Patents

Literature

45results about How to "Eliminate dents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

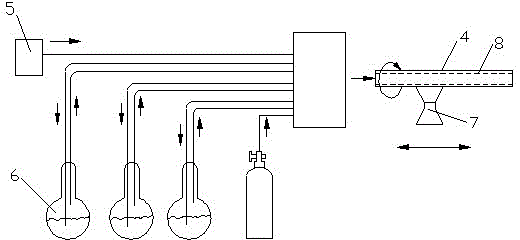

Plasma etching method and device

ActiveCN101153396AHigh control precisionEasy to controlElectric discharge tubesSemiconductor/solid-state device manufacturingPulse controlElectrical conductor

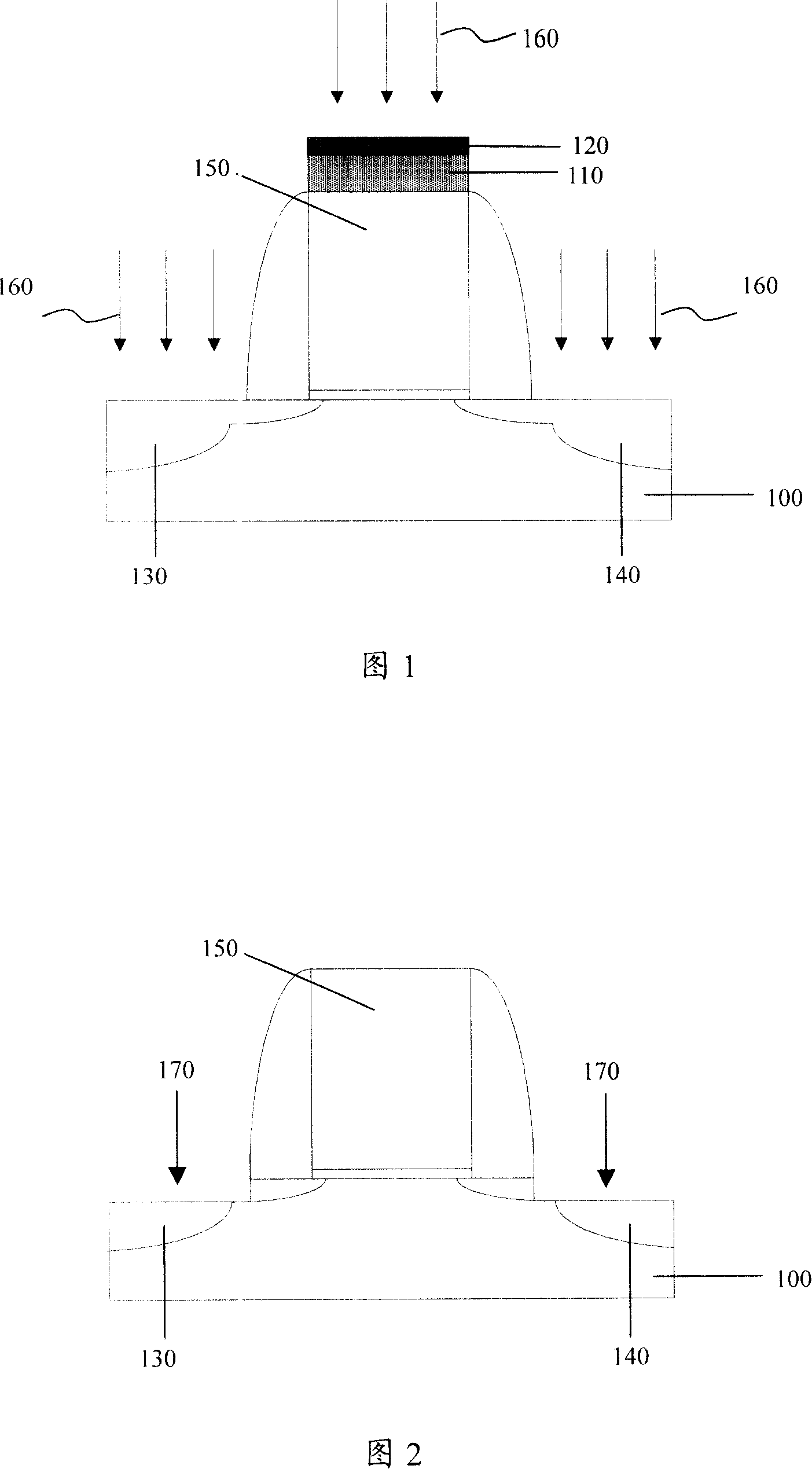

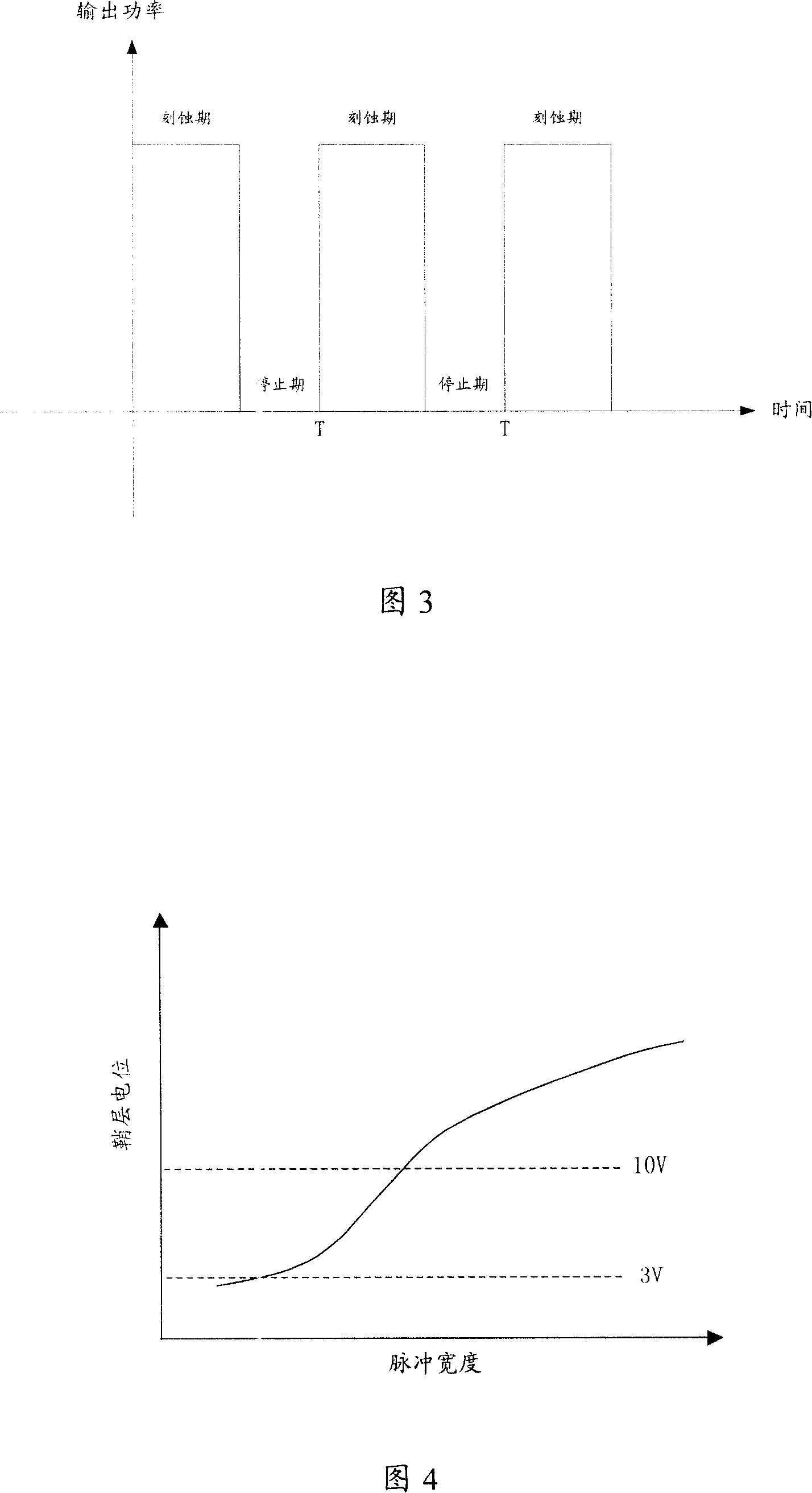

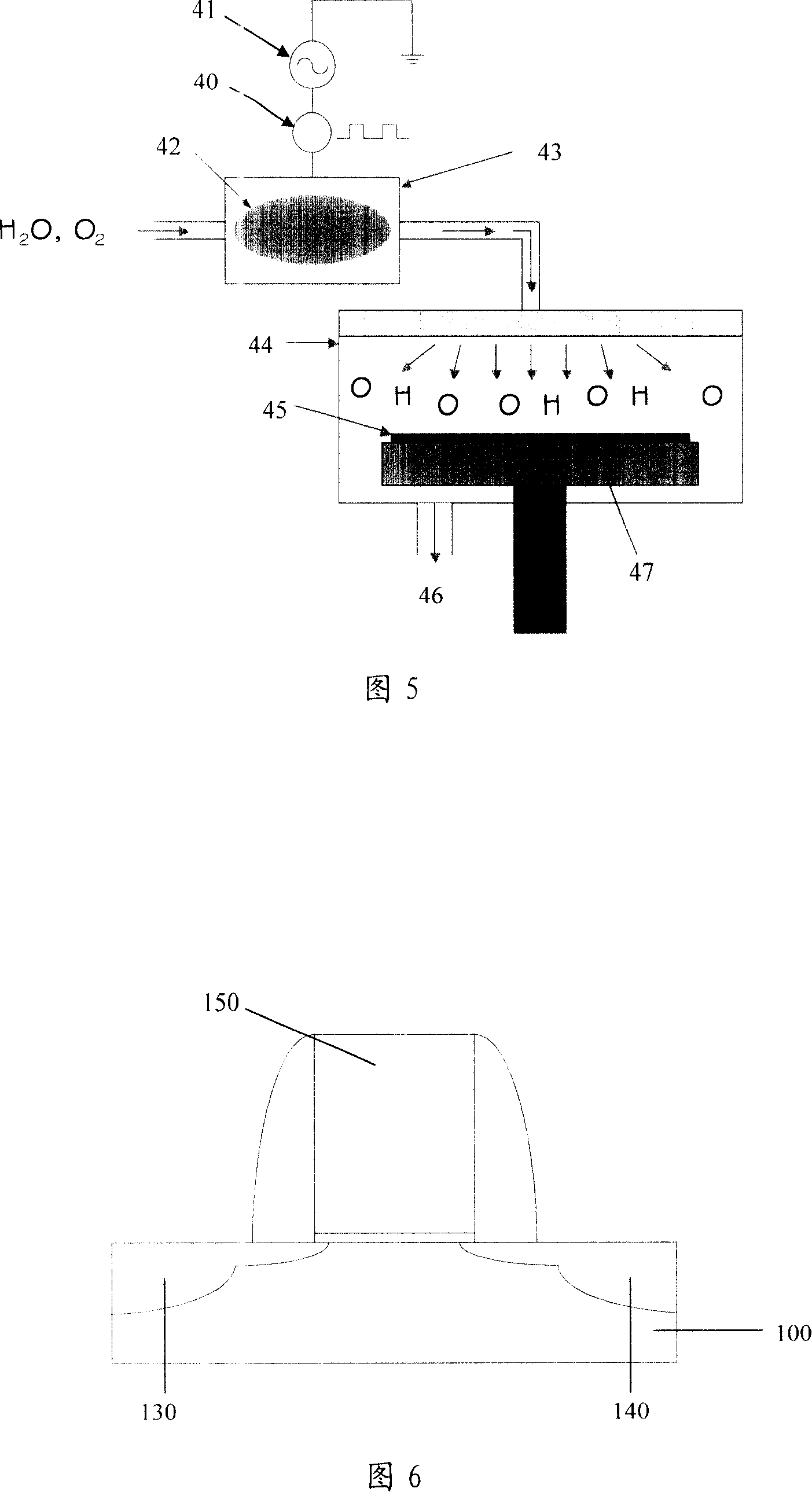

The invention discloses a plasma etching method and device, wherein, the method includes the following steps: the inside of a reaction chamber is provided with a semiconductor substrate which is provided with a to-be-etched material layer; etching gas which is ionized into plasma by a radio frequency power source is fed in the reaction chamber; the radio frequency power source outputs radio frequency power in pulse output mode. The device comprises a reaction chamber, a wafer holder, a first radio frequency power source, a loop winding, a second radio frequency power source and a pulse control circuit, wherein, the inside of the reaction chamber contains the etching gas; the wafer holder is used to bear the weight of a semiconductor wafer; the first radio frequency power source provides bias voltage for the wafer; the loop winding is arranged at the upper part and the top of the reaction chamber; the second radio frequency power source which is used to generate radio frequency power is connected with the loop winding through the pulse control circuit and outputs radio frequency power in pulse output mode to ionize the etching gas into plasma. The invention can generate plasma which is output in pulse mode and used for etching, thereby improving the control precision of etch end point.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

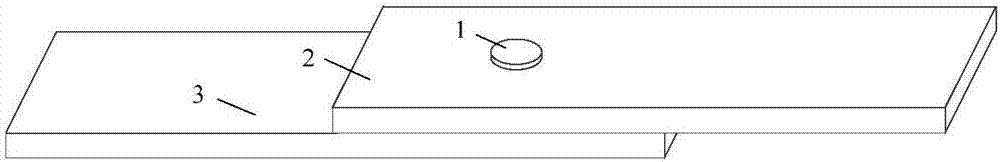

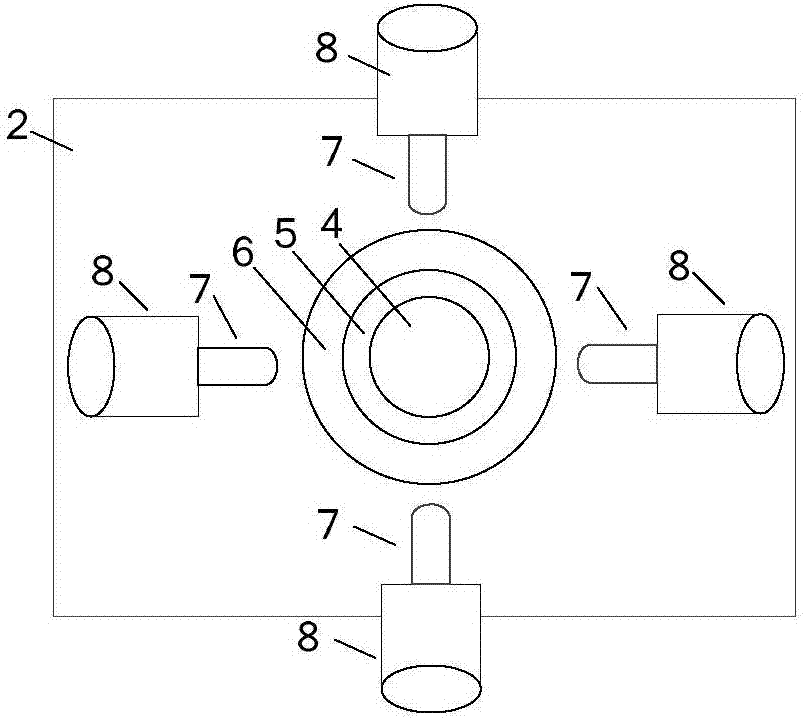

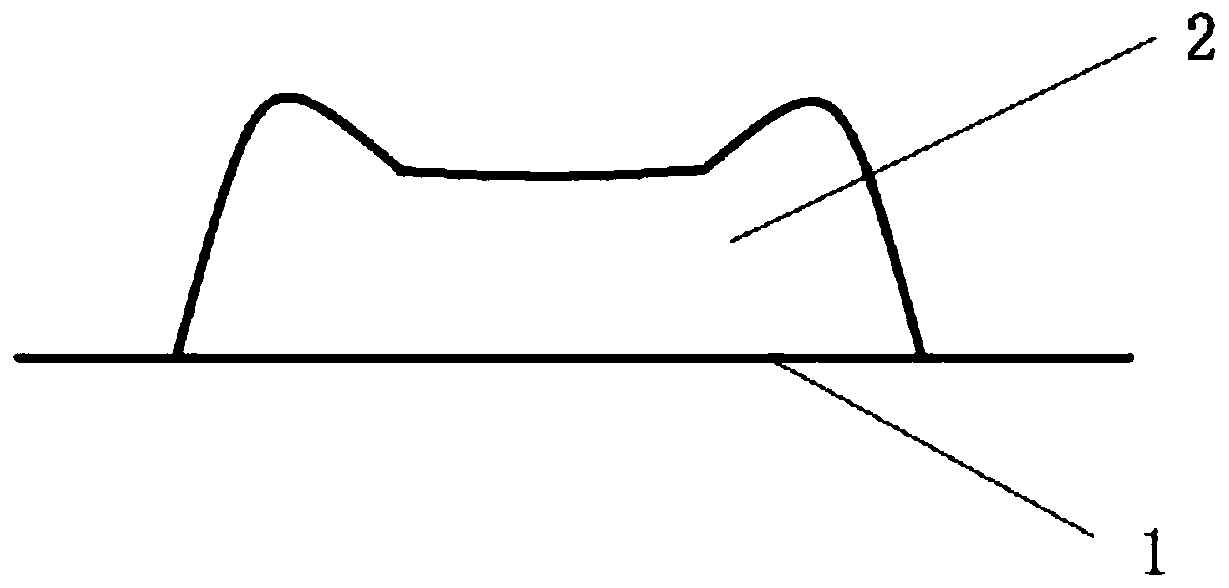

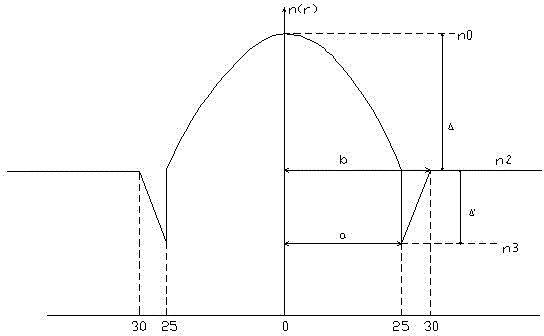

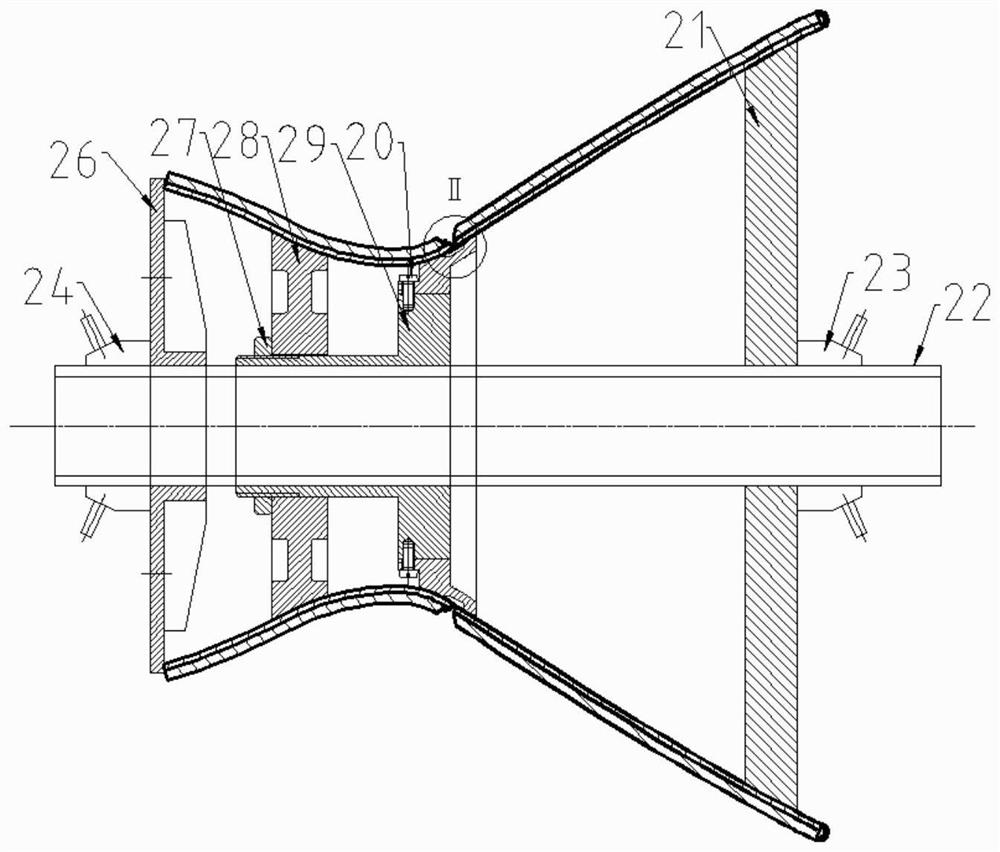

Refill friction stir spot welding method

ActiveCN106862749AEliminate dentsSpeed up the flowNon-electric welding apparatusEngineeringUltrasonic vibration

The invention discloses a refill friction stir spot welding method which is characterized in that a circular convex block is arranged at a welding spot of an upper plate of a workpiece; during welding, a hold-down ring of a stirring head is contacted with the upper plate and surrounds the convex block, and a stirring needle and a sleeve are contacted with the convex block; with the application of ultrasonic vibration to positions, on the outer side of the hold-down ring, of the upper plate, a material in a welding zone is plastified through the rotation of the sleeve and the stirring needle, then the sleeve pricks downwards to penetrate through the upper plate and pricks into a lower plate by a certain depth, the stirring needle is drawn back with the downward pricking of the stirring needle, after the sleeve reaches the designed downward pricking depth, the sleeve and the stirring needle return to initial positions, and continue to rotate and press down in the initial positions to allow the surface of the welding spot to be smooth, and after the stirring head stops rotating, an operator continues to apply the ultrasonic vibration for a certain time. According to the refill friction stir spot welding method, by employing the convex block for compensation, a pit of the welding spot produced after the welding can be eliminated; through the ultrasonic vibration, material flowing and material exchange between the upper plate and the lower plate can be improved, and the joint quality is improved; and the operator continues to apply the ultrasonic vibration after the welding, so that the residual stress of the welding spot can be reduced.

Owner:SHENYANG AEROSPACE UNIVERSITY

Method for producing low-alloy peritectic steel by conventional slab continuous casting machine

ActiveCN106011639AEliminate cracksEliminate dentsManufacturing convertersProcess efficiency improvementAlloyDecarburization

The invention discloses a method for producing low-alloy peritectic steel by a conventional slab continuous casting machine. The method comprises the technological processes of decarburization converter smelting, LF refining and slab continuous casting. Through the adjustment on the continuous casting procedures of the conventional slab continuous casting machine, the phenomenon of large liquid level fluctuation during peritectic steel pouring is eliminated, the shock mark depth of a casting blank is obviously reduced, cracks and concave parts in the surface of the casting blank are eliminated, the conventional slab continuous casting machine can produce flawless low-alloy peritectic steel in batches, and high-quality raw materials are provided for low-alloy high-strength steel stable in production performance.

