Patents

Literature

149 results about "Flow curve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

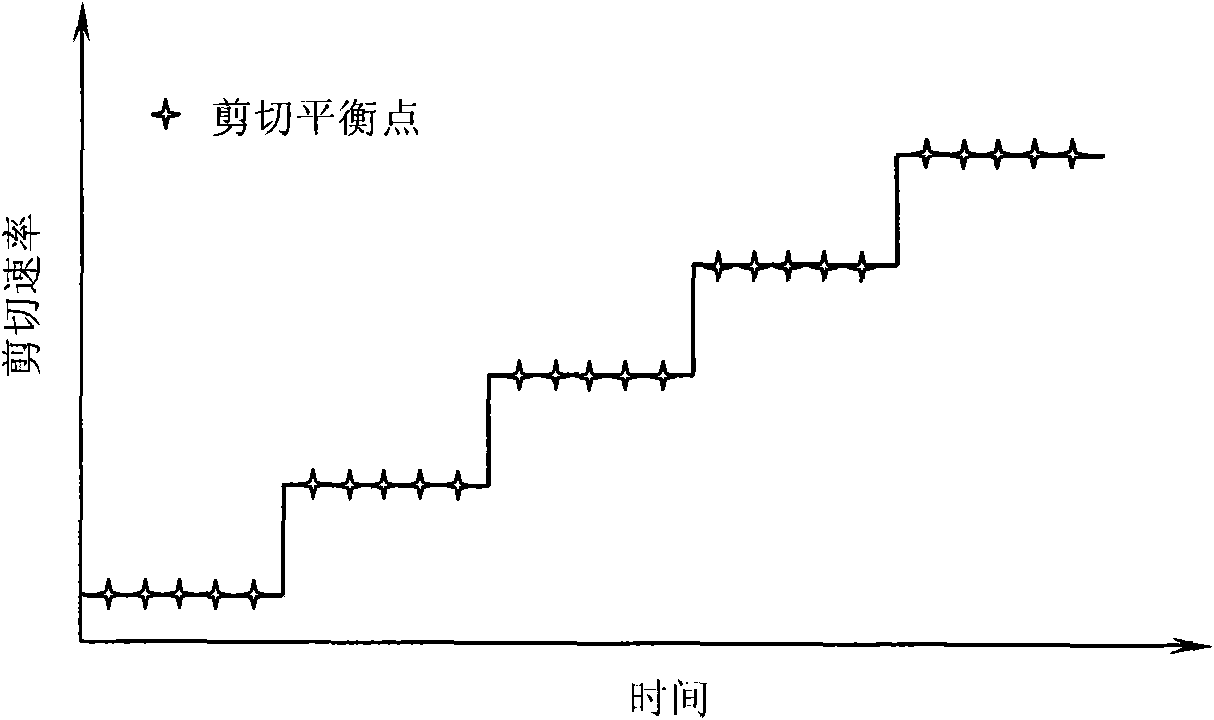

Flow curve. Definition of a flow curve. Typical rotational tests are viscosity functions that depend on shear rate, shear stress, time, or temperature. The results of a rotational test can be displayed on the one hand as a flow curve diagram showing the resulting shear stress values, and on the other hand as the corresponding viscosity function.

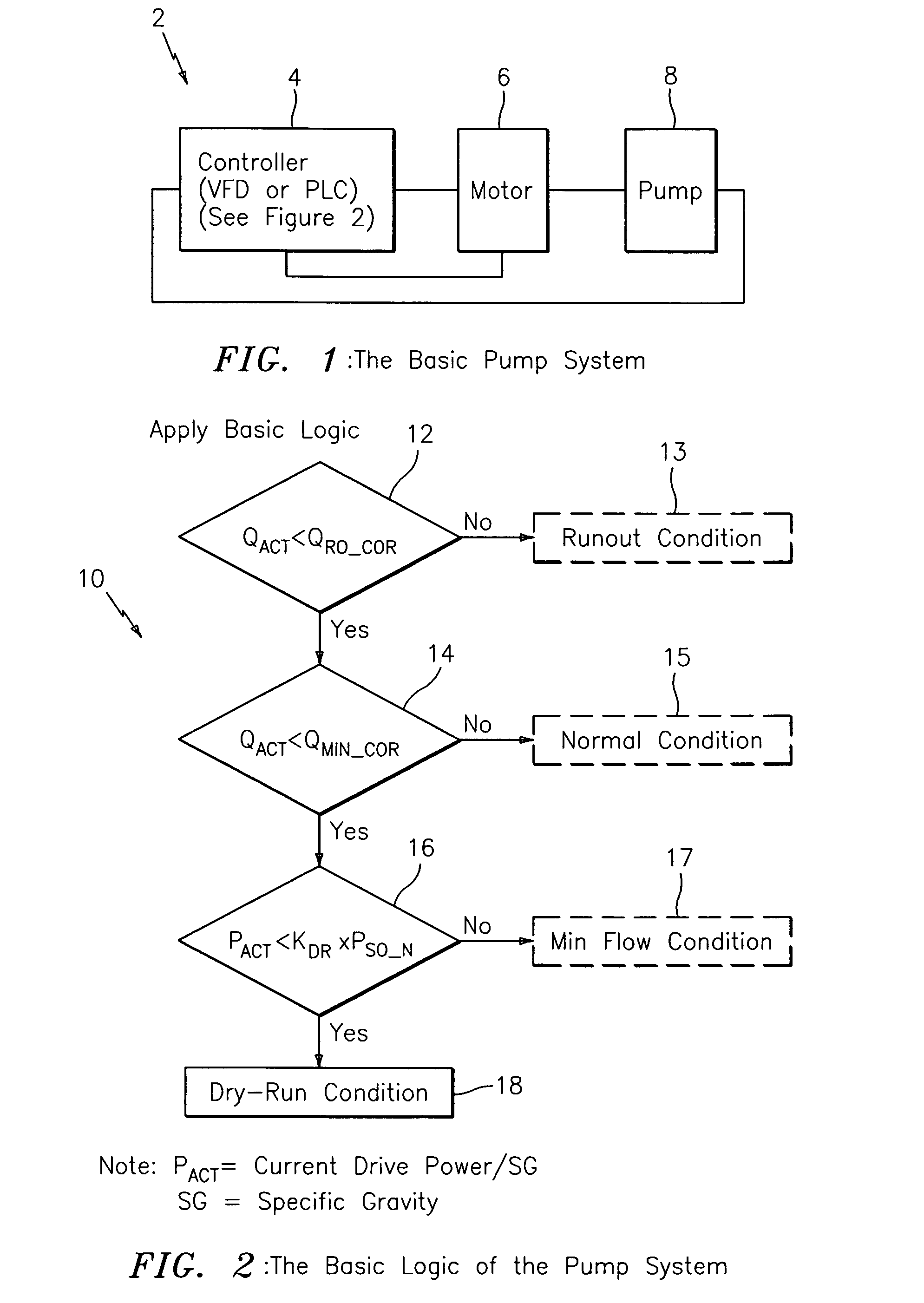

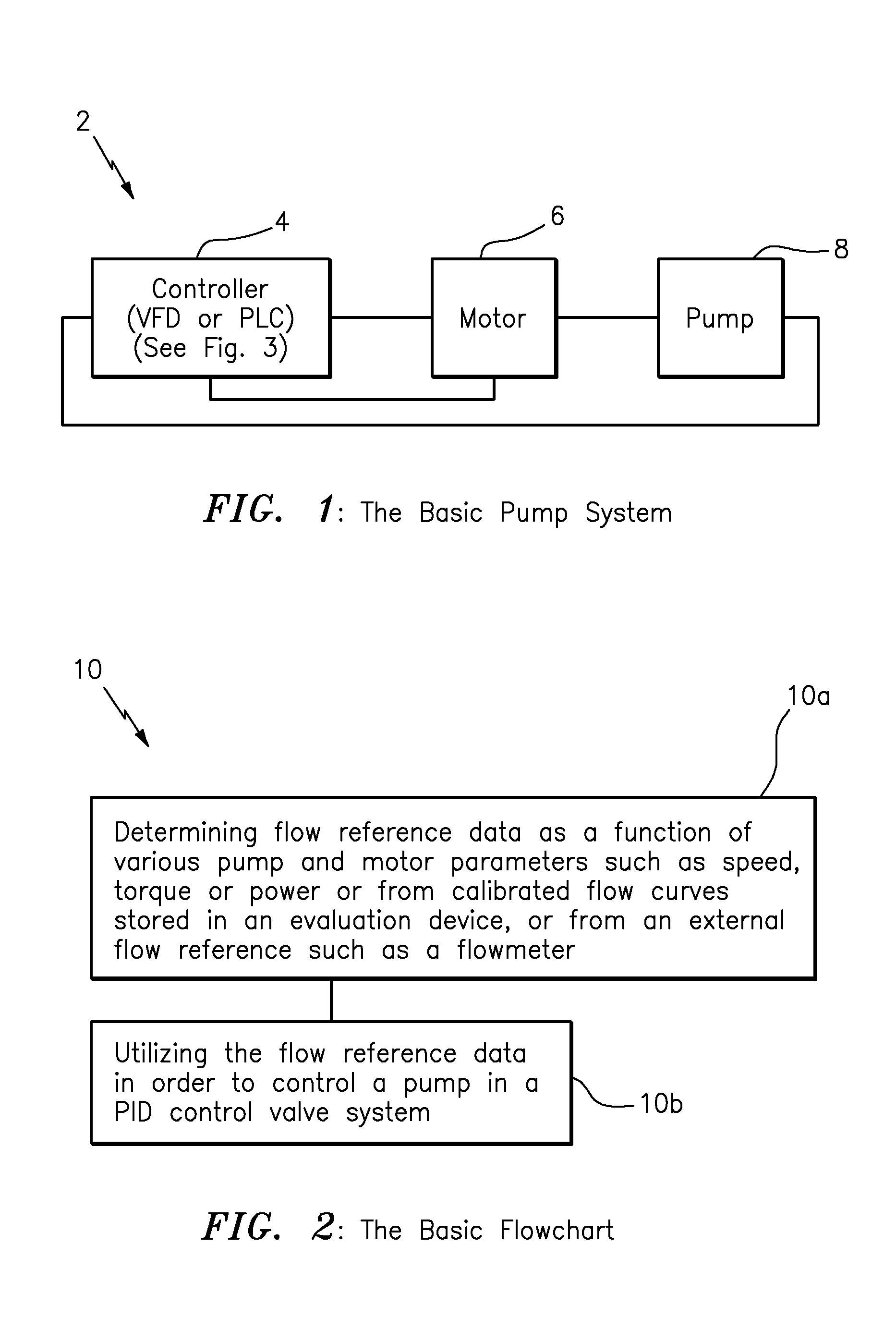

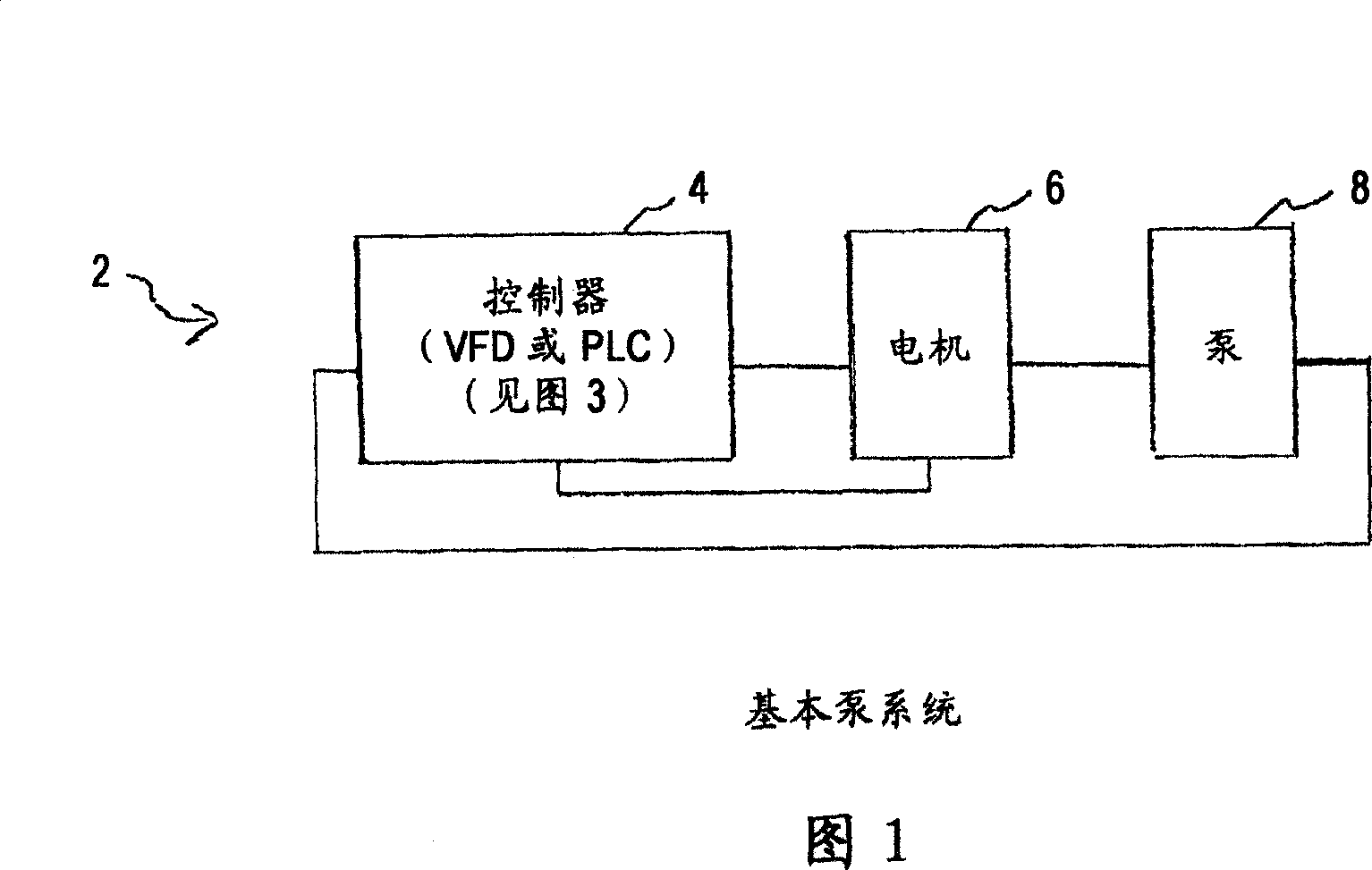

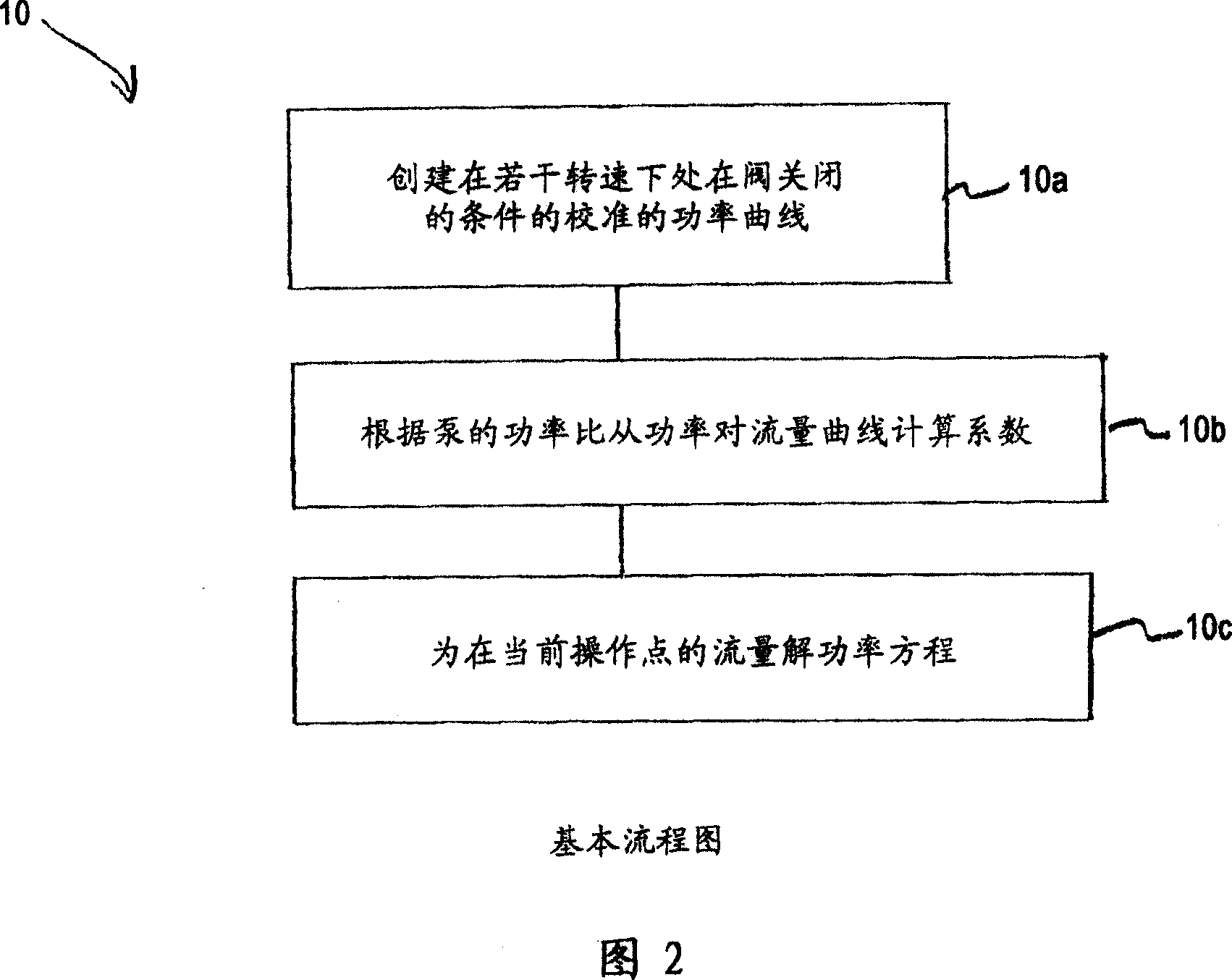

Method for determining pump flow without the use of traditional sensors

ActiveUS20070212210A1Testing/calibration apparatusAmplifier modifications to reduce noise influenceOperating pointMuller's method

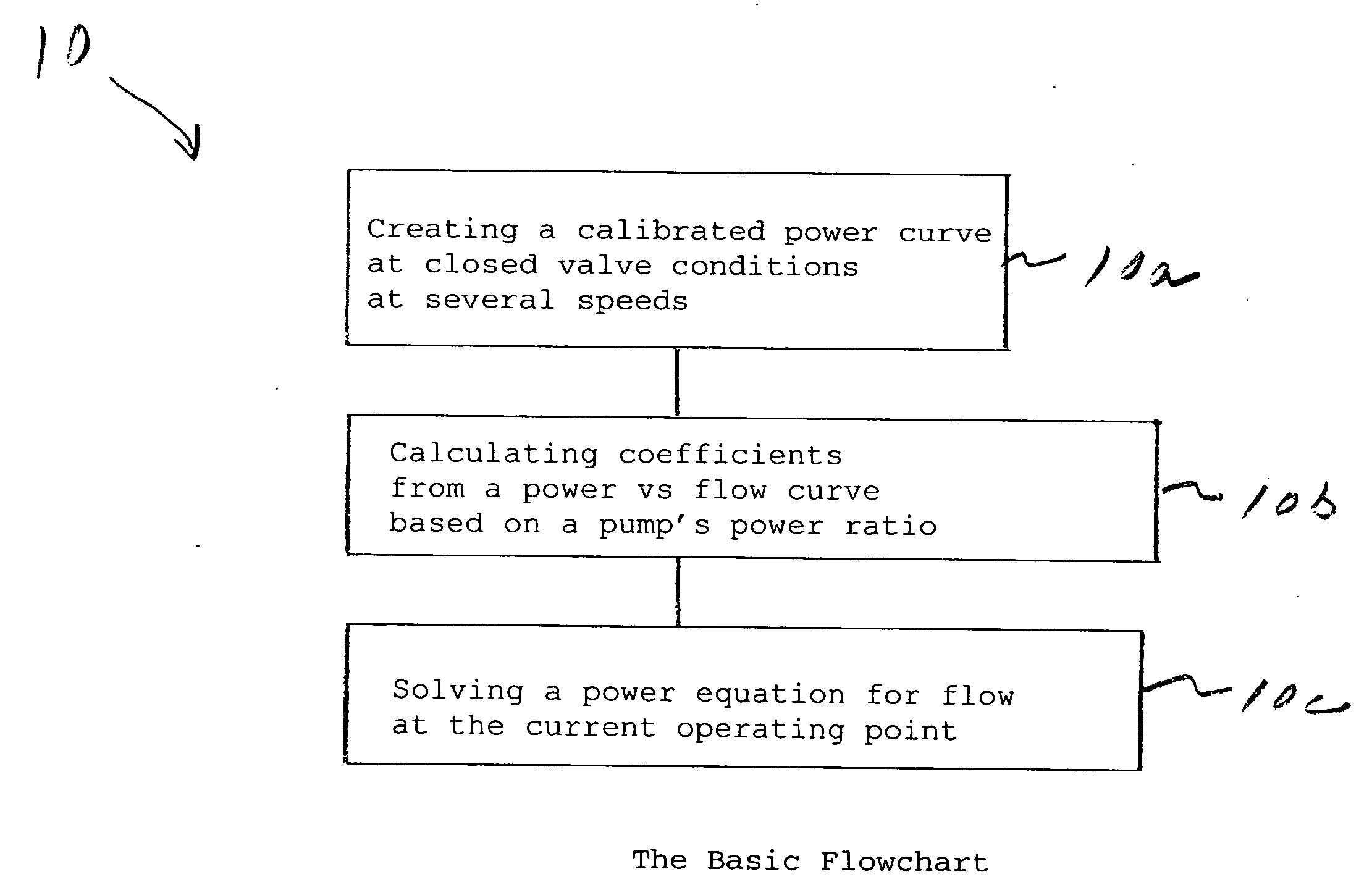

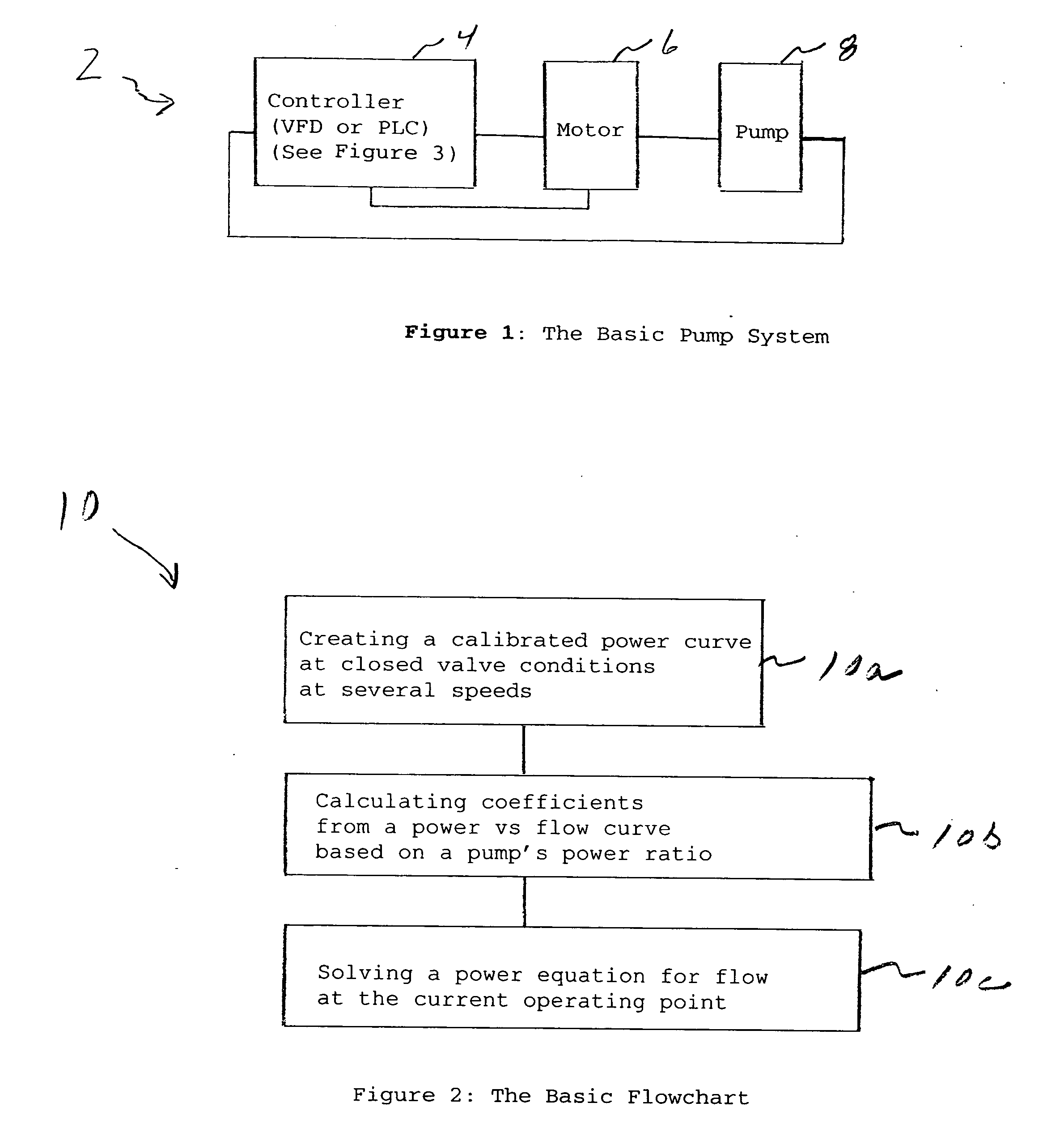

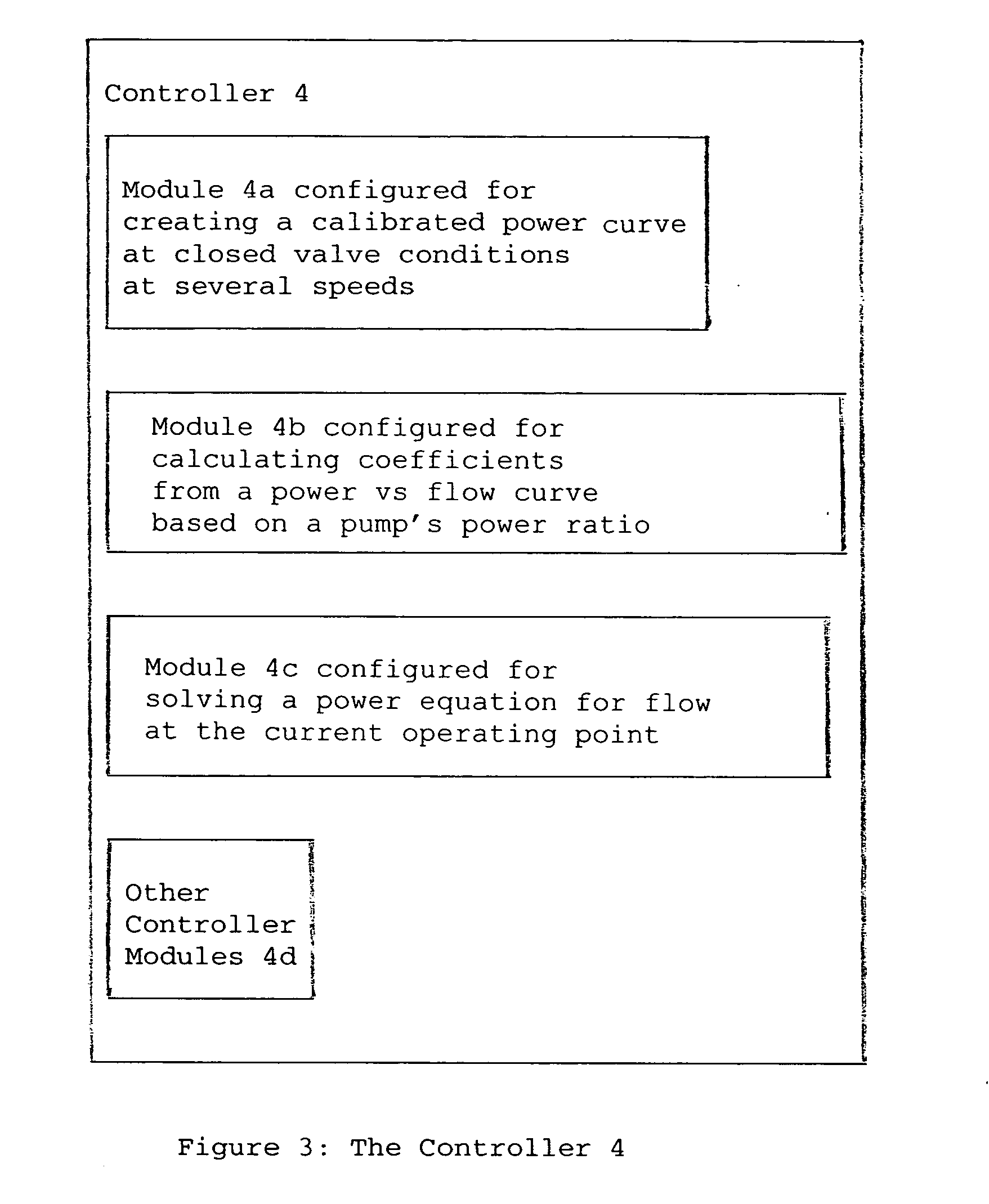

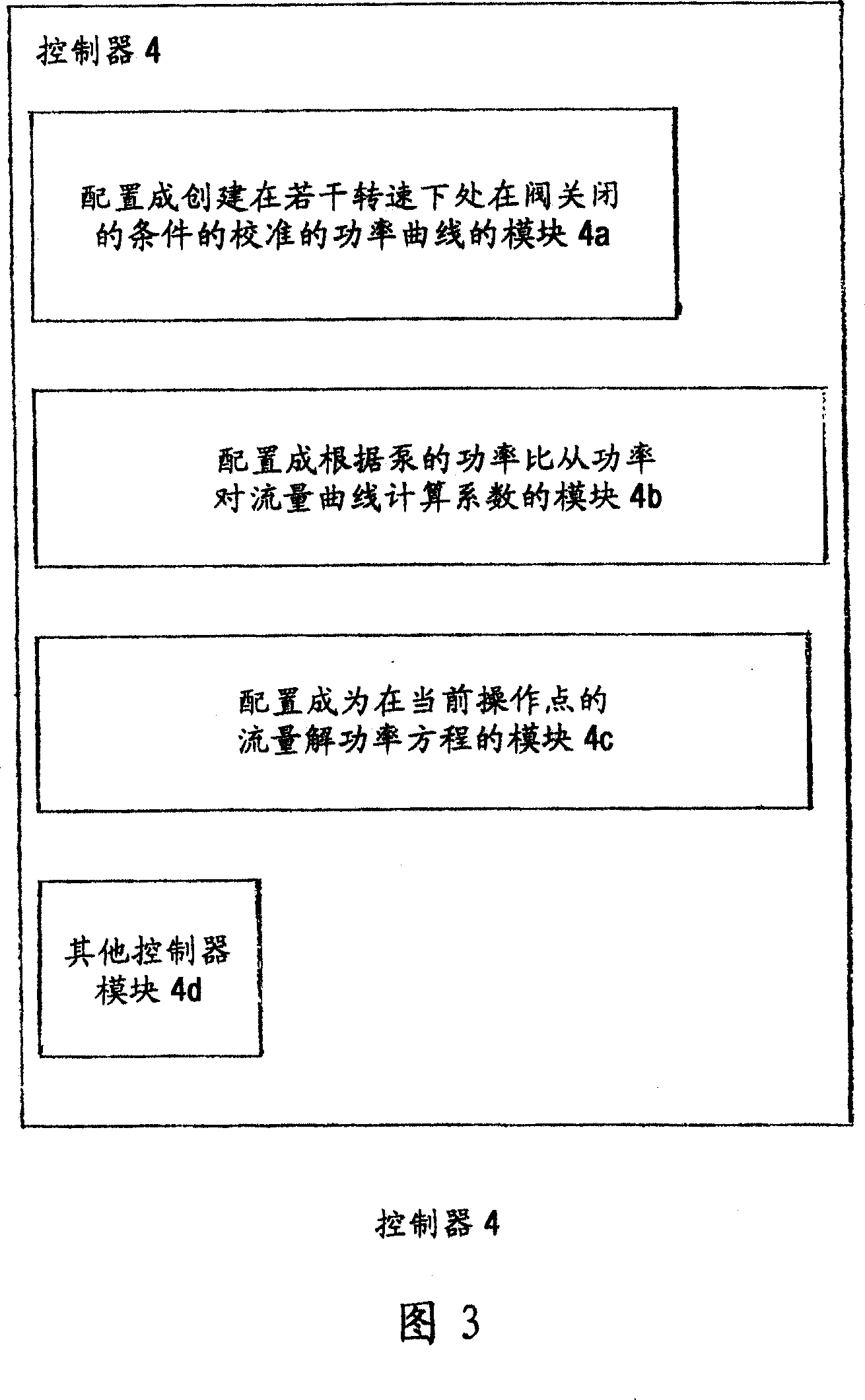

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<sub2>—< / sub2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation. Complex roots may be determined to solve the 3rd order polynomial equation using either Muller's method or some other suitable method, and the calculated actual flow may be determined for a specific operating point.

