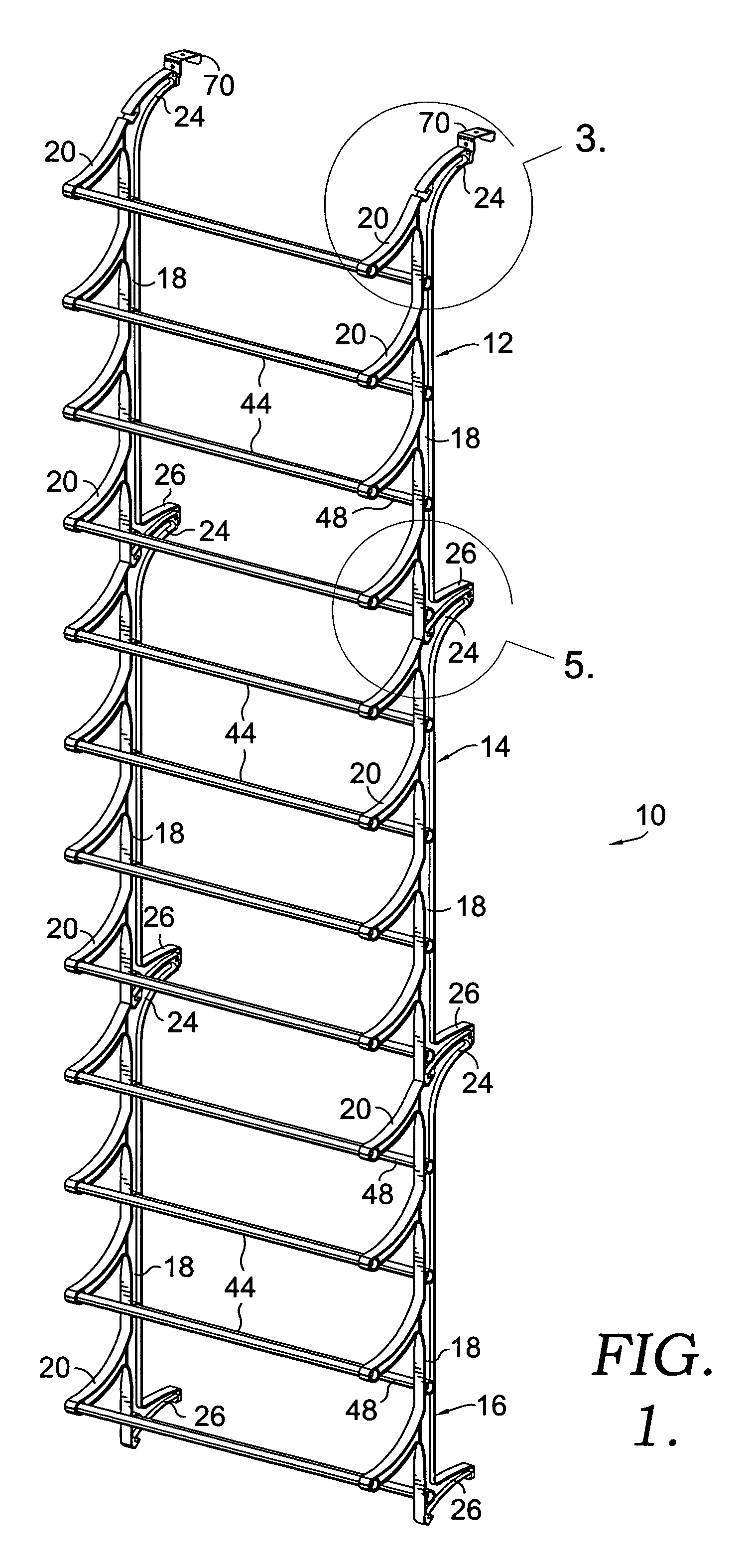

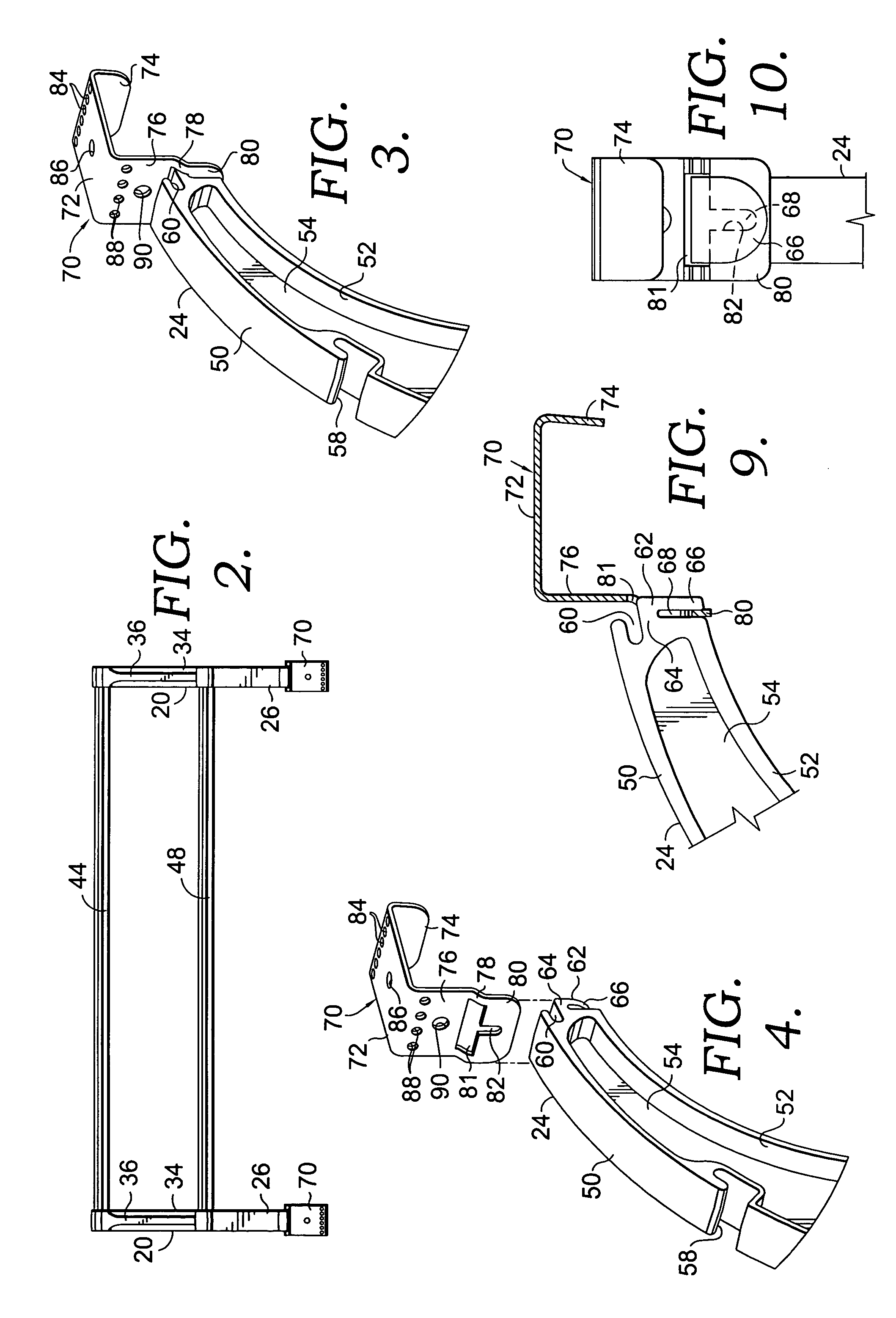

Hanging shoe rack with improved structural features

InactiveUS7293662B2Low costReduce molding cycle timeWardrobesShow shelvesMaterial requirementsUltimate tensile strength

A hanging shoe rack for a closet door or other vertical surface. Frame sections have opposite sides provided with support arms that taper from top to bottom for reduced material requirements. The sections are connected by bars and feet having L-shaped tongues fitting in L-shaped slots with long curved surfaces in contact for enhanced strength. The bars that receive hanger brackets have strong curved connections with the frame sides. The tongues on the bars that hook to the brackets are reinforced by tabs that fit closely in notches in the brackets to resist side to side sway.