Owner:TANGSHAN IRON & STEEL GROUP

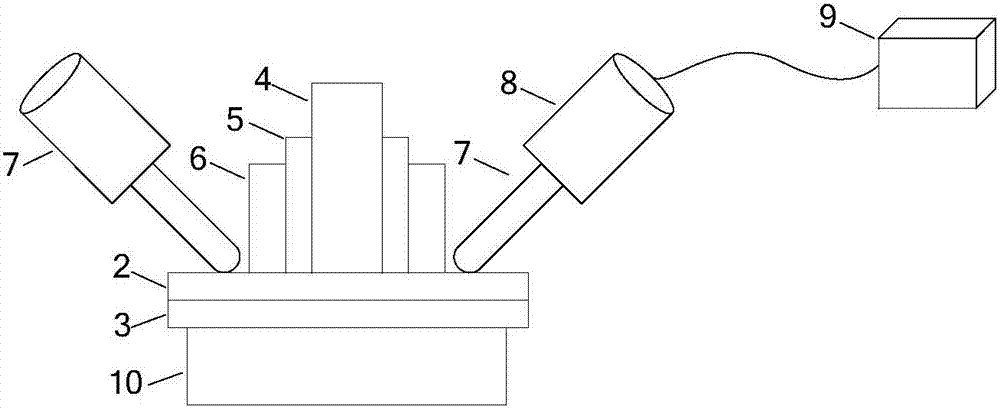

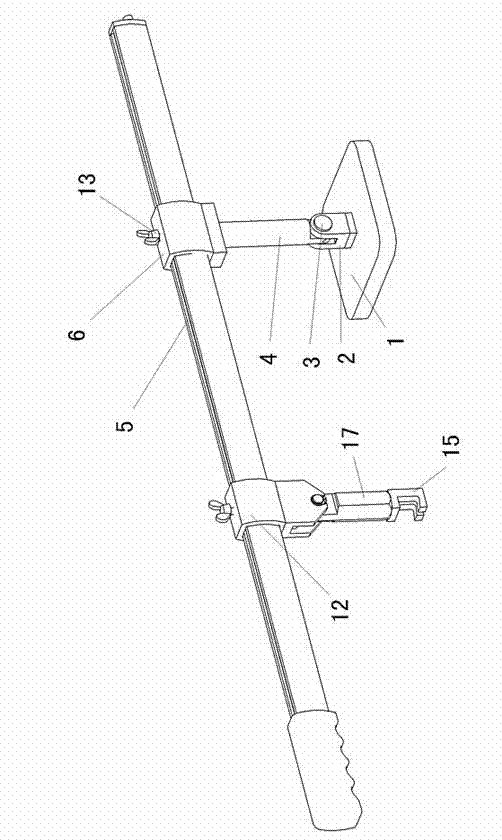

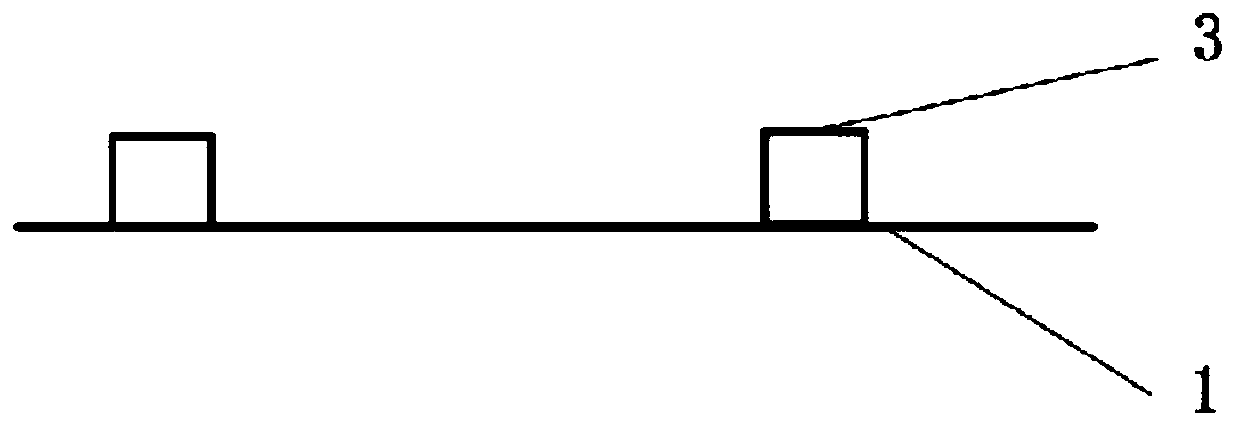

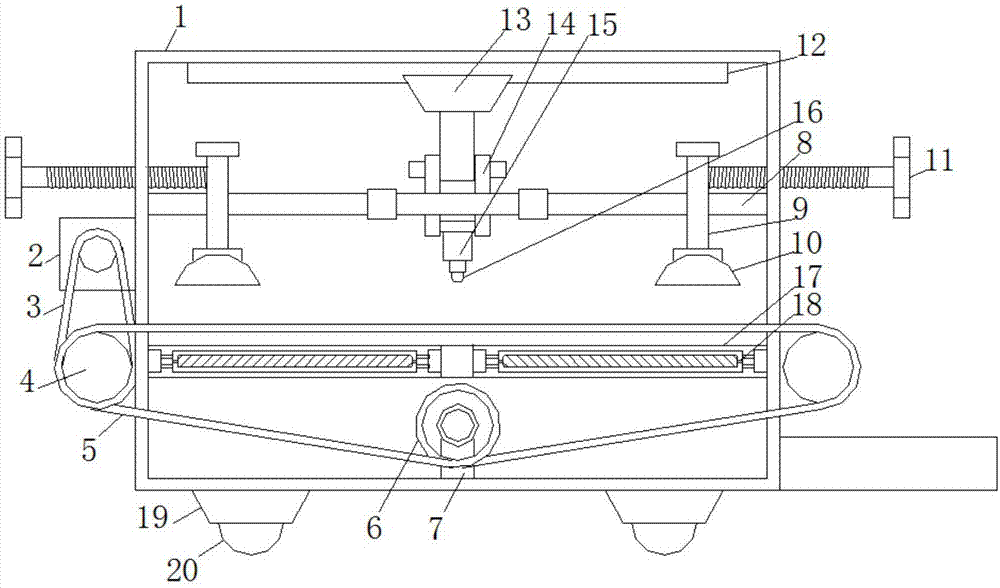

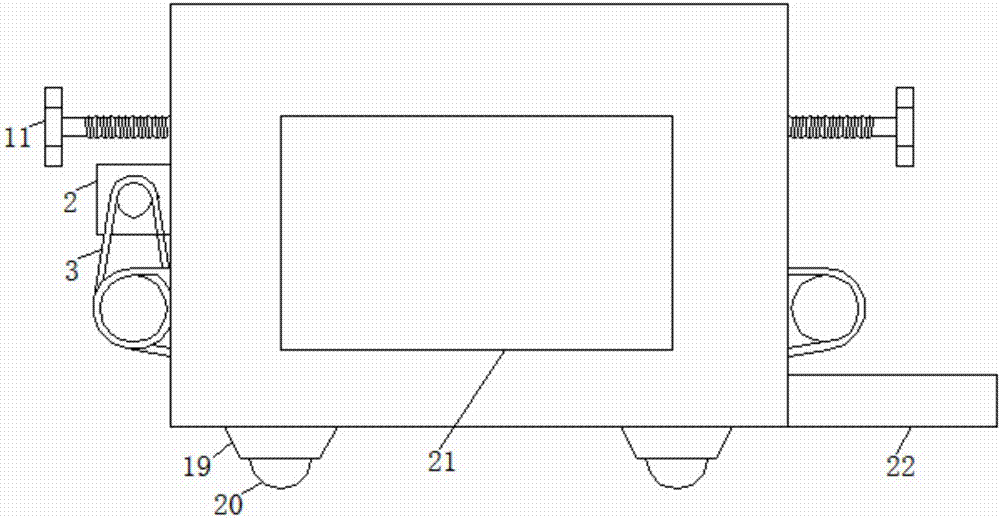

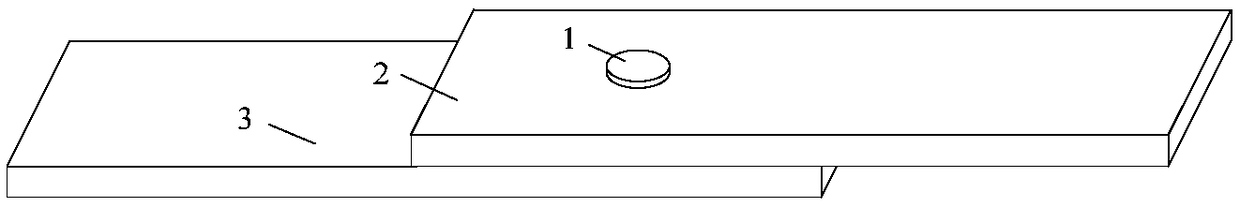

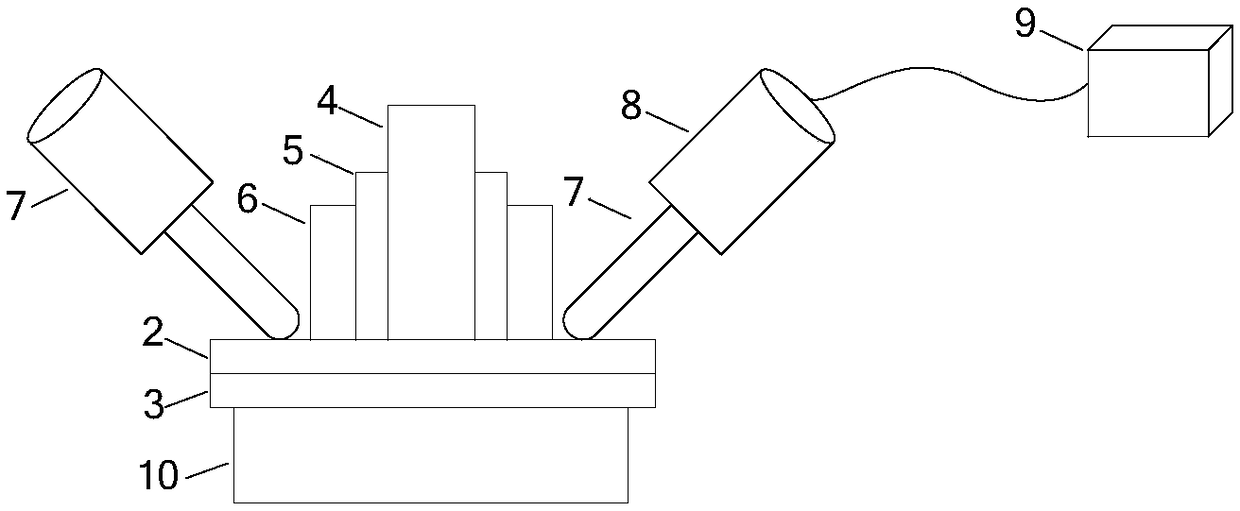

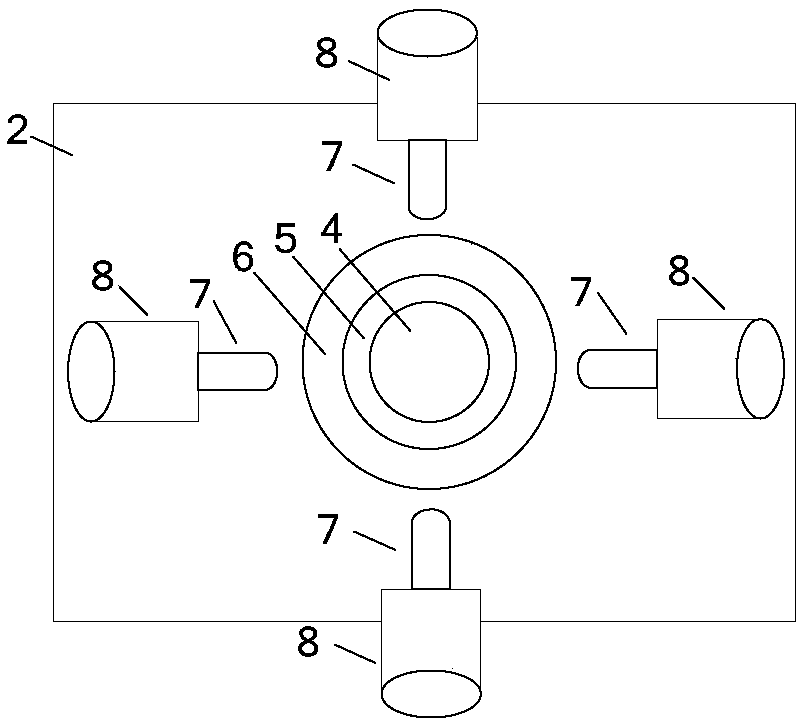

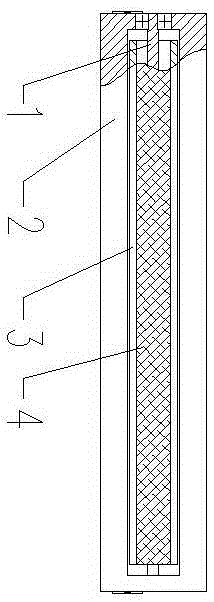

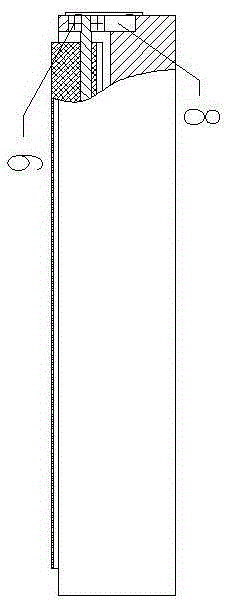

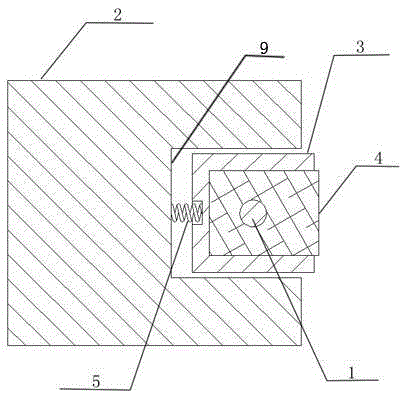

Automotive body profile repairing device

The invention discloses an automotive body profile repairing device which comprises a support plate, wherein a lifting mechanism is arranged above the support plate, and the lifting mechanism is connected with a connecting end. When the automotive body profile repairing device is used, the support plate is placed beside a dent on the surface of an automobile, and then the support plate is connected with the metal plate surface of the dent through the connecting end (the connection can be achieved by means of directly welding, or through a hanging piece in a hanging mode after the hanging piece is welded), and further the metal plate dent portion is pulled up through the lifting mechanism to become flat with the dent eliminated. The automotive body profile repairing device is simple to operate, saving in time and labor, and good in repairing effect.

Owner:DALIAN NEWSTAR TOOL MFG

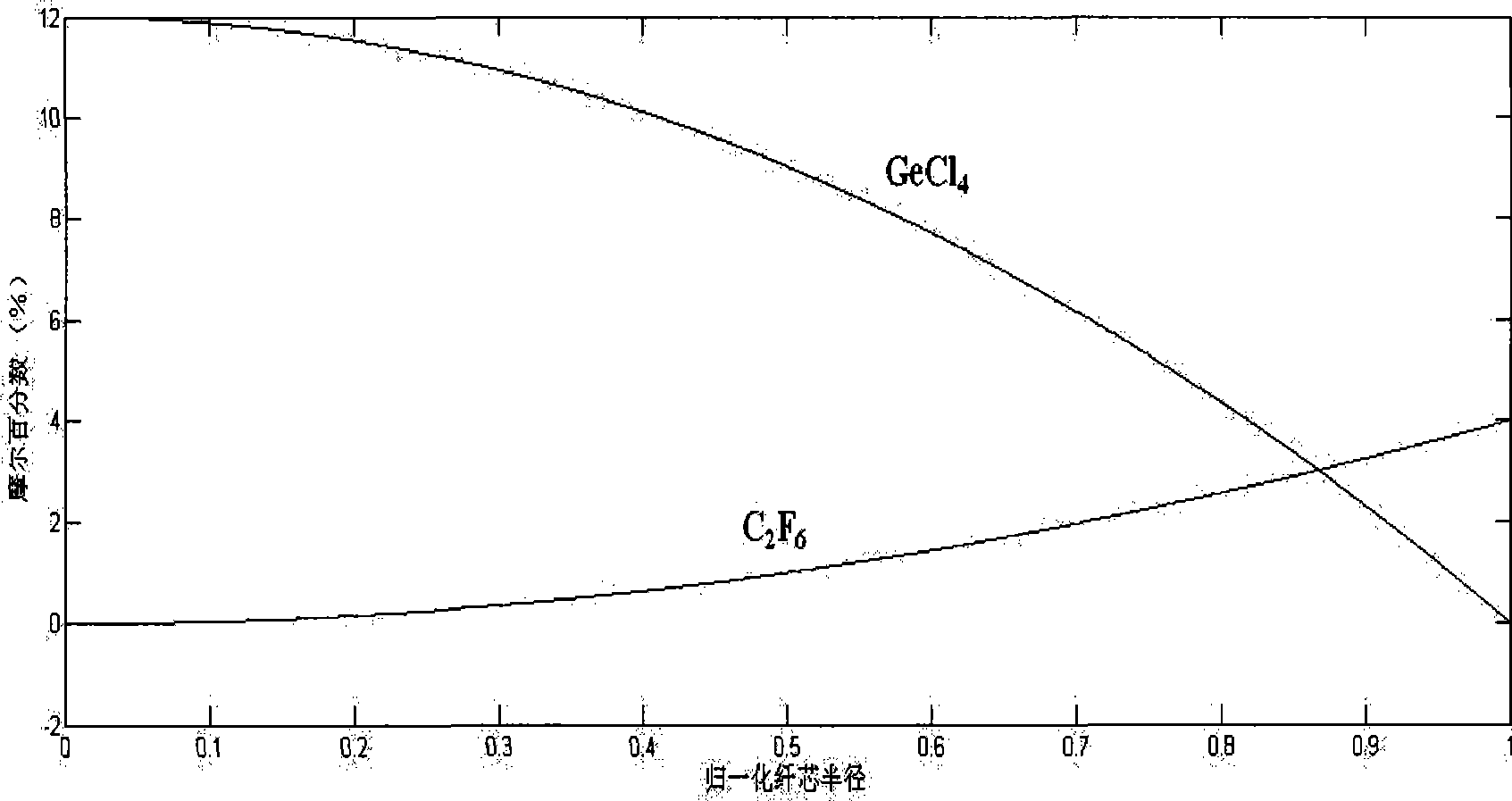

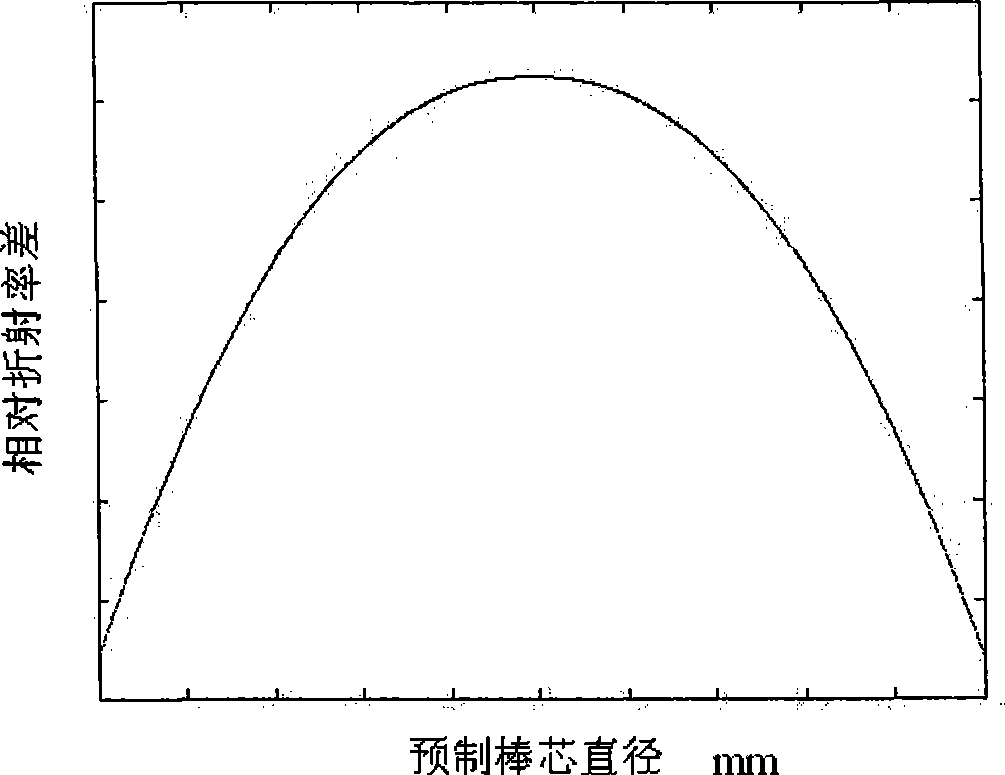

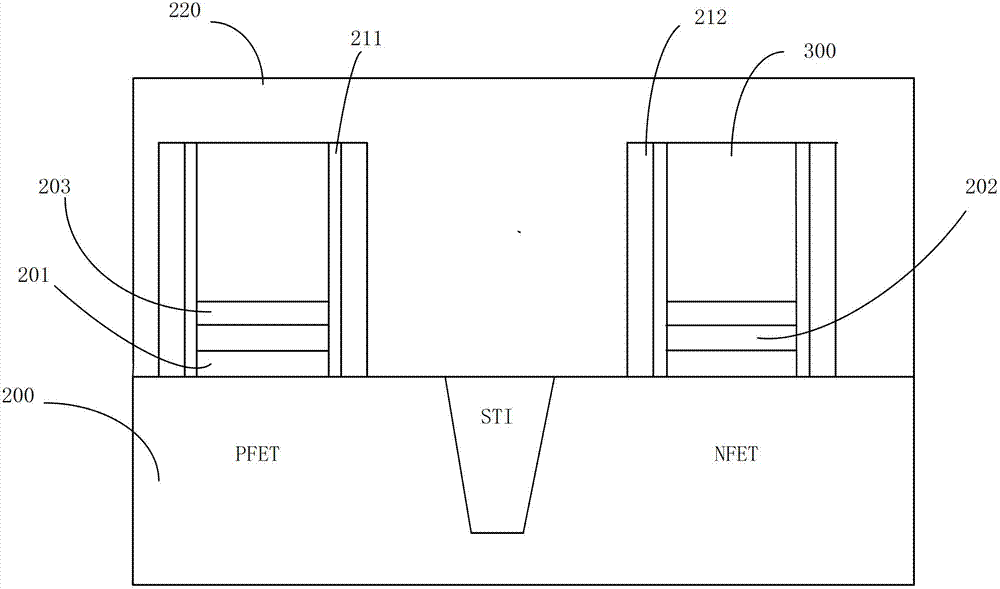

Band-width optimized multi-mould optical fiber and method of manufacturing the same

ActiveCN101458360ALow Differential Mode DelayImprove transmission bandwidthGlass making apparatusOptical fibre with graded refractive index core/claddingFiberLow speed

The invention relates to a bandwidth optimized multimode fiber and a manufacturing method thereof. The multimode fiber comprises three parts, including a fiber core, a quartz glass cladding and a coating with graded index profile. By adopting the method of optimizing the impurity gas flow curve, the refractive index profile parameter of a fiber core is controlled to optimize the optimal bandwidth of the fiber at the communication window of 850nm.The largest change of the differential mode time delay of the fiber is less than 0.22ps / m, the over-filled launch bandwidth is larger than 3,500MHz.km and 500MHz.km respectively at 850nm and 1,300nm and the valid mode bandwidth is larger than 4,700MHz.km and 500MHz.km respectively at 850nm and 1,300nm.The multimode fiber of the invention decreases the chromatic dispersion between modes and the time delay and increases transmission bandwidth, thereby not only meeting the application requirement of a low speed network, but also meeting the application requirement of a gigabit high speed broadband network.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