Owner:ITT MFG ENTERPRISES LLC

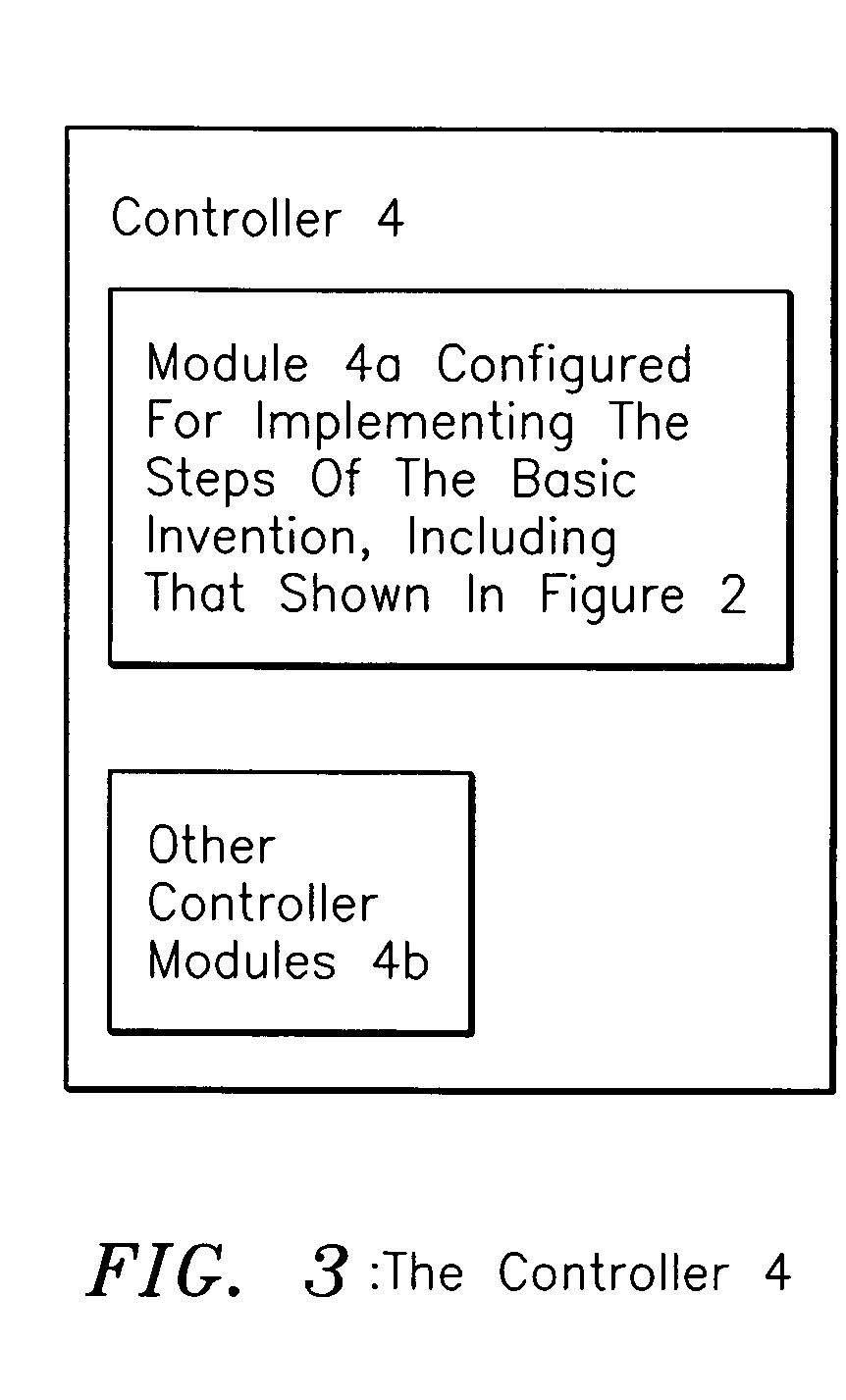

Method and apparatus for pump protection without the use of traditional sensors

ActiveUS20070212229A1Precise processAccurately determine power v flowVolume/mass flow measurementFlexible member pumpsDifferential pressureFlow curve

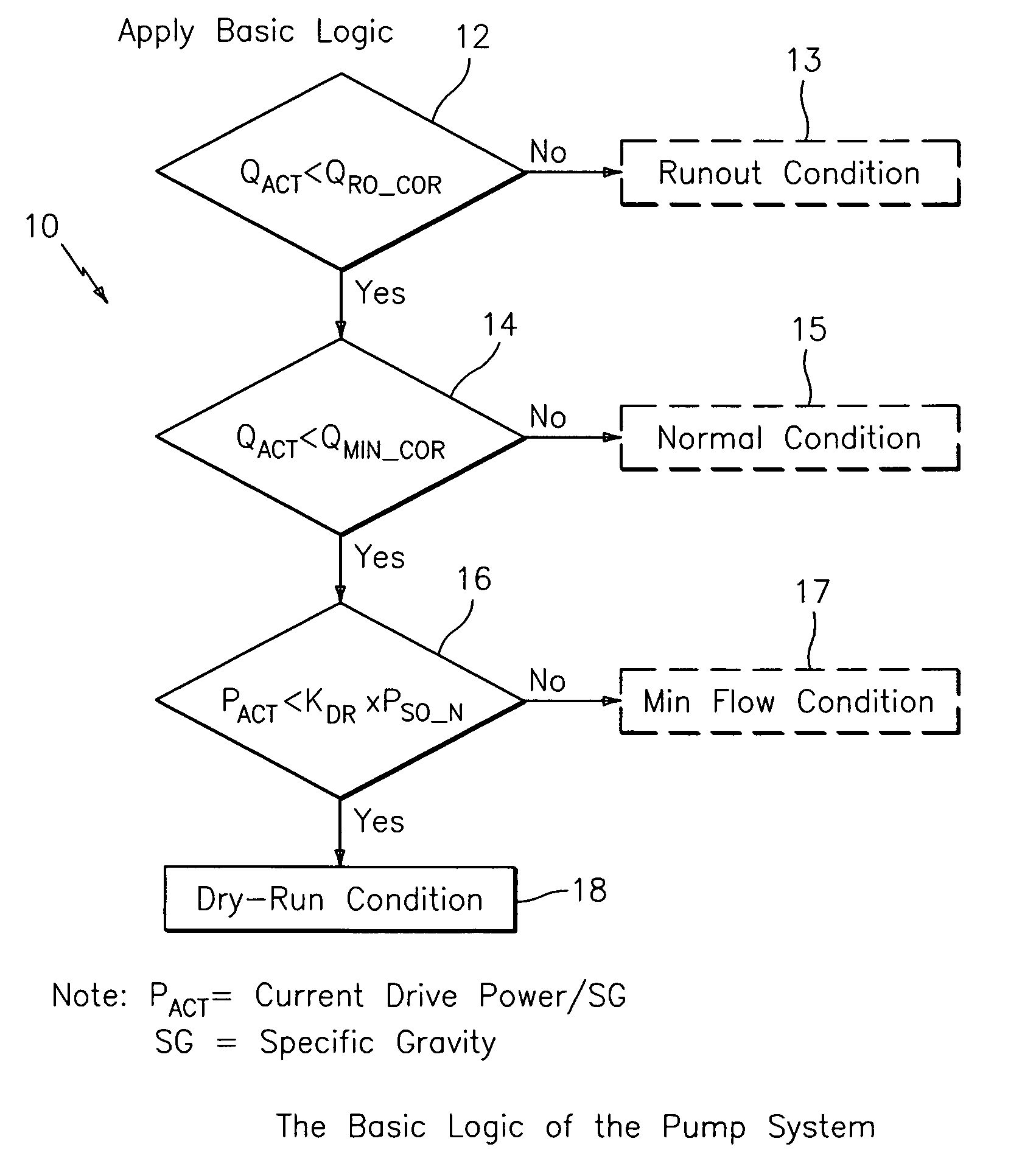

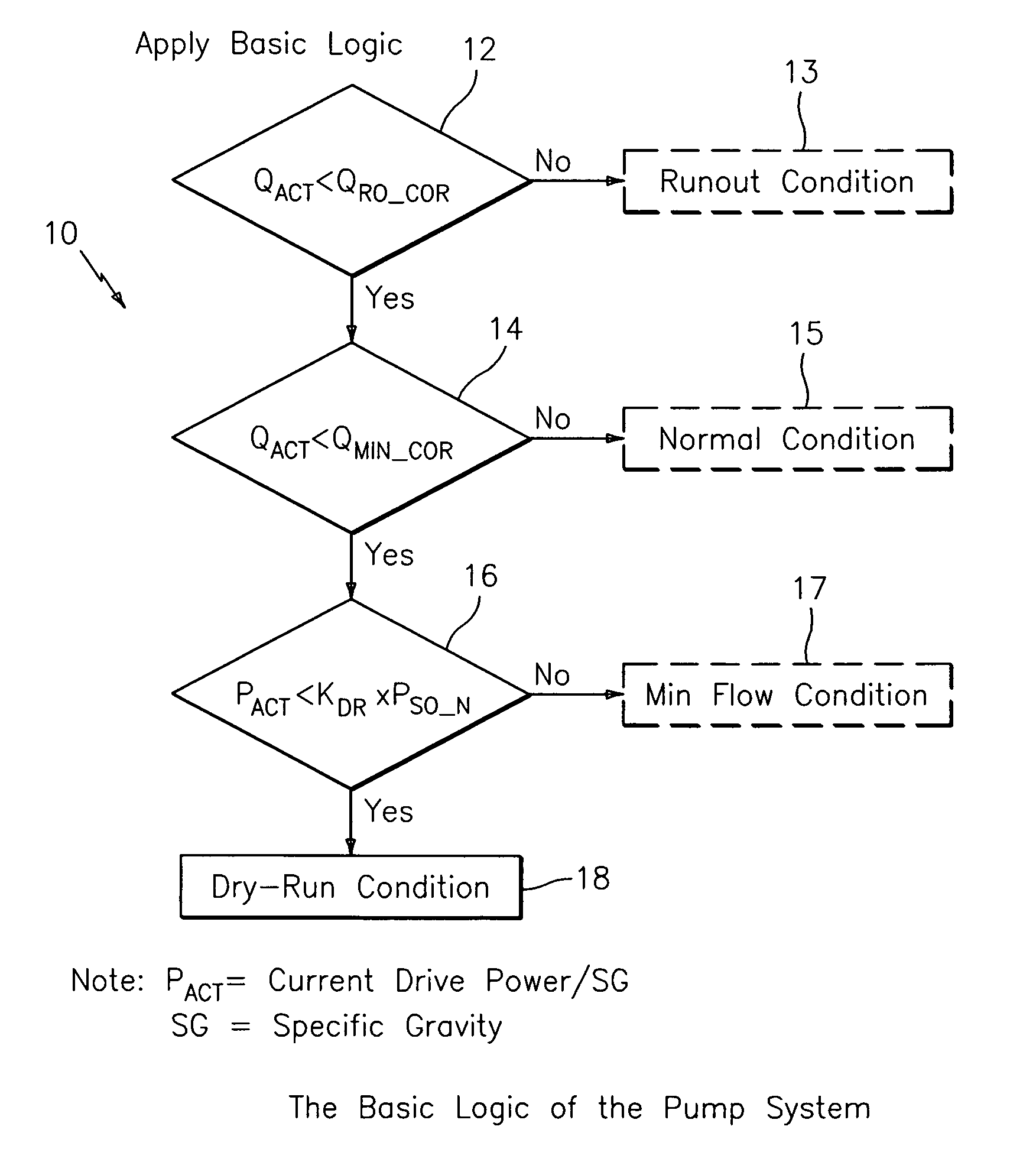

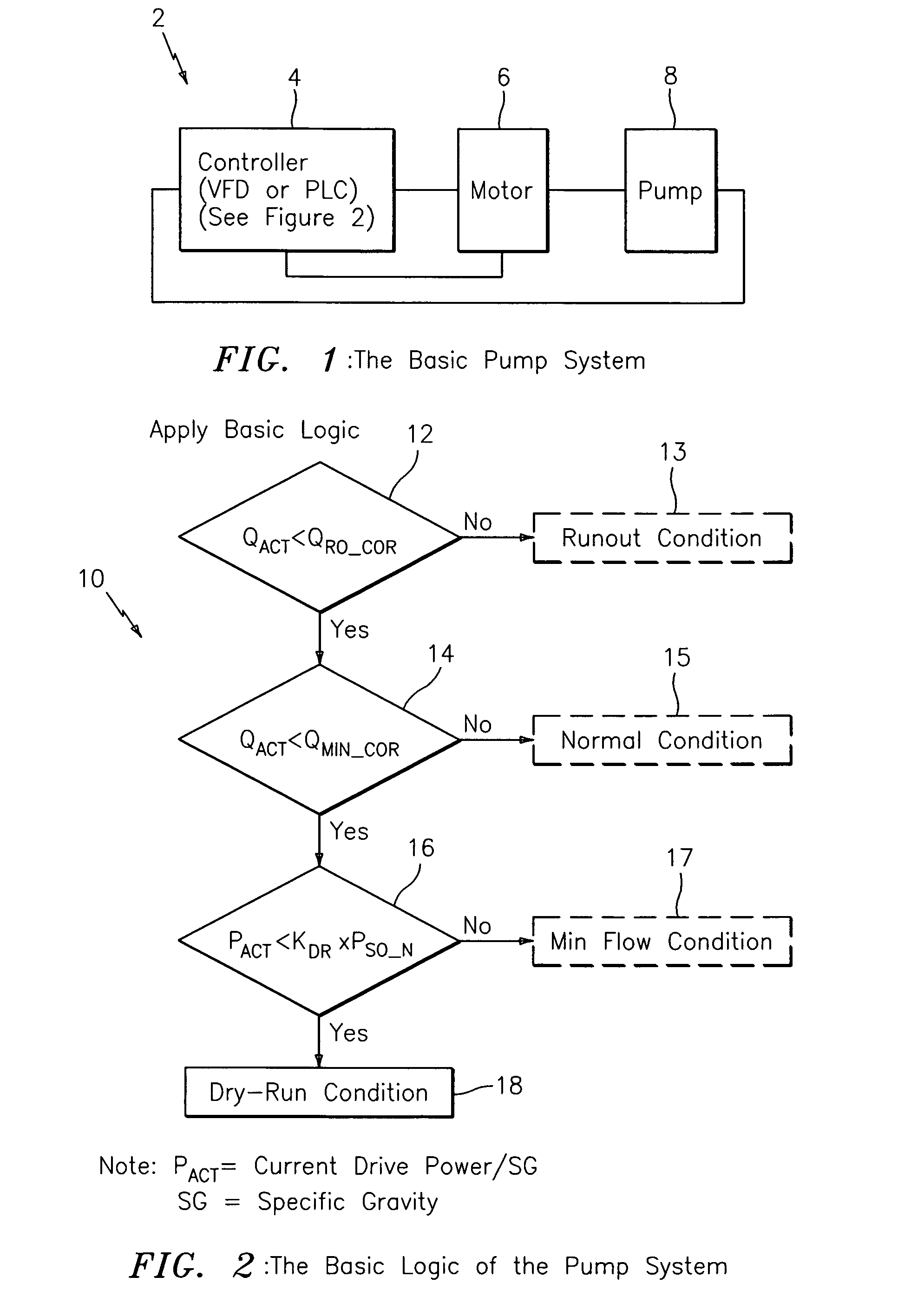

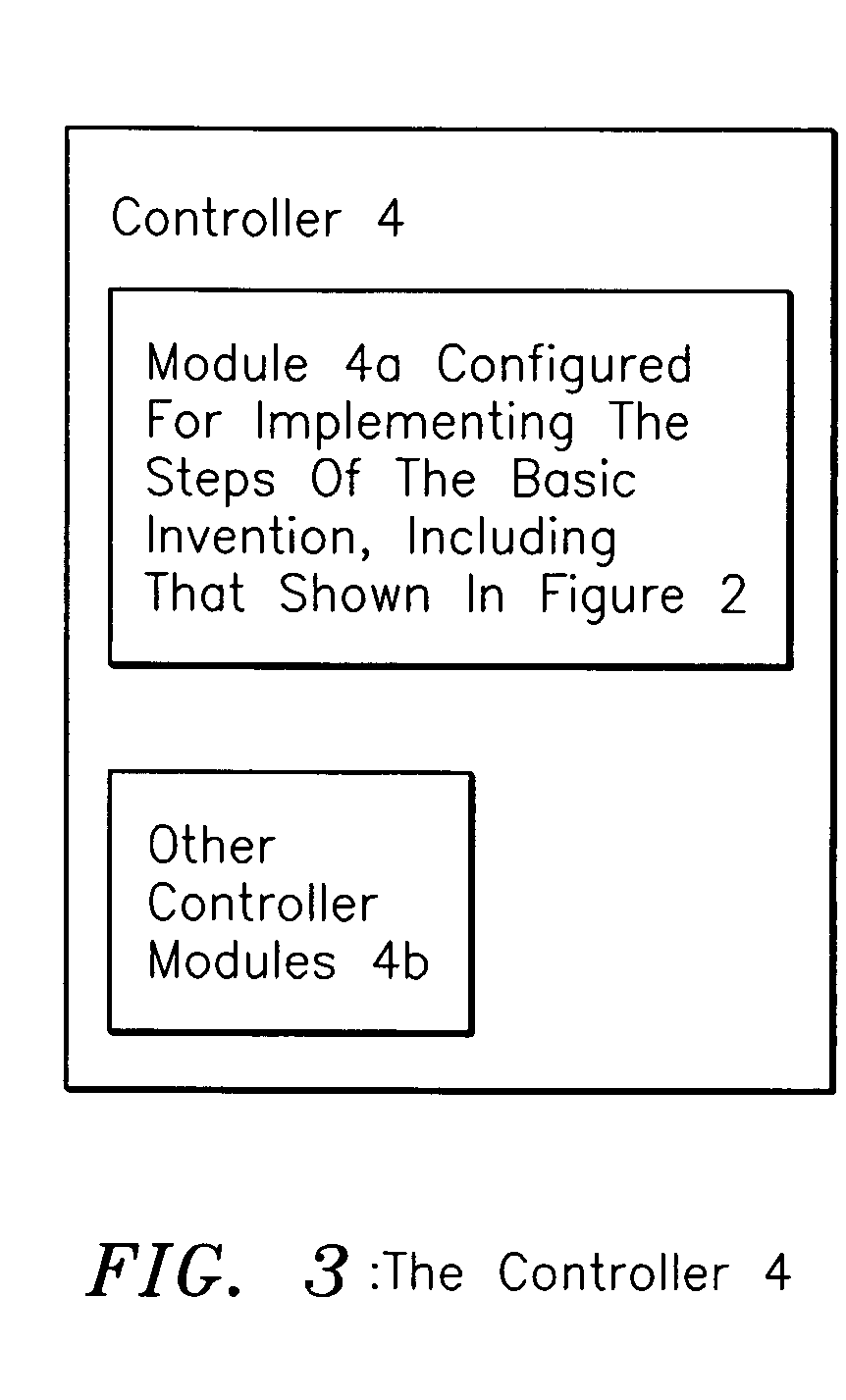

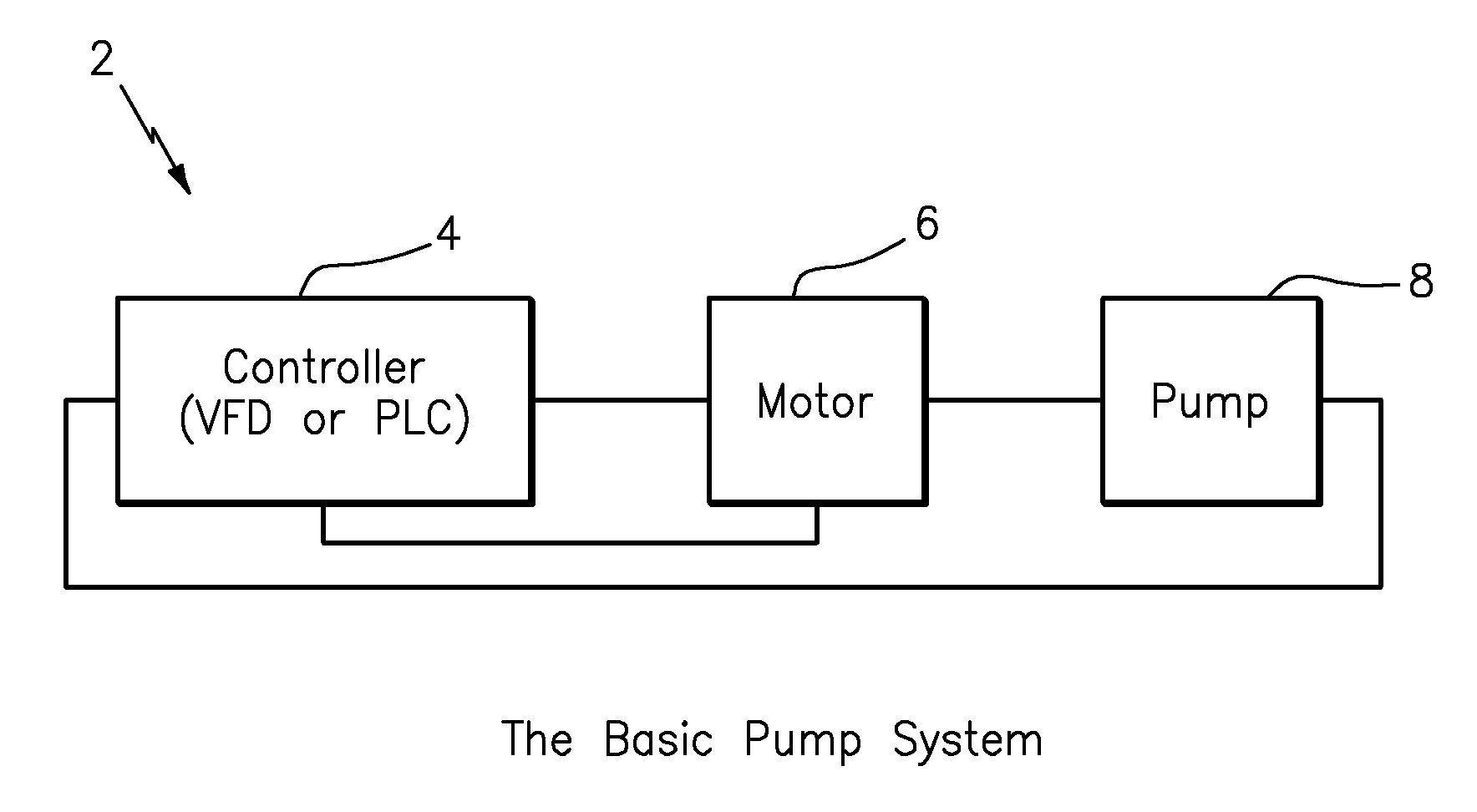

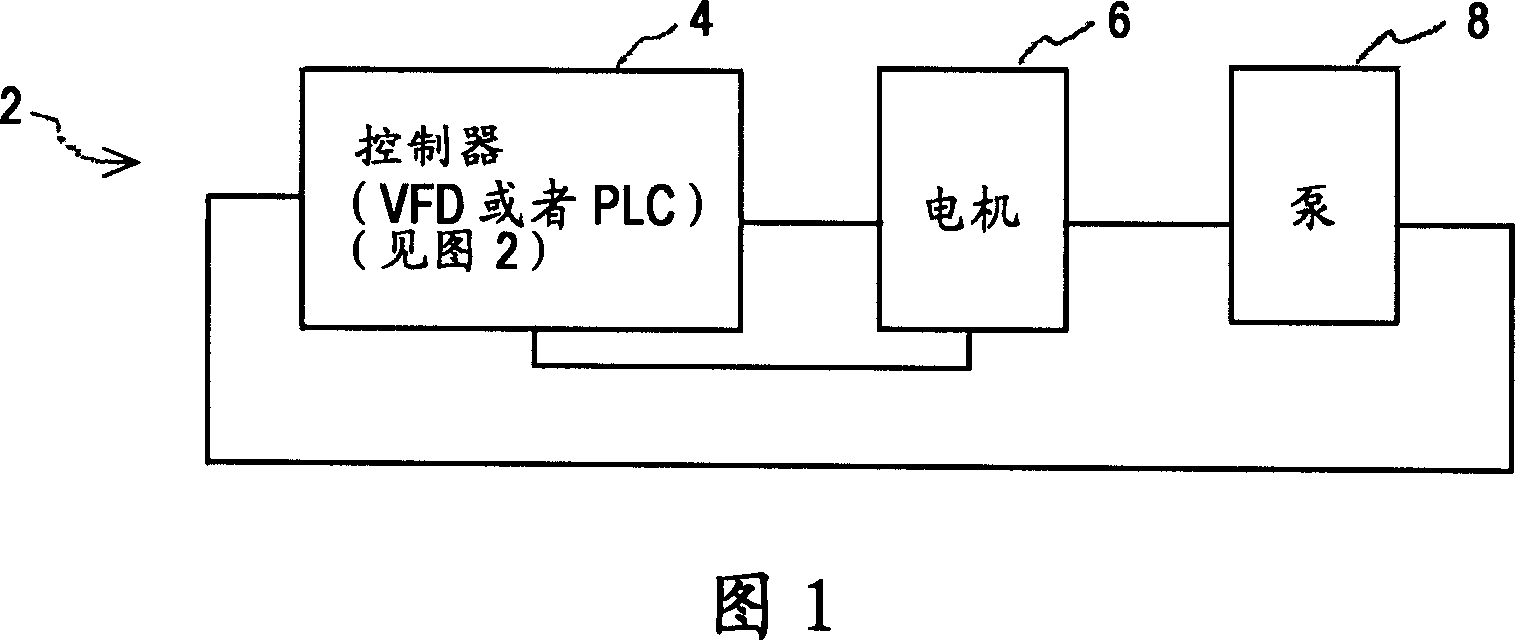

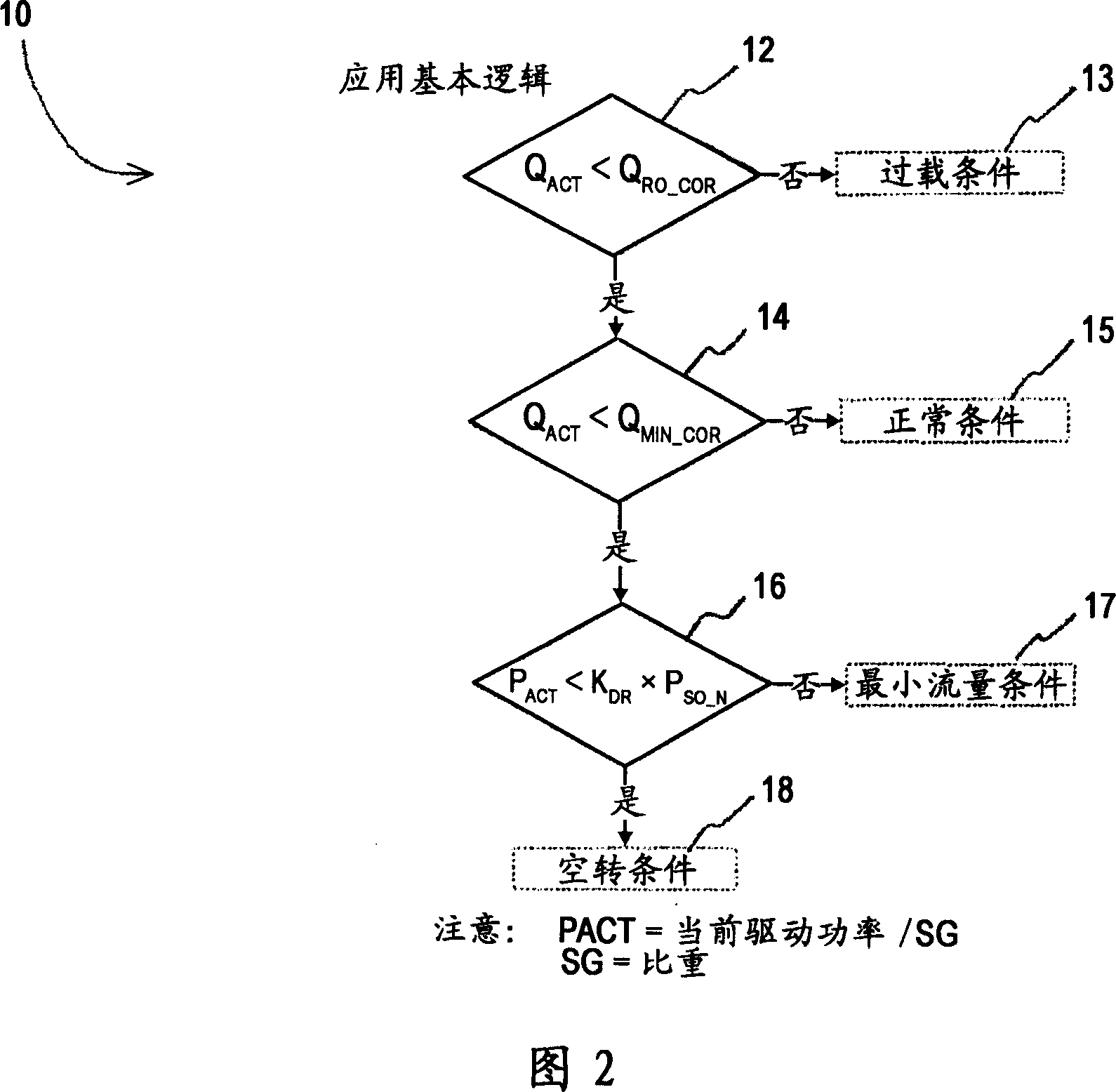

The present invention provides protection for centrifugal pumps while differentiating between dangerous operating conditions (e.g. dry running, minimum flow and runout) and / or conditions where transient conditions (e.g. closed valve operation) may occur and the protection can be revoked once the condition clears. The methodology utilizes a calculated flow value which can be mathematically determined from a calibrated closed valve power vs speed curve and / or various pump and motor parameters such as speed, torque, power and / or differential pressure or from calibrated flow curves stored in the evaluation device. The calculated flow value is then compared to threshold values of flow associated with these adverse operating conditions.

Owner:ITT MFG ENTERPRISES LLC

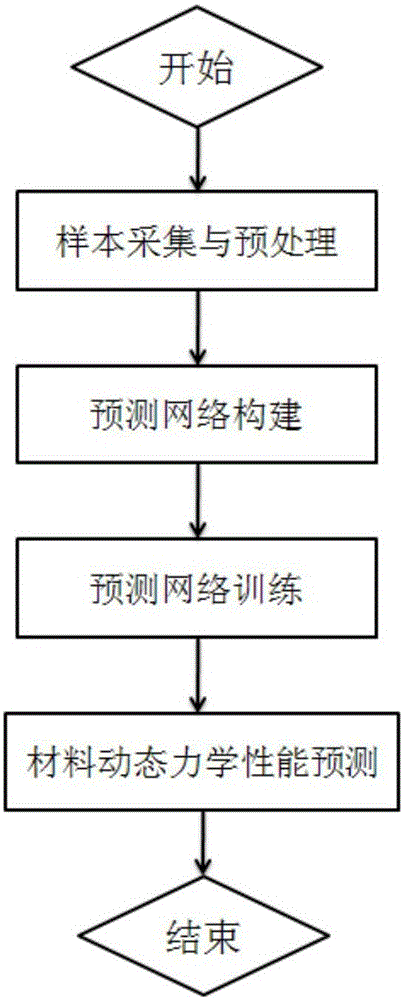

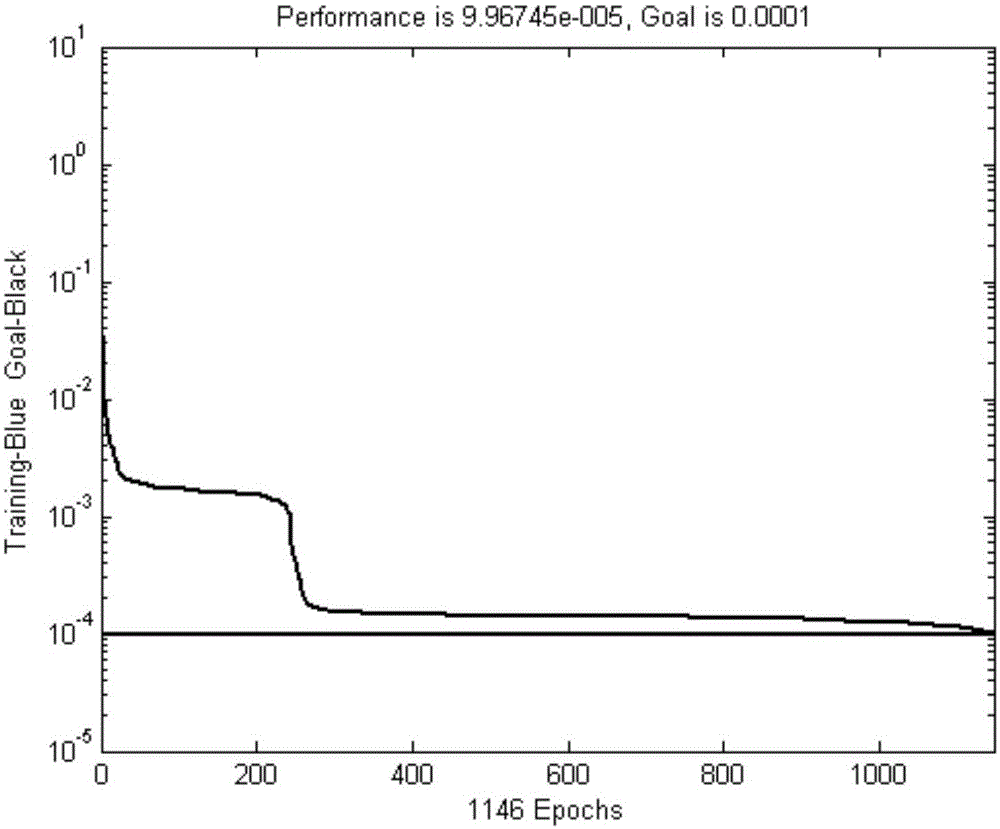

Method for predicting dynamic mechanical property of material based on BP artificial neural network

ActiveCN105095962AImprove simulation accuracyAccurate and fast dynamic mechanical propertiesBiological neural network modelsHidden layerFlow curve

The invention relates to a method for predicting the dynamic mechanical property of a material based on a BP artificial neural network, aims at achieving the prediction of the dynamic mechanical property of the material through the BP artificial neural network, and belongs to the testing field of the dynamic mechanical property of the material. The principle of the method comprises the steps: collecting stress-strain data through employing a high-speed tensile test method, and obtaining a training sample set after normalization preprocessing; building a BP artificial neural network model through designing an input layer, a hidden layer and an output layer, and selecting a proper transfer function, a training function, and a learning function; carrying out the iterative training of the BP artificial neural network through employing the training sample set, and obtaining an optimal prediction network. The above prediction method can be used for the prediction of the dynamic mechanical property of the material, can achieve the quick prediction of a flow curve of the material at different strain rates in a short time, and can provide enough sample data for automobile safety simulation.

