Bottle embryo taking out and cooling system

A technology of cooling system and preform, applied in the field of preform take-out and cooling system, which can solve the problems of shortened preform production cycle time, unstable repeated positioning of the end point, and affecting the stability of the production system, so as to shorten the molding cycle time and shorten the Cooling time, simple structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

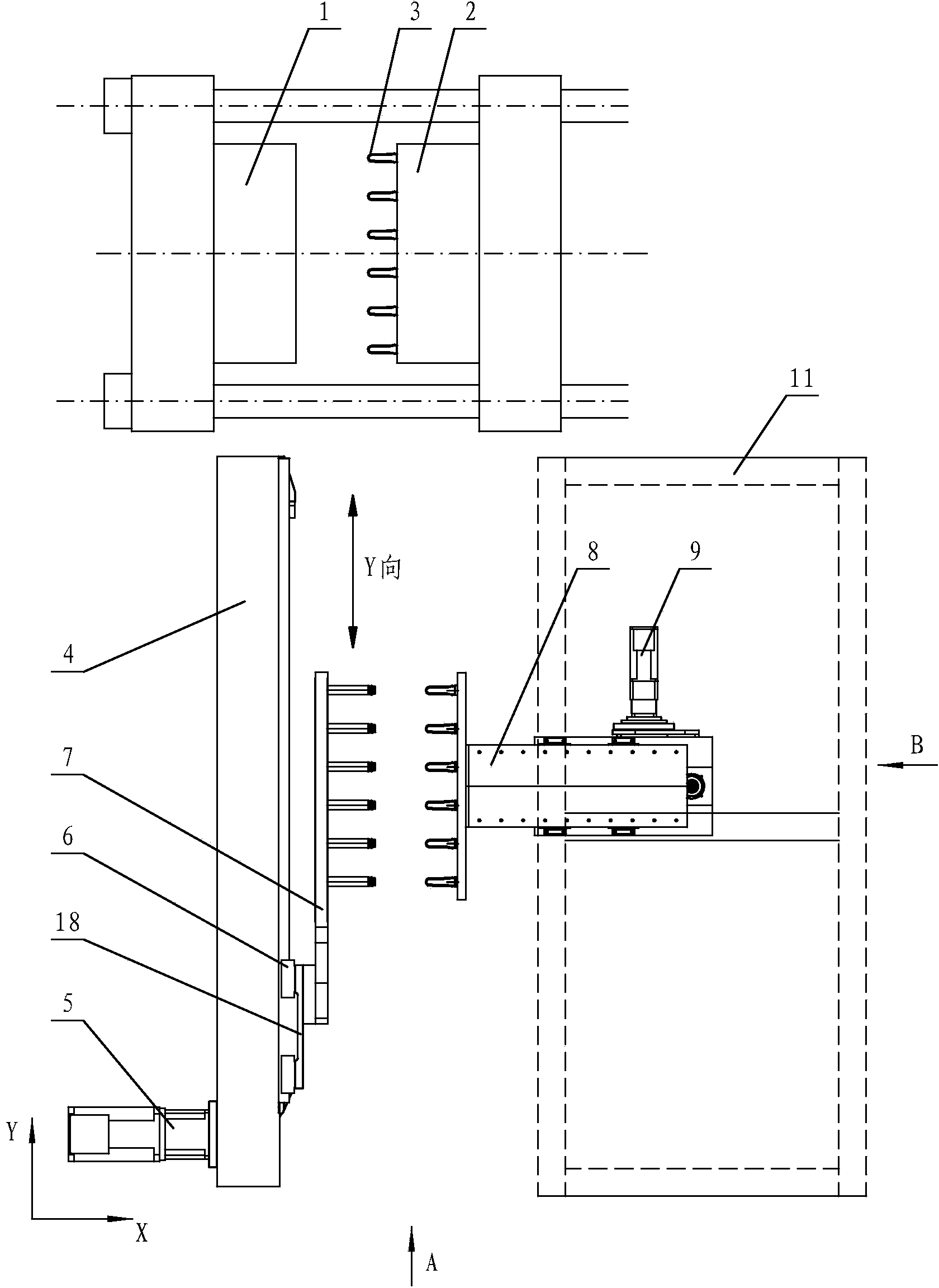

