Patents

Literature

101 results about "Zero shear viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

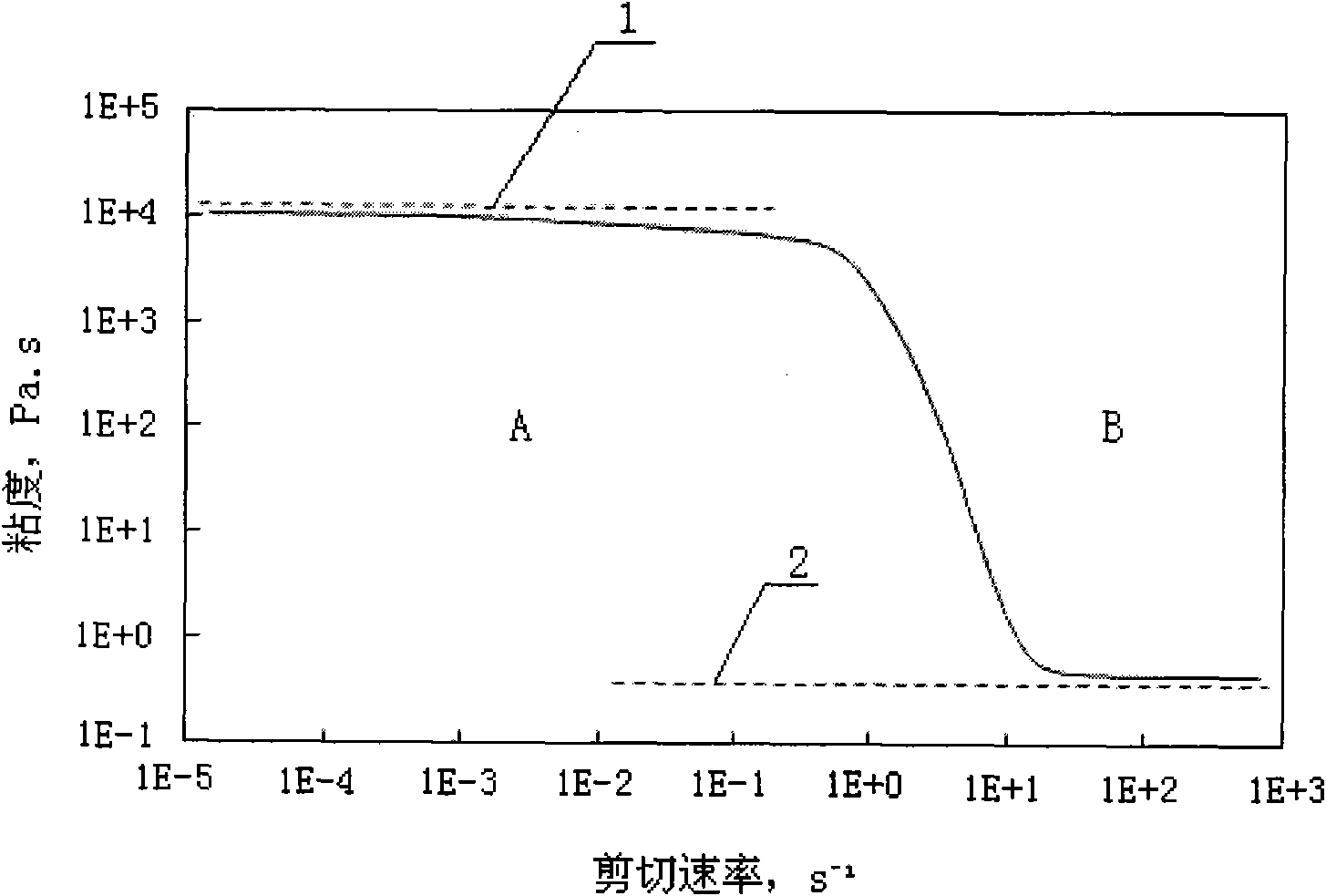

The zero shear viscosity is the viscosity of a material at a shear rate of zero; in other words the viscosity at rest which is typically the conditions to use when studying stability. The material is undergoing no significant deformation forces apart from that of gravity.

Polymeric optical conductors

InactiveUS6766091B2Glass optical fibreOptical fibre with graded refractive index core/claddingFiberZero shear viscosity

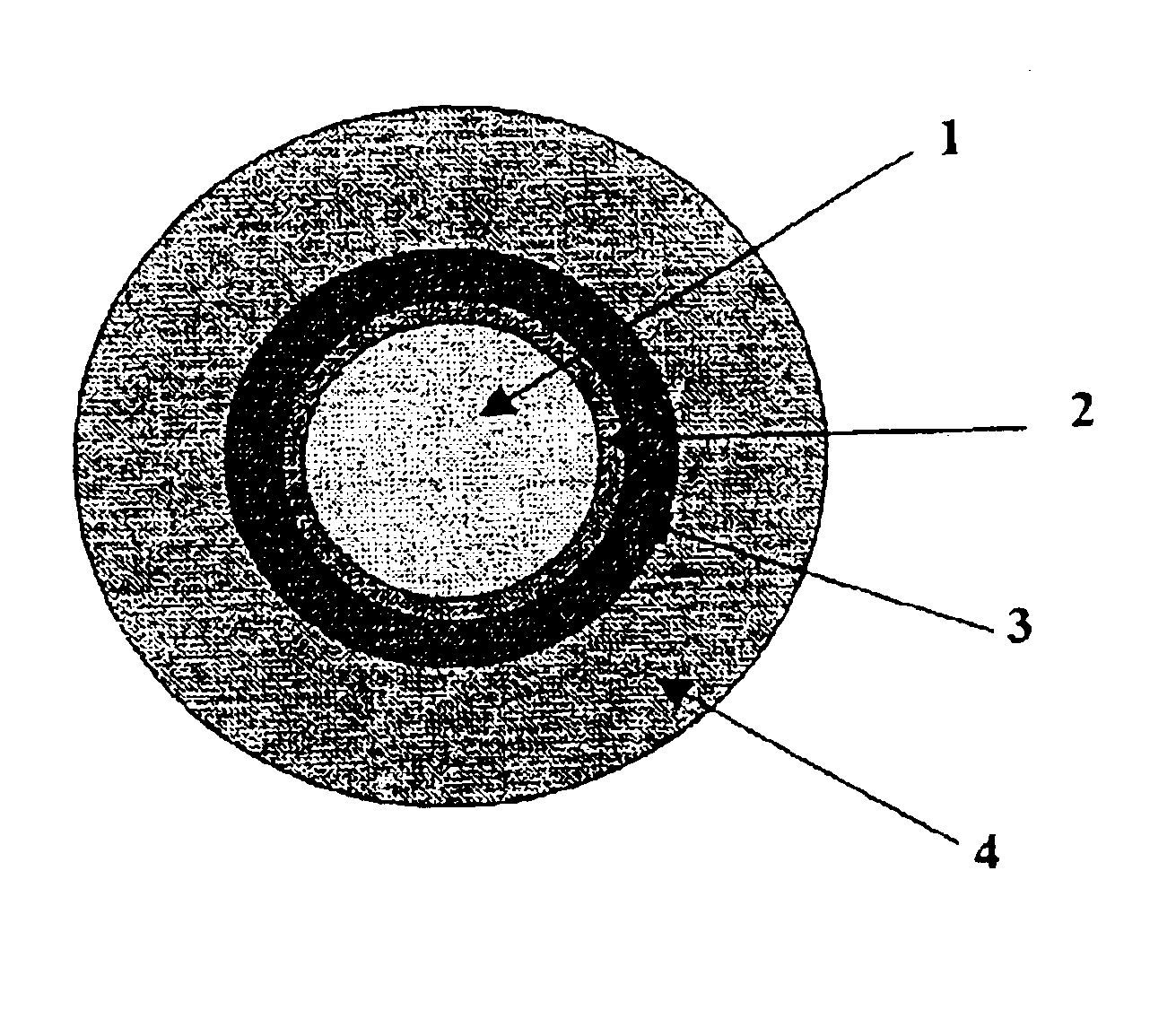

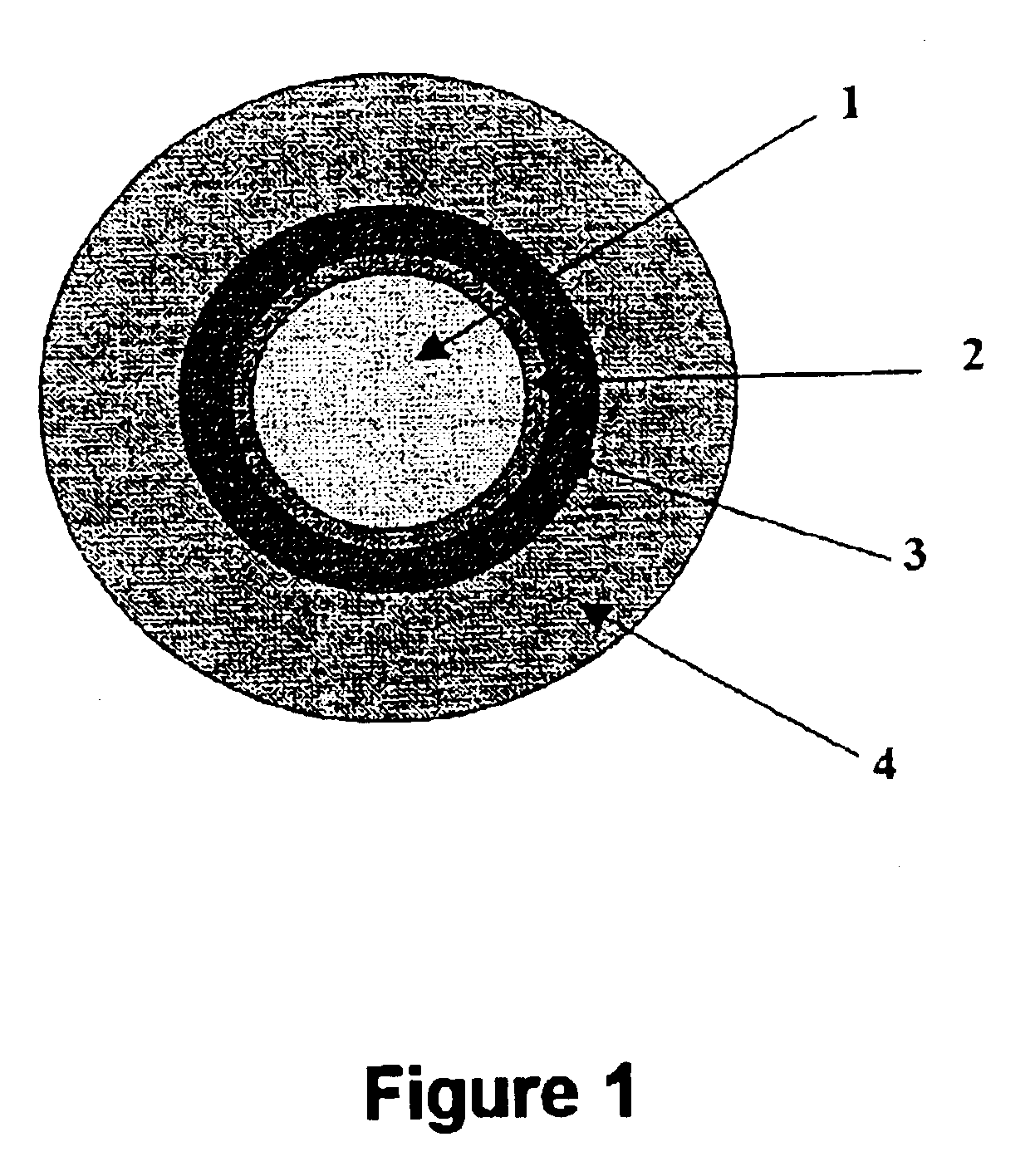

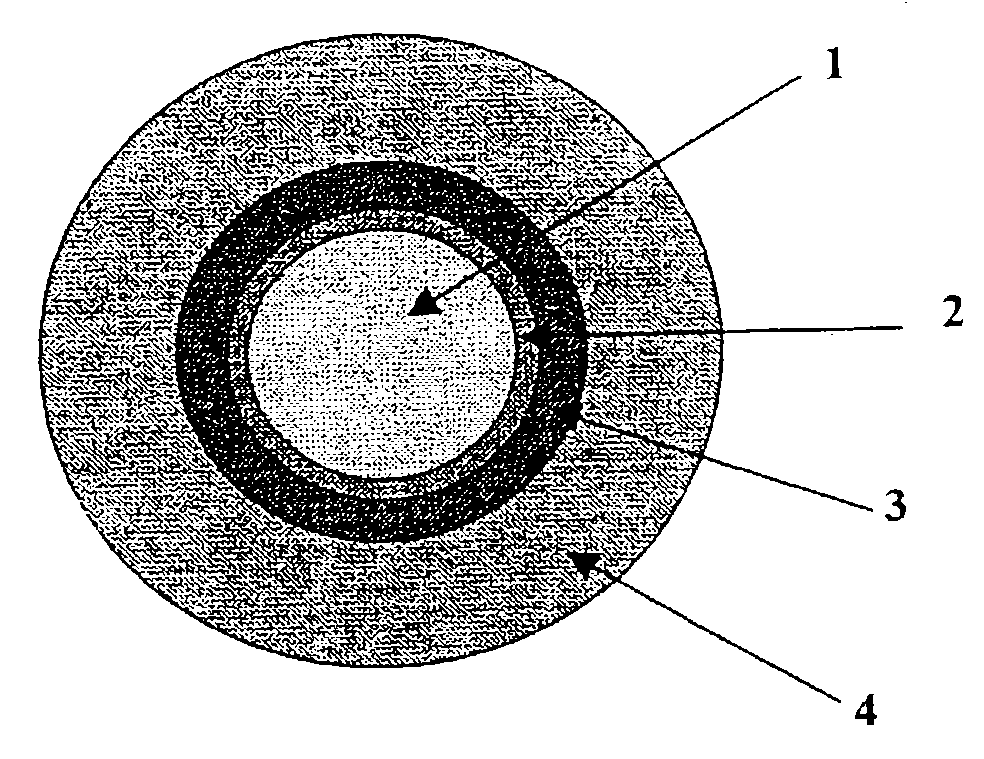

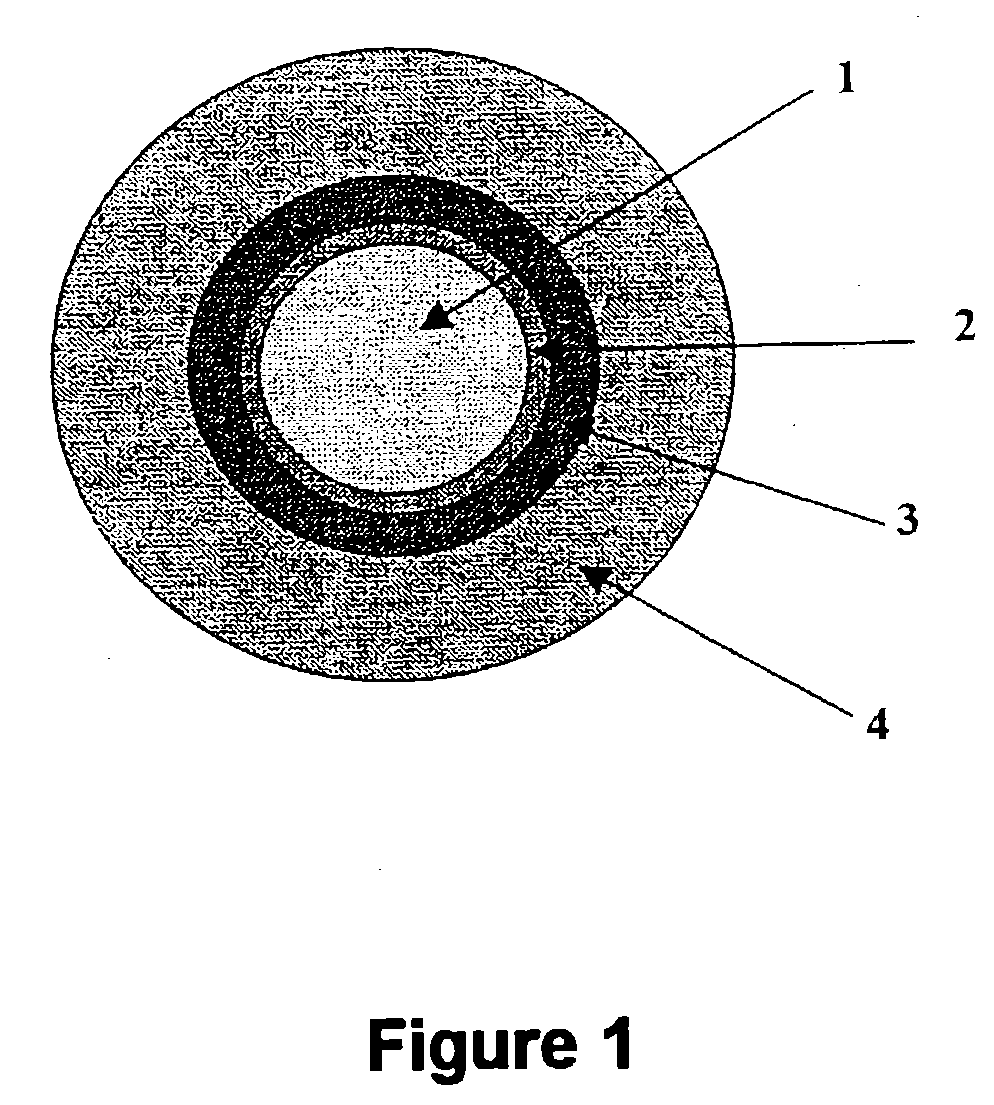

An optical cable, which is flame-retardant, and has excellent adhesion of the protective covering to the fiber cladding and uniform thickness of the fiber cladding, contains a polymer optical conductor containing a fiber core; a single-layer or multi-layer fiber cladding; an inner external layer which adheres to the fiber cladding with a peel force of at least 50 N; and an outer external layer which adheres to the inner external layer with a peel force of not more than 30 N. The inner external layer contains a molding composition having a first polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, and f) mixtures thereof. The first polyamide contains at least 50 mueq / g of amino end groups. The first molding composition has a zero-shear viscosity of from 400 to 6000 Pas. The outer external layer contains a second molding composition which has the following i)-iii): i) from 20 to 95% by weight of a second polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, f) a polyetheramide of at least one of a)-e), and g) mixtures thereof, ii) from 5 to 45% by weight of a flame retardant, and iii) from 0 to 60% by weight of an impact modifier.

Owner:EVONIK DEGUSSA GMBH

Polymeric optical conductors

InactiveUS20040001682A1Optical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingFiberZero shear viscosity

An optical cable, which is flame-retardant, and has excellent adhesion of the protective covering to the fiber cladding and uniform thickness of the fiber cladding, contains a polymer optical conductor containing a fiber core; a single-layer or multi-layer fiber cladding; an inner external layer which adheres to the fiber cladding with a peel force of at least 50 N; and an outer external layer which adheres to the inner external layer with a peel force of not more than 30 N. The inner external layer contains a molding composition having a first polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, and f) mixtures thereof. The first polyamide contains at least 50 mueq / g of amino end groups. The first molding composition has a zero-shear viscosity of from 400 to 6000 Pas. The outer external layer contains a second molding composition which has the following i)-iii): i) from 20 to 95% by weight of a second polyamide selected from a) PA 11, b) PA 12, c) PA 1012, d) PA 1212, e) a copolyamide of at least two of PA 11, PA 12, PA 1012 and PA 1212, said copolyamide containing not more than 30 mol % of a comonomer, f) a polyetheramide of at least one of a)-e), and g) mixtures thereof, ii) from 5 to 45% by weight of a flame retardant, and iii) from 0 to 60% by weight of an impact modifier.

Owner:EVONIK DEGUSSA GMBH

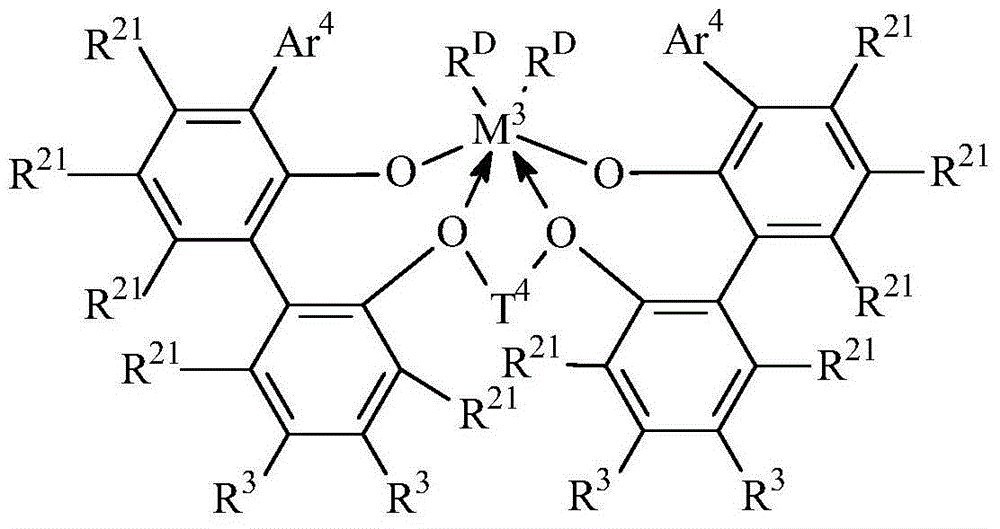

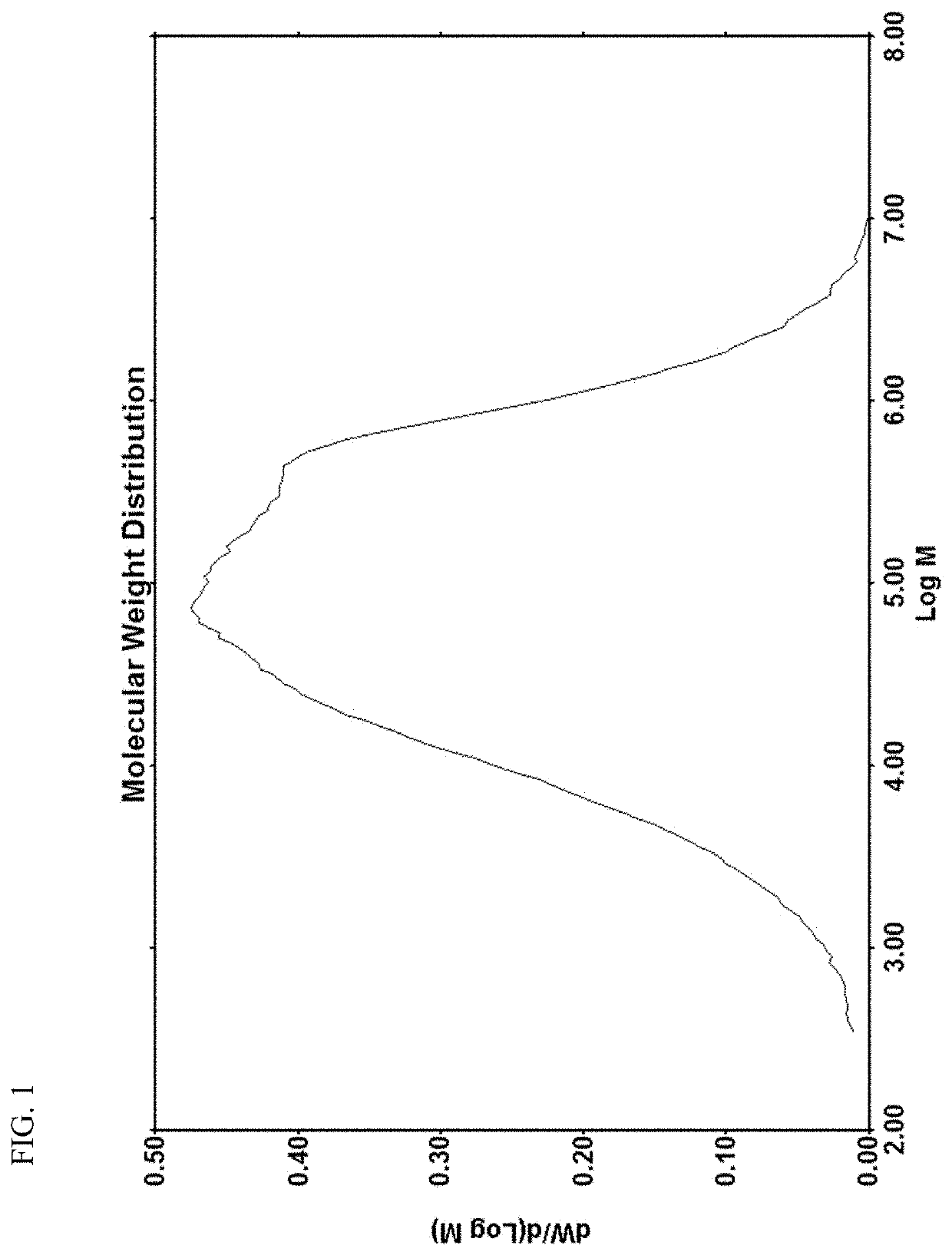

Polyolefin composition

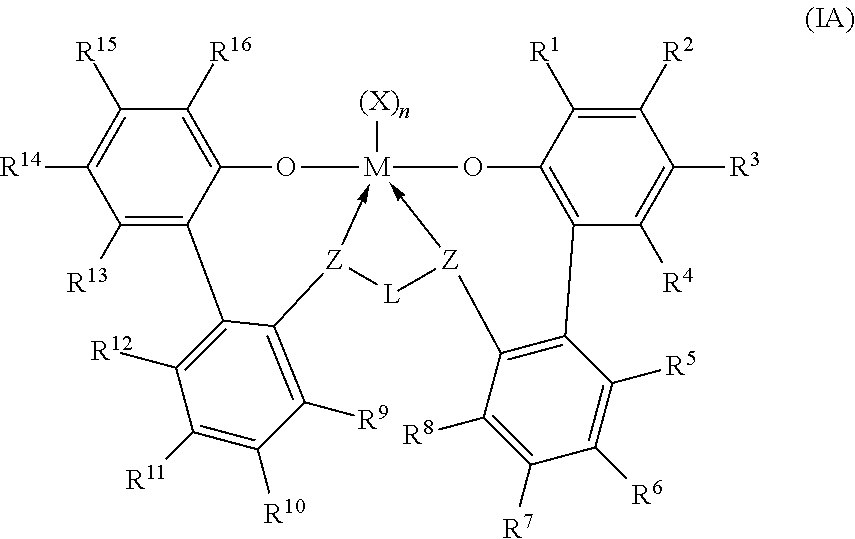

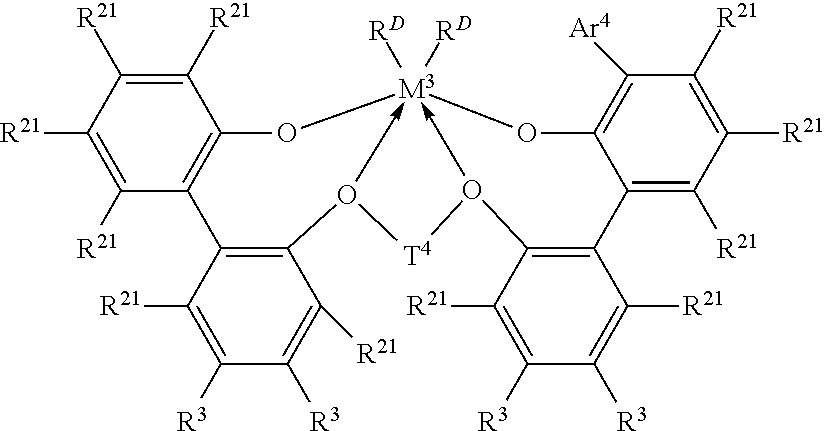

ActiveUS9102819B2Group 4/14 element organic compoundsClosure with auxillary devicesZero shear viscosityPolyolefin

