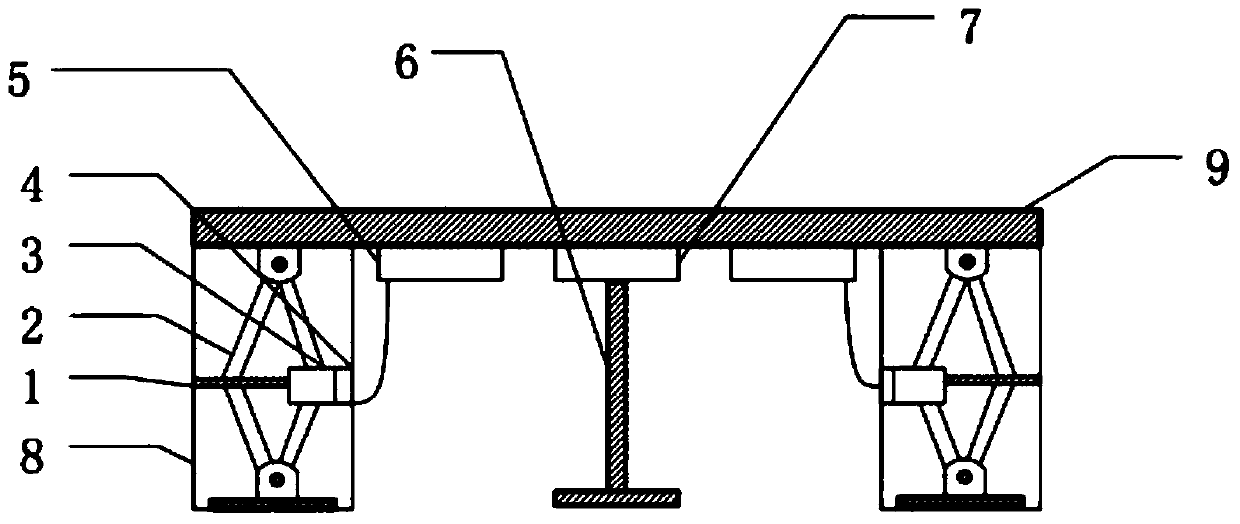

Level adjusting device and method thereof

A technology of leveling device and driving device, which is applied in the direction of use feedback control, etc., can solve the problem of poor load-bearing capacity of automatic adjustment leveling device, and achieve the effect of good self-locking, good load-carrying capacity, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