Owner:LYNK I NC

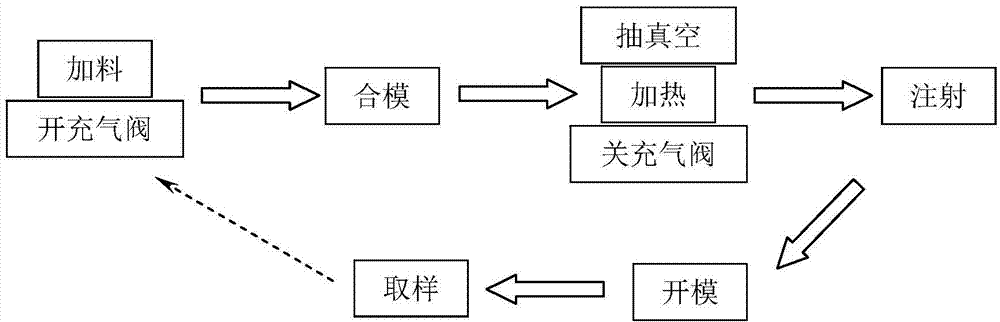

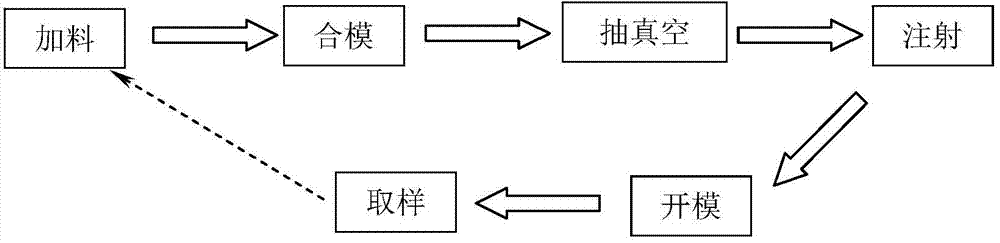

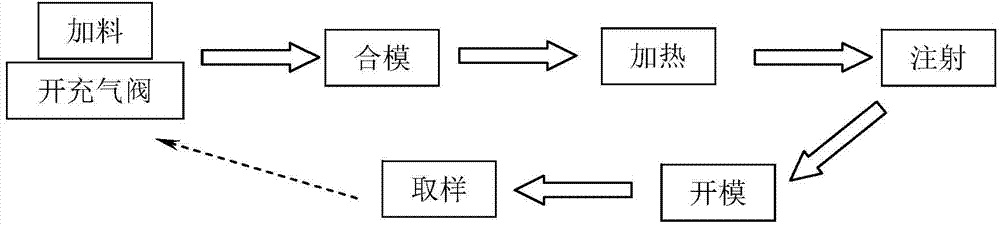

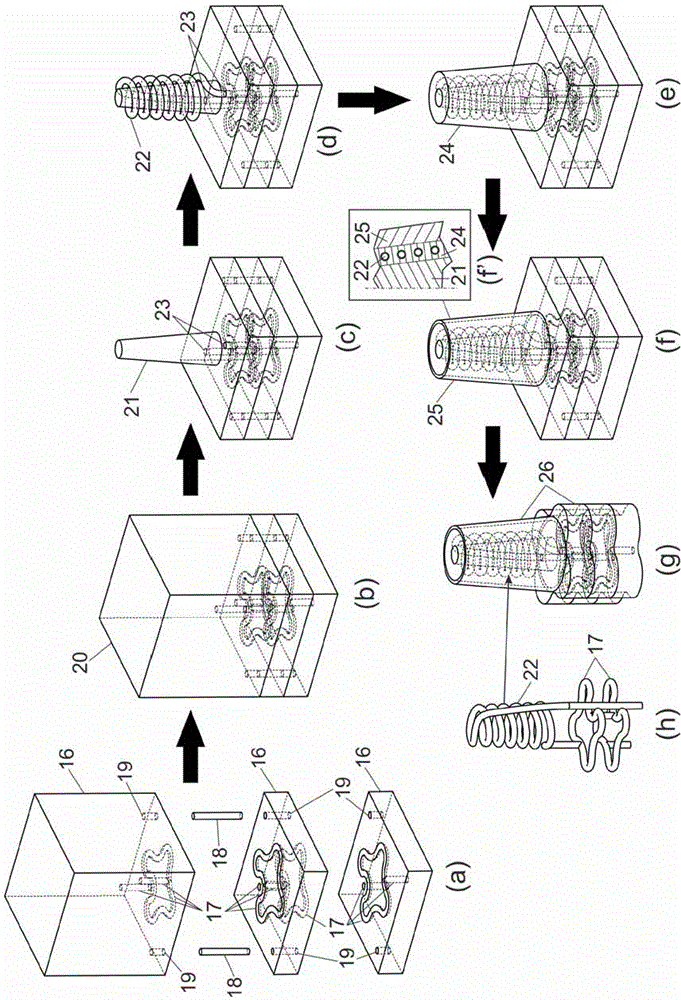

Forming method of amorphous alloy

The invention discloses a forming method of amorphous alloy. The method includes: 1, under protection of inertial gas, heating an amorphous alloy ingot in a crucible in a vacuum chamber; 2, evacuating the vacuum chamber to obtain vacuum pressure of the vacuum chamber, being below 5000Pa, at the temperature lower than a melting point of the amorphous alloy ingot; 3, if the vacuum pressure is obtained in the step 2, continuing to heat the amorphous alloy ingot in the crucible until that the amorphous alloy ingot melts; 4, adding melt obtained in the step 3 under the vacuum condition, into a forming mold so as to obtain a formed amorphous alloy product. The forming method has the advantages that forming cycle can be shortened, production efficiency is improved and the formed amorphous alloy has good quality.

Owner:BYD CO LTD

Polymer compositions and method for producing a molded body

A polymer composition of matter is disclosed which includes a thermoplastic polymer and a fluorine-containing polymer. The thermoplastic polymer is an amorphous non-fluorinated thermoplastic polymer or a crystalline non-fluorinated thermoplastic polymer with a melting point of 180° C. or higher. The fluorine-containing polymer has a zero shear viscosity at 340° C. of 0.2 Pa.s or greater and less than 5000 Pa.s, and is present to the extent of 0.005-2 mass % of the total of the thermoplastic polymer and the fluorine-containing polymer.

Owner:DAIKIN IND LTD

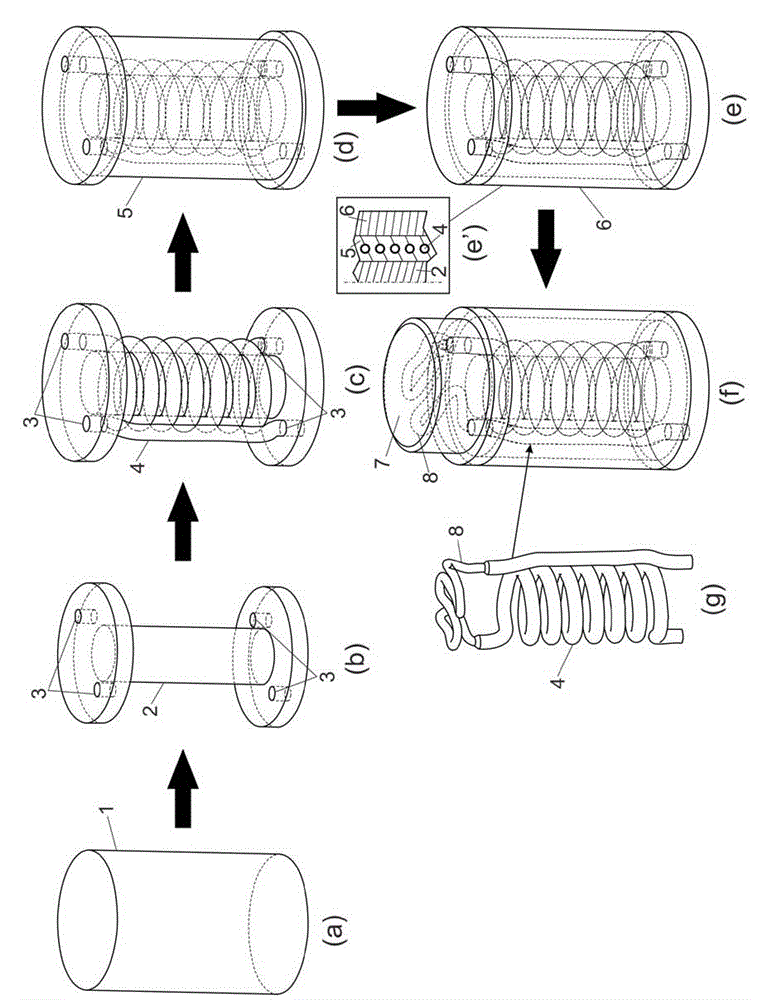

Mold with shape follow-up temperature control pipeline and manufacturing method thereof

ActiveCN105798561ARapid and uniform coolingCutting costsTemperature controlComputer-aided engineering

The invention provides a mold with a shape follow-up temperature control pipeline and a manufacturing method thereof. The manufacturing method comprises the steps that 1, the temperature distribution and change of the mold during cooling are simulated through computer-aided engineering; 2, a mold bottleneck position which is slowest in heat dissipation is calculated; and 3, according to the size dimension, the geometrical shape and the precise requirement condition of the position, the shape follow-up temperature control pipeline is manufactured in the mold by using the processing technology, and the shape of the shape follow-up temperature control pipeline is attached to the profile of the surface of the mold. According to the mold with the shape follow-up temperature control pipeline, a molded product can be quickly and uniformly cooled.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Aqueous binder formulation for metal and ceramic feedstock for injection molding and aqueous coating composition

InactiveUS20060054856A1Low costHigh green strengthStarch adhesivesPiezoelectric/electrostrictive device material selectionWater basedCarrageenan

Low cost water based binder system was developed for shaping ferrous, nonferrous metals and / or ceramics parts by injection molding processes. The process comprises the steps of preparing a mixture containing a gel-forming powder comprising carrageenan, metal and / or ceramic powders, de-ionized water and a gel-strengthening additive. The mixture is injection molded to produce self-supporting articles. The present invention provides a direct compounding and molding of metal and / or ceramic feedstock. Additionally, a coating composition comprising gelatine, water and a metal and / or ceramic powder is used to form coating layers on selected materials.