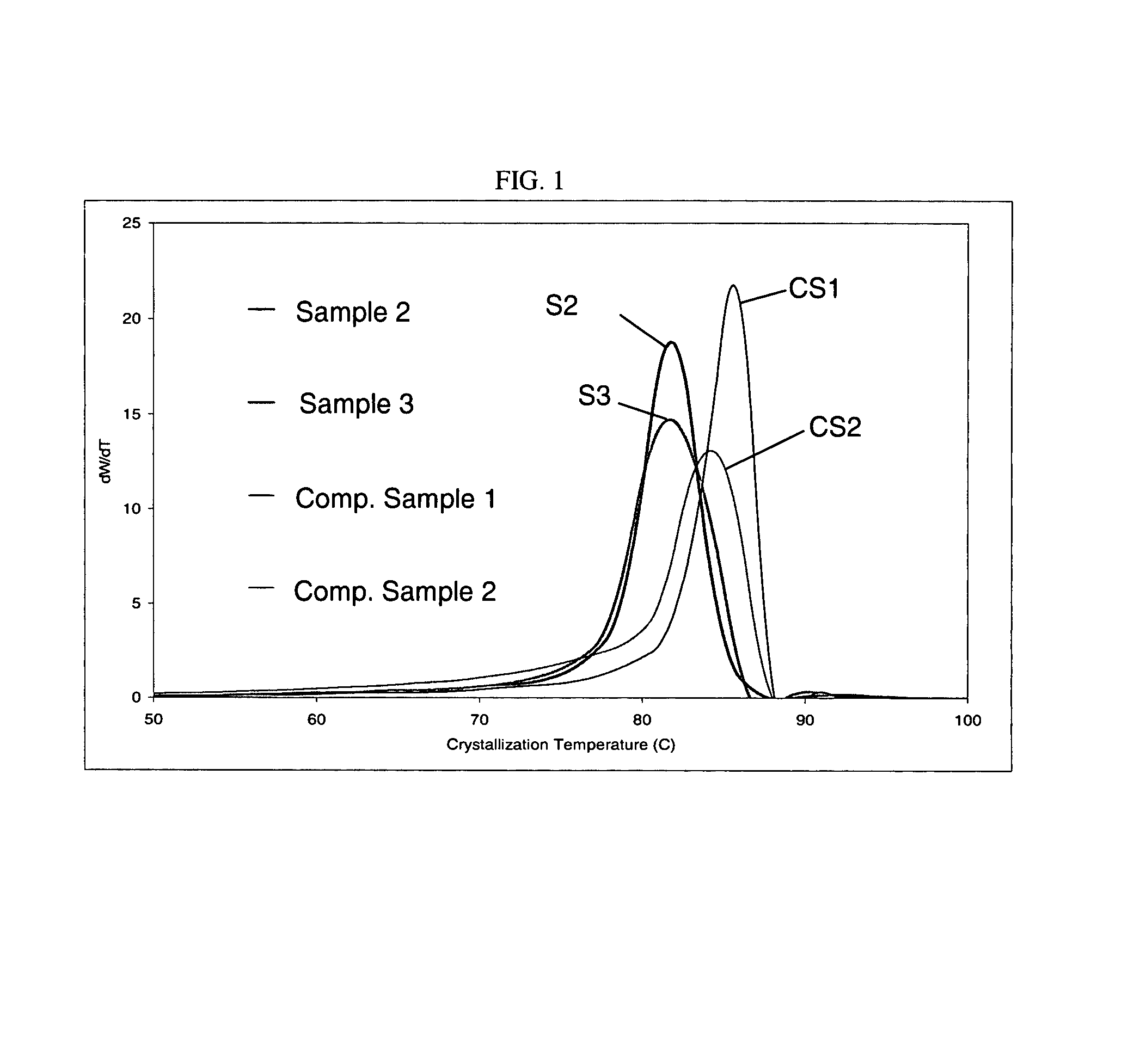

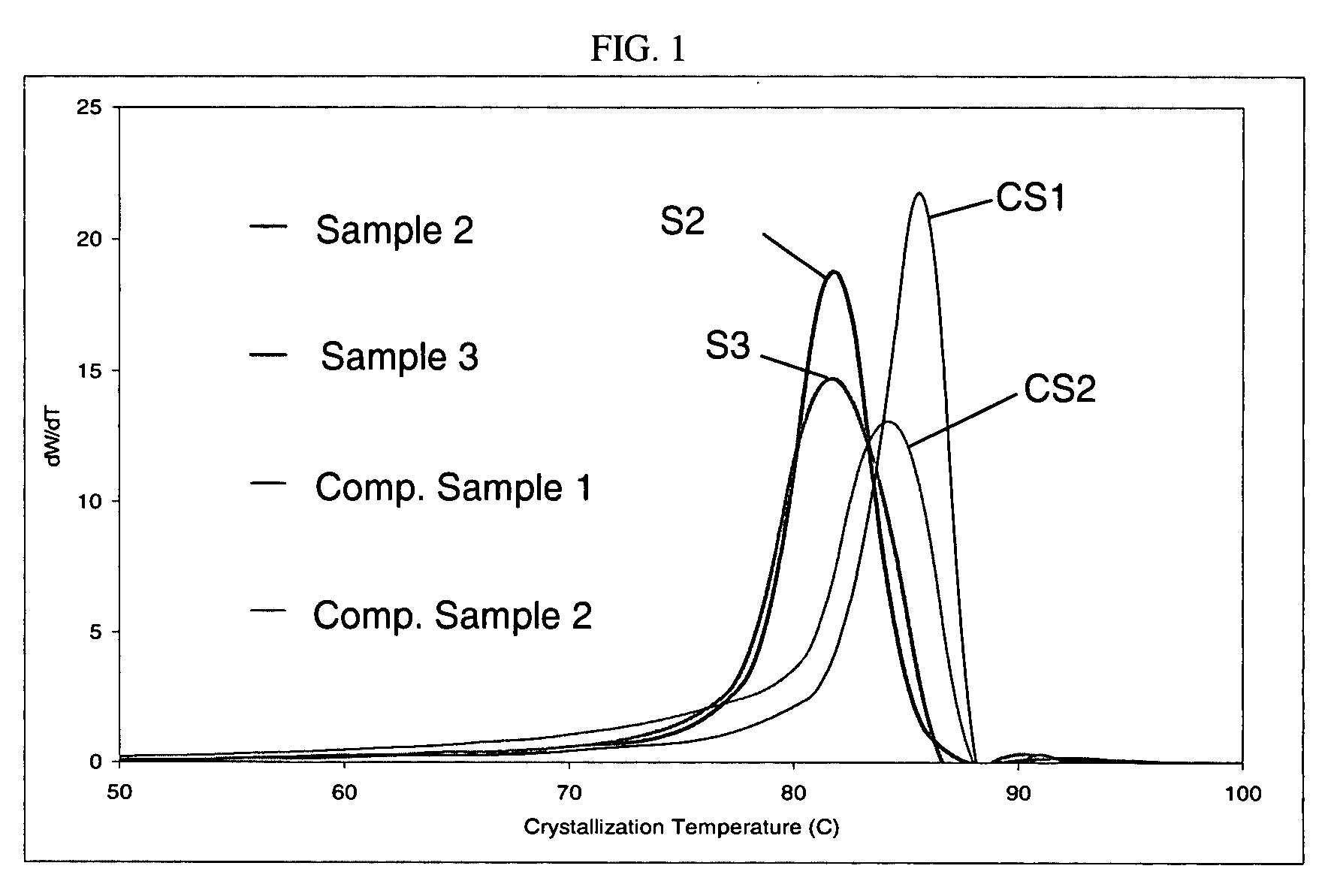

The instant invention provides a polyolefin composition suitable for injection molding applications, and method of making such injection molded articles. The polyolefin composition suitable for injection molding applications comprises: an ethylene / α-olefin interpolymer composition comprising: (a) from 25 to 50 percent by weight of a first ethylene / α-olefin copolymer fraction having a density in the range of from 0.924 to 0.937 g / cm3, a melt index (I2) in the range of from 0.03 to 0.3 g / 10 min, (b) from 50 to 75 percent by weight of a second ethylene homopolymer fraction having a density in the range of from greater than 0.960 g / cm3, a melt index (I2) in the range of from 100 to 180 g / 10 minutes, wherein said ethylene / α-olefin interpolymer composition has a density in the range of from 0.950 to 0.958 g / cm3, a melt index (I2) in the range of from 1.0 g / 10 min to 3.5 g / 10 min, a zero shear viscosity ratio (ZSVR) in the range of from 1.01 to 2.5, a molecular weight distribution (Mw / Mn) in the range of from 2.0 to 4.0, and tan delta at 0.1 radian / second and 190° C. in the range of from 9 to 50.

Owner:DOW GLOBAL TECH LLC

Multi-layered shrink films

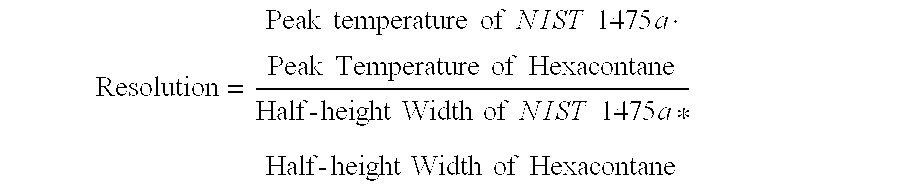

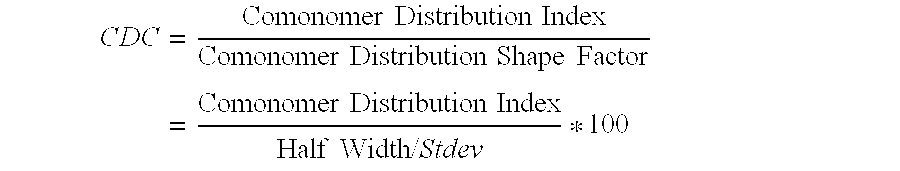

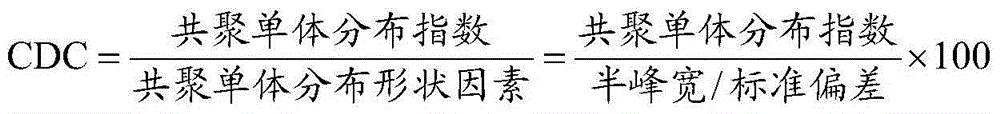

InactiveUS20140255674A1Synthetic resin layered productsThin material handlingZero shear viscosityDistribution constant

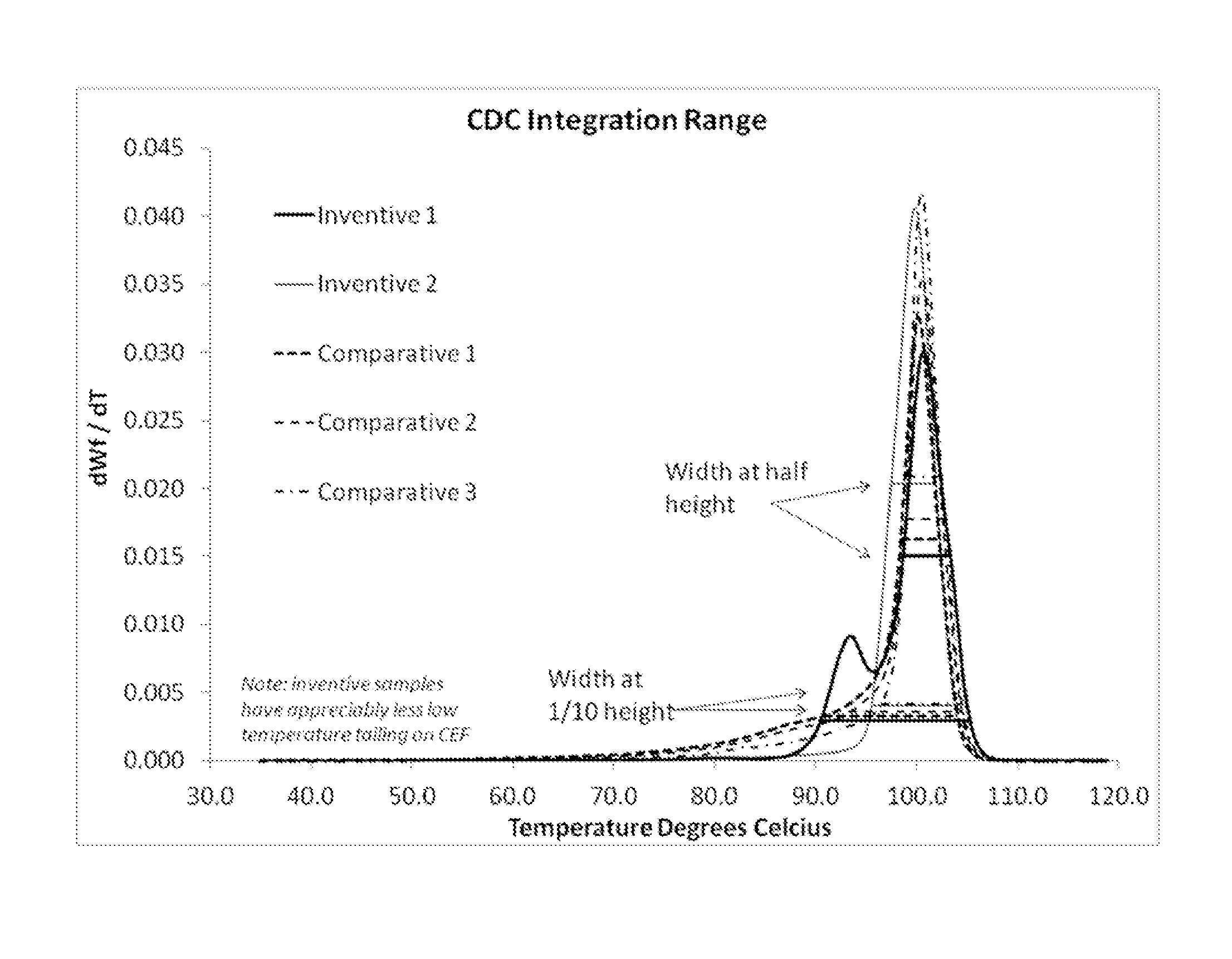

A multi-layered shrink film comprising: at least three layers including two skin layers and at least one core layer; wherein at least one layer comprises from 10 to 100 weight percent units derived from one or more ethylene-based polymer compositions characterized by having Comonomer Distribution Constant in the range of from 75 to 220, a vinyl unsaturation of from 30 to 100 vinyls per one million carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from at least 2.5 to 15; a density in the range of 0.924 to 0.940 g / cm3, a melt index (I2) in the range of from 0.1 to 1 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2.5 to 10, and a molecular weight distribution (Mz / Mw) in the range of from 1.5 to 4; and wherein the multi-layered film exhibits at least one characteristic selected from the group consisting of 45 degree gloss of at least 50%, a total haze of 15% or less, an internal haze of 8% or less, 1% CD Secant Modulus of 43,000 psi or greater, 1% MD Secant Modulus of 38,000 psi or greater, CD shrink tension of at least 0.7 psi, and / or MD shrink tension of at least 10 psi.

Owner:DOW GLOBAL TECH LLC

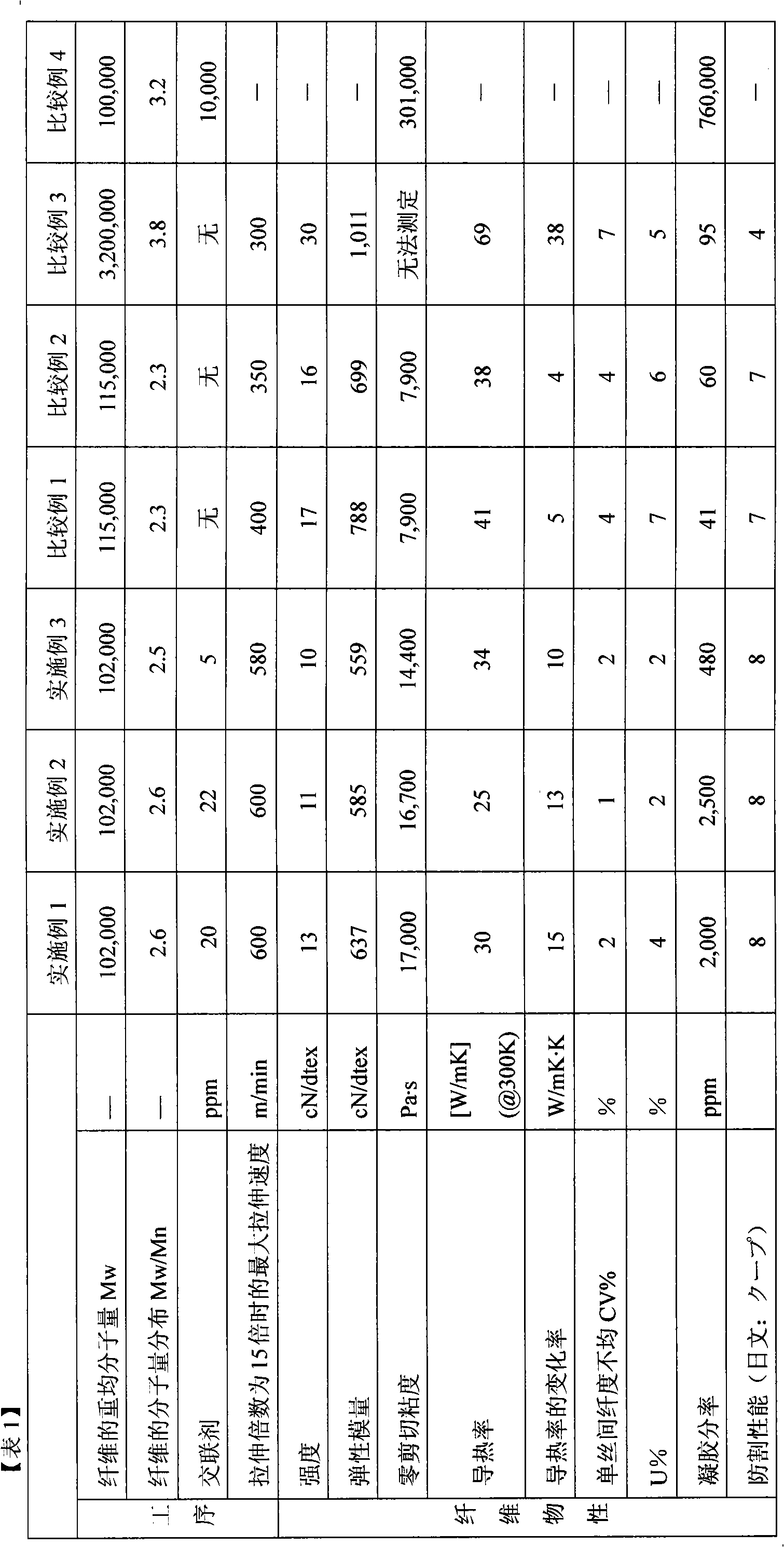

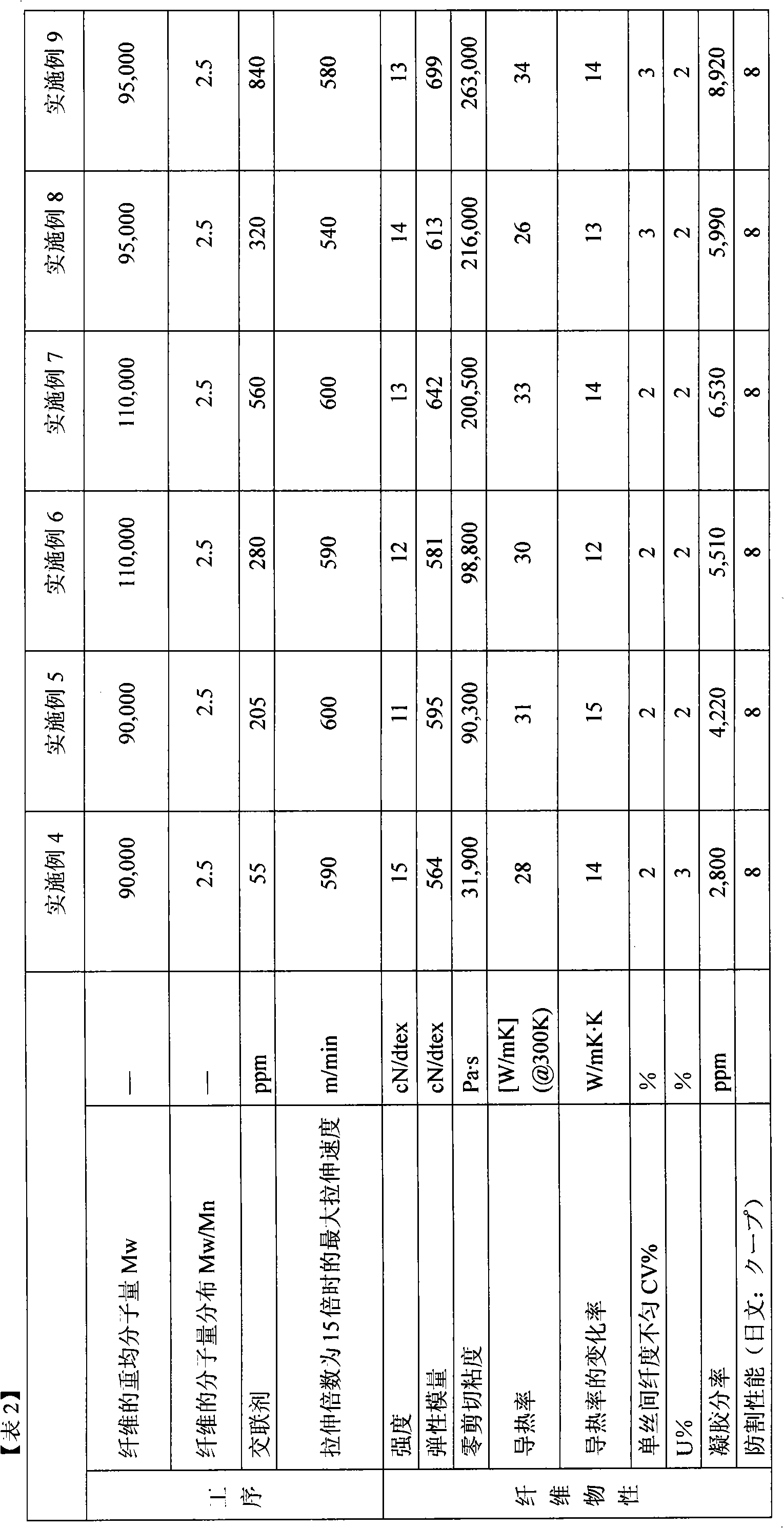

Highly functional polyethylene fiber, woven/knitted fabric comprising same, and glove thereof

ActiveCN102037169AImprove insulation effectImprove cut resistanceGlovesWoven fabricsYarnMolten state

A highly functional polyethylene fiber which combines high heat-insulating properties with cut resistance and is excellent in productivity and suitability for passing through post-processing; and a coated elastic yarn including the fiber, a woven / knitted fabric, and a glove. The polyethylene fiber comprises polyethylene which is constituted of repeating units of substantially ethylene and which, in the fiber state, has a weight-average molecular weight (Mw) of 50,000-300,000 and a ratio of the weight-average molecular weight to the number-average molecular weight (Mn), Mw / Mn, of 4.0 or lower. The polyethylene fiber has a gel content of 100-10,000 ppm or a zero-shear viscosity in a molten state at 190 C of 8,000-300,000 (Pas).

Owner:TOYOBO MC CORP

Spunbond nonwoven fabrics

ActiveUS20140248811A1Synthetic resin layered productsWoven fabricsZero shear viscosityDistribution constant

The instant invention provides nonwoven fabrics and staple or binder fibres prepared from an ethylene-based polymer having a Comonomer Distribution Constant in the range of from greater than from 100 to 400, a vinyl unsaturation of less than 0.1 vinyls per one thousand carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from 1 to less than 2; a density in the range of 0.930 to 0. 970 g / cm3, a melt index (12) in the range of from 15 to 30 or from 10 to 50 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2 to 3.5, and a molecular weight distribution (Mz / Mw) in the range of from less than 2.

Owner:THE DOW CHEM CO

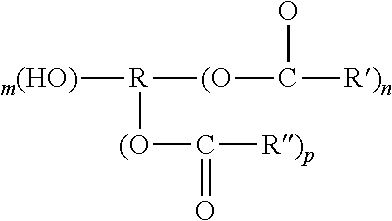

Hair care composition comprising discrete particle of oily component

InactiveUS20160095808A1Improved conditioning benefitClean feelCosmetic preparationsHair cosmeticsZero shear viscosityDiscrete particle

Disclosed is a hair care composition comprising: a discrete particle comprising an oily component, wherein the oily component comprises one or more materials selected from the group consisting of: (A) metathesized unsaturated polyol esters; (B) sucrose polyesters; (C) fatty esters with a molecular weight greater than or equal to 1500; and mixtures thereof, wherein the oily component has a Zero Shear Viscosity at 25° C. of from about 102 Pa·s to about 109 Pa·s, and has a melting point of from about 35° C. to about 60° C.; and wherein the discrete particle has an average particle size in the hair care composition of from about 0.5 microns to about 20 microns. The hair care composition provides improved conditioning benefits, clean feel, and / or hair styling benefit.

