Band-width optimized multi-mould optical fiber and method of manufacturing the same

A manufacturing method and technology for multimode optical fibers, which can be applied to graded-index core/clad optical fibers, clad optical fibers, and manufacturing tools, etc., and can solve the problems of sharpness or depression in the center of the refractive index profile, large aberration, etc., to eliminate the The effect of tipping and sag, improving uniformity, good economic benefits and application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

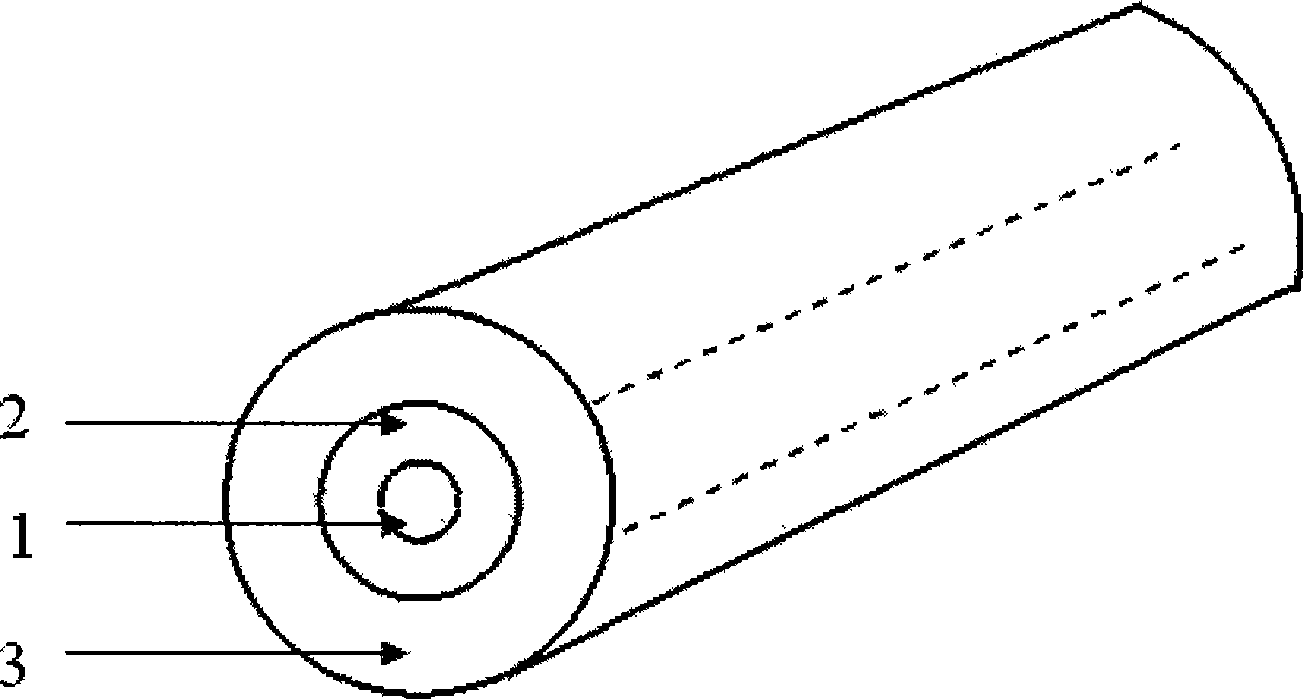

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] The present invention relates to the following terms:

[0031]Deposition: the process in which optical fiber raw materials undergo a chemical reaction in a certain environment to form doped quartz glass;

[0032] Melting: the process of gradually firing the deposited hollow glass tube into a solid glass rod under a certain heat source;

[0033] Sleeve: a high-purity quartz glass tube with a certain cross-sectional area and uniform size;

[0034] Substrate tube: high-purity quartz glass tube for deposition;