Owner:UNITED MATERIALS TECH

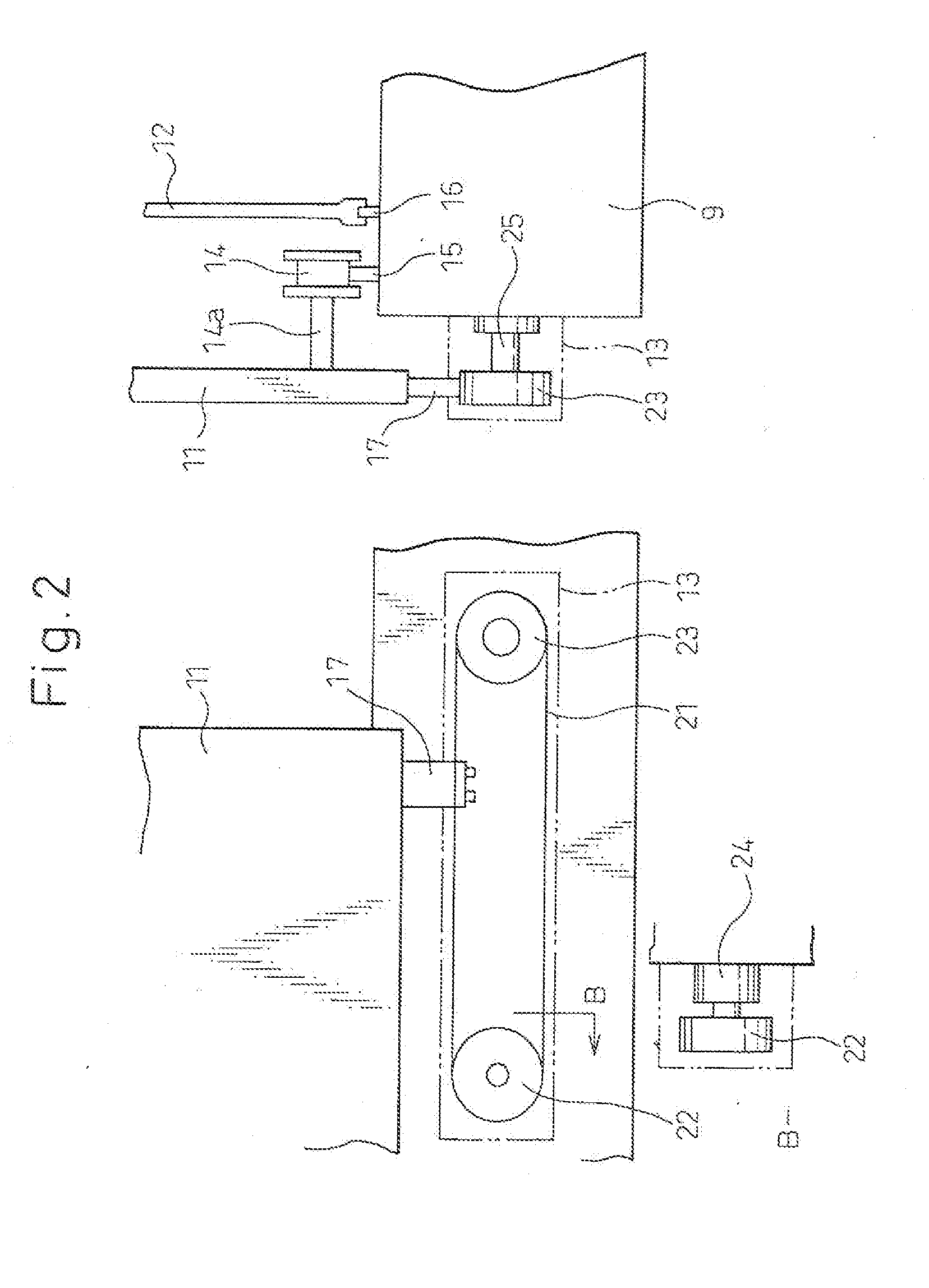

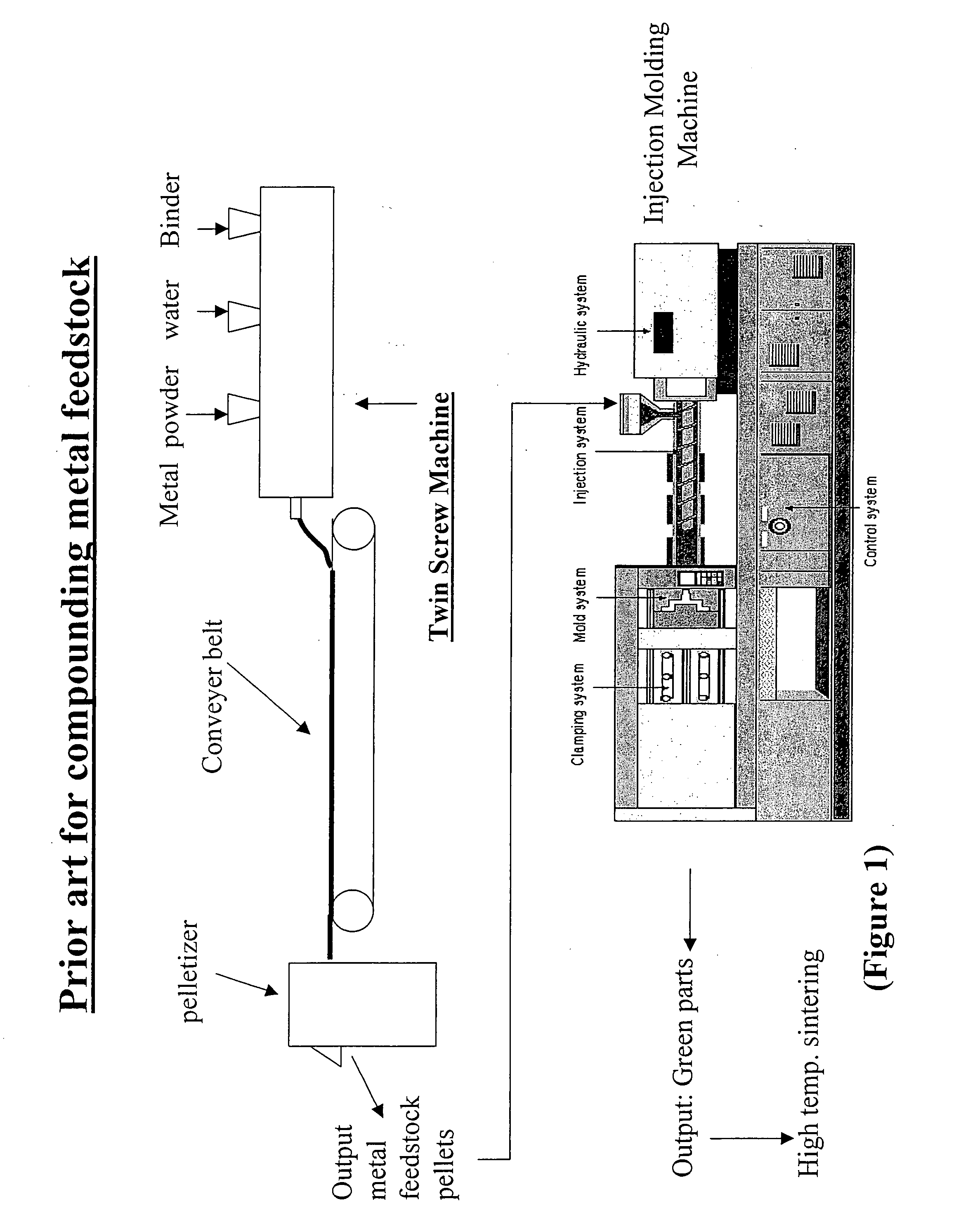

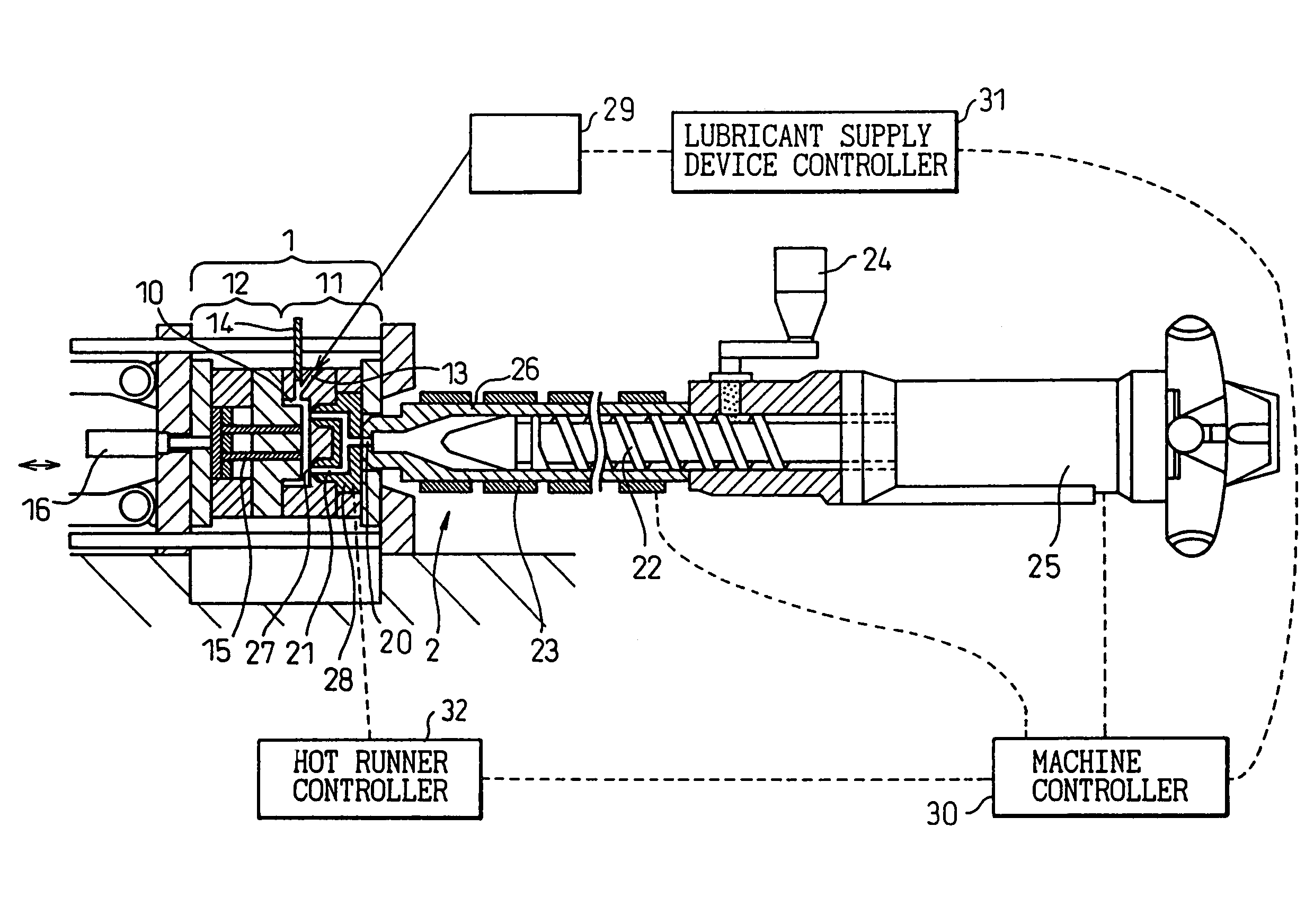

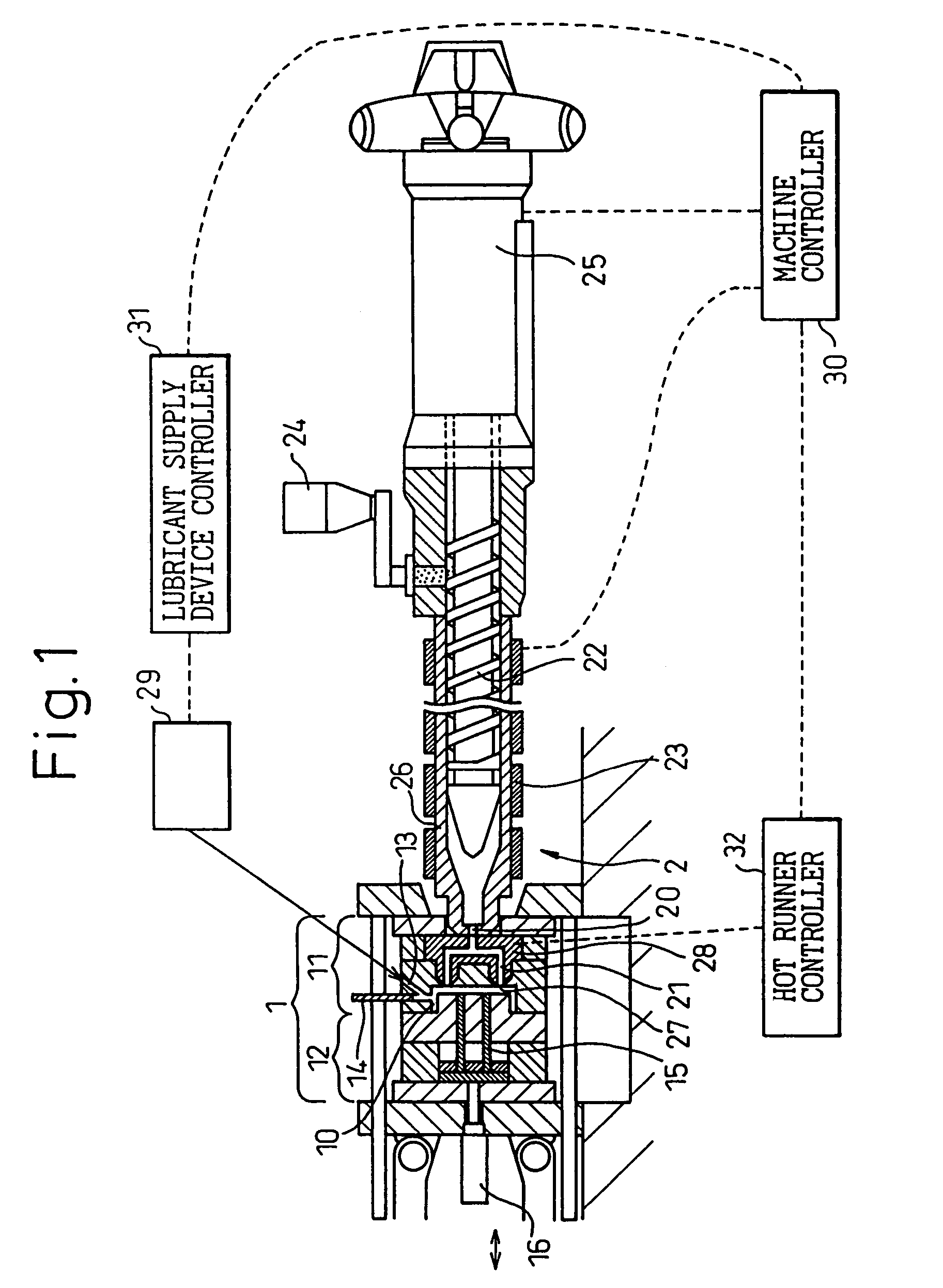

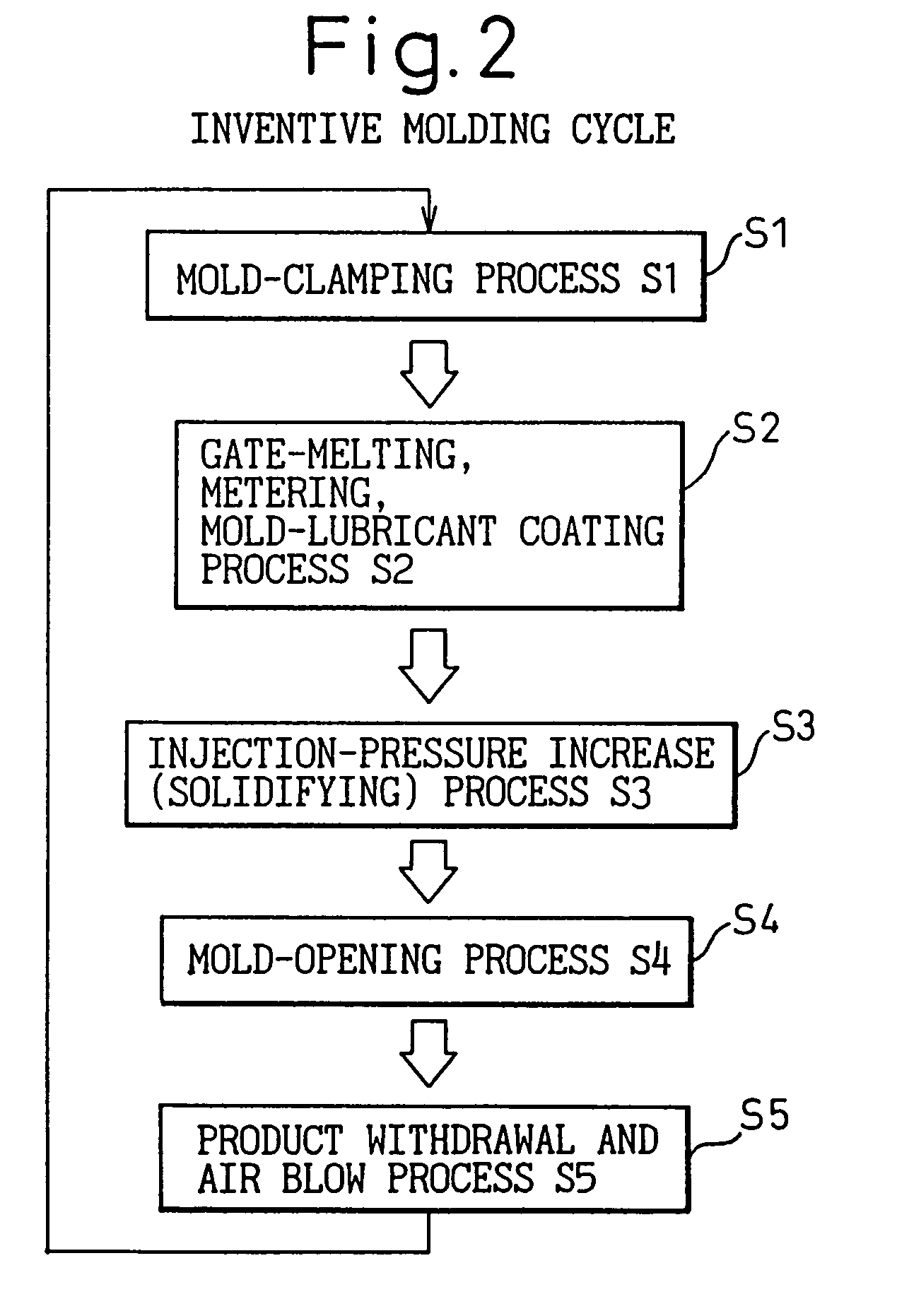

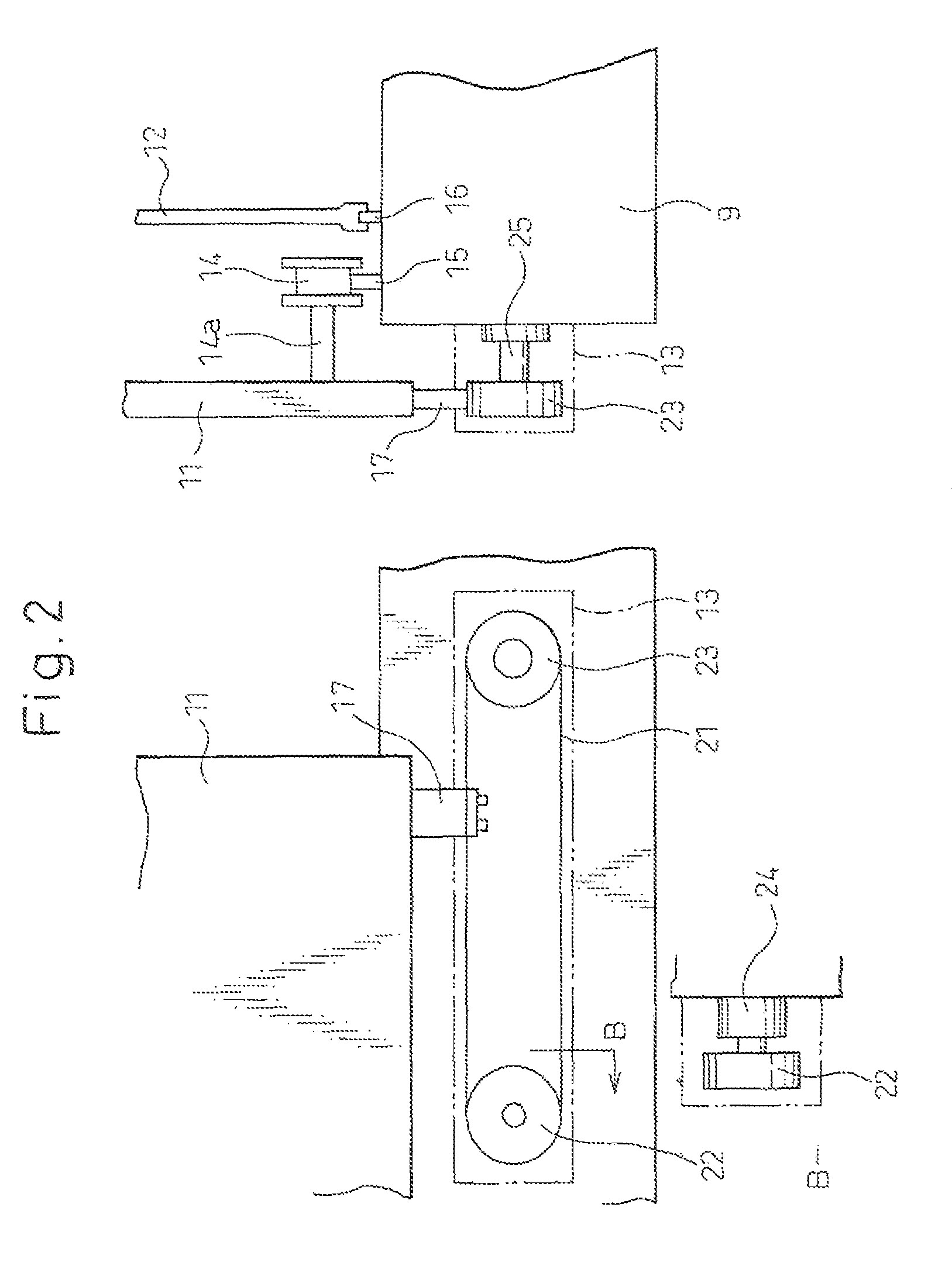

Metal molding method and apparatus

InactiveUS7331375B2Preventing the lubricant from being splashed outwardAvoid pollutionCasting safety devicesFoundry mouldsInjection pressureHot runner

According to the present invention, between the mold-clamping process S1 in which the mold 1 is closed and the injection-pressure increase (solidifying) process S3, the gate-melting process for heating the hot runner 21 to melt the plug (metallic material) of the gate 27, the mold-lubricant coating process for spraying the lubricant onto the wall surface of the cavity 10, and the material-metering process are simultaneously carried out in parallel to each other. Thus, the molding cycle time can be reduced to a great extent.