Owner:THE PROCTER & GAMBLE COMPANY

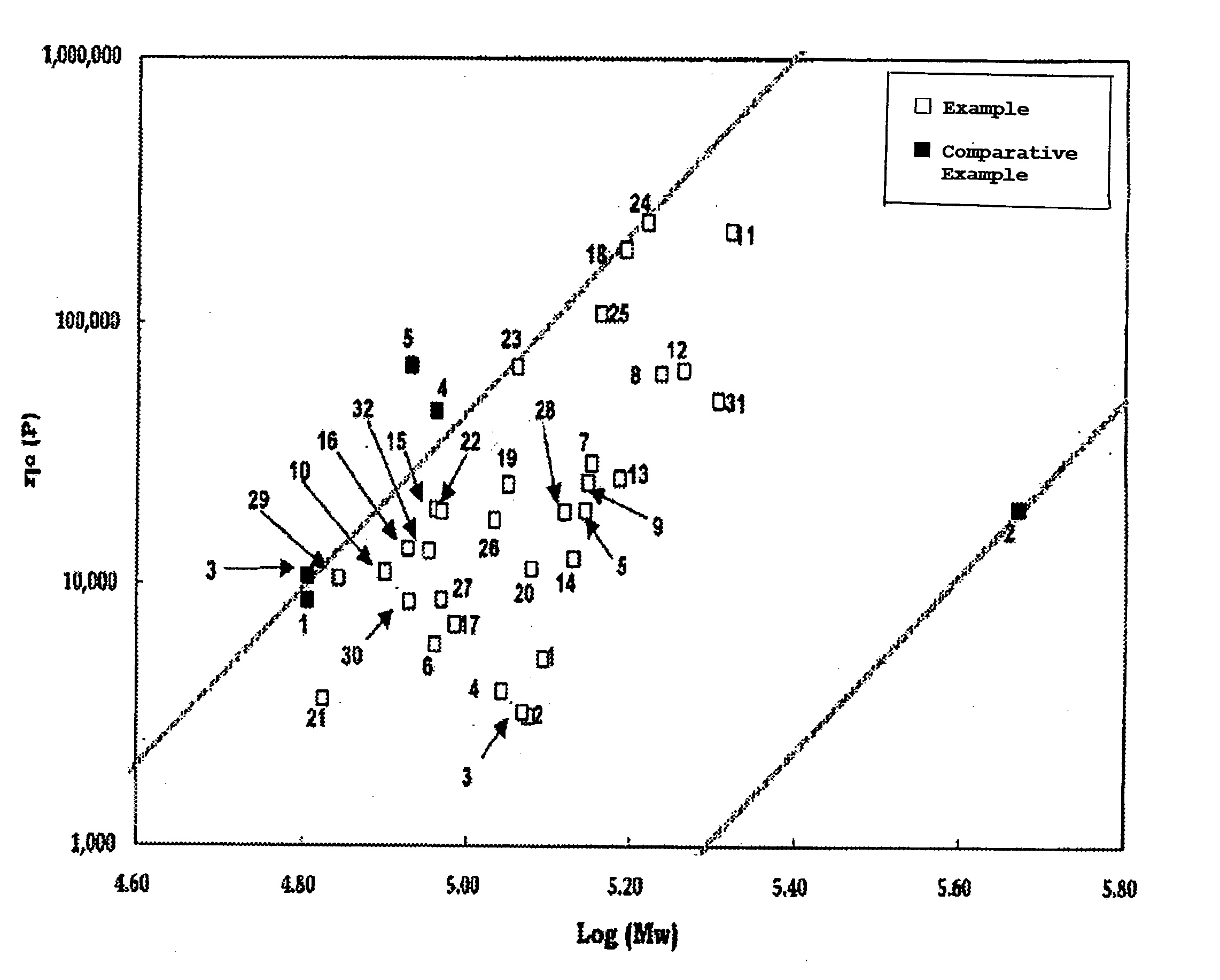

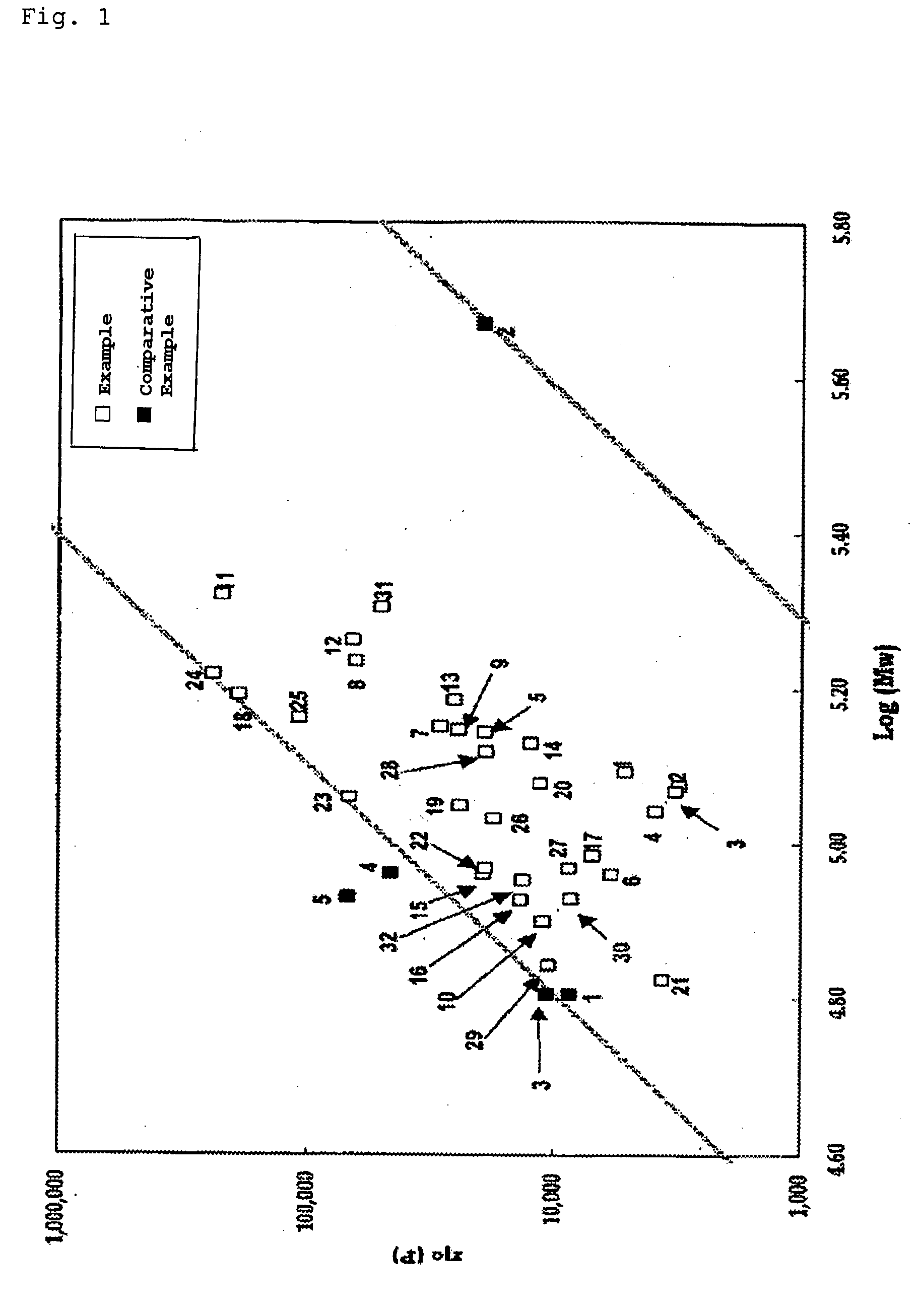

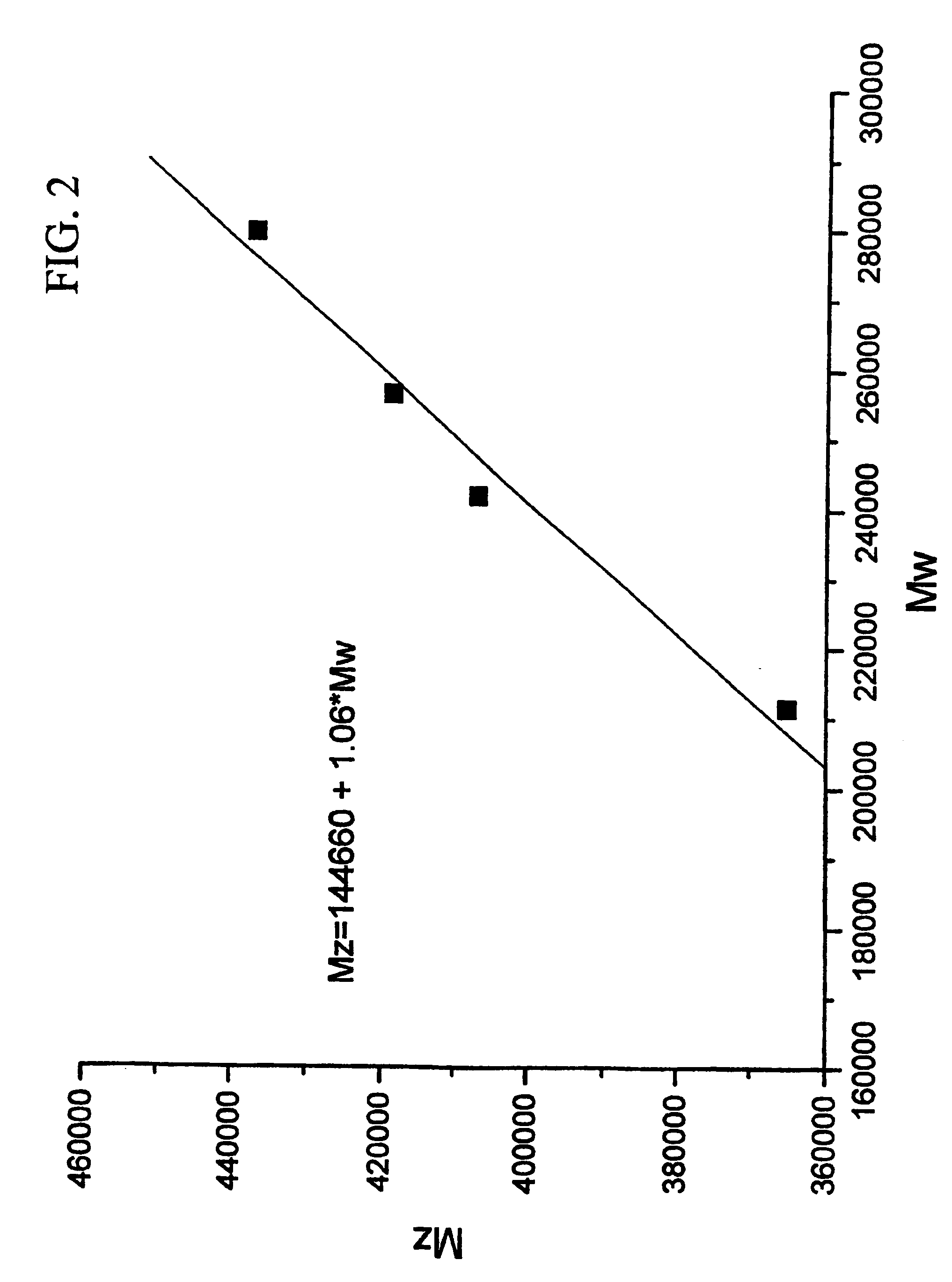

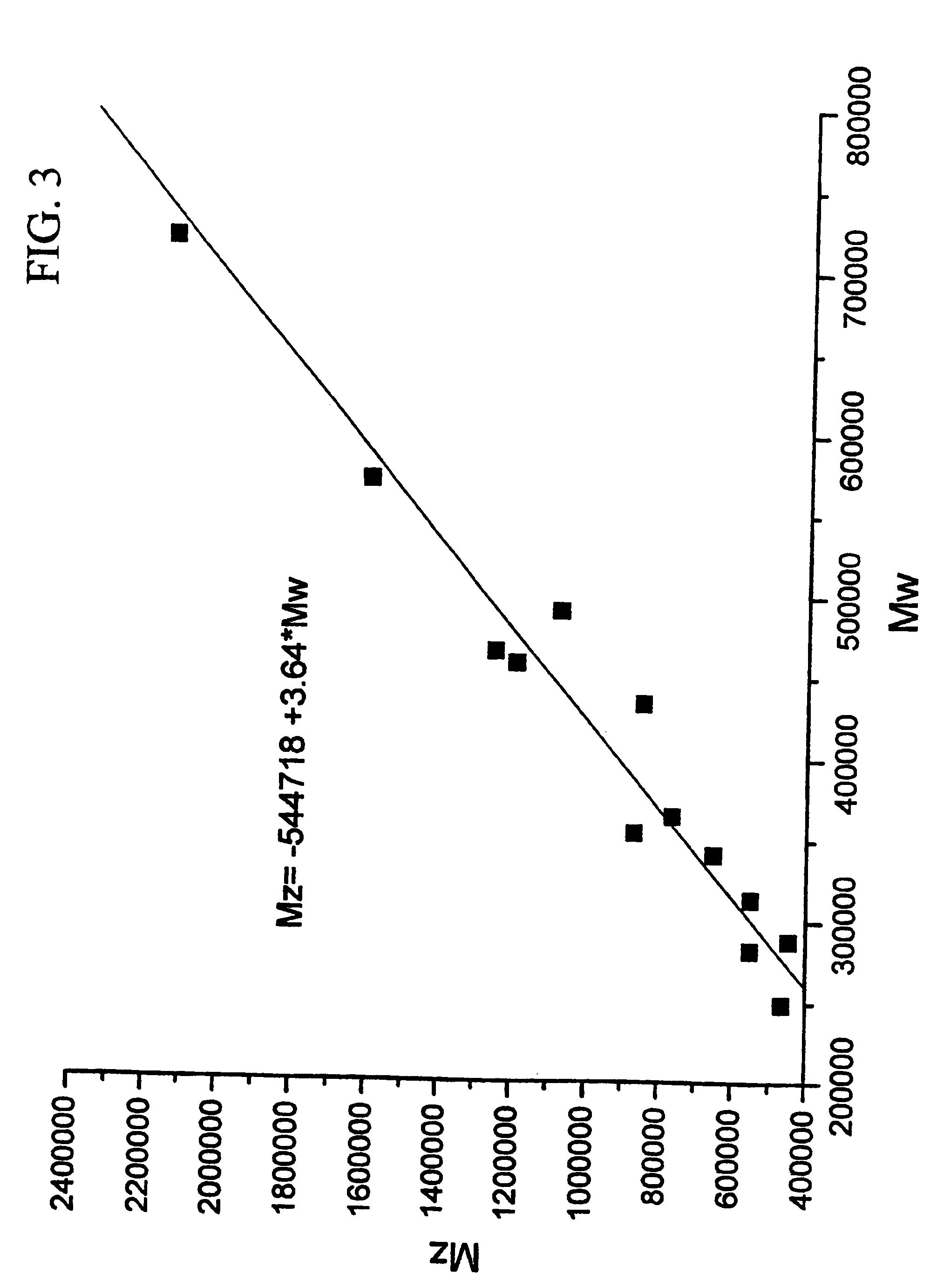

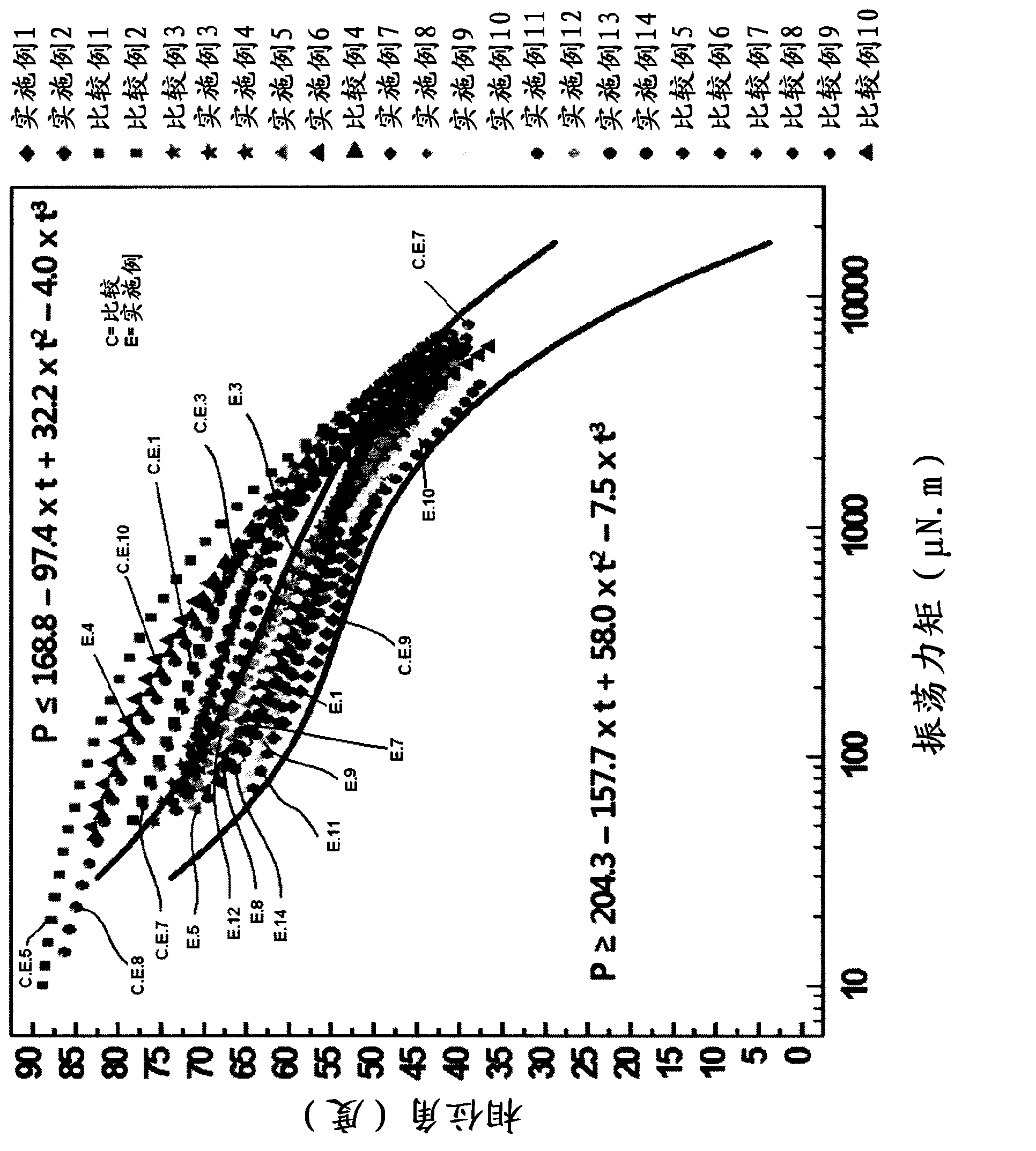

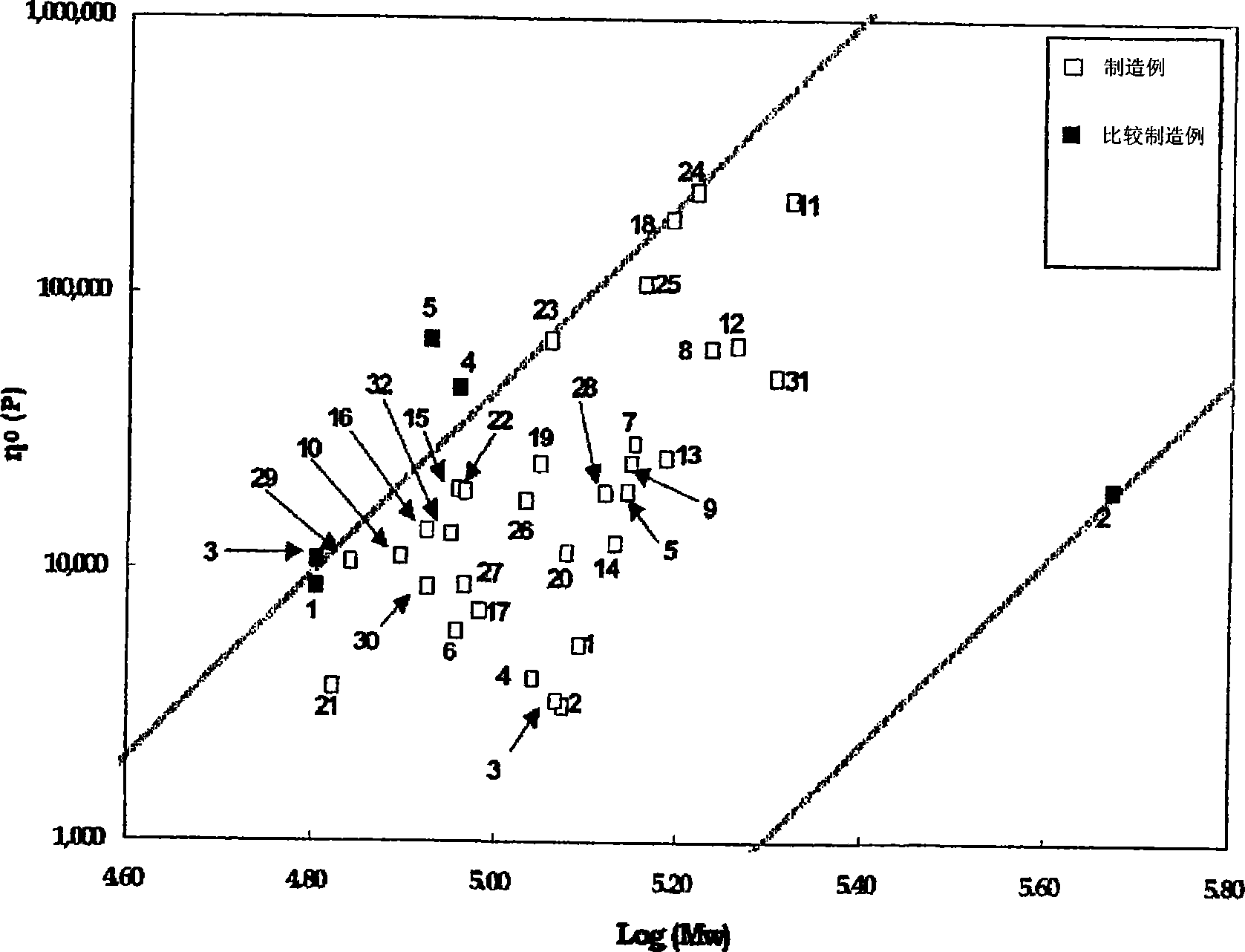

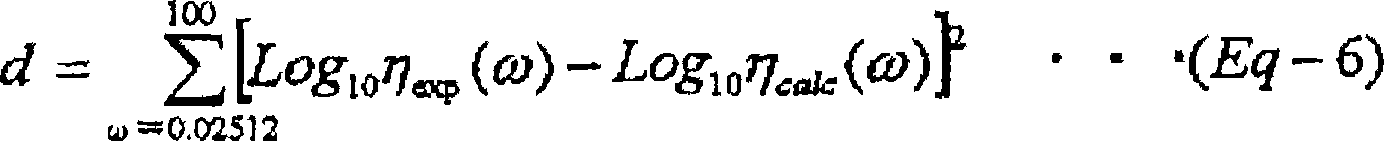

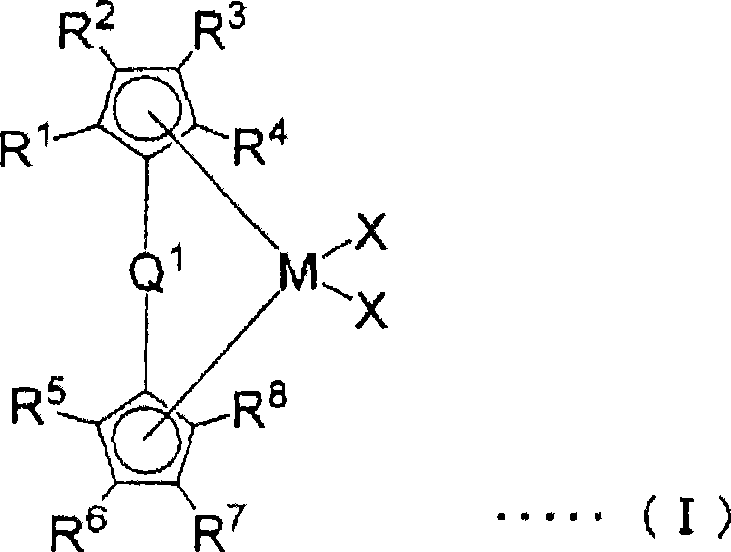

Ethylene-Based Resin and Molded Object Obtained Therefrom

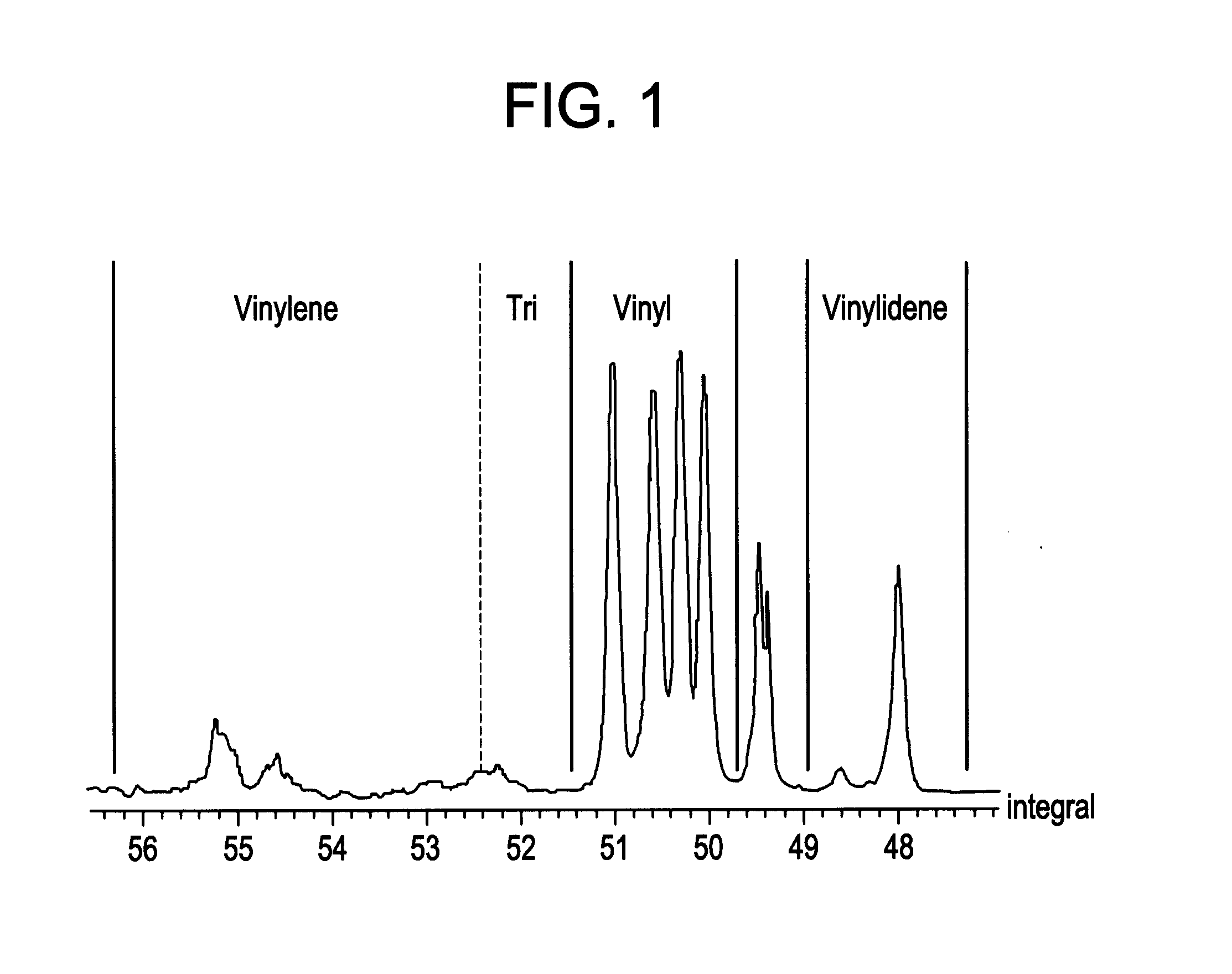

Ethylene-based resin, which exhibits a satisfactorily high melt tension and can provide a molded object excellent in mechanical strength, the ethylene-based resin characterized in simultaneously satisfying the requirements [1] to [5] described below: [1] melt flow rate (MFR) under a loading of 2.16 kg at 190° C. is in the range of 0.1 to 100 g / 10 minutes; [2] density (d) is in the range of 875 to 970 kg / m3; [3] ratio [MT / η*(g / P)] of melt tension [MT(g)] at 190° C. to shearing viscosity [η*(P)] at 200° C. at an angular velocity of 1.0 rad / sec. is in the range of 1.50×10−4 to 9.00×10−4; [4] sum [(A+B)( / 1000C)] of the number of methyl branches [A( / 1000C)] and the number of ethyl branches [B( / 1000C)] per 1000 carbon atoms measured by 13C-NMR is 1.8 or less; and [5] zero shear viscosity [η0(P)] at 200° C. and weight-average molecular weight (Mw) measured by GPC-viscosity detector method (GPC-VISCO) satisfy the following relational expression (Eq-1): 0.01×−13×Mw3.4≦η0≦4.5×10−13×Mw3.4 (Eq-1)

Owner:MITSUI CHEM INC

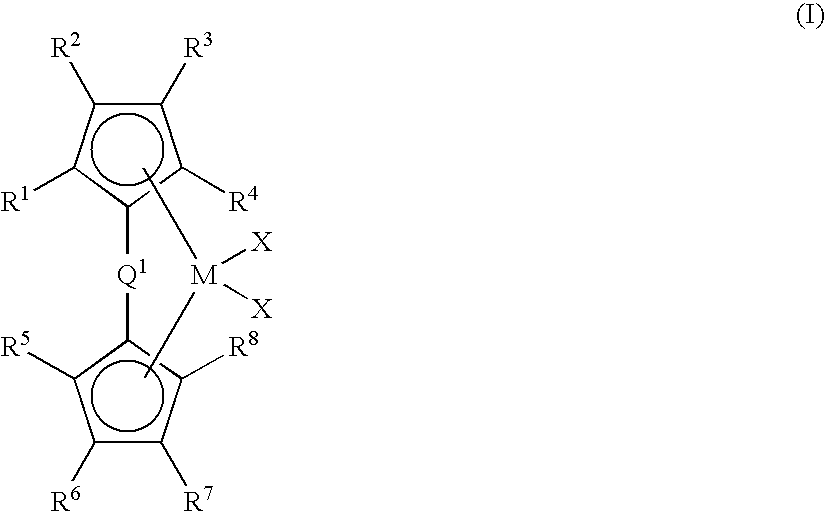

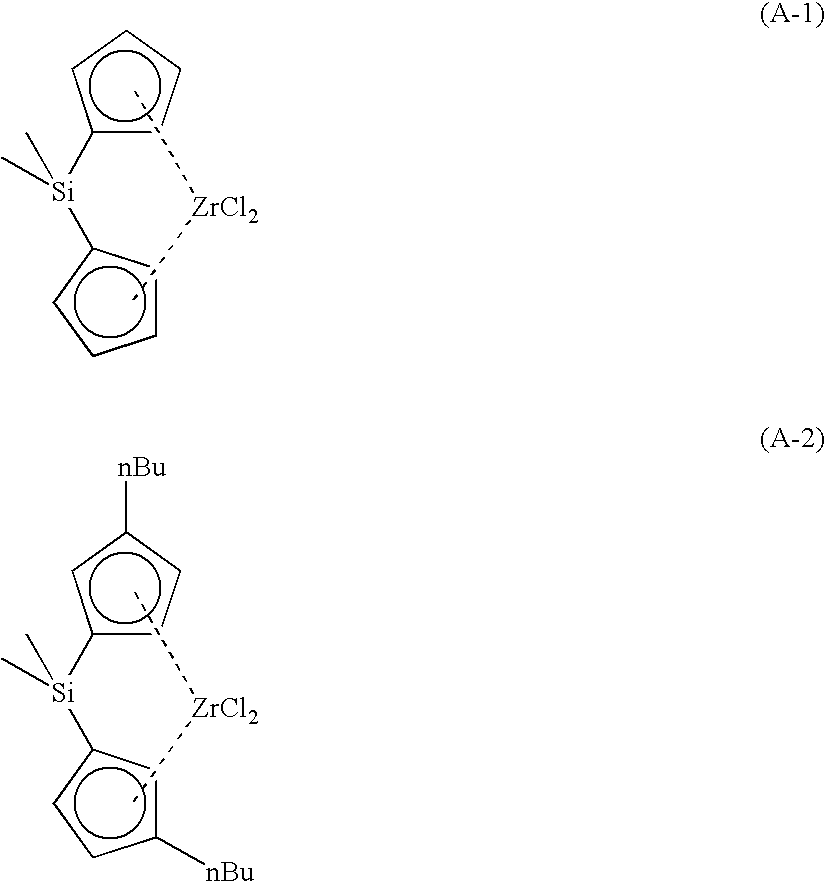

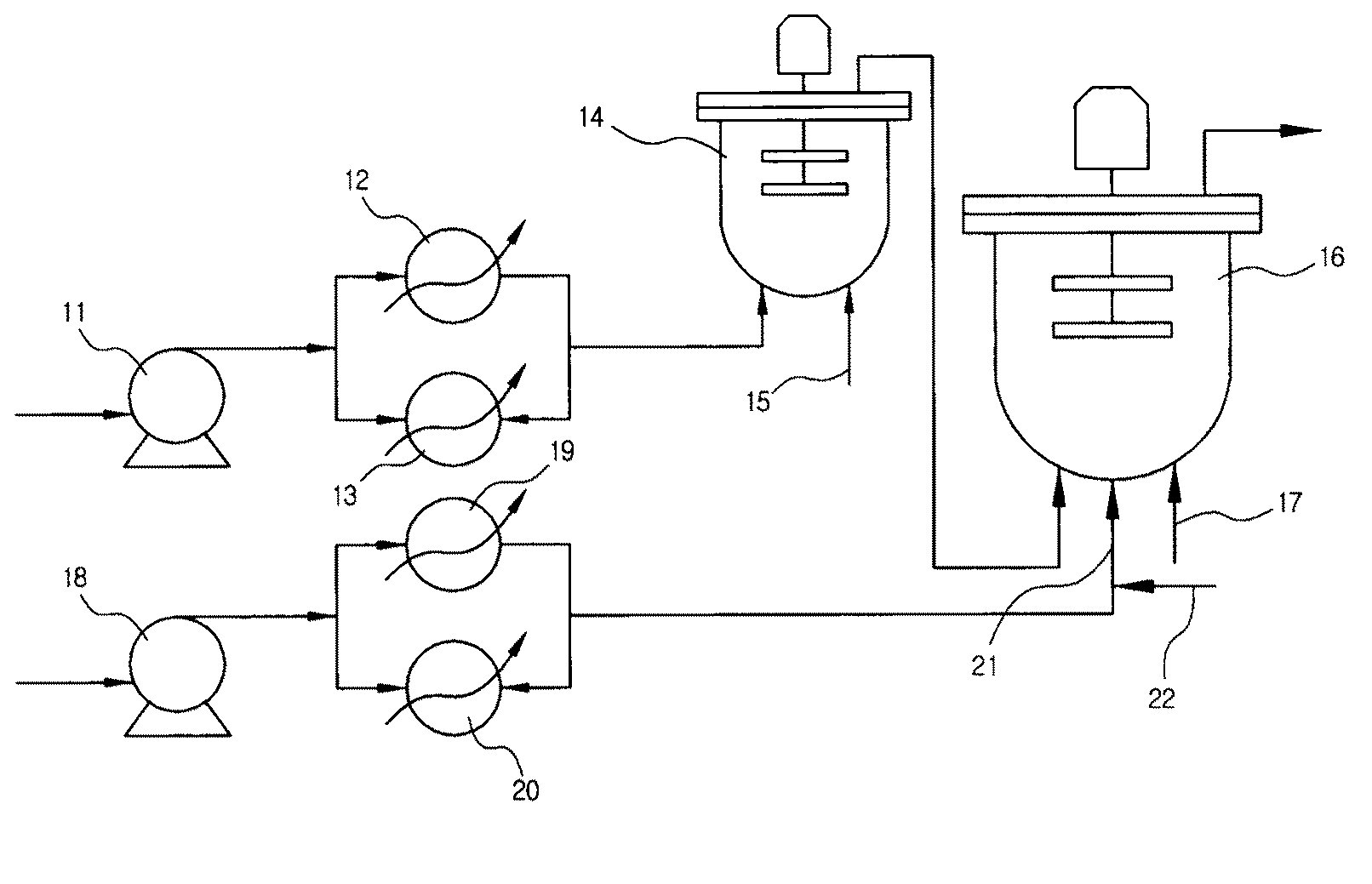

Polymers made with metallocene catalysts, for use in rotomolding and injection molding products

Ethylene alpha-olefin copolymers formed by contacting at least one supported metallocene catalyst, ethylene, and an alpha-olefin in a gas phase reactor are disclosed. In some embodiments, the polymer may have: a density of between 0.890 and 0.970 g / cc; a melt index of between 0.7 and 200 dg / min; a melt index ratio of less than 30; an ESCR value of greater than 1000 hours; and a 1% secant modulus of greater than 75,000 psi. In other embodiments, the polymer may have: a density of between 0.930 g / cc and 0.970 g / cc; a melt index of between 10 dg / min and 200 dg / min; a melt index ratio of between 10 and 25; a part weight of greater than 3 g and a part length of greater than 38 cm in a spiral flow test, and; a zero shear viscosity of less than 150 Pa·s. Processes to produce these polymers are also disclosed.

