Electron beam processing equipment precision acceleration power supply device and control method thereof

A technology of electron beam processing and power supply device, which is applied in the direction of output power conversion device, electrical components, AC power input to AC power output, etc. It can solve the problems of light-load current peak pulse voltage, etc. The effect of improving machining accuracy and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

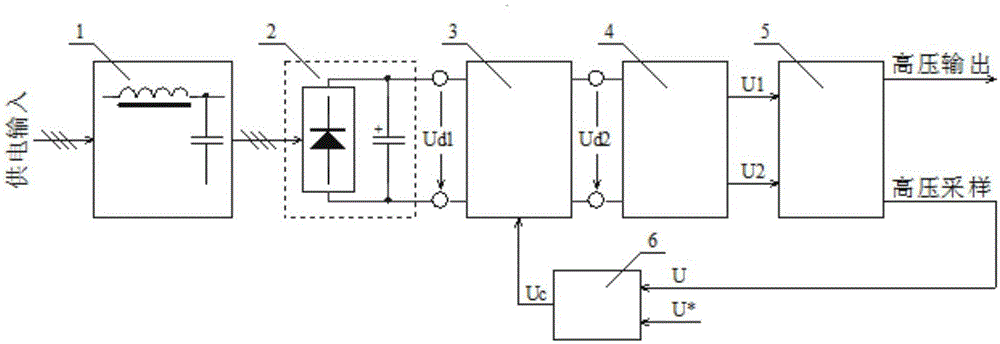

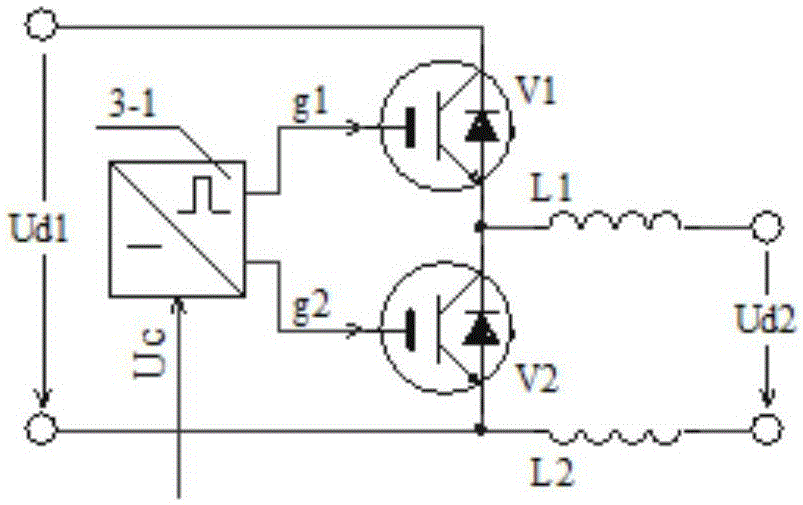

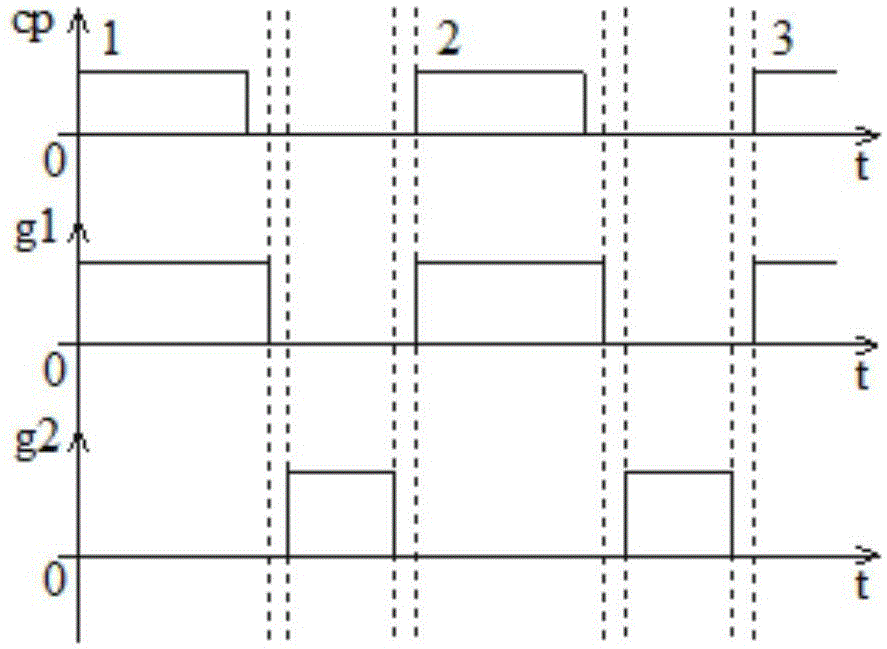

[0064] like figure 1 As shown, a precision acceleration power supply device for electron beam processing equipment includes a line filter 1, a low-voltage rectification filter unit 2, a DC-DC conversion unit 3, an inverter unit 4, a high-voltage unit 5 and a regulator 6. The input end of the line filter 1 is connected to the external grid, and the output end of the line filter 1, the input end of the low-voltage rectification filter unit 2, the DC-DC conversion unit 3, the inverter unit 4 and the high-voltage unit 5 are connected in series in sequence, The high-voltage output end of the high-voltage unit 5 outputs a high-voltage electric connection to the cathode of the electron gun, and the high-voltage feedback signal U output by the signal end of the high-voltage unit 5 is sent to the second input end of the regulator 6, and the second input terminal of the regulator 6 One input input high voltage given signal U * , the output end of the regulator 6 is connected to the sig...

Embodiment 2

[0101] The structure of Embodiment 2 is basically the same as that of Embodiment 1, except for the inverter unit 4 .

[0102] like Figure 5 As shown, the inverter unit 4 includes a capacitor C5, a C-phase inverter, a D-phase inverter and a third drive pulse generator 4-2, and the C-phase inverter and the D-phase inverter are all connected to the third drive pulse generator 4-2;

[0103] The capacitor C5 is connected in parallel to both ends of the output of the DC-DC conversion unit 3;

[0104] The C-phase inverter includes switching power transistors V7-V10, the collector of the switching power transistor V7 is connected to the positive output terminal of the DC-DC conversion unit 3, the emitter of the switching power transistor V7 is connected to the The collectors of the switching power tube V9 are connected to each other, and serve as the first output terminal of the C-phase inverter, and the emitter of the switching power tube V9 is connected to the negative output ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com