Owner:DENSO CORP

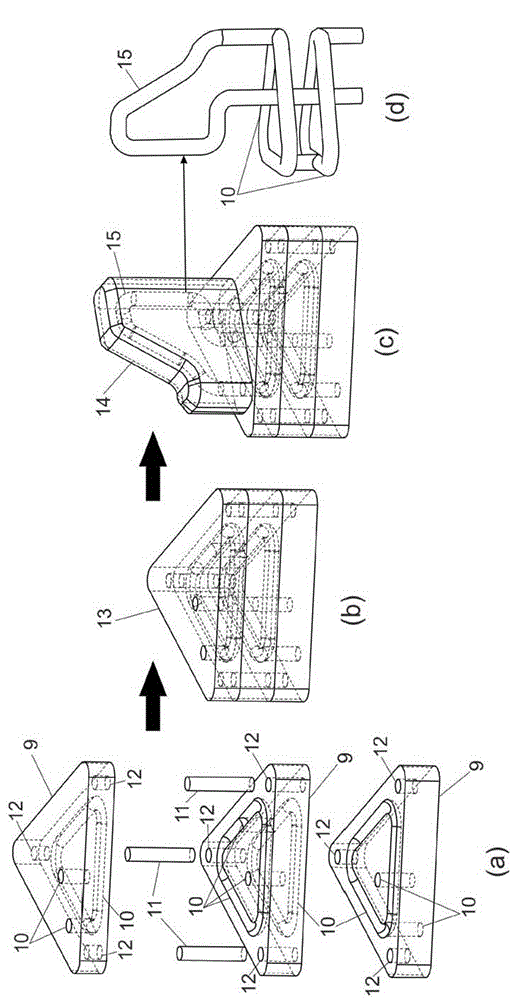

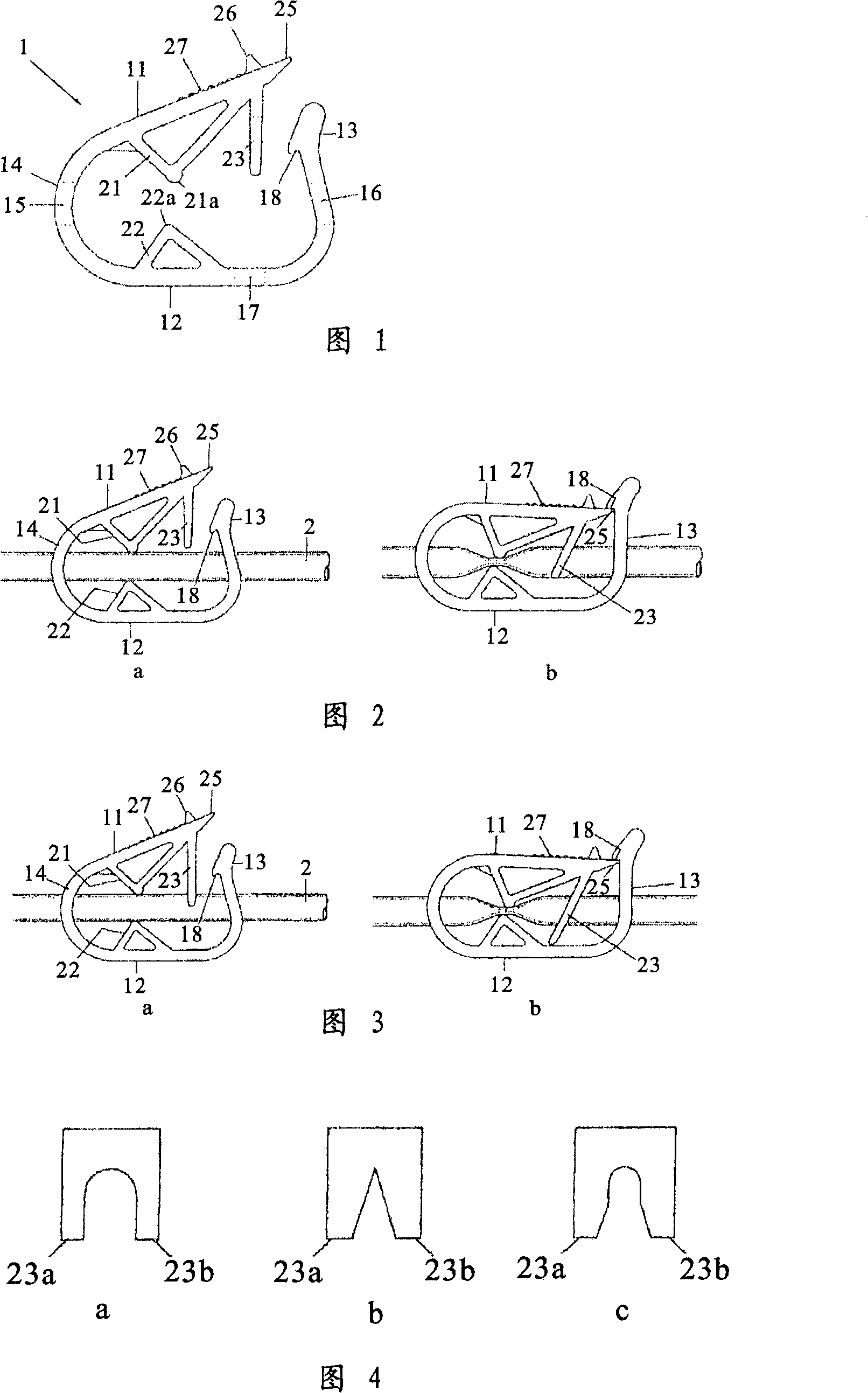

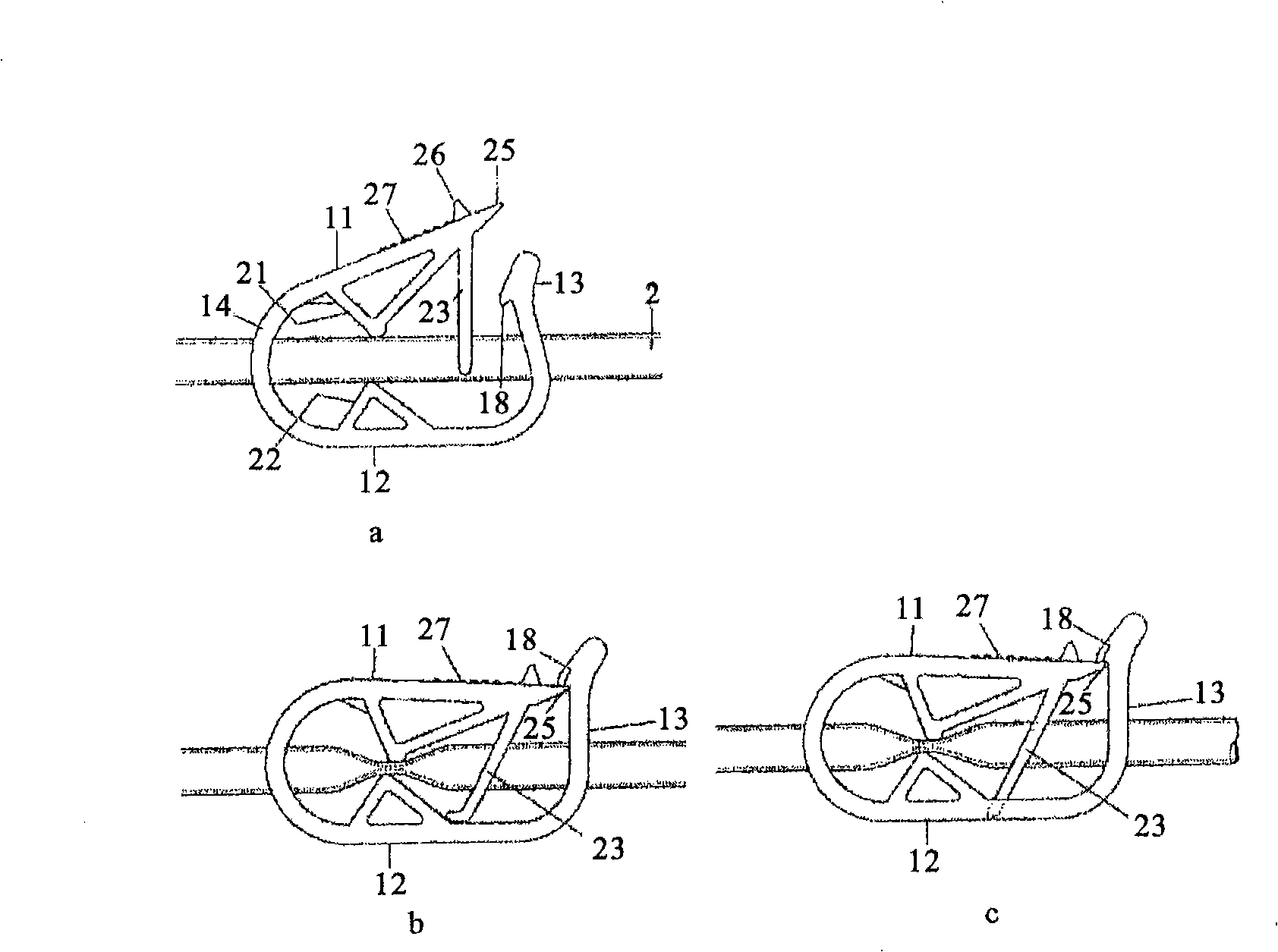

Clamping device for an operation

InactiveCN101352589ACheap manufacturingReduce molding cycle timeIntravenous devicesFlow controlMechanical engineering