Owner:UNIVATION TECH LLC

Polymers made with metallocene catalysts, for use in rotomolding and injection molding products

Ethylene alpha-olefin copolymers formed by contacting at least one supported metallocene catalyst, ethylene, and an alpha-olefin in a gas phase reactor are disclosed. In some embodiments, the polymer may have: a density of between 0.890 and 0.970 g / cc; a melt index of between 0.7 and 200 dg / min; a melt index ratio of less than 30; an ESCR value of greater than 1000 hours; and a 1% secant modulus of greater than 75,000 psi. In other embodiments, the polymer may have: a density of between 0.930 g / cc and 0.970 g / cc; a melt index of between 10 dg / min and 200 dg / min; a melt index ratio of between 10 and 25; a part weight of greater than 3 g and a part length of greater than 38 cm in a spiral flow test, and; a zero shear viscosity of less than 150 Pa·s. Processes to produce these polymers are also disclosed.

Owner:UNIVATION TECH LLC

Scalp Care Composition

A scalp care composition comprising from 1% to 99% of a volatile carrier; from 0.05% to 10% of a polymeric rheology modifier and mixtures thereof; from 0.03% to 1% of particulate scalp benefit agent wherein the composition is shear thinning and has (1) a zero shear viscosity value measured at 0.01 Pa of greater than about 1,500 Pa s; (2) a moderate stress viscosity value measured at 1 Pa viscosity of greater than about 1,000 Pa s; and (3) a high shear rate viscosity value measured at 100 1 / s of less than about 0.5 Pa s.

Owner:THE PROCTER & GAMBLE COMPANY

Slush moldable thermoplastic polyolefin formulation for interior skin

A thermoplastic polyolefin composition suitable for slush molding comprising a blend of polypropylene, styrenic elastomer, linear low density polyethylene and a hydrocarbon-based process oil. Optional components include an ethylene copolymer elastomer, polymer additives such as polymer surface modifiers, powder flow additives, stabilizers and / or color pigments. The compositions exhibit a low melt viscosity during processing and improved surface quality for the molded article. An exemplary composition includes about 20-50 wt. % polypropylene or copolymer thereof, about 20-60 wt. % of a styrenic elastomer, about 5-50 wt. % linear low density polyethylene, and about 2-25 wt. % of a hydrocarbon-based process oil. The zero shear viscosity of the composition suitable for slush molding is in the range of about 300-900 Pa·s over a processing temperature range of 180-260° C.

Owner:DELPHI TECH INC

Multi-layered shrink films

InactiveCN104010816ASynthetic resin layered productsThin material handlingZero shear viscosityDistribution constant

A multi-layered shrink film comprising: at least three layers including two skin layers and at least one core layer; wherein at least one layer comprises from 10 to 100 weight percent units derived from one or more ethylene-based polymer compositions characterized by having Comonomer Distribution Constant in the range of from 75 to 220, a vinyl unsaturation of from 30 to 100 vinyls per one million carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from at least 2.5 to 15; a density in the range of 0.924 to 0.940 g / cm3, a melt index (I2) in the range of from 0.1 to 1 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2.5 to 10, and a molecular weight distribution (Mz / Mw) in the range of from 1.5 to 4; and wherein the multi-layered film exhibits at least one characteristic selected from the group consisting of 45 degree gloss of at least 50%, a total haze of 15% or less, an internal haze of 8% or less, 1% CD Secant Modulus of 43,000 psi or greater, 1% MD Secant Modulus of 38,000 psi or greater, CD shrink tension of at least 0.7 psi, and / or MD shrink tension of at least 10 psi.