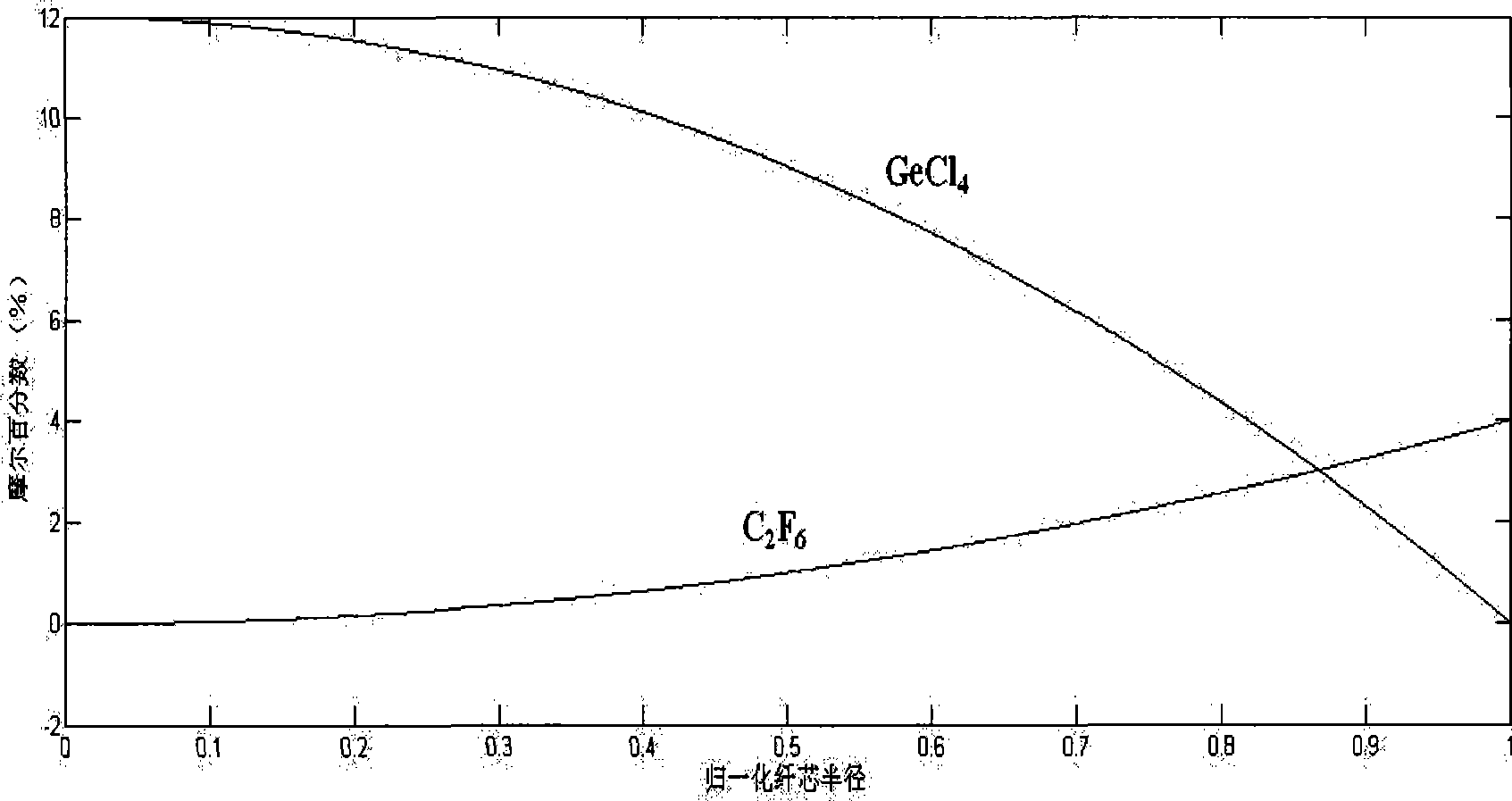

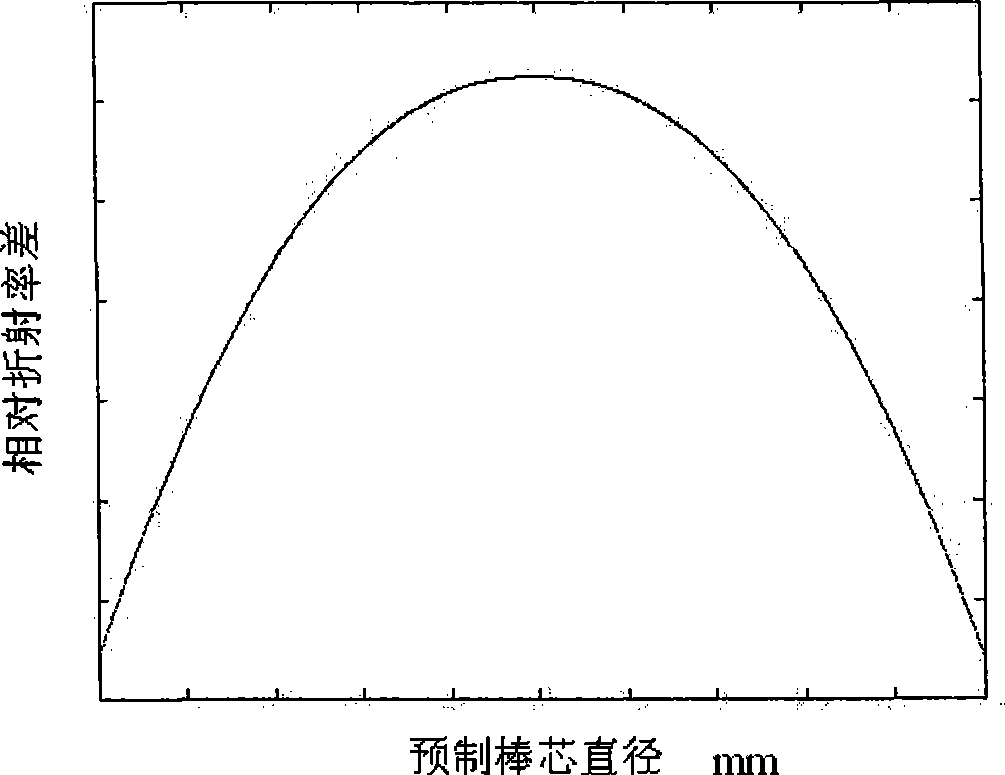

[0035] Refractive Index Profile (RIP): The relationship between the refractive index of an optical fiber or an optical fiber preform (including an optical fiber core rod) and its radius;

[0036] Absolute refractive index difference (δn): the difference between the refractive index of each part in the optical fiber preform and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com