Owner:CHINA AUTOMOTIVE ENG RES INST

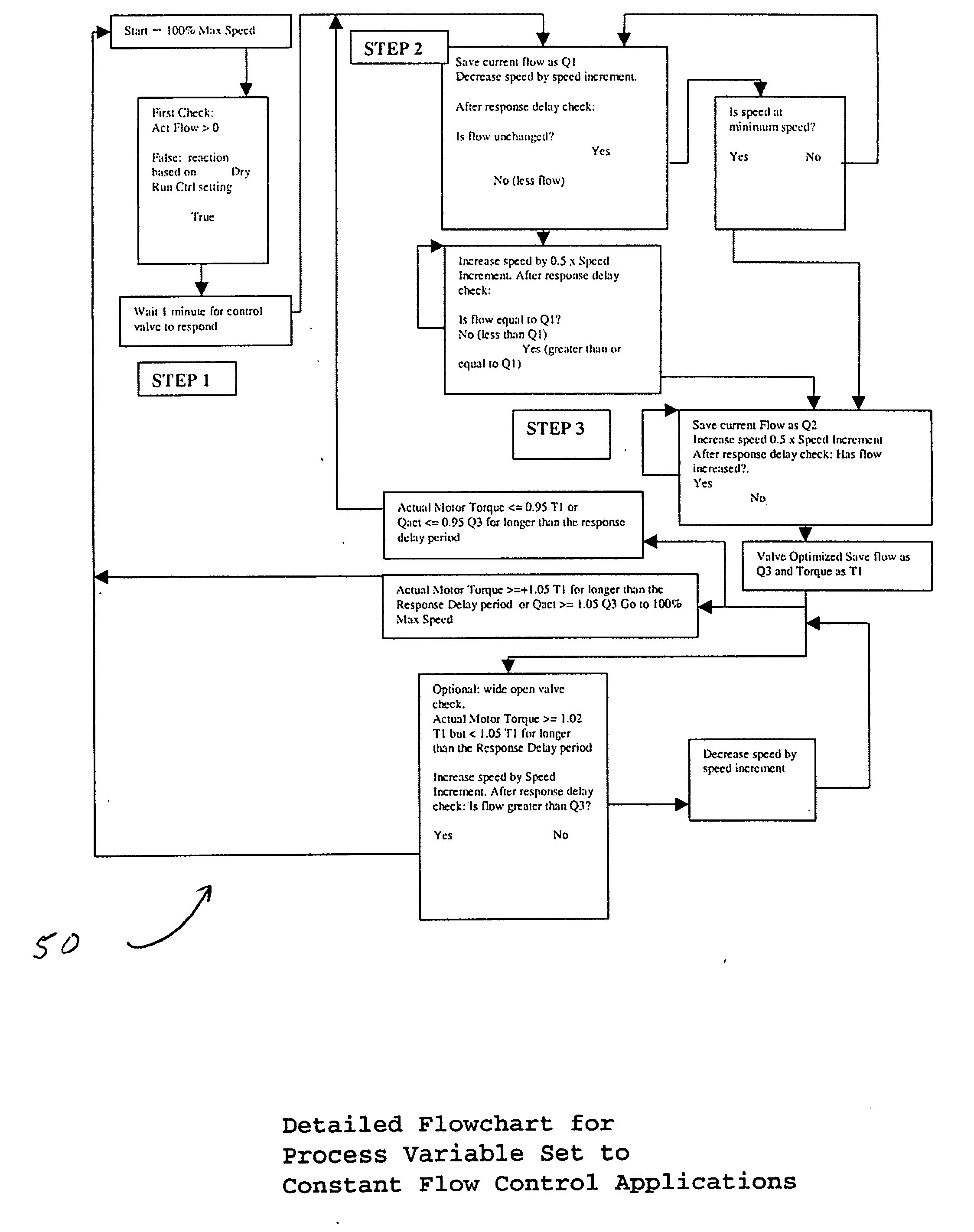

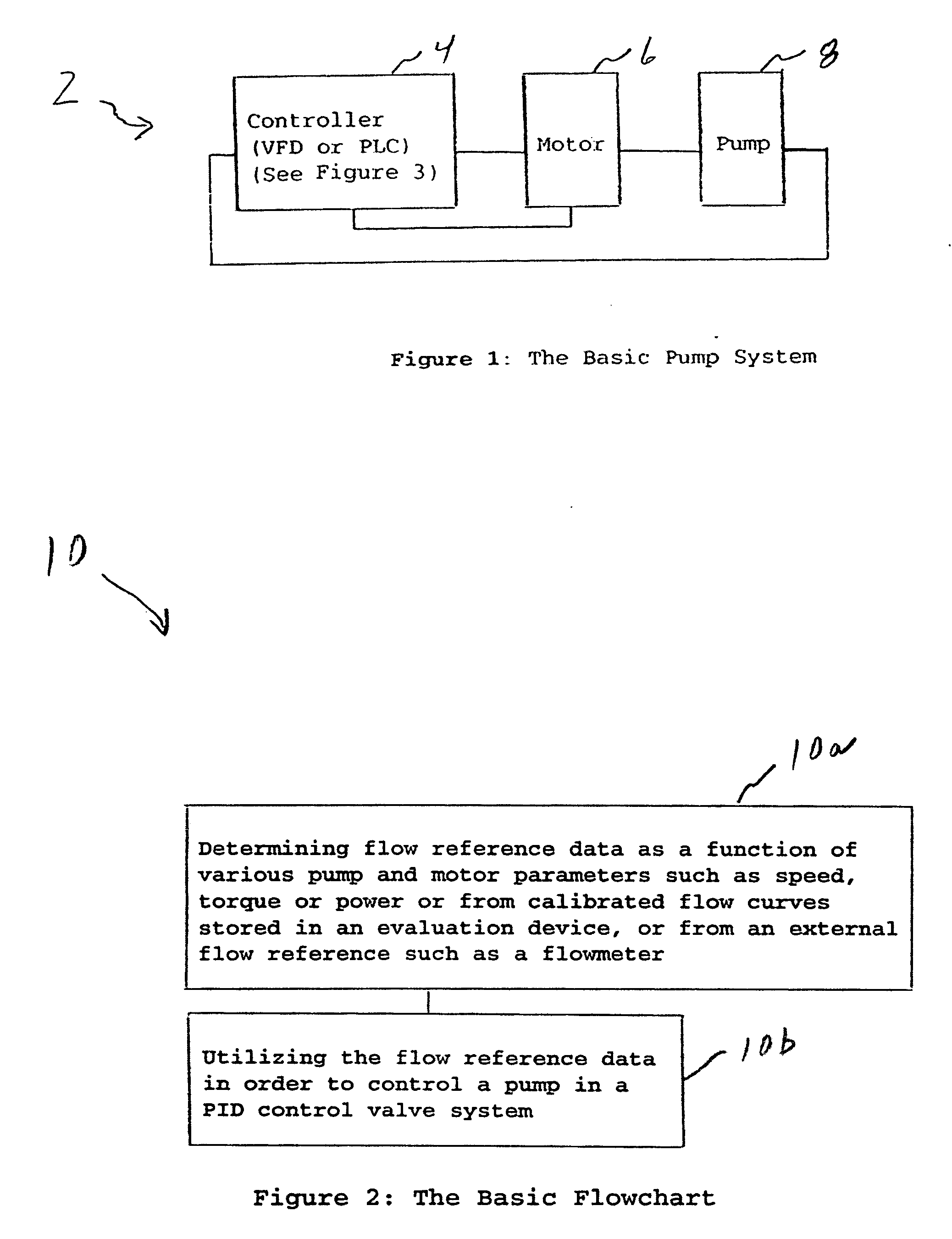

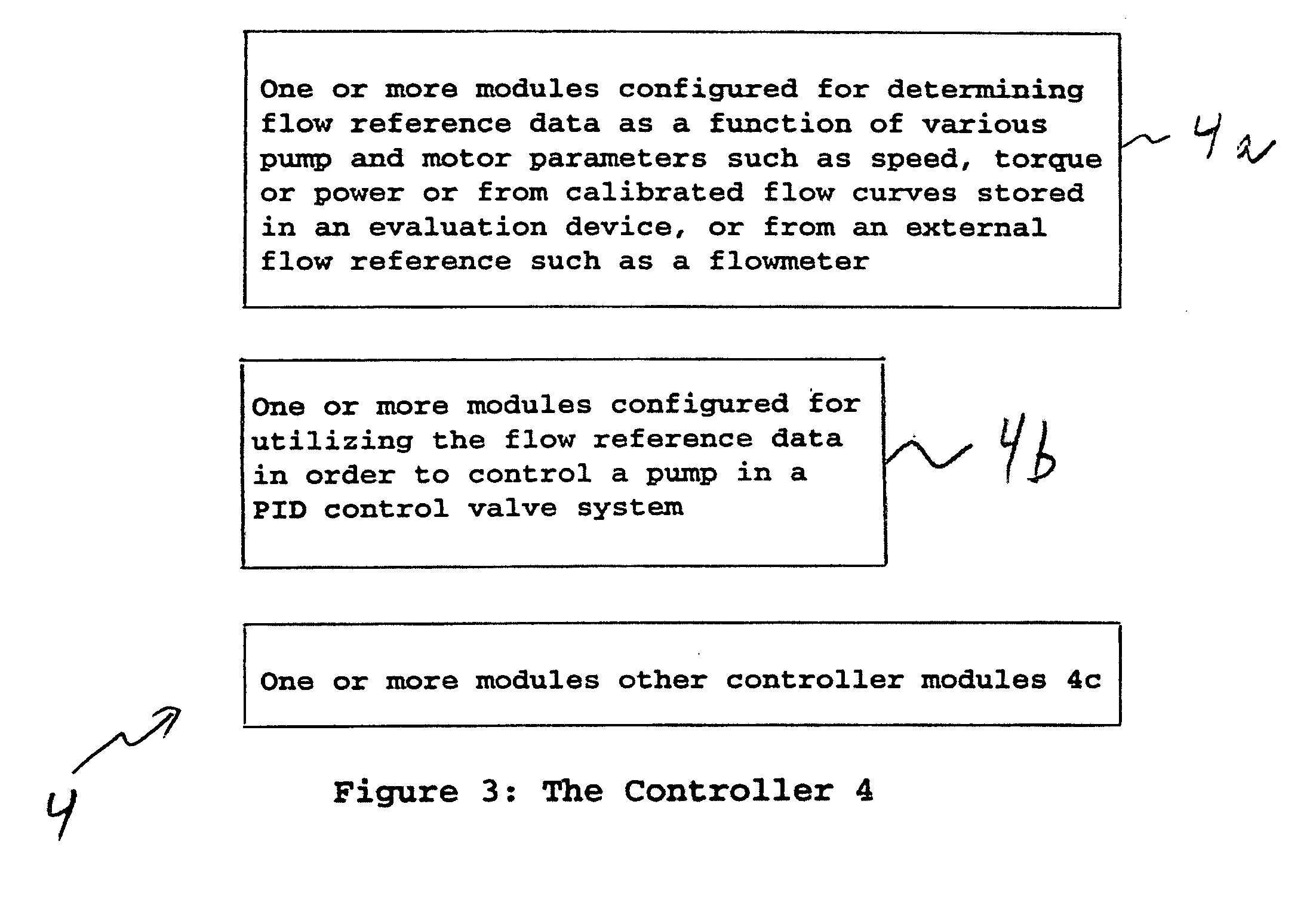

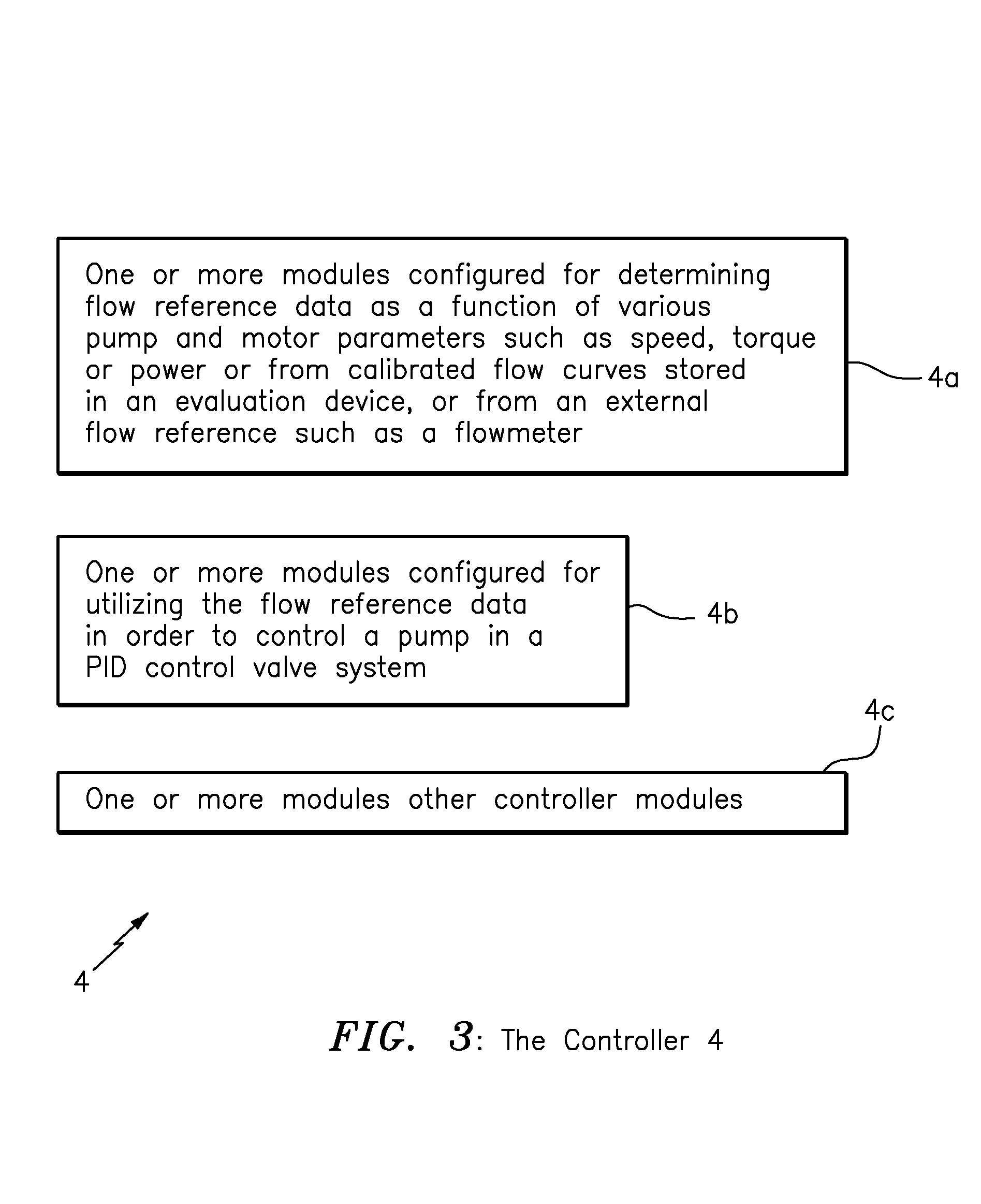

Method for optimizing valve position and pump speed in a PID control valve system without the use of external signals

InactiveUS20070212230A1Overcomes shortcomingImprove positionPump controlRatio controlFlow curveControl valves

The present invention provides an algorithm that utilizes flow reference data which can be mathematically determined as a function of various pump and motor parameters such as speed, torque or power or from calibrated flow curves stored in an evaluation device, or from an external flow reference such as a flowmeter. Once the PID control valve has reached its steady state condition a calculated flow value is captured and compared to the current flow value obtained after the variable frequency drive has decreased in frequency (speed). The valve position is optimized just prior to the speed threshold where the flow condition of the algorithm is no longer true.

Owner:ITT MFG ENTERPRISES LLC

Method and apparatus for pump protection without the use of traditional sensors

Owner:ITT MFG ENTERPRISES LLC

Method for optimizing valve position and pump speed in a PID control valve system without the use of external signals

InactiveUS7925385B2Overcomes shortcomingImprove positionPump controlRatio controlFlow curveControl valves

The present invention provides an algorithm that utilizes flow reference data which can be mathematically determined as a function of various pump and motor parameters such as speed, torque or power or from calibrated flow curves stored in an evaluation device, or from an external flow reference such as a flowmeter. Once the PID control valve has reached its steady state condition a calculated flow value is captured and compared to the current flow value obtained after the variable frequency drive has decreased in frequency (speed). The valve position is optimized just prior to the speed threshold where the flow condition of the algorithm is no longer true.

Owner:ITT MFG ENTERPRISES LLC

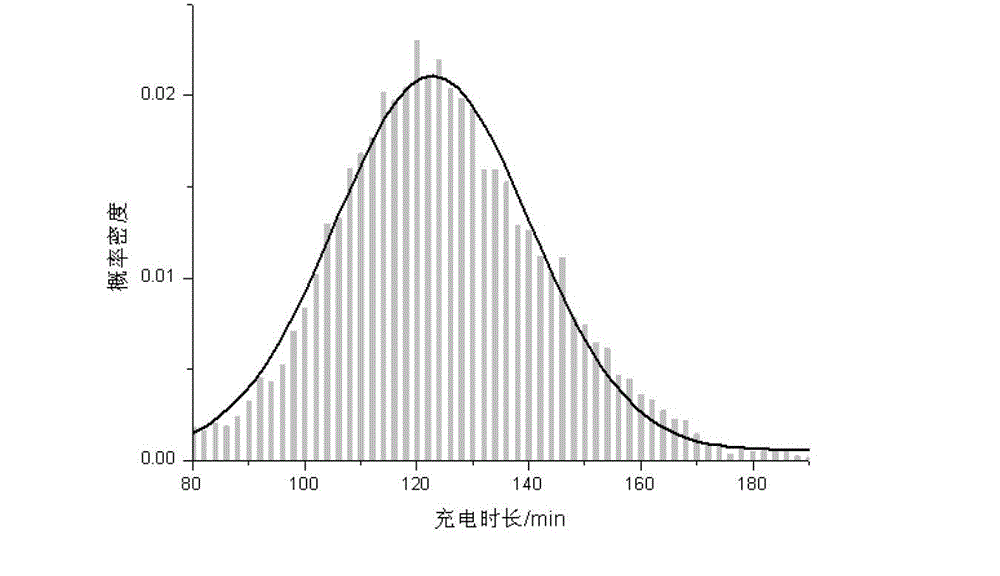

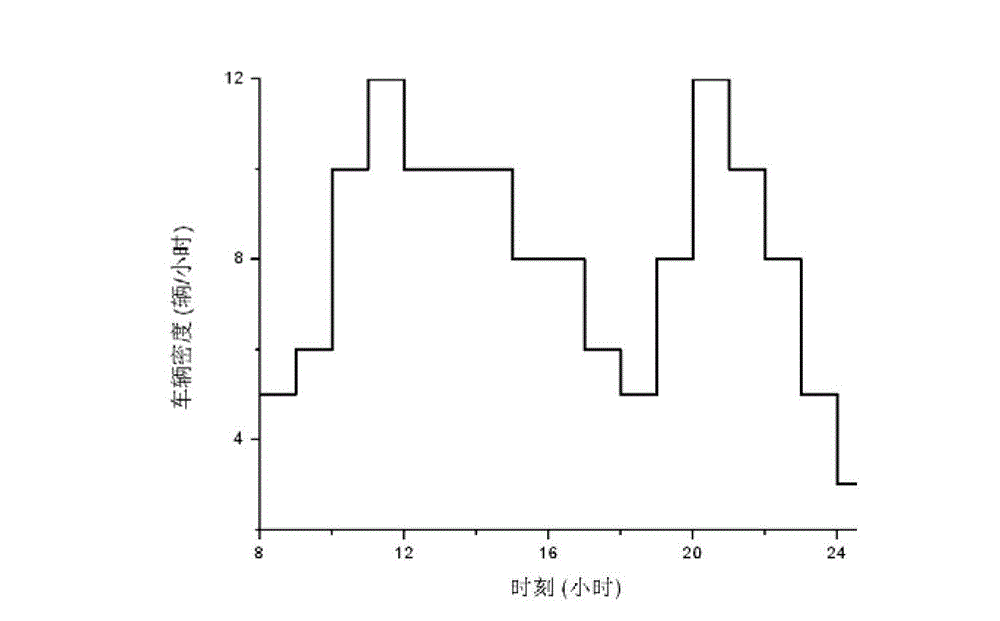

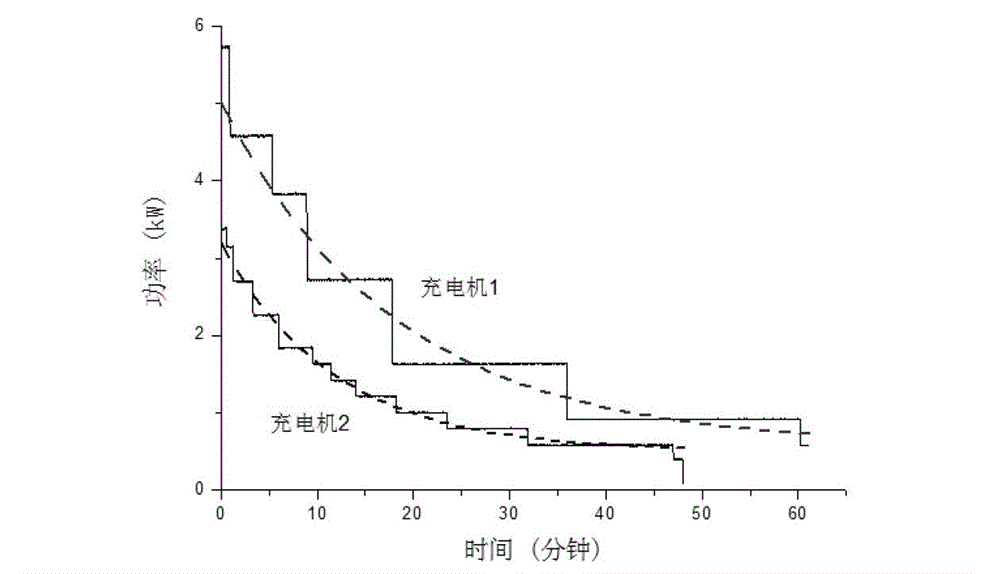

Electric vehicle charging station load forecasting method

An electric vehicle charging station load forecasting method is divided into a simplified method and a dynamic simulation method. The simplifying method comprises the following steps of counting a vehicle entering a station flow in a typical set time interval in a day by a historical statistics data so that a section curve description formula of an electric vehicle entering the station flow curve is obtained; solving the number of the vehicles entering in the station and being charged in the interval [t-TC, t]; and calculating active power at any time. The dynamic simulation method comprises the following steps of describing charging time by a normal distribution probability density function; performing counting and curve fitting to historical charging time to get a mean value and a standard deviation; and obtaining the whole number of the vehicles being charged and the charging power of the vehicles at every time in a day so that overall charging power of the charging station is calculated. The method is simple in arithmetic, definite in a data interface, fast in operation speed and capable of supporting dynamic interactive simulation of the electric vehicles in a large scale so that time and space distribution of charging load of the electric vehicles can be forecasted and the foundation method can be offered for studying influence on an electric power system by the charging load.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

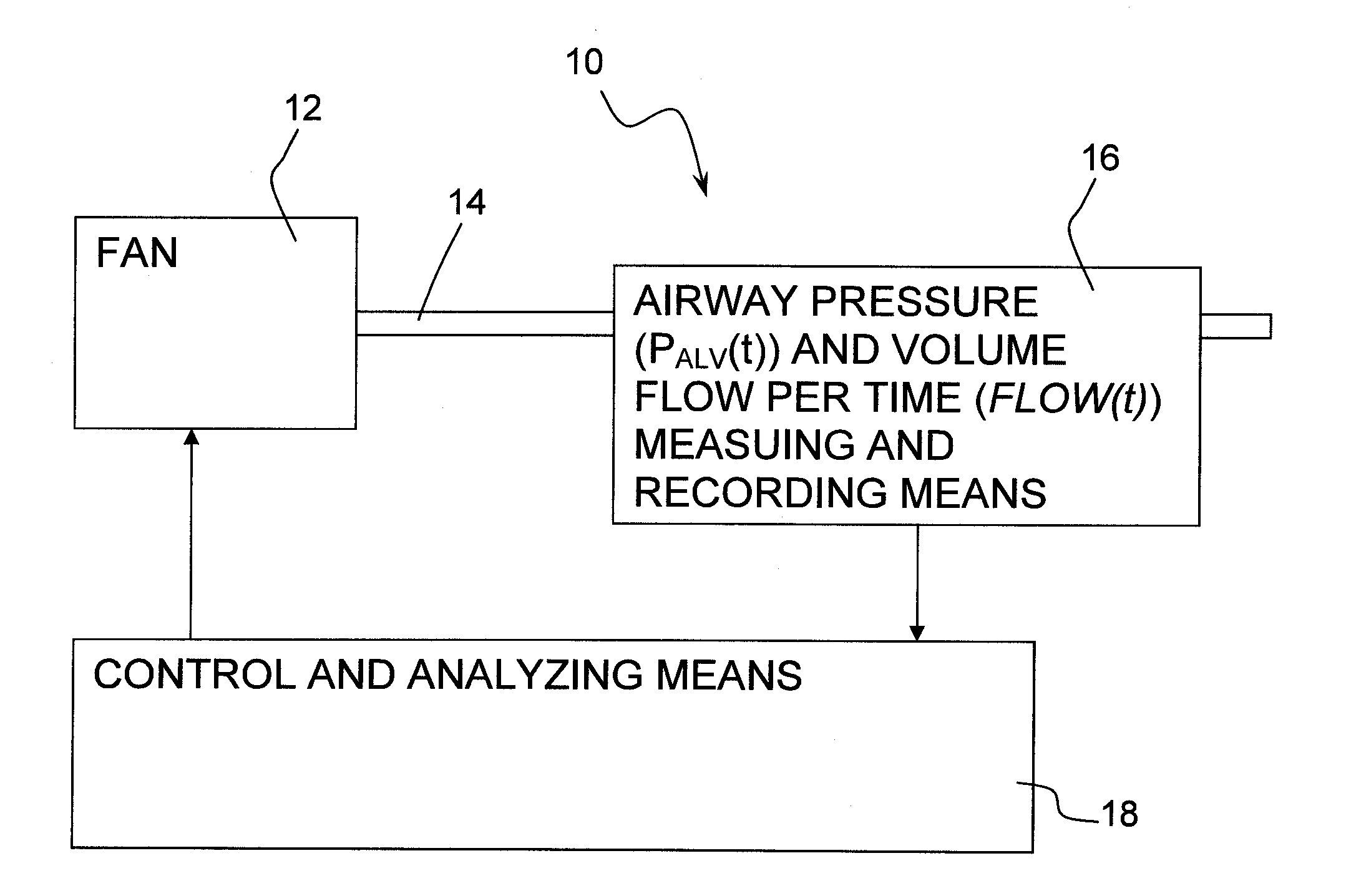

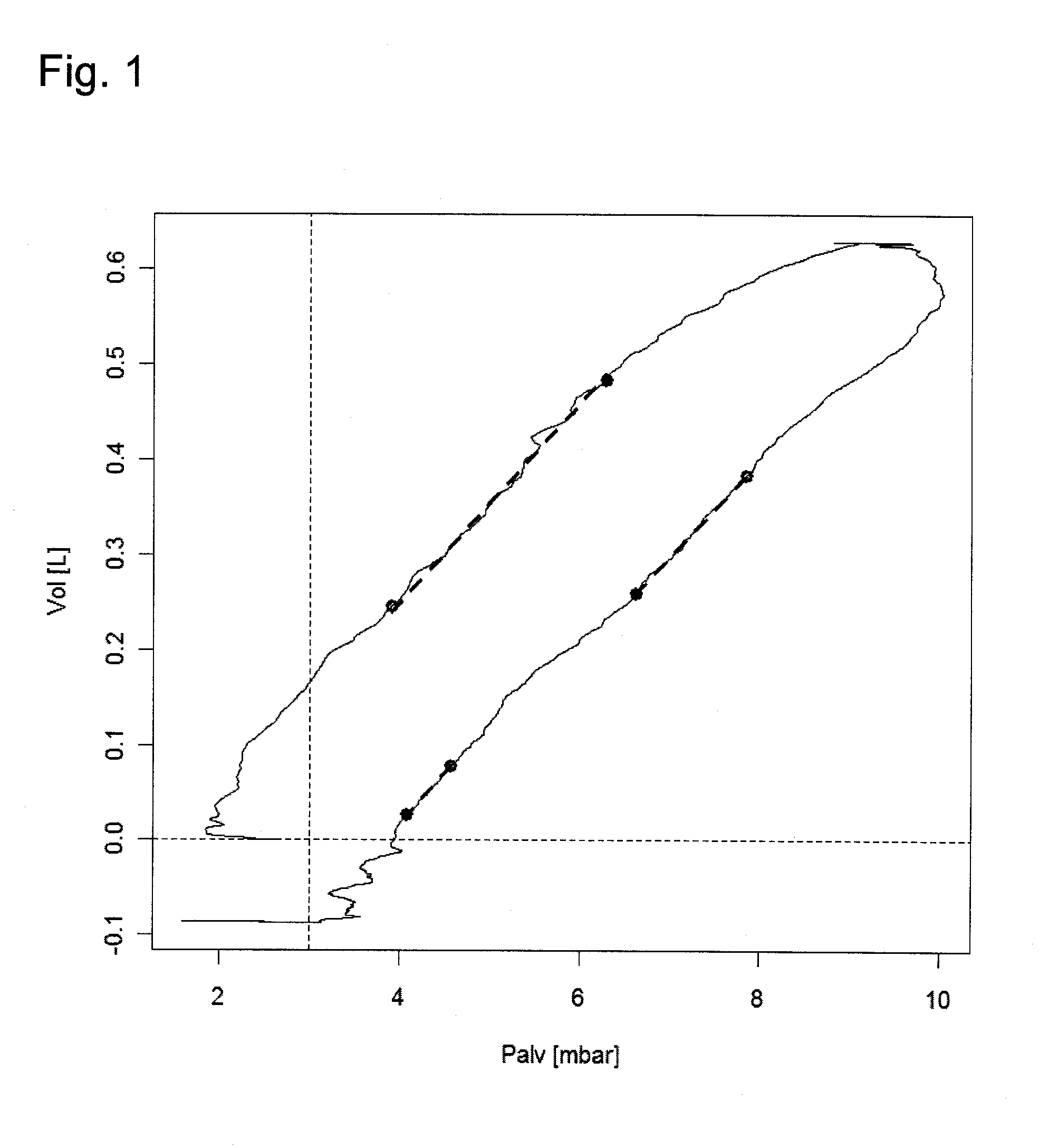

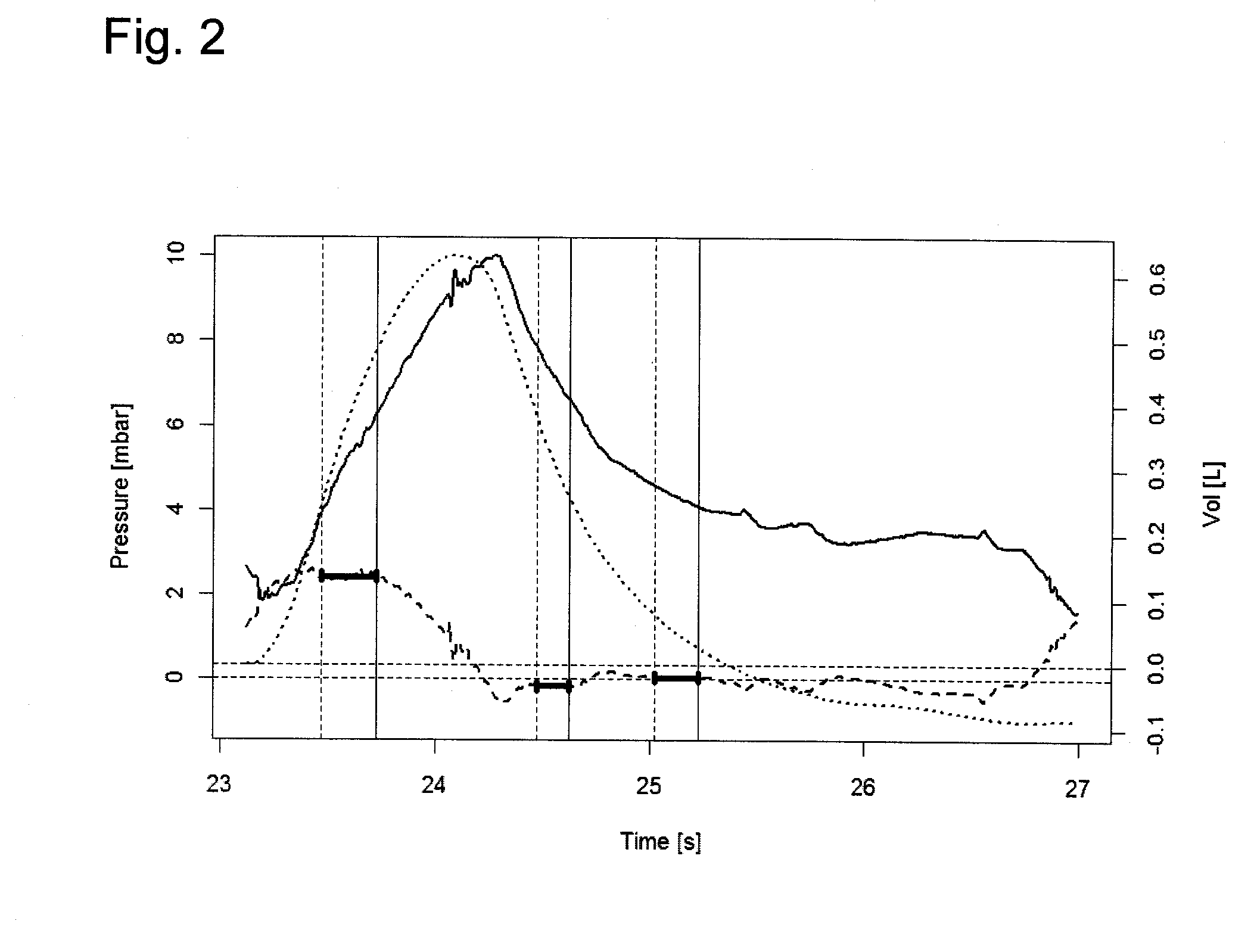

Respirator with automatically controlled pressure-assist respiration

InactiveUS20100307499A1RespiratorsOperating means/releasing devices for valvesElectrical resistance and conductanceAutomatic control

A respirator with an adjustable pressure or volume flow curve has a control and analyzing unit, which is set up to determine the resistance R and the alveolar pressure Palv(t). The control and analyzing unit checks the functional dependence of Palv(t) and of the tidal volume Vol(t) for time intervals in which an indicator of the quality of a linear functional dependence of Palv(t) and Vol(t) meets a preset threshold criterion and to determine the elastance E or compliance C from the rise of the alveolar pressure Palv(t) as a function of the volume Vol(t) only in the time intervals thus determined.