Owner:DOW GLOBAL TECH LLC

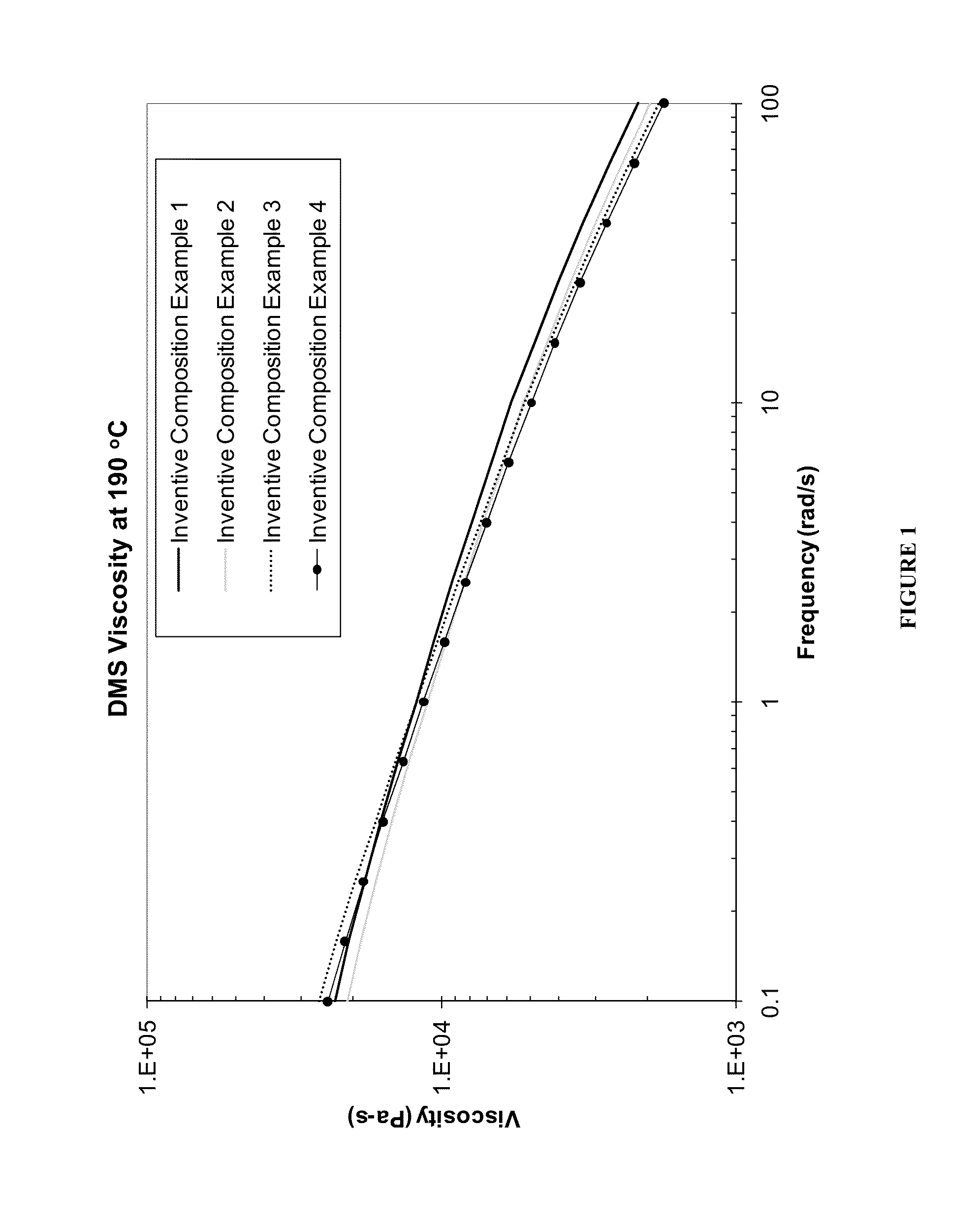

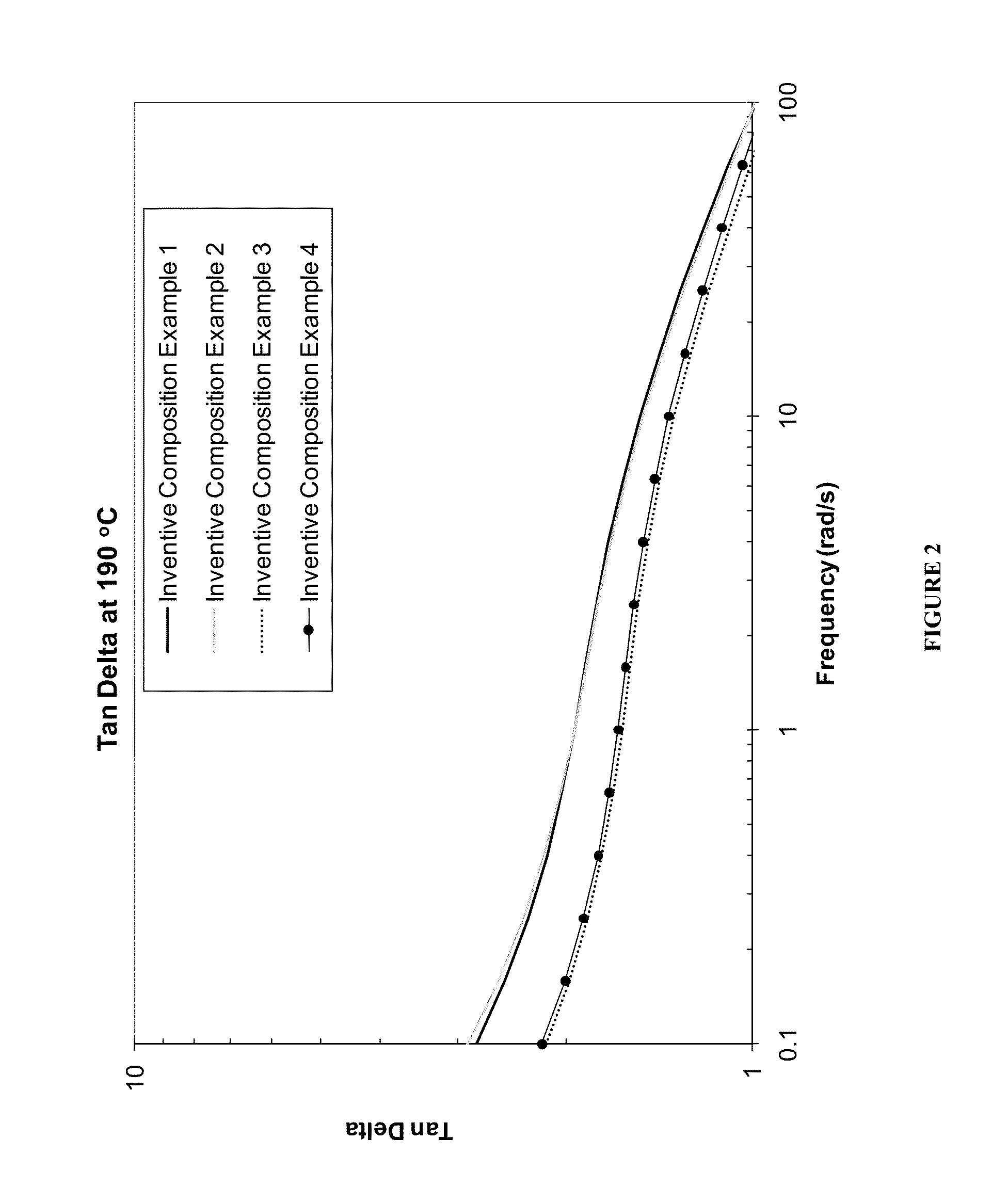

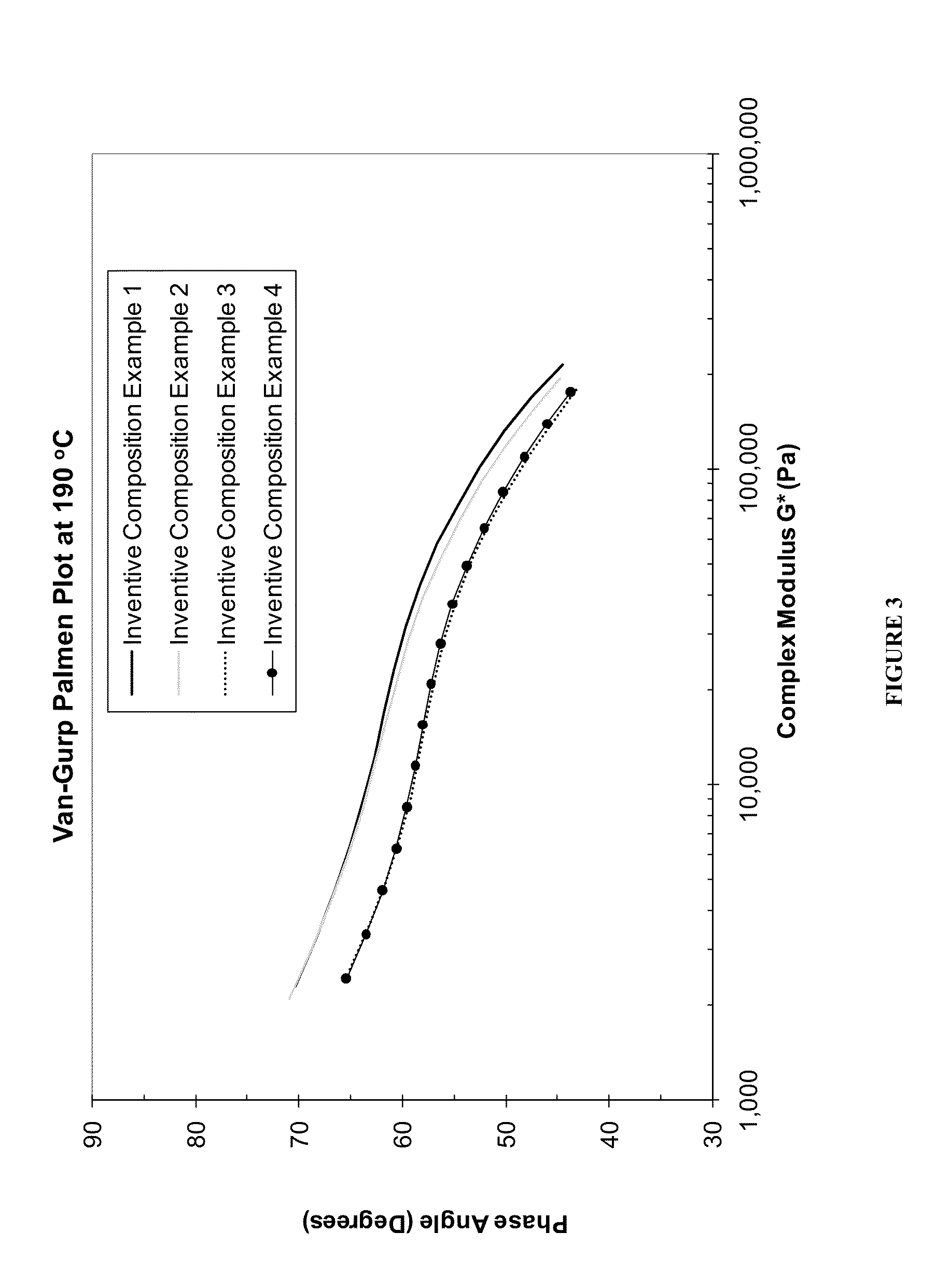

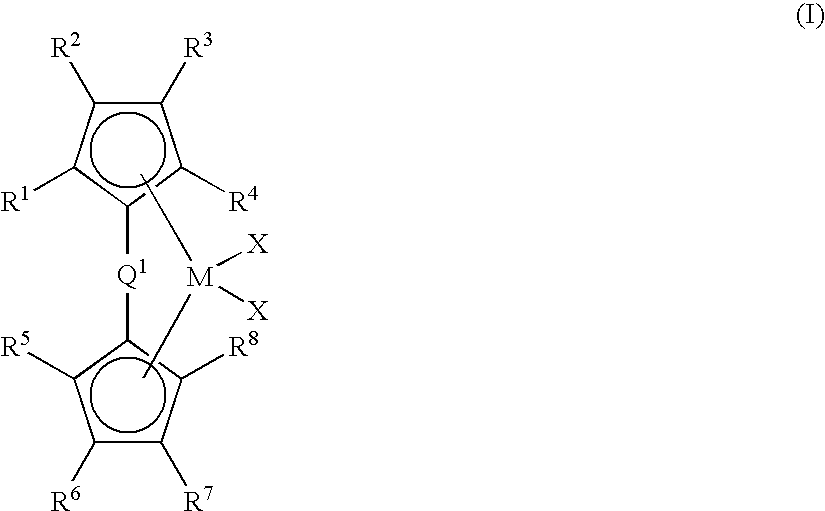

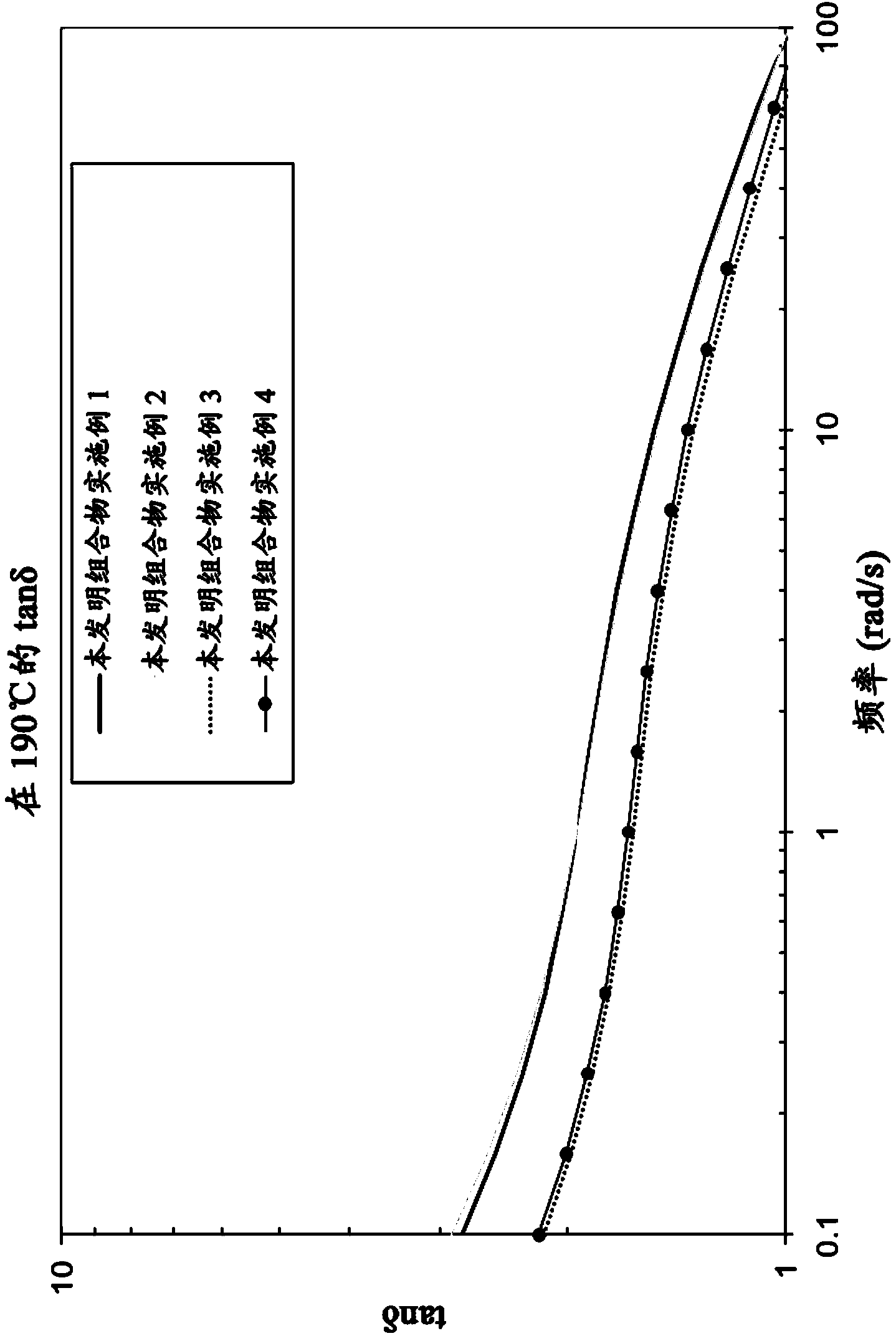

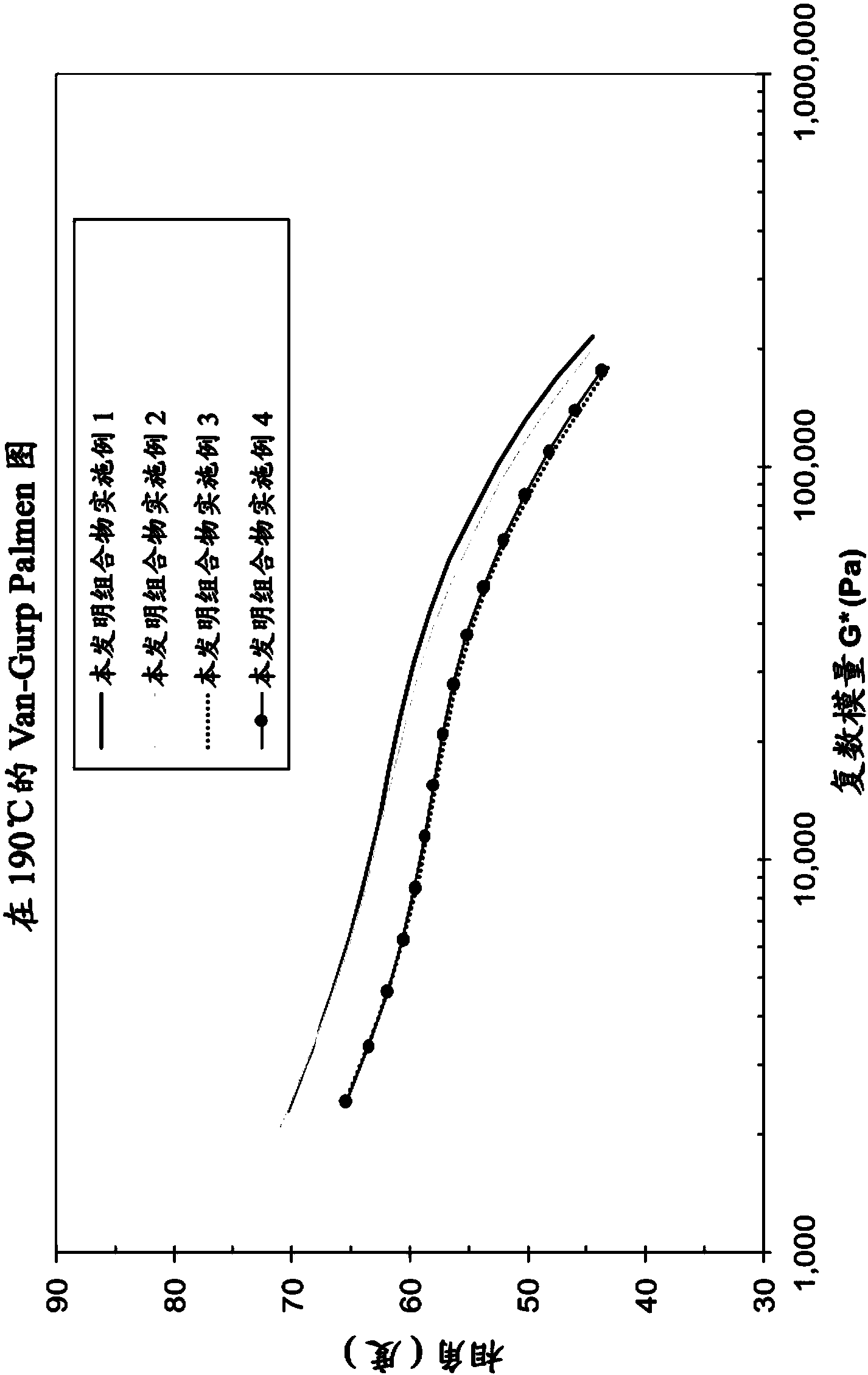

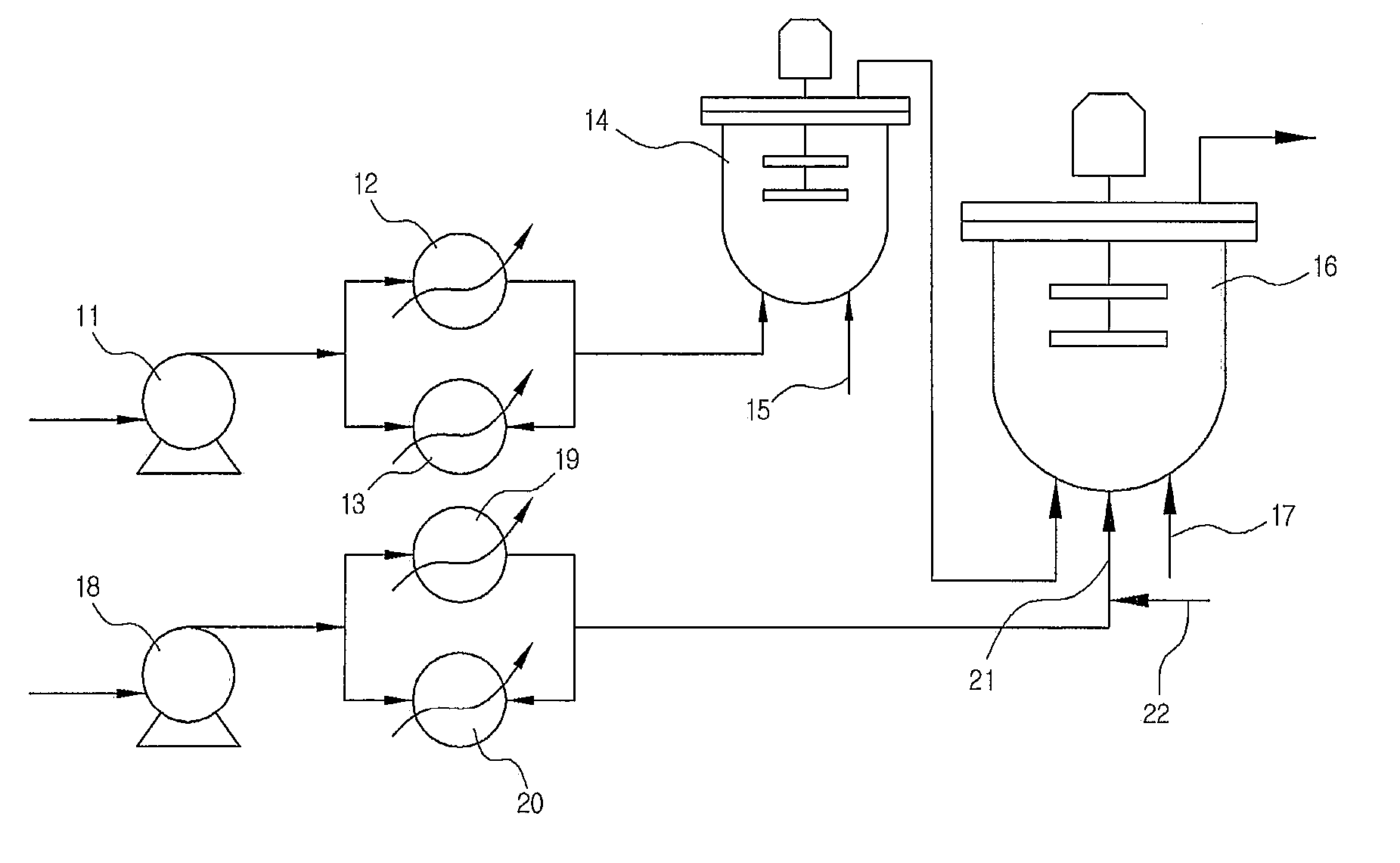

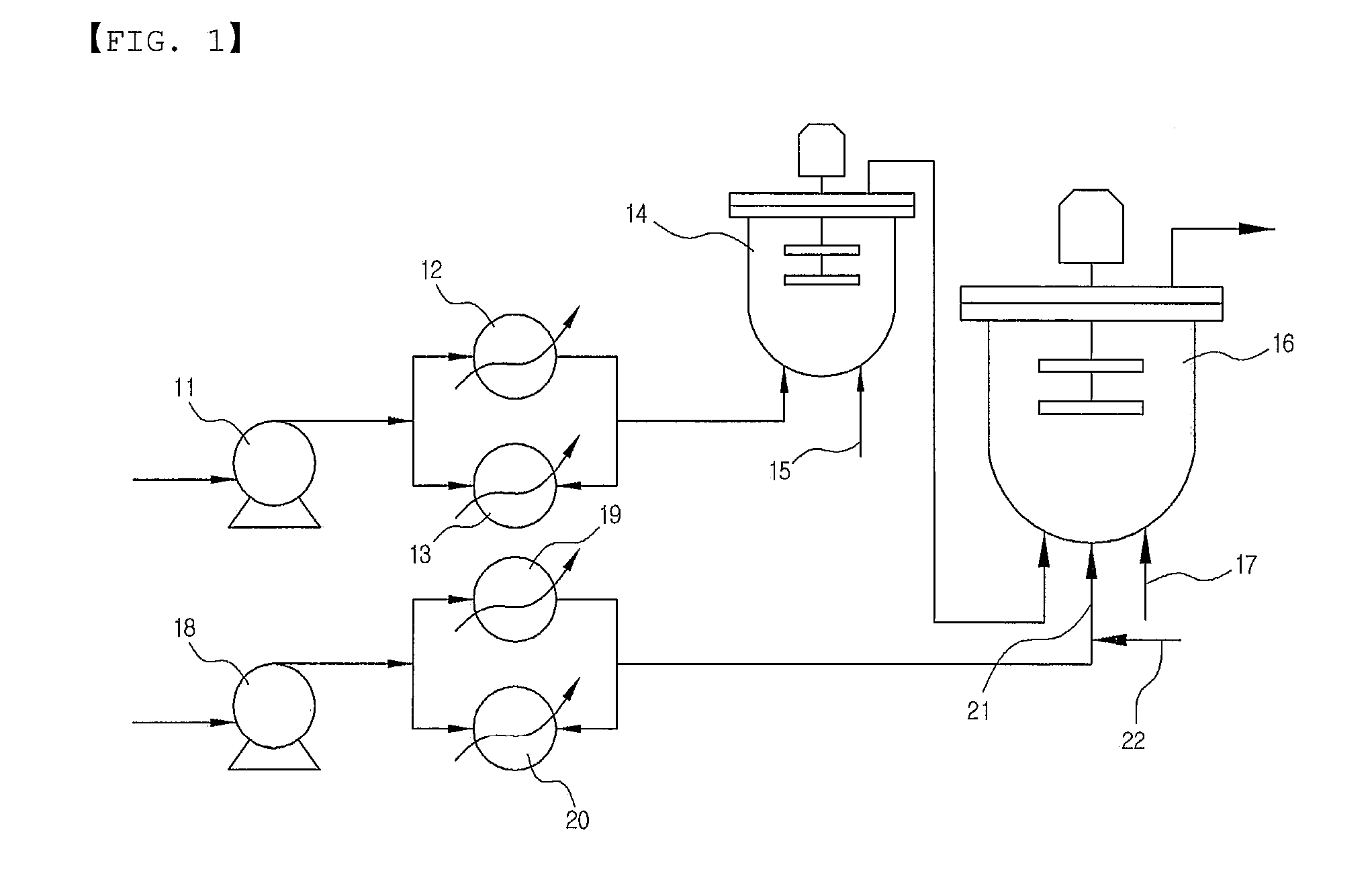

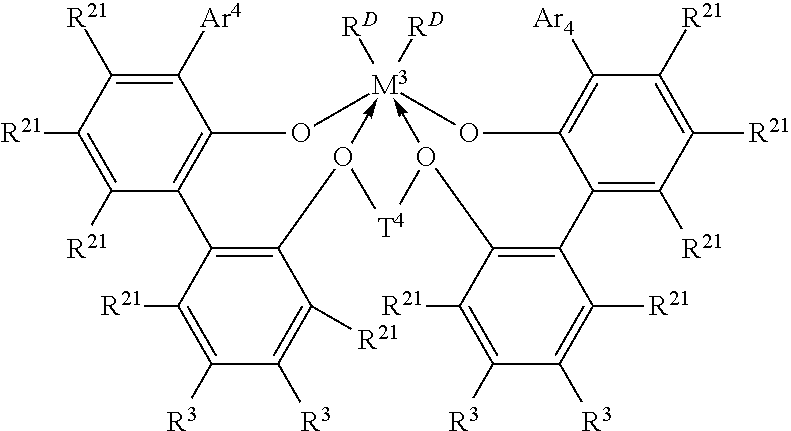

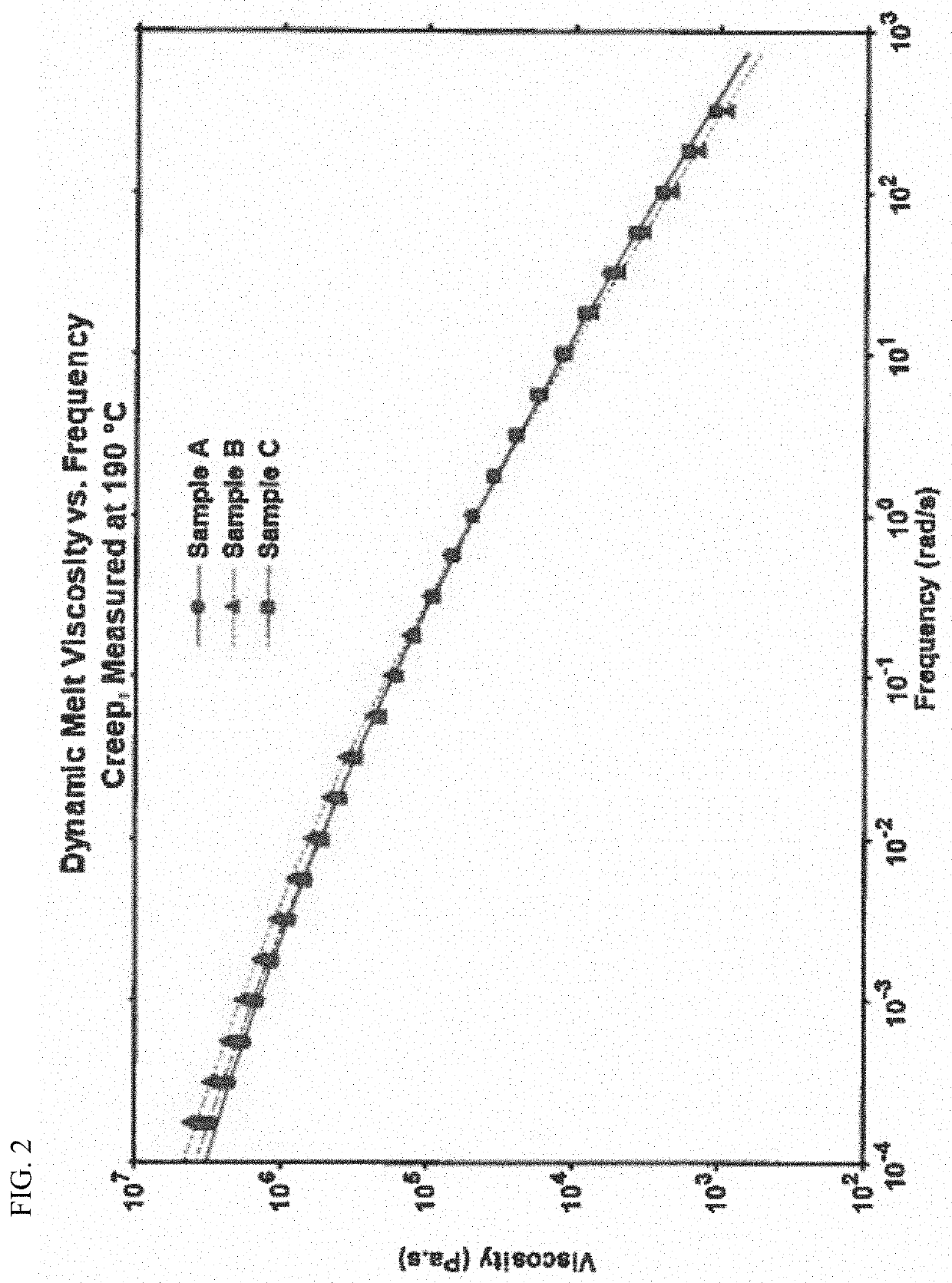

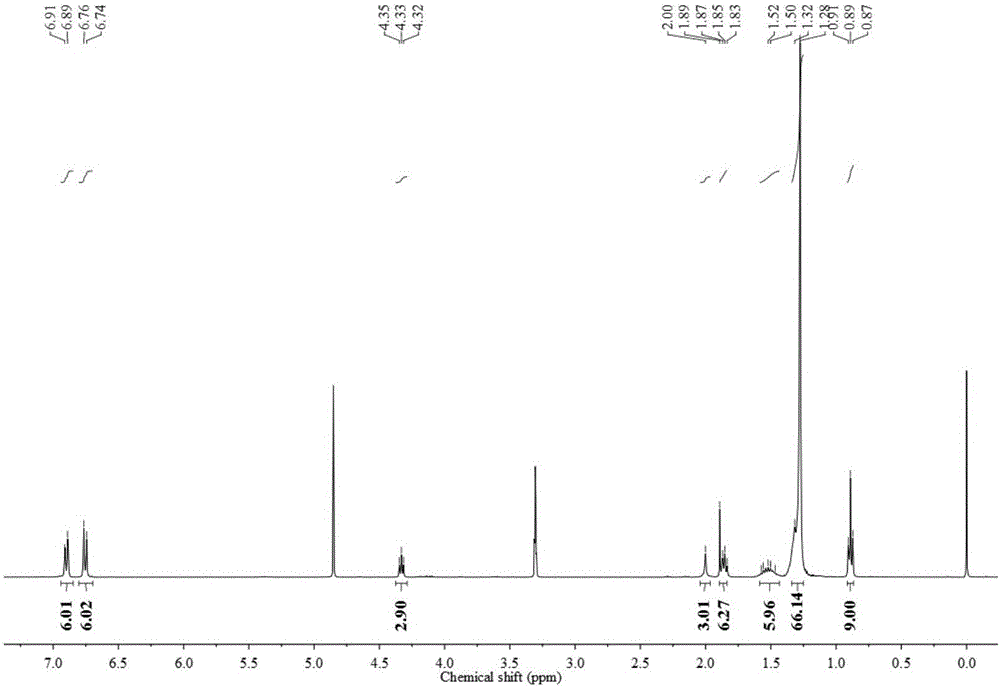

Ethylene Copolymer with Improved Elasticity and Processibility

InactiveUS20120015123A1Increase elasticityImproving processibilitySynthetic resin layered productsThin material handlingPolymer scienceZero shear viscosity

Provided is an ethylene copolymer with improved elasticity and processibility. More specifically, provided is an ethylene copolymer which exhibits a high zero shear viscosity and a large degree of shear thinning degree, and shows rheological characteristics behaviors differentiated from products manufactured by using the existing metallocene and Ziegler-Natta catalysts. In addition, provided is an ethylene copolymer which has a low processing load, shows differentiated behavior in Van-Gurp Palmen analysis, and exhibits excellent Neck-in characteristics.

Owner:SK INNOVATION CO LTD

Artificial turf yarn

InactiveUS20140242304A1Dead plant preservationArtificial flowers and garlandsYarnZero shear viscosity

An artificial turf comprising a turf yarn prepared from an ethylene-based polymer composition comprising less than or equal to 100 percent by weight of the units derived from ethylene; and less than 30 percent by weight of units derived from one or more α-olefin comonomers; wherein said ethylene-based polymer composition is characterized by having a Comonomer Distribution Constant of equal to or greater than 40, a vinyl unsaturation of less than 100 vinyls per one million carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) equal to or greater than 1.75; a density in the range of 0.915 to 0.930 g / cm3, a melt index (12) in the range of from 0.8 to 5 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2 to 3.6, and a molecular weight distribution (Mz / Mw) equal to or less than 3; and wherein the turf yarn exhibits one or more of the following properties (a) shrink of less than 4.8%, and (b) curl of less than 0.5 is provided.

Owner:SANDKUEHLER PETER +1

Cellulose dope and method for producing the same

InactiveUS7108907B1Stable and free from gelationHigh degree of polymerizationArtificial filaments from cellulose solutionsCellulosic plastic layered productsCelluloseZero shear viscosity

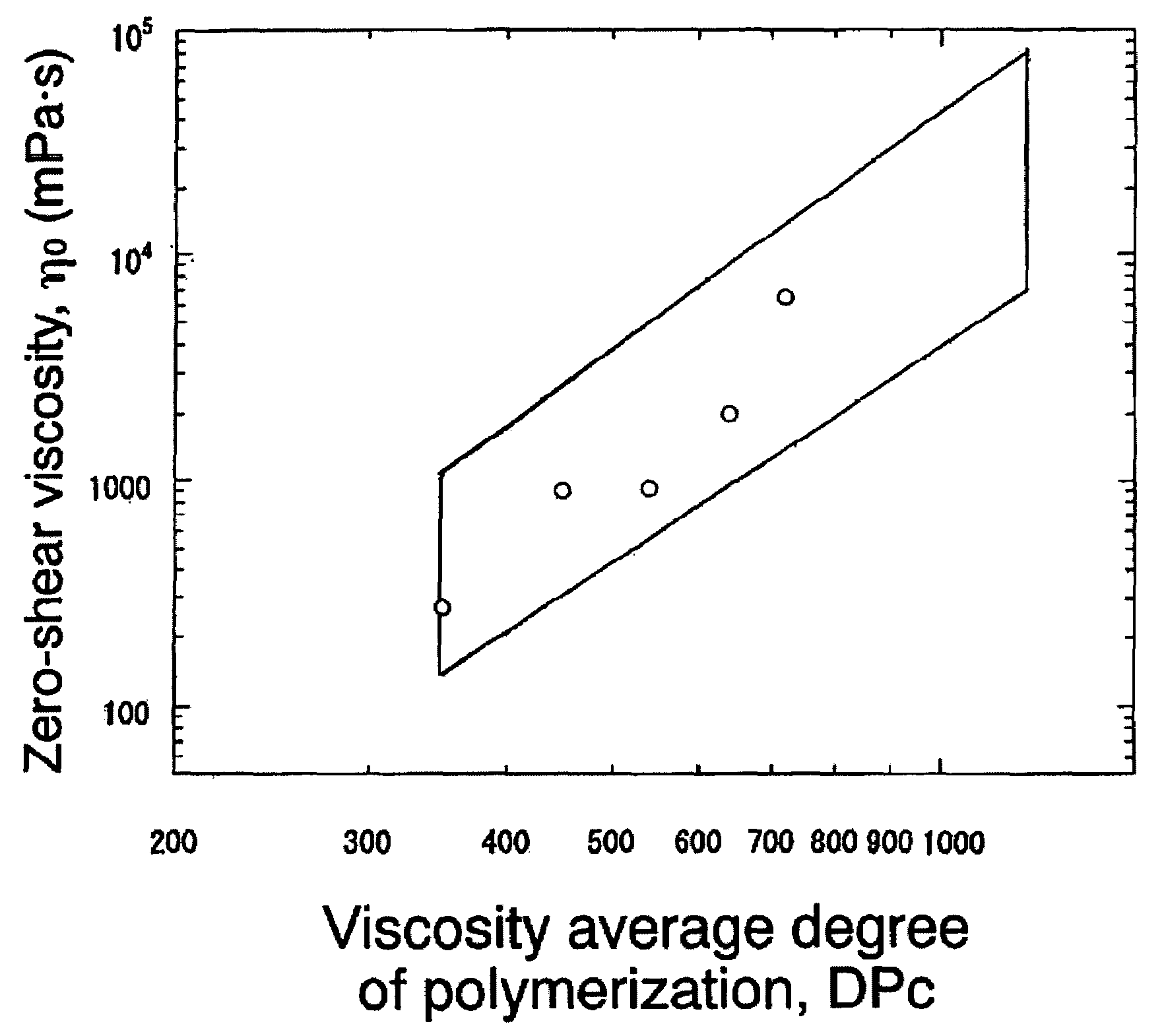

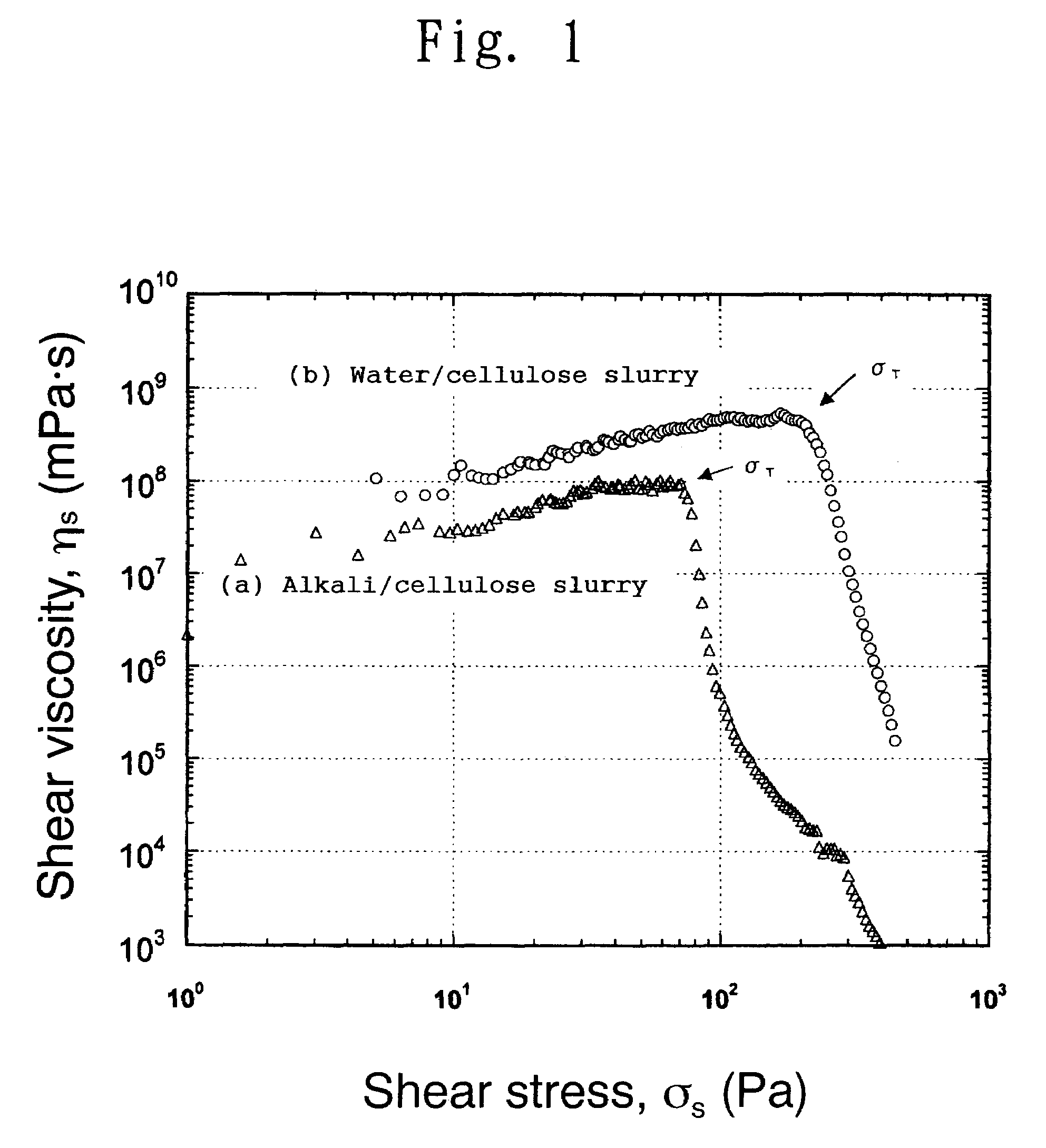

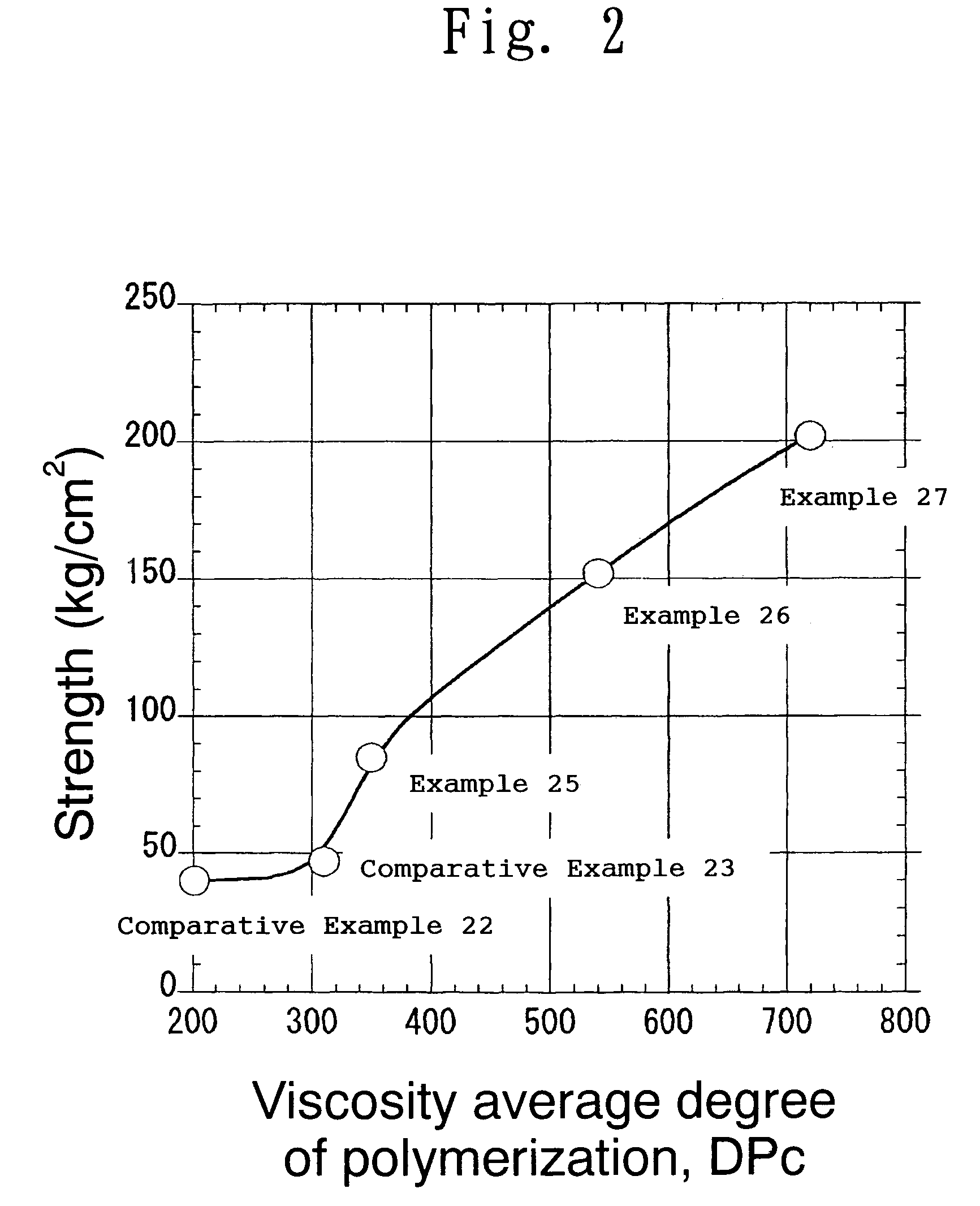

A cellulose dope comprising an aqueous sodium hydroxide solution and cellulose dissolved in the solution, wherein the cellulose dope has a sodium hydroxide concentration (CNa) of from 6.5 to 11% by weight, a cellulose content (Cc) of from 5 to 10% by weight, a viscosity average degree of polymerization (DPc) of the cellulose of from 350 to 1,200 and a cellulose dissolution ratio (Sc) of 99.0% by weight or more, and wherein the zero-shear viscosity (η0) and the cellulose content (Cc) of the cellulose dope and the viscosity average degree of polymerization (DPc) of the cellulose in the cellulose dope satisfy the following formula (1):η0=kCcm×DPcp (1)wherein:η0 represents the zero-shear viscosity (mPa·s) of the cellulose dope,Cc represents the cellulose content (% by weight) of the cellulose dope,DPc represents the viscosity average degree of polymerization of the cellulose in the cellulose dope,k=3.9×10−11,m is a number of from 5 to 7, andp is a number of from 3 to 4.

Owner:ASAHI KASEI KK

Linear low density polyethylene composition suitable for cast film

ActiveUS20150225520A1Low densityPersonal careSynthetic resin layered productsLinear low-density polyethyleneZero shear viscosity

The instant invention provides a linear low density polyethylene composition suitable for cast film, films made therefrom, and packaging devices comprising one or more such film layers. The linear low density polyethylene composition suitable for cast film according to the present invention comprises an ethylene / α-olefin interpolymer composition having a Comonomer Distribution Constant (CDC) in the range of from 40 to 200, for example from 40 to 150, a vinyl unsaturation of less than 0.12 vinyls per one thousand carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from 1.2 to 5, for example from 1.5 to 4; a density in the range of from 0.910 to 0.935, for example from 0.915 to 0.925, g / cm3, a melt index (I2) in a range of from 1 to 10, for example from 2 to 6 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2 to 3.5.