Owner:HANACO MEDICAL CO LTD

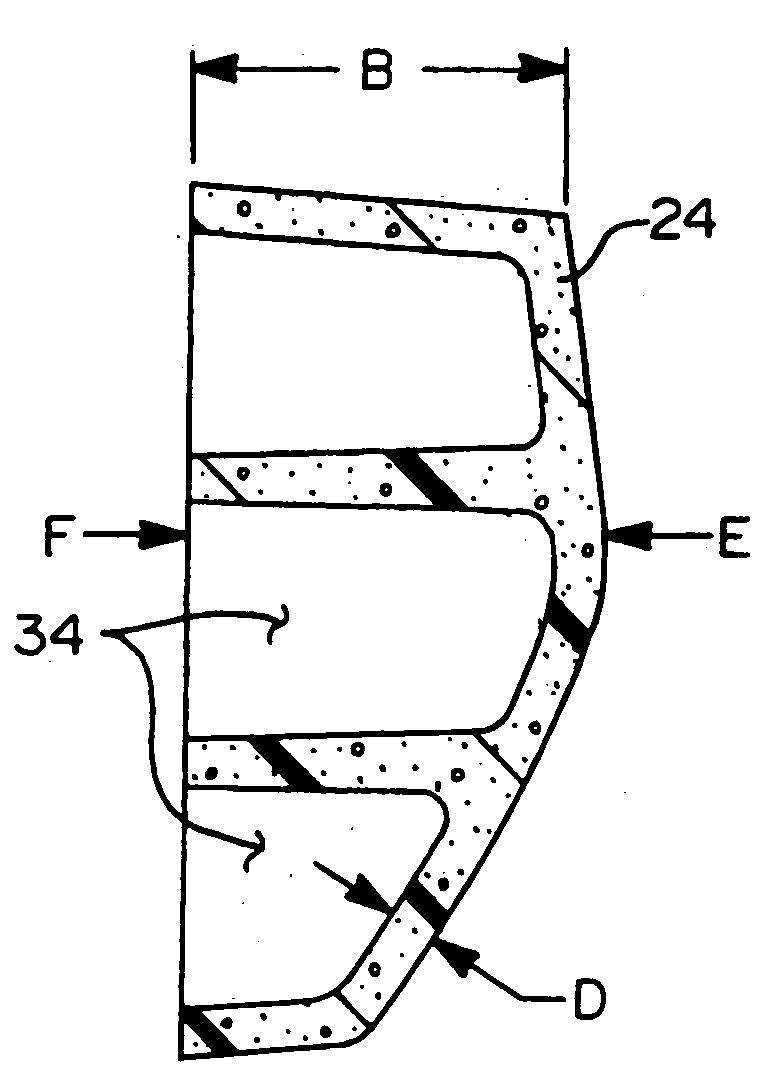

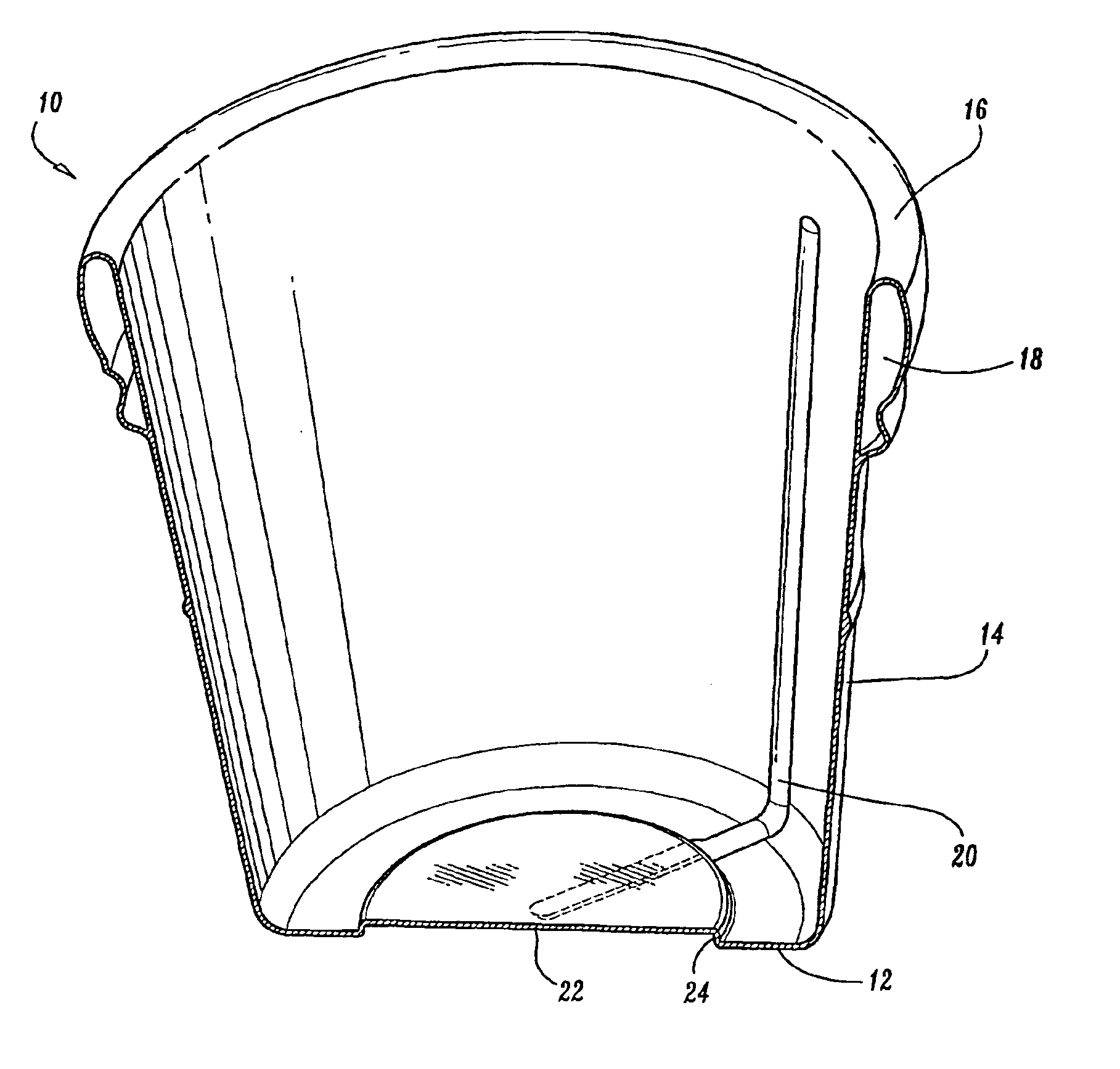

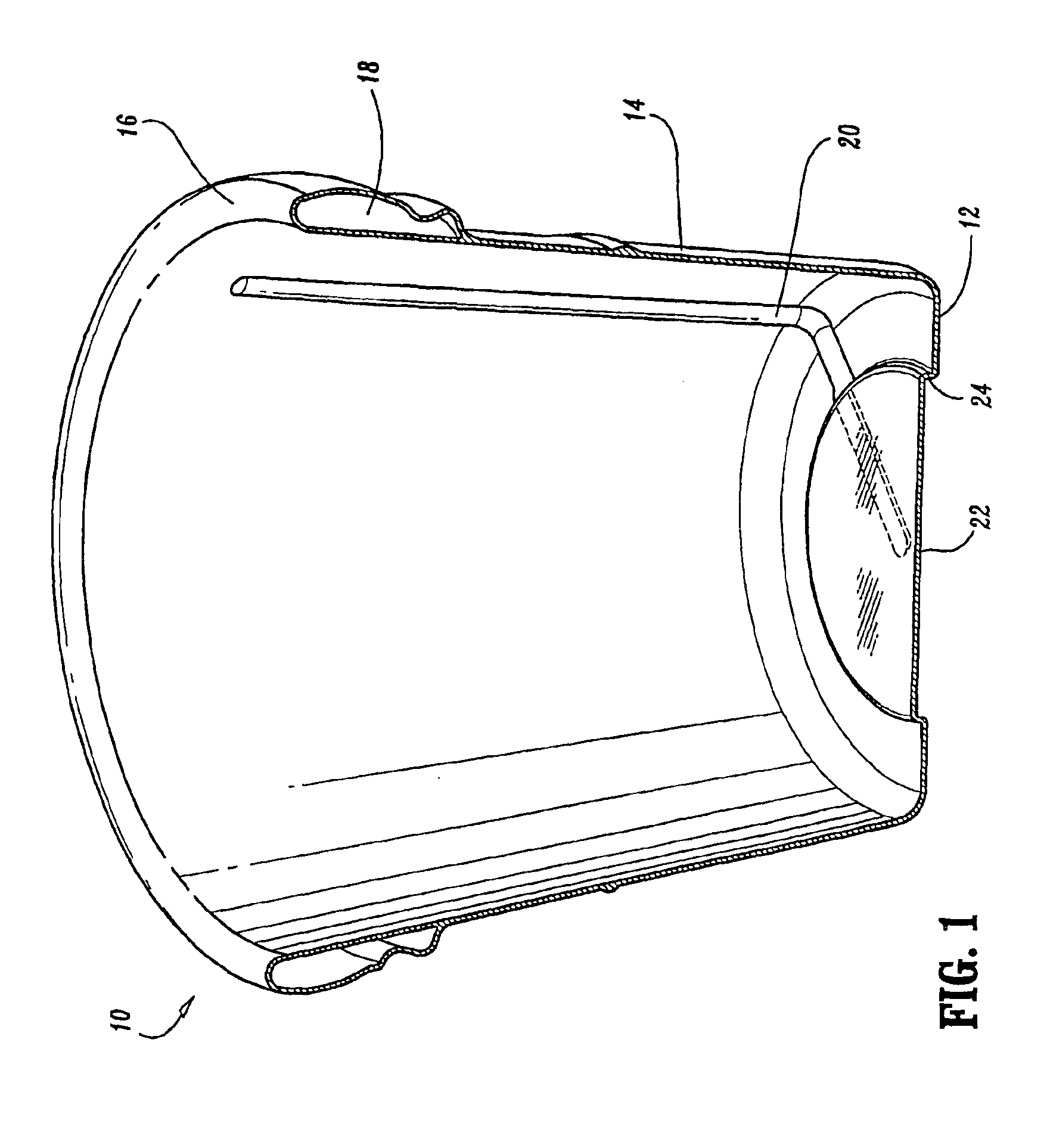

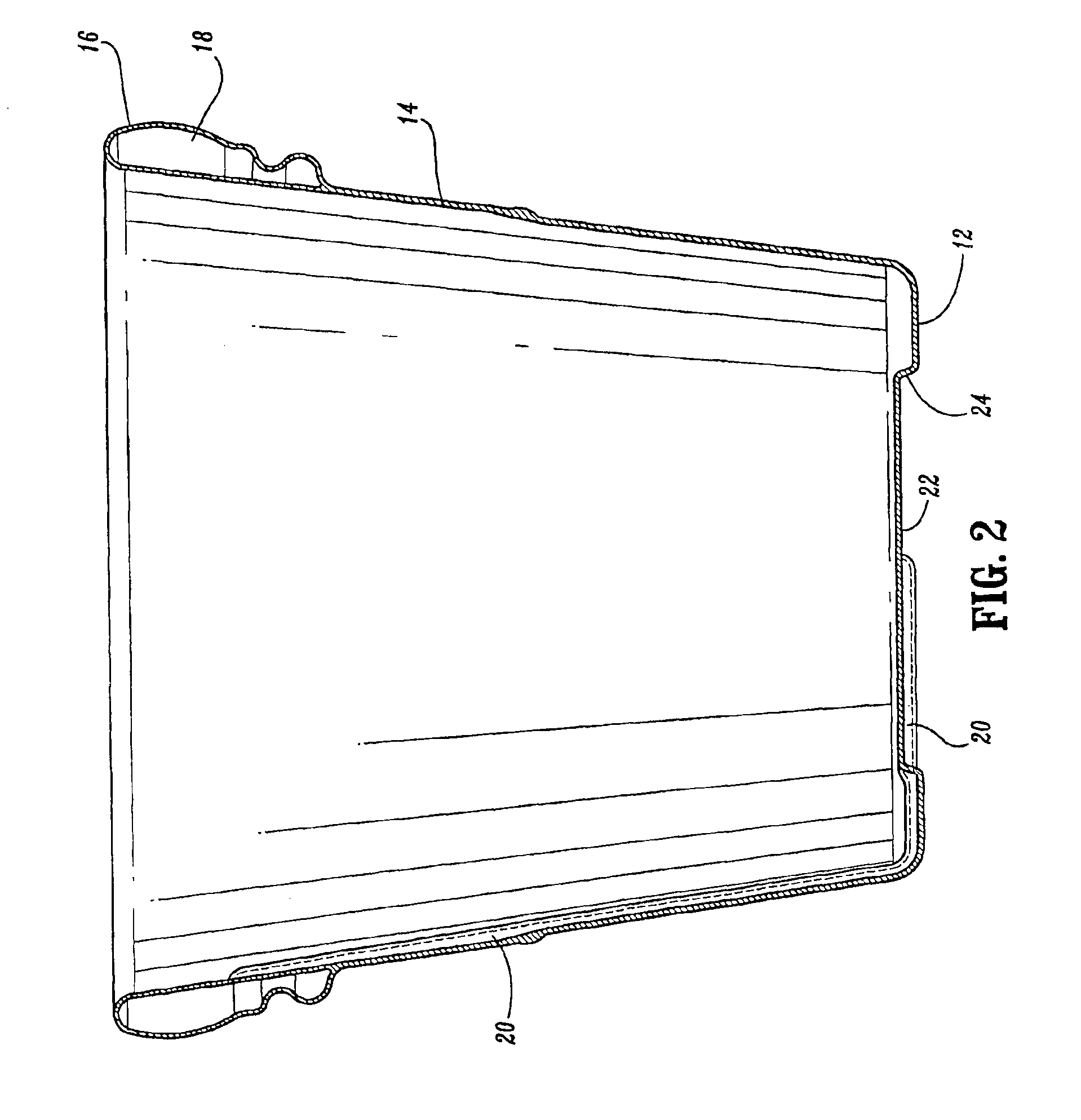

Molded article having hollow rim portion and process for producing articles

InactiveUS6887406B2Minimizes visible volumetric shrinkageReduces a clamp tonnageEnvelopes/bags making machineryLayered productsEngineeringInjection molding machine

A process for producing an injection molded article with a hollow rim portion in an injection molding machine including the steps of injecting a short shot of injection molding material into a mold via an injection nozzle, permitting a mold cavity to fill in an unbalanced manner as a result of a gas channel formed in a wall of the mold, closing the injection nozzle; and injecting a pressurized gas into the short shot of injection molding material, wherein the pressurized gas travels through the gas channel into a rim portion of the mold thereby expanding the injection molding material throughout the mold and simultaneously creating a hollow cavity within the rim portion of the mold.

Owner:IAMS +1

Safety door automatic opening/closing device in injection molding machine and the like and method of controlling the same

InactiveUS8336601B2Shorten the timeReduce molding cycle timeDoors/windowsMoulding plantsEngineeringInjection molding machine

A safety door automatic opening / closing device is capable of freely (arbitrarily) setting and controlling the opening / closing speed and the open position to shorten a waiting time required to open / close a safety door and capable of eliminating a touch switch; and a method of controlling the same.