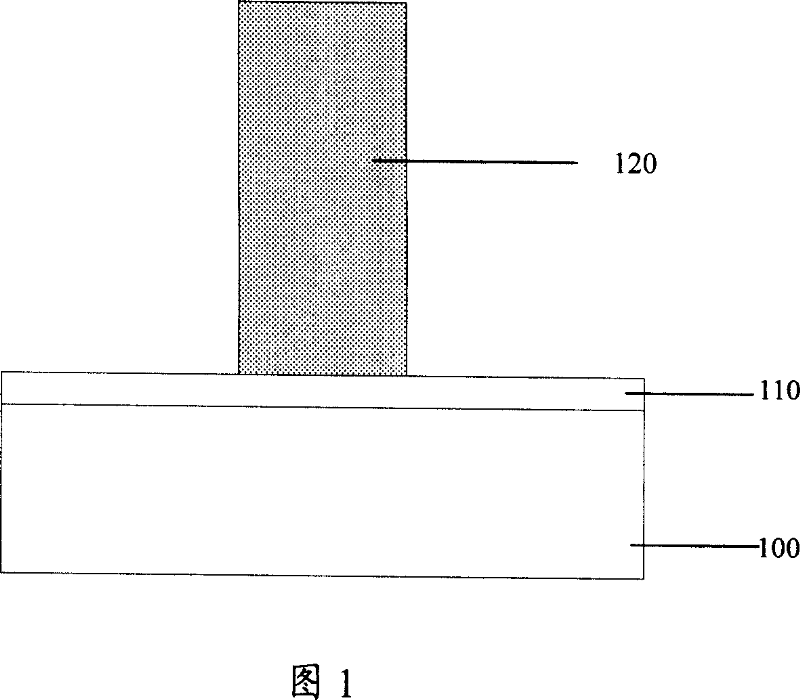

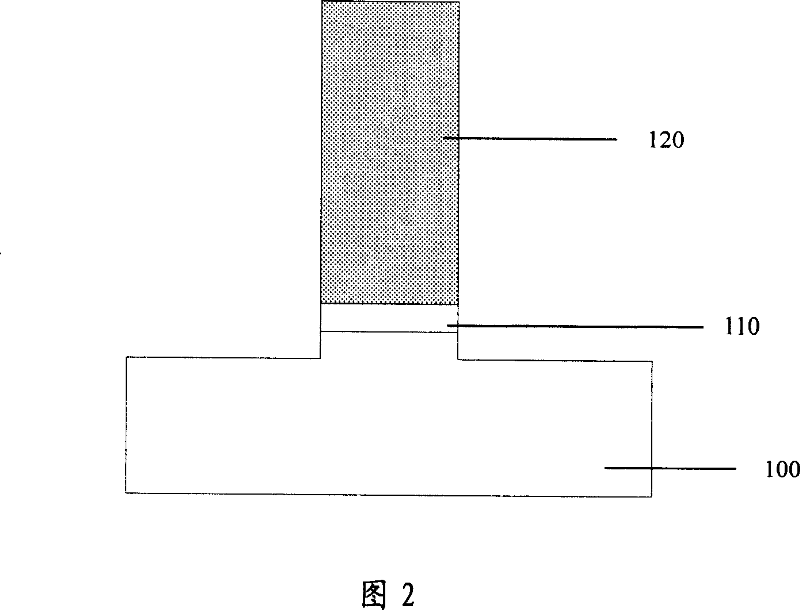

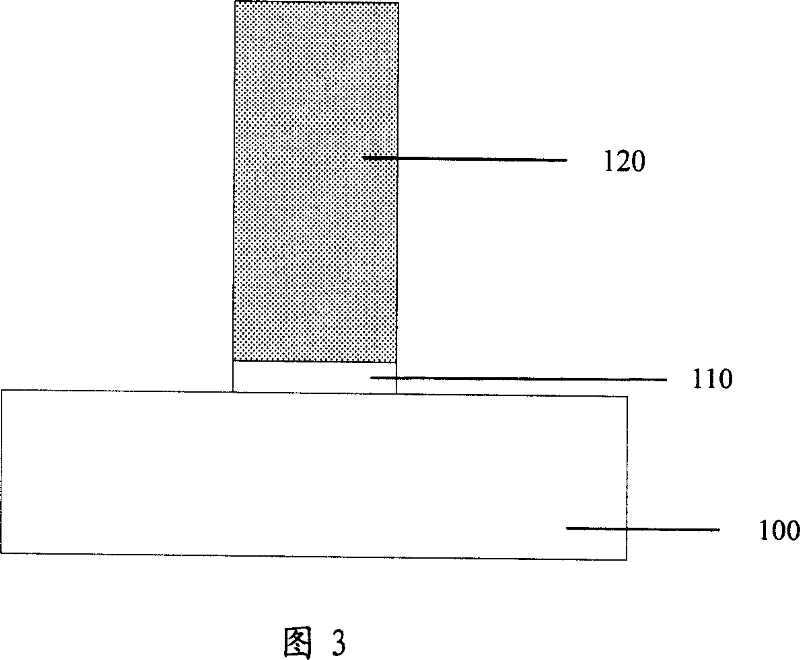

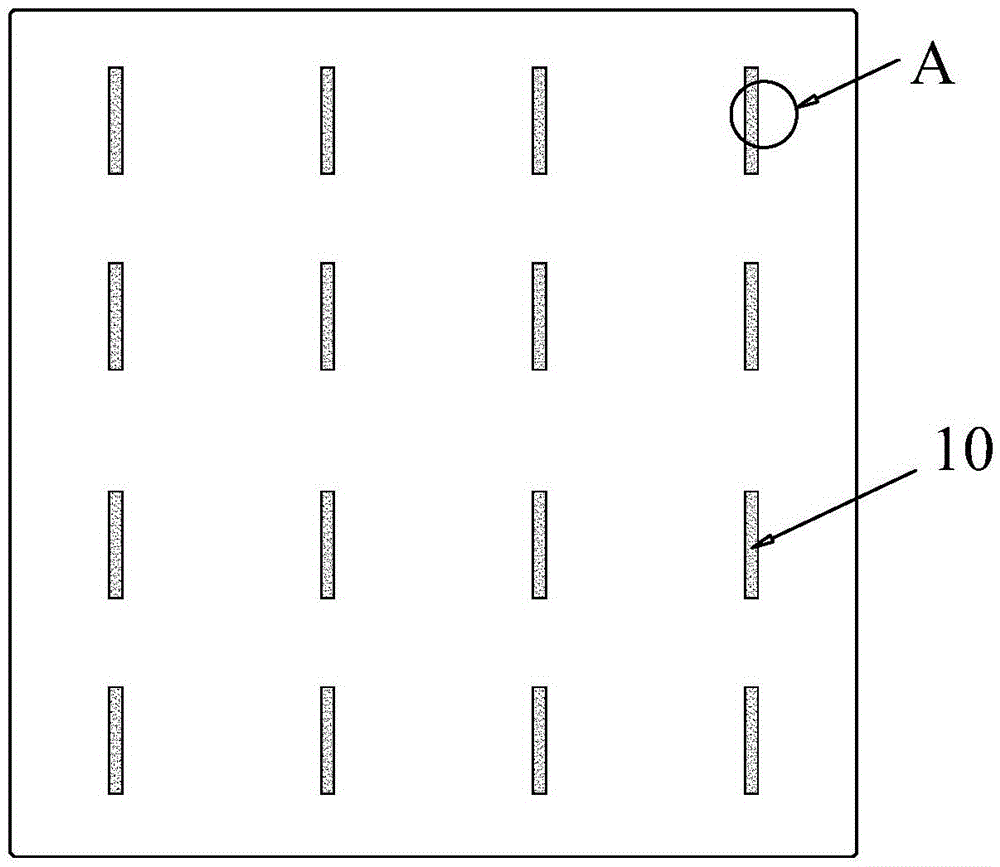

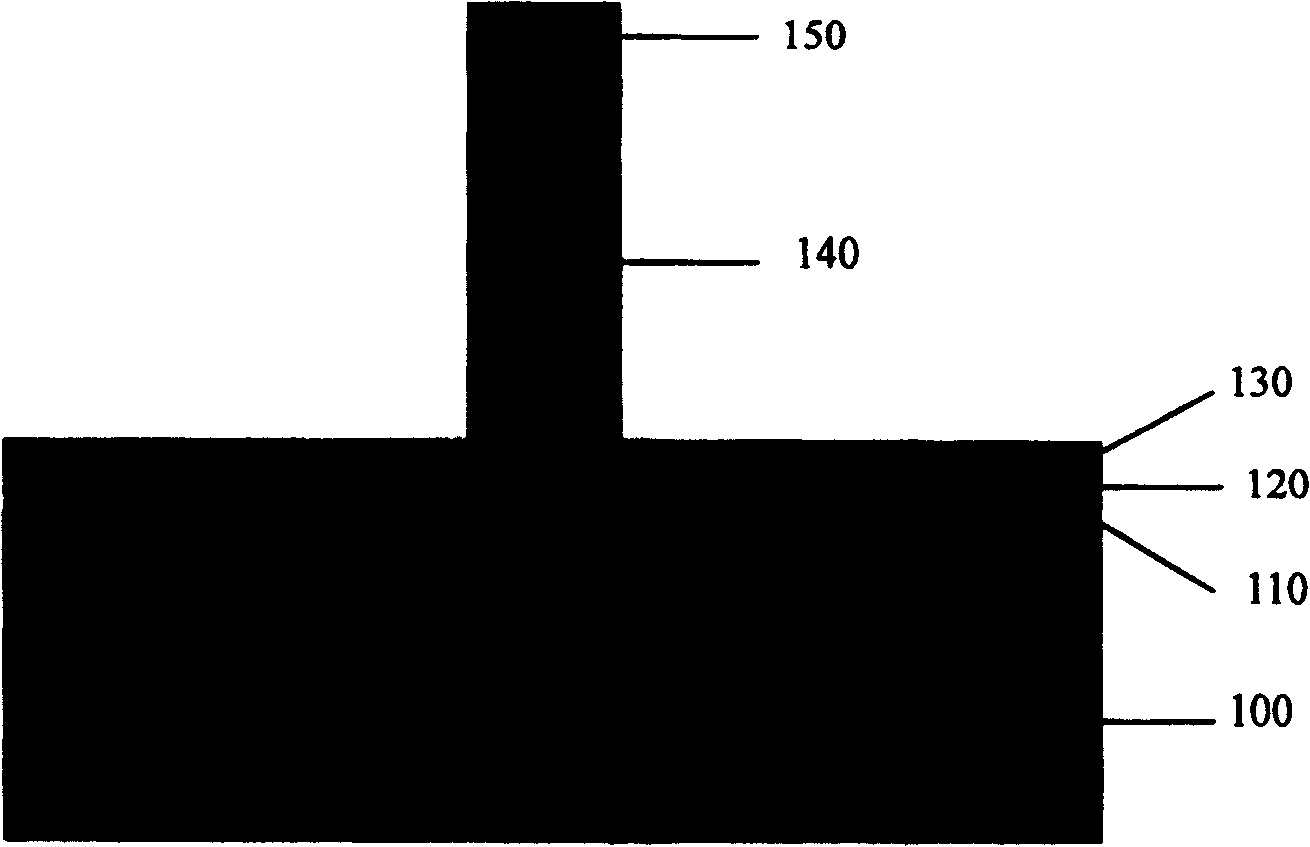

Method for manufacturing grid structure of semiconductor device

ActiveCN101038870APrecise thickness controlPrecisely control the depth of etchingSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorManufacturing grid

The invention provides a mehtod for making grid structure of semiconductor device, which includes providing a semiconductor substrate, and forming a grid medium layer on the substrate, and forming a grid electrode layer on the grid medium layer, and forming a mask layer on the grid electrode layer, and then inducing etching gas to etch the polysilicon grid electrode layer by employing plasma output by a plasma source, wherein the plasma source etches the grid medium layer in pulse outputting power manner. The invention provide method for making grid structure of semiconductor device is very effective for accuracy controlling the thickness of the grid oxide layer in a process node no more then 65 nm, and the etching depth can perfectly stop at the surface of the grid oxide layer without hurting the surface of an active region.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

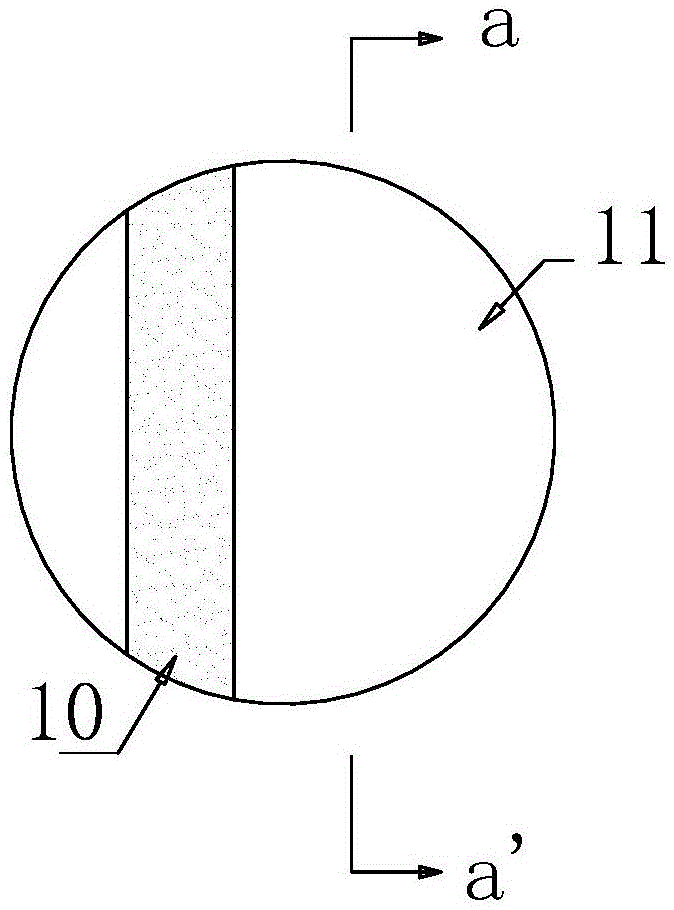

Deposition method of crystalline silicon battery back electrode, and obtained crystalline silicon battery

ActiveCN105576051APrevent dissolution and diffusionSolution diffusion barrierPhotovoltaic energy generationSemiconductor devicesContact positionCrystalline silicon

The invention relates to a deposition method of a crystalline silicon battery back electrode. The method is characterized in that an electrode capable of preventing dissolving diffusion of element silicon to element aluminum at a preset temperature is deposited around the periphery of the local opening of crystalline silicon undergoing a passive film local opening technology; or the electrode capable of preventing dissolving diffusion of element silicon to element aluminum at the preset temperature is deposited around the periphery of the predetermined local opening position of crystalline silicon undergoing a passive film generation technology; and the preset temperature is not greater than 950DEG C. The method can eliminate recesses and cavities in the local contact position in current common aluminum silicon sintering processes, and reduces absorption of a sintered aluminum layer to long-wavelength photons; and local back field, local electric contact and mechanical tension are formed through arranging an electrode, so the back reflection of a PERC battery is further improved, and the current is improved.