Owner:THE DOW CHEM CO

Multiaxial Fabric With Strain-Responsive Viscous Liquid Polymers

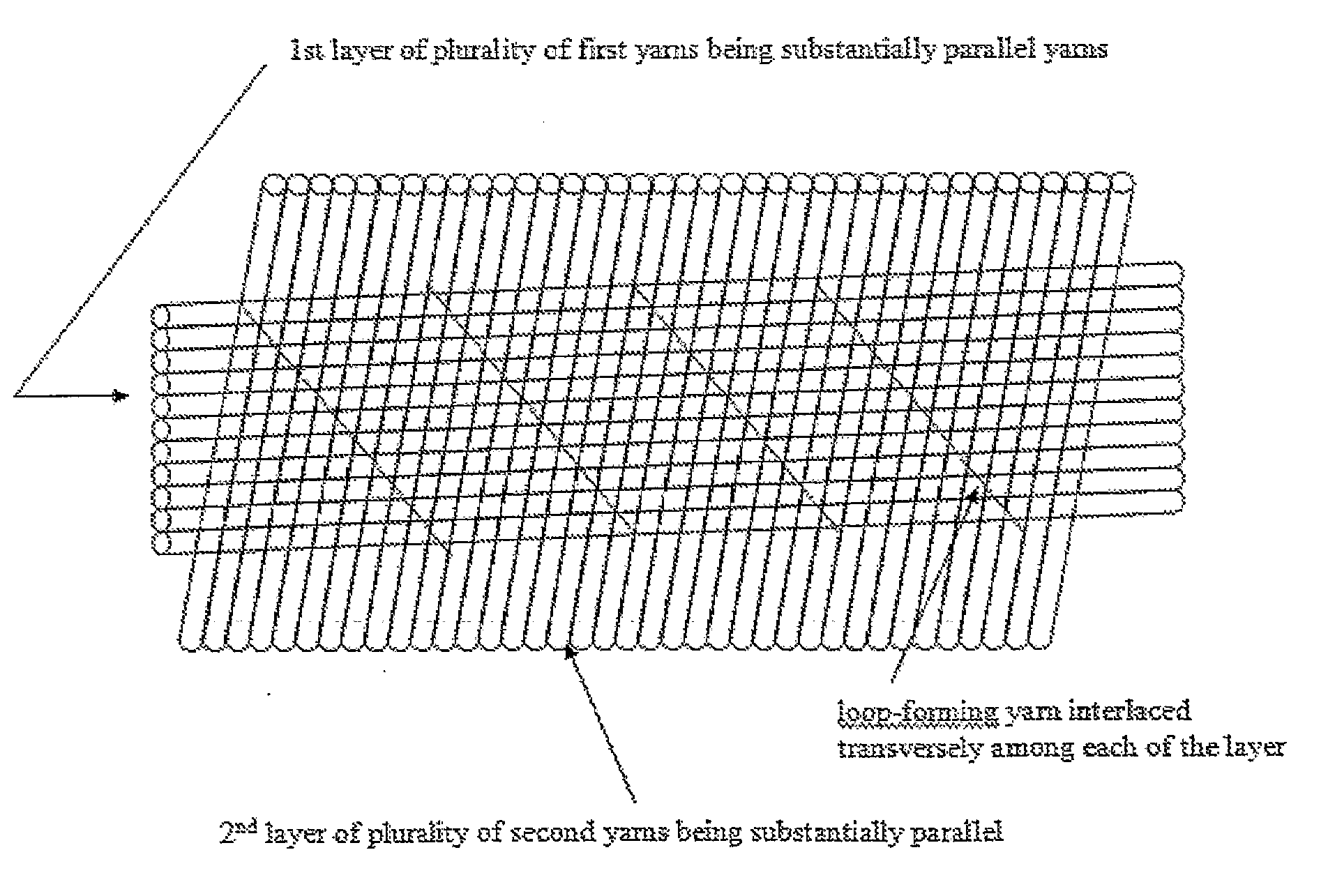

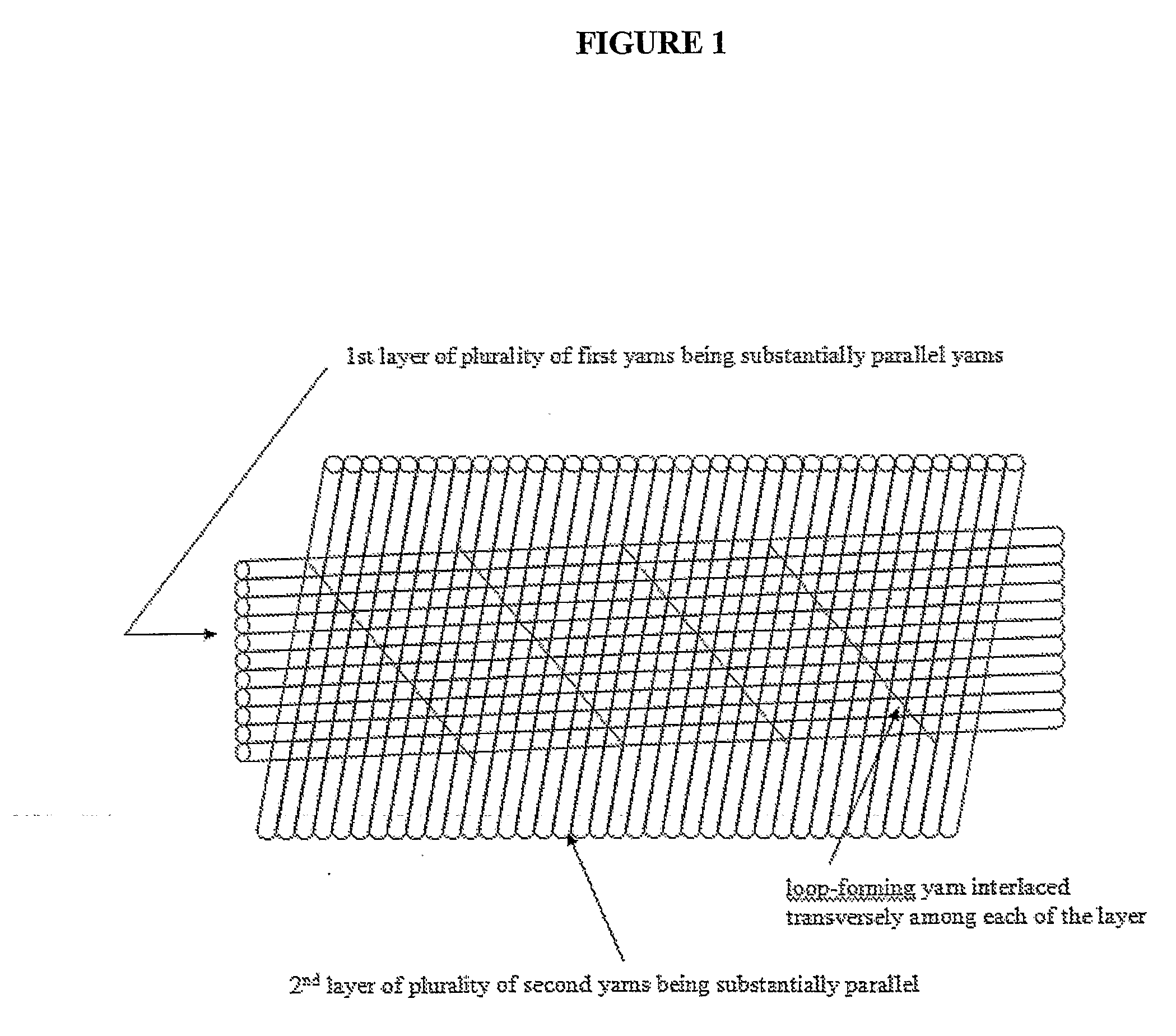

The invention concerns multiaxial fabrics comprising a first layer comprising a plurality of first yarns being substantially parallel in a first direction, a second layer comprising a plurality of second yarns being substantially parallel in a second direction and skew or off-set with respect to the first yarns, transverse yarn interlaced transversely within the layers; wherein each layer is coated with a high viscosity polymer that has a Tg in the range of about −40 to about 0° C., and a zero shear viscosity of about 2×106 to about 1013 poise at 20° C.

Owner:DUPONT SAFETY & CONSTR INC

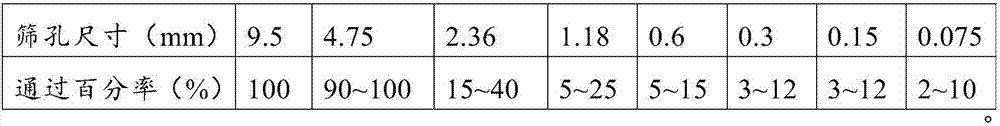

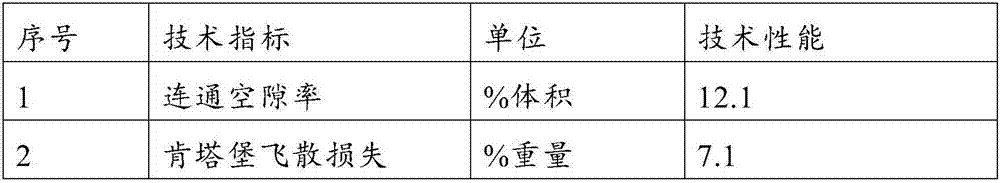

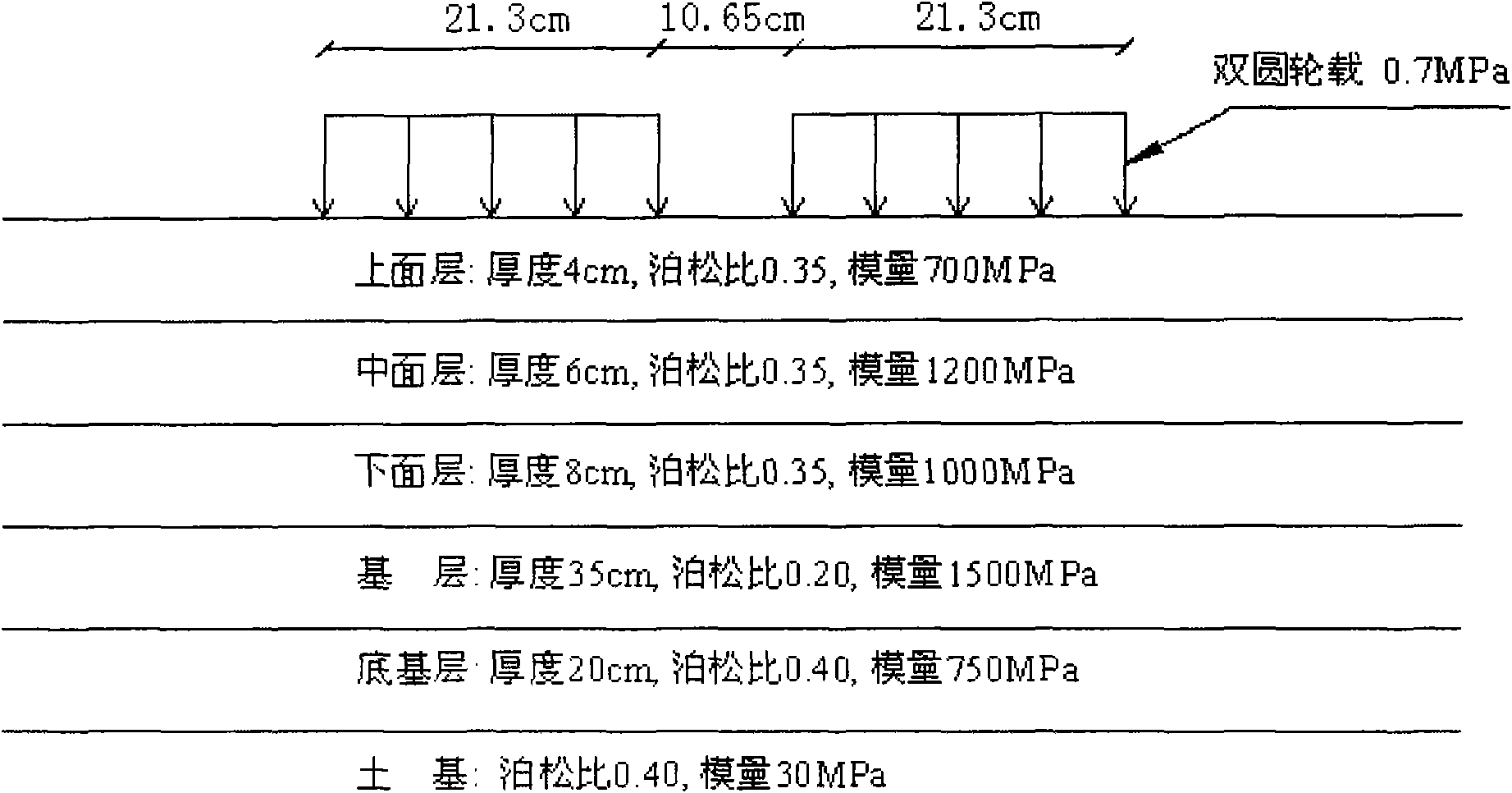

Small-particle-size open-graded asphalt mixture for ultra-thin overlay

The invention provides a small-particle-size open-graded asphalt mixture for an ultra-thin overlay. The mixture is prepared from 85%-92% by weight of aggregate, 2%-8% by weight of filler and 5.5%-7.5% by weight of polymer modified asphalt, the nominal maximum aggregate size is 4.75 mm and the thickness of a pavement layer is 1.0-1.5 cm; preferably, the aggregate is basalt or diabase, the filler is the mixture of limestone mineral powder and cement in the mass ratio being (1:1)-(3:1), and the polymer modified asphalt is POE composite modified asphalt and has the zero-shear viscosity being 30,000 Pa.s or higher at 60 DEG C and the softening point equal to or higher than 90 DEG C. The small-particle-size open-graded asphalt mixture for ultra-thin overlay can reduce the thickness of a thin overlay, reduce building cost of a project and reduce noise during driving, two levels of hard building stones with the particle size being 3-5 mm or 0-3 mm can be utilized, the environment and resource stress of superfluous corresponding building stones due to large-scale application of SMA (stone mastic asphalt) pavements is reduced, and the small-particle-size open-graded asphalt mixture is ingenious in design, simple and convenient to prepare, low in cost and suitable for large-scale popularization and application.