Owner:UBE MASCH CORP LTD

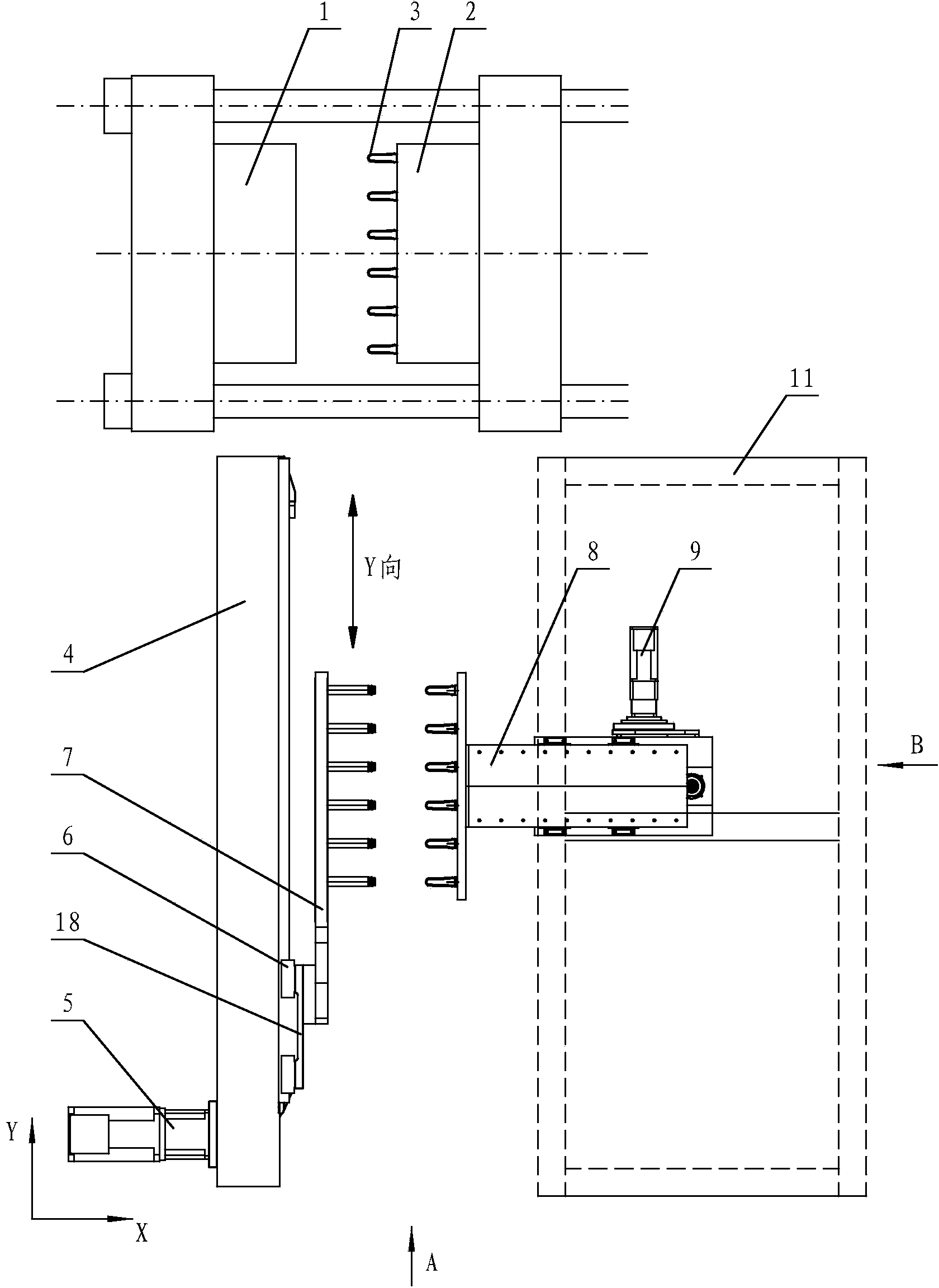

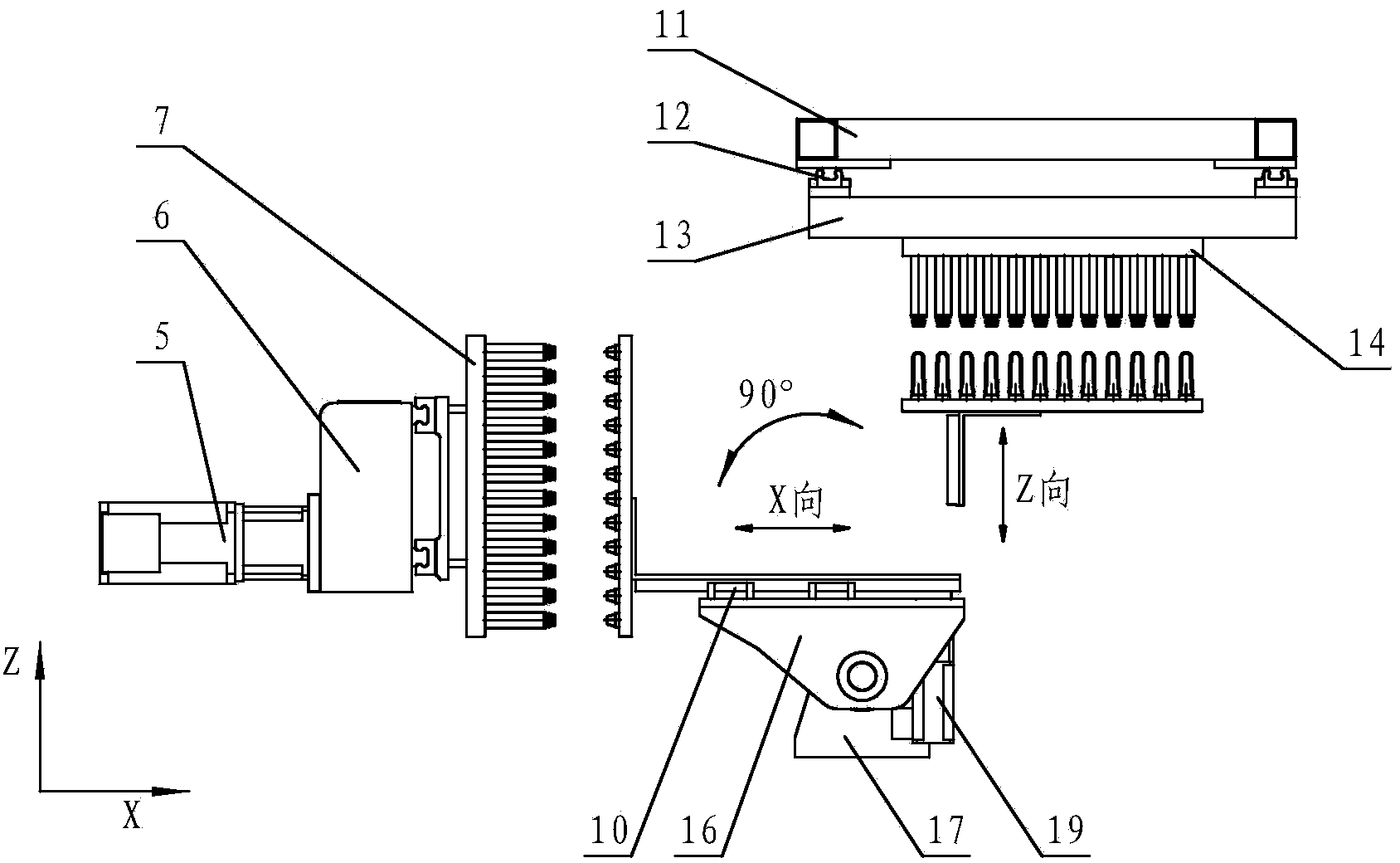

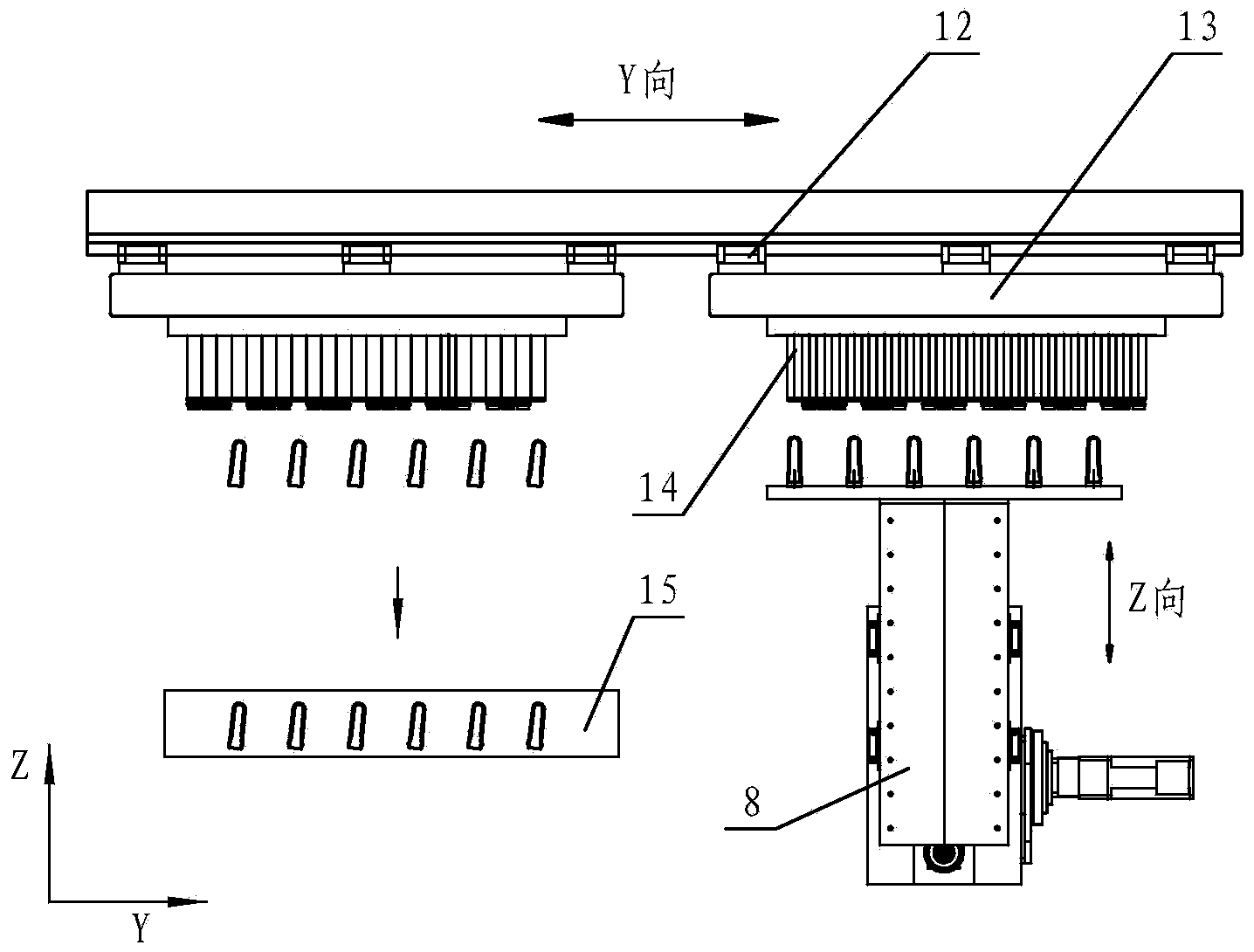

Bottle embryo taking out and cooling system

The invention relates to a bottle embryo taking out and cooling system. The system comprises a fixing die and a moving die that are arranged on an injection molding machine and a bottle embryo arranged between the fixing die and the moving die, and further comprises a taking embryo cooling device, wherein the taking embryo cooling device comprises a fixing seat, a first ball linear guideway, a sliding block seat, and a taking out jig that contains a cooling device and a servo motor belt transmission mechanism; the fixing seat is connected with the head plate of the injection molding machine; one end of the fixing seat faces the part between the fixing die and the moving die; the servo motor belt transmission mechanism is arranged on the fixing seat; the first ball linear guideway is arranged on the fixing seat; a first sliding block is arranged on the first ball linear guideway in a sliding manner; the sliding block seat is arranged on the first sliding block, and driven by the servo motor belt transmission mechanism to perform a linear to-and-fro movement on the fixing seat; the taking out jig that contains a cooling bottle embryo and a vacuum extraction bottle embryo is mounted at the front end of the sliding block seat. According to the invention, the system has the characteristics of flexibility for operation, high operating speed, low driving power, small controlling difficulty and stability for operation.

Owner:GUANGDONG YIZUMI HIGH SPEED PACKAGING SYST COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com