Owner:CSI CELLS CO LTD

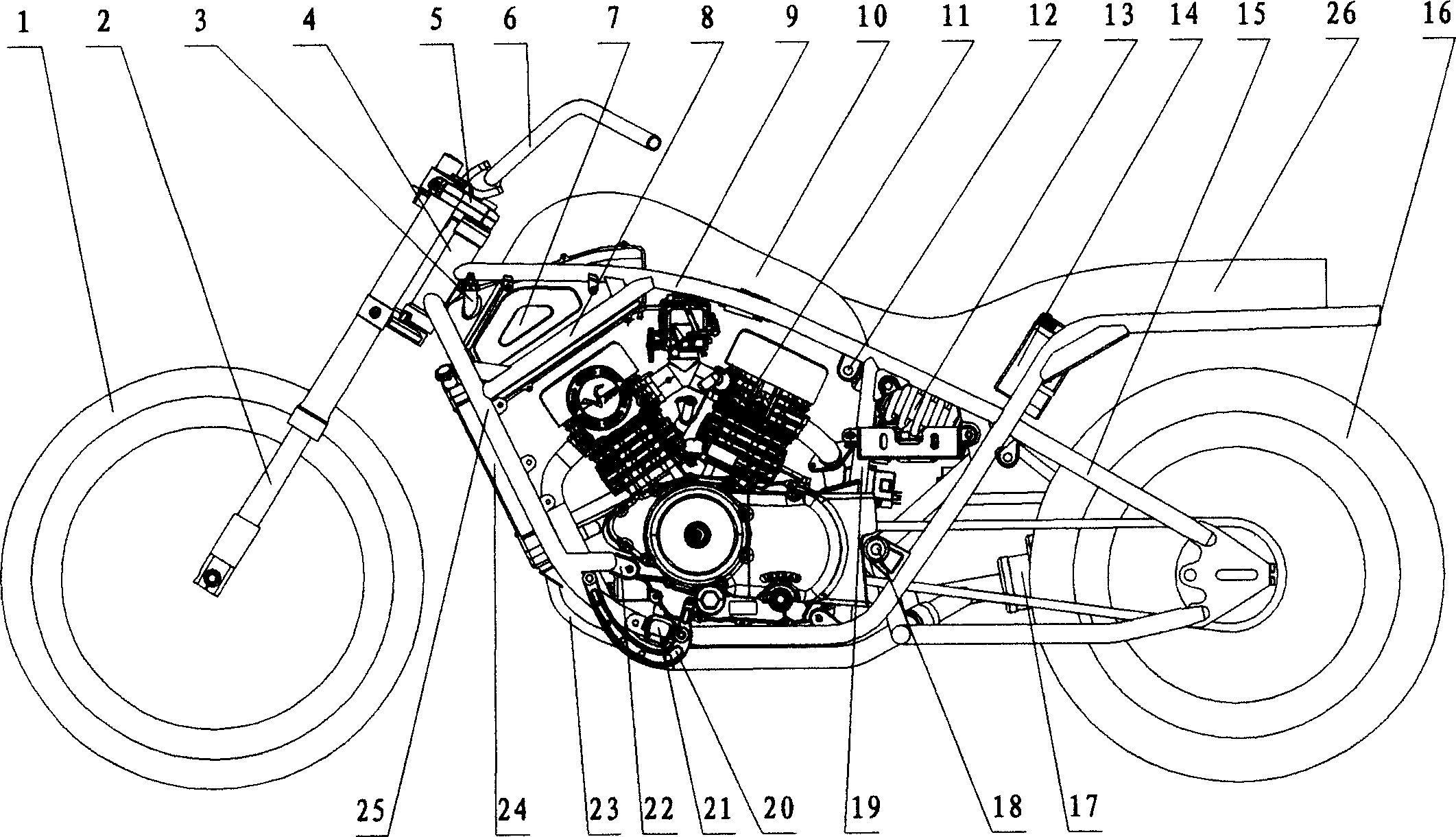

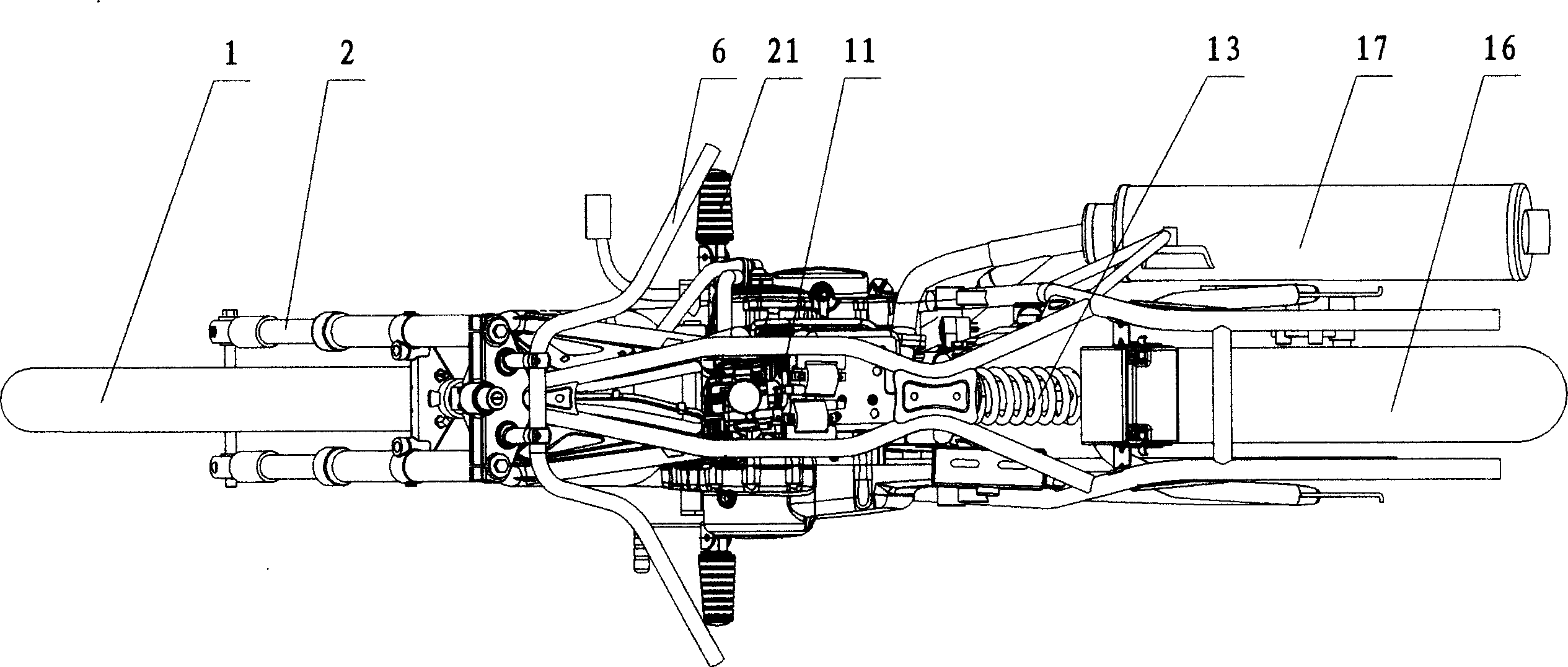

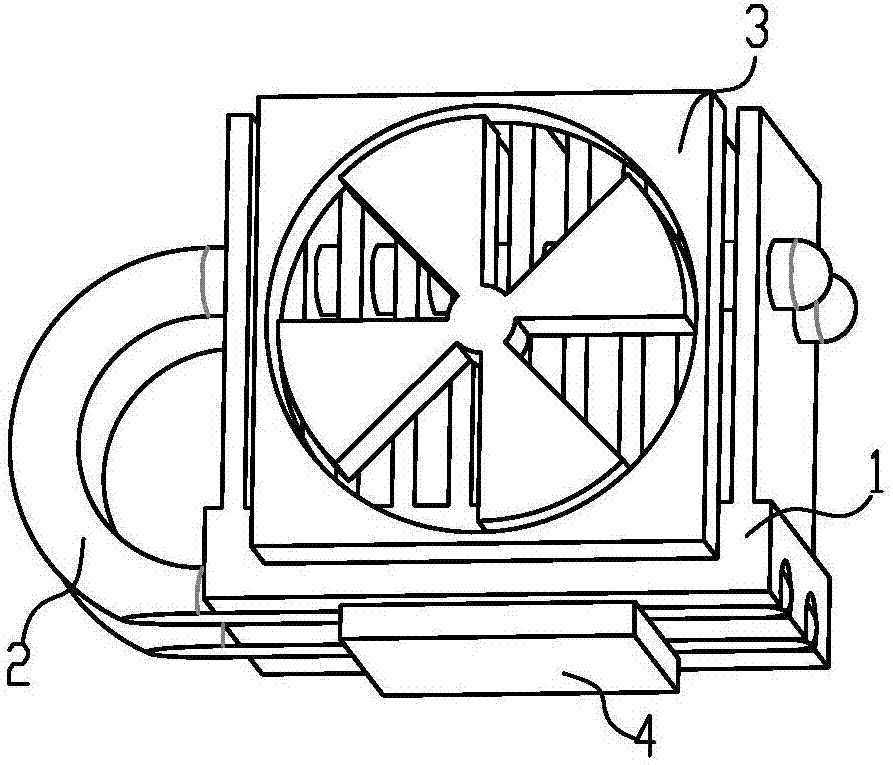

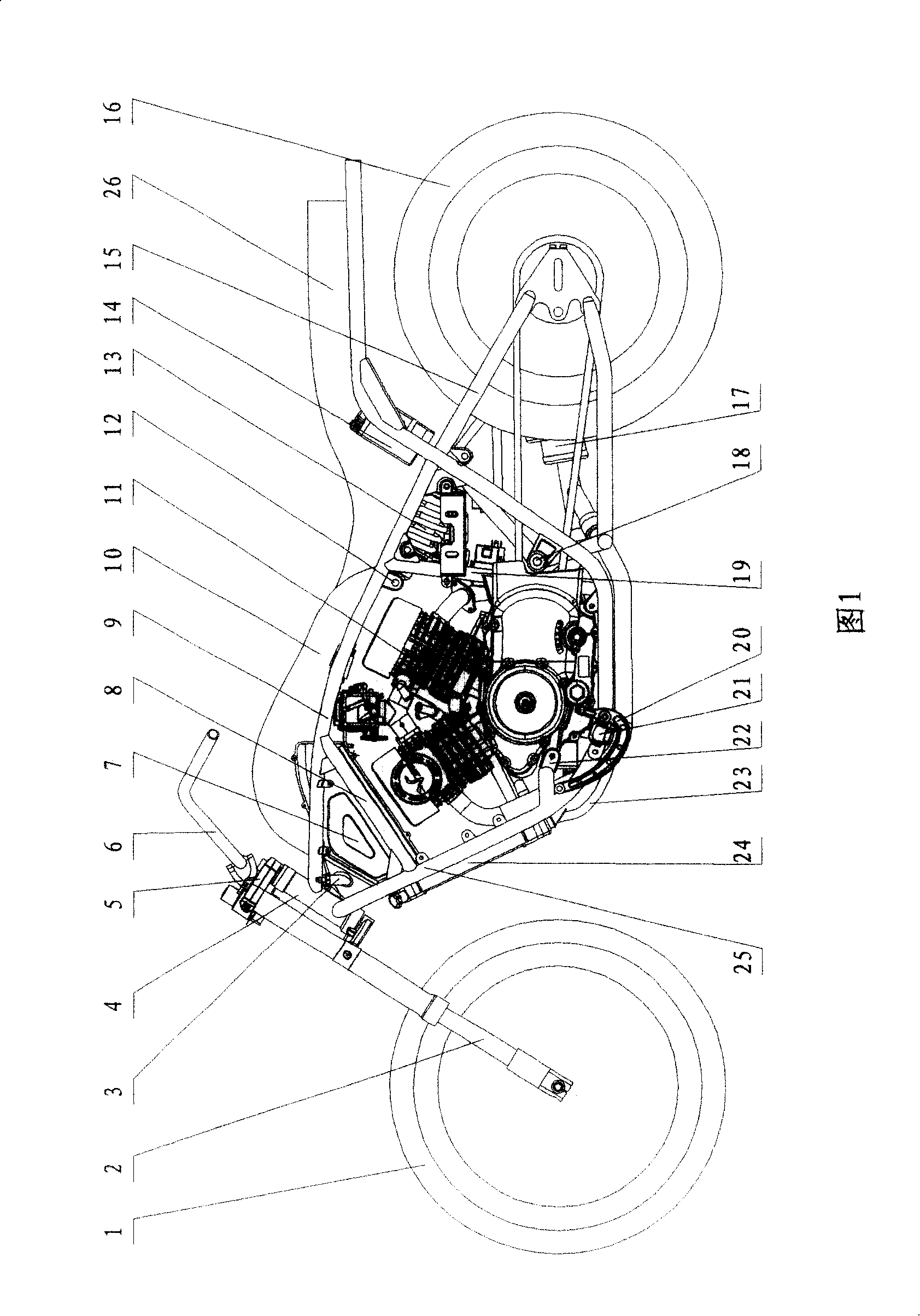

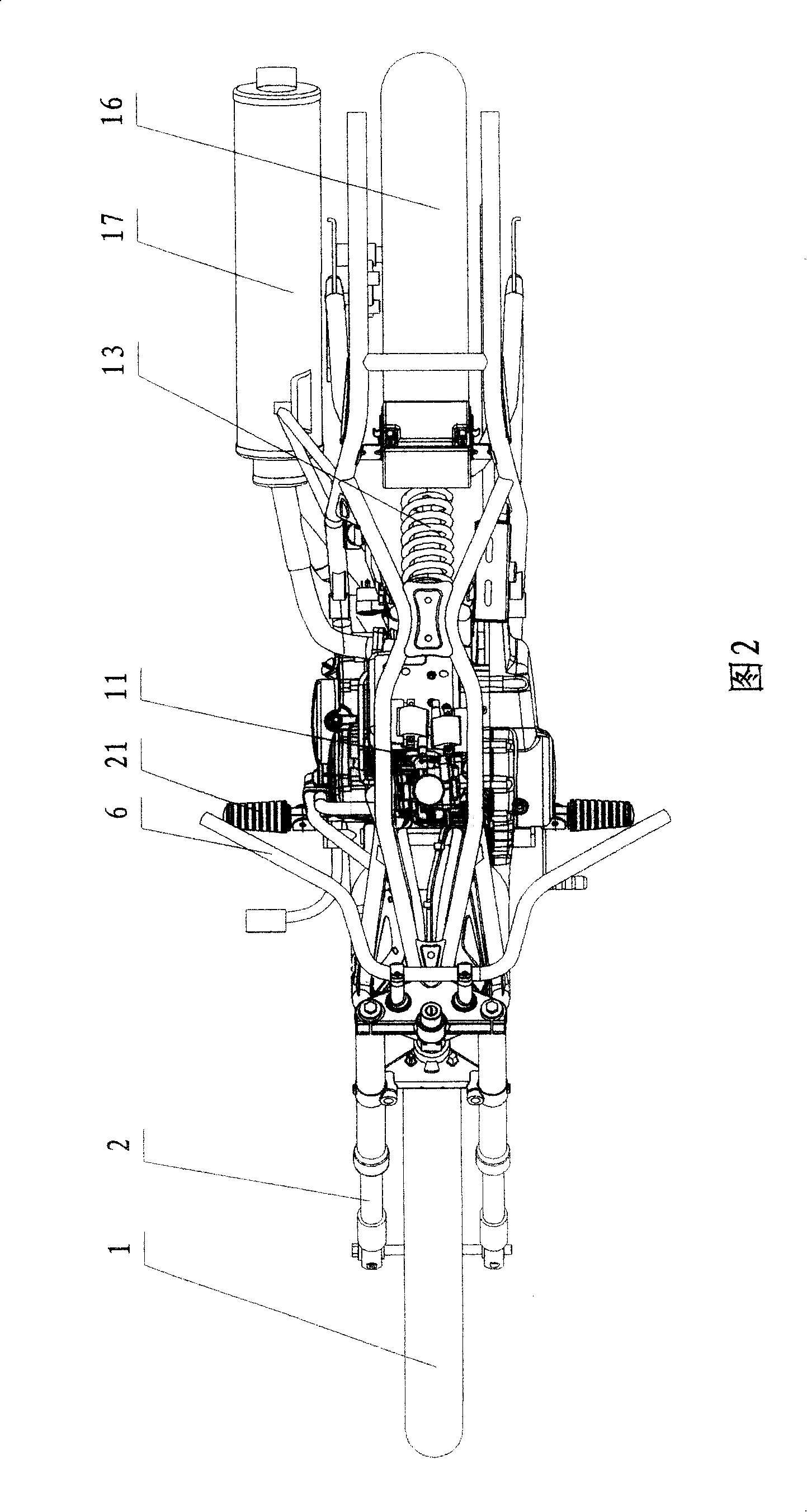

Riding type two-wheel motorcycle

The invention discloses a bestriding type of dual-wheel motorcycle. The frame of the motorcycle consists of two parallel upper longitudinal beams and two parallel lower transverse bent beams, which are connected to the main tube of the motorcycle head. The rear end of the frame is ream jointed to one flat triangle fork through the flat folk spindle. The upper longitudinal beams have a rear section which gradually declined downward for the purpose of reducing the height of the motorcycle seat. The upper inclined forked tube of the flat triangle fork extends itself along the extending line of the rear section of the upper longitudinal beam. The rear shock absorber, which is horizontally mounted, is parallel with the rear section of the upper longitudinal beam and is located below the seat. The front end and the rear end of the rear shock absorber are beam jointed with the upper longitudinal beam and the flat triangle fork respectively. An air filter is available near the point where the upper longitudinal beam, the lower bent beam connected with the main tube of the motorcycle head. Below this point and on the lower bent beam, a water cooler is equipped. A water-cooling motor is mounted on the suspending device equipped on the frame. The front pedals are mounted on the front turning points, which are near the lower end of the lower bent beam. The two pedals extrude out of the frame on both the right side and left side. These pedals can reduce the height of the seat and improve the shock-absorbing effect and comfort in driving.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

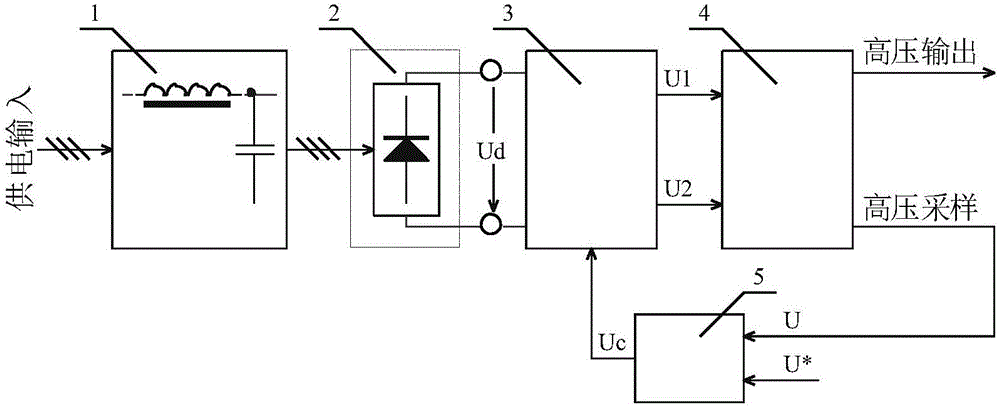

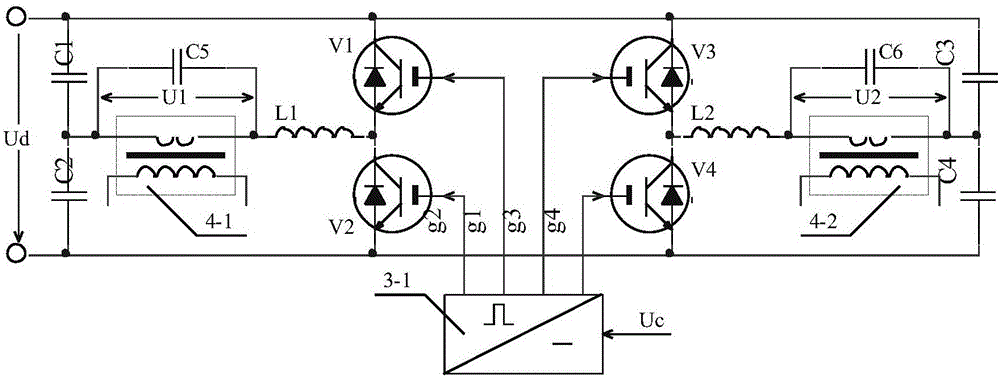

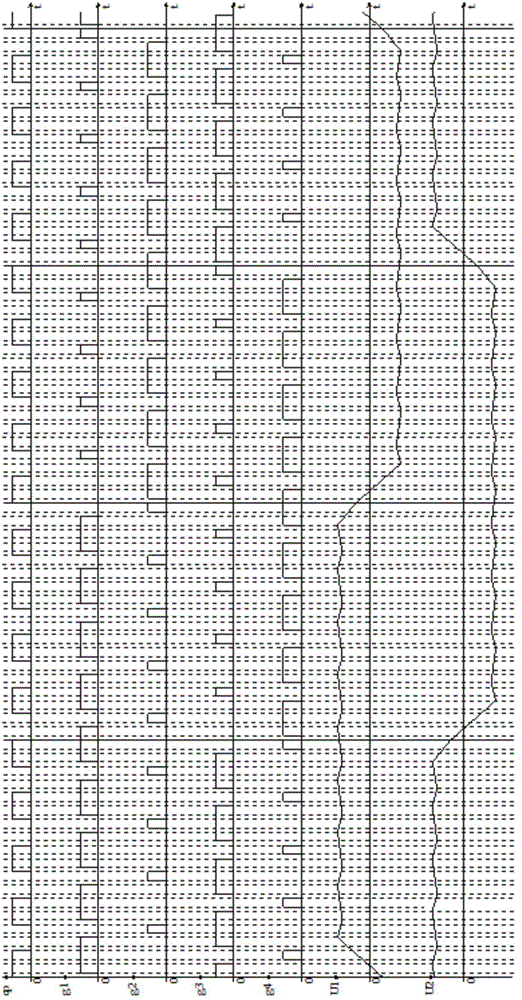

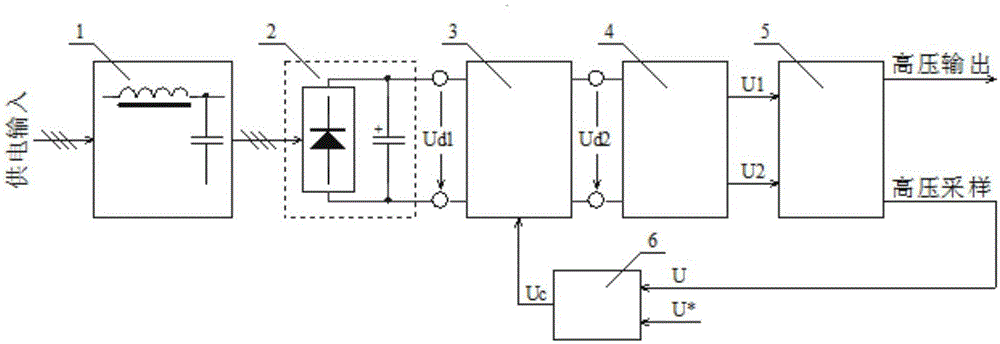

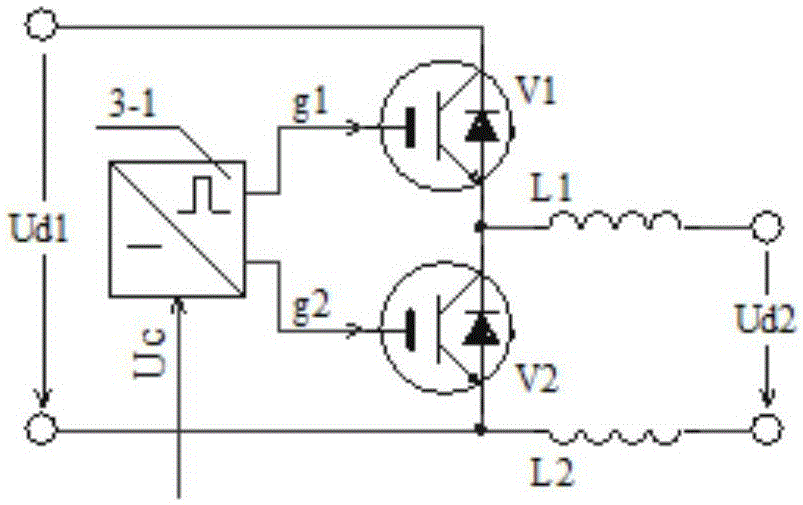

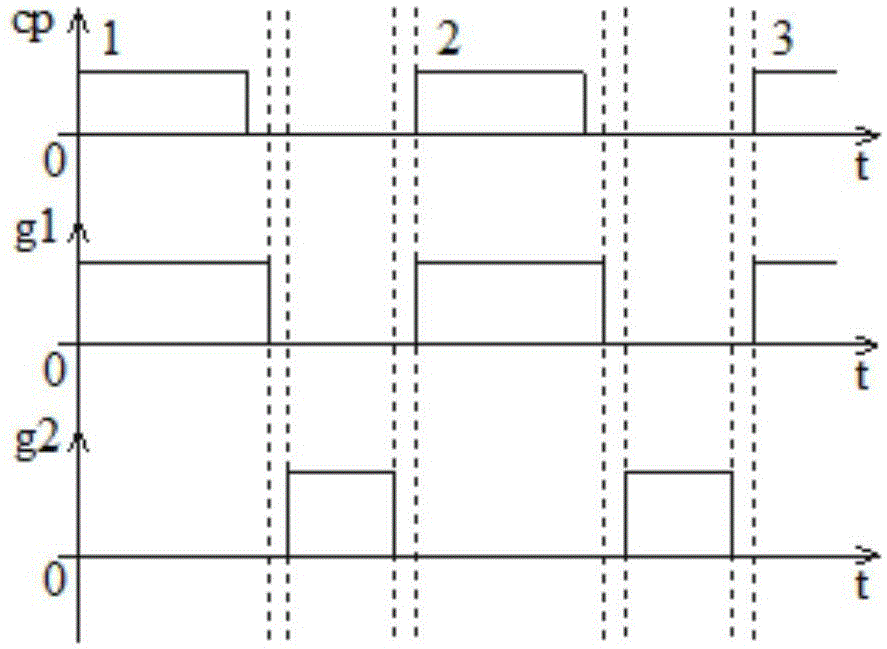

Accelerator power supply apparatus of electron beam microfabrication equipment and control method thereof

ActiveCN105141149AChange the output voltage amplitudeStable outputAc-dc conversion without reversalConversion without intermediate conversion to dcLow voltagePower grid

The present invention relates to an accelerator power supply apparatus of electron beam microfabrication equipment and a control method thereof. The apparatus includes an incoming line filter, a low-voltage rectifier bridge, an invert unit, a high-voltage unit and a regulator. The input end of the incoming line filter connects an external power grid. The output end of the incoming line filter, the low-voltage rectifier bridge, the invert unit and the input end of the high-voltage unit are connected in series orderly. The high-voltage output end of the high-voltage unit outputs high voltage, a high-voltage feedback signal U outputted by the signal end of the high-voltage unit is transmitted to the second input end of the regulator, the first input end of the regulator inputs a high-voltage setting signal U*, and the output end of the regulator connects the signal end of the invert unit. Compared to the prior art, the acceleration power supply apparatus of electron beam microfabrication equipment and the control method thereof solve a problem that the output end of an accelerator power supply occurs a spike voltage caused by a PWM converter working in a discontinuous current mode.