Owner:DRAGERWERK AG

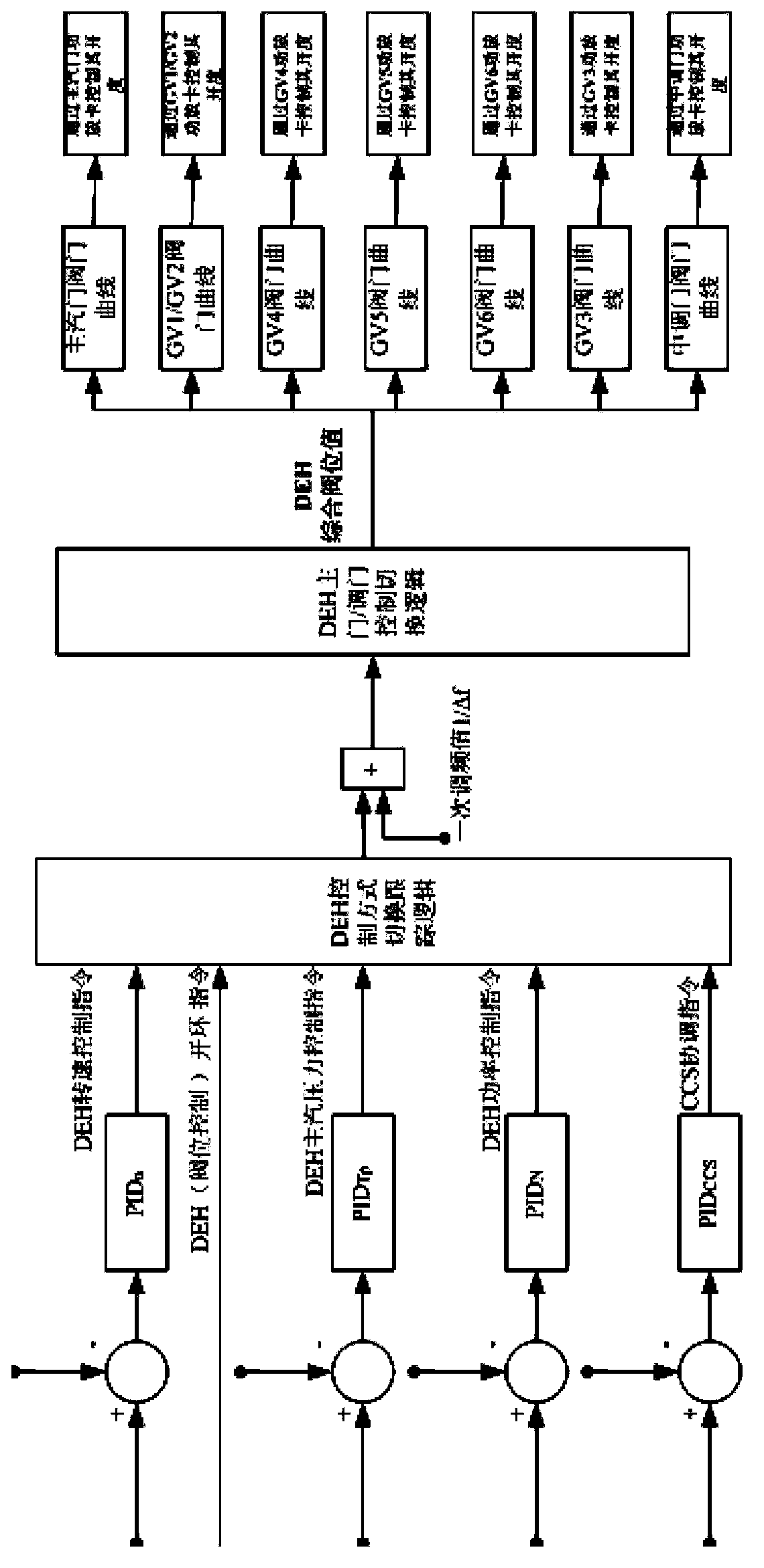

Adjustment method for steam turbine control valve flows in thermal power plant

InactiveCN103670536AAvoid swingingImprove linearizationMachines/enginesEngine componentsFlow curveEngineering

The invention provides an adjustment method for steam turbine control valve flows in a thermal power plant. The adjustment method includes the following steps that step1, a control valve optimization experiment is performed, all experimental data are determined, and a load up-and-down experiment needing to be performed for a current valve curve linear relation, a high control valve flow characteristic experiment, and determining on maximum strokes and sequence valve curves of all high control valve equalizing valves, sequence valve curves after on-line inspection and modification and maximum flow point positions of intermediate control valves are sequentially performed; step2, a control valve flow curve optimization scheme is obtained through calculation and analysis performed on control valve flow curve experimental data. The adjustment method can effectively improve the flow characteristic of steam turbine control valves, improve load variation and primary frequency modulation performance of a generator set, effectively improve adjustment quality of the generator set, and improve running safety and service life of high control valves and the intermediate control valves and economy of the set.

Owner:GANSU DATANG INT LIANCHENG POWER GENERATION

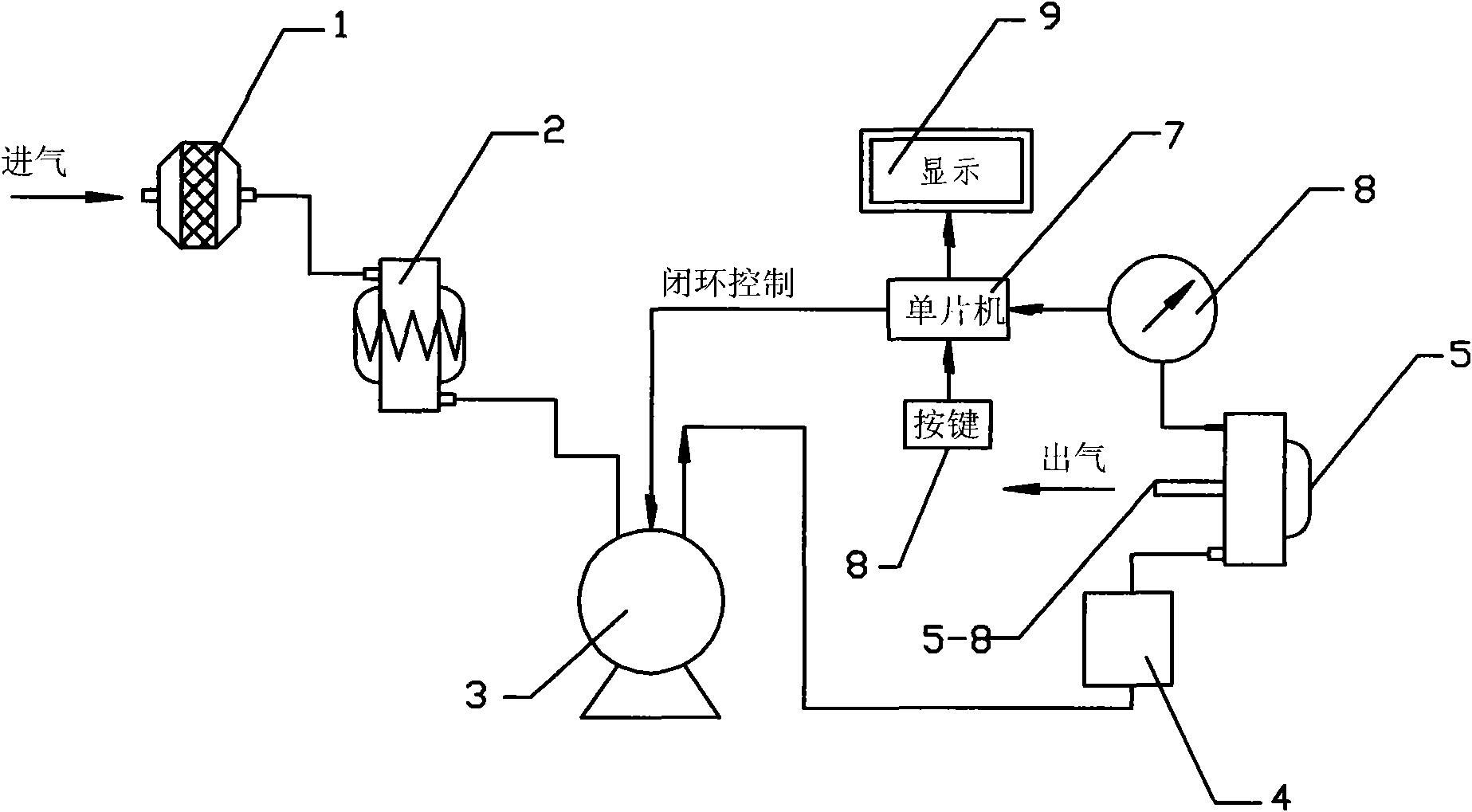

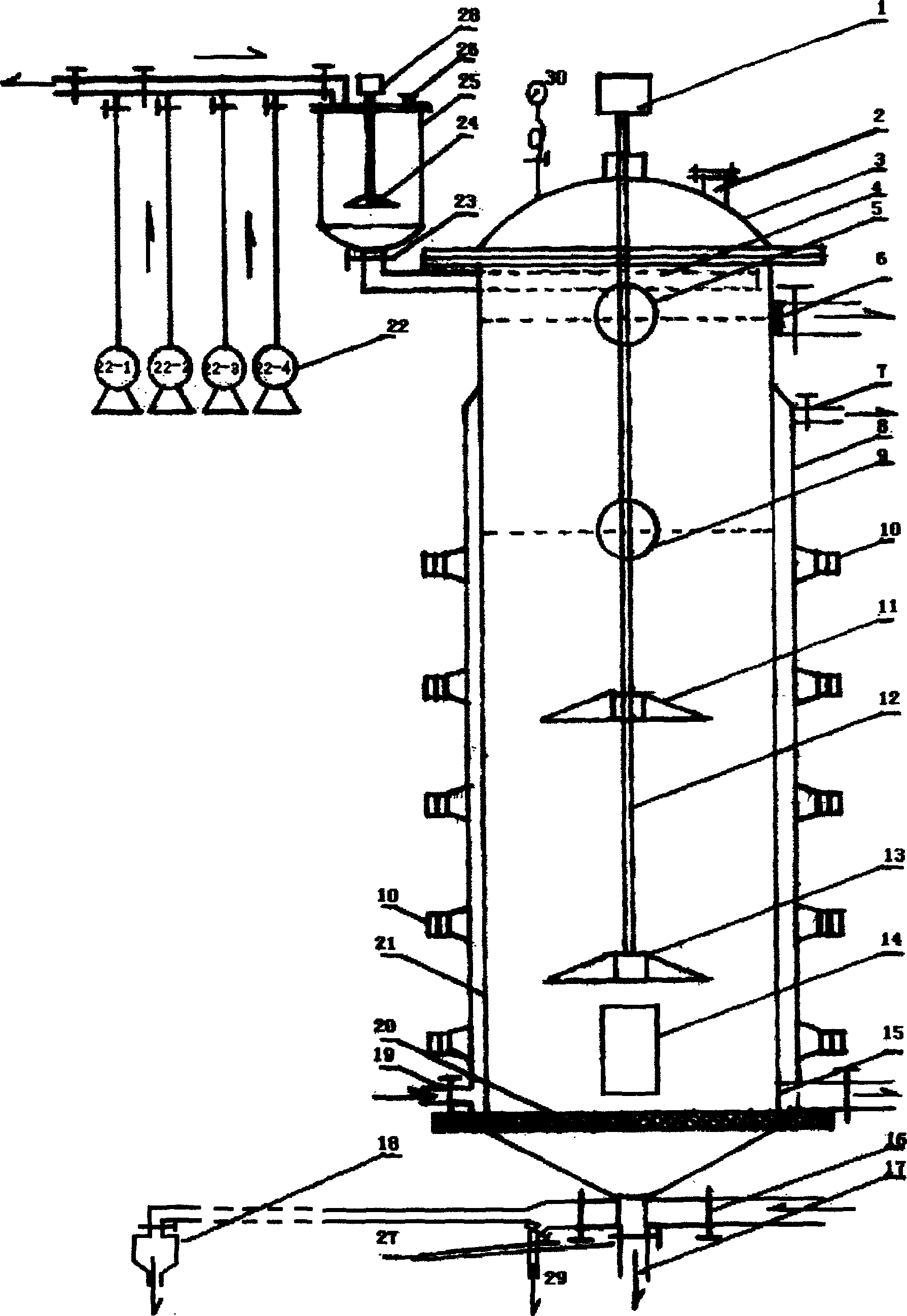

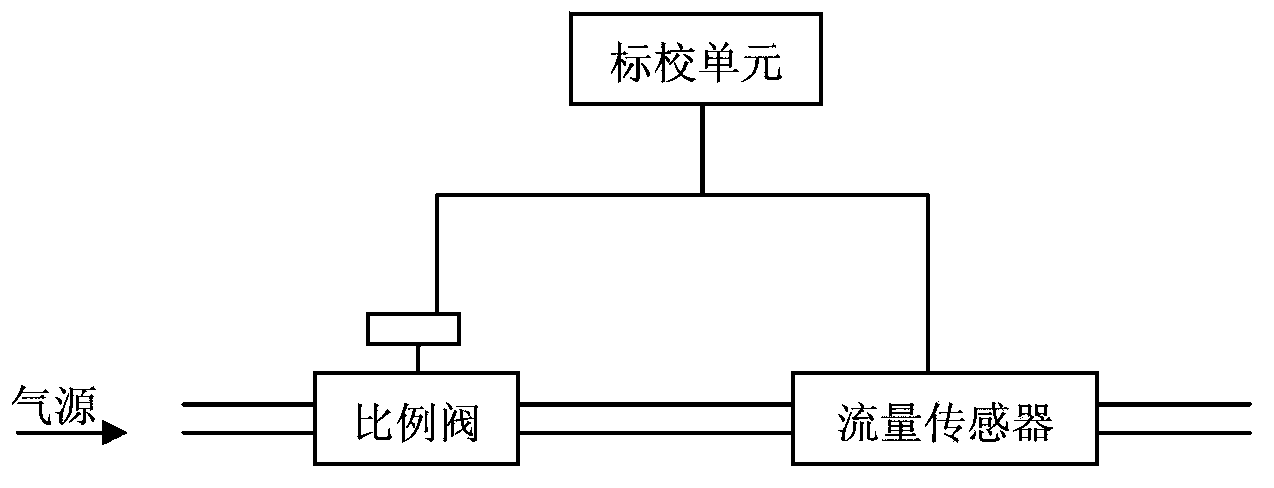

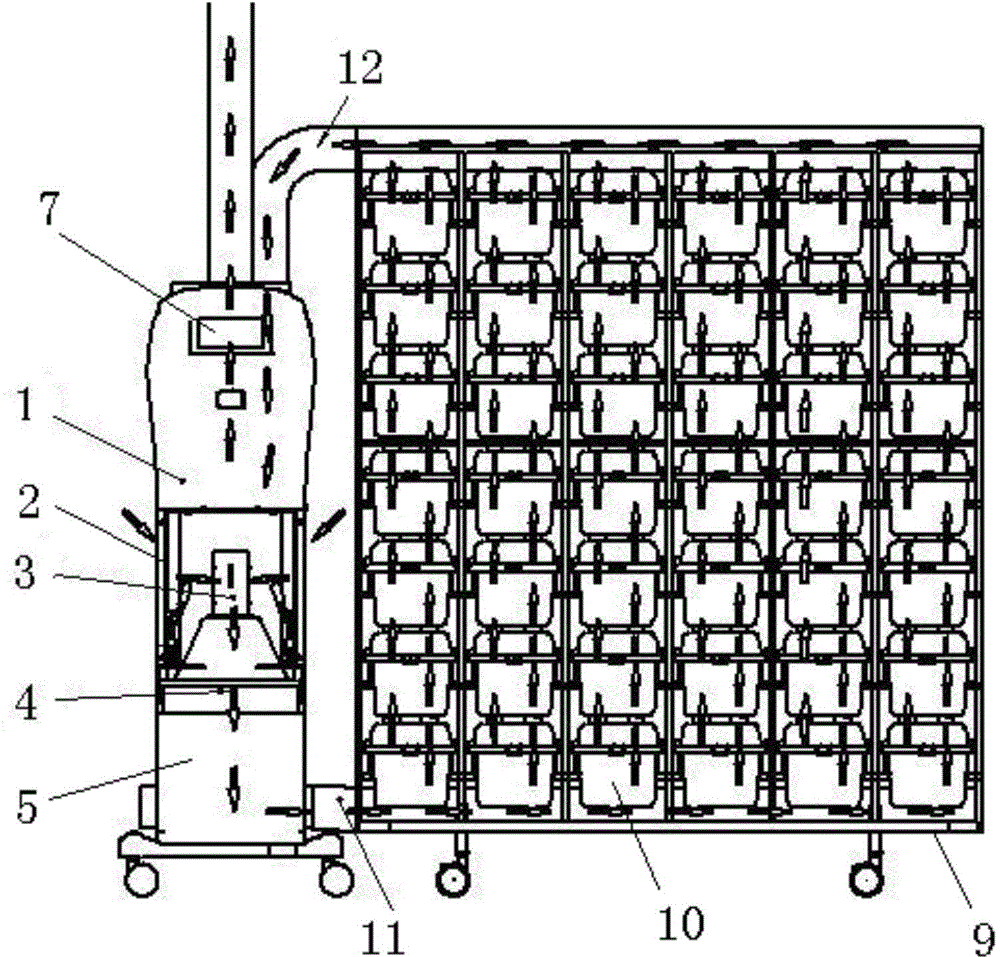

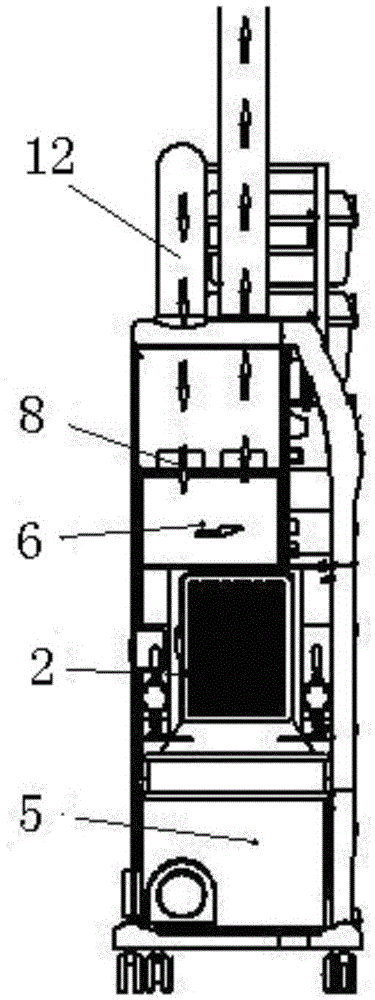

Intelligent constant-flow individual air dust sampler and constant-flow control method

ActiveCN101858832AHigh measurement accuracyRealize closed-loop automatic controlWithdrawing sample devicesFlow control using electric meansMicrocontrollerLoop control

The invention discloses an intelligent constant-flow individual air dust sampler and a constant-flow control method. The sampler is provided with a buffering air capacitor (2), an air capacitor (4), a flow closed-loop control circuit (16), pressure measuring openings (5, 6 and 7) and a differential pressure sensor (6), wherein the test end of the differential pressure sensor (6) is communicated with the pressure measuring opening on an air chamber (5) through a hose; the signal output end of the differential pressure sensor (6) is connected with an input port of a singlechip (7) through an amplifier and an A / D converter; and the output control end of the singlechip is connected with the electrical signal control end of the driving motor of an air pump (3) through an air pump control unit (19). The constant-flow control method comprises: a, establishing a flow correction curve; b, testing the backpressure of working gas at the outlet of the air chamber (5); and c, comparing a measured current backpressure with the flow curve and controlling the air pump (3) to implement constant-flow output. The sampler and the method can realize flow closed-loop control and automatic constant-flow sampling, improve the accuracy of dust mass concentration measurement and ensure reliable use and accurate control.

Owner:武汉碧海云天科技股份有限公司

Left ofloxacin and Pidotimod compound preparation tech and its appts.

Tea leaves is used as raw material, by using water or solvent, to extract tea-polyphenol, then settle, centrifugal separation, column absorbing, extracting by ethyl acetate, vacuum concentrating, drying to obtain crude tea-polyphenol. Said crude product is then dissolved in water, absorbed by resin column, washed-off by agent gradient adding-in, based-on standard flowing curve to obtain 7 monomer catechins with purity>99%. For this purpose, full automatic absorbing resin column is equiped with metering pump to adjust fed-in of water, solution and solvent, HPLC real-time monitoring and pick-correcting to washing-off liquid is achieved by proportional flow-splitter. Automatic back-wash and resin-exchanging are achieved by being equiped with over-flow hole, resin discharging hole and others.

Owner:胡绍海

Use of water-soluble polymer complexes in aqueous systems

InactiveUS20050183837A1High viscosityCosmetic preparationsNatural cellulose pulp/paperSludgeFlow curve

A water-soluble interjacent complex that includes a first water-soluble polymer and one or more water-soluble monomers polymerized to form a second water-soluble polymer in the presence of the first water-soluble polymer. The water-soluble interjacent complex forms a solution in water that is free of insoluble polymer particles. The interjacent complexes may be used to treat a waste sludge by adding an effective amount thereof to the waste sludge. The interjacent complexes may also be used in making paper by adding an effective amount thereof to a pulp or a forming sheet at a suitable location on a paper making machine. The interjacent complexes may further be used as a rheology modifier in aqueous systems by adding an effective amount thereof to an aqueous medium to effect a desired viscosity, rheology, or flow curve property.

Owner:SOLVAY USA

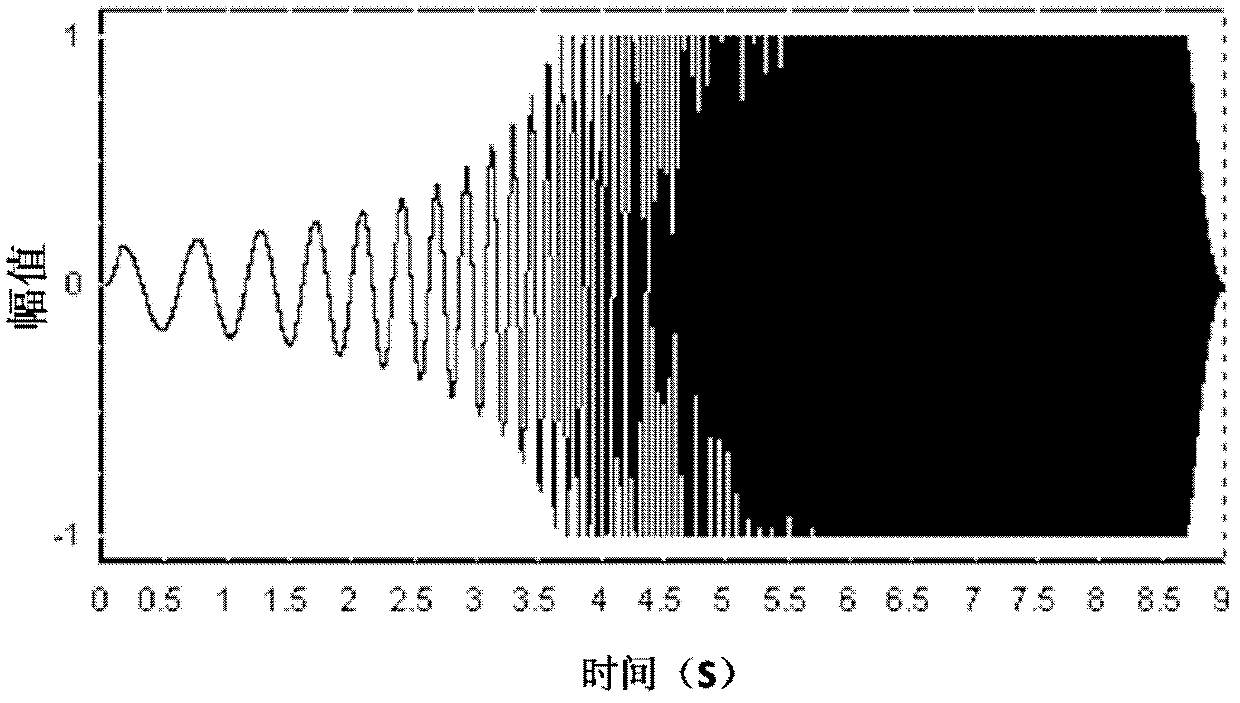

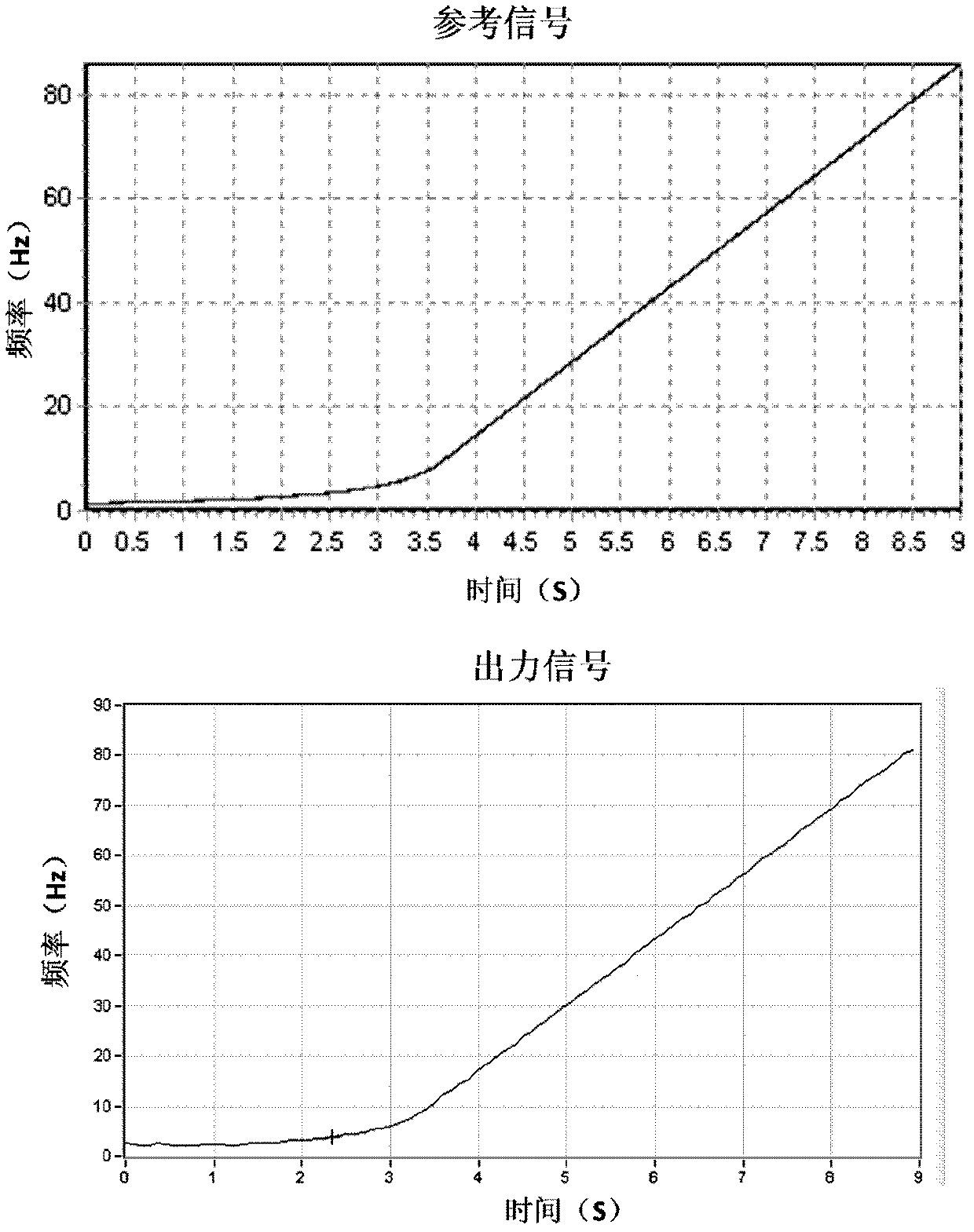

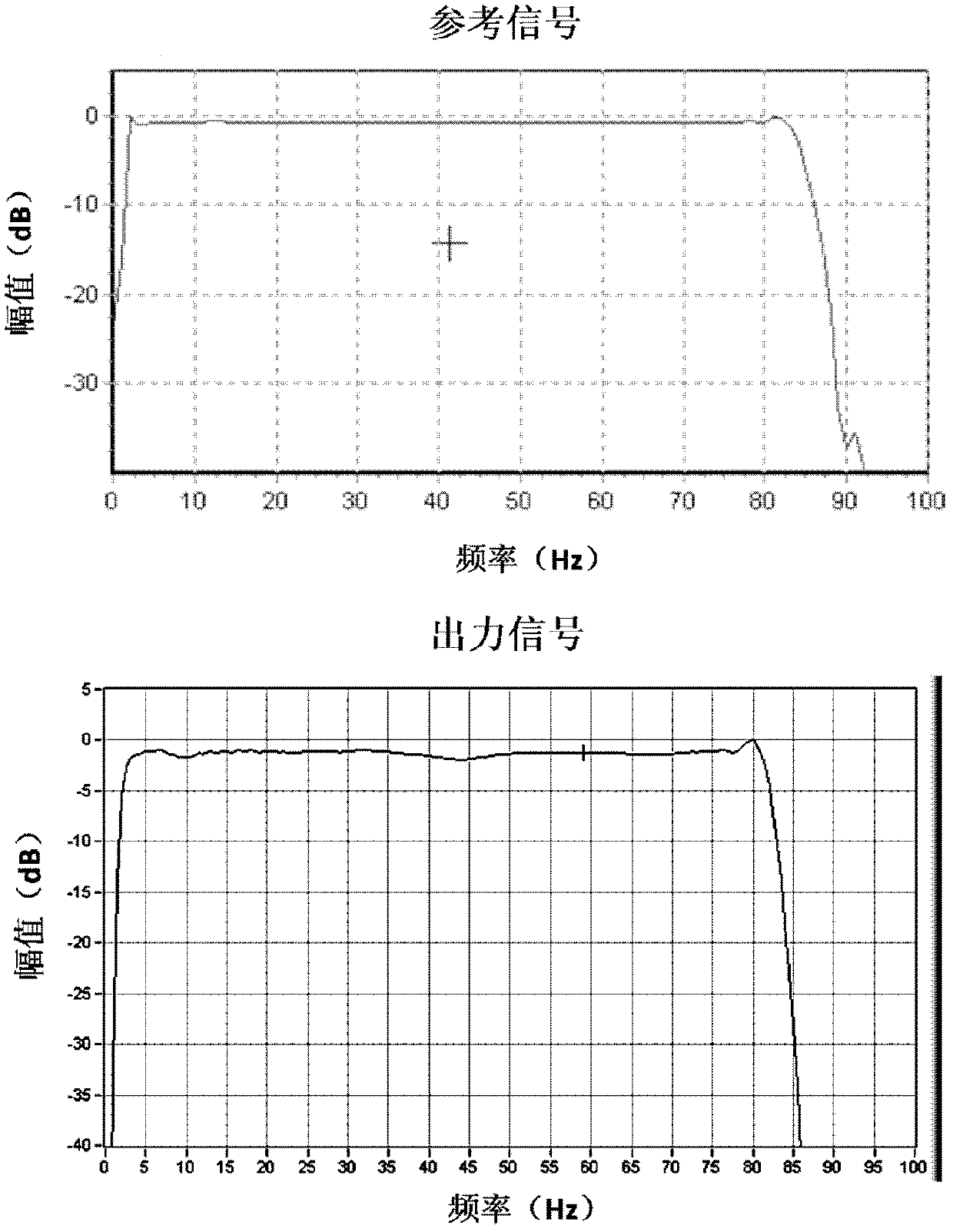

Method determining controllable vibration source best low-frequency scanning signal

ActiveCN103323876AImprove protectionSeismic data acquisitionSeismic signal processingFrequency spectrumFlow curve

