Loxiong viscosity behavior measuring method of high-viscosity modified asphalt and application thereof

A technology of modified asphalt and measurement method, applied in the directions of flow characteristics, measuring devices, instruments, etc., can solve the problems of inability to determine the viscosity characteristics of capillary tube viscosity, inability to determine the shear rate of capillary tube viscosity, cumbersome test process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

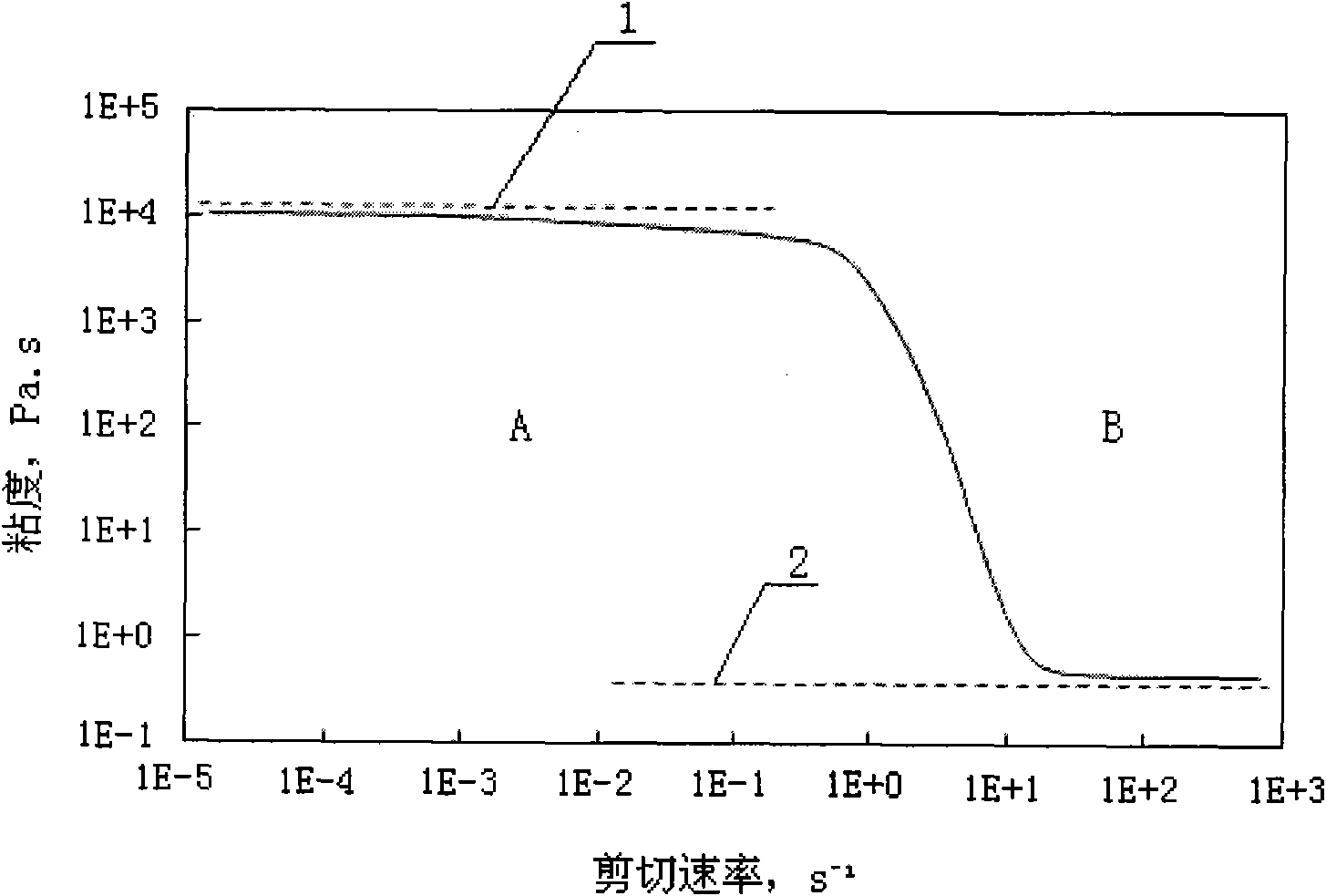

[0049] In order to clarify the 60°C zero-shear viscosity test method of high-viscosity modified asphalt, a typical test is now used to describe it.