Owner:GUILIN UNIV OF ELECTRONIC TECH

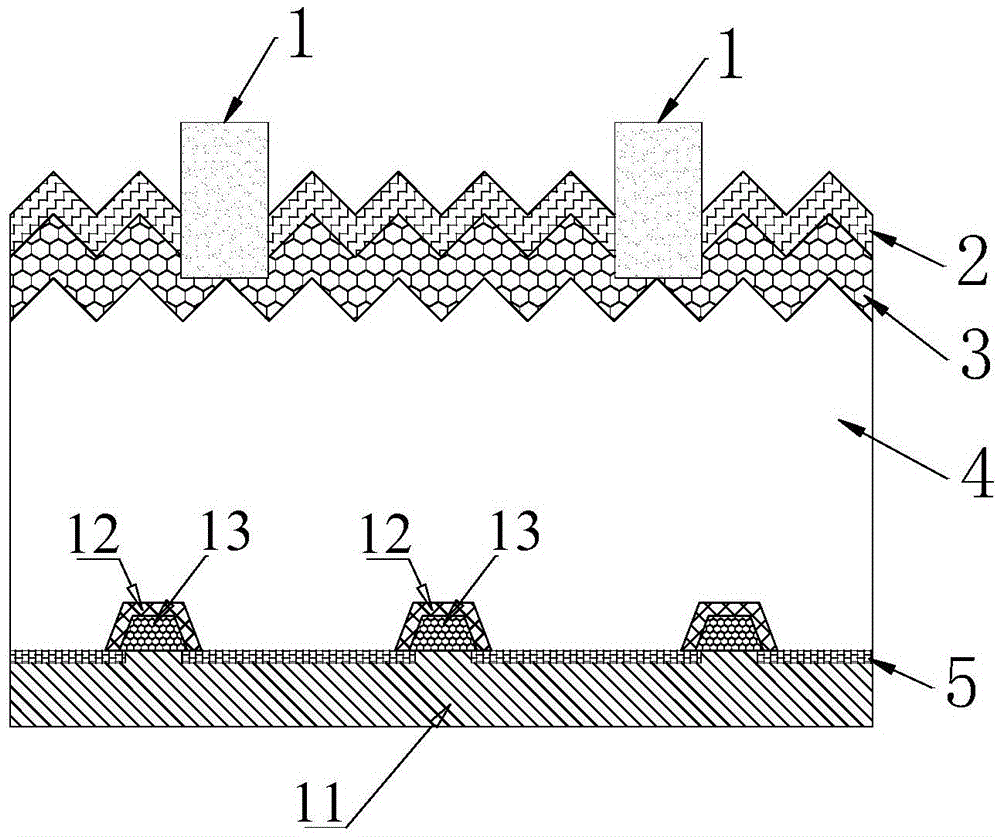

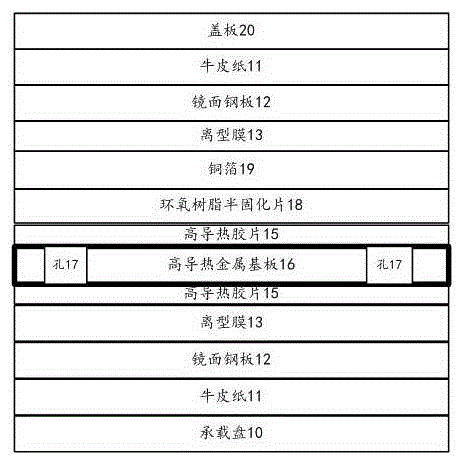

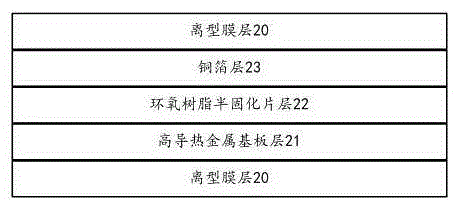

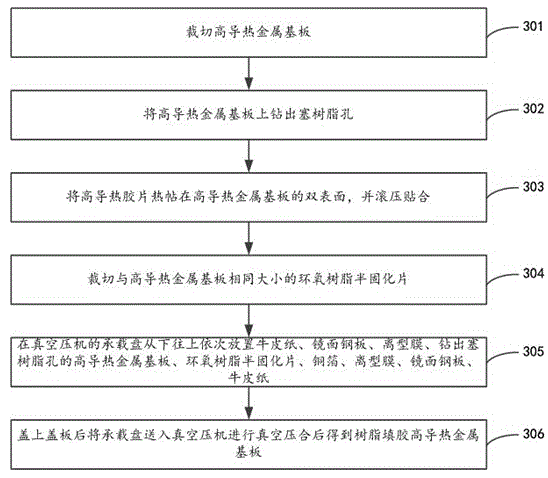

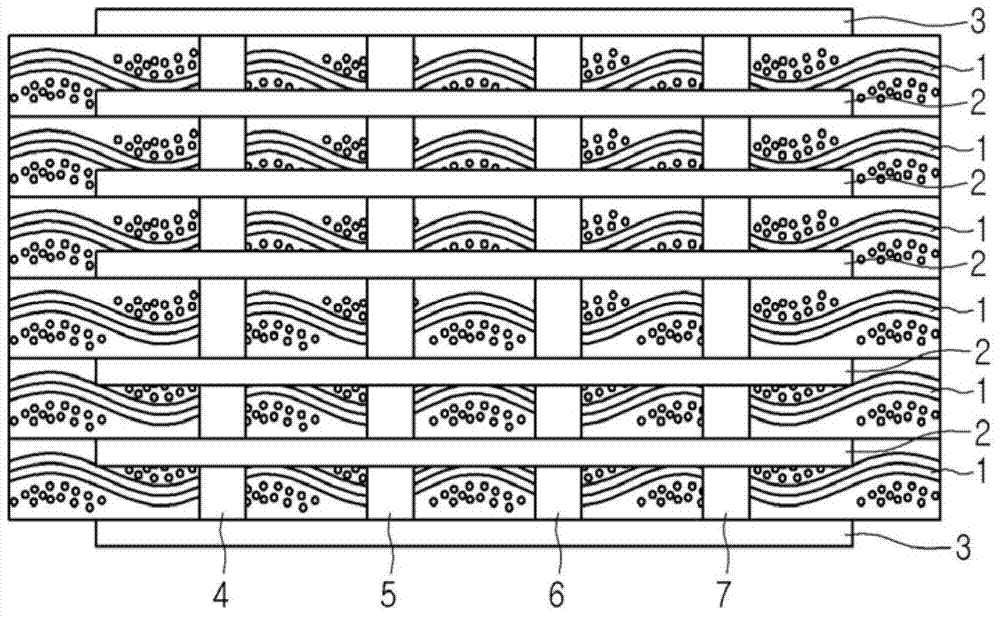

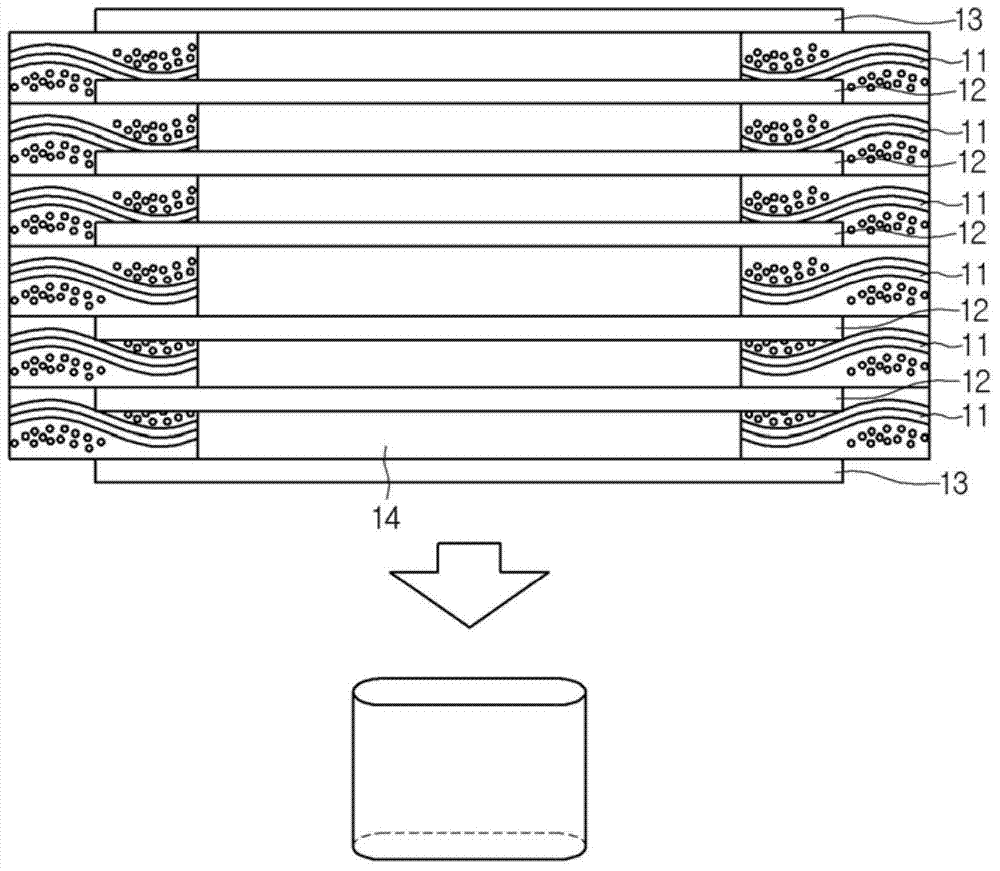

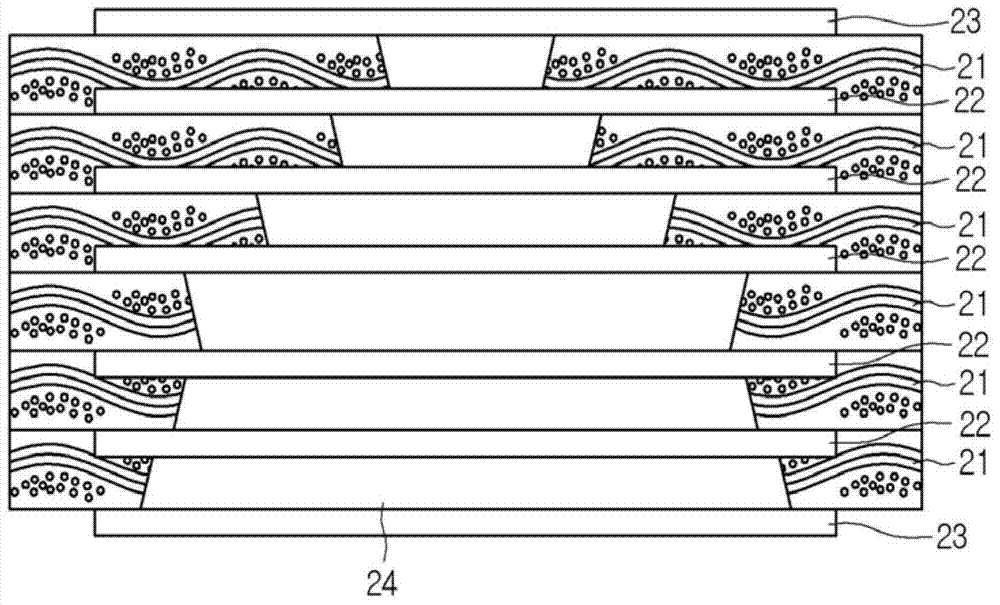

High-heat-conduction metal substrate resin glue filling method, vacuum press fit structure and metal substrate

InactiveCN105216400AEasy to separateAvoid complaintsElectrical equipmentCircuit susbtrate materialsEpoxyCopper foil

The invention discloses a high-heat-conduction metal substrate resin glue filing method, a vacuum press fit structure and a metal substrate, used for improving the production quality of a high-heat-conduction metal substrate. The method comprises the steps of cutting the high-heat-conduction metal substrate; drilling plugging resin holes in the high-heat-conduction metal substrate, hotly attaching high-heat-conduction films to the double surfaces of the high-heat-conduction metal substrate, and carrying out rolling attaching; cutting epoxy resin prepreg with the size same as that of the high-heat-conduction metal substrate; sequentially arranging kraft paper, a mirror surface steel plate, a release film, the high-heat-conduction metal substrate drilled with the plugging resin holes, the epoxy resin prepreg, a copper foil, a release film, a mirror surface steel plate and kraft paper on a bearing disc of a vacuum press from bottom to top in sequence; and after being covered by a cover plate, feeding the bearing disc to the vacuum press to be subjected to vacuum press fit, thus obtaining the high-heat-conduction metal substrate filled with resin.

Owner:HUIZHOU YUXINDA TECH CO LTD

Display device packaging method

ActiveCN110993830ASolve the problem of sagIncrease temperatureSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingDisplay device

The invention discloses a display device packaging method. The method comprises the following steps of coating the cover plate glass with a heating decomposable glue; carrying out screen printing on the frit glue, wherein the frit glue is positioned on the heating decomposable glue; and baking the heating decomposable glue and the frit glue. The decomposition temperature of the heating decomposable glue is different from the curing crystallization temperature of the frit glue, and the frit glue is still in a molten state at the decomposition temperature required for the heating decomposable glue, so that the height generated by the decomposed frit glue is poor. The frit glue in the molten state automatically flows to fill the position occupied by the original heating decomposable glue, sothat recesses generated during the screen printing of the frit glue are eliminated, and the frit glue is cured and crystallized along with the temperature rise, and accordingly the recesses generatedby the screen printing of the frit glue are eliminated, and the quality of a packaging process is improved.

Owner:FUJIAN HUAJIACAI CO LTD

Method for producing anhydrous citric acid crystals

ActiveCN103483184AReduce moisture contentAppearance rulesCarboxylic compound separation/purificationSlurryCitric acid

The invention discloses a method for producing anhydrous citric acid crystals. The method comprises the following steps: crystallizing a citric acid solution under the circulating stirring condition to obtain a crystal slurry solution; changing the initial temperature of the crystal slurry solution to repair crystals in the crystal slurry solution, and obtaining a solution containing the anhydrous citric acid crystals, wherein the process of changing the initial temperature of the crystal slurry solution comprises the following steps: (1) heating the crystal slurry solution to 2-20 DEG C after crystallization; (2) cooling the crystal slurry solution to 1-10 DEG C after crystallization; or (3) heating the crystal slurry solution to 2-20 DEG C at first after crystallization and then cooling the heated crystal slurry solution to 2-25 DEG C. Through the technical scheme, recesses in crystal surfaces can be effectively removed, and residues in mother liquid in the crystals are reduced, so that the content of water in the crystals is reduced; moreover, anhydrous citric acid molecules on the crystal surfaces are rearranged in a repair process, so that the quality is effectively improved and readily carbonizable substances are reduced.

Owner:COFCO BIOTECHNOLOGY CO LTD

Electron beam processing equipment precision acceleration power supply device and control method thereof

InactiveCN105141169AAvoid short passthroughFast adjustmentAc-ac conversionElectricityHigh voltage igbt

The present invention relates to an electron beam processing equipment precision acceleration power supply device and a control method thereof. The electron beam processing equipment precision acceleration power supply device comprises an incoming line filter, a low voltage rectification filtering unit, a DC-DC conversion unit, an inverter unit, a high voltage unit and a regulator, the input end of the incoming line filter is connected with an external power grid, and the output end of the incoming line filter, the low voltage rectification filtering unit, the DC-DC conversion unit, the inverter unit and the input end of the high voltage unit are connected in series orderly, and the high voltage output end of the high voltage unit outputs a high voltage and is electrically connected with the cathode of an electronic gun. A high voltage feedback signal U outputted by the signal end of the high voltage unit is sent to the second input end of the regulator, the first input end of the regulator inputs a high voltage given signal U*, and the output end of the regulator is connected with the signal end of the DC-DC conversion unit. Relative to the prior art, the electron beam processing equipment precision acceleration power supply device and the control method thereof of the present invention utilize a synchronous Buck circuit to regulate the voltage, thereby solving the problem that a light load current generates a peak pulse voltage interruptedly.