The invention discloses a method determining a controllable vibration source best low-frequency scanning signal. Equal-frequency scanning signals are adopted, vibration source output force is increased gradually to carry out excitation, the least square method is used for carrying out matching on measured vibration source low-frequency sampling point actual output maximum output force, a controllable vibration source low-frequency output curve is determined according to a fitting heavy punch maximum displacement curve and the focus of a system flow curve, a low-frequency section scanning time length is calculated, the frequency, amplitude and phase of each sampling point of the low-frequency section are calculated, a scanning signal is generated to carry out practical testing on the vibration source, and the best low-frequency scanning signal is obtained until a vibration result does not exceed heavy hammer displacement limitation or the flow limitation. According to the method determining the controllable vibration source best low-frequency scanning signal, the low-frequency components of the controllable vibration source scanning signal are significantly enhanced, the method determining the controllable vibration source best low-frequency scanning signal is suitable for an existing controllable vibration source, can exert the maximum potential of the low frequency of the controllable vibration source, the low frequency signal is small in signal distortion, the output frequency spectrum of the controllable vibration source is smooth and white-noised, and the controllable vibration source can be protected well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

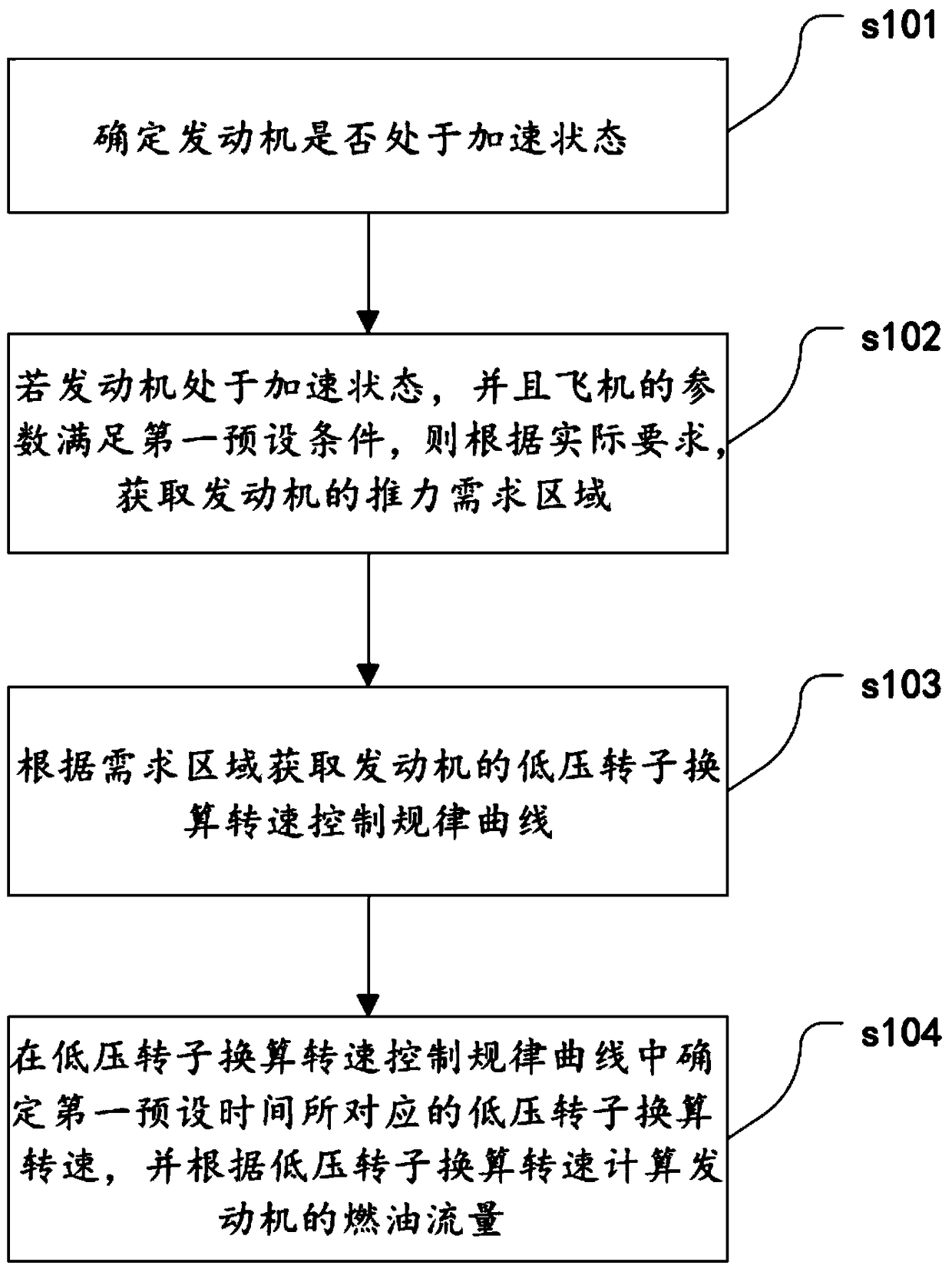

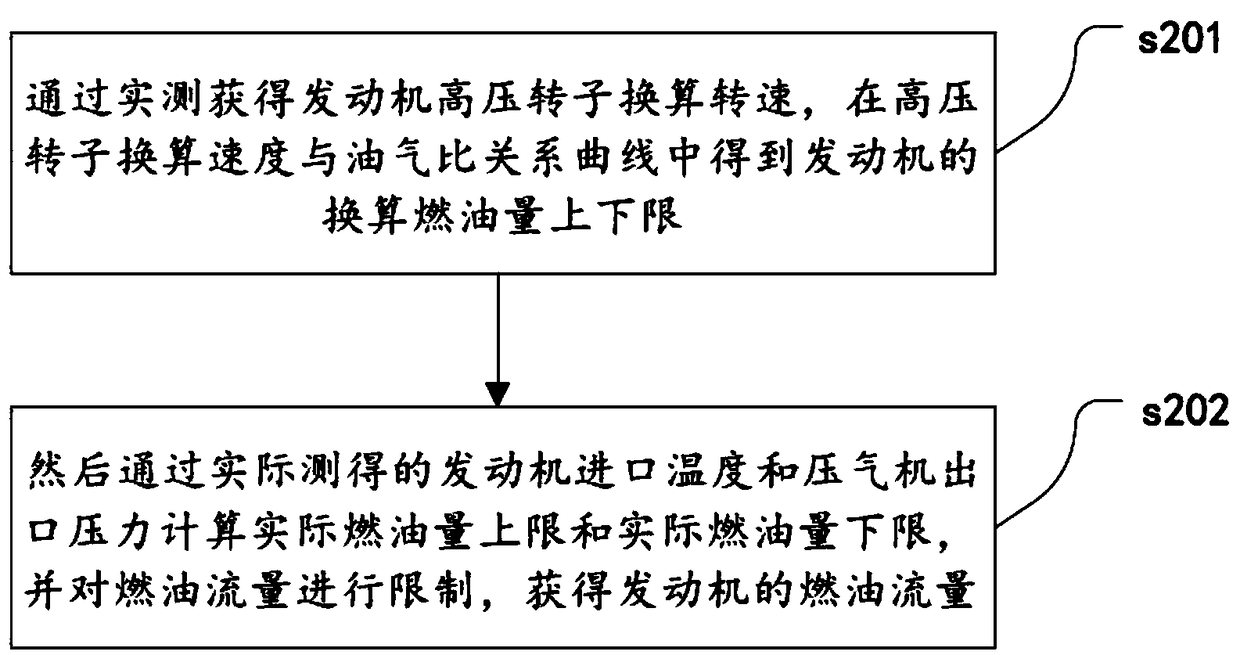

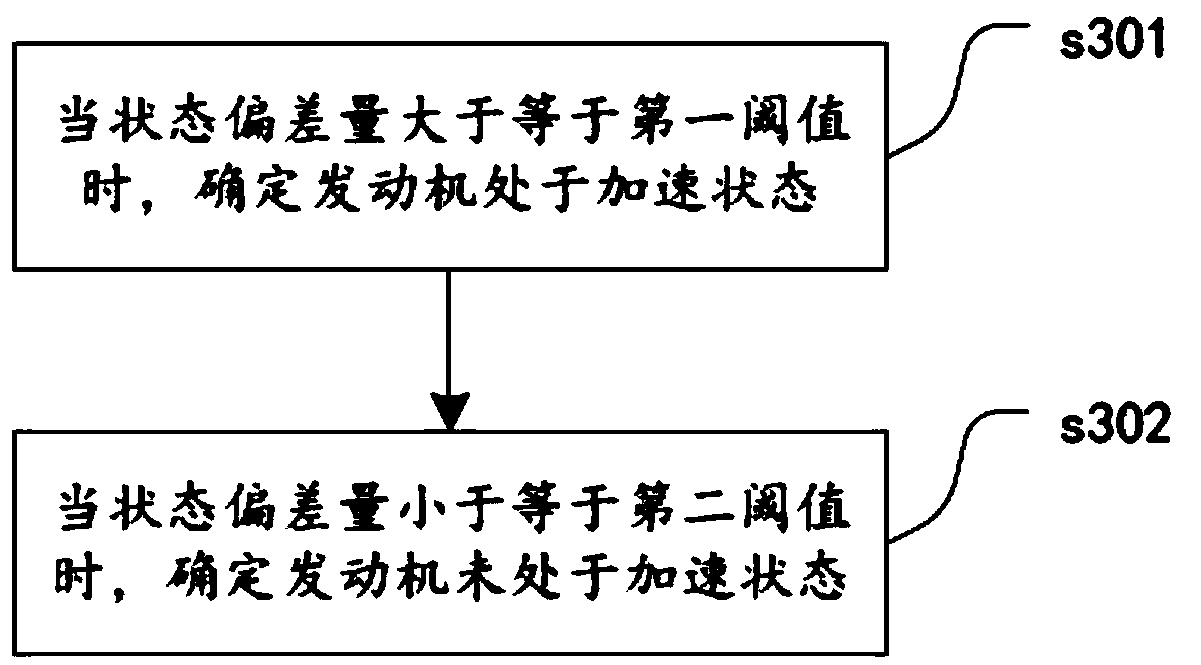

Method for acquiring thrust limiting rules of big and small accelerator of aircraft engine

ActiveCN108894882AAvoid stabilityAvoid Compatibility IssuesTurbine/propulsion fuel controlFlow curveFuel oil

The invention discloses a method for acquiring thrust limiting rules of big and small accelerators of an aircraft engine. The method comprises the following steps: calculating a state deviation valueof the engine, and determining whether the engine is in an acceleration state according to the state deviation value; if the engine is in the acceleration state, acquiring a low-pressure rotor conversion rotational speed control rule curve of the engine when parameters of the aircraft meet the first preset condition; and determining a low-pressure rotor conversion rotational speed corresponding toa first preset time in the low-pressure rotor conversion rotational speed control rule curve, and calculating a fuel oil flow curve of the engine according to the low-pressure rotor conversion rotational speed. By utilizing the control method implemented in the invention, the supply amounts of the fuel oil flow during the actions of the big and small accelerators of the engine can be independently controlled, and the requirement of the thrust change rate is realized.

Owner:AECC SHENYANG ENGINE RES INST

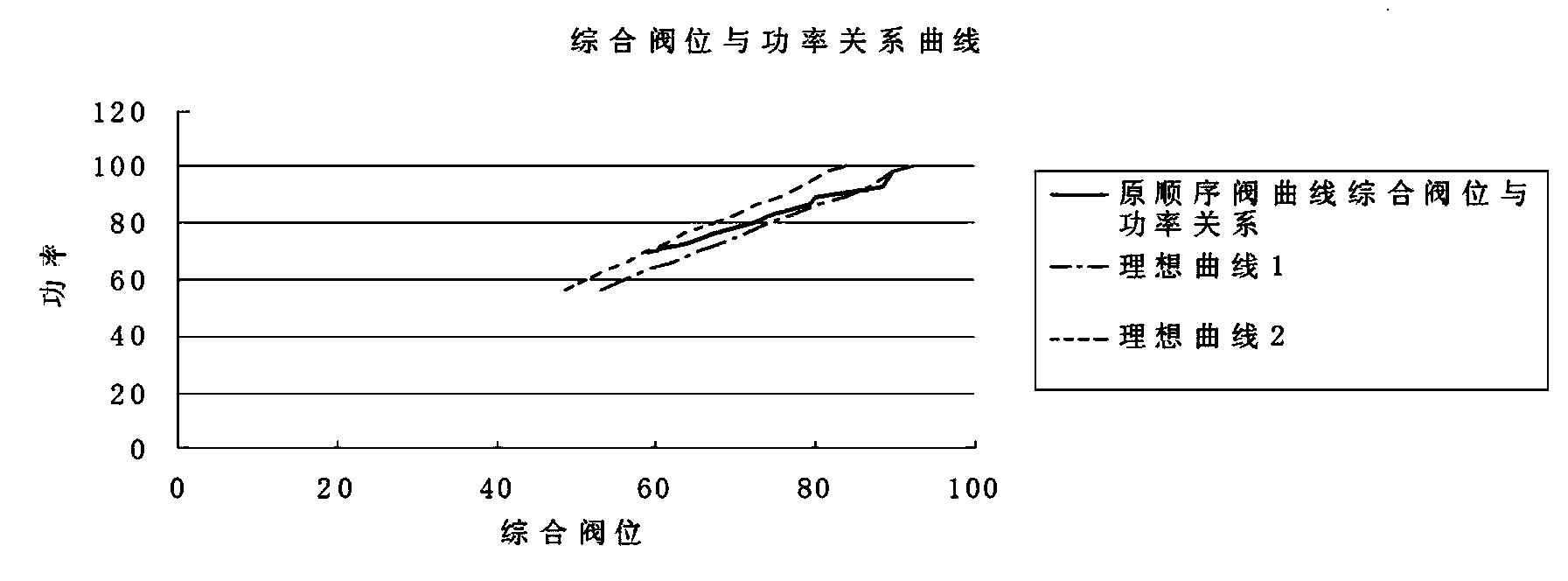

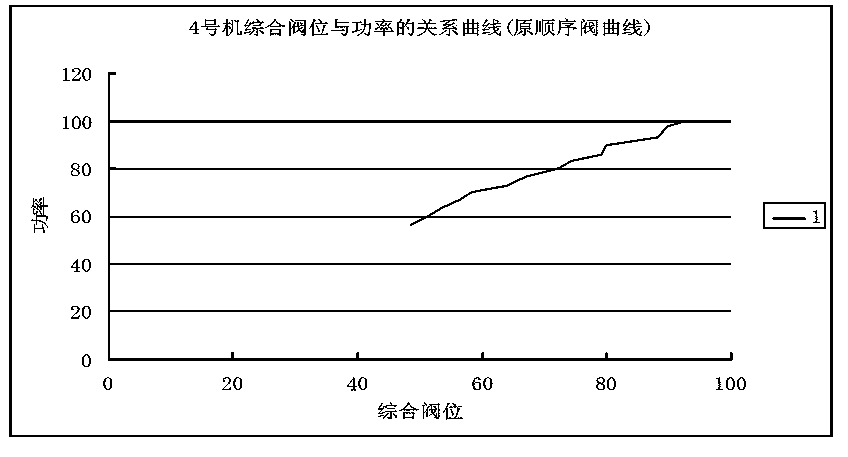

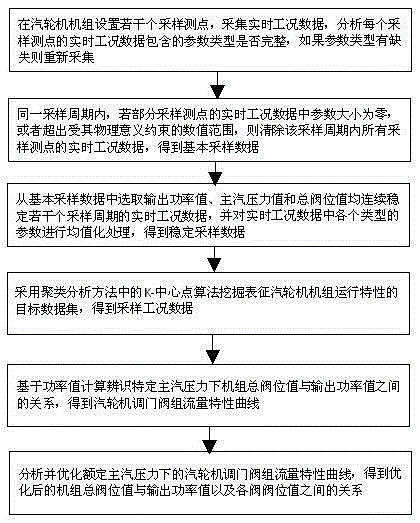

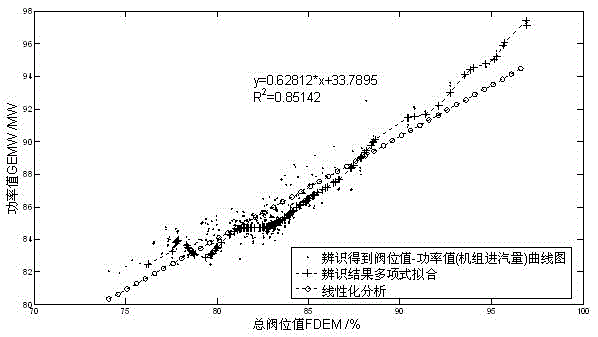

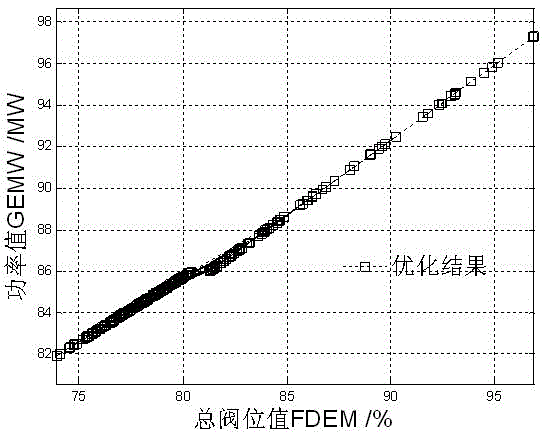

Steam turbine flow curve identification and optimization method based on power value calculation

ActiveCN105275508AImprove the quality of running regulationMachines/enginesEngine componentsData setSteam pressure

The invention discloses a steam turbine flow curve identification and optimization method based on power value calculation. The method includes the following steps that firstly, a plurality of sampling test points are set, and real-time working condition data are collected; secondly, vacancy working condition data and abnormal working condition data are deleted; thirdly, an output power value, a main steam pressure value and a total valve position value are selected to continuously stabilize the real-time working condition data of a plurality of sampling periods, and mean value treatment is carried out on various parameters; fourthly, a target data set is mined through the K-central point algorithm; fifthly, on the basis of power value calculation, a steam turbine adjustment valve bank flow characteristic curve under specific main steam pressure is identified; and sixthly, a steam turbine adjustment valve bank flow characteristic curve under rated main steam pressure is extracted, and a sector with unreasonable linearity is analyzed and optimized. The steam turbine flow curve identification and optimization method can be used for identifying the actual flow characteristic curve under the specific main steam pressure of a steam turbine adjustment valve bank, so that the specific adjustment valve bank flow characteristic curve is consistent with the actual curve, and safe and stable operation of a steam turbine unit is guaranteed.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +3

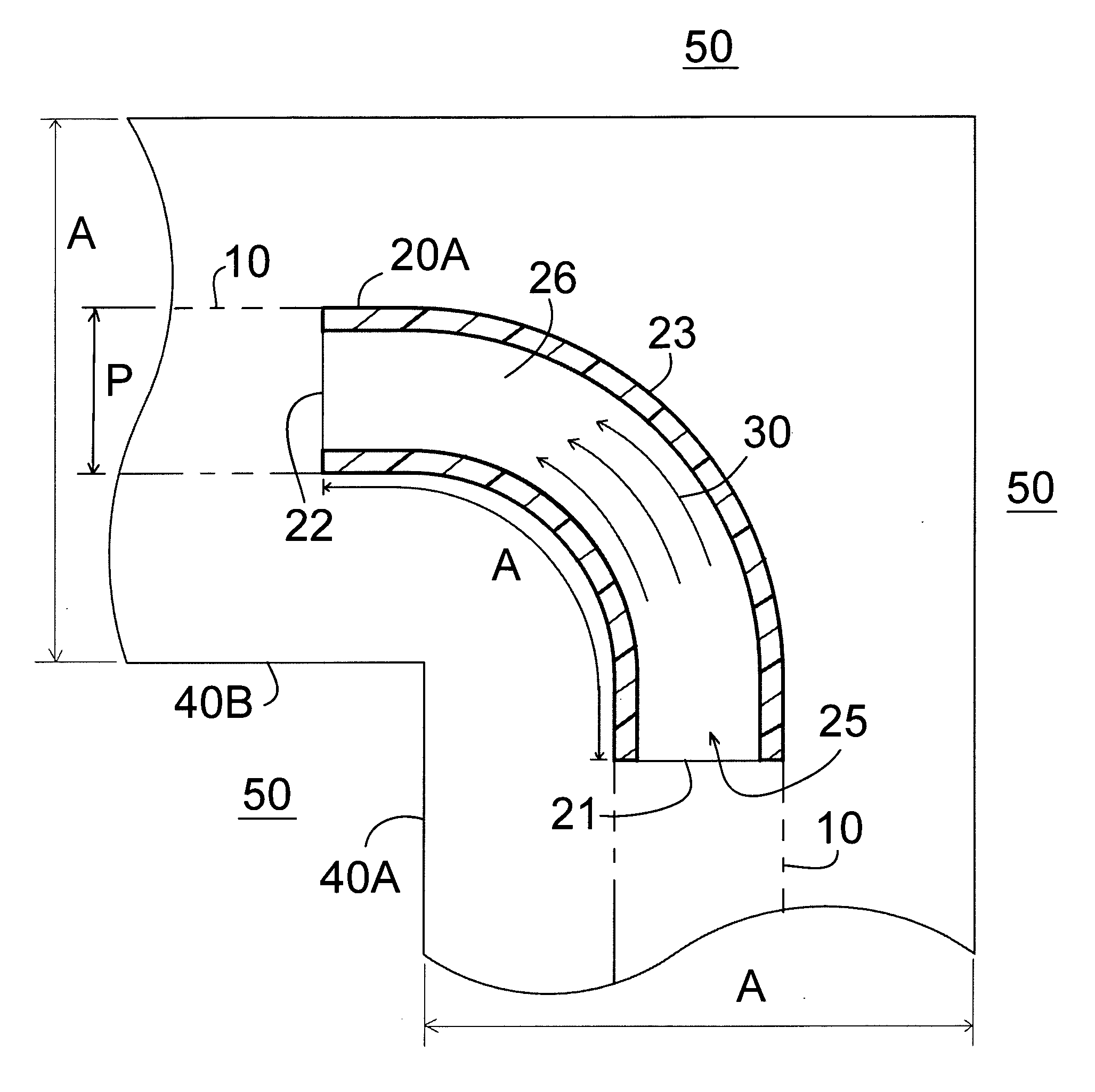

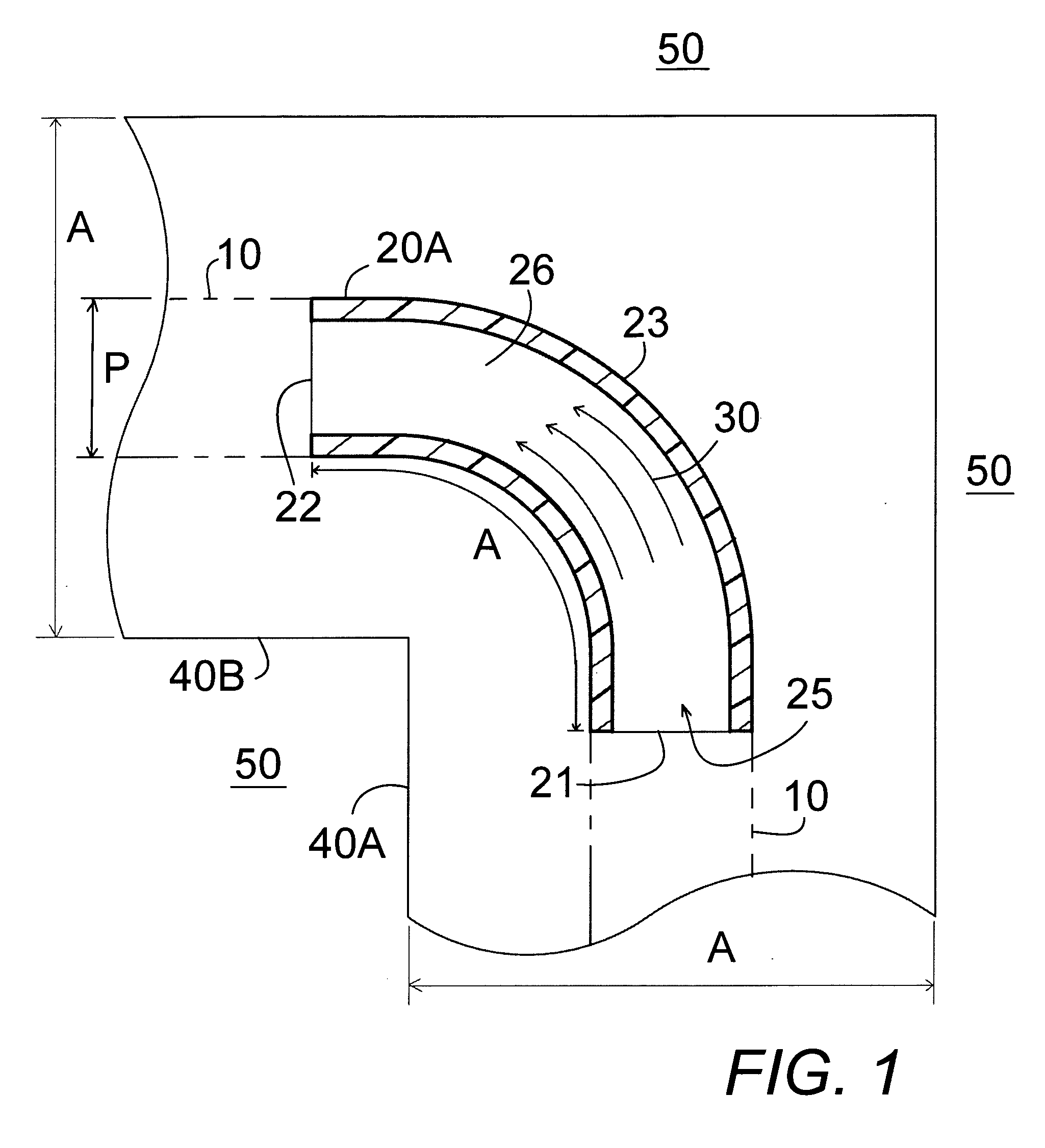

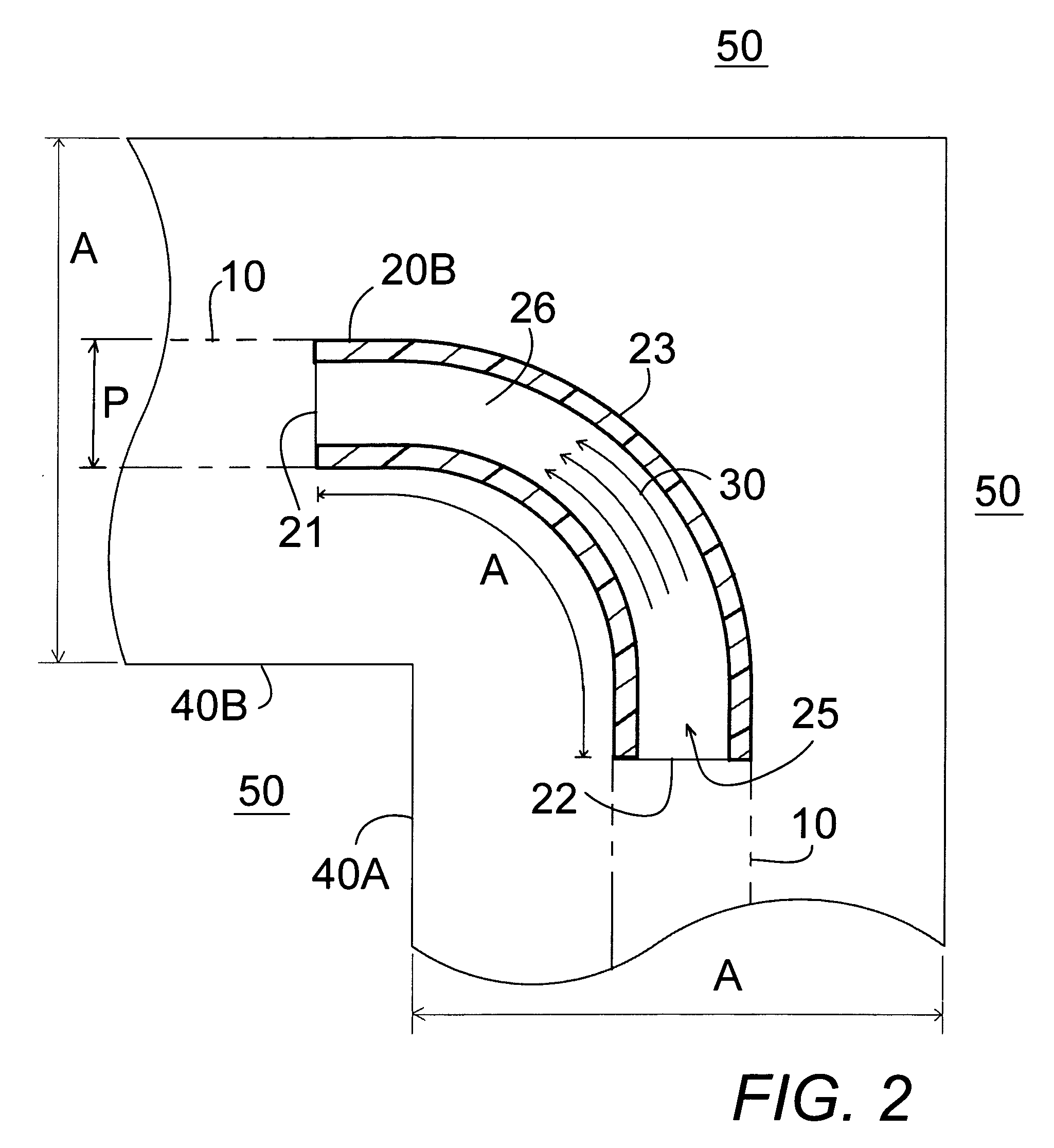

Smooth flow pipe connector for lawn sprinkler system

InactiveUS20050035592A1Increase pressureEasy to movePipeline expansion-compensationBranching pipesSprinkler systemFlow curve

Owner:WILLIAMS LARRY FRLIN

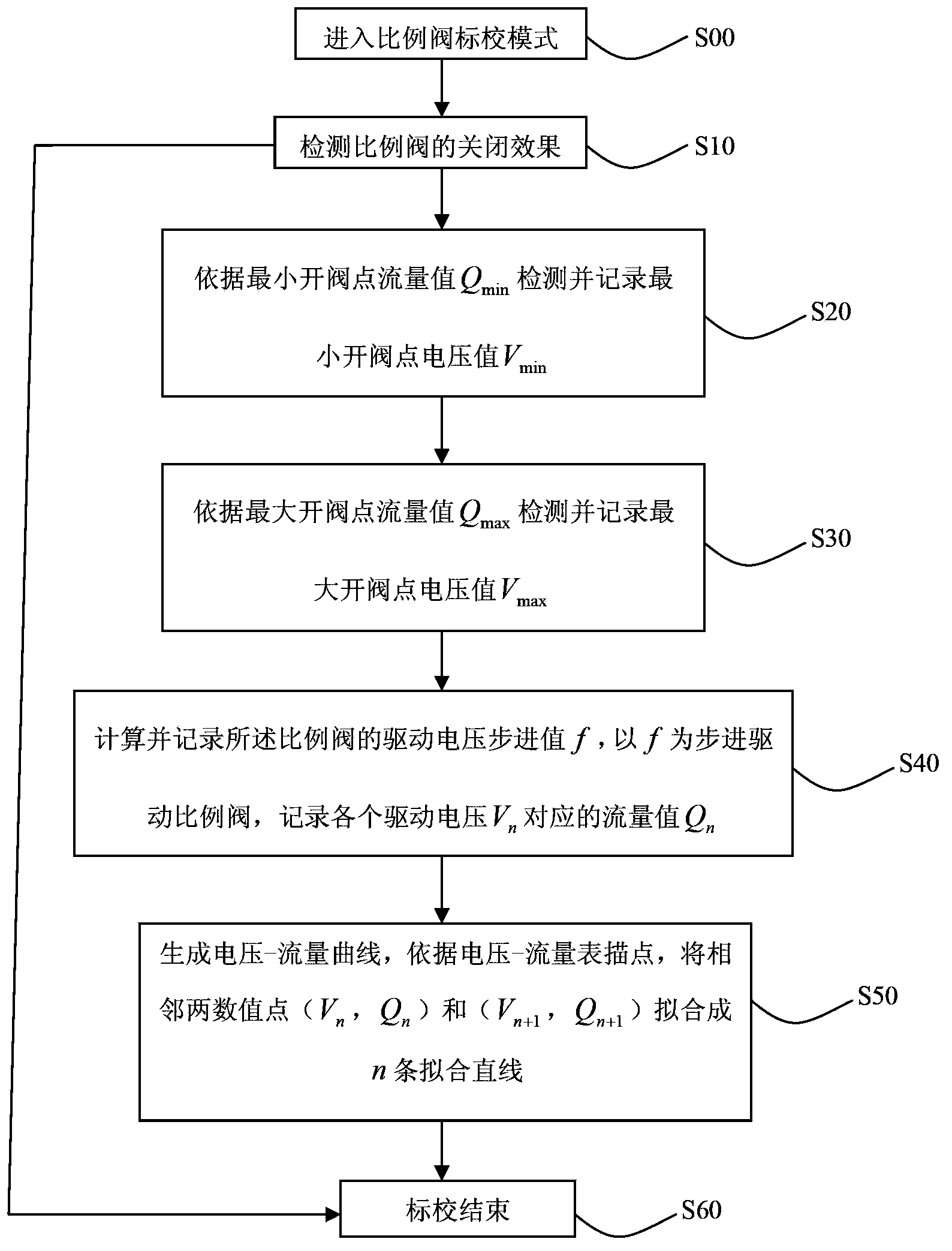

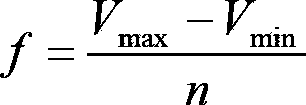

Method for calibrating nonlinear proportional valve of respirator

ActiveCN103893891ASimplify the tedious calculation processImprove accuracyRespiratorsMachine part testingRespiratorFlow curve

The invention discloses a method for calibrating a nonlinear proportional valve of a respirator. The method is achieved through a calibration unit on the respirator, after a proportional valve calibration mode is entered in, the closing effect of the proportional valve is detected first, if the proportional valve passes the detection, calibration is continued, then the calibration unit detects and records the minimum valve opening point voltage value Vmin and the maximum valve opening point voltage value Vmax of the proportional valve, a stepping value f is calculated and recorded, then the calibration unit drives the proportional valve by using the stepping valve f as steeping output drive voltages Vn, the flow values Qn flowing through the proportional valve under all driving voltages Vn are detected through a flow sensor, at last, the calibration unit generates a voltage-flow table according to detected data, the data in the voltage-flow table are fit to be n fitting straight lines to be stored, and calibration is achieved. According to the method, the voltage-flow curve of the nonlinear proportional valve is locally linearized, the voltage-flow relation of the nonlinear proportional valve can be well matched, the calculation process is simplified, and the accuracy of the calibration process is improved.