[0050](1) Forming test piece: heat the asphalt to a flowing state, pour at least 3 circular parallel test pieces with a diameter of about 25 mm and a height of 1 mm to 2 mm, and place the asphalt test pieces at room temperature to cool for no less than 30 minutes.

[0051] (2) Place the test piece: choose a circular plate fixture with a diameter of 25 mm, place the asphalt test piece between the fixtures, adjust the distance between the upper and lower fixtures to 1050 μm, and adjust the distance between the fixtures to 1000 μm after trimming the sample.

[0052] (3) Heat preservation: immerse the trimmed asphalt specimen and fixtures in a 60°C water bath for heat preservation, and the heat preservation of the specimen should not be less than 10 minutes.

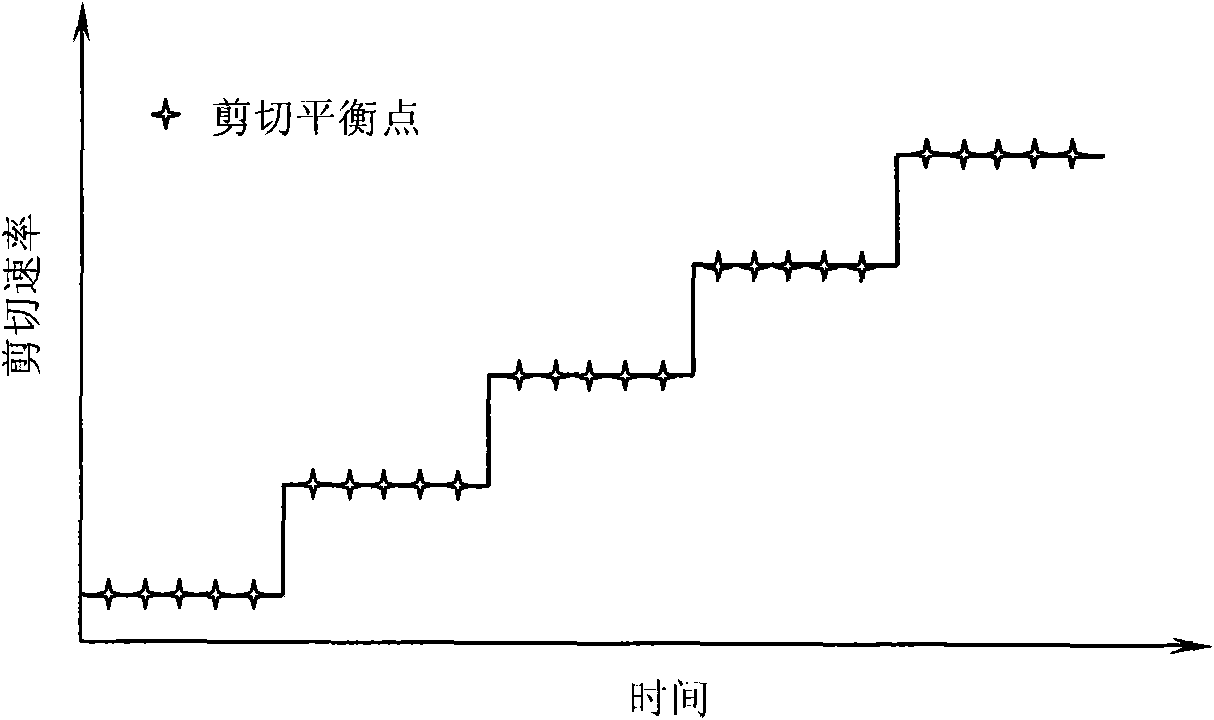

[0053] (4) Carry out the shear rate scanning test: the steady flow loading...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com