Vacuum electron beam welding method for chromium bronze butt joint of annular workpiece of sandwich structure

A technology of vacuum electron beam and butt joints, which is applied in the direction of electron beam welding equipment, welding equipment, welding equipment, etc., can solve the problems of reducing production efficiency, reducing the bearing capacity of welded parts, and increasing production costs, so as to improve the effective thickness and The effect of bearing capacity, reducing the number of rework welding, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

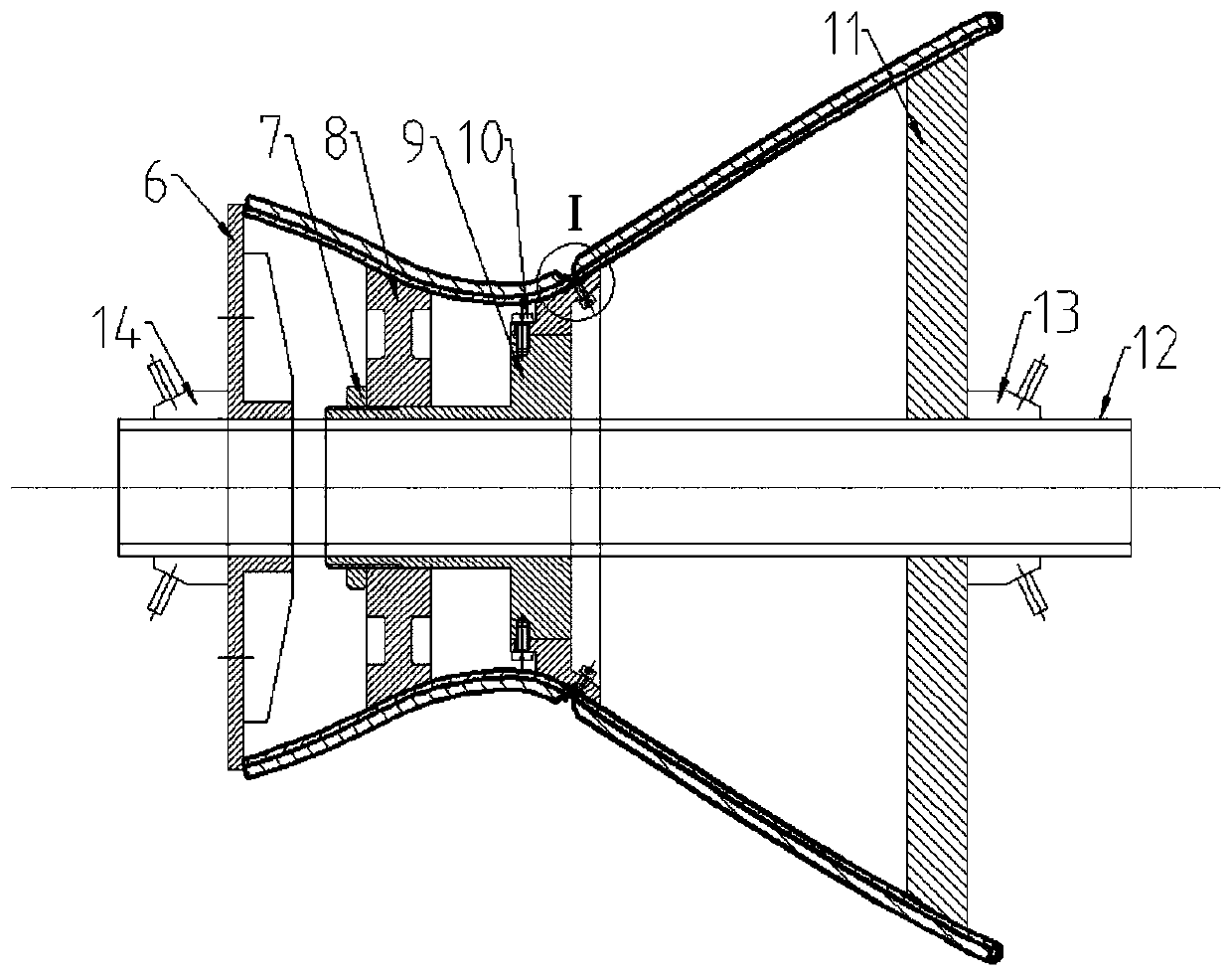

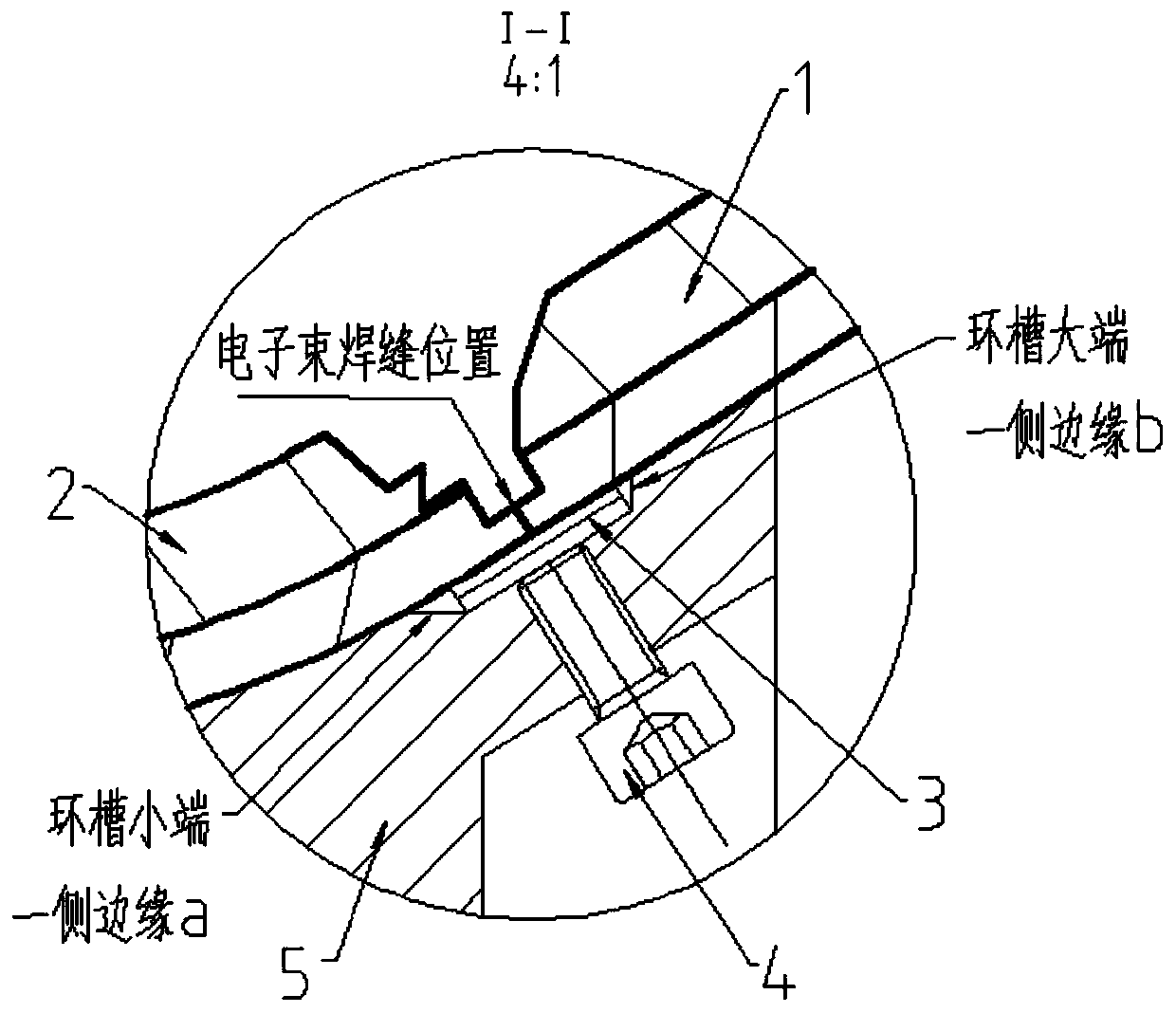

[0053] (1) Workpieces A and B are brazed rings with a sandwich structure whose outer wall is stainless steel and whose inner wall is chrome bronze. The inner wall thickness of the chrome bronze of workpiece A and workpiece B is 1.2mm, the material grade is QCr0.8, and the weld diameter is φ260mm. Use blade scraping to clean the chrome-bronze joint surfaces of workpiece A and workpiece B to expose the metallic luster, and perform welding within 24 hours.

[0054] (2) Positioning pieces A and B are positioned on the outer wall by manual argon arc welding, and the distance between adjacent positioning pieces is 180mm. The misalignment of the back of the chrome bronze butt weld after the positioning of workpiece A and workpiece B is 0.1mm, and the gap is 0.1mm. The material of the copper backing plate clamped on the back of the weld is consistent with the inner wall of the workpiece, the width is 12mm, and the thickness of each layer is 1mm. After overlapping the two layers of co...