Owner:GUILIN THD TECH CO LTD

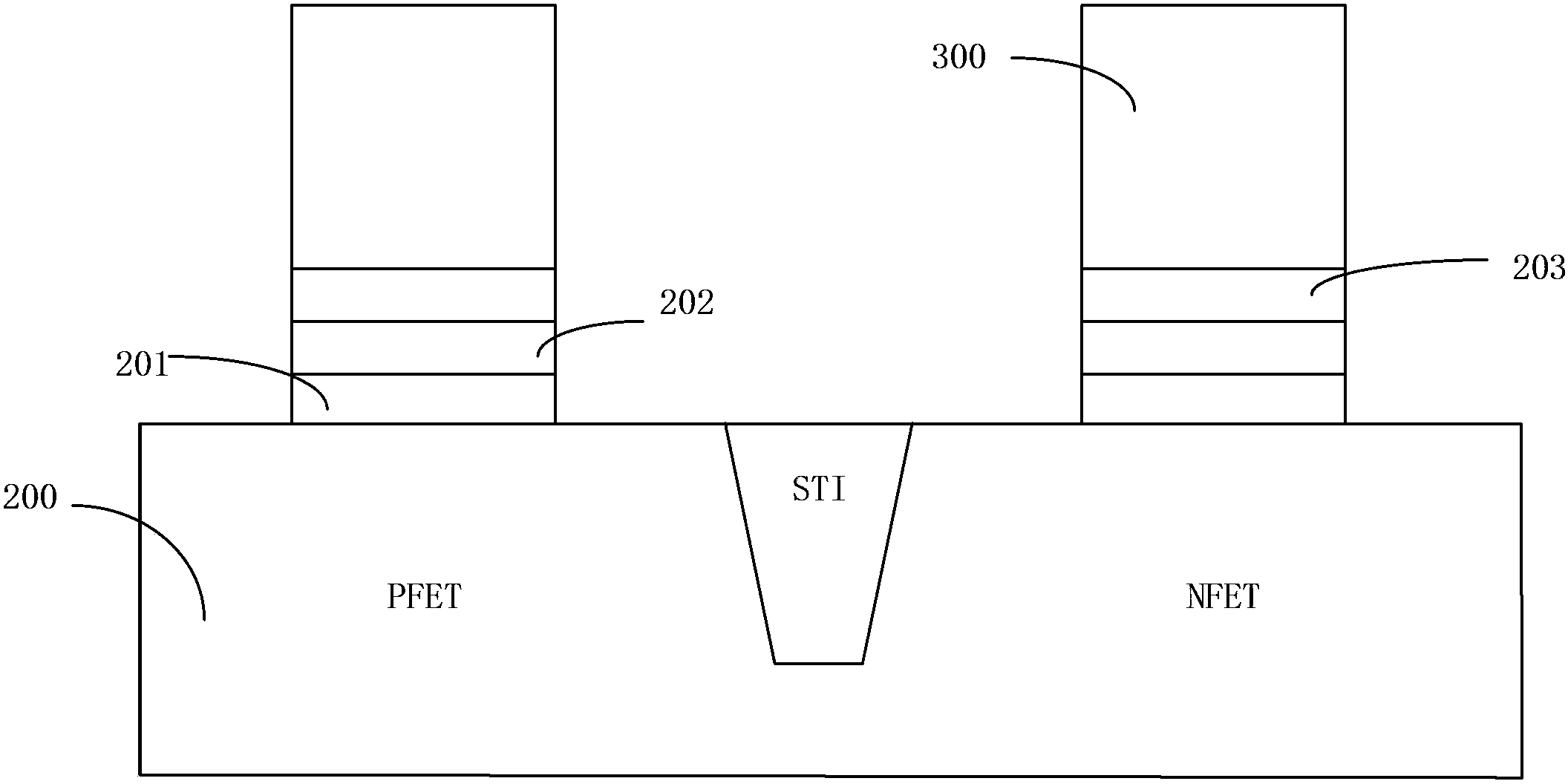

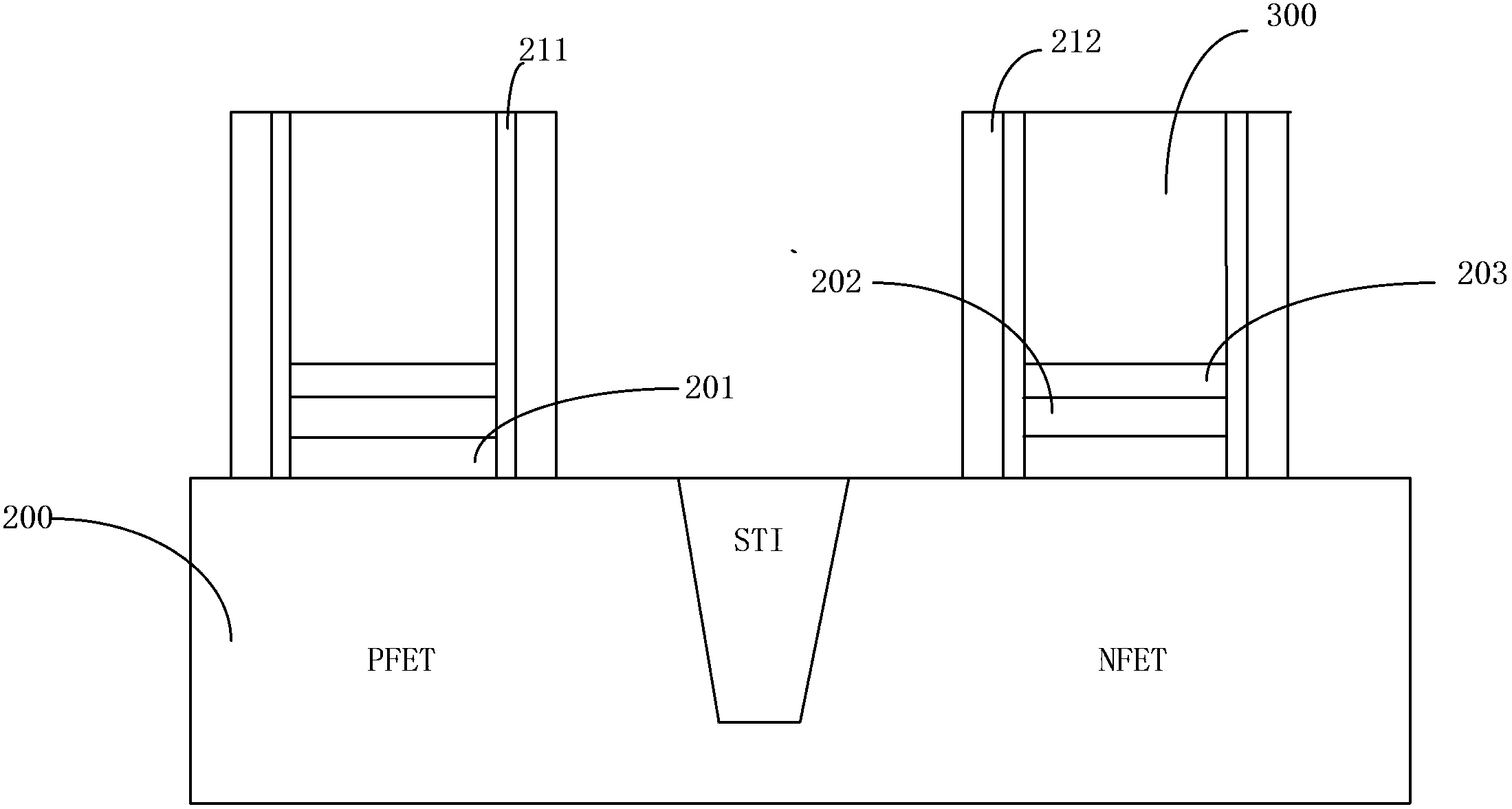

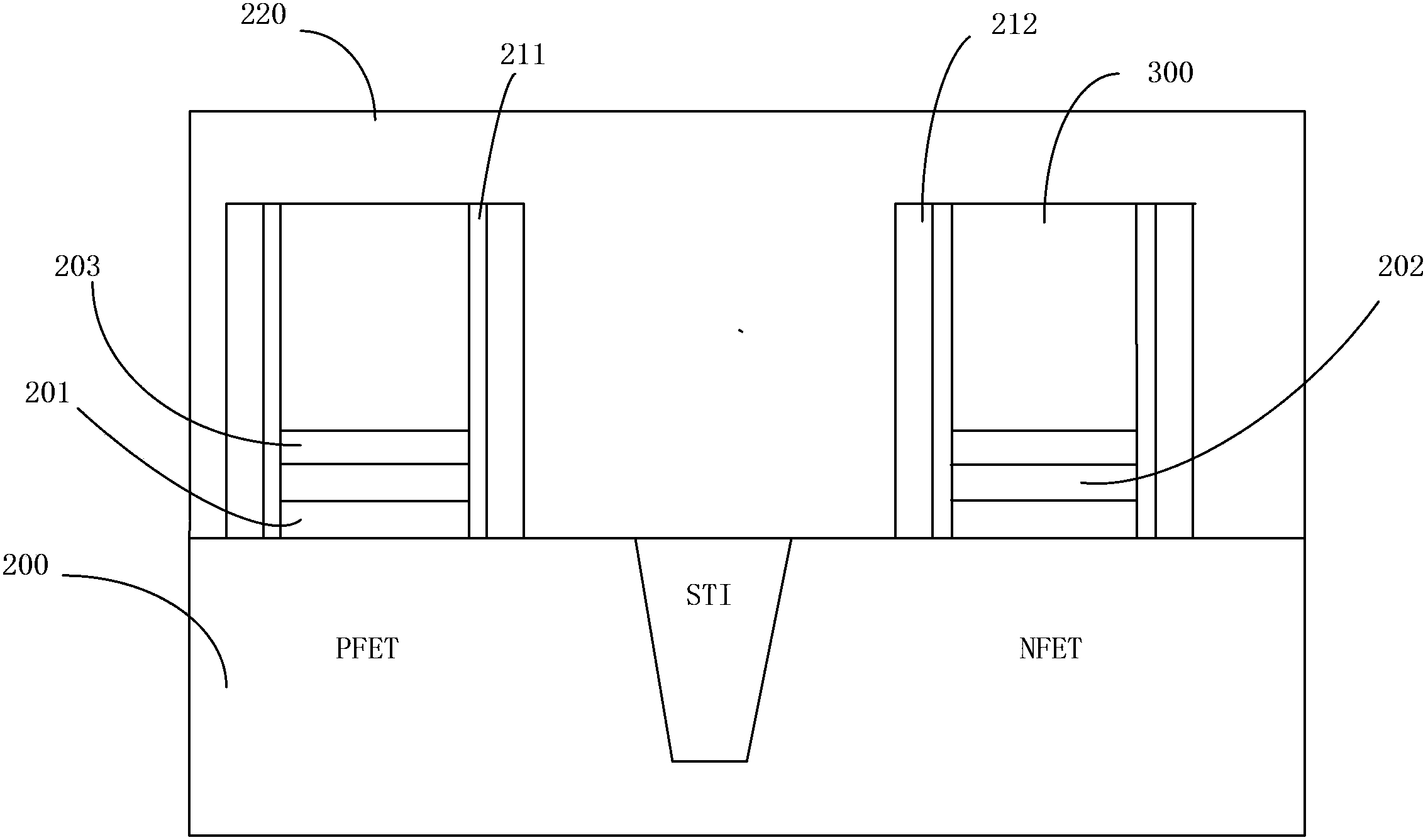

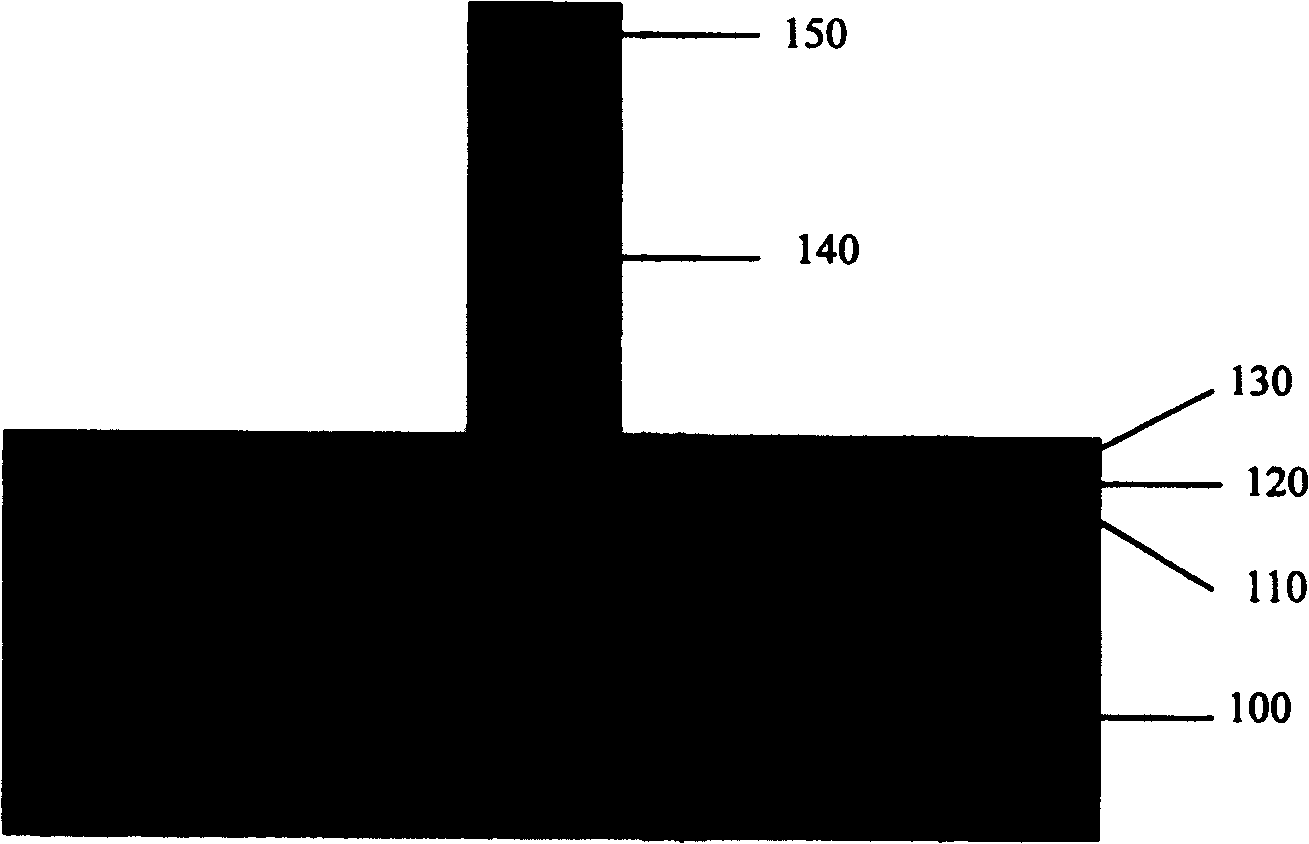

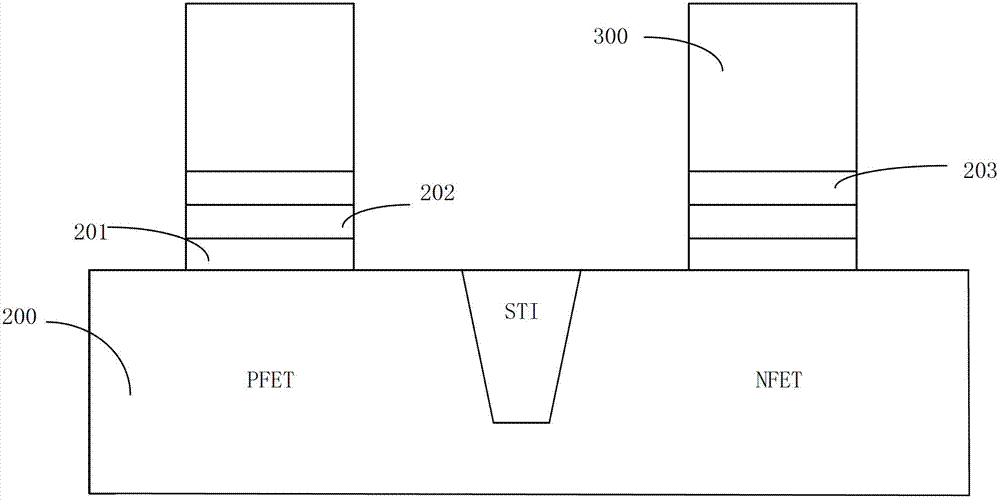

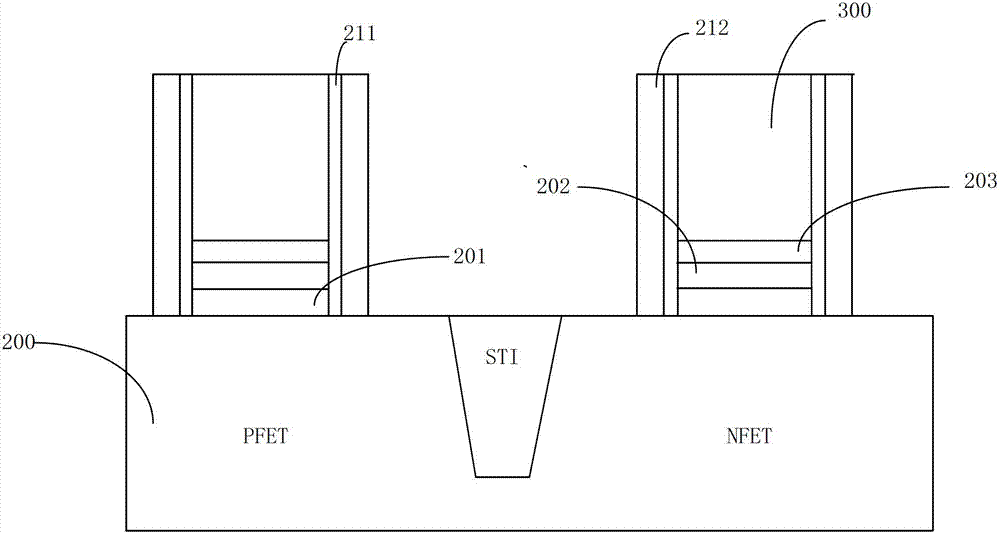

Method for using dummy grids to manufacture semiconductor device

ActiveCN103545181ASimple processImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceEtching

The invention provides a method for using dummy grids to manufacture a semiconductor device. The method includes: providing a semiconductor substrate containing a first area and a second area; forming the first dummy grid on the first area of the substrate, and forming the second dummy grid on the second area of the substrate, wherein each of the first dummy grid and the second dummy grid comprises a grid dielectric layer, a covering layer, a grid barrier layer and a grid electrode layer which are sequentially stacked; forming a source drain in the substrate; using wet etching to remove the grid electrode layer of the first dummy grid to form a channel; filling the channel to form a metal grid. By the method, recess, caused by steps such as etching during the dummy grid replacement process, of the surface of the inter layer dielectric (ILD) layer can be eliminated, wider operation range can be achieved, and accordingly device performance and the semiconductor device process are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Curing furnace integrating drying and painting make-up functions

InactiveCN107952640AImprove curing efficiencyTo achieve the curing effectPretreated surfacesCoatingsLacquerUltraviolet

The invention discloses a curing furnace integrating the functions of drying and paint repairing. It comprises a furnace body, a motor is fixedly installed on one side of the furnace body, and a first conveyor belt is connected to the output end of the motor. The side is connected with one side of the fixed pulley, and the fixed pulley is connected with the second transmission belt, and one side of the second transmission belt is connected with the belt winding wheel. In the present invention, by setting a slide bar, a paint repair box and a paint spraying head, the painted product is sent into the furnace body from the second conveyor belt on the left side of the furnace body, and then the paint on its surface is treated by the ultraviolet irradiation lamp on the left side of the furnace body. Curing, the product after the first curing continues to move, and the product is repainted through the paint spraying head to fill the tiny depressions that will appear after the paint on the product surface is heated. The product that has been repainted continues to move and passes through the furnace on the right side Ultraviolet irradiation lamps perform secondary curing for the product, which not only achieves the curing effect but also eliminates the depression on the product surface.

Owner:杨明桂

Injection molding process for multi-air-channel auxiliary plastic mold

The invention discloses a multi-air channel auxiliary plastic mold injection molding process, comprising the following steps: step (1) plastic mold design; step (2) mold precooling stage; step (3) melt injection stage; step (4) multiple Airway gas injection control stage; step (5) partial nitrogen filling stage; step (6) gas injection end stage; step (7) gas withdrawal stage. The invention eliminates the internal stress existing in the injection molded parts, so that the quality of the injection molded parts is high, and the production efficiency and yield of the mold are greatly improved.

Owner:滁州市博康模具塑料有限公司

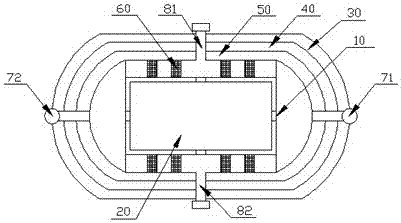

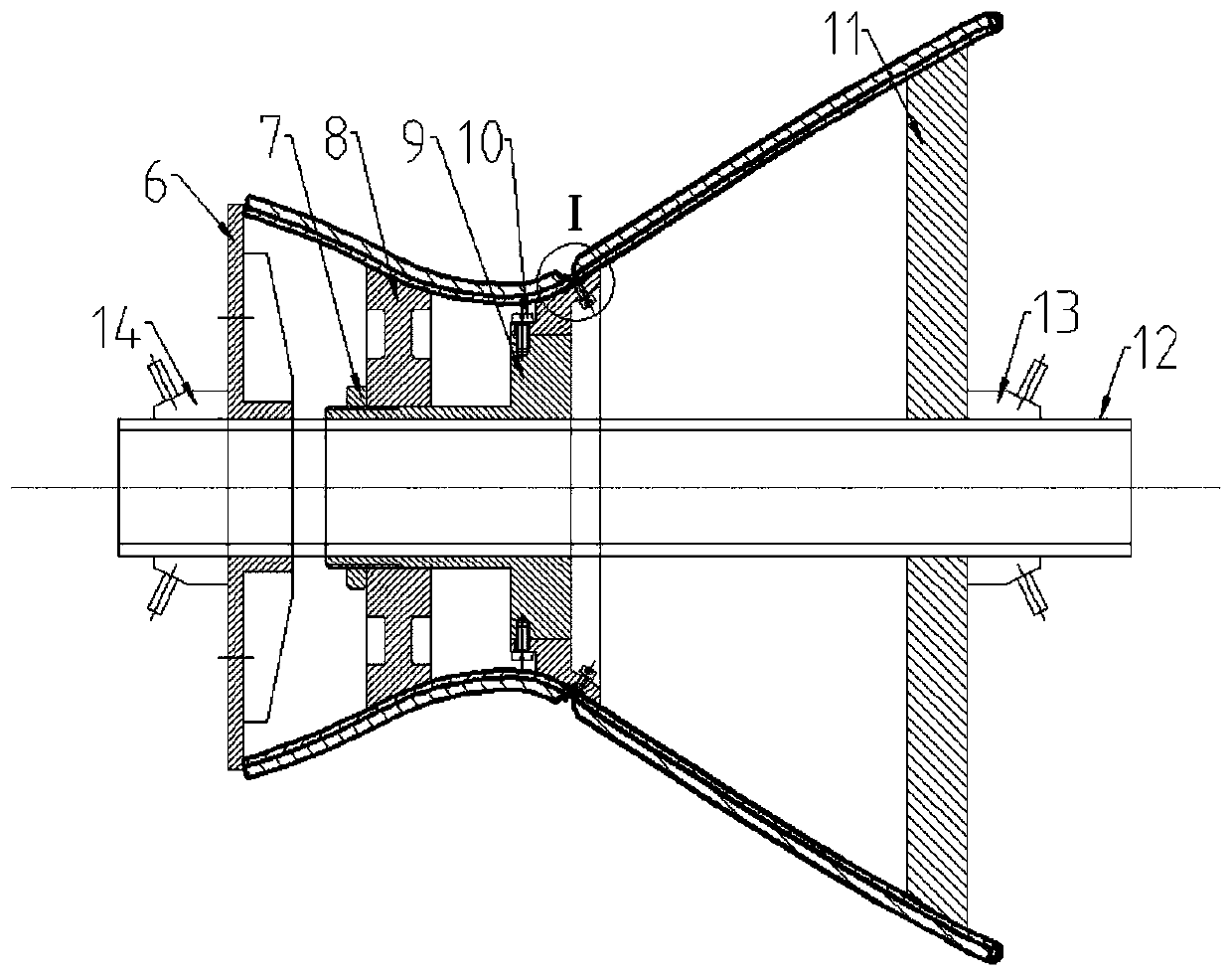

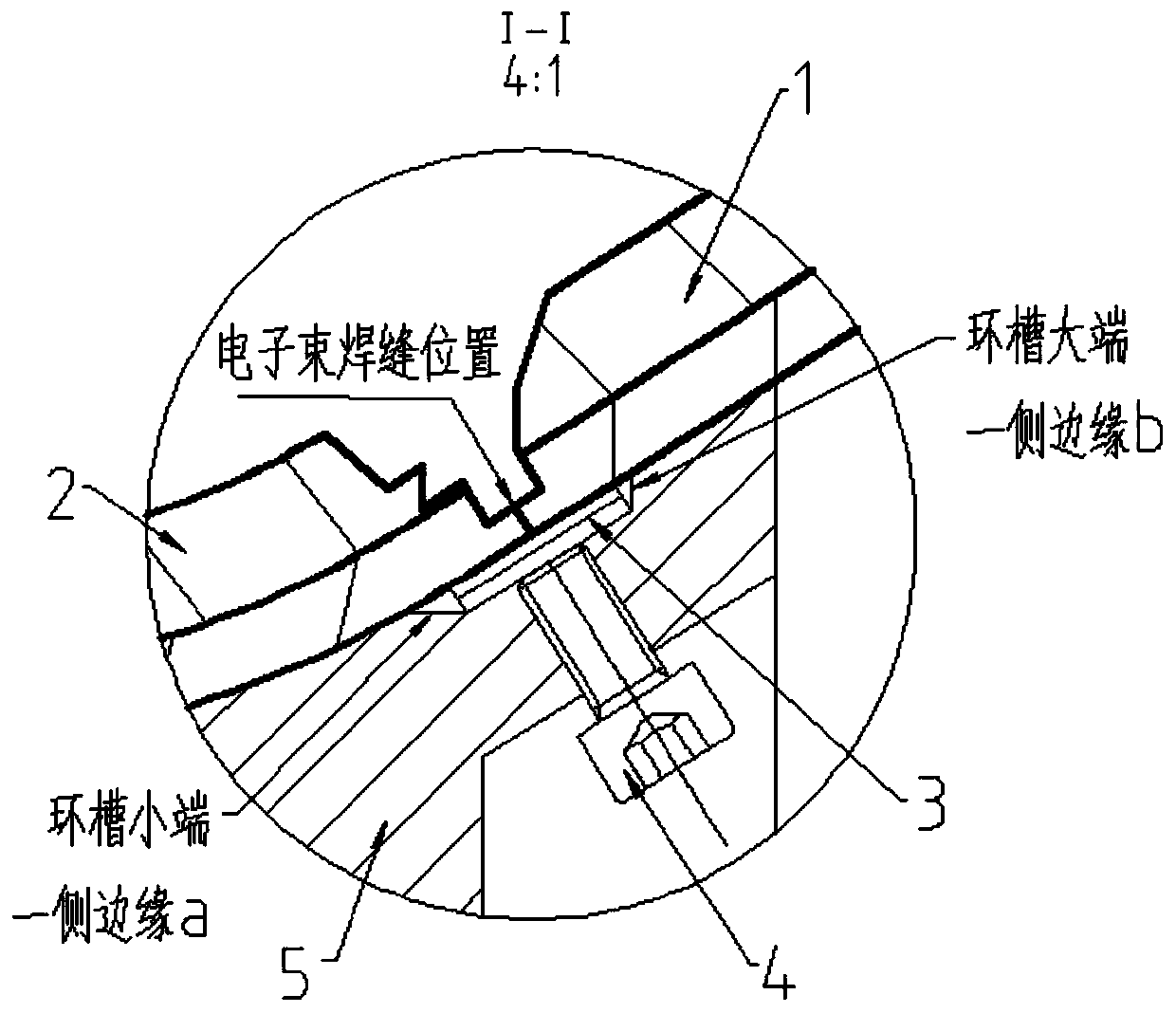

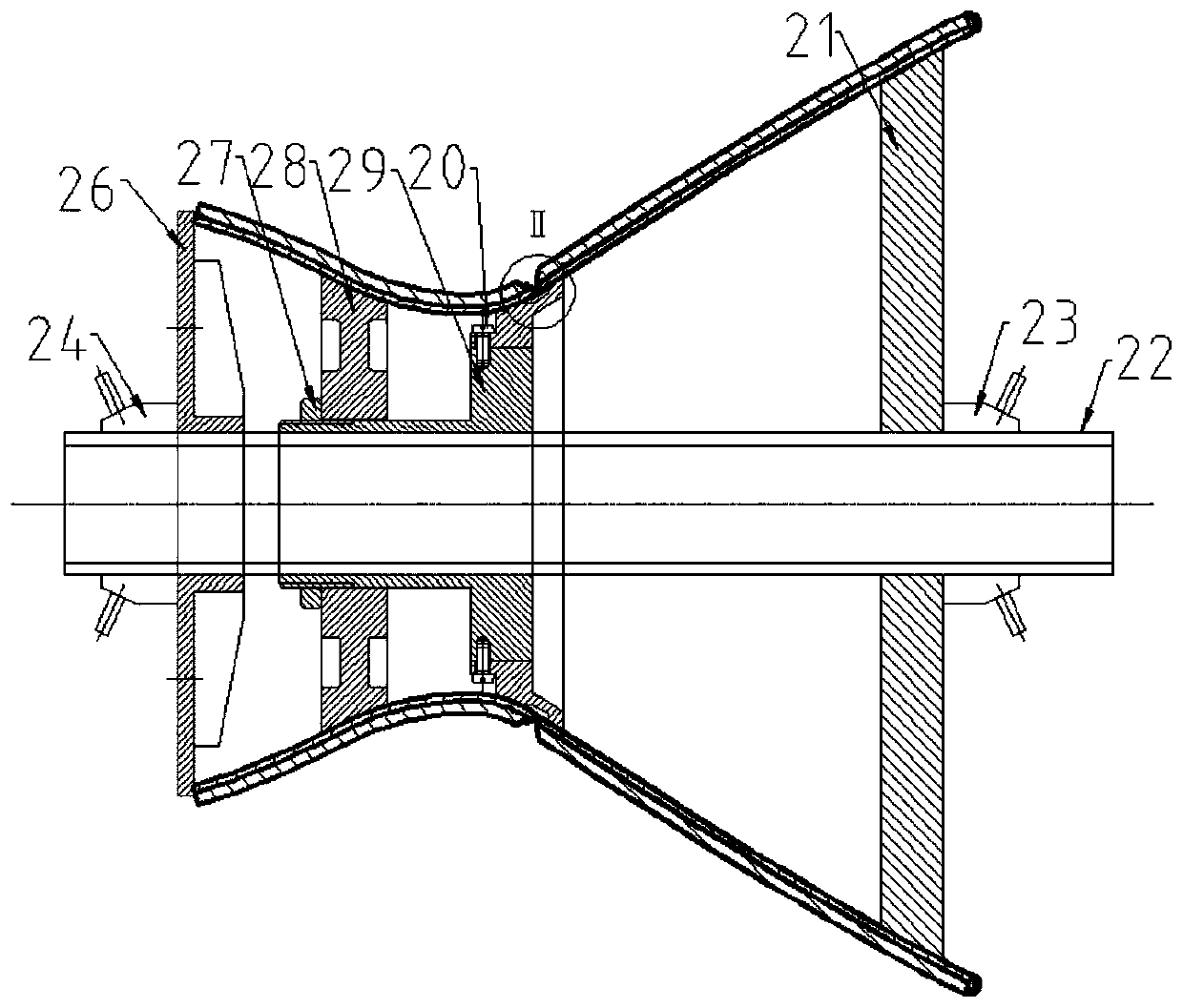

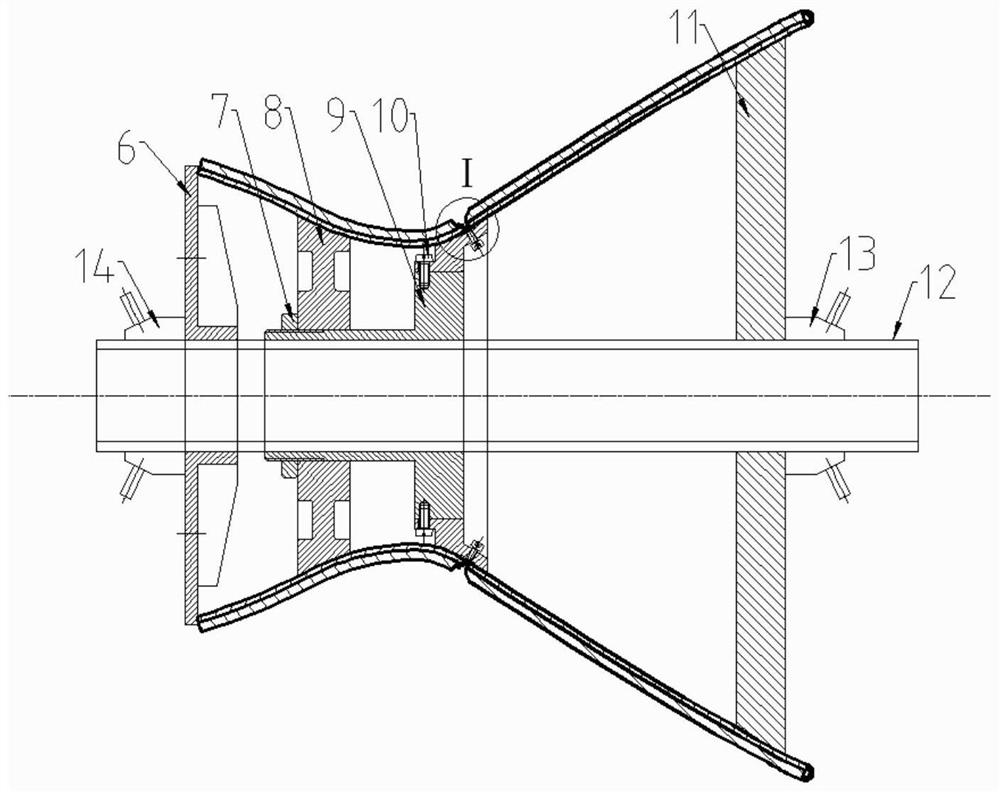

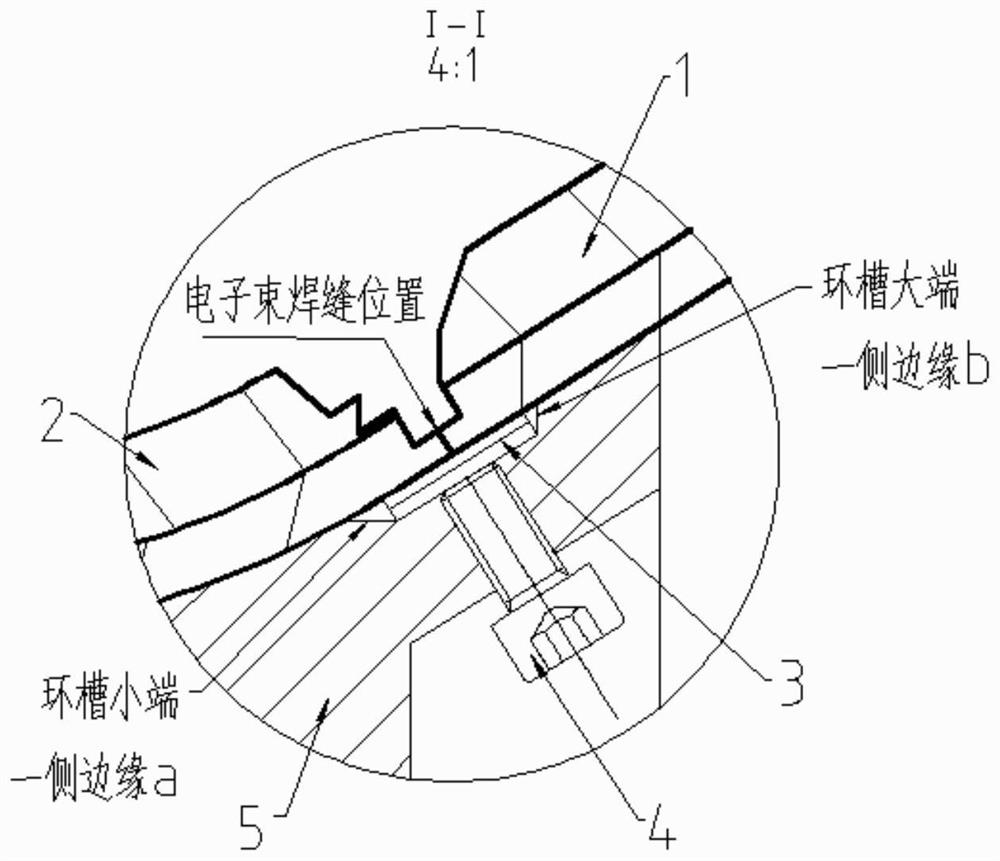

Vacuum electron beam welding method for chromium bronze butt joint of annular workpiece of sandwich structure

ActiveCN111037082AIncreased effective thickness and load carrying capacityReduce porosityWelding/cutting auxillary devicesAuxillary welding devicesVacuum electronicsWeld bead

The invention provides a vacuum electron beam welding method for a chromium bronze butt joint of an annular workpiece of a sandwich structure. The vacuum electron beam welding method comprises the following steps of clamping the workpiece by adopting a first clamping tool; enabling a copper base plate to be tightly attached to the back surface of a weld joint of the workpiece; after electron beamsegmented positioning welding is carried out, disassembling the workpiece and the first clamping tool, correcting the copper base plate on the back surface of the weld joint, and enabling the back surface of the weld joint to be tightly attached to the copper base plate; and clamping the workpiece by using a second clamping tool for formal welding, allowing the chromium bronze butt joint weld joint of the workpiece and the copper base plate to be completely welded by the second clamping tool, and removing the copper base plate on the back surface of the weld joint of the workpiece by adoptinga manual grinding mode after welding. According to the vacuum electron beam welding method, the problem that the back surface of the chromium bronze electron beam weld joint is prone to generating pits is solved, meanwhile, the probability that air holes appear in the chromium bronze electron beam weld joint is obviously reduced, so that the first-pass yield of X-ray inspection of the workpiece isremarkably improved, the number of times of repair welding of the workpiece is reduced, and the production cost is reduced.