Owner:BEIJING AEONMED

Method for determining pump flow without the use of traditional sensors

ActiveCN101033748AAccurately determineAvoid errorsVolume/mass flow measurementEfficient regulation technologiesOperating pointFlow curve

A technique for determining pump flow without using traditional sensors features steps and modules for creating a calibrated power curve at closed valve conditions at several speeds; calculating coefficients from a normalized power curve based on a pump's power ratio; and solving a polynomial power equation for flow at the current operating point. The calibrated power curve may be created by increasing the speed of the pump from a minimum speed to a maximum speed and operating the pump with a closed discharge valve. This data is used to correct published performance for shutoff power and best efficiency point power at rated speed in order to determine the pump's power ratio. It is also used to accurately determine closed valve power at the current operating speed. The pump's power ratio is determined by the equation: Pratio=Pshutoff @100% / PBEP<SUB2>-< / SUB2>corr. The polynomial power equation may, for example, include a 3rd order polynomial equation developed using coefficients from the normalized power versus flow curve, and corrections may be made for speed, hydraulic efficiency and specific gravity in the polynomial power equation.

Owner:ITT MFG ENTERPRISES LLC

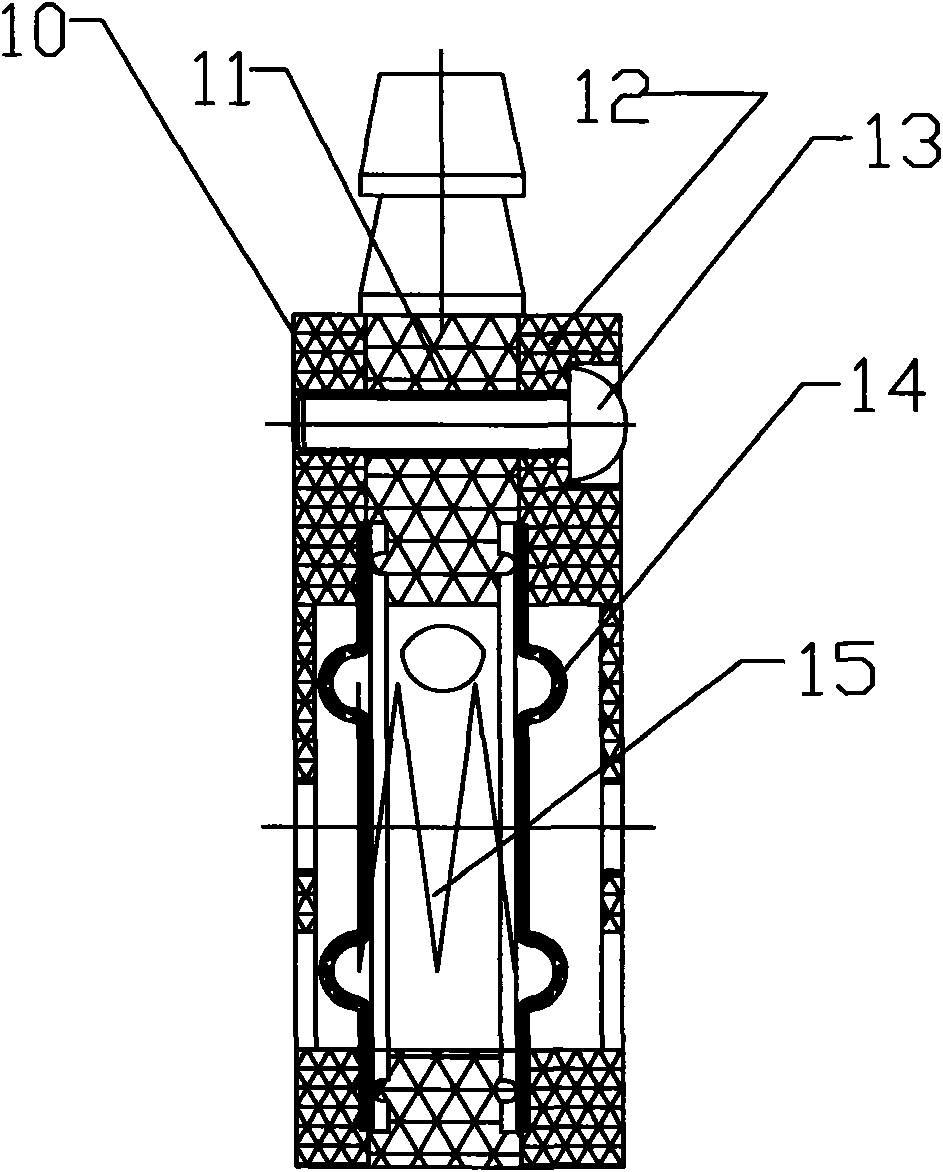

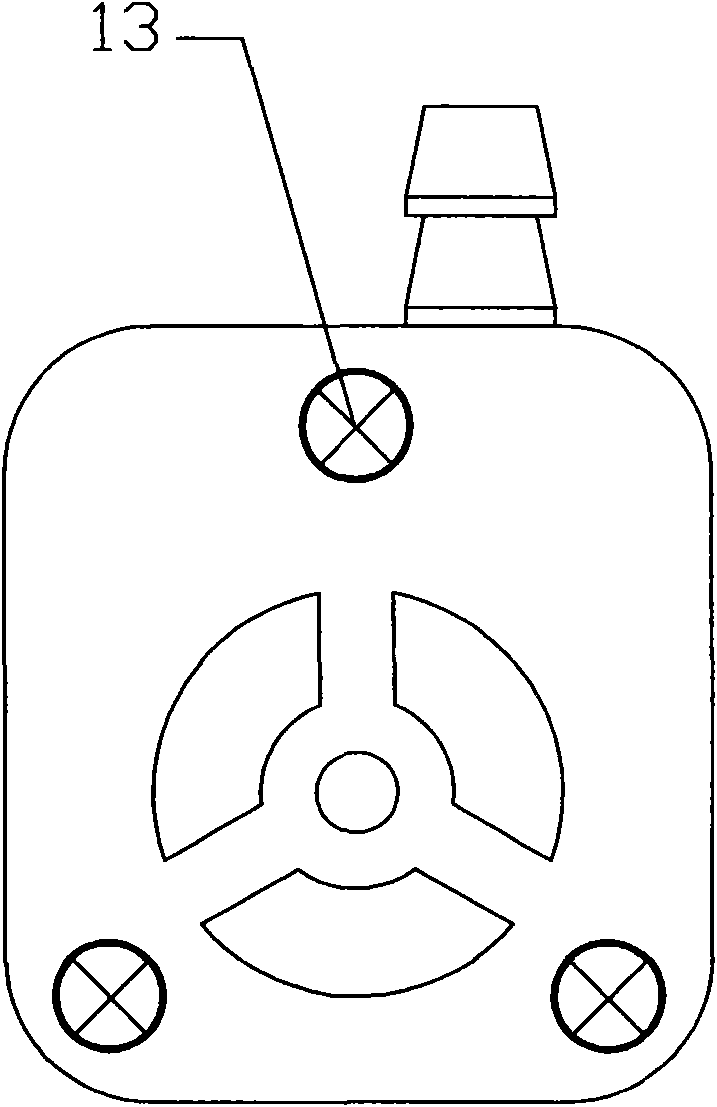

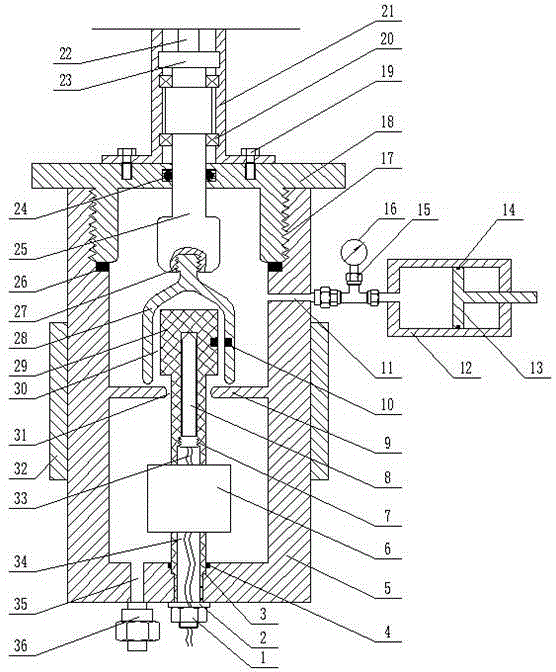

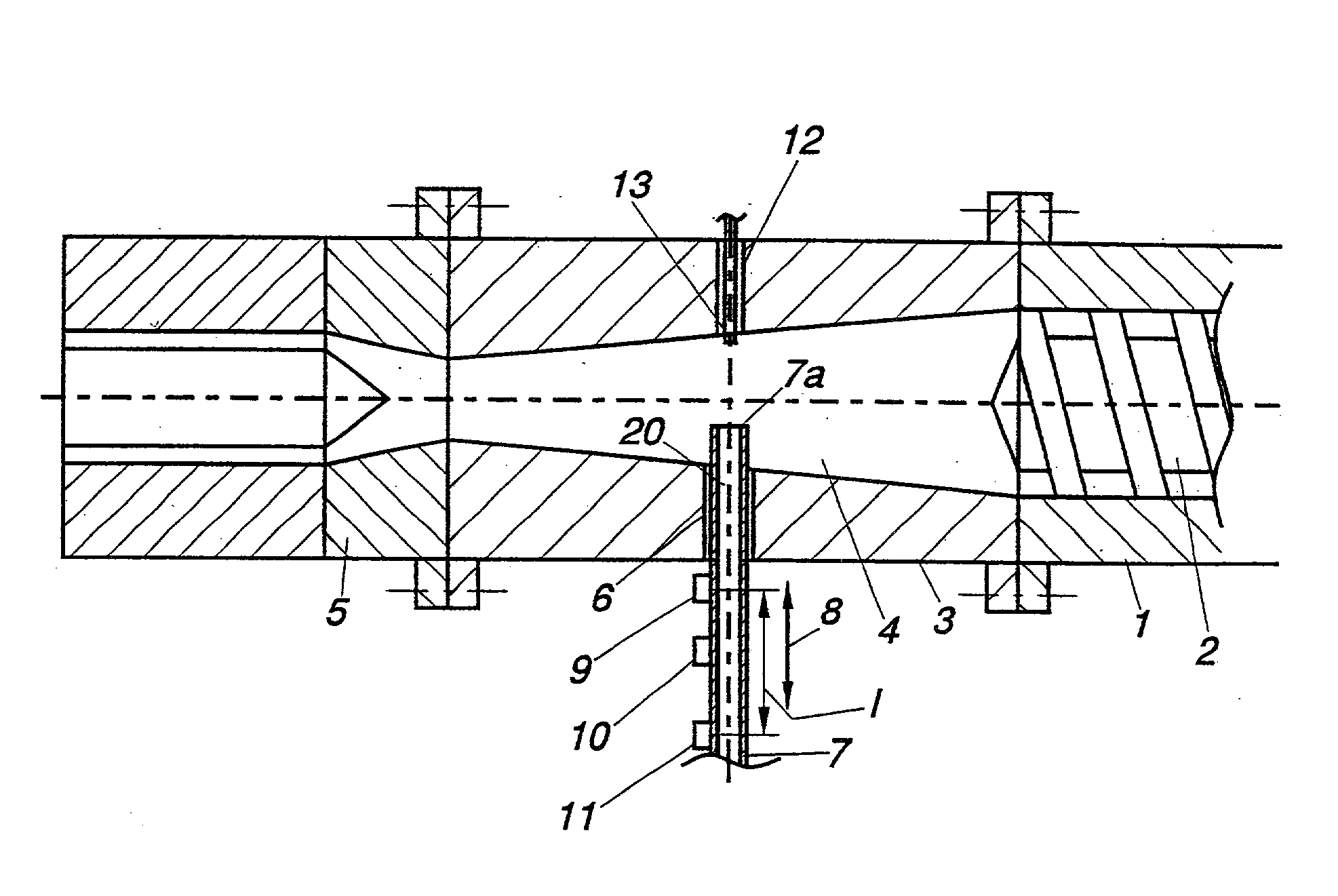

High-temperature high-pressure high-shear rate lubricating oil rheometer

The invention discloses a high-temperature high-pressure high-shear rate lubricating oil rheometer. The high-temperature high-pressure high-shear rate lubricating oil rheometer comprises a lock nut, a cylinder body, a static torque sensor, a temperature sensor, a splitter plate, a micro-gap measurer, a cylinder cover, a motor frame, a coupling, a rotating shaft sealing device, a rotating shaft, a threaded hole, an outer barrel, an inner barrel, a heater, an inner barrel hole, and the like. When the rheometer runs, the outer barrel rotates, and a lubricating oil sample is subjected to a shearing force, and then the shearing force of the lubricating oil sample acts on the inner barrel according to the principle of force balance; the micro-gap measurer is used for real-time measurement of the gap between the outer barrel and the inner barrel; the temperature sensor, the torque sensor, a pressure gage, a motor speed counter, and the like are connected with a computer, and data information is sent to the computer. Flow curves of the lubricating oil sample are drew by using a specific program in the computer, and constitutive equations of the lubricating oil sample is further determined, so that a relatively accurate lubricating oil rheological model is provided for theory and engineering practice.

Owner:SHANDONG UNIV OF TECH

Method and apparatus for pump protection without the use of traditional sensors

The present invention provides protection for centrifugal pumps while differentiating between dangerous operating conditions (e.g. dry running, minimum flow and runout) and / or conditions where transient conditions (e.g. closed valve operation) may occur and the protection can be revoked once the condition clears. The methodology utilizes a calculated flow value which can be mathematically determined from a calibrated closed valve power vs speed curve and / or various pump and motor parameters such as speed, torque, power and / or differential pressure or from calibrated flow curves stored in the evaluation device. The calculated flow value is then compared to threshold values of flow associated with these adverse operating conditions.

Owner:ITT MFG ENTERPRISES LLC

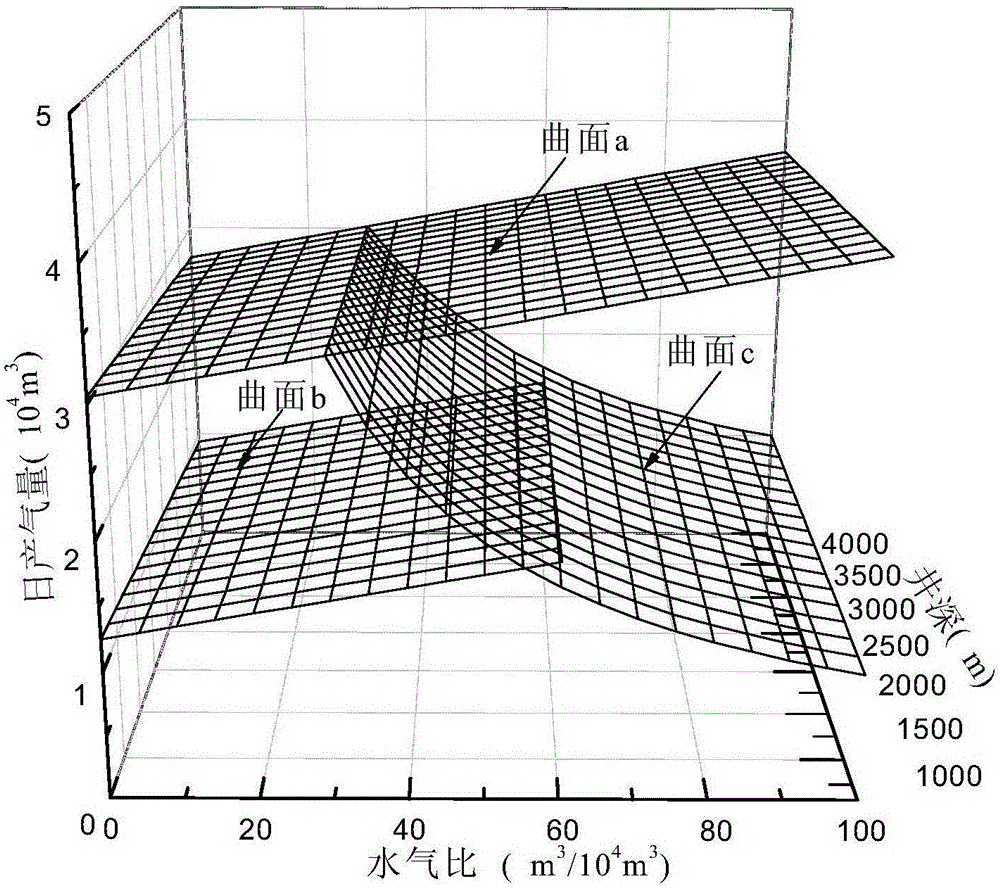

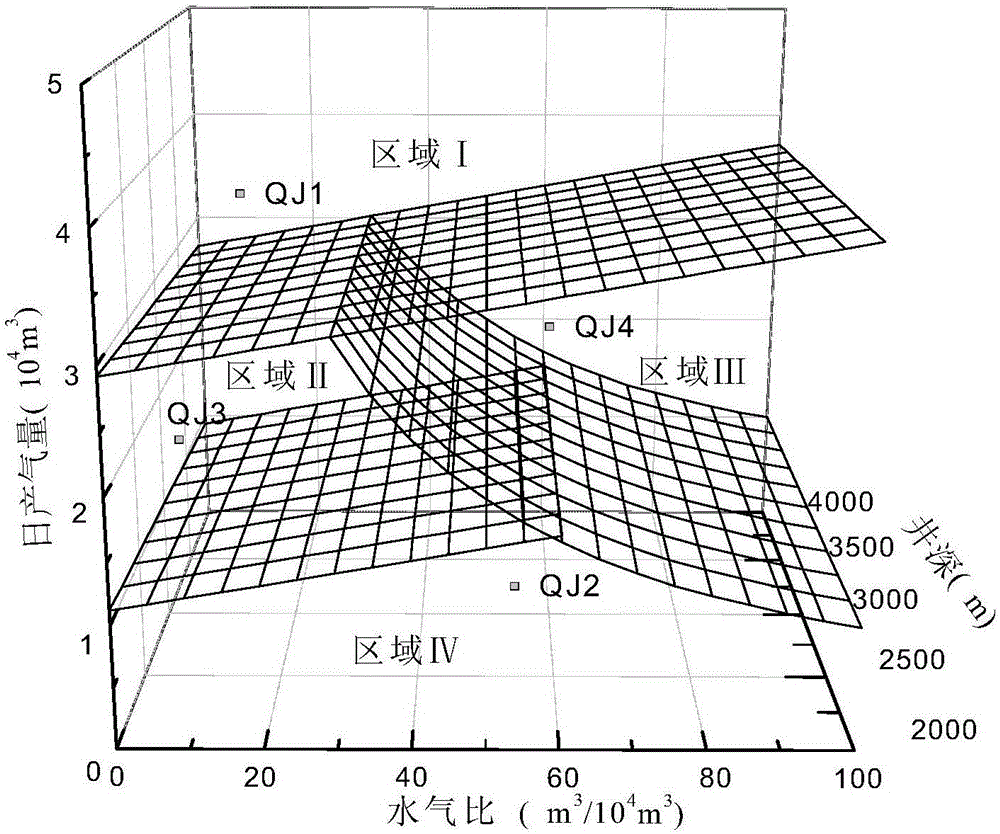

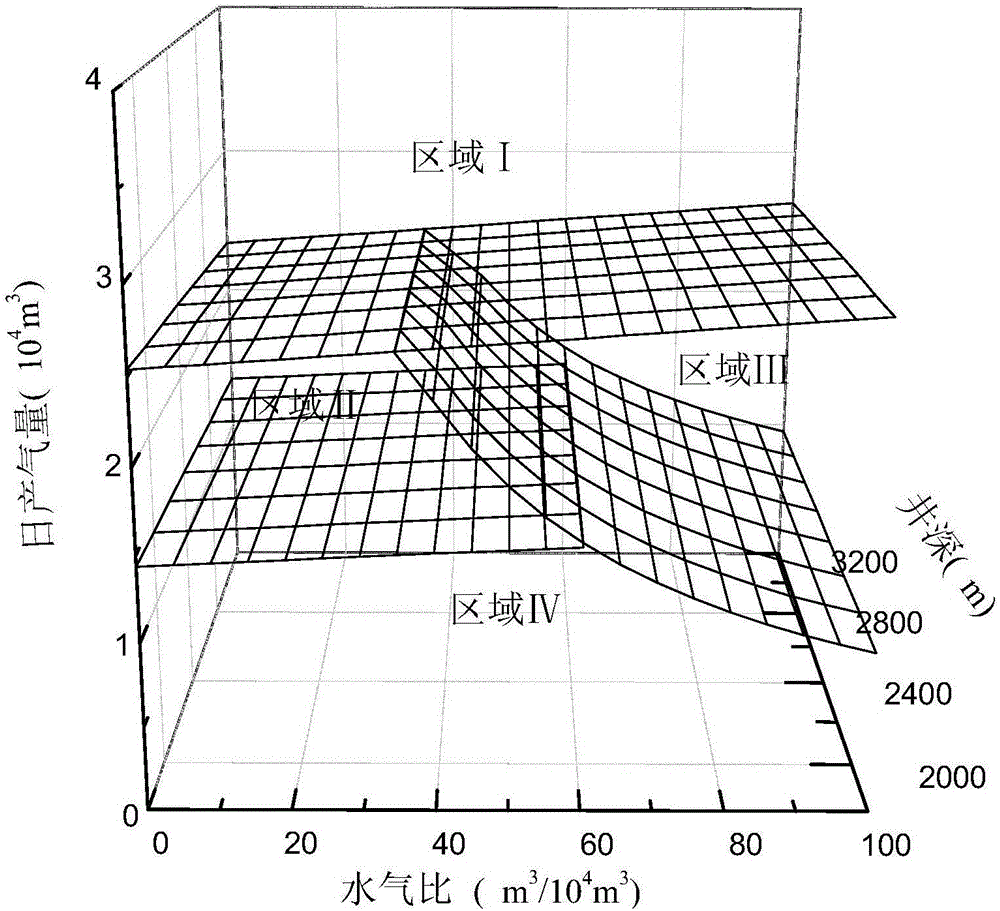

Building method and application of three parameter-gas well drainage gas recovery technology optimizing model

ActiveCN106570273ADrainage gas recovery process is simpleDrainage gas recovery process is fastSpecial data processing applicationsDepth in a wellFlow curve

The invention relates to the technical field of natural gas exploitation and in particular relates to a building method and an application of a three parameter-gas well drainage gas recovery technology optimizing model. A difficulty of rapid selection of drainage gas recovery technology for water-producing gas well is solved. The building method comprises steps of first, collecting production parameters of a water-producing gas well of a gas field, then calculating different daily gas production of a given oil pipe aperture and natural gas critical liquid carrying flow under a water-gas ratio at different well depths, drawing out natural gas critical liquid carrying flow curves (a,b) of maximum and minimum oil pipe apertures on daily gas production, water-gas ratio and well depth three-dimensional model, and drawing out a curve (c) with liquid production amount being 95m<3> on the three-dimensional model. The natural gas critical liquid carrying flow calculated by the method meets on-site production condition in a better way; and the building method is advantaged by quick determination of gas well drainage gas recovery technology based on simple parameters such as daily gas production, water-gas ratio and the well depth.

Owner:PETROCHINA CO LTD +1

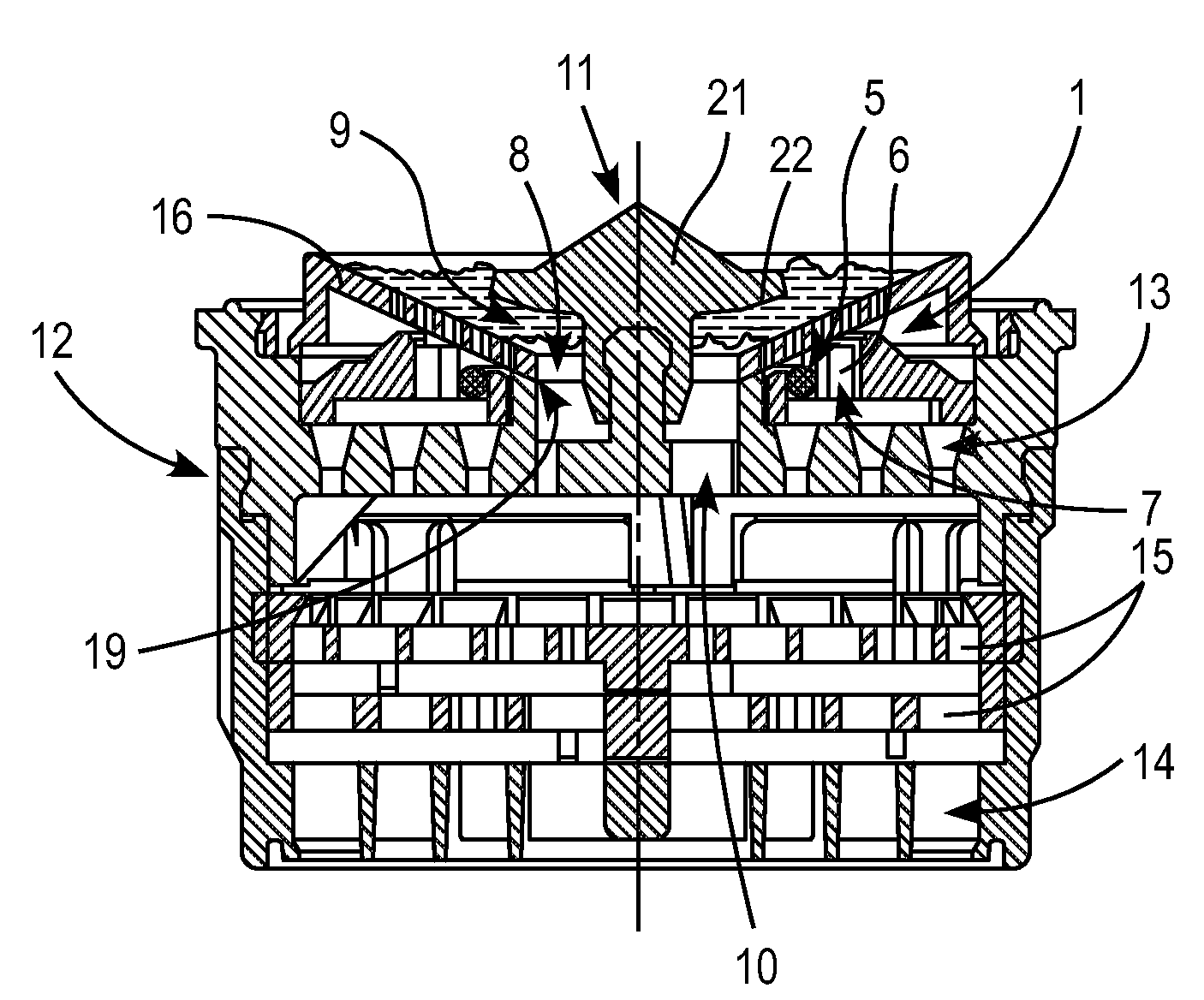

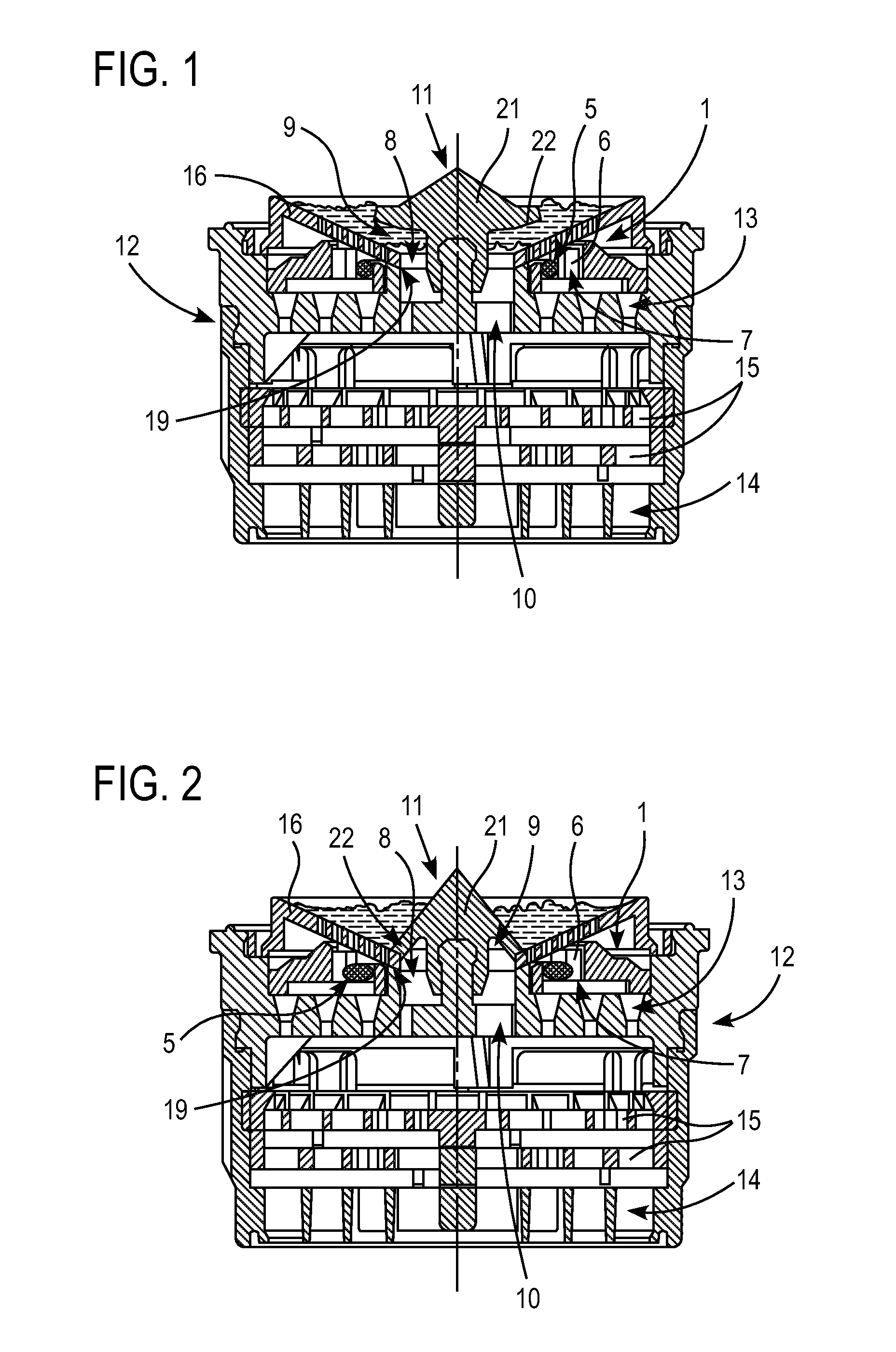

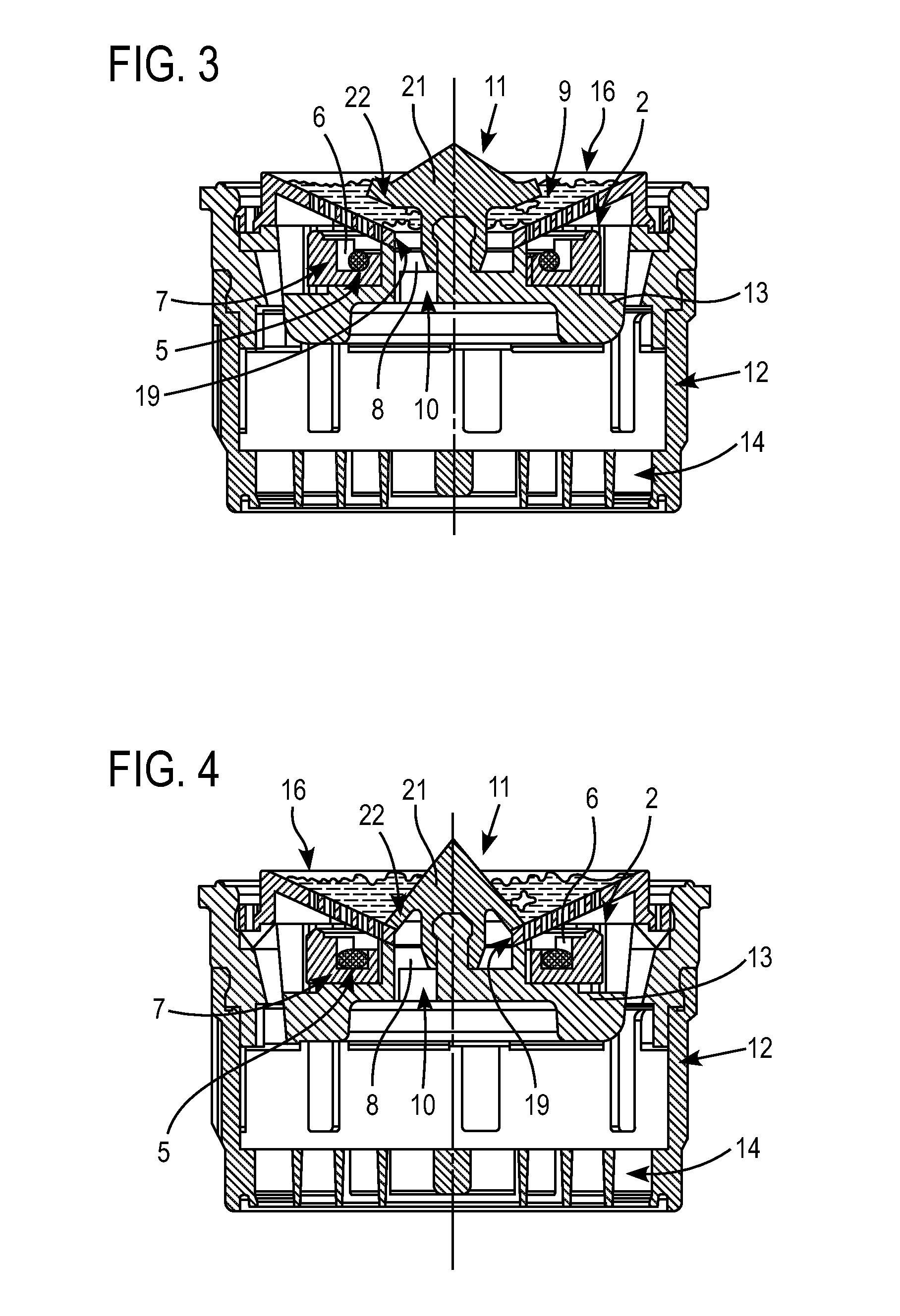

Flow-volume regulator

ActiveUS8402995B2Increased functional reliabilityOperating means/releasing devices for valvesDomestic plumbingFlow curveEngineering

A flow-volume regulator has an elastic throttle body which delimits, between itself and a housing wall, a control gap that changes under the pressure of a fluid flow, and at least one associated bypass and / or cleaning channel that has at least one channel inlet arranged upstream of the control gap and at least one channel outlet arranged downstream of the control gap. The bypass and / or cleaning channel contains a valve which can move against a restoring force under the pressure of the oncoming fluid, from an open position into a closed position, and seals the bypass and / or cleaning channel in its closed position. The flow-volume regulator allows an additional volume of the fluid through the bypass channel when the oncoming fluid is at low pressure, so that its flow curve is significantly increased in the low pressure range.

