Method for detecting molecular weight of hydrolyzed polyacrylamide

A polyacrylamide and molecular weight technology, which is applied in measurement devices, analytical materials, flow characteristics, etc., can solve the problems of low work efficiency, cumbersome testing process, and difficulty in cleaning Ubbelohde viscometers, and achieve high work efficiency and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of hydrolyzed polyacrylamide solutions with different molecular weights:

[0034] Raw materials: Five kinds of hydrolyzed polyacrylamides were selected, with molecular weights of 400, 800, 1566, 1907, and 32.68 million, respectively, from Daqing Refining and Chemical Company. These five kinds of hydrolyzed polyacrylamides were prepared into solutions. For the preparation method, see the sample solution in the determination method of the degree of hydrolysis of partially hydrolyzed polyacrylamide for oil flooding in the relevant standards of China Petroleum and Natural Gas Corporation Standard Q / SY 119-2005. preparation.

[0035] 2. Measure the rheological curves of different molecular weight hydrolyzed polyacrylamide solutions in step 1:

[0036] 1) Start the ARES-LS1 rotational rheometer produced by TA Company in the United States according to the correct start-up procedure;

[0037] 2) Turn on the computer, double-click the TA Orchestrator icon on the...

Embodiment 2

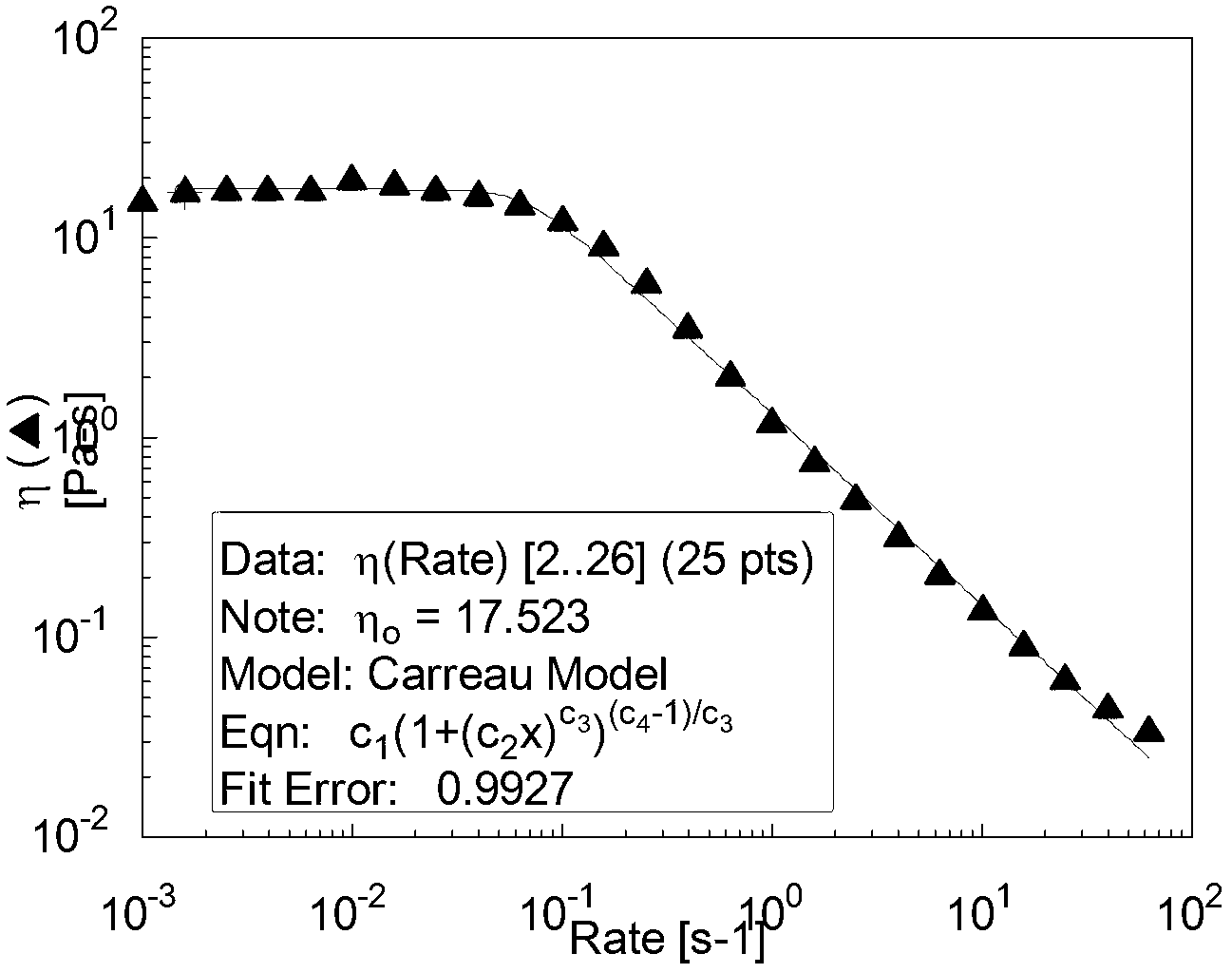

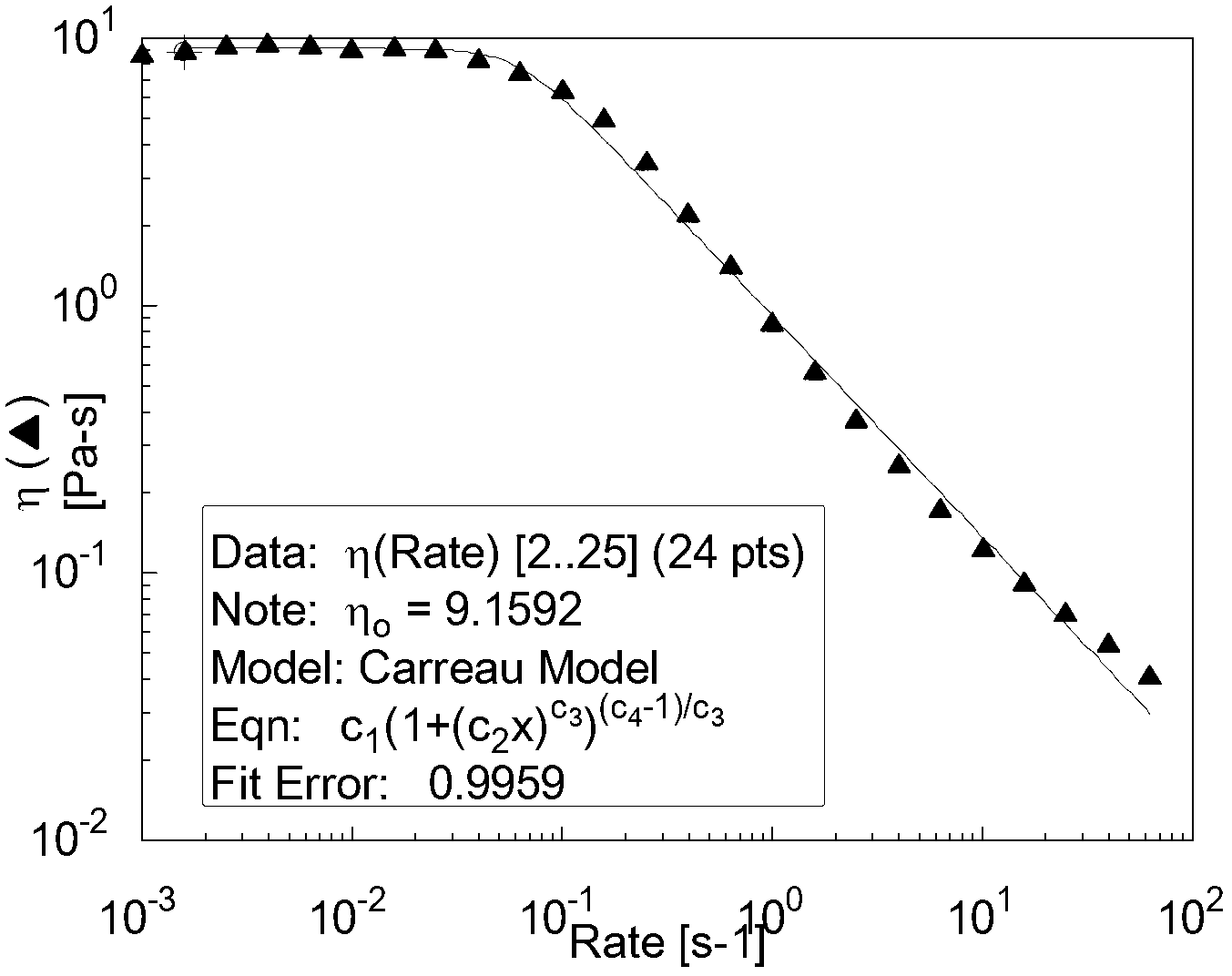