Owner:XIAN SPACE ENGINE CO LTD

A method for producing low-alloy peritectic steel by conventional slab continuous casting machine

ActiveCN106011639BEliminate cracksEliminate dentsManufacturing convertersProcess efficiency improvementAlloyDecarburization

The invention discloses a method for producing low-alloy peritectic steel by a conventional slab continuous casting machine. The method comprises the technological processes of decarburization converter smelting, LF refining and slab continuous casting. Through the adjustment on the continuous casting procedures of the conventional slab continuous casting machine, the phenomenon of large liquid level fluctuation during peritectic steel pouring is eliminated, the shock mark depth of a casting blank is obviously reduced, cracks and concave parts in the surface of the casting blank are eliminated, the conventional slab continuous casting machine can produce flawless low-alloy peritectic steel in batches, and high-quality raw materials are provided for low-alloy high-strength steel stable in production performance.

Owner:TANGSHAN IRON & STEEL GROUP

A backfilling friction stir spot welding method

ActiveCN106862749BEliminate dentsSpeed up the flowNon-electric welding apparatusEngineeringUltrasonic vibration

The invention discloses a refill friction stir spot welding method which is characterized in that a circular convex block is arranged at a welding spot of an upper plate of a workpiece; during welding, a hold-down ring of a stirring head is contacted with the upper plate and surrounds the convex block, and a stirring needle and a sleeve are contacted with the convex block; with the application of ultrasonic vibration to positions, on the outer side of the hold-down ring, of the upper plate, a material in a welding zone is plastified through the rotation of the sleeve and the stirring needle, then the sleeve pricks downwards to penetrate through the upper plate and pricks into a lower plate by a certain depth, the stirring needle is drawn back with the downward pricking of the stirring needle, after the sleeve reaches the designed downward pricking depth, the sleeve and the stirring needle return to initial positions, and continue to rotate and press down in the initial positions to allow the surface of the welding spot to be smooth, and after the stirring head stops rotating, an operator continues to apply the ultrasonic vibration for a certain time. According to the refill friction stir spot welding method, by employing the convex block for compensation, a pit of the welding spot produced after the welding can be eliminated; through the ultrasonic vibration, material flowing and material exchange between the upper plate and the lower plate can be improved, and the joint quality is improved; and the operator continues to apply the ultrasonic vibration after the welding, so that the residual stress of the welding spot can be reduced.

Owner:SHENYANG AEROSPACE UNIVERSITY

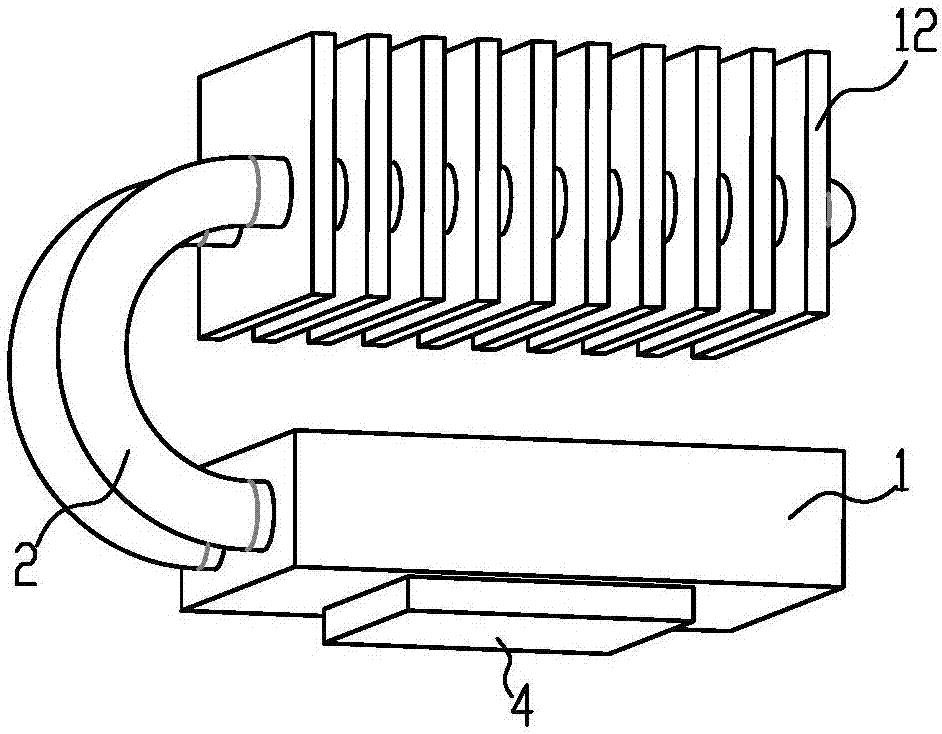

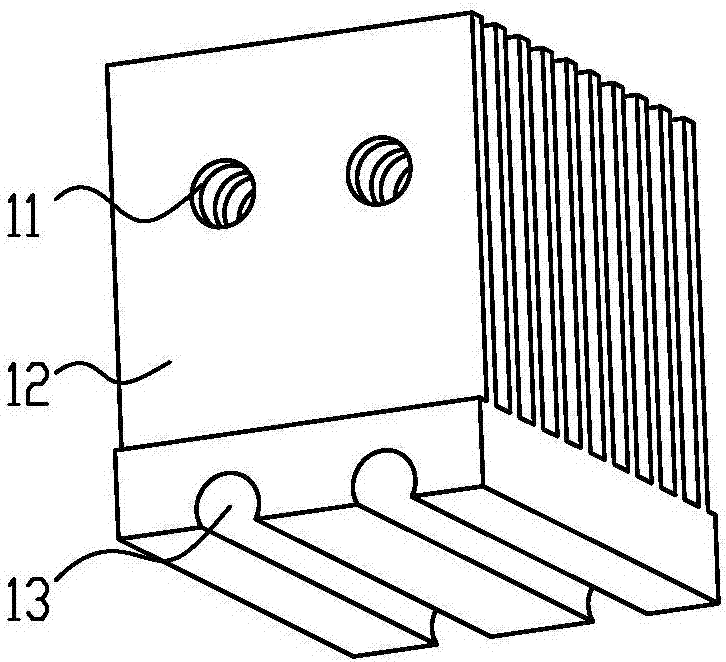

Cooling device with embedded hot pipe and manufacturing method of cooling device

PendingCN107968078AReduce thermal resistanceIncreased conduction pathwaySemiconductor/solid-state device detailsSolid-state devicesHeat sinkEngineering

The invention relates to a cooling device with an embedded hot pipe. The cooling device comprises a heat sink and a hot pipe, wherein a groove is formed in a bottom surface of the heat sink, an opening direction of the groove faces a surface, connected with a heat generation chip, of the heat sink, one end of the hot pipe is arranged in the groove, a part of a surface of the hot pipe is exposed out of the groove and can be in contact with the heat generation chip, and the hot pipe exposed out of the groove is flush with a bottom surface of the heat sink. In the device, the hot pipe is in direct with the heat generation chip; and compared with an existing hot pipe inserted into the heat sink, the heat resistance between the heat generation chip and the hot pipe can be effectively reduced. The fabrication method comprises the steps of a) sintering and annealing the hot pipe to obtain a soft hot pipe; and b) forming the groove in the bottom surface of the heat sink, coating heat conduction paste in the groove, placing one end of the hot pipe in the grove, and allowing the other end of the hot pipe to penetrate through a plurality of through holes in fins and be closely matched with the through holes. According to the manufacturing method of the device, the cooling device of which the heat generation chip is in direct contact with the hot pipe can be obtained, the sunken problem generated when the hot pipe is pressed is eliminated, and meanwhile, the pressed hot pipe is more closely contacted with the groove.

Owner:SOUTH CHINA UNIV OF TECH +1

Printed circuit board and method of manufacturing the same

ActiveCN104853518AShorten the timeReduce manufacturing costPrinted circuit aspectsElectrical connection printed elementsEngineeringPrinted circuit board

A printed circuit board according to the embodiment includes an insulating layer; a first pad on a top surface of the insulating layer; a second pad on a bottom surface of the insulating layer; and a via formed in the insulating layer and having one surface connected to the first pad and an opposite surface connected to the second pad, wherein the via includes a plurality of via parts which are at least partially overlapped with each other.

Owner:LG INNOTEK CO LTD

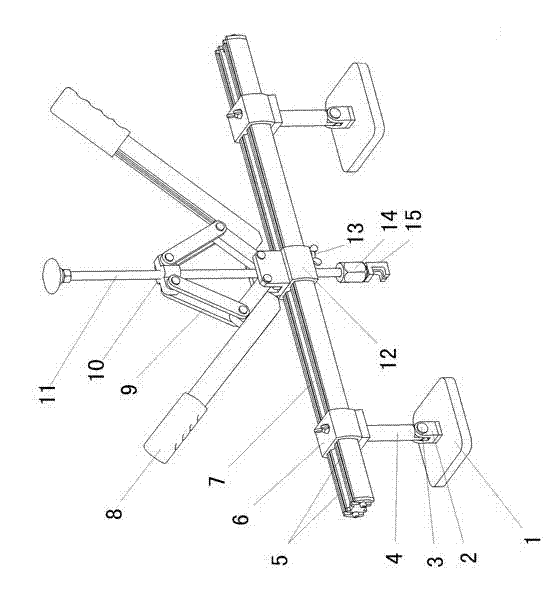

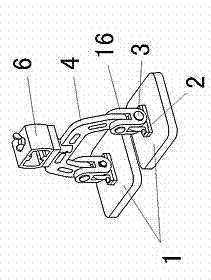

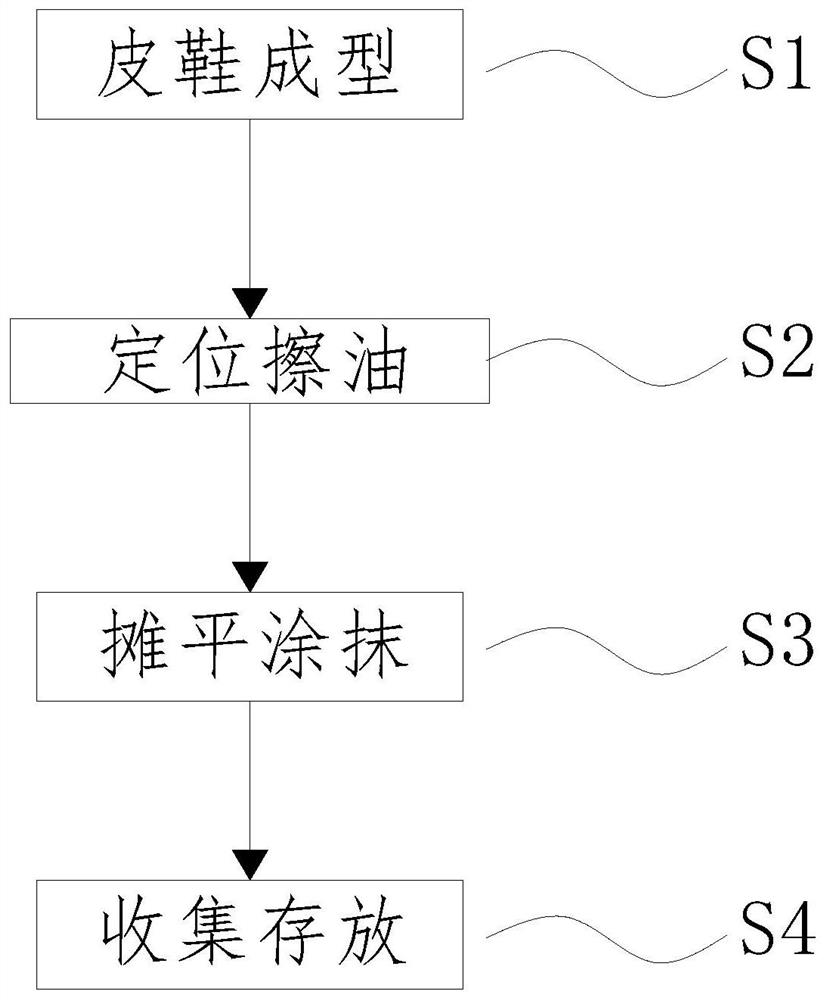

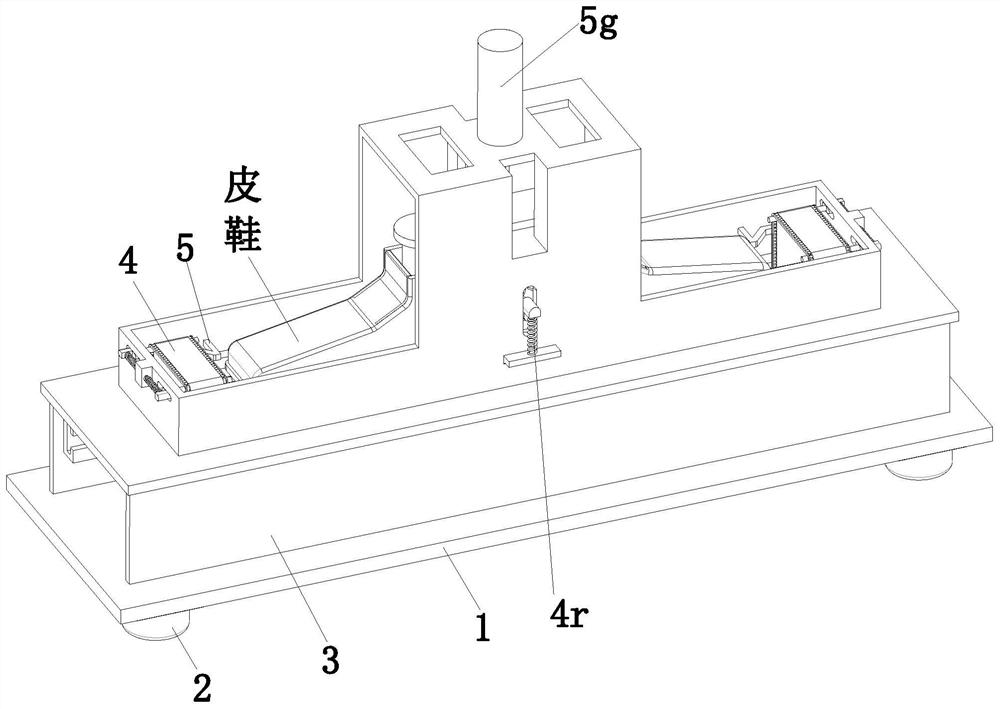

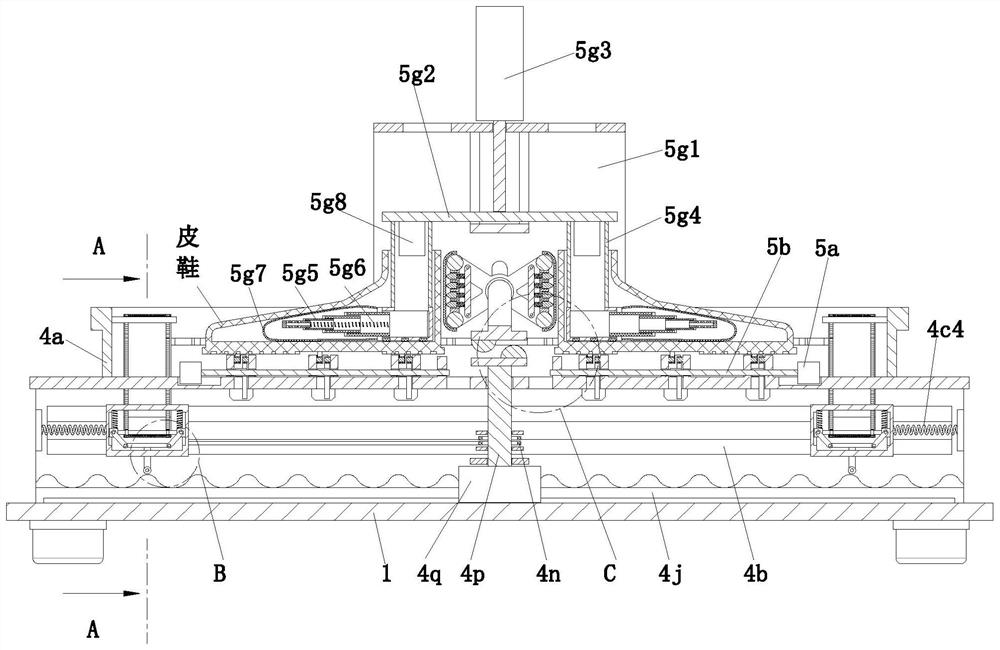

Leather shoe manufacturing process

The invention relates to a leather shoe manufacturing process, a leather shoe manufacturing device is used, the leather shoe manufacturing device comprises a mounting bottom plate, supporting legs, a supporting U-shaped frame, a smearing mechanism and a positioning mechanism, and the leather shoe manufacturing process can solve the problem that in the leather shoe manufacturing process, leather shoes are often held by hands, then oil applying and polishing operation is conducted, the working mode of leather shoe oiling and polishing operation is low in efficiency, when the leather shoe oiling and polishing operation is manually carried out, wrinkles and pits are likely to be generated on the surface of the leather shoe, uniform smearing of leather shoe oil and the overall attractiveness of the leather shoe are not facilitated, and the leather shoe oil is difficult to evenly smear on the cambered surfaces of different areas of the leather shoe; and the shoe heel part is difficult to polish when the shoe upper of the leather shoe is polished, the leather shoe needs to be polished for many times, and the working efficiency of the leather shoe polishing operation is reduced.

Owner:武汉楚韵华章商贸发展有限公司

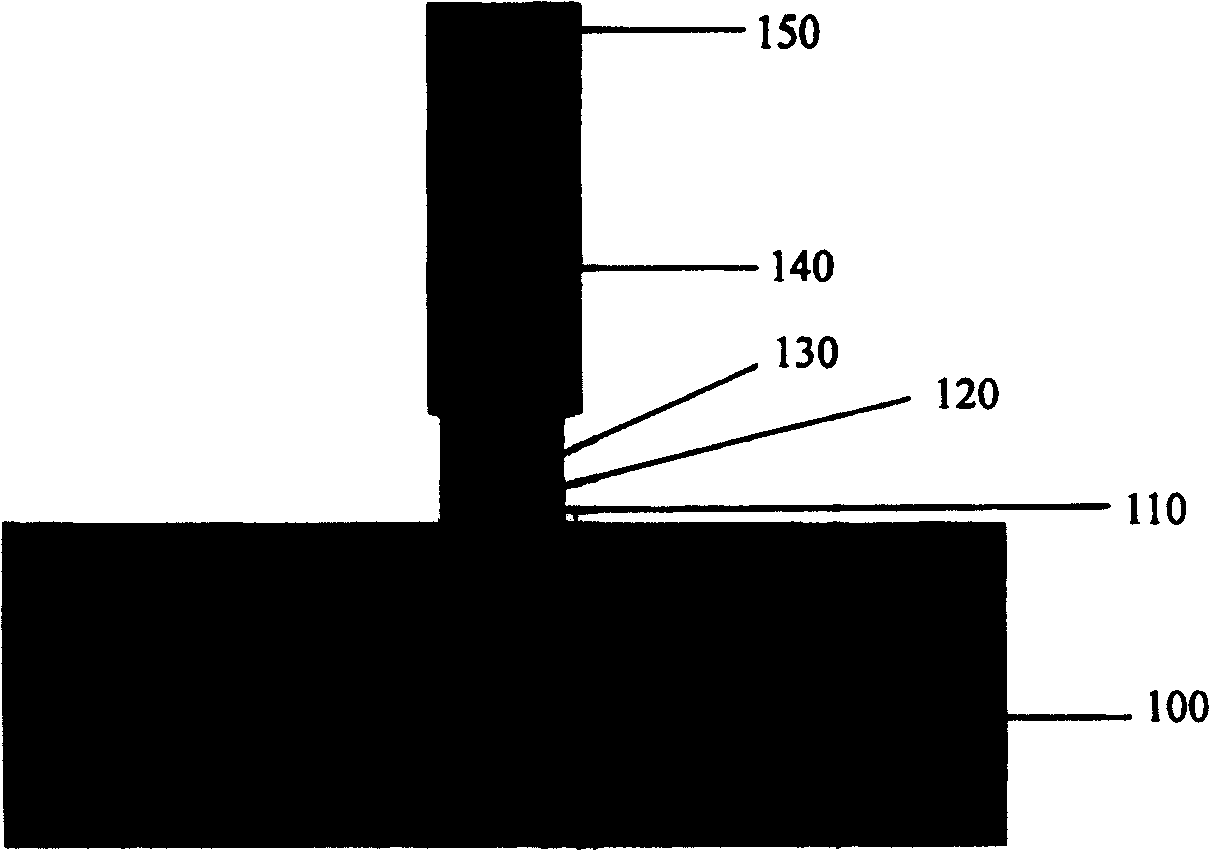

Method for producing semiconductor device

InactiveCN100428416CEliminate dentsSimplify the etch processSemiconductor/solid-state device manufacturingSemiconductor devicesPolysilicon gateSemiconductor

When etching ONO laminated construction of SONOS parts, the method uses mixed gas of carbon tetrafluoride (CF4) and fluoroform (CHF3) as main etching gas instead of mixed gas of HBr and C2F6, and uses CHF3 as over etching gas instead of mixed gas of CH2F2 / SF6. Using mixed gas of CF4 and CHF3 accomplishes main etching and over etching step for one time so as to simplify etching technique. Based on good etching selectivity and suitable etching speed, the method controls and buffers effect for etching ONO laminated construction by plasma of etching gas. In procedure for etching wafer thin oxidizing layer of grid electrode, the method is capable of controlling etching depth accurately, stopping etching at oxidation surface at low layer of ONO. Moreover, the method eliminates concave phenomena at sidewall and root part of polysilicon gate caused by transversal etching.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A method of manufacturing a semiconductor device using a dummy gate

ActiveCN103545181BSimple processImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesPower semiconductor deviceEtching

The invention provides a method for using dummy grids to manufacture a semiconductor device. The method includes: providing a semiconductor substrate containing a first area and a second area; forming the first dummy grid on the first area of the substrate, and forming the second dummy grid on the second area of the substrate, wherein each of the first dummy grid and the second dummy grid comprises a grid dielectric layer, a covering layer, a grid barrier layer and a grid electrode layer which are sequentially stacked; forming a source drain in the substrate; using wet etching to remove the grid electrode layer of the first dummy grid to form a channel; filling the channel to form a metal grid. By the method, recess, caused by steps such as etching during the dummy grid replacement process, of the surface of the inter layer dielectric (ILD) layer can be eliminated, wider operation range can be achieved, and accordingly device performance and the semiconductor device process are improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

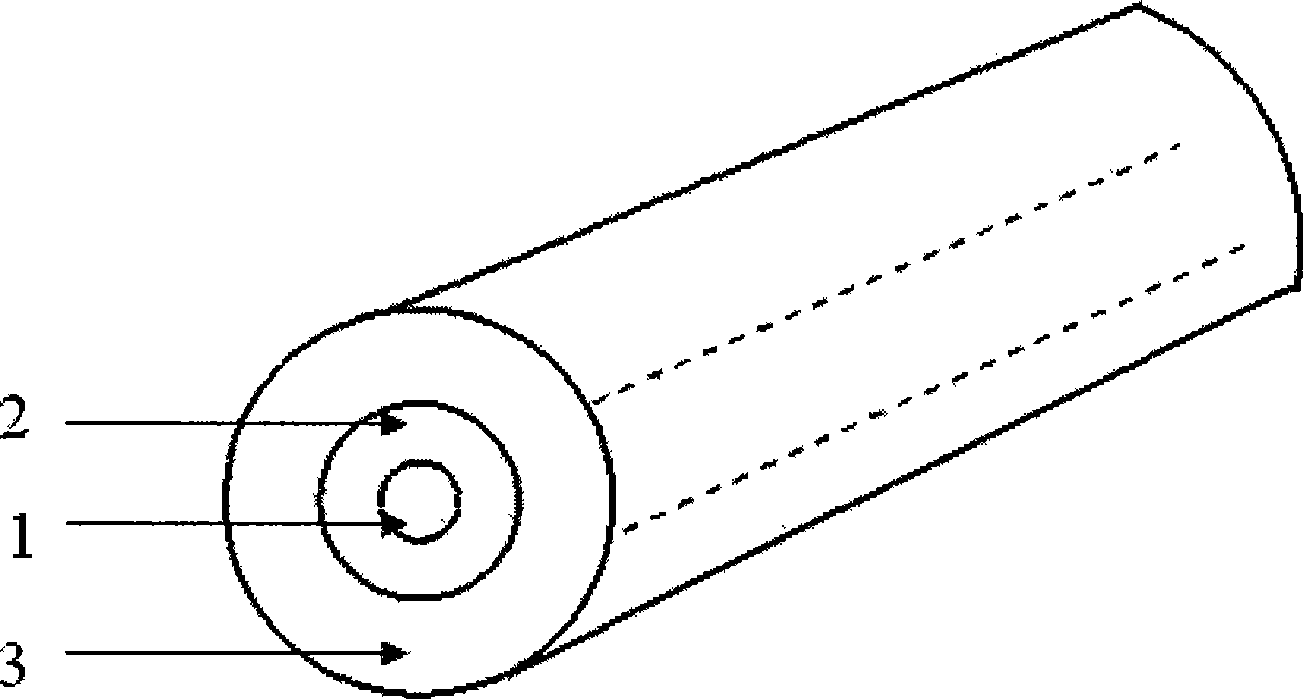

Method for making bend-insensitive multimode optical fiber

ActiveCN103513327BImprove bending resistanceImprove conduction abilityGlass making apparatusOptical fibre with multilayer core/claddingFiberLight guide

The invention discloses a bent and insensitive multimode optical fiber. A light guiding interface layer is arranged between a core rod and an outer wrapping layer, a conduit interface layer is formed by a fluoride-doped inner wrapping layer tube arranged on the core rod in a sleeved mode, and the outer wrapping layer wraps the fluoride-doped inner wrapping layer tube. The manufacturing method includes the first step of manufacturing the core rod, the second step of manufacturing the fluoride-doped inner wrapping layer tube, the third step of manufacturing the outer wrapping layer, enabling a silica dioxide porous body to be deposited outside a fluoride-doped transparent silicon dioxide glass tube, and obtaining the outer wrapping layer wrapping a fluoride-doped inner wrapping layer, the fourth step of manufacturing an integral fiber rod, heating a pipe body which is subjected to the third step, inserting the core rod which is manufactured in the first step into the pipe body, and sintering the core rod and the pipe body into a whole to form the integral fiber rod, and the fifth step of carrying out optical fiber drawing. Through the method, the conductivity of an original high-order guided mode in an optical fiber core is enhanced greatly and the bending resistance of the optical fiber is improved effectively; the manufacturing method can be used for accurately controlling the refractive index distribution of the optical fiber, eliminating center sag and improving the properties of the optical fiber.