Owner:NEOPERL

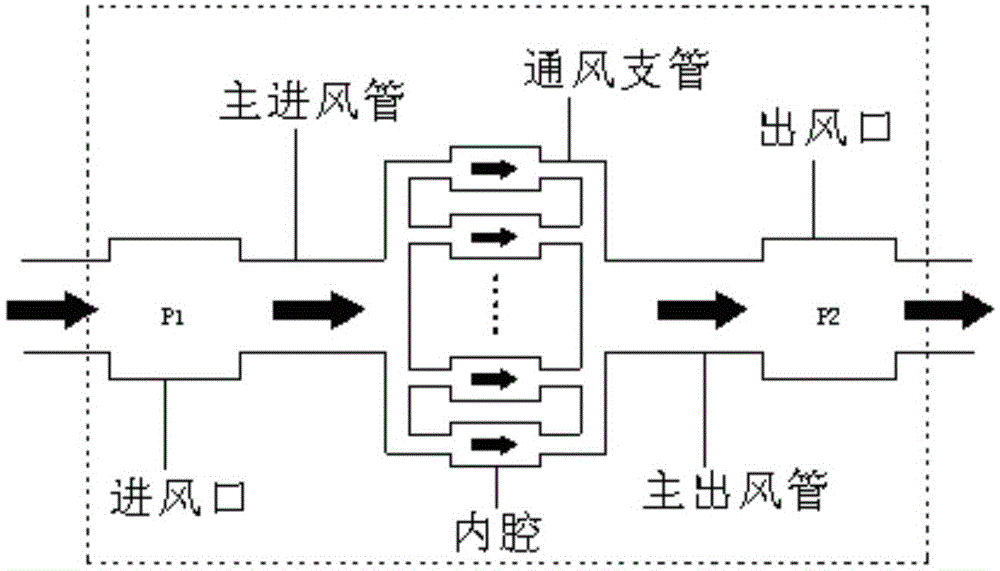

Independent ventilation cage flow measurement method, cage box external pressure difference measurement method, control system and control method

InactiveCN103548700AAccurate measurementThe method is simple and flexibleAnimal housingVolume/mass flow by differential pressureRegression analysisDifferential pressure

The invention discloses an independent ventilation cage flow measurement method which comprises the following steps of (1) dividing the voltage of an air inlet fan motor into N sampling points and dividing the voltage of an air outlet fan motor into M sampling points; (2) controlling the air inlet fan motor to work on a first sampling point, controlling the air outlet fan motor to work on a 0 sampling point and an M sampling point, collecting pressure difference between an air inlet box and an air outlet box through a pressure difference sensor, and utilizing a standard flow measurement instrument to demarcate flow in an independent ventilation cage of the air outlet fan motor on each of the sampling points; (3) repeating the step (1) and the step (2) when the air inlet fan motor works on other sampling points; (4) performing regression analysis on M+1 groups of pressure difference-flow data to obtain N pressure difference-flow curves meeting the following formula: deltaP+ K1 (v+ K2) 2= C, demarcating N groups of weight factors K1 and K2 when the air inlet fan motor works on different sampling points, and storing the N groups of weight factors K1 and K2 into a controller; (5) during actual operation, selecting the nearest voltage sampling point of an air inlet fan according to the voltage of the air inlet fan motor through the controller, and calculating the flow v by means of the weight factors of the nearest voltage sampling point and the measured pressure difference. The invention further discloses a cage box external pressure difference measurement method and a control method based on the independent ventilation cage flow measurement method and the cage box external pressure difference measurement method.

Owner:上海鸣励实验室科技发展有限公司

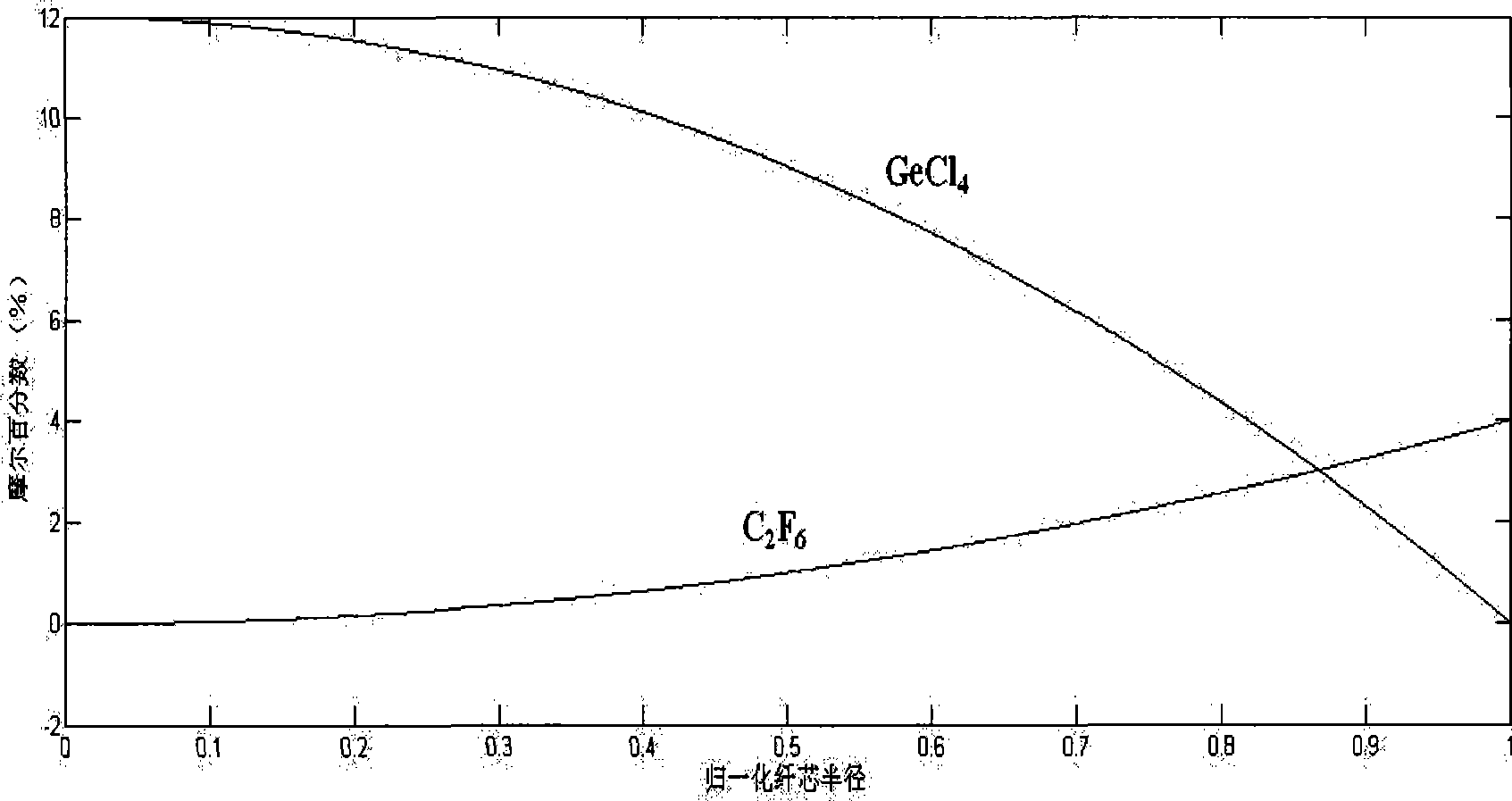

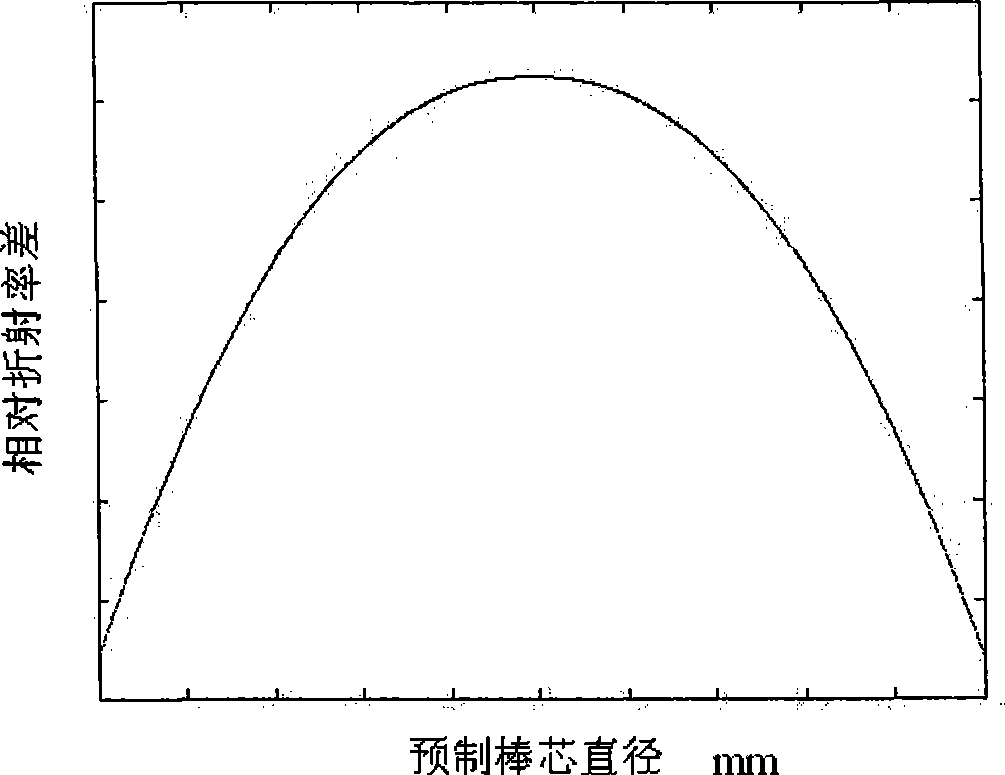

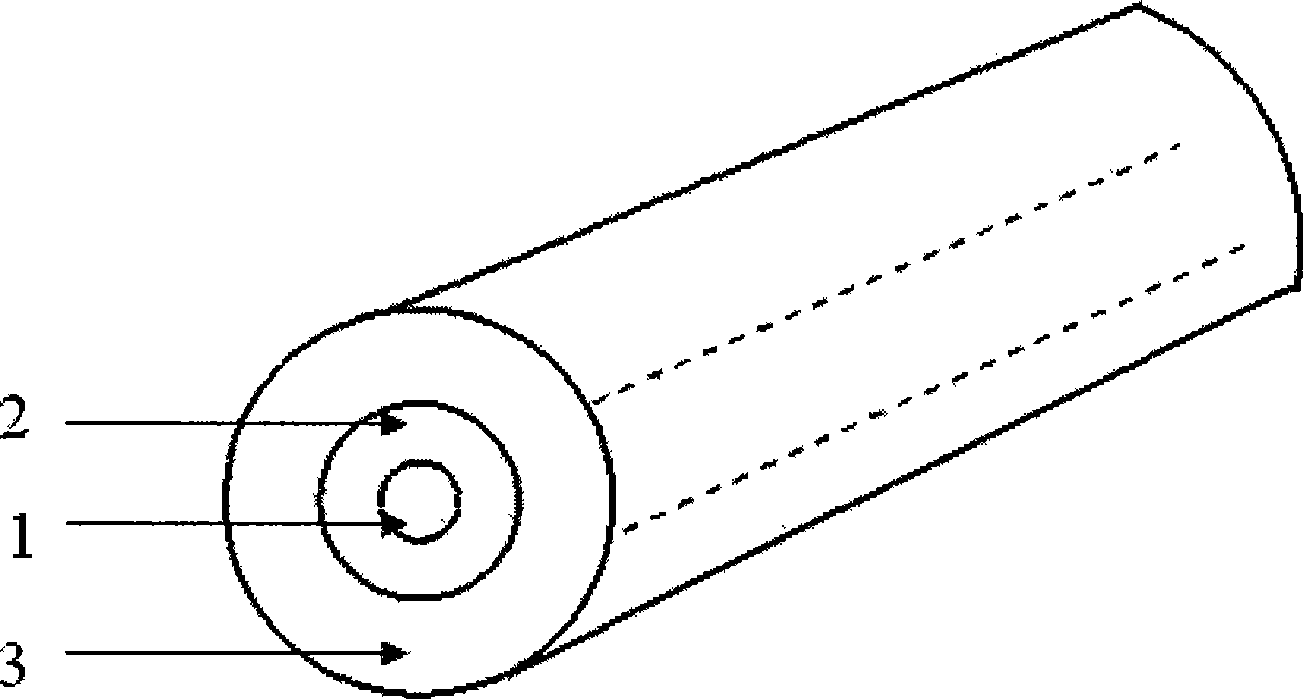

Band-width optimized multi-mould optical fiber and method of manufacturing the same

ActiveCN101458360ALow Differential Mode DelayImprove transmission bandwidthGlass making apparatusOptical fibre with graded refractive index core/claddingFiberLow speed

The invention relates to a bandwidth optimized multimode fiber and a manufacturing method thereof. The multimode fiber comprises three parts, including a fiber core, a quartz glass cladding and a coating with graded index profile. By adopting the method of optimizing the impurity gas flow curve, the refractive index profile parameter of a fiber core is controlled to optimize the optimal bandwidth of the fiber at the communication window of 850nm.The largest change of the differential mode time delay of the fiber is less than 0.22ps / m, the over-filled launch bandwidth is larger than 3,500MHz.km and 500MHz.km respectively at 850nm and 1,300nm and the valid mode bandwidth is larger than 4,700MHz.km and 500MHz.km respectively at 850nm and 1,300nm.The multimode fiber of the invention decreases the chromatic dispersion between modes and the time delay and increases transmission bandwidth, thereby not only meeting the application requirement of a low speed network, but also meeting the application requirement of a gigabit high speed broadband network.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

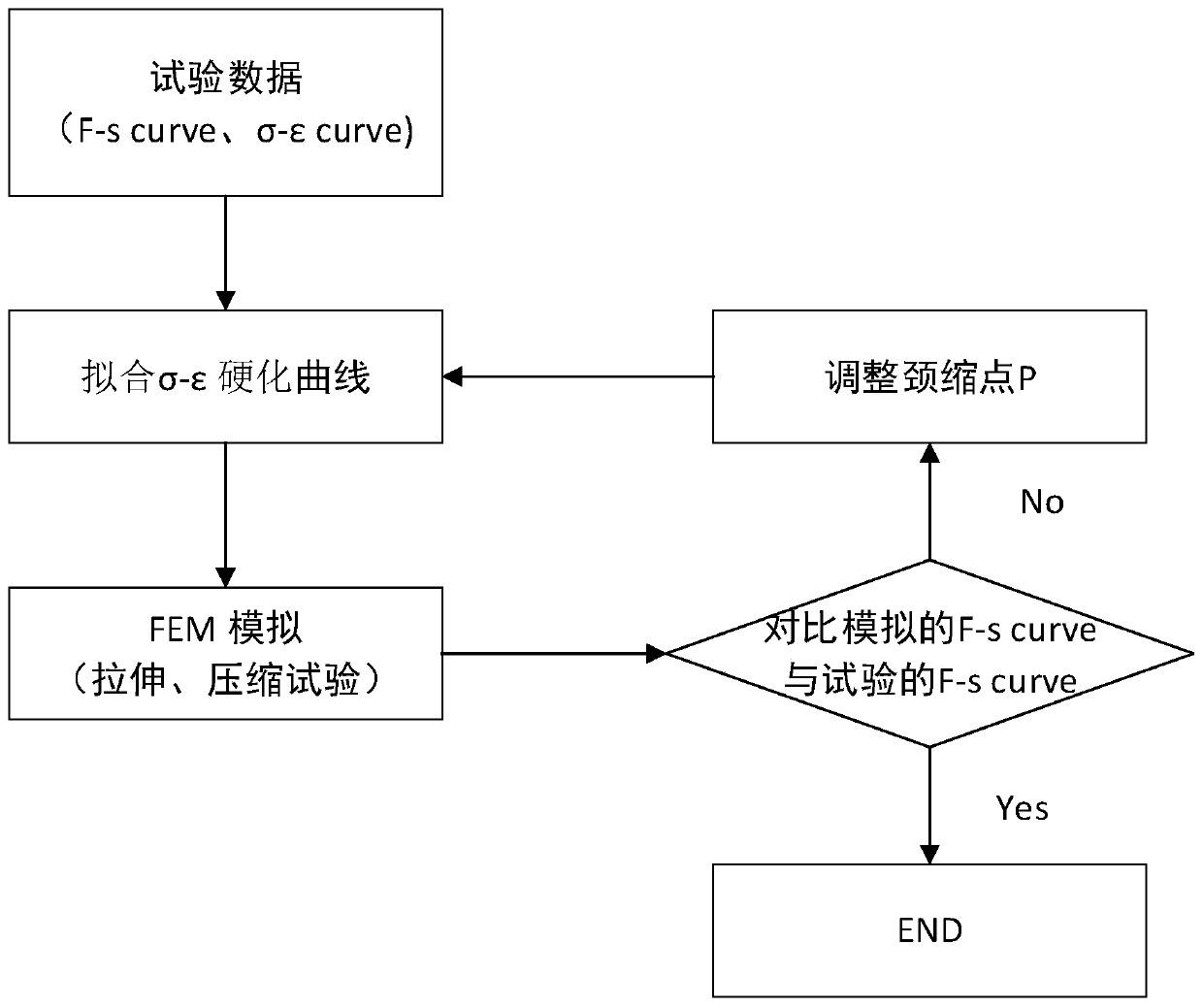

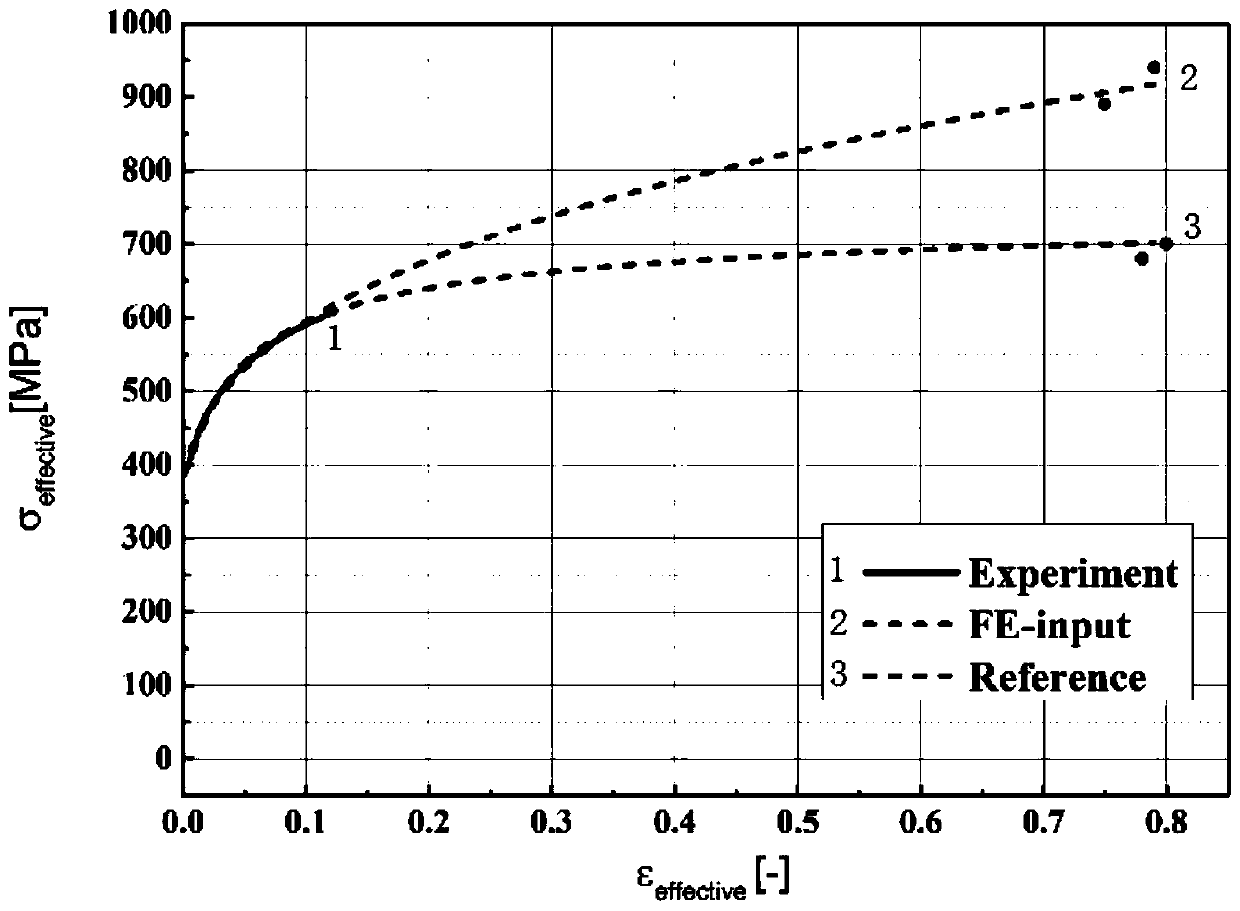

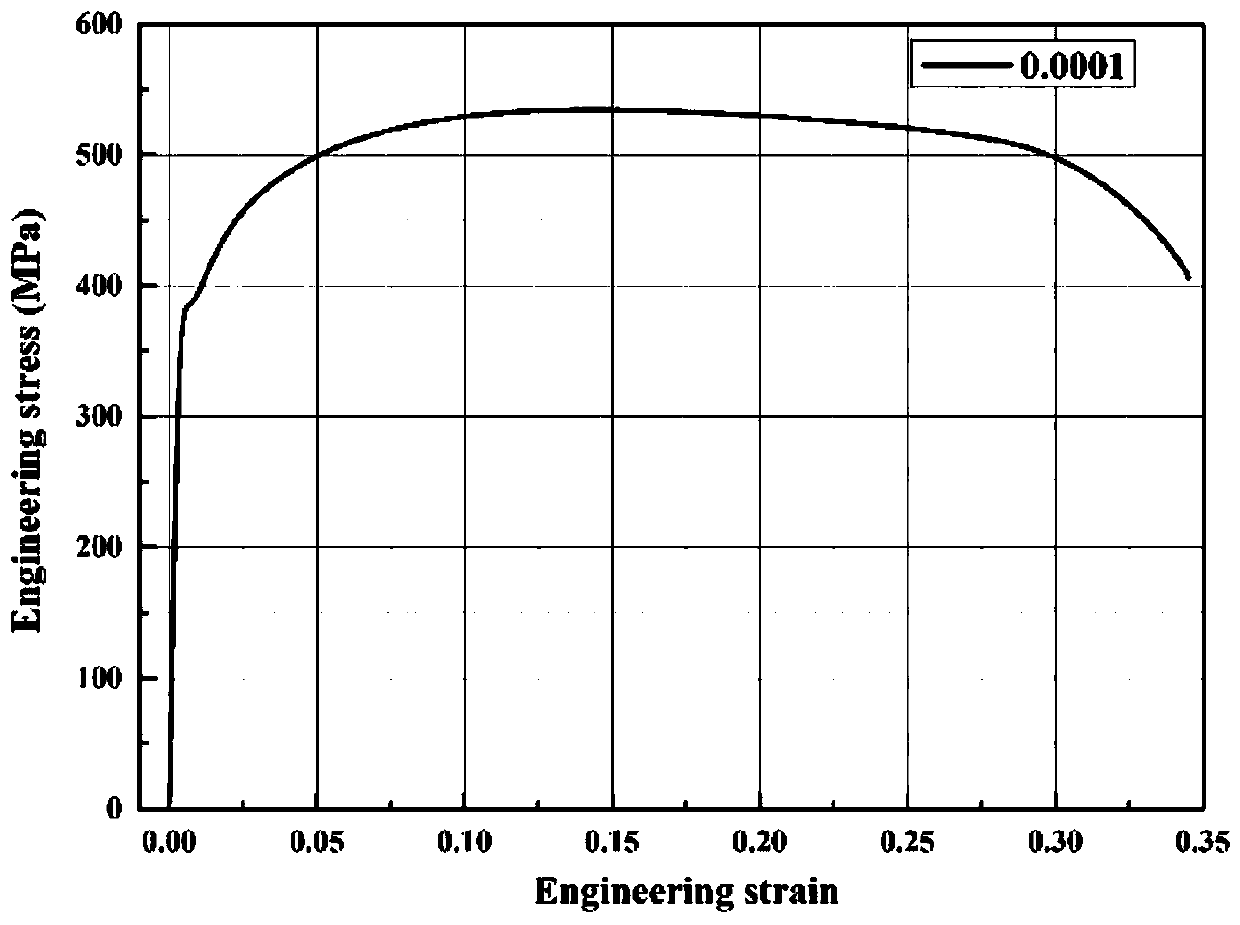

Virtual prediction method for material hardening behavior under large strain condition

PendingCN111339703AAccurate predictionAccurately simulate conditionsDesign optimisation/simulationComputational theoretical chemistryFlow curveEngineering

The invention relates to the field of mechanical property characterization, in particular to a virtual prediction method for a material hardening behavior under a large strain condition. The method comprises the following steps: obtaining force displacement and stress-strain data through a uniaxial tension test, fitting a stress-strain curve obtained through the test, establishing a finite elementmodel, simulating a uniaxial tension test process, comparing force displacement results of the simulation and the test, correcting model parameters according to a comparison result, and determining areasonable hardening model. According to the method, the mechanical behavior of the material in the plastic deformation process under the condition of large strain can be accurately predicted by utilizing a finite element method and a uniaxial tension test result. Due to the fact that the maximum strain often exceeds 0.5 in the body forming process, test data of the large strain cannot be obtained generally in the uniaxial tension test. By optimizing the parameters of the material hardening model, the flow curve of the material after epitaxy can be obtained, and the metal flow of the materialin the forging, extruding and rolling processes can also be predicted.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

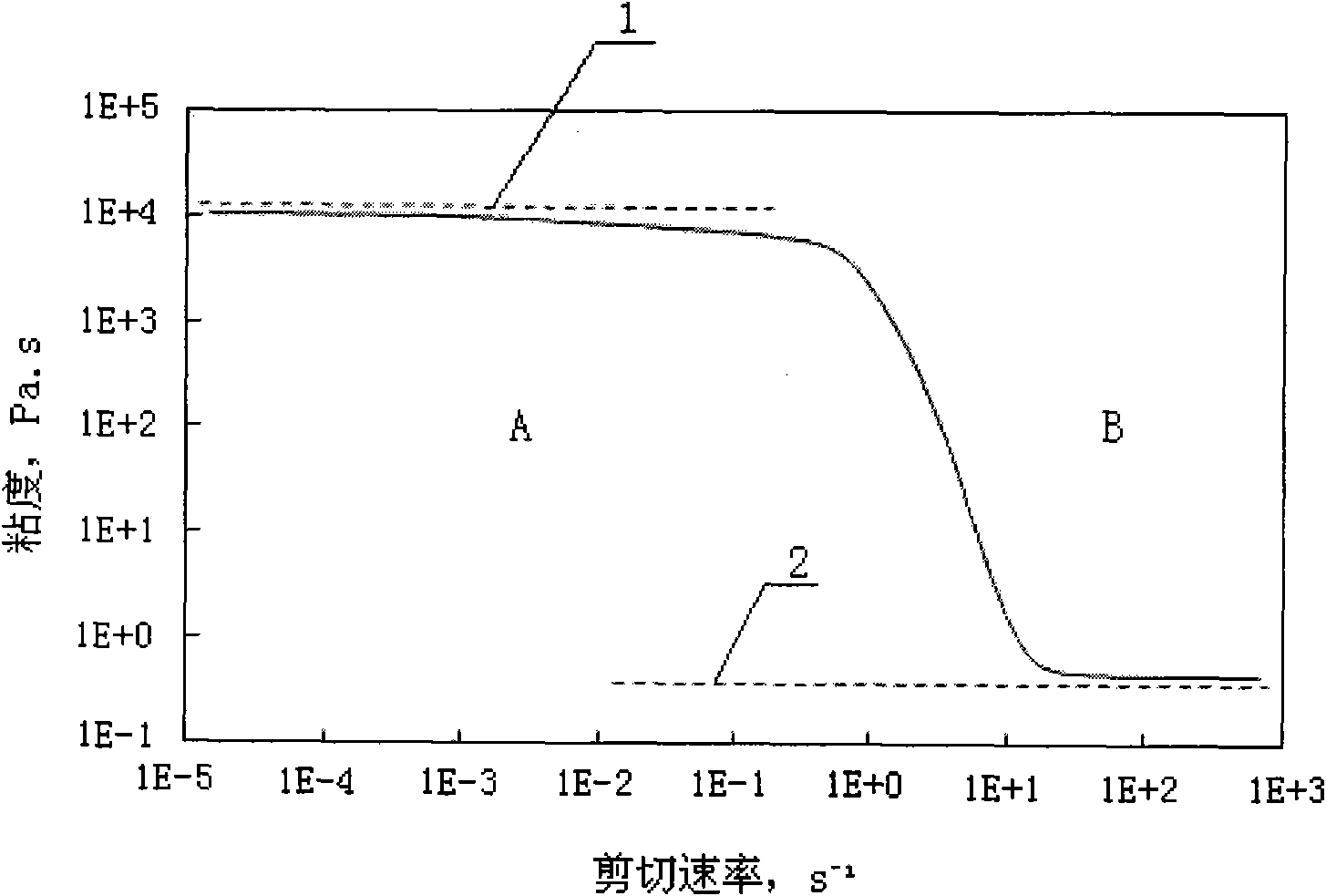

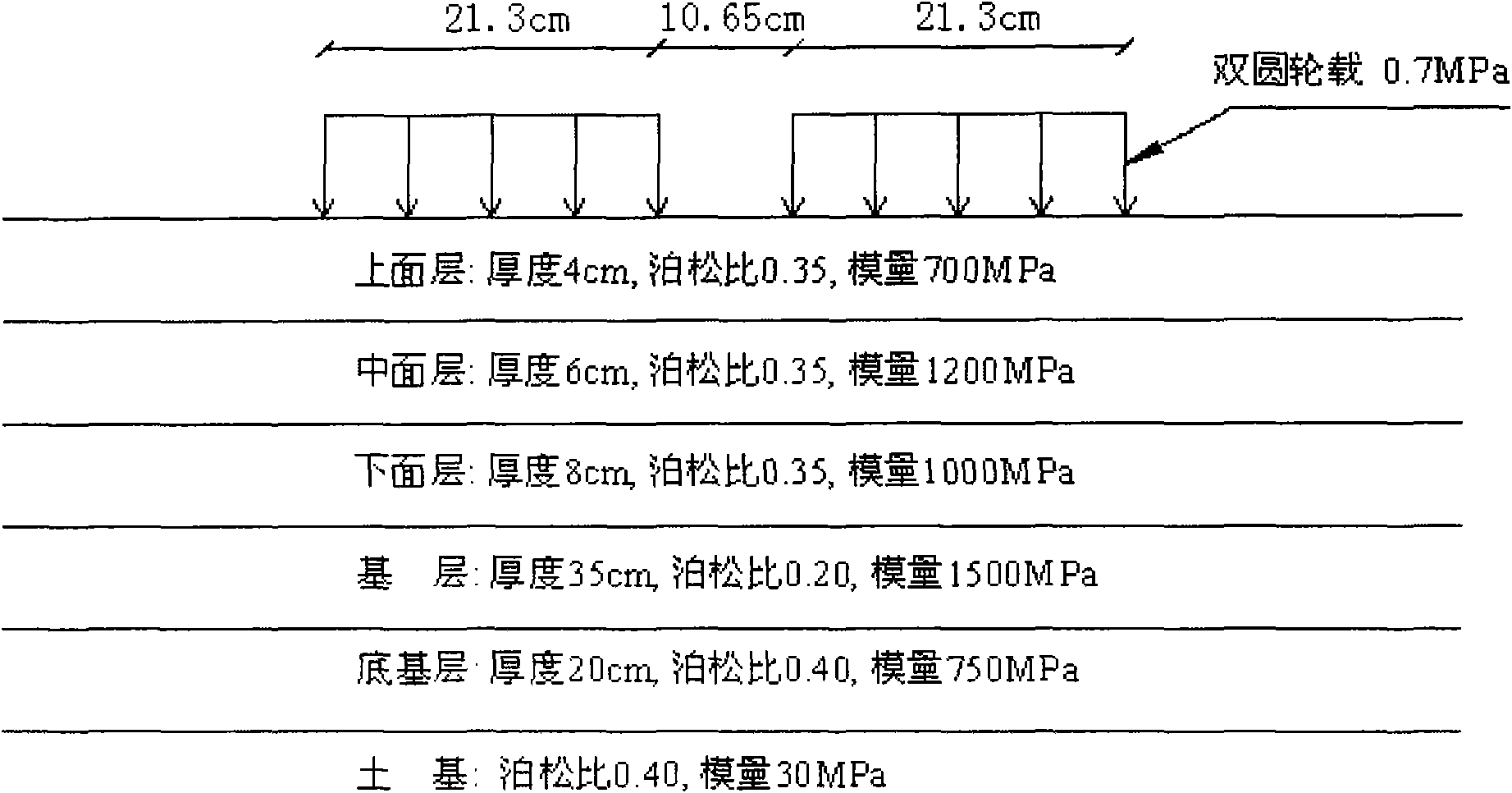

Loxiong viscosity behavior measuring method of high-viscosity modified asphalt and application thereof

The invention relates to a loxiong viscosity behavior measuring method of a high-viscosity modified asphalt and an application thereof, which comprises the following steps: A. using the shearing rate scan test to obtain the viscosity-shearing rate flow curve of the high-viscosity modified asphalt at 60 DEG C; and B. fitting the curve obtained in the step A to obtain the 60 DEG C zero shear viscosity. The 60 DEG C zero shear viscosity obtained by using the method can be used for evaluating the viscosity behavior of the high-viscosity modified asphalt in a pavement structure. The invention is based on following references: the high-viscosity modified asphalt presents the characteristic of pseudo-plastic fluid at the shearing rate of 1.25*10<-5>s<-1>-1250s<-1>, the viscosity tends to be the zero shear viscosity in a first Newtonian region, and the common range in the first Newtonian region is completely matched with the shearing rate range in the pavement structure in the aspect of magnitude order, so the 60 DEG C zero shear viscosity can effectively reflect the viscosity characteristic of the high-viscosity modified asphalt in the pavement structure.