Embodiment 2

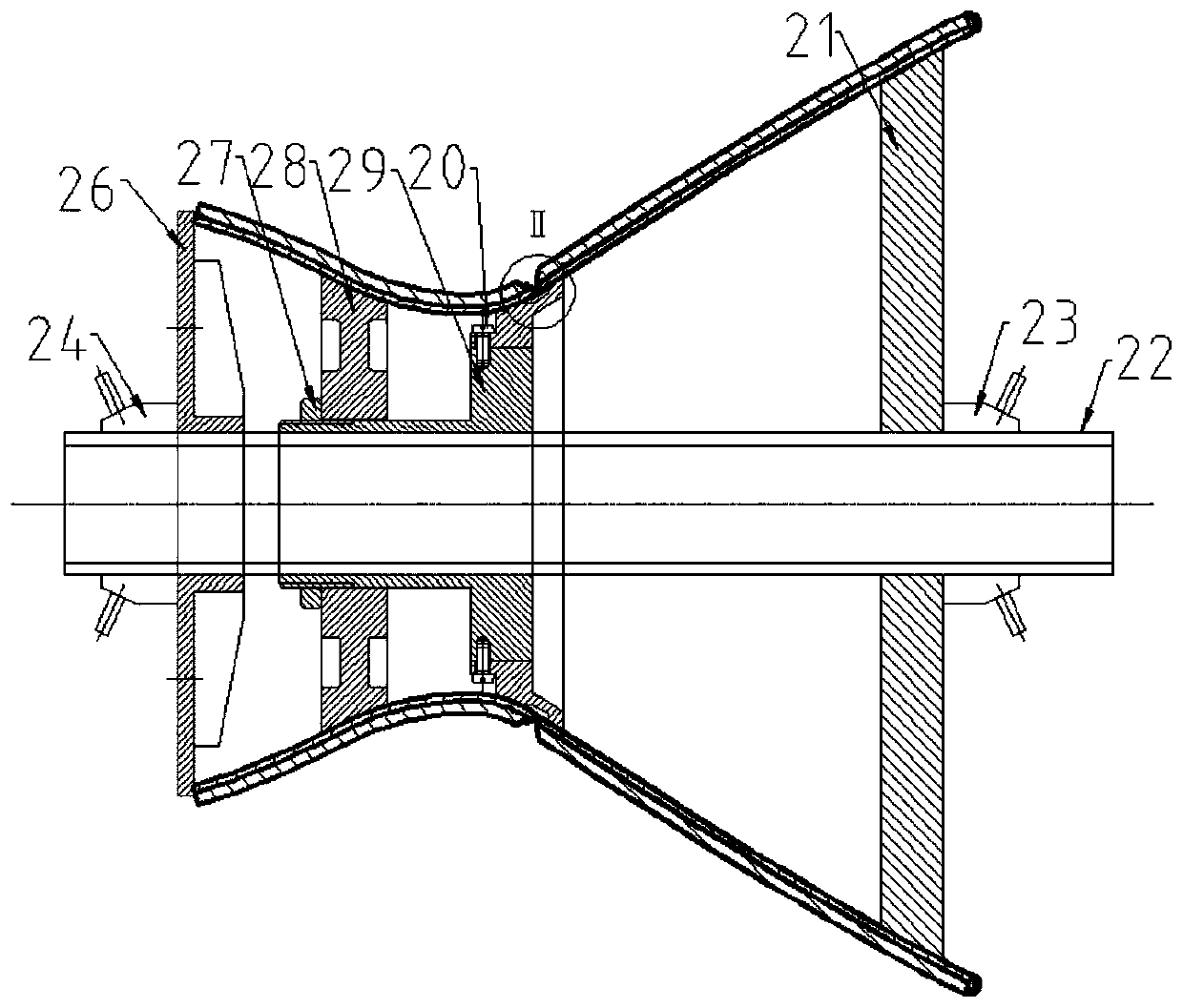

[0059] (1) Workpieces A and B are brazed rings with a sandwich structure whose outer wall is stainless steel and whose inner wall is chrome bronze. The chrome bronze inner wall thickness of workpiece A and workpiece B is 2mm, the material grade is QCr0.8, and the weld seam diameter is φ120mm. Use blade scraping to clean the chrome-bronze joint surfaces of workpiece A and workpiece B to expose the metallic luster, and perform welding within 24 hours.

[0060] (2) Use positioning pieces to position A workpiece and B workpiece by manual argon arc welding on the outer wall, and the distance between adjacent positioning pieces is 150mm. The misalignment of the back of the chrome bronze butt weld after the positioning of workpiece A and workpiece B is 0.05mm, and the gap is 0.05mm. The material of the copper backing plate clamped on the back of the weld is consistent with the inner wall of the workpiece, the width is 10mm, and the thickness of each layer is 1mm. After overlapping t...

Embodiment 3

[0065] (1) Workpieces A and B are brazed rings with a sandwich structure whose outer wall is stainless steel and whose inner wall is chrome bronze. The chrome bronze inner wall thickness of workpiece A and workpiece B is 3mm, the material grade is QCr0.8, and the weld seam diameter is φ800mm. Use blade scraping to clean the chrome-bronze joint surfaces of workpiece A and workpiece B to expose the metallic luster, and perform welding within 24 hours.

[0066](2) Positioning pieces A and B are positioned on the outer wall by manual argon arc welding, and the distance between adjacent positioning pieces is 200mm. The misalignment of the back of the chrome bronze butt weld after the positioning of workpiece A and workpiece B is 0.1mm, and the gap is 0.1mm. The material of the copper backing plate clamped on the back of the weld is consistent with the inner wall of the workpiece, the width is 14mm, and the thickness of each layer is 1mm. After overlapping the two layers of copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com