Owner:JIANGSU NANFANG COMM TECH

Riding type two-wheel motorcycle

The invention discloses a bestriding type of dual-wheel motorcycle. The frame of the motorcycle consists of two parallel upper longitudinal beams and two parallel lower transverse bent beams, which are connected to the main tube of the motorcycle head. The rear end of the frame is ream jointed to one flat triangle fork through the flat folk spindle. The upper longitudinal beams have a rear section which gradually declined downward for the purpose of reducing the height of the motorcycle seat. The upper inclined forked tube of the flat triangle fork extends itself along the extending line of the rear section of the upper longitudinal beam. The rear shock absorber, which is horizontally mounted, is parallel with the rear section of the upper longitudinal beam and is located below the seat. The front end and the rear end of the rear shock absorber are beam jointed with the upper longitudinal beam and the flat triangle fork respectively. An air filter is available near the point where the upper longitudinal beam, the lower bent beam connected with the main tube of the motorcycle head. Below this point and on the lower bent beam, a water cooler is equipped. A water-cooling motor is mounted on the suspending device equipped on the frame. The front pedals are mounted on the front turning points, which are near the lower end of the lower bent beam. The two pedals extrude out of the frame on both the right side and left side. These pedals can reduce the height of the seat and improve the shock-absorbing effect and comfort in driving.

Owner:CHONGQING ZONGSHEN INNOVATION TECH RES INST CO LTD

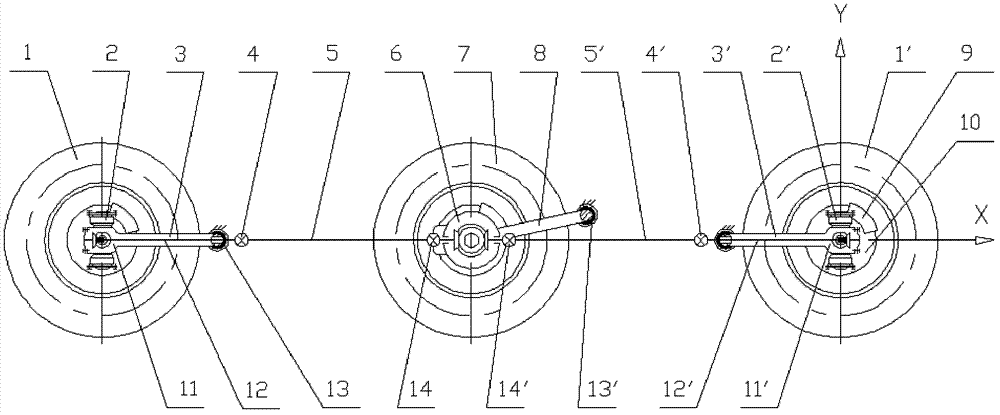

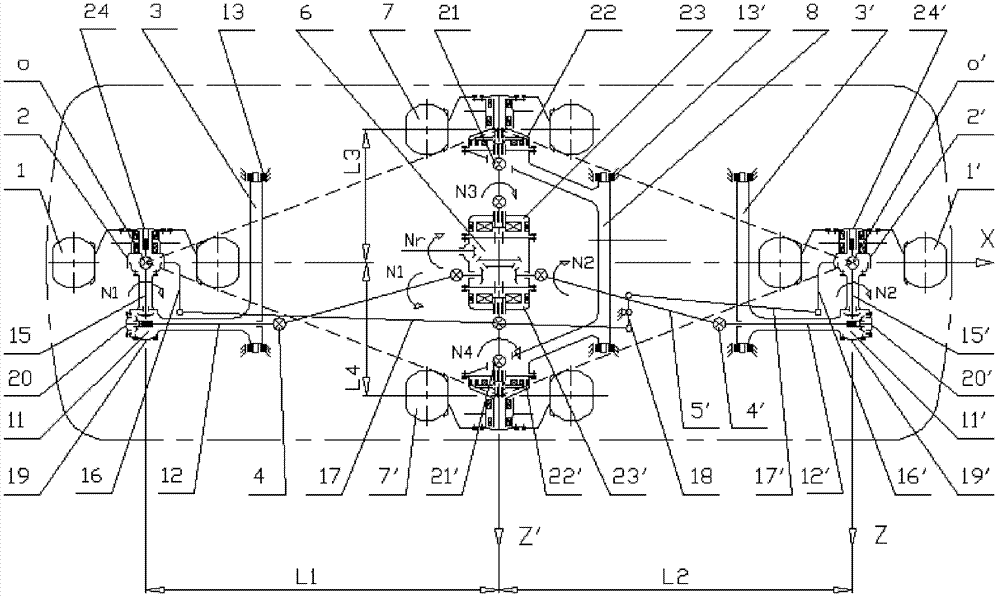

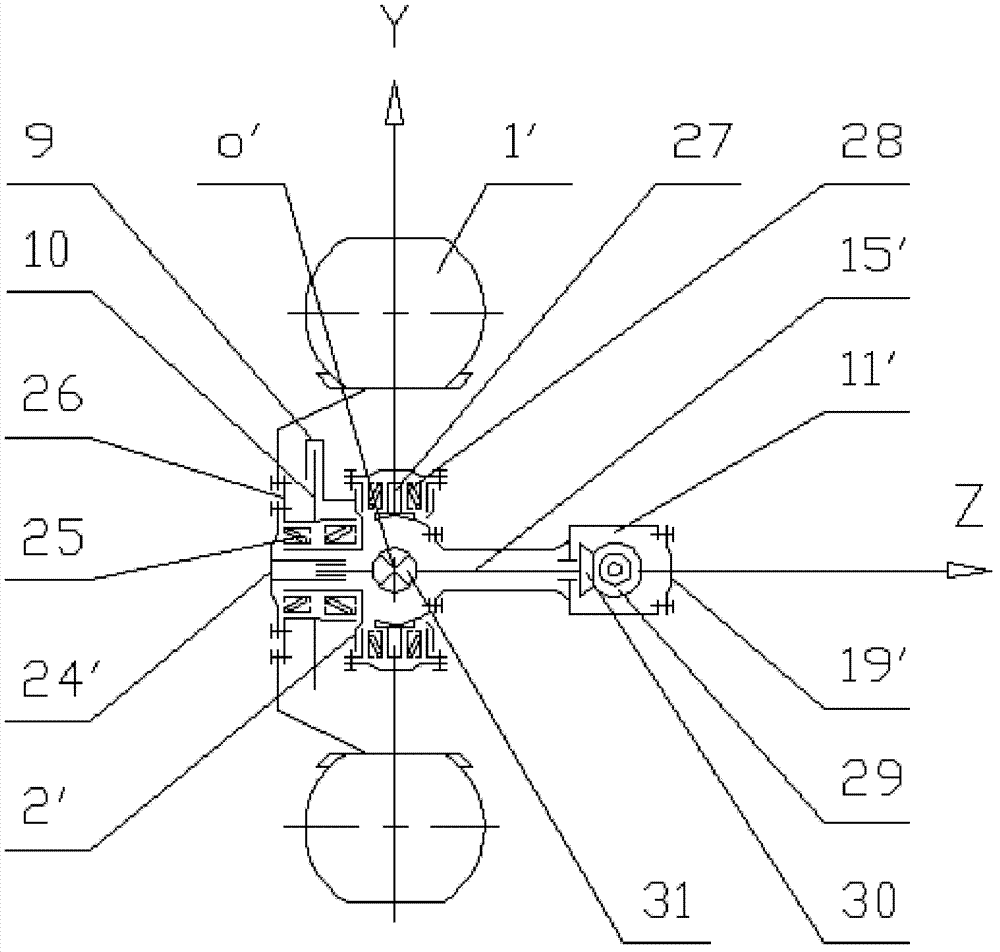

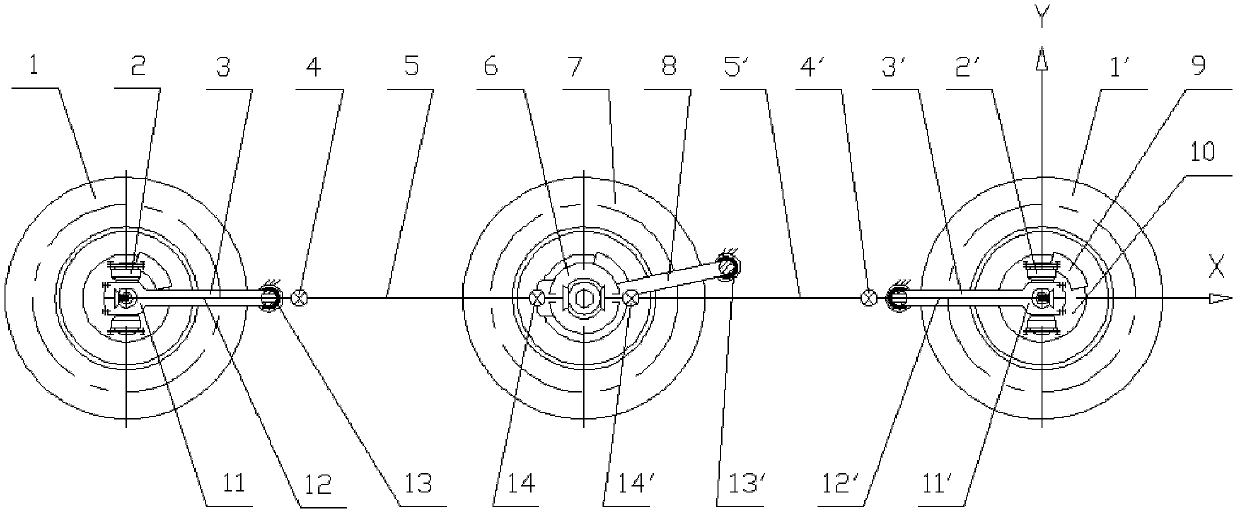

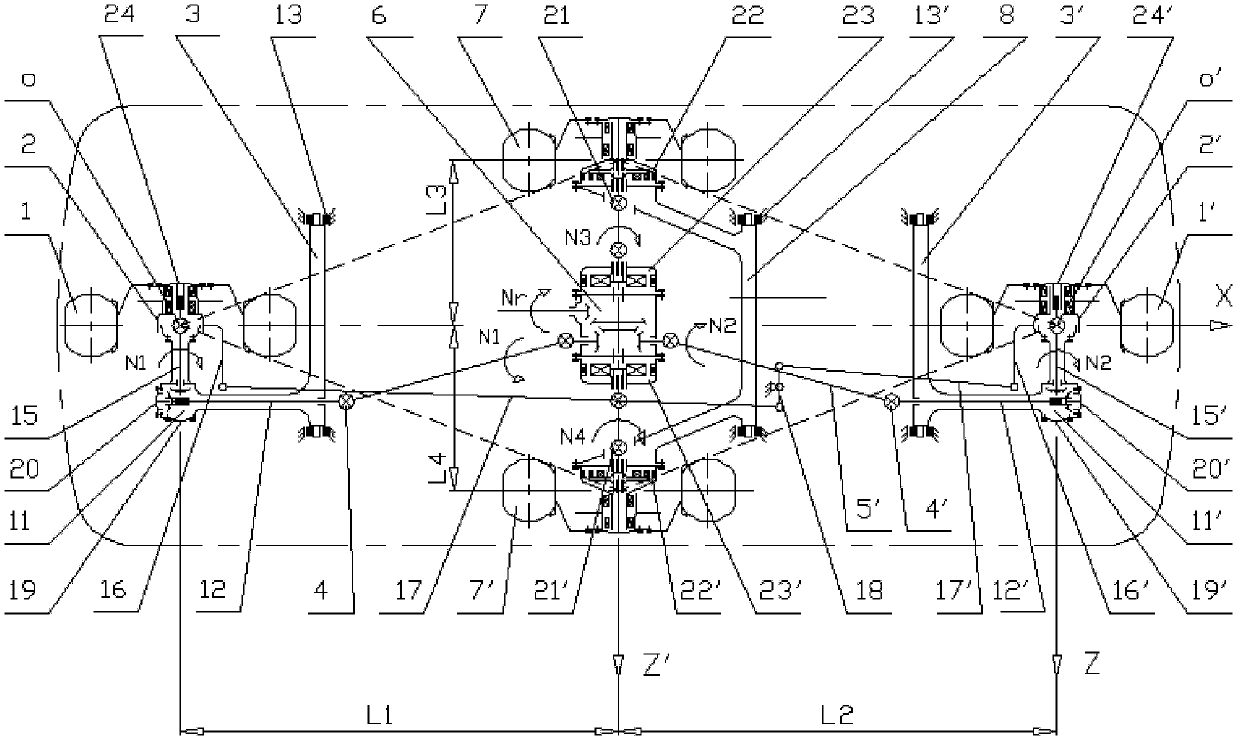

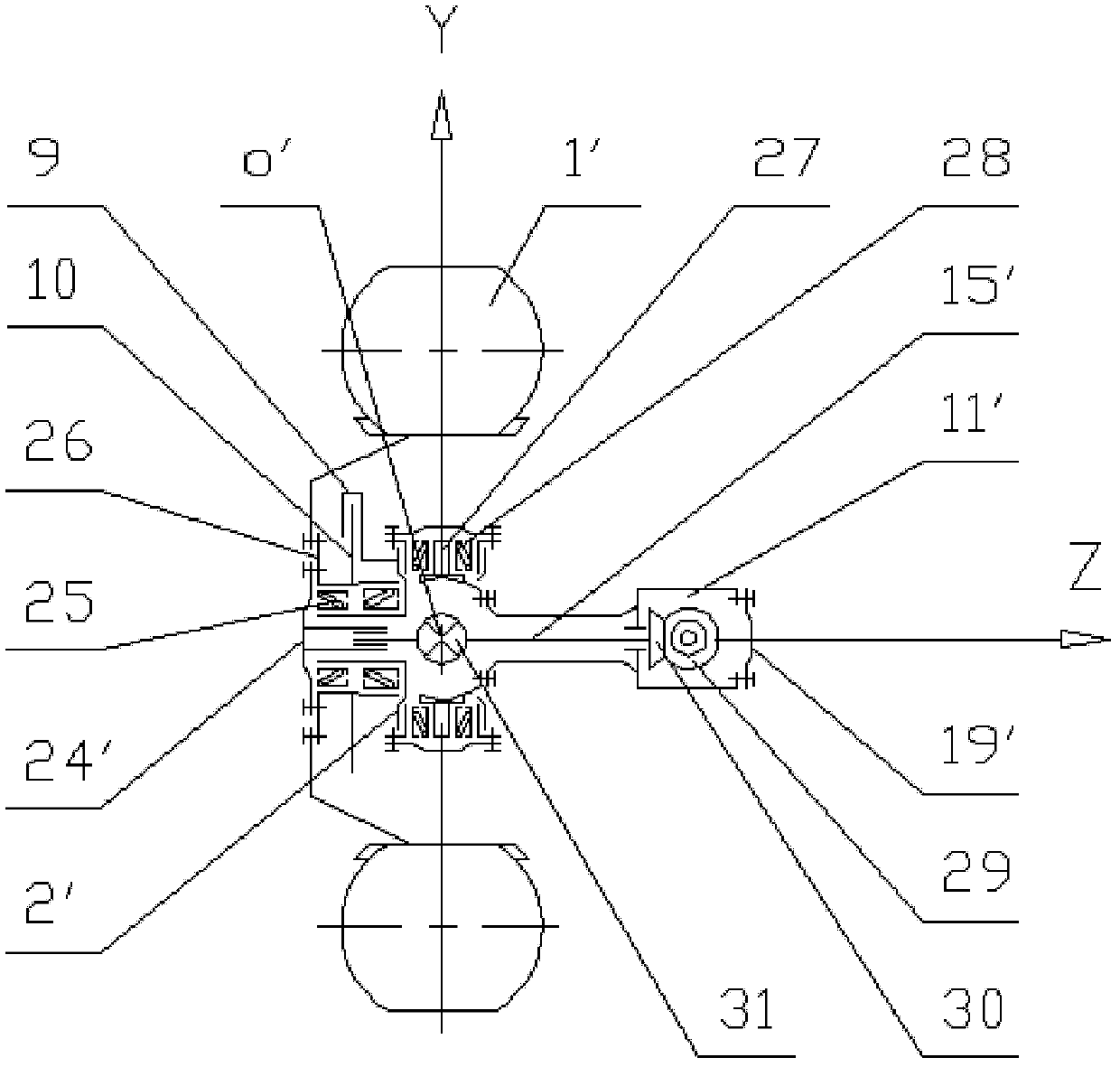

Rhomboid wheel-arranged cross-shaped axle 4WD (4 wheel drive) mechanism

InactiveCN102530123BIncrease profitEliminate dentsSteering linkagesVehiclesRoad surfacePosition control

The invention relates to a rhomboid wheel-arranged cross-shaped axle 4WD (4 wheel drive) mechanism which comprises four wheels, a driver, suspensions, steering king-pin assemblies and a fore-and-aft steering driving mechanism; and the 4WD mechanism is characterized in that the four wheels (left, right, upper and lower wheels) are rhomboidally arranged at four corners; the left wheel, a left steering king-pin assembly, a left suspension, the driver, a right suspension, a right steering king-pin assembly and the right wheels form a left-and-right steering drive axle; the upper wheel, an upper electric clutch, an upper electromotor, a middle suspension, a lower electromotor, a lower electric clutch and the lower wheel form an up-and-down drive axle; and the left-and-right steering drive axleand the up-and-down drive axle form an intersecting cross-shaped drive axle. By using the 4WD mechanism provided by the invention, the rolling uniformity of the wheels on the road surface is improved; a modularly combined drive mode of an engine and an electromotor is realized; the 4WD mechanism has an antiskid 4WD function; and the initiative steering of the front and rear wheels is realized, thereby improving the accuracy of car motion position control.

Owner:JILIN UNIV

Method of Vacuum Electron Beam Welding of Chromium Bronze Butt Joints of Annular Workpieces with Sandwich Structure

ActiveCN111037082BIncreasing the thicknessImprove carrying capacityWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

The vacuum electron beam welding method for the chromium bronze butt joint of the sandwich structure circular workpiece is to use the first clamping tool to clamp the workpiece, so that the copper backing plate is closely attached to the back of the weld seam of the workpiece, and after the electron beam segmental positioning welding, the workpiece and The first clamping tool is disassembled, and the copper backing plate on the back of the weld is corrected so that the back of the weld and the copper backing plate are closely attached. Use the second clamping tool to clamp the workpiece for formal welding. The second clamping tool allows the chrome bronze butt weld and copper backing plate of the workpiece to be welded through. After welding, the copper backing plate on the back of the workpiece weld is removed by manual grinding. . The invention solves the easy-to-produce depression on the back of the chrome bronze electron beam weld, and at the same time significantly reduces the probability of air holes inside the chrome bronze electron beam weld, so that the first pass rate of the X-ray inspection of the workpiece is significantly improved, and the number of rework welding of the workpiece is reduced , reducing production costs.

Owner:XIAN SPACE ENGINE CO LTD

Rhomboid wheel-arranged cross-shaped axle 4WD (4 wheel drive) mechanism

InactiveCN102530123AIncrease profitImprove passabilitySteering linkagesVehiclesRoad surfaceEngineering

The invention relates to a rhomboid wheel-arranged cross-shaped axle 4WD (4 wheel drive) mechanism which comprises four wheels, a driver, suspensions, steering king-pin assemblies and a fore-and-aft steering driving mechanism; and the 4WD mechanism is characterized in that the four wheels (left, right, upper and lower wheels) are rhomboidally arranged at four corners; the left wheel, a left steering king-pin assembly, a left suspension, the driver, a right suspension, a right steering king-pin assembly and the right wheels form a left-and-right steering drive axle; the upper wheel, an upper electric clutch, an upper electromotor, a middle suspension, a lower electromotor, a lower electric clutch and the lower wheel form an up-and-down drive axle; and the left-and-right steering drive axleand the up-and-down drive axle form an intersecting cross-shaped drive axle. By using the 4WD mechanism provided by the invention, the rolling uniformity of the wheels on the road surface is improved; a modularly combined drive mode of an engine and an electromotor is realized; the 4WD mechanism has an antiskid 4WD function; and the initiative steering of the front and rear wheels is realized, thereby improving the accuracy of car motion position control.

Owner:JILIN UNIV

A kind of push handle used for cigarette collecting machine

The invention belongs to a push handle for a cigarette collecting machine, comprising a push handle main body, a groove is arranged on one side of the push handle main body for pushing cigarettes, a spring is fixed at the bottom of the groove, and a metal frame is connected to the other end of the spring, and inside the metal frame Filled with asbestos pads; the main body of the push hand is provided with a shaft, which passes through the metal frame and the asbestos pad in turn, and bearings are installed at both ends of the shaft, and the two ends of the main body of the push hand are provided with guide rail grooves for bearing movement, and there are gears on the outside of the guide rail grooves. plate. The invention eliminates the dents on the long side of the cigarette and the quality defects of the small inner box caused by the large impact force of the conventional push hand, greatly reduces the probability of scratches, and improves the appearance quality of the cigarette.

Owner:CHINA TOBACCO HENAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com