Owner:TONGJI UNIV

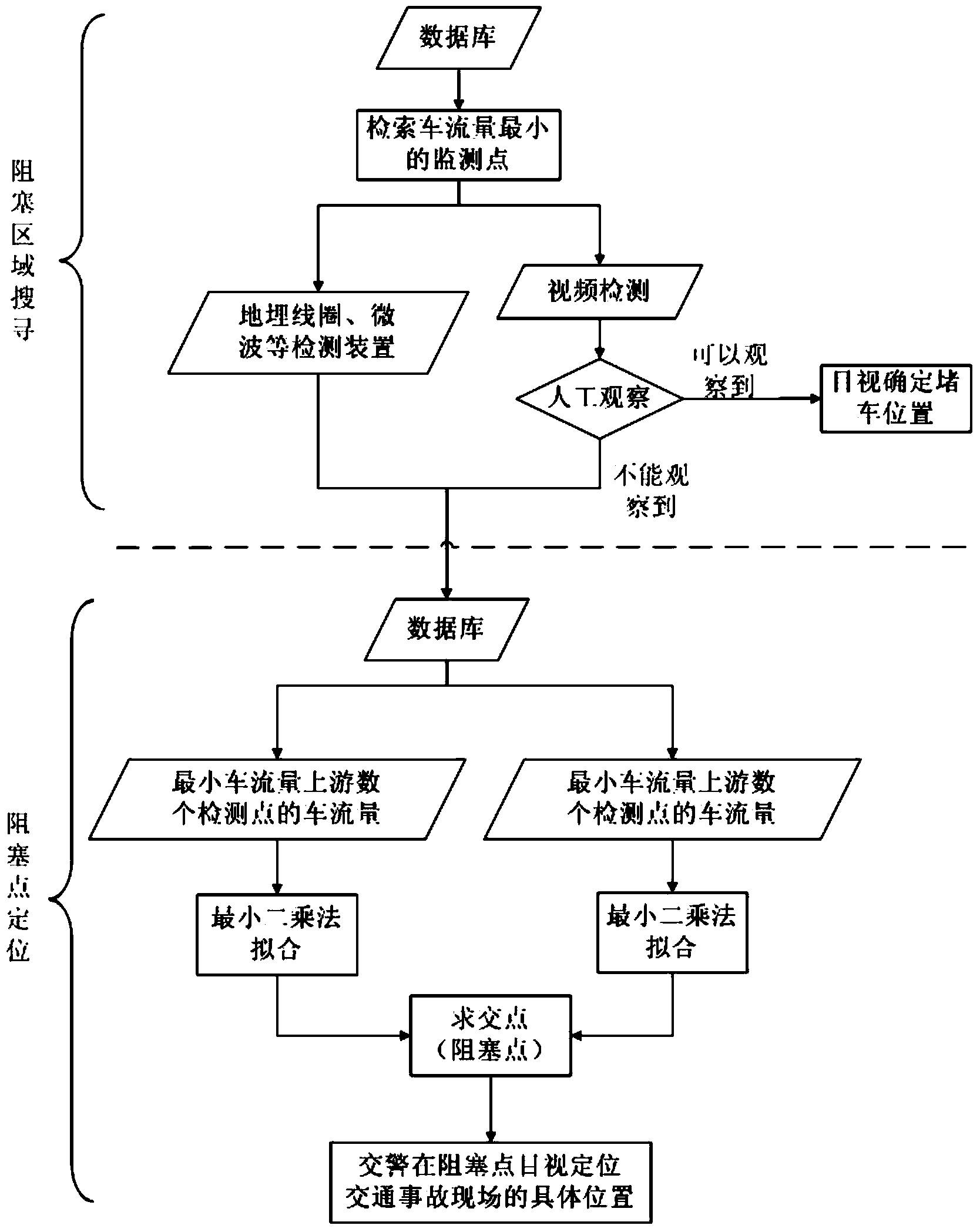

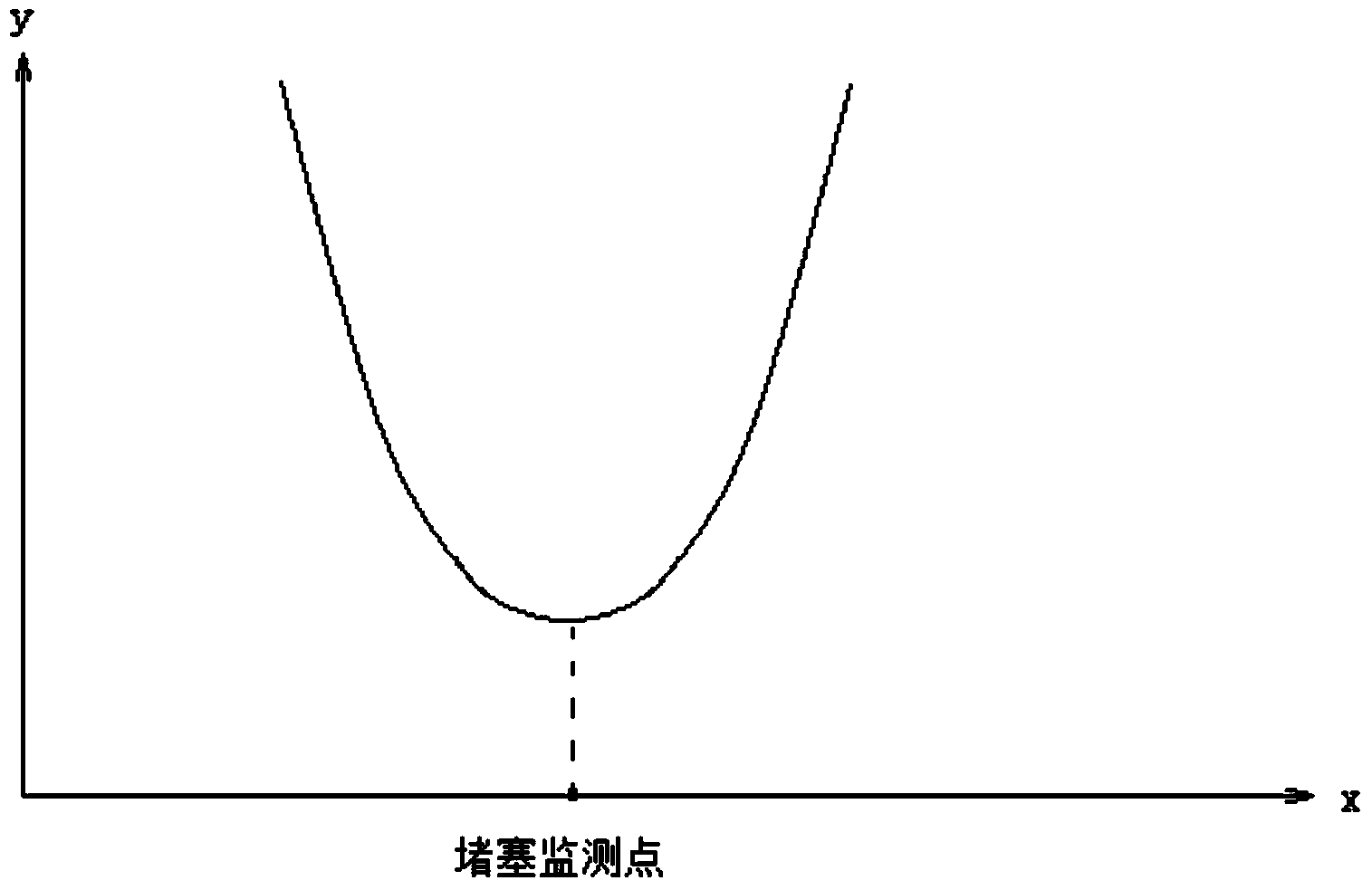

Highway traffic jam locating and searching method

ActiveCN104050808AAvoid the effects of bad weatherAvoid influenceDetection of traffic movementVisual monitoringMonitoring system

The invention discloses a highway traffic jam locating and searching method which is implemented on the basis of monitoring systems arranged on the way. The method includes jam area searching and jam point locating and searching. As for a monitoring system which is visual and can fully monitor road situations between two monitoring points, the jam area searching mode is adopted. As for a monitoring system which is visual but can not fully monitor the road situations between the two monitoring points and a non-visual monitoring system, the jam point locating and searching mode is adopted. The jam point locating and searching mode includes the steps that traffic flow data of multiple monitoring points of the upstream of the minimum traffic flow obtained through the monitoring system are fitted into an upstream flow curve; traffic flow data of multiple monitoring points of the downstream of the minimum traffic flow are fitted to form a downstream flow curve; the intersection of the two curves is obtained to serve as a jam point. By means of the method, specific positions of traffic jams and accidents and particularly blind areas between the monitoring points can be accurately located, and adverse effects of rainy and snowy days can be overcome.

Owner:BEIJING AEROSPACE FUDAO HIGH TECH

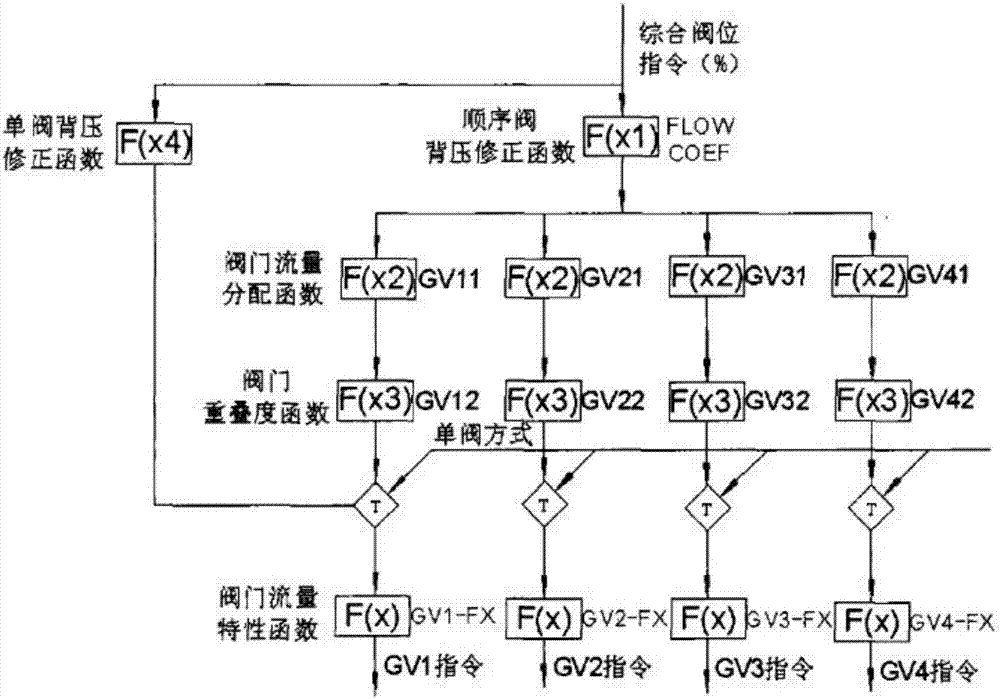

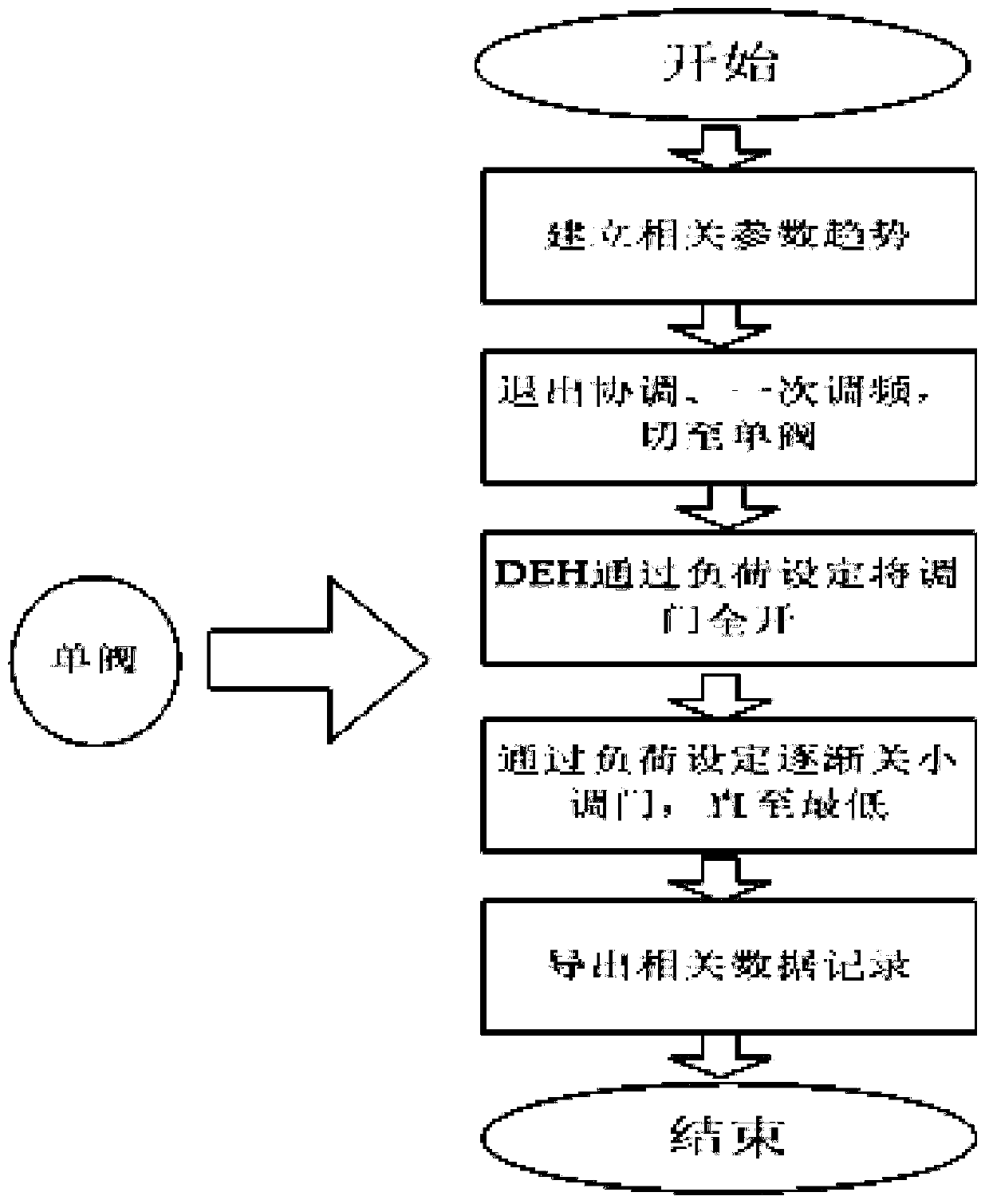

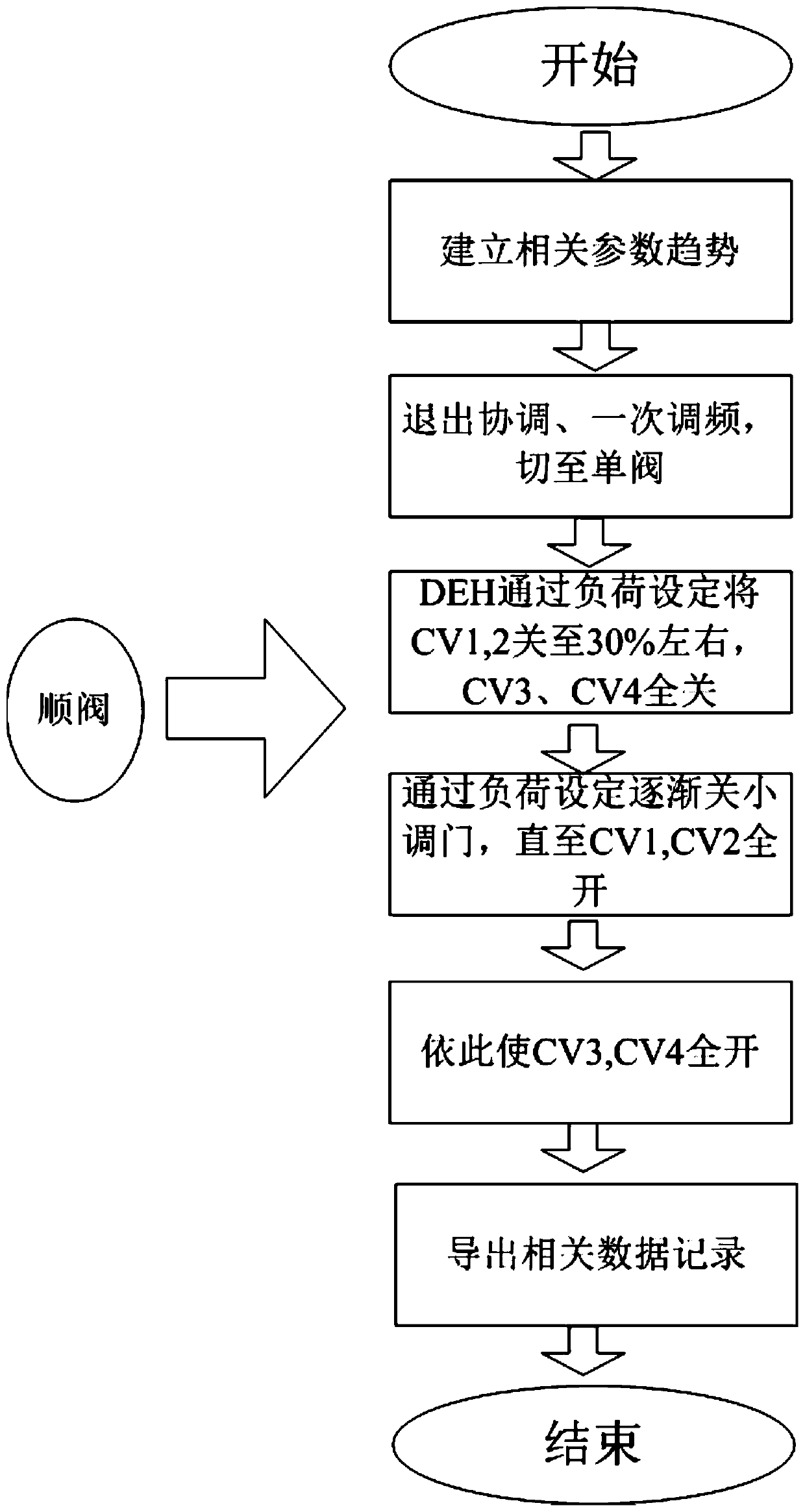

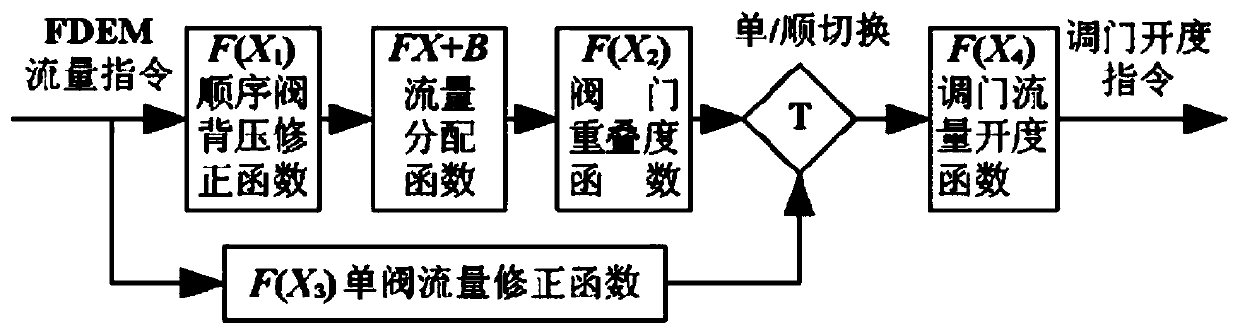

Turbine valve control optimization method based on DEH system

InactiveCN107387173AStable pressureFlow changes smoothlyMachines/enginesEngine componentsTraffic capacitySteam pressure

The invention relates to a turbine valve control optimization method based on a DEH system. The method includes the steps that a turbine unit exits from primary frequency modulation and AGC, and the turbine unit can be switched to be in a valve control mode for detection; relevant flow calculation data obtained when valves of the turbine unit operate in a single-valve mode and relevant flow calculation data obtained when the valves of the turbine unit operate in a sequence valve mode are acquired on the premise that the main steam pressure of the turbine unit is within a preset range; actual flow data of the valves at different opening degrees are calculated according to the obtained relevant flow calculation data, test data are fitted with a least square method and a neural network algorithm through combination of the valve opening degrees corresponding to the actual flow, the fitting effect is verified after fitting with the test data, and an actual valve opening degree-flow curve is obtained after verification is successful; and the DEH system obtains the valve opening degree-flow curve, and the opening degrees of all the valves are controlled based on the valve opening degree-flow curve.

Owner:DATANG DONGBEI ELECTRIC POWER TESTING & RES INST

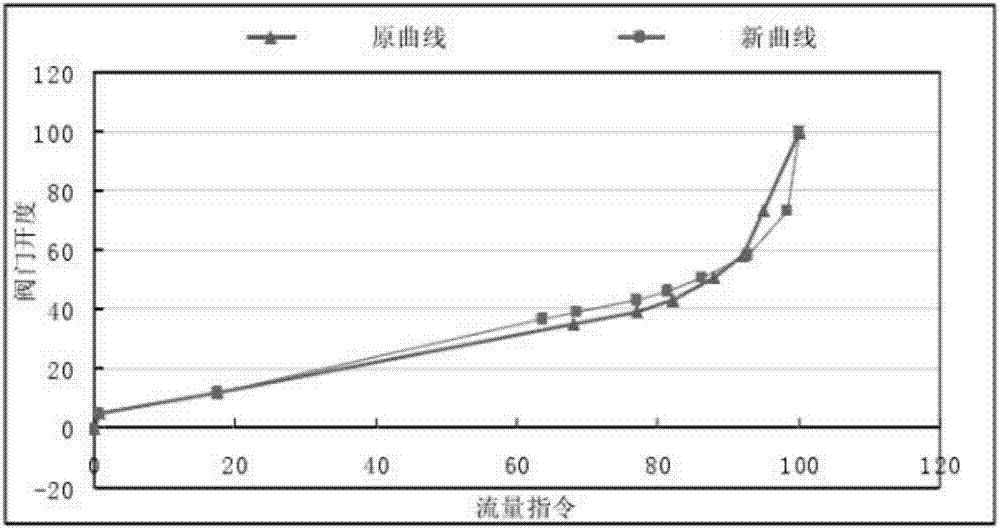

Method for setting valve flow characteristic curve of steam turbine

InactiveCN110346121AVerify reliabilityImprove accuracyMachine valve testingData validationFlow curve

The invention discloses a method for setting a valve flow characteristic curve of a steam turbine and belongs to the technical field of steam turbines. An overlap function is calculated by using datain single valve operation of a unit to obtain a new valve flow curve, and the reliability of a new characteristic curve is verified by using the data obtained in sequence valve operation of the unit.According to the method, valve flow characteristic parameters of the steam turbine can be completely and specifically set, so that switching between single valve and sequence valves is smooth, steam flow change is gentle during switching, load fluctuation is small, segment temperature and vibration do not greatly change and safe and stable operation of the unit is ensured; the response rate of AGCis optimized and the primary frequency modulation effect is improved; the overlap of regulating valves is reduced to improve the economy of the unit; and computation is simplified by using MATLAB programming.

Owner:JILIN ELECTRIC POWER RES INST +1

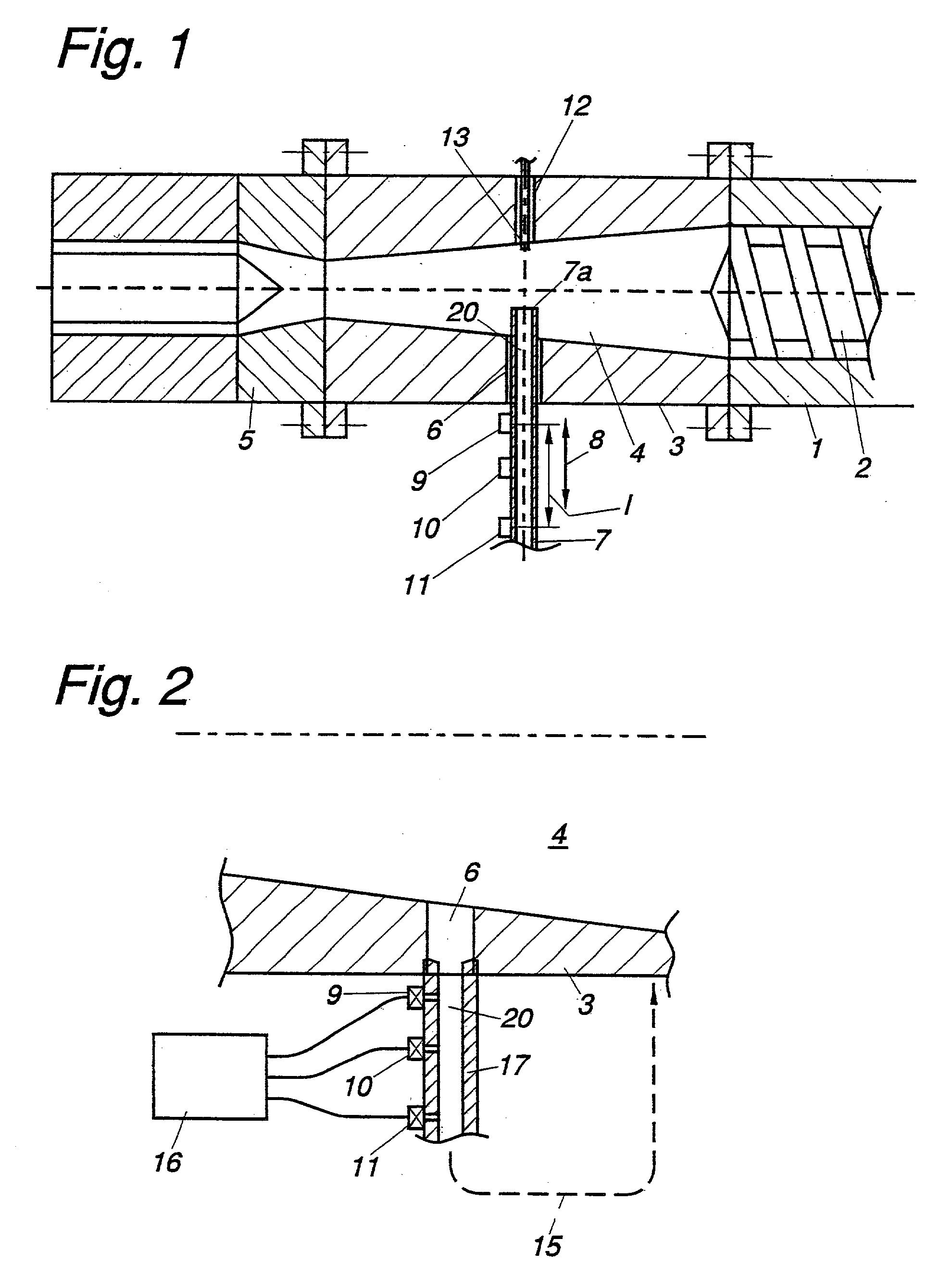

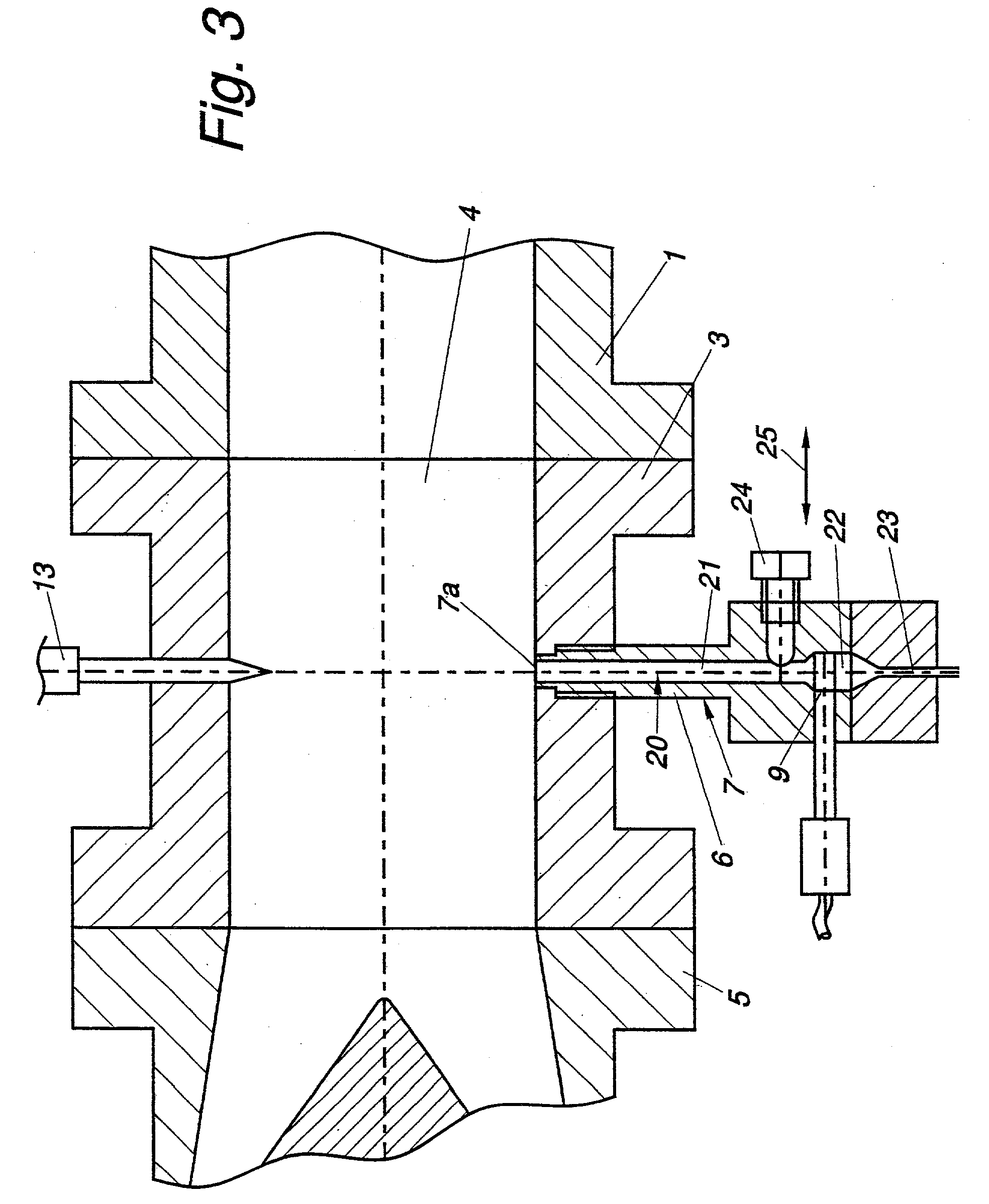

Method and an apparatus for adjusting an extrusion die in an extruder

InactiveUS20020185765A1Minimise measureIntuitive measurement resultsMouldsConfectioneryFlow curveEngineering

The invention relates to a method for adjusting an extrusion die in an extruder by recording at least one master flow curve (40, 41) in a first extruder to which the extrusion die is optimized, in which curve the volume flow is entered over the pressure, which master flow curve (40, 41) is obtained in a measuring channel (20) which branches off in the extruder, the extrusion die or in any interposed adapter part from the flow channel (4), and the repeated recording of flow curves (30, 31) in the same or similar measuring channels (20) as in the first extruder after the assembly of the extrusion tool in the extruder to be checked and adjusted, and the purposeful change of process parameters for such a time until the flow curves (30, 31) correspond to the master flow curves (40, 41) within predetermined tolerance ranges.

Owner:TECHNOPLAST KUNST GES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com