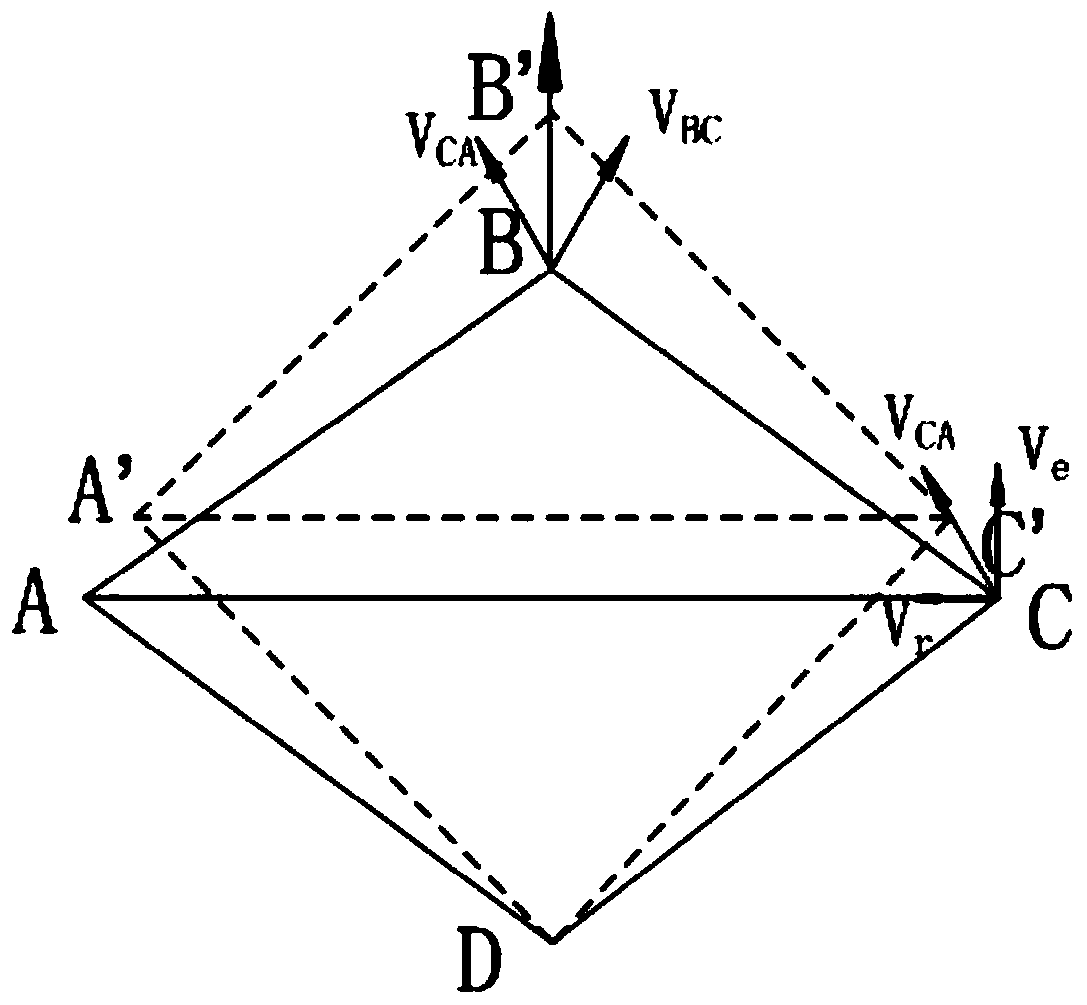

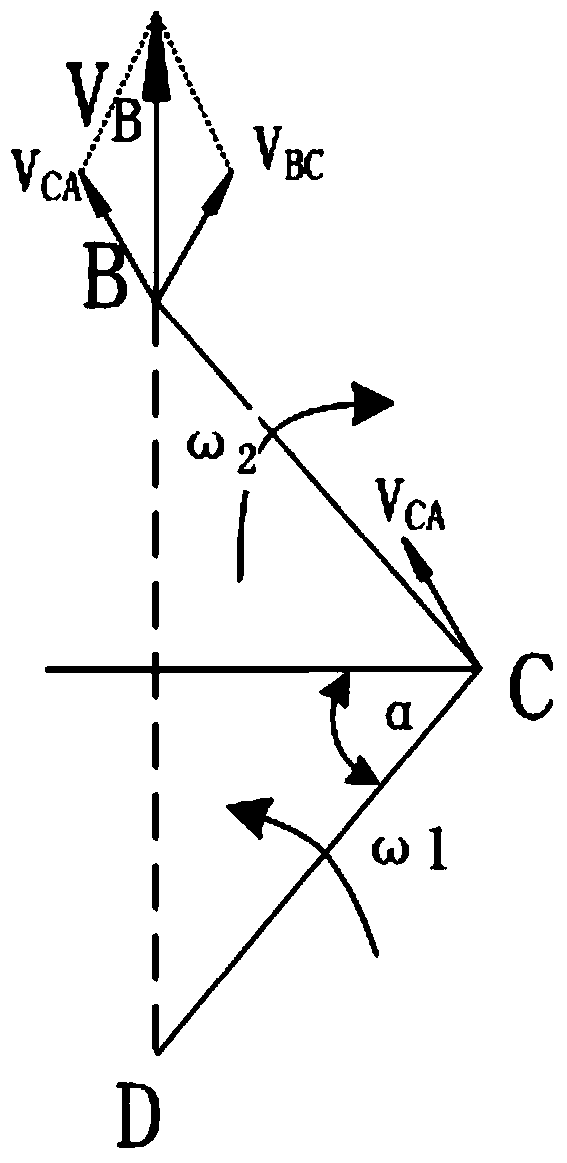

[0037] The following is a further modeling analysis of the scissor jack.

[0038] 1. Modeling analysis of scissor jack

[0039] According to the actual movement of the scissor jack, one section of the screw kinematic pair is an articulated pair, and the other section is a moving pair. When the motor drives the screw to rotate, the connecting nut moves horizontally relative to the horizontal rod and drives the lifting arm up and down (when the screw rotates clockwise, the connecting nut moves toward the hinged end relative to the screw, and the lifting arm rises; when the screw rotates counterclockwise, the connecting The nut moves away from the hinged end relative to the screw rod, and the lifting arm descends). From this, a motion model diagram is established, such as figure 2 , taking D as the coordinate origin (0, 0), setting the angle between the screw rod and the lifting arm as α (0°<α<90°), and the arm length as L, then the hinge point A, vertex B and point C of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com