Owner:SHANGHAI MUNICIPAL PLANNING & DESIGN INST CO LTD

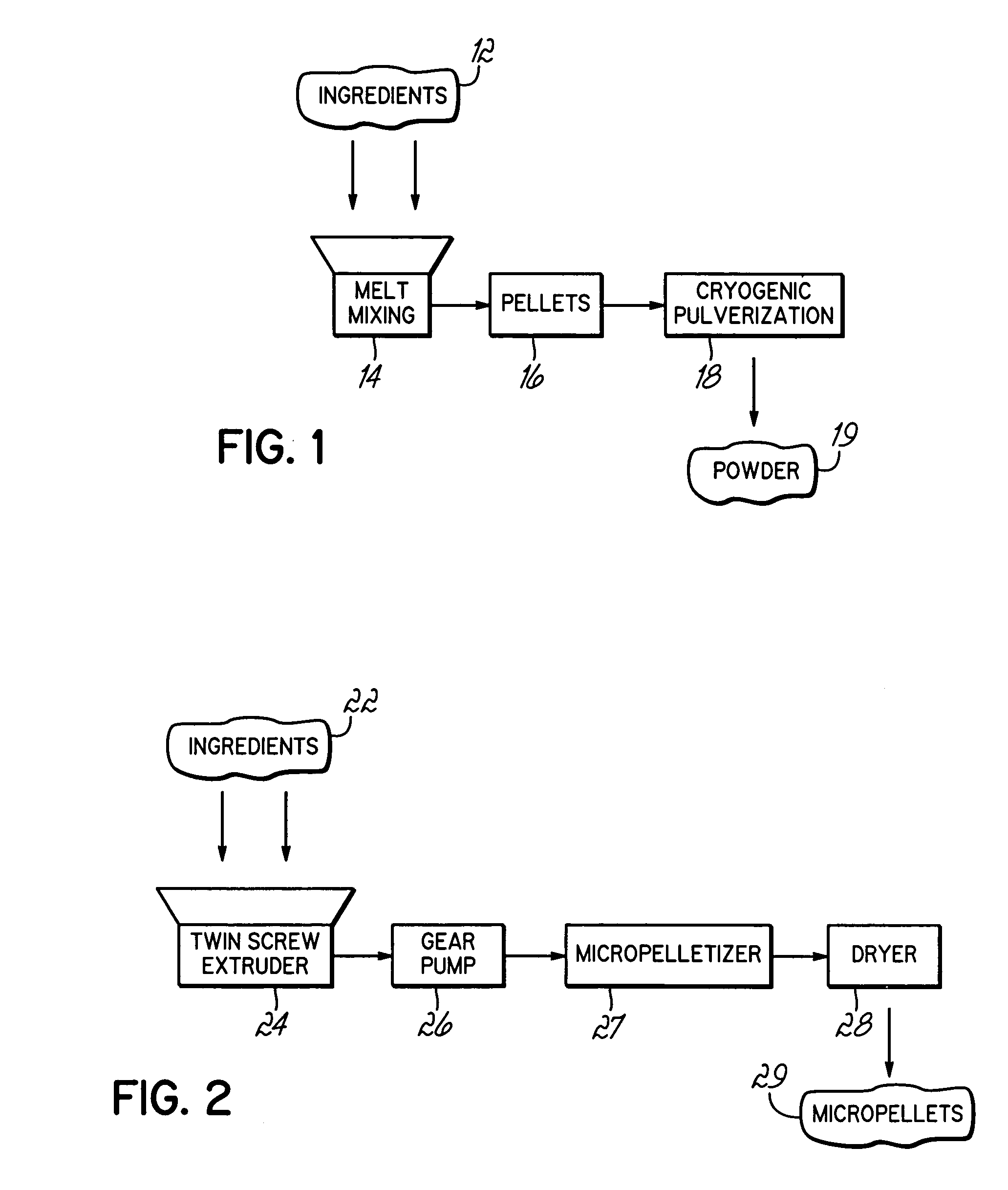

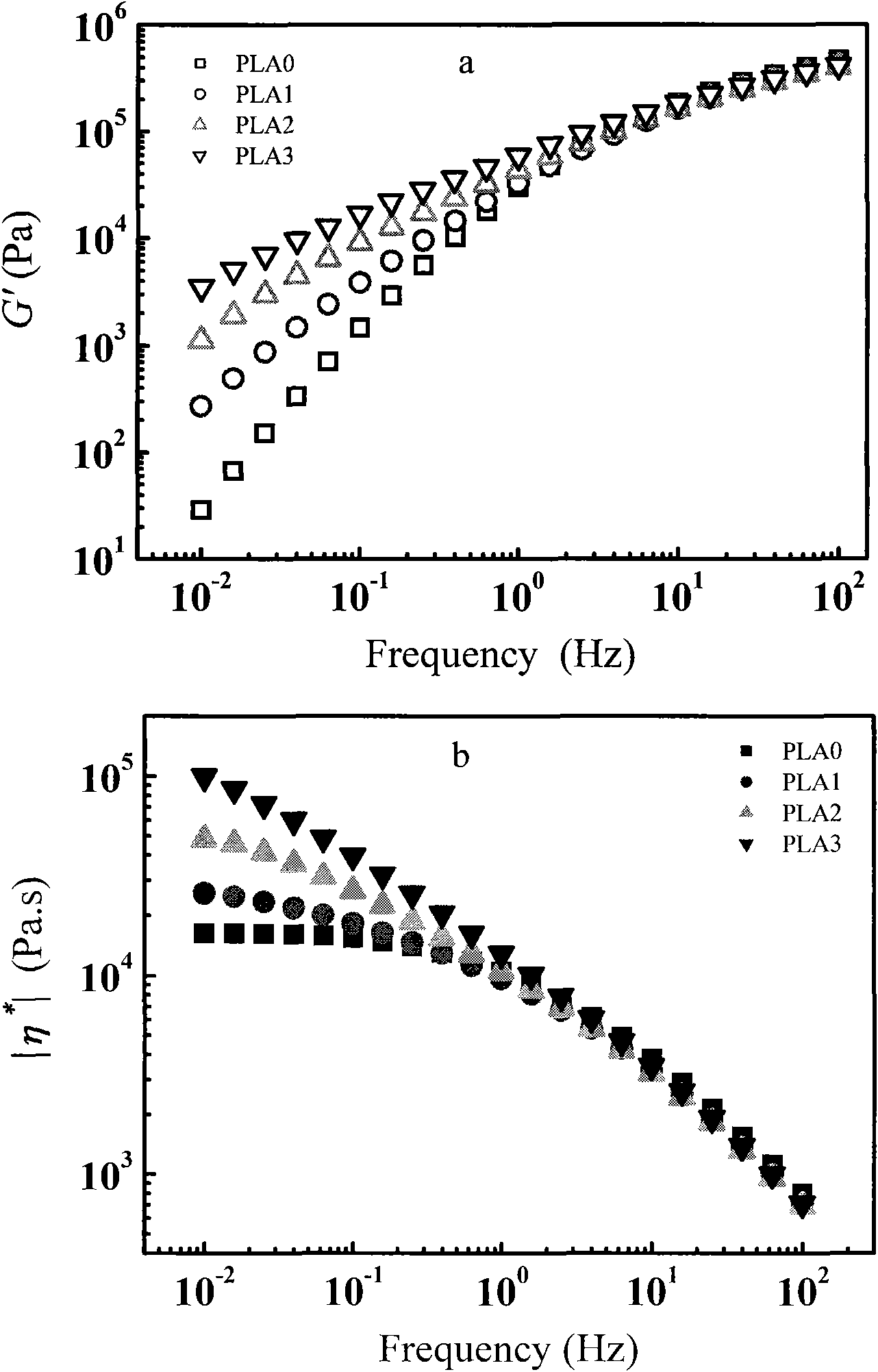

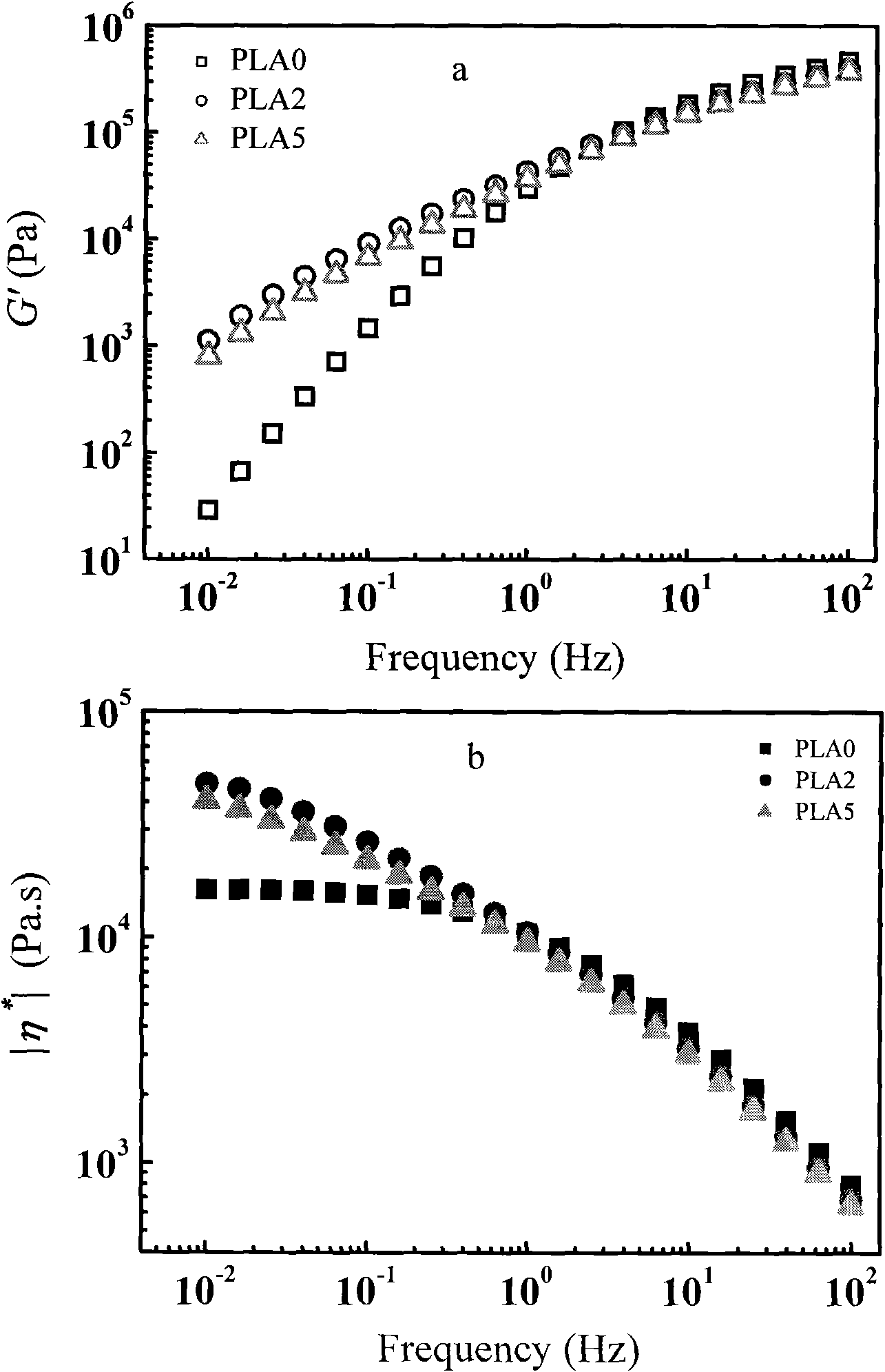

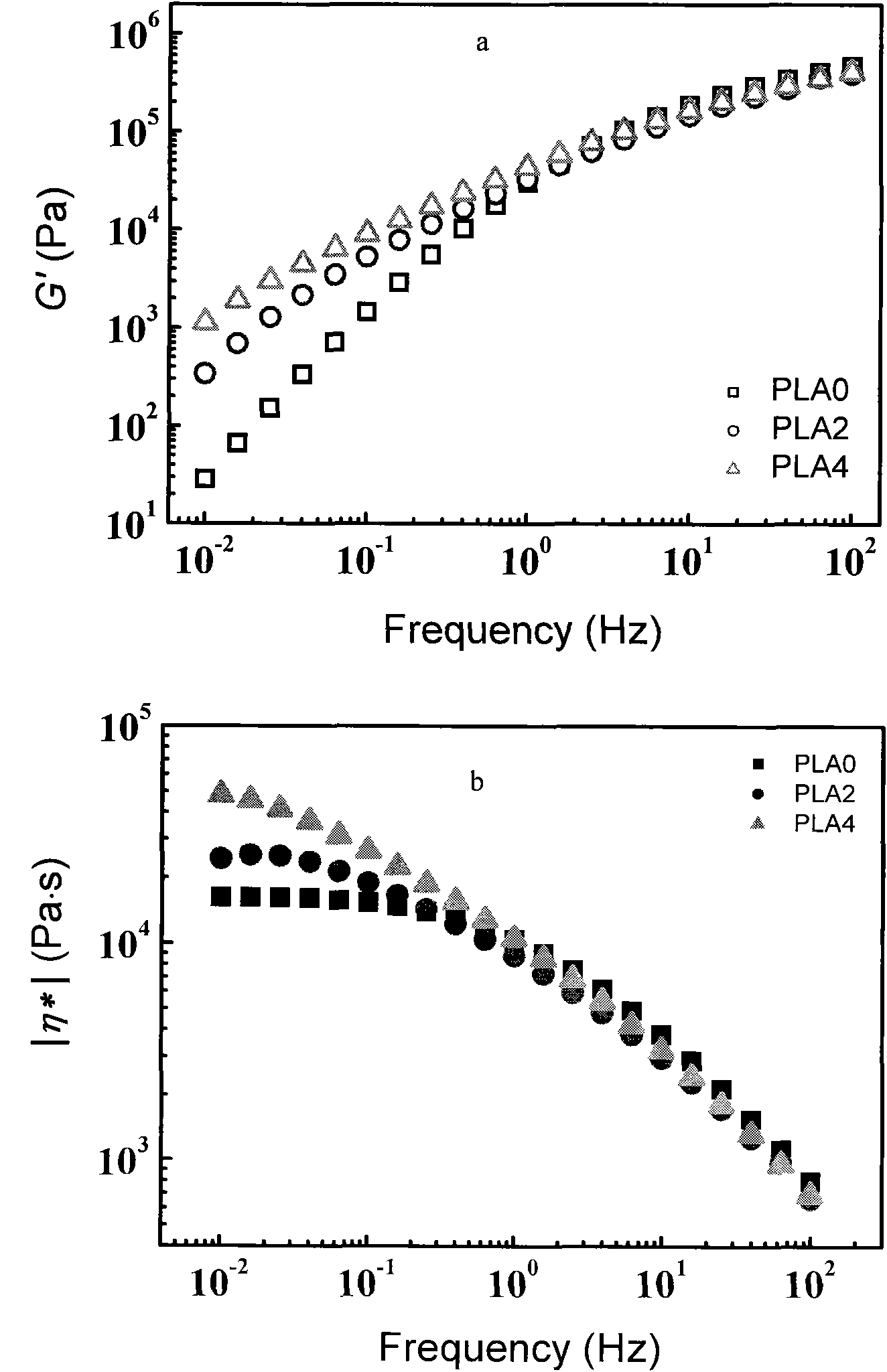

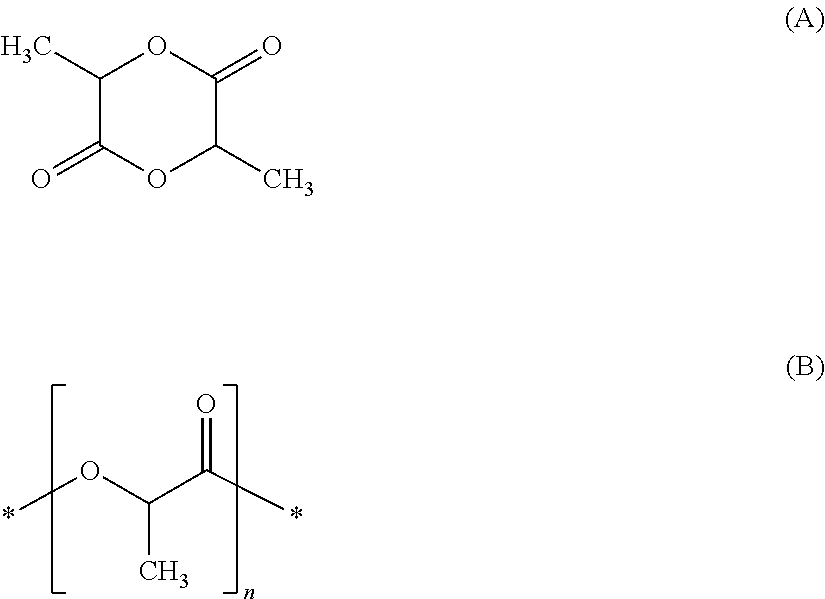

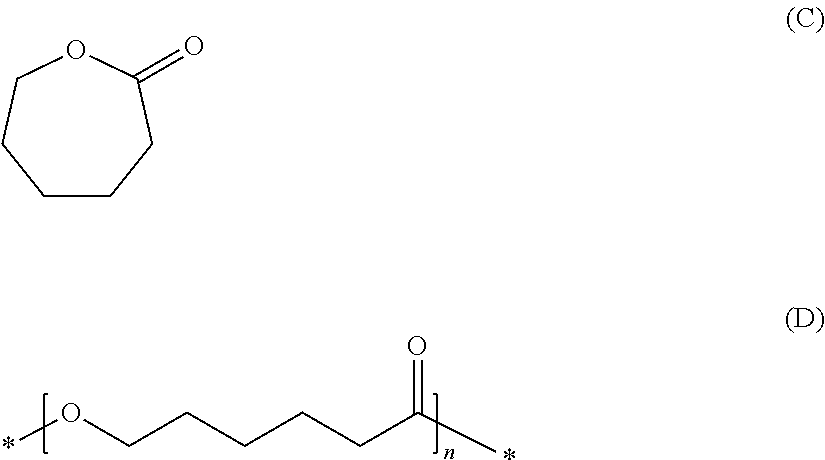

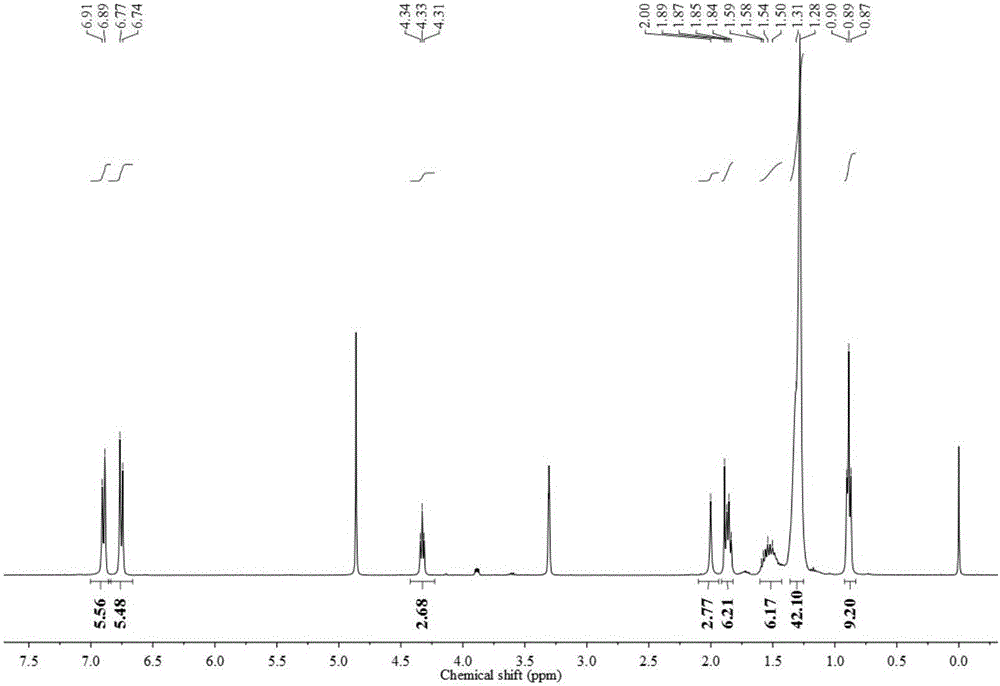

Long chain branching polylactic resin and preparation method thereof

InactiveCN101921371AImprove formation efficiencyHas strain hardening propertiesPolymer scienceZero shear viscosity

The invention discloses a long chain branching polylactic resin and a preparation method thereof. In the long chain branching polylactic resin, constitutional repeating units of a main chain and branch chains are lactic acid, wherein branch points on the main chain are tertiary carbon atoms in the lactic acid constitutional repeating units of the main chain. The preparation method comprises the steps of uniformly mixing a solution-mixed aid and a linear polylactic resin, and forming a long chain branching structure through internal melt mixing or double-screw reaction extrusion. The branch chain molecular weight Mb is larger than the entanglement molecular weight Me, the molecular weight is obviously improved, low-frequency end storage modulus G' and zero shear viscosity eta 0 are obviously improved during shear flow, the gel content is less than 1 percent, obvious strain hardening characteristic is shown during extensional flow, the requirement for secondary forming processing is met, and the tensile strength is obviously improved to 64MPa. The resin can be applied to the fields such as foaming, melt spinning and the like, and can be expansively applied to the fields such as foam packaging materials and clothing fibers.

Owner:INST OF CHEM CHINESE ACAD OF SCI

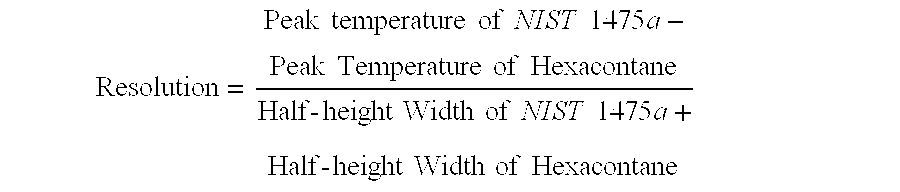

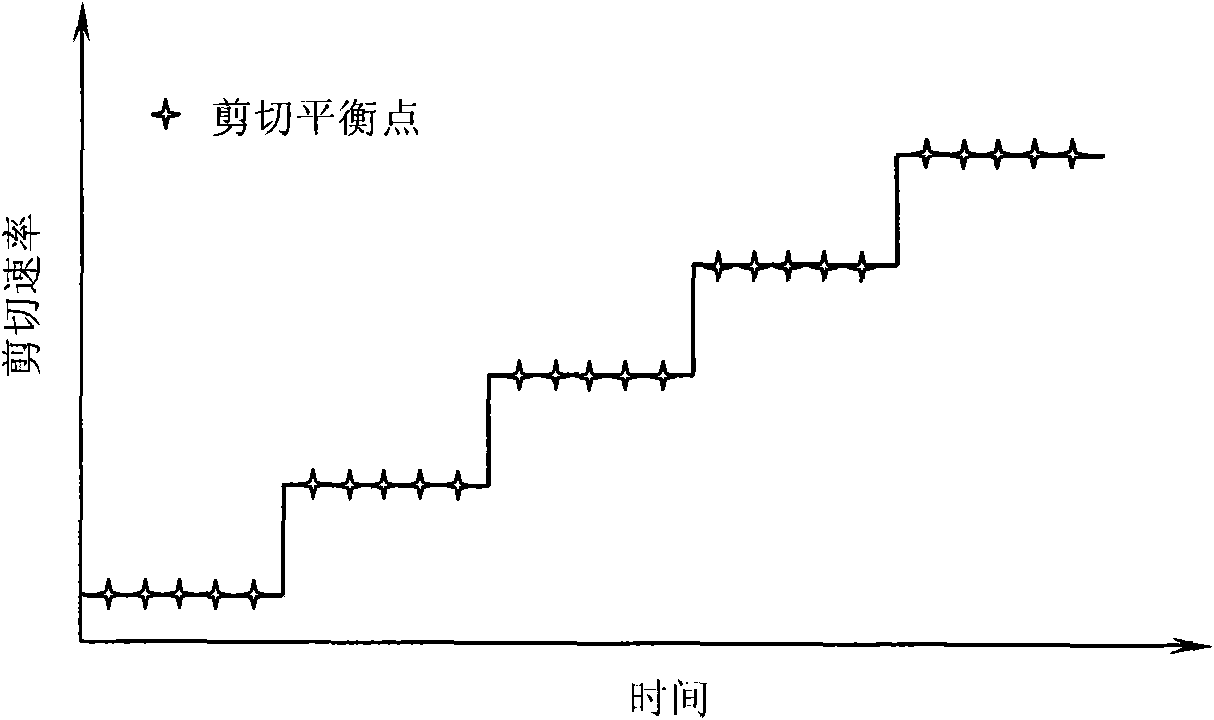

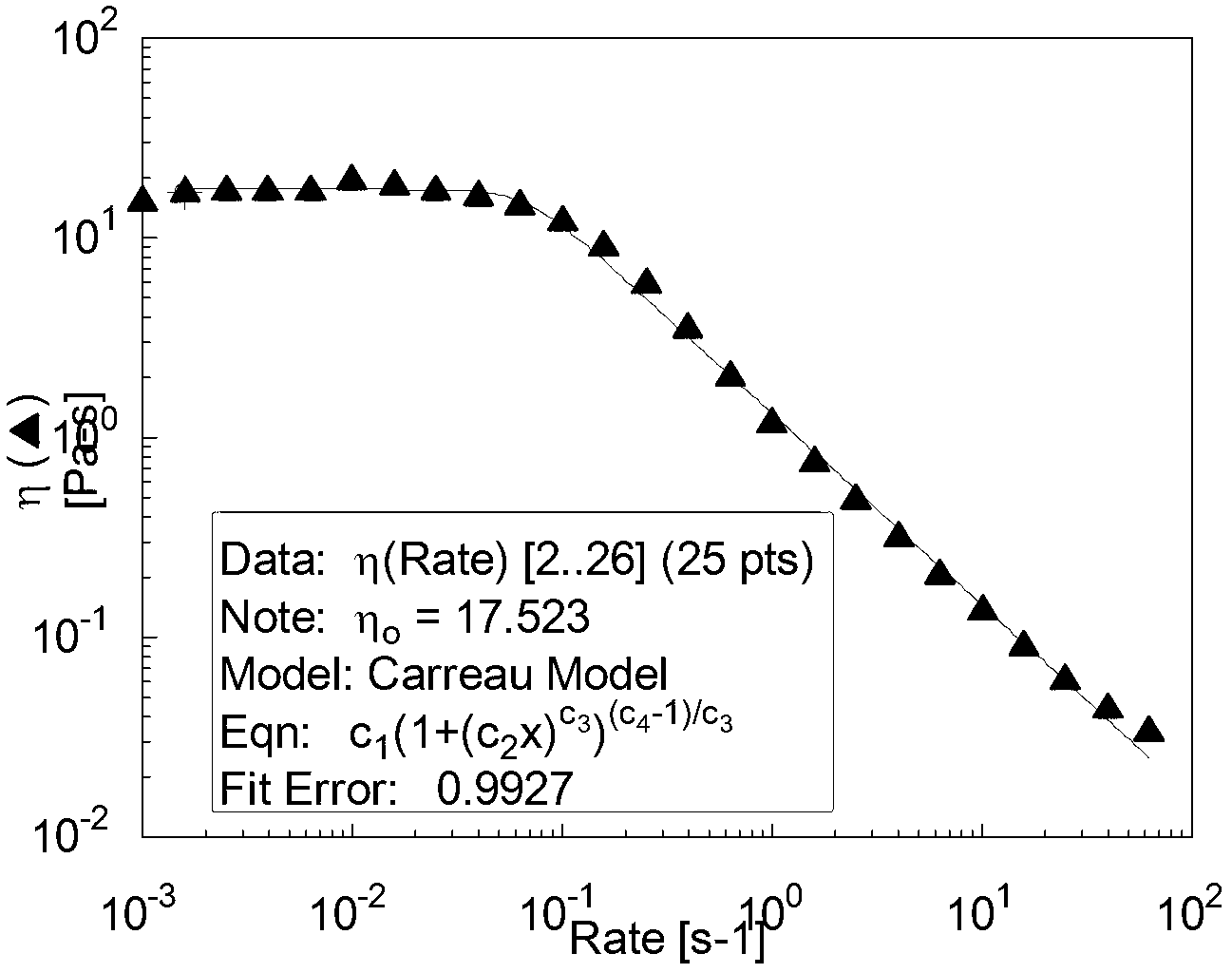

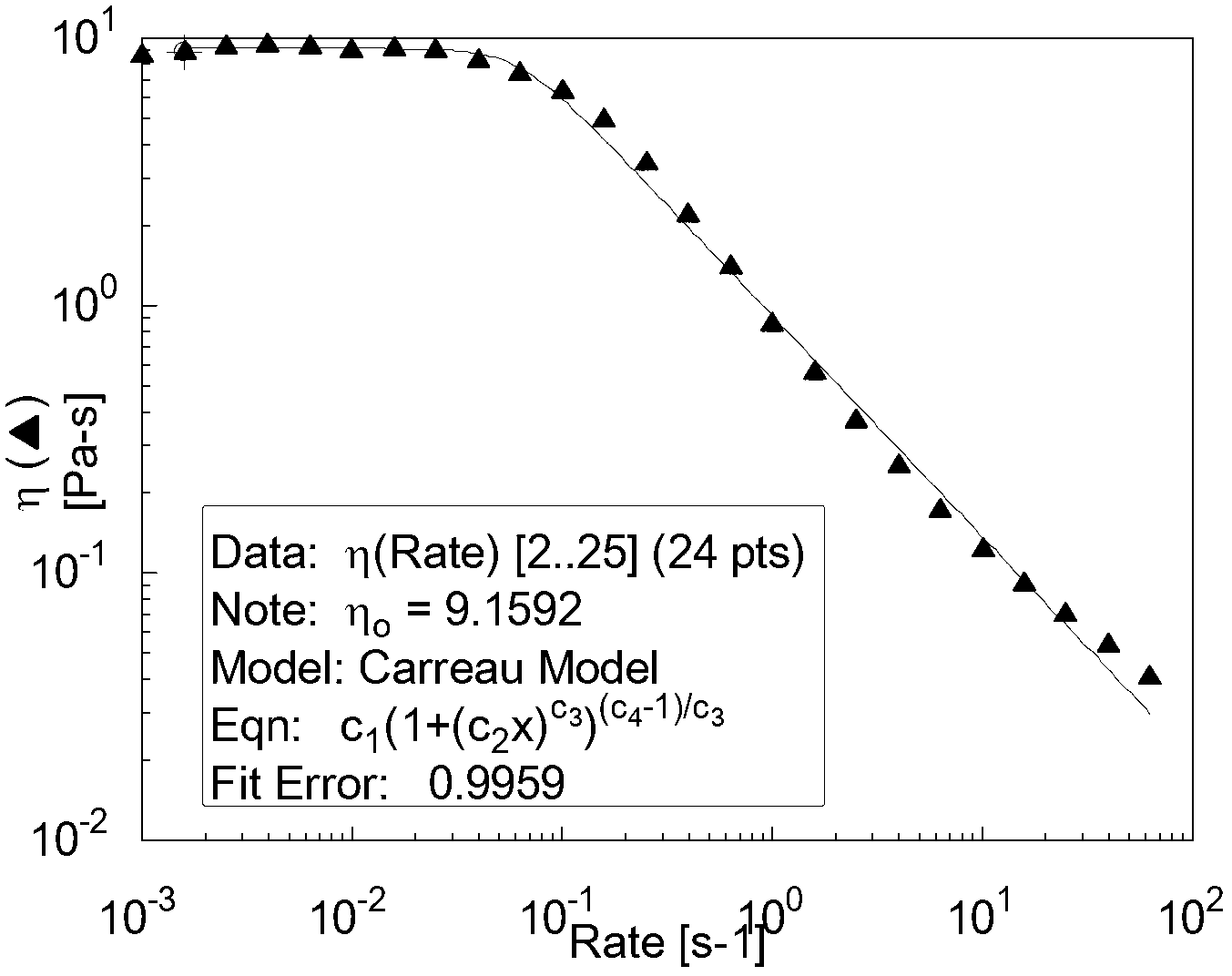

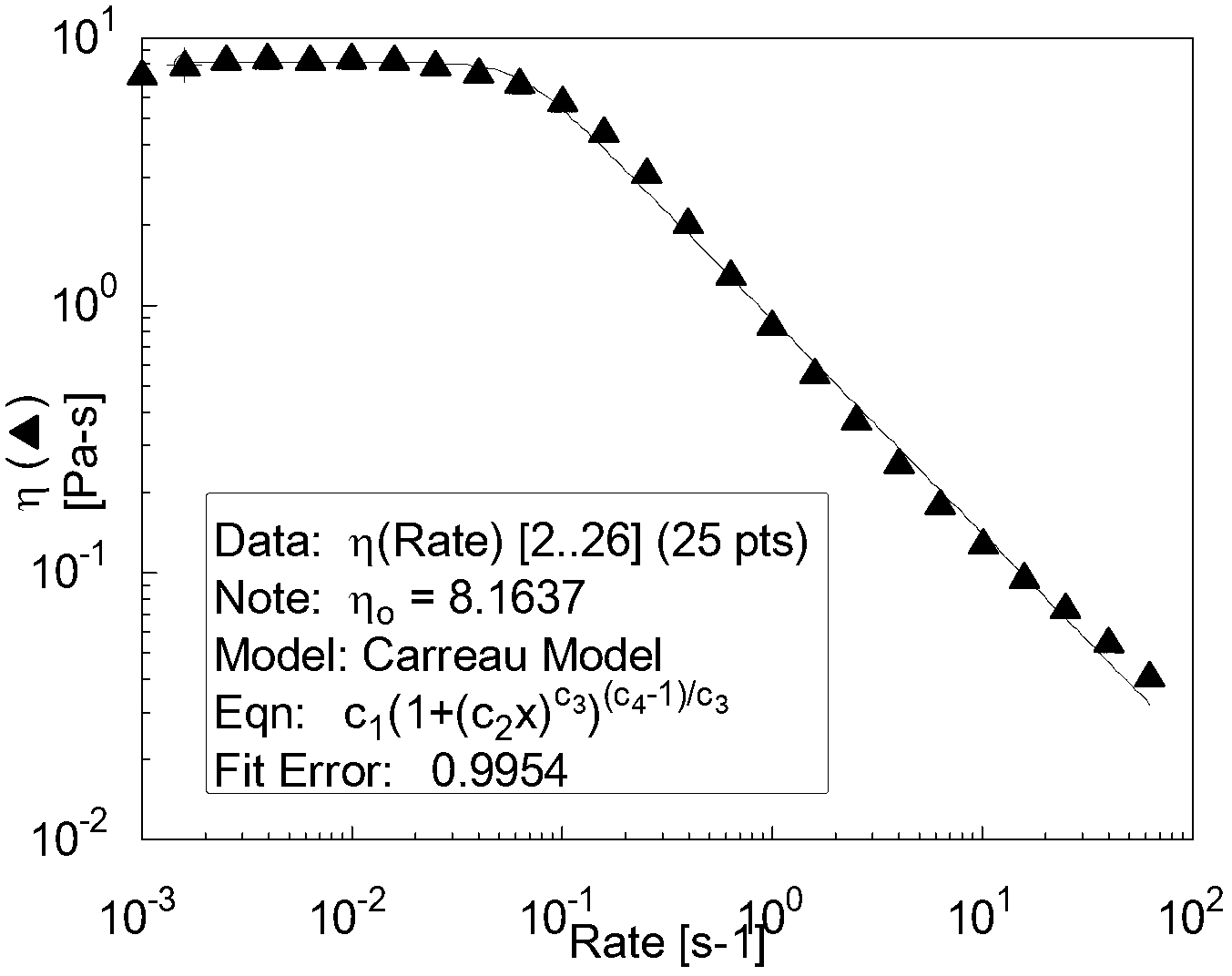

Loxiong viscosity behavior measuring method of high-viscosity modified asphalt and application thereof

The invention relates to a loxiong viscosity behavior measuring method of a high-viscosity modified asphalt and an application thereof, which comprises the following steps: A. using the shearing rate scan test to obtain the viscosity-shearing rate flow curve of the high-viscosity modified asphalt at 60 DEG C; and B. fitting the curve obtained in the step A to obtain the 60 DEG C zero shear viscosity. The 60 DEG C zero shear viscosity obtained by using the method can be used for evaluating the viscosity behavior of the high-viscosity modified asphalt in a pavement structure. The invention is based on following references: the high-viscosity modified asphalt presents the characteristic of pseudo-plastic fluid at the shearing rate of 1.25*10<-5>s<-1>-1250s<-1>, the viscosity tends to be the zero shear viscosity in a first Newtonian region, and the common range in the first Newtonian region is completely matched with the shearing rate range in the pavement structure in the aspect of magnitude order, so the 60 DEG C zero shear viscosity can effectively reflect the viscosity characteristic of the high-viscosity modified asphalt in the pavement structure.

Owner:TONGJI UNIV

Spunbond nonwoven fabrics

The instant invention provides nonwoven fabrics and staple or binder fibres prepared from an ethylene-based polymer having a Comonomer Distribution Constant in the range of from greater than from 100 to 400, a vinyl unsaturation of less than 0.1 vinyls per one thousand carbon atoms present in the backbone of the ethylene-based polymer composition; a zero shear viscosity ratio (ZSVR) in the range from 1 to less than 2; a density in the range of 0.930 to 0. 970 g / cm3, a melt index (I2) in the range of from 15 to 30 or from 10 to 50 g / 10 minutes, a molecular weight distribution (Mw / Mn) in the range of from 2 to 3.5, and a molecular weight distribution (Mz / Mw) in the range of from less than 2.

Owner:DOW GLOBAL TECH LLC

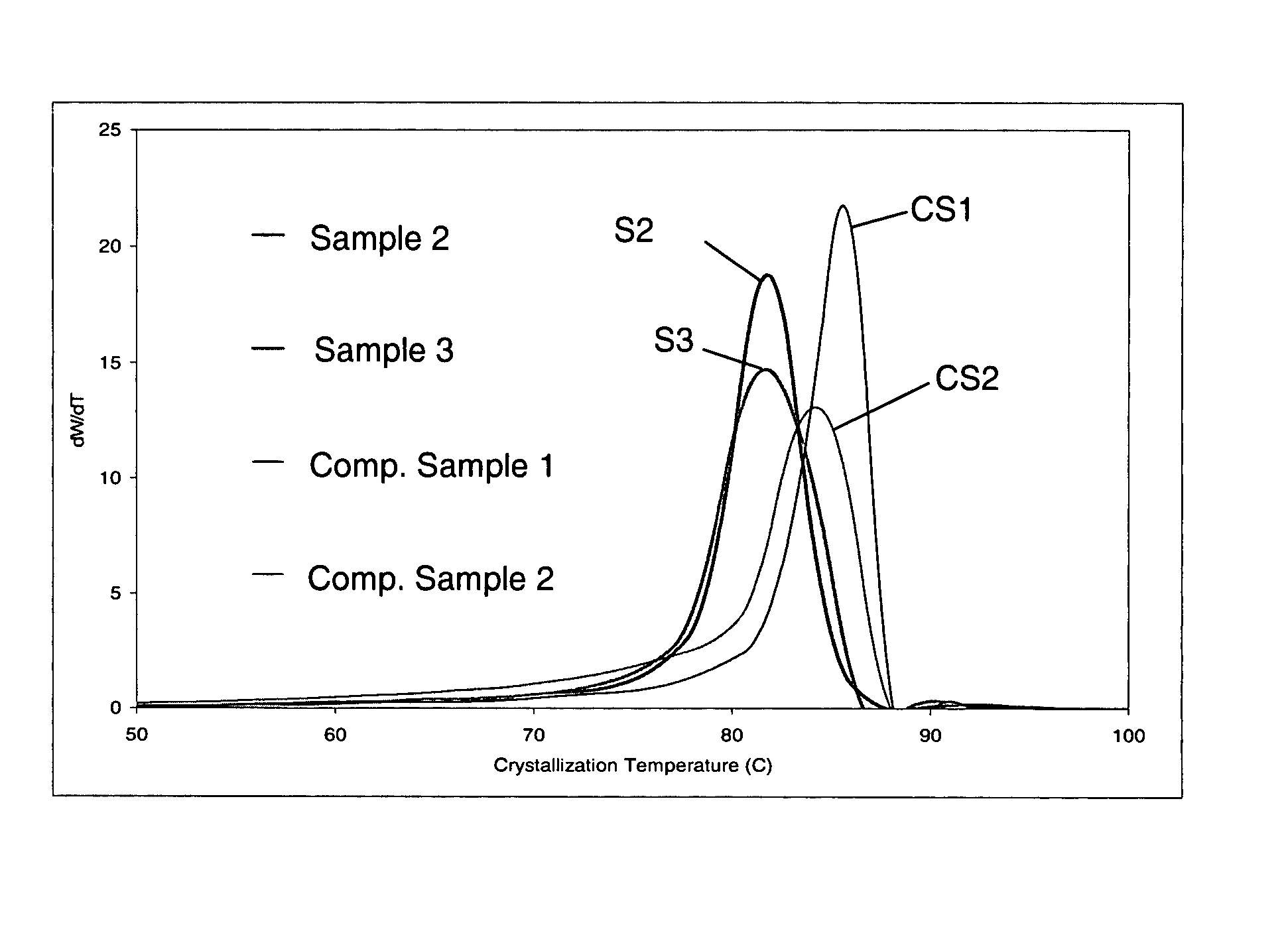

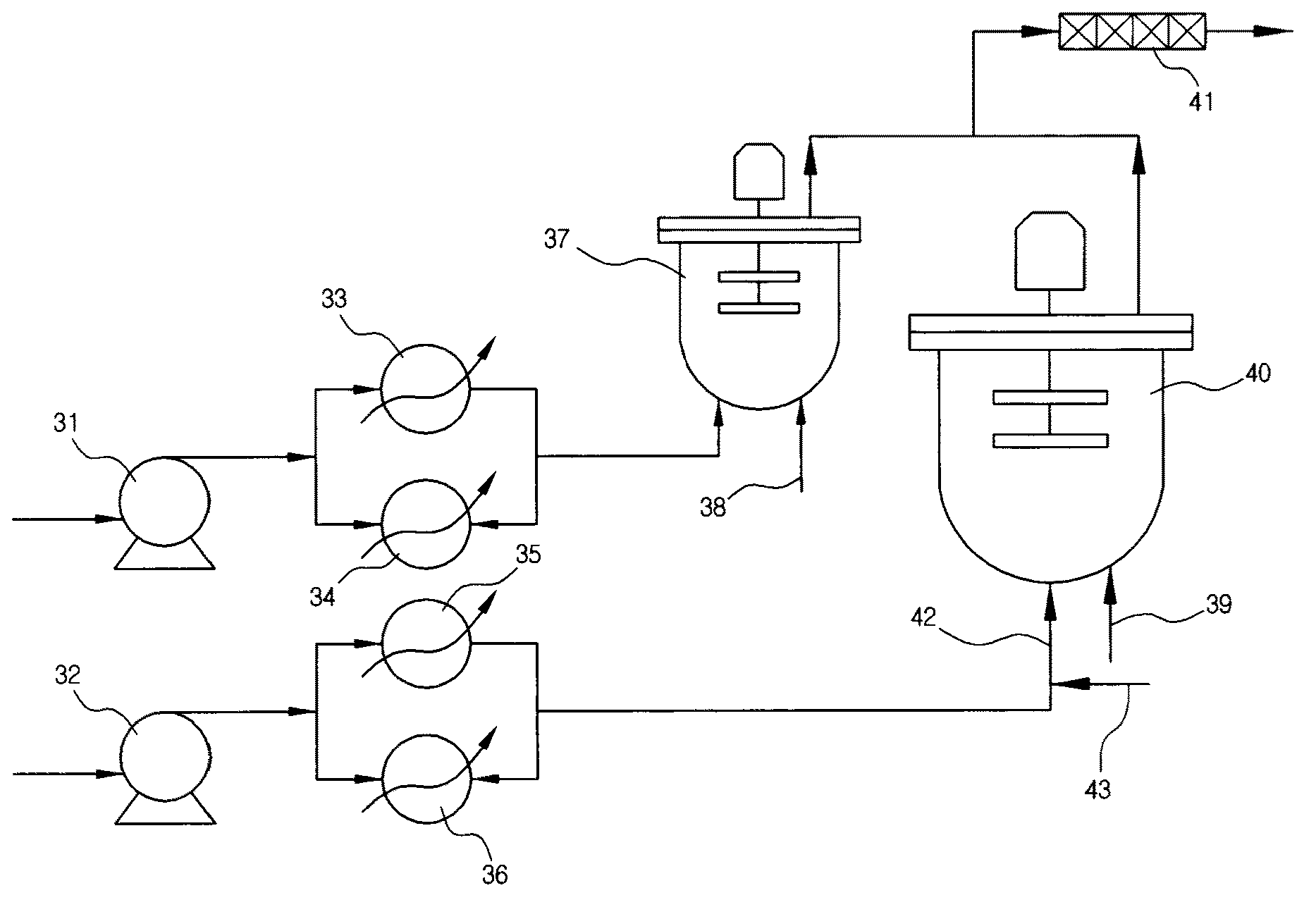

Bimodal polyethylene resins and pipes produced therefrom

Disclosed herein are ethylene-based polymers generally characterized by a density of at least 0.94 g / cm3, a high load melt index from 4 to 20 g / 10 min, a zero-shear viscosity at 190° C. from 20,000 to 400,000 kPa-sec, and a relaxation time at 190° C. from 225 to 3000 sec. These ethylene polymers can be produced by peroxide-treating a broad molecular weight distribution Ziegler-catalyzed resin, and can be used in large diameter, thick wall pipes and other end-use applications.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