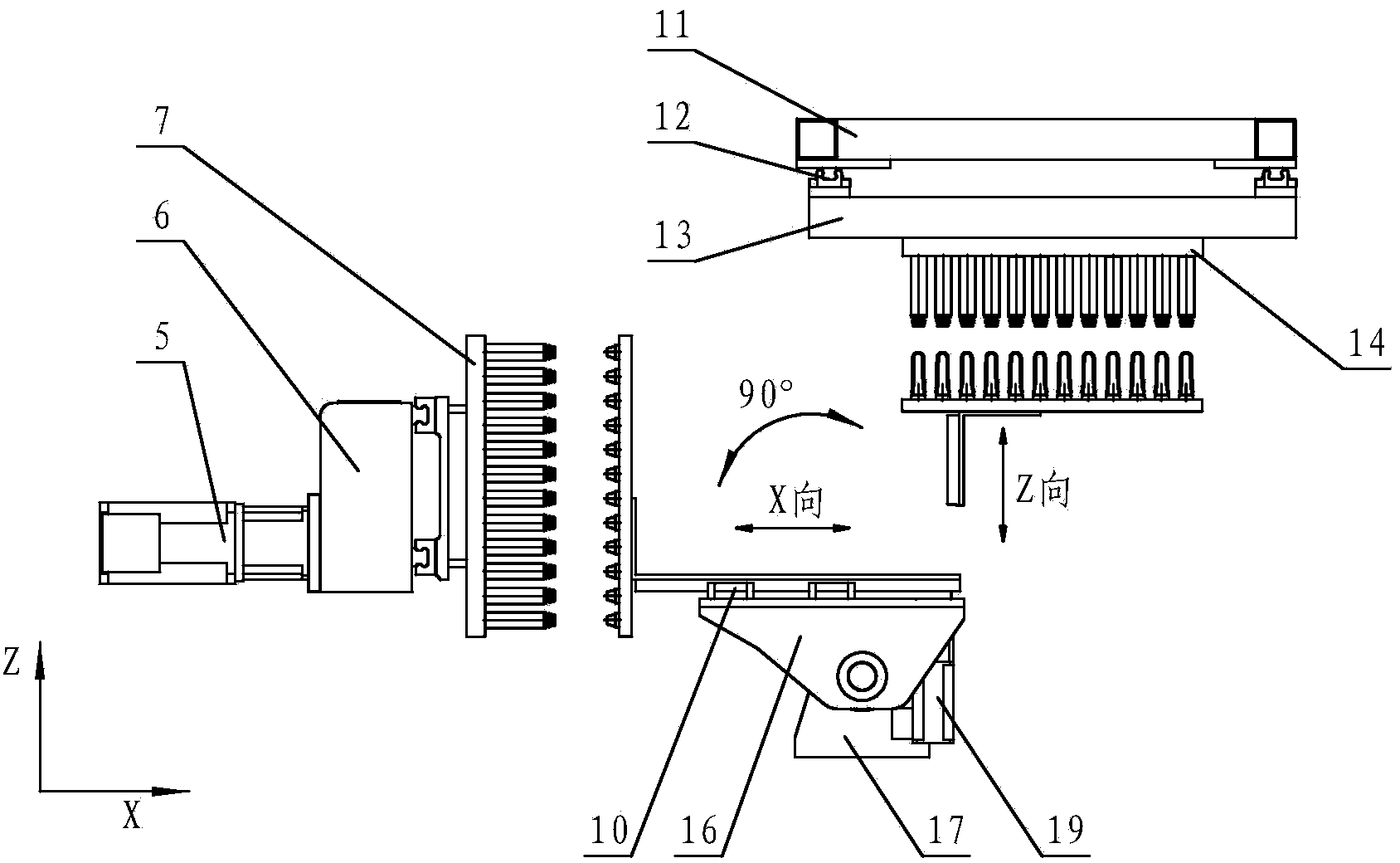

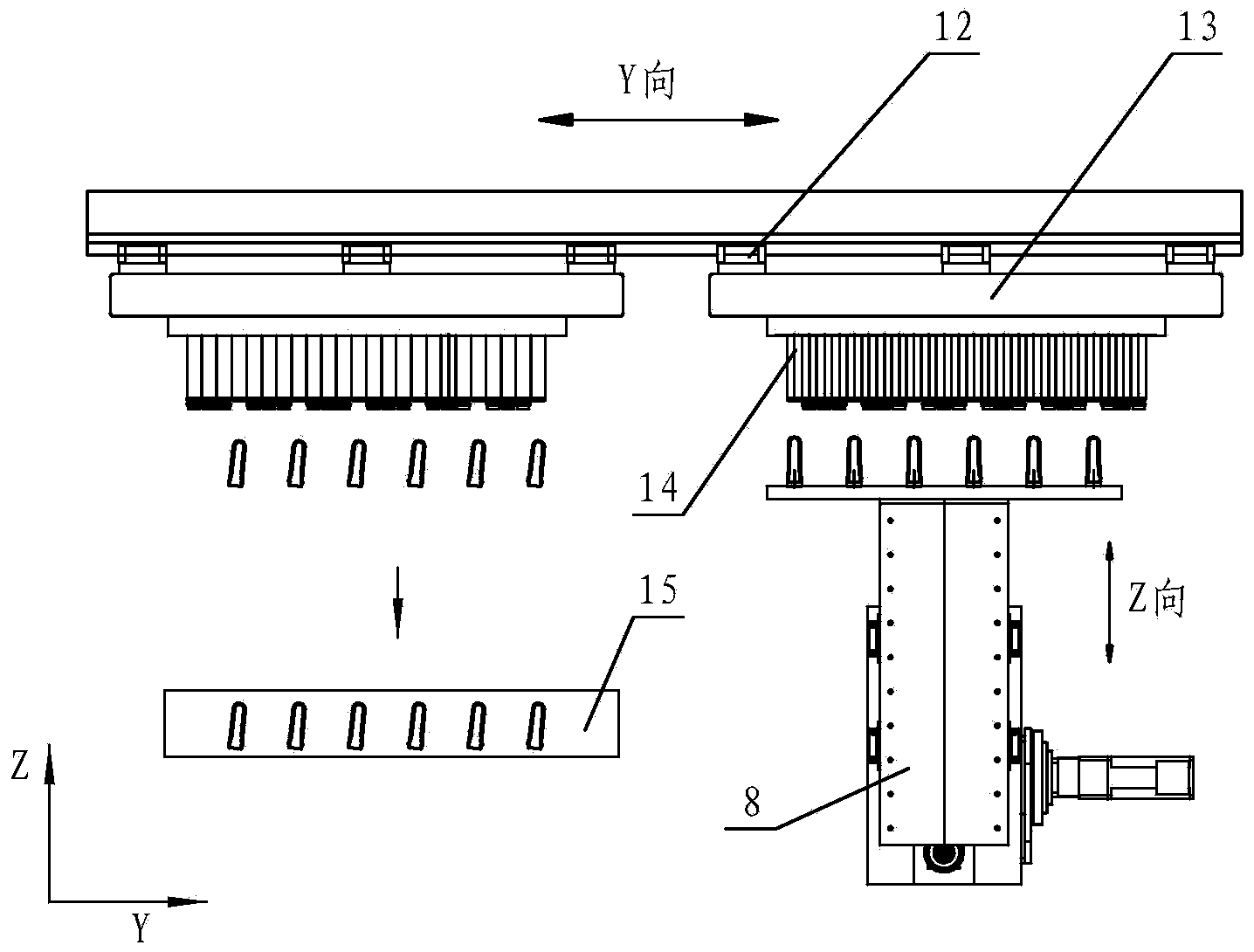

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] see Figure 1-Figure 3 , the preform take-out and cooling system, including the fixed mold 1 and the movable mold 2 arranged on the injection molding machine and the preform 3 between the fixed mold 1 and the movable mold 2, also includes a preform cooling device, the preform cooling The device includes a fixed seat 4, a first ball linear guide 6, a slider seat 18, a take-out jig 7 containing a cooling device, and a servo motor belt transmission mechanism 5, wherein the fixed seat 4 is connected with the head plate of the injection molding machine, and the fixed seat One end of 4 faces between the fixed mold 1 and the movable mold 2, and the servo motor belt transmission mechanism 5 is arranged on the fixed seat 4. The first ball linear guide 6 is arranged on the fixed seat 4, the first slider is arranged slidingly on the first ball linear guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com