Display device packaging method

A packaging method and display device technology, applied in semiconductor devices, electrical solid state devices, semiconductor/solid state device manufacturing, etc., can solve problems such as inability to completely eliminate depressions, infringement of TFT substrates and organic light-emitting materials, and shortened bonding lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

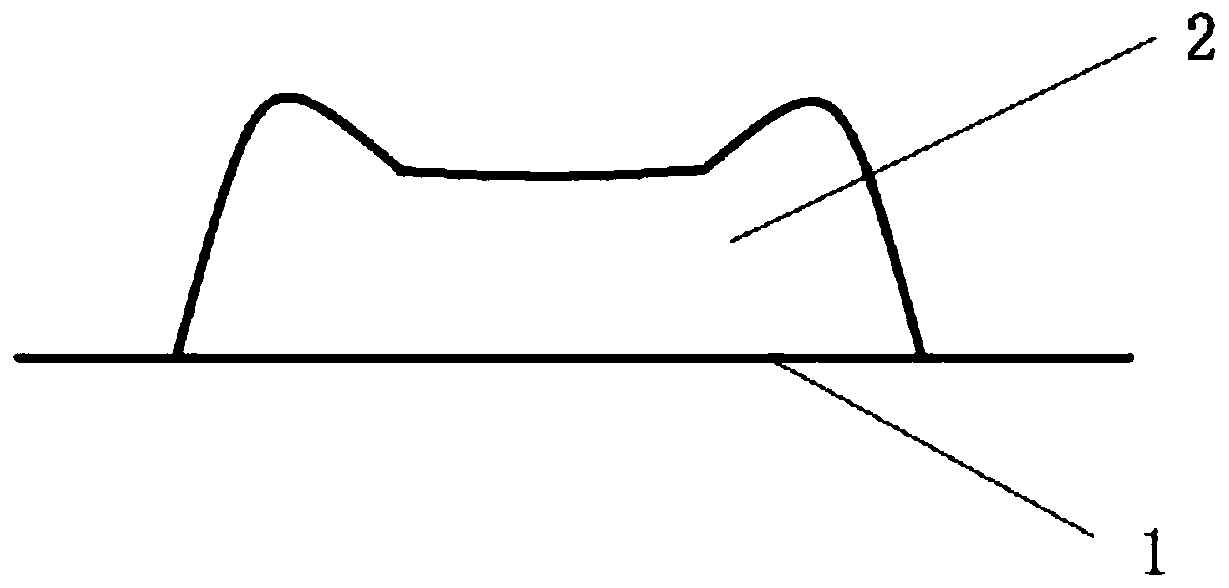

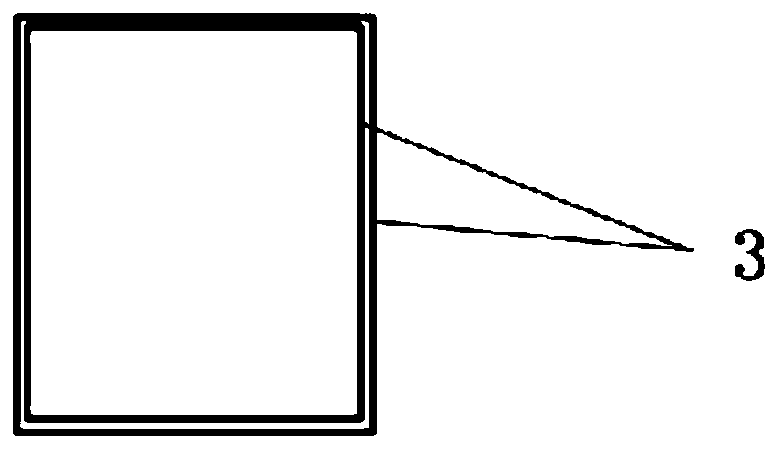

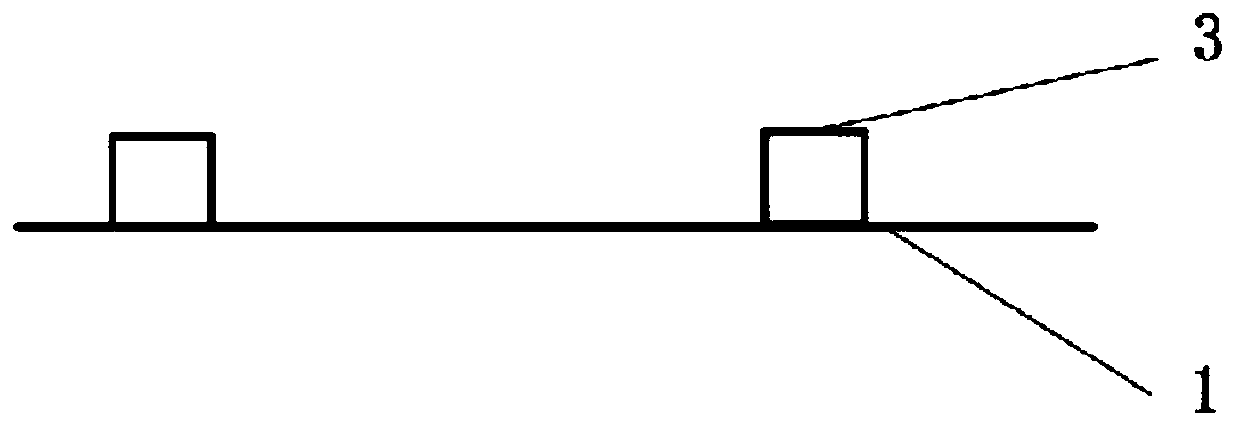

[0031] see Figure 1 to Figure 5 , the present embodiment provides a display device packaging method, using a Dispenser (automatic glue dispenser) or other gluing equipment to coat a strip of heating decomposable glue 3 on a panel of the cover glass 1, the heating The top view of the decomposable glue 3 is coated in the shape of a "mouth". The printed height and width are determined by the degree of depression of the frit glue 2 (melted and solidified glass glue) in actual production, and the actual shape of the heat-decomposable glue 3 may be "saddle shape" or other shapes. The heating decomposable glue 3 can be replaced by other materials that can be cured and decomposed into gas, and according to the different materials selected, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com