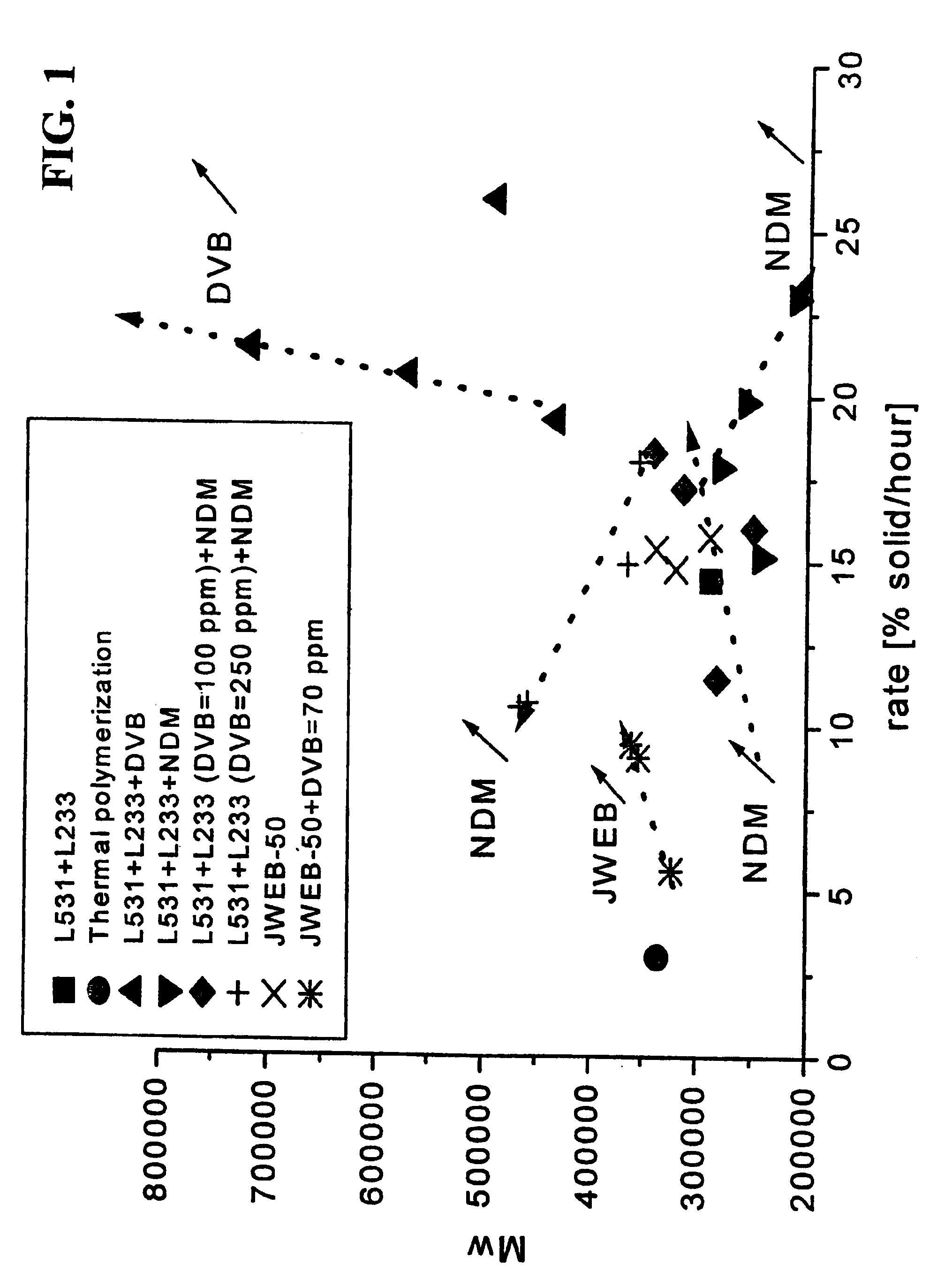

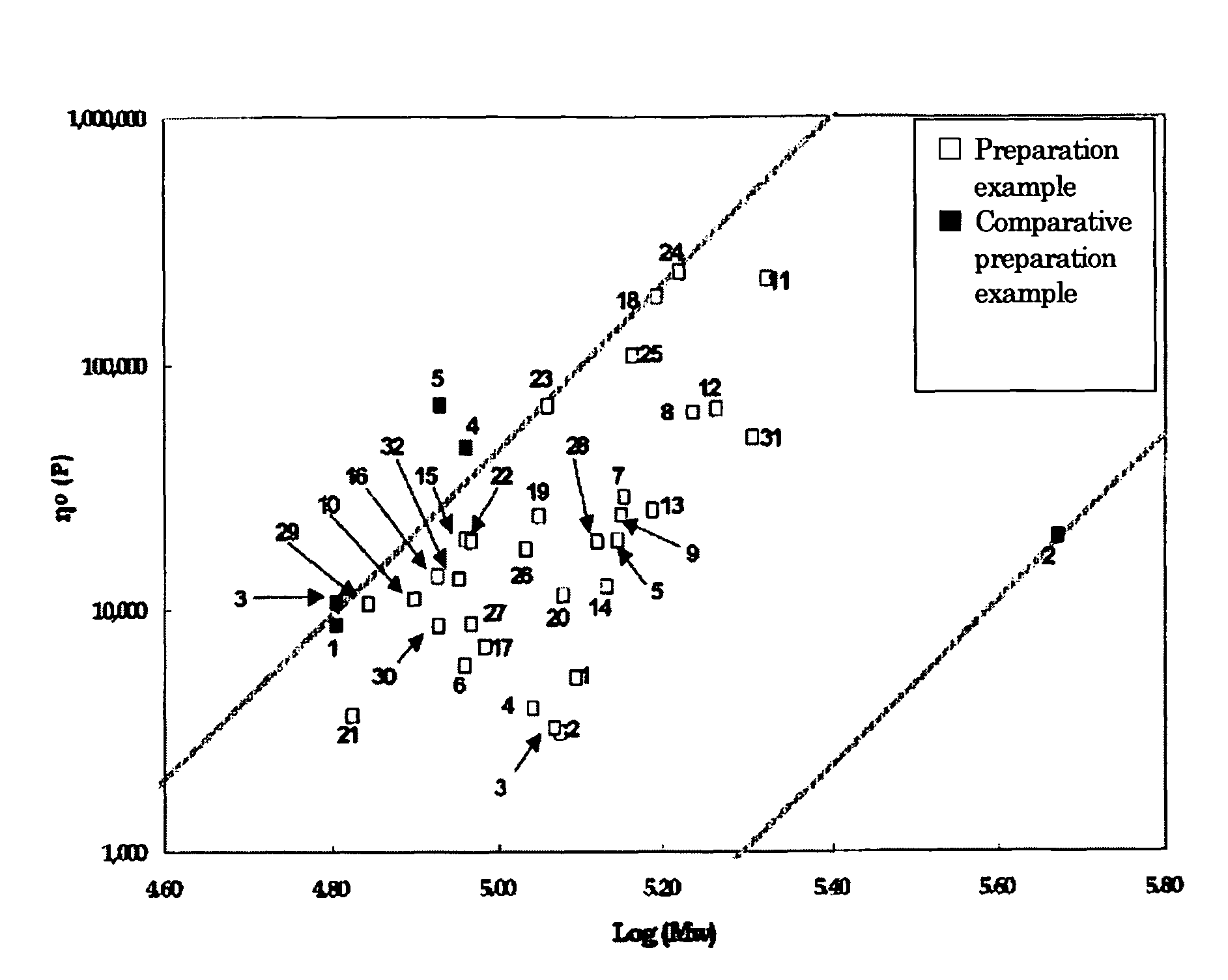

Optimizing polystyrene in the presence of additives

It has been discovered that improved polystyrene products may be obtained by polymerizing styrene in the presence of at least one multifunctional initiator, at least one chain transfer agent, and at least one cross-linking agent. The presence of the multifunctional initiator tends to cause more branched structures in the polystyrene. A mathematical model that helps optimize the levels of these additives for given molecular weights, melt flow indices (MFIs) and zero shear viscosities (η0) has also been discovered.

Owner:FINA TECH

Film or laminate comprising ethylene-based resin or ethylene-based resin composition

ActiveUS8299193B2High heat sealing strengthHigh mechanical strengthSynthetic resin layered productsCellulosic plastic layered productsPolymer scienceZero shear viscosity

The present invention provides a film including, in at least a part thereof, a layer comprising an ethylene-based resin, which is a copolymer of ethylene and an α-olefin of 4 to 10 carbon atoms, and satisfies the following requirements (1) to (5) at the same time or an ethylene-based resin composition containing the resin;(I) the melt flow rate at 190° C. under a load of 2.16 kg is in the range of 0.1 to 50 g / 10 min,(II) the density is in the range of 875 to 970 kg / m3,(III) the ratio of a melt tension at 190° C. to a shear viscosity at 200° C. and an angular velocity of 1.0 rad / sec is in the range of 1.00×10−4 to 9.00×10−4,(IV) the sum of the number of methyl branches and the number of ethyl branches, each number being based on 1000 carbon atoms and measured by 13C-NMR, is not more than 1.8, and(V) the zero shear viscosity [η0(P)] at 200° C. and the weight-average molecular weight (Mw) as measured by a GPC-viscosity detector method (GPC-VISCO) satisfy the following relational formula (Eq-1):0.01×10−13×Mw3.4≦η0≦4.5×10−13×Mw3.4 (Eq-1).

Owner:MITSUI CHEM INC

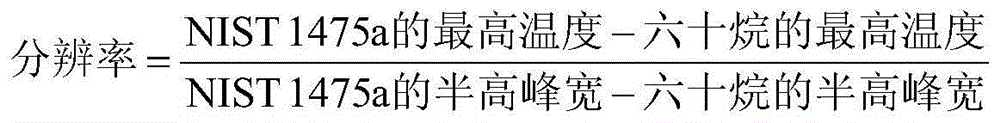

Method for detecting molecular weight of hydrolyzed polyacrylamide

InactiveCN103217360AEasy to cleanImprove work efficiencyFlow propertiesChemical physicsZero shear viscosity

The invention discloses a method for detecting the molecular weight of hydrolyzed polyacrylamide, which solves the problem that the operation is complicated in an existing detection method. According to the method, a rotational rheometer is adopted to measure a rheological curve of hydrolyzed polyacrylamide solutions with the different molecular weights; a Carreu model is used for calculating the zero shear viscosity of the hydrolyzed polyacrylamide solutions with the different molecular weights; the zero shear viscosity is used as a horizontal coordinate to draw a picture of the molecular weights to obtain a relation between the zero shear viscosity and the molecular weights; then the zero shear viscosity of the hydrolyzed polyacrylamide to be detected is measured; and the molecular weight of the hydrolyzed polyacrylamide to be detected is obtained by utilizing the relation. According to the method disclosed by the invention, an operation process is simplified, the working time is shortened and the working efficiency is improved under the precondition of ensuring the measurement accuracy.

Owner:PETROCHINA CO LTD +1

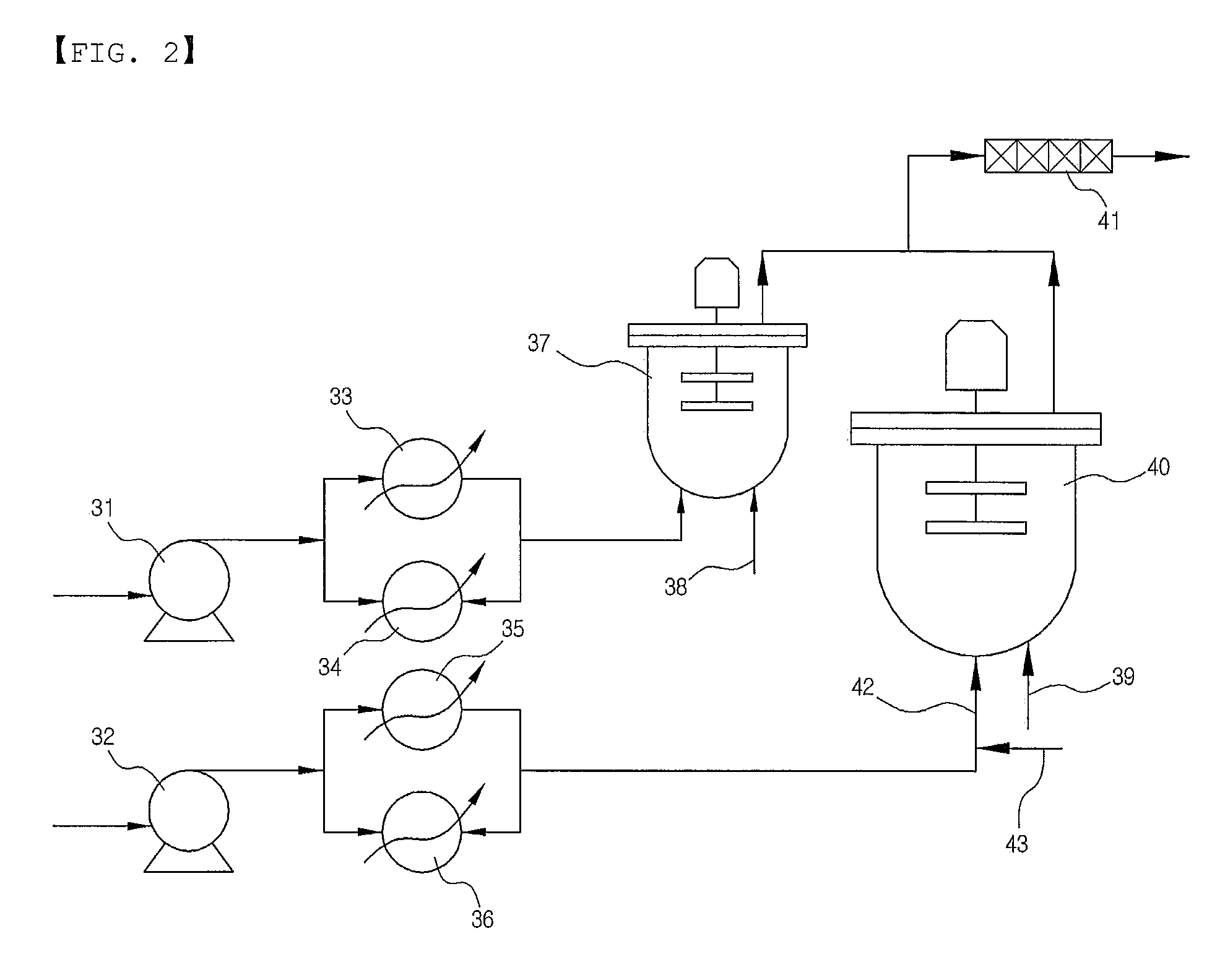

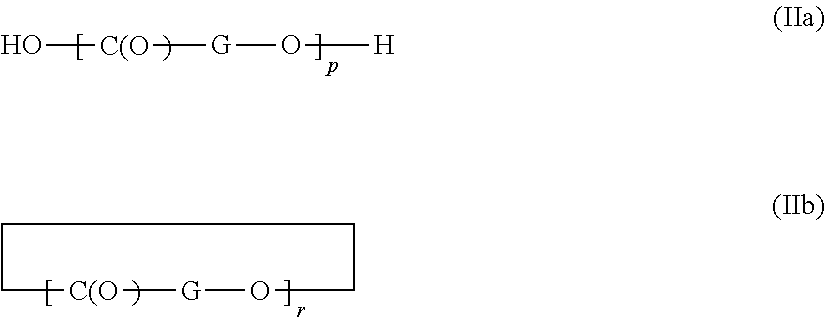

Process for producing aqueous dispersions of thermoplastic polyesters

The present invention relates to a process for producing aqueous dispersions of thermoplastic polymers which have a plurality of ester groups and / or carbonate groups in the main polymer chain and which have an acid number of less than 5 mg KOH / g, in particular at most 3 mg KOH / g, and which have a zero-shear viscosity η0 (180° C.) of at least 60 Pa·s at 180° C. The invention also relates to the polymer dispersions obtainable by said process, and to the use thereof.

Owner:BASF AG

Trimeric anionic surfactant with long rigid linking group and viscoelastic solution formed by trimeric anionic surfactant

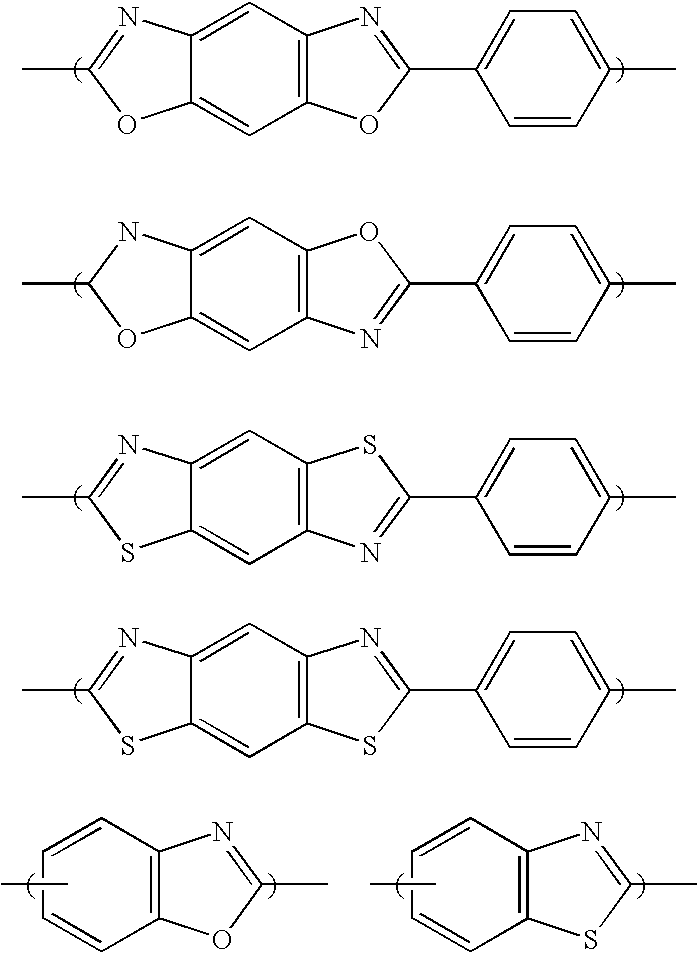

ActiveCN105879772AReduce use costEliminate defects such as chromatographic separation effectsPreparation from carboxylic acid halidesOrganic compound preparationZero shear viscosityBiocompatibility Testing

The invention relates to a trimeric anionic surfactant with a long rigid linking group and a viscoelastic solution formed by the trimeric anionic surfactant, wherein the molecular structure of the trimeric anionic surfactant C-TrisPhC<n>Na(n=10,12,14) is show as the accompanying drawing, and R=C<n>H2<n+1>(n=10,12,14); the trimeric anionic surfactant can form the viscoelastic solution under the condition without any additives. When the hydrophobic chain length of the C-TrisPhC<n>Na is greater, the viscoelastic performance of the formed solution is better. When the concentration of the surfactant is only 65mmol L<-1>, the zero shear viscosity of a C-TrisPhC14Na solution can reach 1380Pa s. As a one-class anionic surfactant, the C-TrisPhC<n>Na has good biocompatibility; the formed viscoelastic solution can be applied to formulas of oil field fracturing fluid, dragging drag reducers and daily detergents.

Owner:SHANDONG DAMING FINE CHEM CO LTD

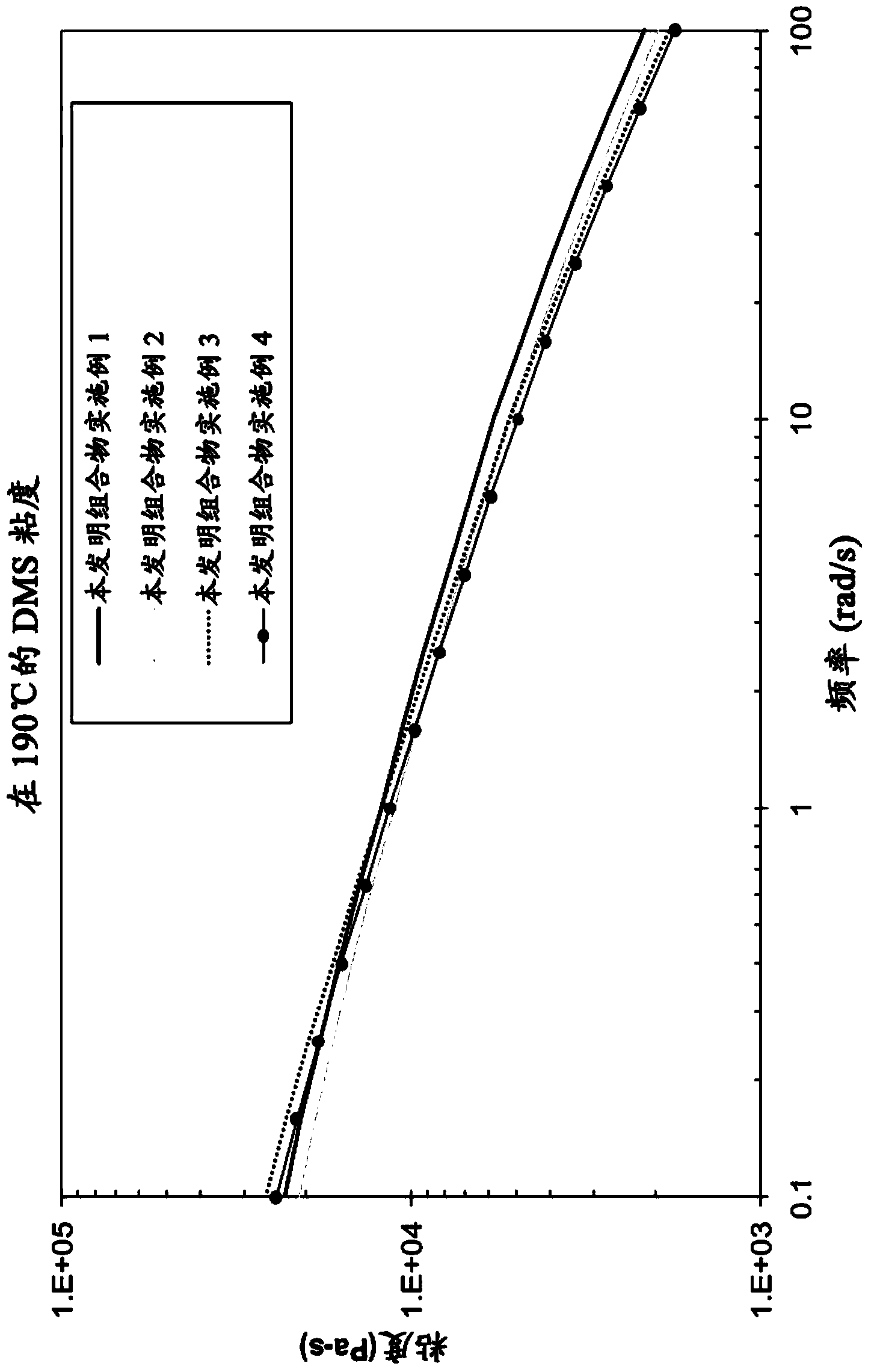

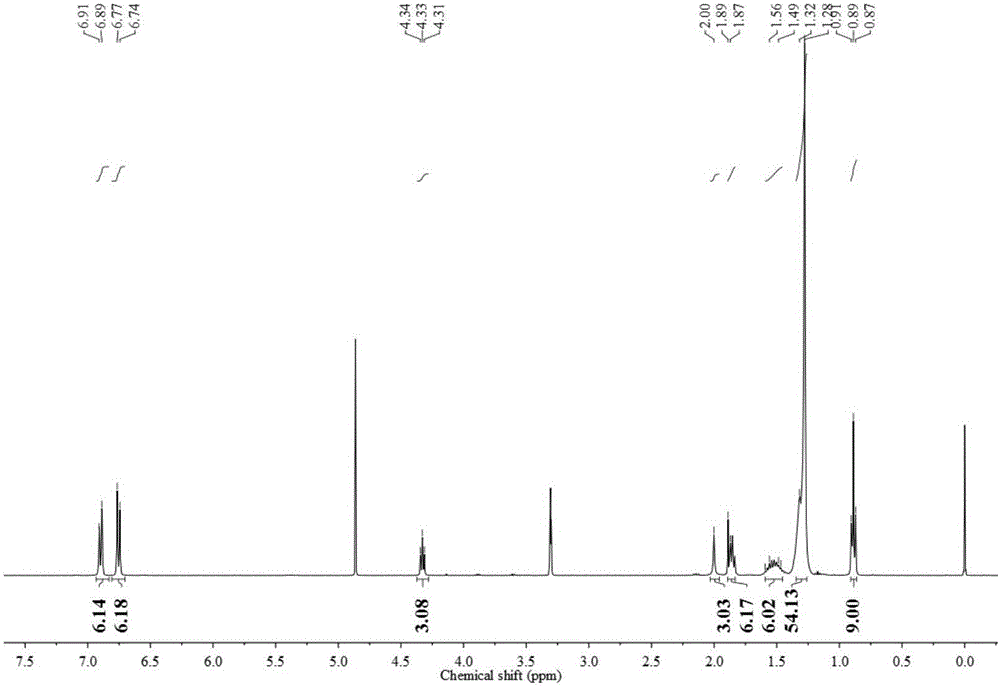

Ethylene copolymer with improved elasticity and processibility

InactiveCN103003318AIncrease elasticityEasy to processThin material handlingPolymer scienceZero shear viscosity

Provided is an ethylene copolymer with improved elasticity and processibility. More specifically, provided is an ethylene copolymer which exhibits a high zero shear viscosity and a large degree of shear thinning degree, and shows rheological characteristics behaviors differentiated from products manufactured by using the existing metallocene and Ziegler-Natta catalysts. In addition, provided is an ethylene copolymer which has a low processing load, shows differentiated behavior in Van-Gurp Palmen analysis, and exhibits excellent Neck-in characteristics.

Owner:SABIC NEXLENE CO PTE LTD

Film or laminate comprising ethylene resin or ethylene resin composition

ActiveCN101490116AExcellent heat seal strengthHigh mechanical strengthSynthetic resin layered productsZero shear viscosityPolymer science

The present invention provides a film including, in at least a part thereof, a layer comprising an ethylene-based resin, which is a copolymer of ethylene and an alpha-olefin of 4 to 10 carbon atoms, and satisfies the following requirements (1) to (5) at the same time or an ethylene-based resin composition containing the resin; (I) the melt flow rate at 190 DEG C under a load of 2.16 kg is in the range of 0.1 to 50 g / 10 min, (II) the density is in the range of 875 to 970 kg / m, (III) the ratio of a melt tension at 190 DEG C to a shear viscosity at 200 DEG C and an angular velocity of 1.0 rad / sec is in the range of 1.00*10 to 9.00*10, (IV) the sum of the number of methyl branches and the number of ethyl branches, each number being based on 1000 carbon atoms and measured byC-NMR, is not more than 1.8, and (V) the zero shear viscosity [ eta 0 (P)] at 200 DEG C and the weight-average molecular weight (Mw) as measured by a GPC-viscosity detector method (GPC-VISCO) satisfy the following relational formula (Eq-1): 0.01*10*Mw*Mw...(Eq-1).

Owner:MITSUI CHEM INC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com