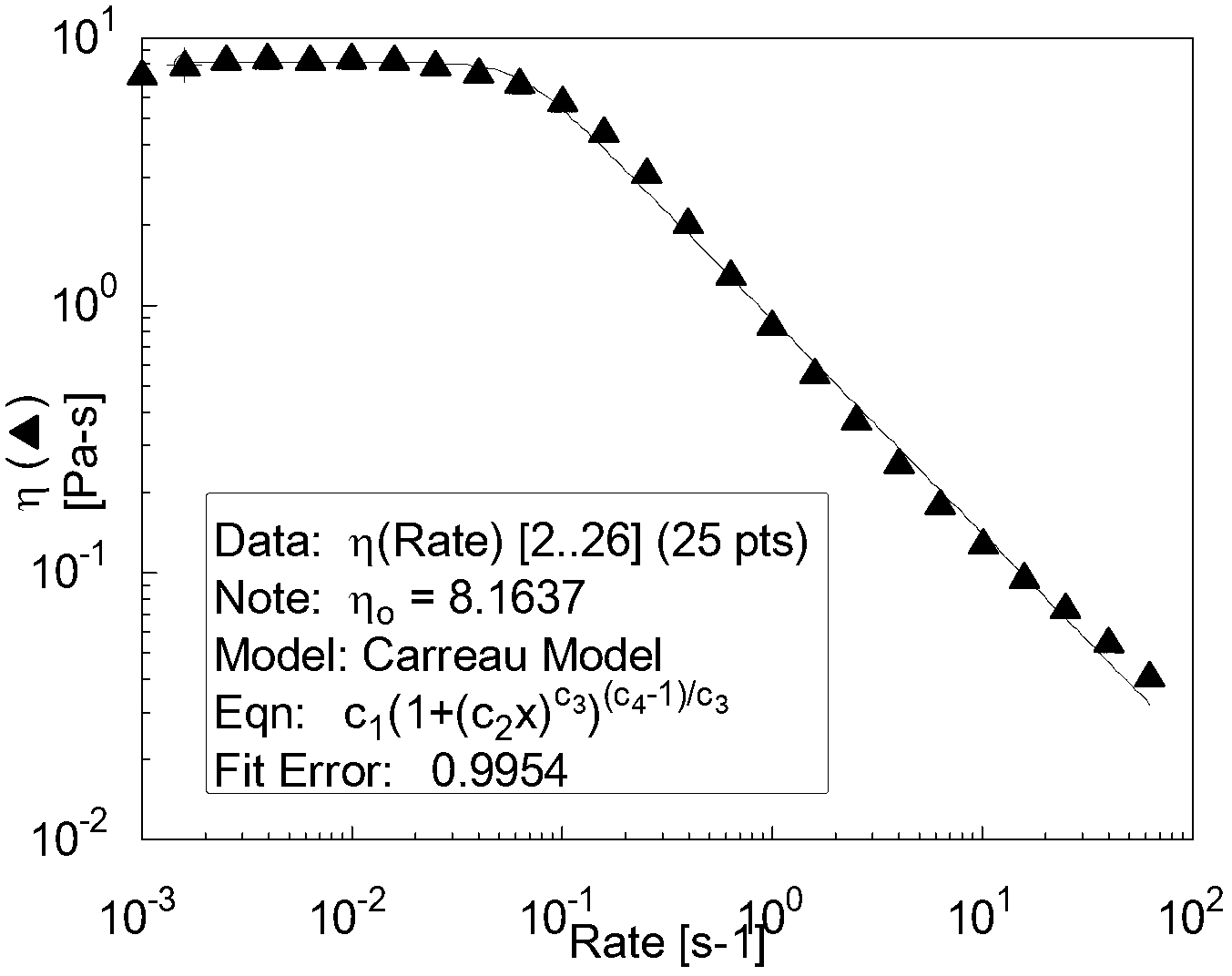

[0070] Embodiment 2: repeatability experiment

[0071] A hydrolyzed polyacrylamide sample with a molecular weight of 31.53 million was selected and measured three times using the method of the present invention to obtain three rheological curves. See the attached Figure 8 , It can be seen from the three rheological curves that the repeatability is good, and the fitted zero-shear viscosity is 17.4155Pa.s, 17.2.19Pa.s, and 16.7211Pa.s respectively. The calculated molecular weights were 30.89 million, 30.62 million, and 30.02 million, respectively. The relative deviation is 0.43%, indicating that the repeatability of the experiment is very good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com